Fig DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 460 of 2627

TESTING

COLD CRANKING TEST

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. The battery must be fully-

charged and load-tested before proceeding. Refer to

Batteryin 8, Battery.

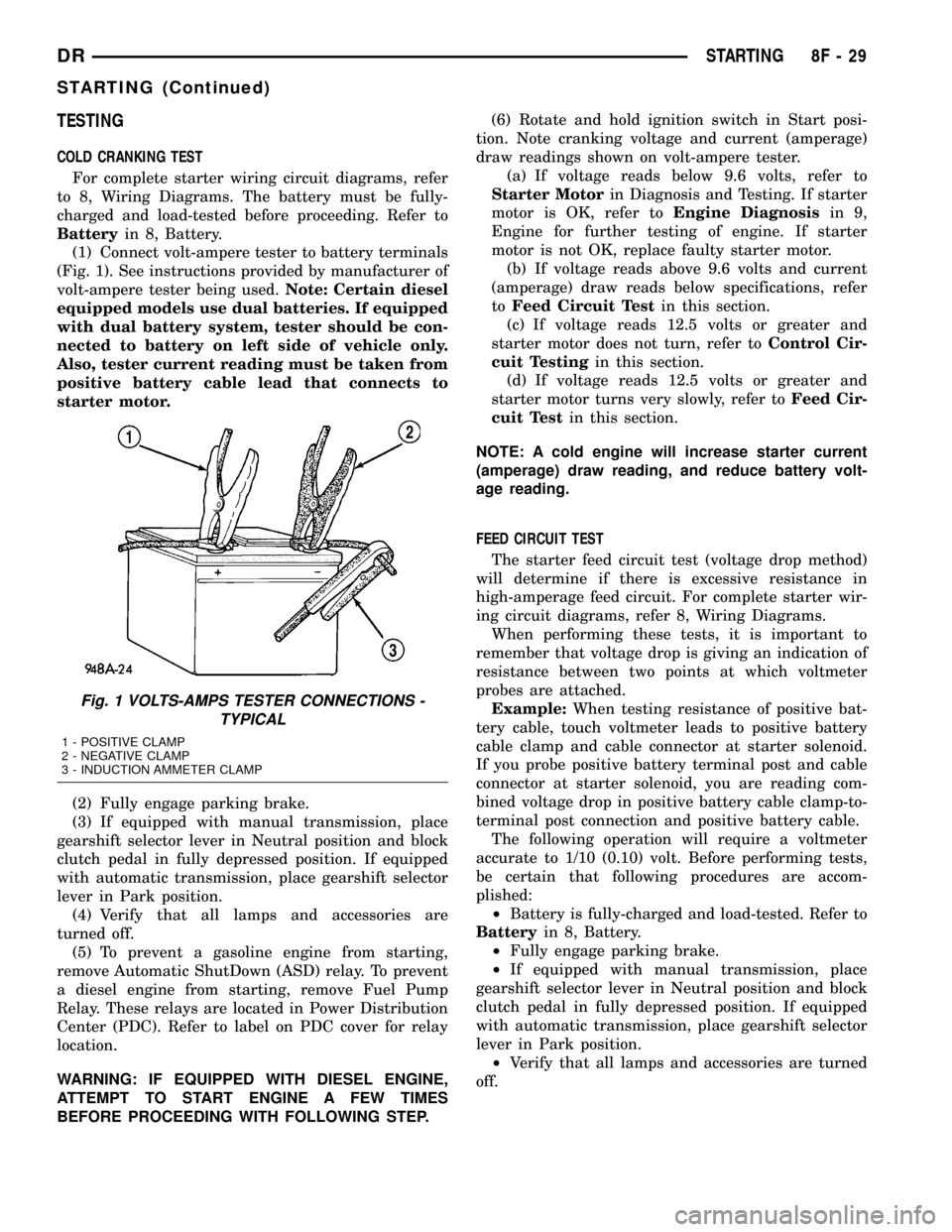

(1) Connect volt-ampere tester to battery terminals

(Fig. 1). See instructions provided by manufacturer of

volt-ampere tester being used.Note: Certain diesel

equipped models use dual batteries. If equipped

with dual battery system, tester should be con-

nected to battery on left side of vehicle only.

Also, tester current reading must be taken from

positive battery cable lead that connects to

starter motor.

(2) Fully engage parking brake.

(3) If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent a gasoline engine from starting,

remove Automatic ShutDown (ASD) relay. To prevent

a diesel engine from starting, remove Fuel Pump

Relay. These relays are located in Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

WARNING: IF EQUIPPED WITH DIESEL ENGINE,

ATTEMPT TO START ENGINE A FEW TIMES

BEFORE PROCEEDING WITH FOLLOWING STEP.(6) Rotate and hold ignition switch in Start posi-

tion. Note cranking voltage and current (amperage)

draw readings shown on volt-ampere tester.

(a) If voltage reads below 9.6 volts, refer to

Starter Motorin Diagnosis and Testing. If starter

motor is OK, refer toEngine Diagnosisin 9,

Engine for further testing of engine. If starter

motor is not OK, replace faulty starter motor.

(b) If voltage reads above 9.6 volts and current

(amperage) draw reads below specifications, refer

toFeed Circuit Testin this section.

(c) If voltage reads 12.5 volts or greater and

starter motor does not turn, refer toControl Cir-

cuit Testingin this section.

(d) If voltage reads 12.5 volts or greater and

starter motor turns very slowly, refer toFeed Cir-

cuit Testin this section.

NOTE: A cold engine will increase starter current

(amperage) draw reading, and reduce battery volt-

age reading.

FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in

high-amperage feed circuit. For complete starter wir-

ing circuit diagrams, refer 8, Wiring Diagrams.

When performing these tests, it is important to

remember that voltage drop is giving an indication of

resistance between two points at which voltmeter

probes are attached.

Example:When testing resistance of positive bat-

tery cable, touch voltmeter leads to positive battery

cable clamp and cable connector at starter solenoid.

If you probe positive battery terminal post and cable

connector at starter solenoid, you are reading com-

bined voltage drop in positive battery cable clamp-to-

terminal post connection and positive battery cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing tests,

be certain that following procedures are accom-

plished:

²Battery is fully-charged and load-tested. Refer to

Batteryin 8, Battery.

²Fully engage parking brake.

²If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

²Verify that all lamps and accessories are turned

off.

Fig. 1 VOLTS-AMPS TESTER CONNECTIONS -

TYPICAL

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

DRSTARTING 8F - 29

STARTING (Continued)

Page 461 of 2627

²To prevent a gasoline engine from starting,

remove Automatic ShutDown (ASD) relay. To prevent

a diesel engine from starting, remove Fuel Pump

Relay. These relays are located in Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

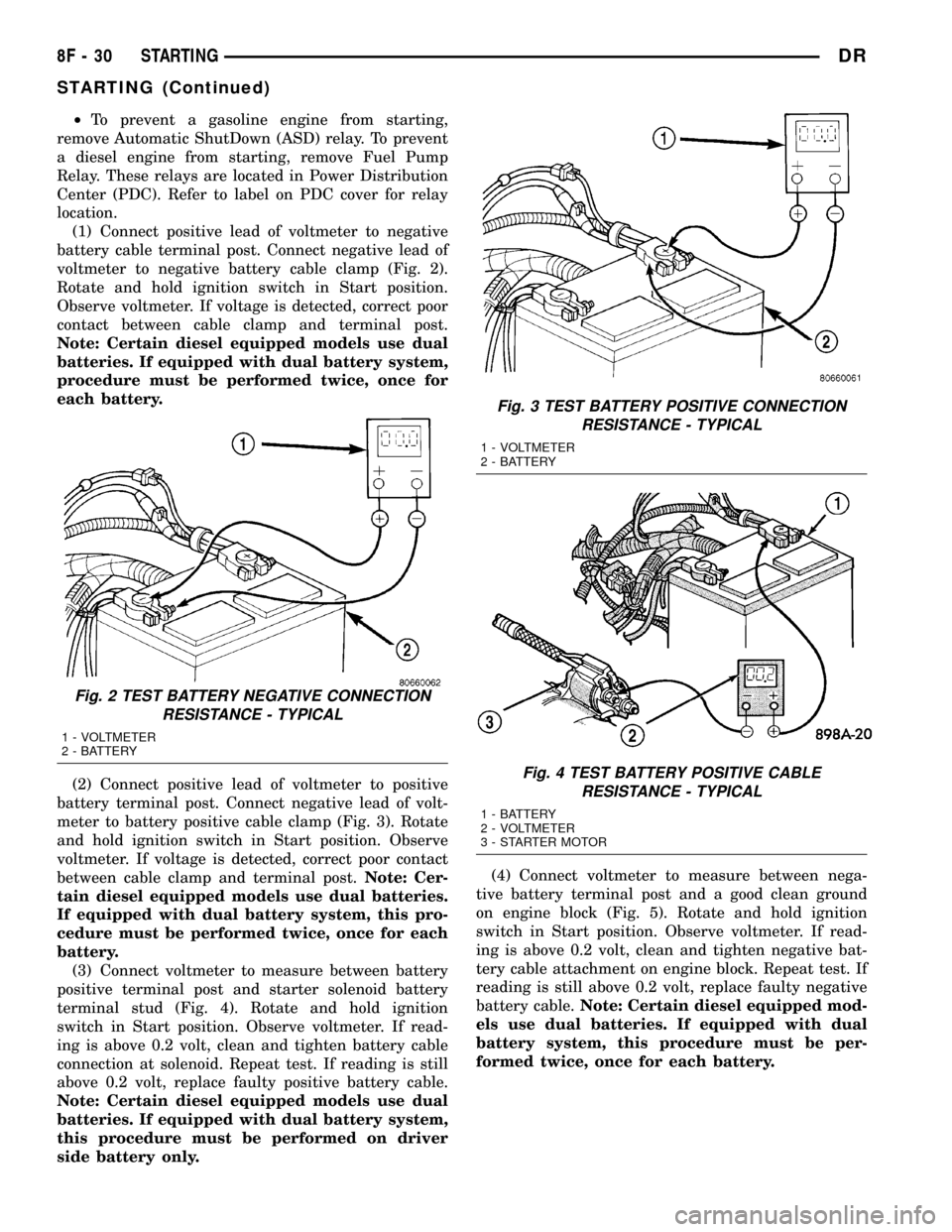

(1) Connect positive lead of voltmeter to negative

battery cable terminal post. Connect negative lead of

voltmeter to negative battery cable clamp (Fig. 2).

Rotate and hold ignition switch in Start position.

Observe voltmeter. If voltage is detected, correct poor

contact between cable clamp and terminal post.

Note: Certain diesel equipped models use dual

batteries. If equipped with dual battery system,

procedure must be performed twice, once for

each battery.

(2) Connect positive lead of voltmeter to positive

battery terminal post. Connect negative lead of volt-

meter to battery positive cable clamp (Fig. 3). Rotate

and hold ignition switch in Start position. Observe

voltmeter. If voltage is detected, correct poor contact

between cable clamp and terminal post.Note: Cer-

tain diesel equipped models use dual batteries.

If equipped with dual battery system, this pro-

cedure must be performed twice, once for each

battery.

(3) Connect voltmeter to measure between battery

positive terminal post and starter solenoid battery

terminal stud (Fig. 4). Rotate and hold ignition

switch in Start position. Observe voltmeter. If read-

ing is above 0.2 volt, clean and tighten battery cable

connection at solenoid. Repeat test. If reading is still

above 0.2 volt, replace faulty positive battery cable.

Note: Certain diesel equipped models use dual

batteries. If equipped with dual battery system,

this procedure must be performed on driver

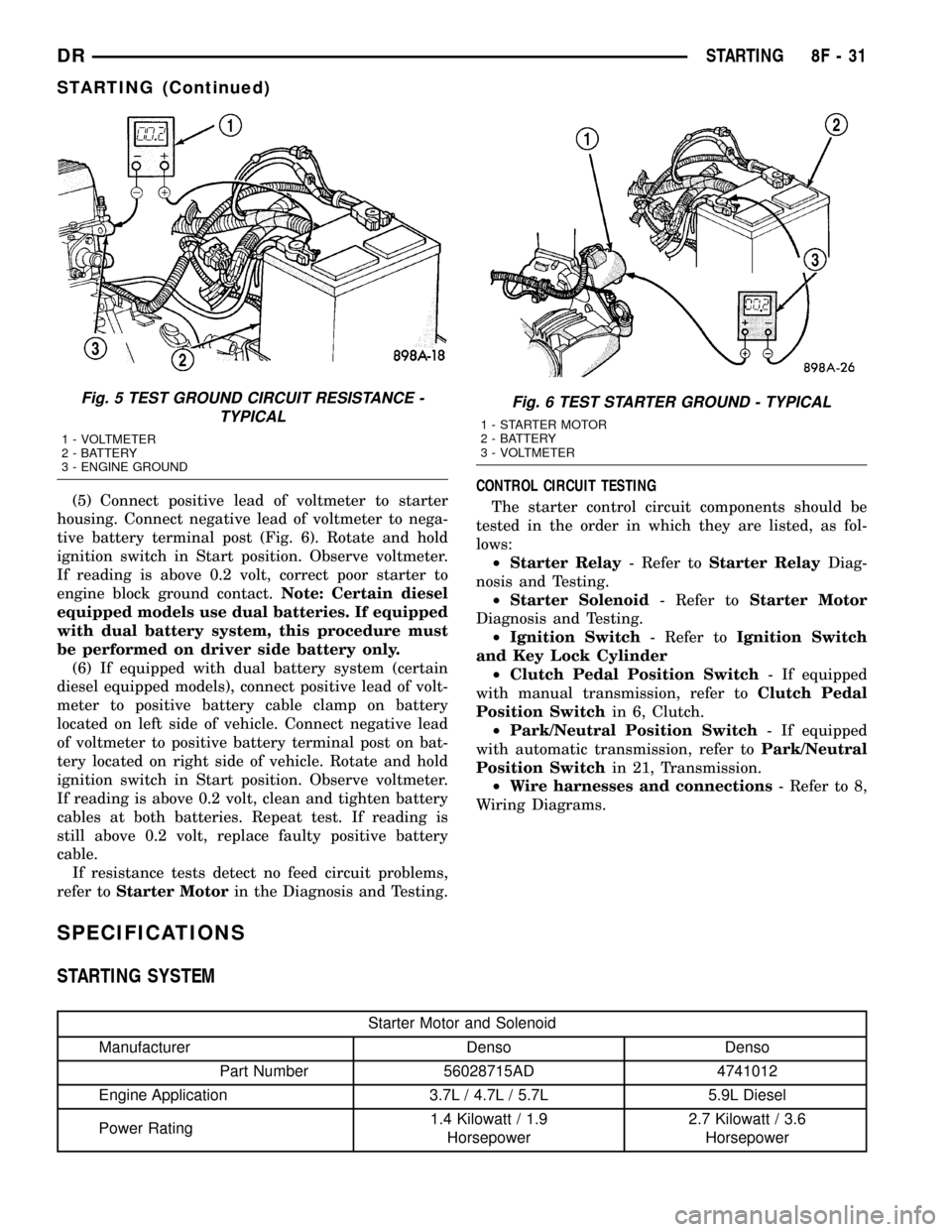

side battery only.(4) Connect voltmeter to measure between nega-

tive battery terminal post and a good clean ground

on engine block (Fig. 5). Rotate and hold ignition

switch in Start position. Observe voltmeter. If read-

ing is above 0.2 volt, clean and tighten negative bat-

tery cable attachment on engine block. Repeat test. If

reading is still above 0.2 volt, replace faulty negative

battery cable.Note: Certain diesel equipped mod-

els use dual batteries. If equipped with dual

battery system, this procedure must be per-

formed twice, once for each battery.

Fig. 2 TEST BATTERY NEGATIVE CONNECTION

RESISTANCE - TYPICAL

1 - VOLTMETER

2 - BATTERY

Fig. 3 TEST BATTERY POSITIVE CONNECTION

RESISTANCE - TYPICAL

1 - VOLTMETER

2 - BATTERY

Fig. 4 TEST BATTERY POSITIVE CABLE

RESISTANCE - TYPICAL

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

8F - 30 STARTINGDR

STARTING (Continued)

Page 462 of 2627

(5) Connect positive lead of voltmeter to starter

housing. Connect negative lead of voltmeter to nega-

tive battery terminal post (Fig. 6). Rotate and hold

ignition switch in Start position. Observe voltmeter.

If reading is above 0.2 volt, correct poor starter to

engine block ground contact.Note: Certain diesel

equipped models use dual batteries. If equipped

with dual battery system, this procedure must

be performed on driver side battery only.

(6) If equipped with dual battery system (certain

diesel equipped models), connect positive lead of volt-

meter to positive battery cable clamp on battery

located on left side of vehicle. Connect negative lead

of voltmeter to positive battery terminal post on bat-

tery located on right side of vehicle. Rotate and hold

ignition switch in Start position. Observe voltmeter.

If reading is above 0.2 volt, clean and tighten battery

cables at both batteries. Repeat test. If reading is

still above 0.2 volt, replace faulty positive battery

cable.

If resistance tests detect no feed circuit problems,

refer toStarter Motorin the Diagnosis and Testing.CONTROL CIRCUIT TESTING

The starter control circuit components should be

tested in the order in which they are listed, as fol-

lows:

²Starter Relay- Refer toStarter RelayDiag-

nosis and Testing.

²Starter Solenoid- Refer toStarter Motor

Diagnosis and Testing.

²Ignition Switch- Refer toIgnition Switch

and Key Lock Cylinder

²Clutch Pedal Position Switch- If equipped

with manual transmission, refer toClutch Pedal

Position Switchin 6, Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, refer toPark/Neutral

Position Switchin 21, Transmission.

²Wire harnesses and connections- Refer to 8,

Wiring Diagrams.

SPECIFICATIONS

STARTING SYSTEM

Starter Motor and Solenoid

Manufacturer Denso Denso

Part Number 56028715AD 4741012

Engine Application 3.7L / 4.7L / 5.7L 5.9L Diesel

Power Rating1.4 Kilowatt / 1.9

Horsepower2.7 Kilowatt / 3.6

Horsepower

Fig. 5 TEST GROUND CIRCUIT RESISTANCE -

TYPICAL

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 6 TEST STARTER GROUND - TYPICAL

1 - STARTER MOTOR

2 - BATTERY

3 - VOLTMETER

DRSTARTING 8F - 31

STARTING (Continued)

Page 464 of 2627

(6) Note reading on ammeter and compare reading

to free running test maximum amperage draw. Refer

to Specifications for starter motor free running test

maximum amperage draw specifications.

(7) If ammeter reading exceeds maximum amper-

age draw specification, replace faulty starter motor

assembly.

STARTER SOLENOID

This test can only be performed with starter motor

removed from vehicle.

(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Disconnect wire from solenoid field coil termi-

nal.

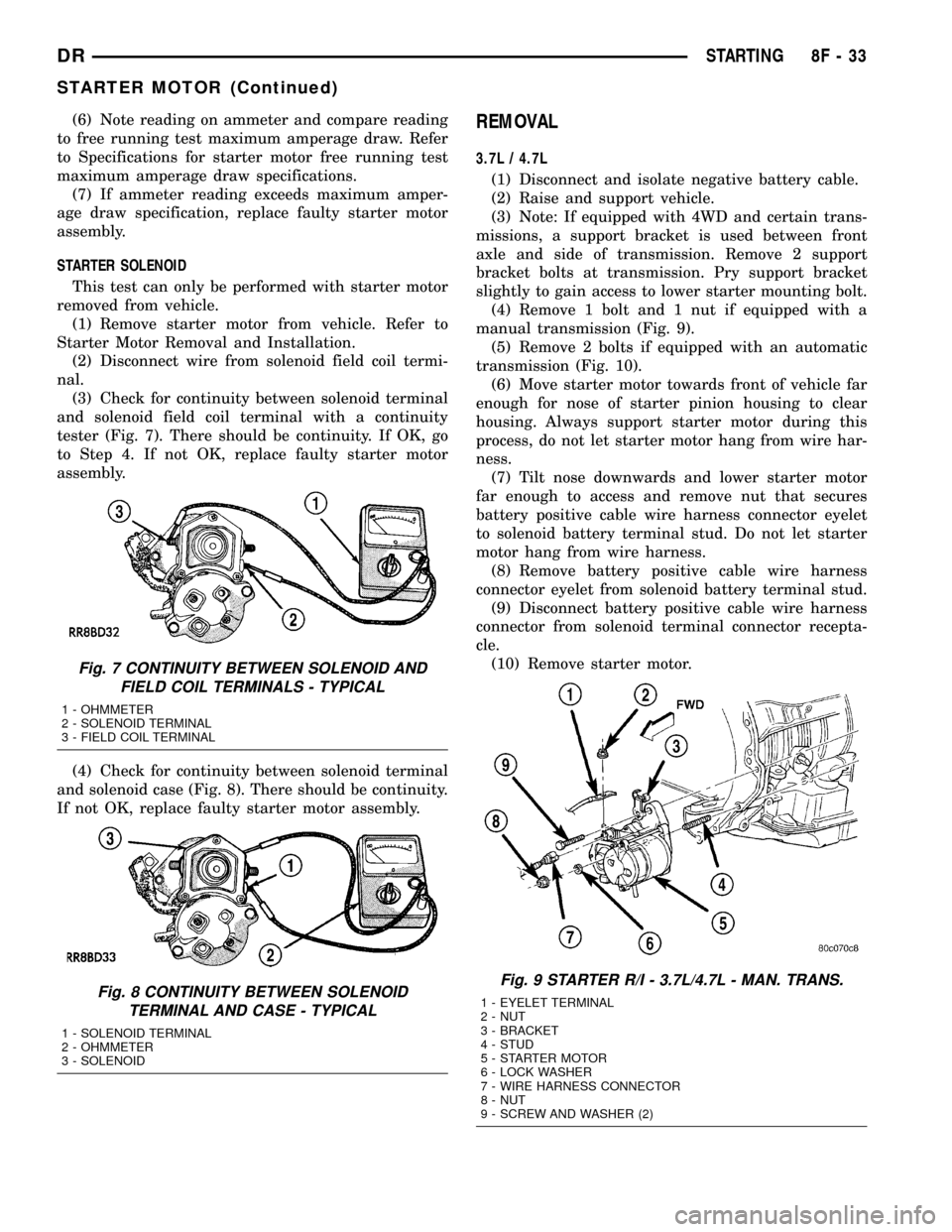

(3) Check for continuity between solenoid terminal

and solenoid field coil terminal with a continuity

tester (Fig. 7). There should be continuity. If OK, go

to Step 4. If not OK, replace faulty starter motor

assembly.

(4) Check for continuity between solenoid terminal

and solenoid case (Fig. 8). There should be continuity.

If not OK, replace faulty starter motor assembly.REMOVAL

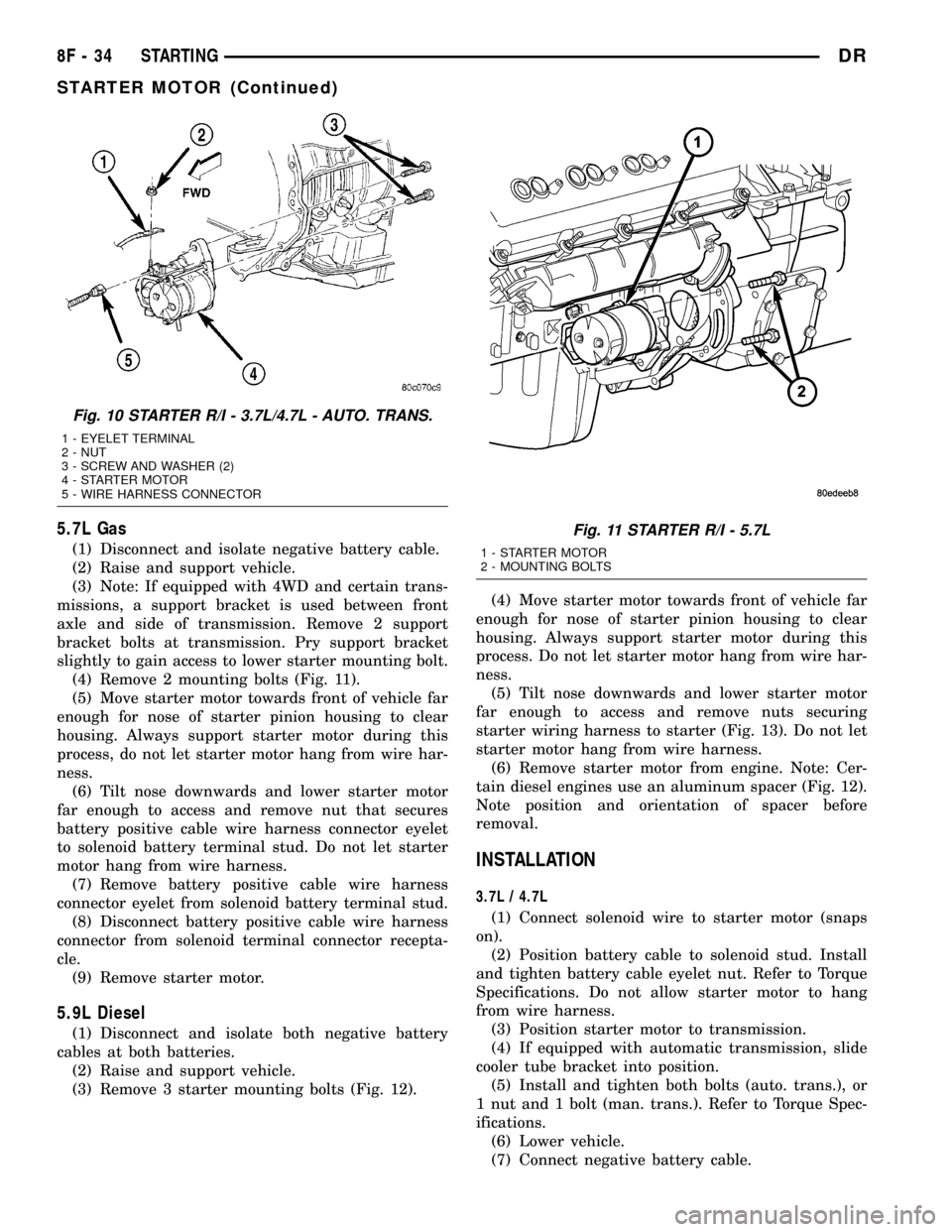

3.7L / 4.7L

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Note: If equipped with 4WD and certain trans-

missions, a support bracket is used between front

axle and side of transmission. Remove 2 support

bracket bolts at transmission. Pry support bracket

slightly to gain access to lower starter mounting bolt.

(4) Remove 1 bolt and 1 nut if equipped with a

manual transmission (Fig. 9).

(5) Remove 2 bolts if equipped with an automatic

transmission (Fig. 10).

(6) Move starter motor towards front of vehicle far

enough for nose of starter pinion housing to clear

housing. Always support starter motor during this

process, do not let starter motor hang from wire har-

ness.

(7) Tilt nose downwards and lower starter motor

far enough to access and remove nut that secures

battery positive cable wire harness connector eyelet

to solenoid battery terminal stud. Do not let starter

motor hang from wire harness.

(8) Remove battery positive cable wire harness

connector eyelet from solenoid battery terminal stud.

(9) Disconnect battery positive cable wire harness

connector from solenoid terminal connector recepta-

cle.

(10) Remove starter motor.

Fig. 7 CONTINUITY BETWEEN SOLENOID AND

FIELD COIL TERMINALS - TYPICAL

1 - OHMMETER

2 - SOLENOID TERMINAL

3 - FIELD COIL TERMINAL

Fig. 8 CONTINUITY BETWEEN SOLENOID

TERMINAL AND CASE - TYPICAL

1 - SOLENOID TERMINAL

2 - OHMMETER

3 - SOLENOID

Fig. 9 STARTER R/I - 3.7L/4.7L - MAN. TRANS.

1 - EYELET TERMINAL

2 - NUT

3 - BRACKET

4 - STUD

5 - STARTER MOTOR

6 - LOCK WASHER

7 - WIRE HARNESS CONNECTOR

8 - NUT

9 - SCREW AND WASHER (2)

DRSTARTING 8F - 33

STARTER MOTOR (Continued)

Page 465 of 2627

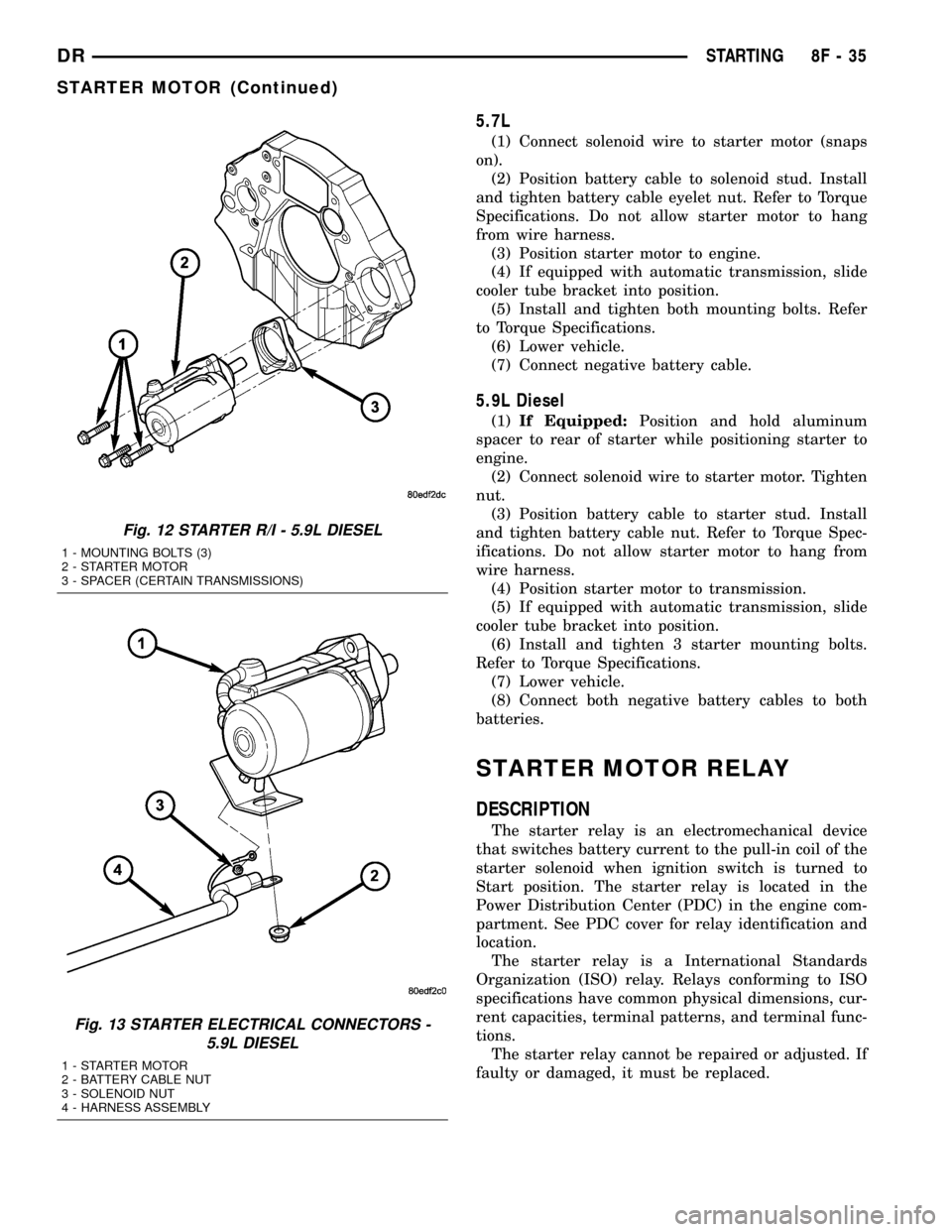

5.7L Gas

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Note: If equipped with 4WD and certain trans-

missions, a support bracket is used between front

axle and side of transmission. Remove 2 support

bracket bolts at transmission. Pry support bracket

slightly to gain access to lower starter mounting bolt.

(4) Remove 2 mounting bolts (Fig. 11).

(5) Move starter motor towards front of vehicle far

enough for nose of starter pinion housing to clear

housing. Always support starter motor during this

process, do not let starter motor hang from wire har-

ness.

(6) Tilt nose downwards and lower starter motor

far enough to access and remove nut that secures

battery positive cable wire harness connector eyelet

to solenoid battery terminal stud. Do not let starter

motor hang from wire harness.

(7) Remove battery positive cable wire harness

connector eyelet from solenoid battery terminal stud.

(8) Disconnect battery positive cable wire harness

connector from solenoid terminal connector recepta-

cle.

(9) Remove starter motor.

5.9L Diesel

(1) Disconnect and isolate both negative battery

cables at both batteries.

(2) Raise and support vehicle.

(3) Remove 3 starter mounting bolts (Fig. 12).(4) Move starter motor towards front of vehicle far

enough for nose of starter pinion housing to clear

housing. Always support starter motor during this

process. Do not let starter motor hang from wire har-

ness.

(5) Tilt nose downwards and lower starter motor

far enough to access and remove nuts securing

starter wiring harness to starter (Fig. 13). Do not let

starter motor hang from wire harness.

(6) Remove starter motor from engine. Note: Cer-

tain diesel engines use an aluminum spacer (Fig. 12).

Note position and orientation of spacer before

removal.

INSTALLATION

3.7L / 4.7L

(1) Connect solenoid wire to starter motor (snaps

on).

(2) Position battery cable to solenoid stud. Install

and tighten battery cable eyelet nut. Refer to Torque

Specifications. Do not allow starter motor to hang

from wire harness.

(3) Position starter motor to transmission.

(4) If equipped with automatic transmission, slide

cooler tube bracket into position.

(5) Install and tighten both bolts (auto. trans.), or

1 nut and 1 bolt (man. trans.). Refer to Torque Spec-

ifications.

(6) Lower vehicle.

(7) Connect negative battery cable.

Fig. 10 STARTER R/I - 3.7L/4.7L - AUTO. TRANS.

1 - EYELET TERMINAL

2 - NUT

3 - SCREW AND WASHER (2)

4 - STARTER MOTOR

5 - WIRE HARNESS CONNECTOR

Fig. 11 STARTER R/I - 5.7L

1 - STARTER MOTOR

2 - MOUNTING BOLTS

8F - 34 STARTINGDR

STARTER MOTOR (Continued)

Page 466 of 2627

5.7L

(1) Connect solenoid wire to starter motor (snaps

on).

(2) Position battery cable to solenoid stud. Install

and tighten battery cable eyelet nut. Refer to Torque

Specifications. Do not allow starter motor to hang

from wire harness.

(3) Position starter motor to engine.

(4) If equipped with automatic transmission, slide

cooler tube bracket into position.

(5) Install and tighten both mounting bolts. Refer

to Torque Specifications.

(6) Lower vehicle.

(7) Connect negative battery cable.

5.9L Diesel

(1)If Equipped:Position and hold aluminum

spacer to rear of starter while positioning starter to

engine.

(2) Connect solenoid wire to starter motor. Tighten

nut.

(3) Position battery cable to starter stud. Install

and tighten battery cable nut. Refer to Torque Spec-

ifications. Do not allow starter motor to hang from

wire harness.

(4) Position starter motor to transmission.

(5) If equipped with automatic transmission, slide

cooler tube bracket into position.

(6) Install and tighten 3 starter mounting bolts.

Refer to Torque Specifications.

(7) Lower vehicle.

(8) Connect both negative battery cables to both

batteries.

STARTER MOTOR RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when ignition switch is turned to

Start position. The starter relay is located in the

Power Distribution Center (PDC) in the engine com-

partment. See PDC cover for relay identification and

location.

The starter relay is a International Standards

Organization (ISO) relay. Relays conforming to ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions.

The starter relay cannot be repaired or adjusted. If

faulty or damaged, it must be replaced.

Fig. 12 STARTER R/I - 5.9L DIESEL

1 - MOUNTING BOLTS (3)

2 - STARTER MOTOR

3 - SPACER (CERTAIN TRANSMISSIONS)

Fig. 13 STARTER ELECTRICAL CONNECTORS -

5.9L DIESEL

1 - STARTER MOTOR

2 - BATTERY CABLE NUT

3 - SOLENOID NUT

4 - HARNESS ASSEMBLY

DRSTARTING 8F - 35

STARTER MOTOR (Continued)

Page 467 of 2627

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When electro-

magnetic coil is energized, it draws the movable con-

tact away from normally closed fixed contact, and

holds it against the other (normally open) fixed con-

tact.

When electromagnetic coil is de-energized, spring

pressure returns movable contact to normally closed

position. The resistor or diode is connected in parallel

with electromagnetic coil within relay, and helps to

dissipate voltage spikes produced when coil is de-en-

ergized.

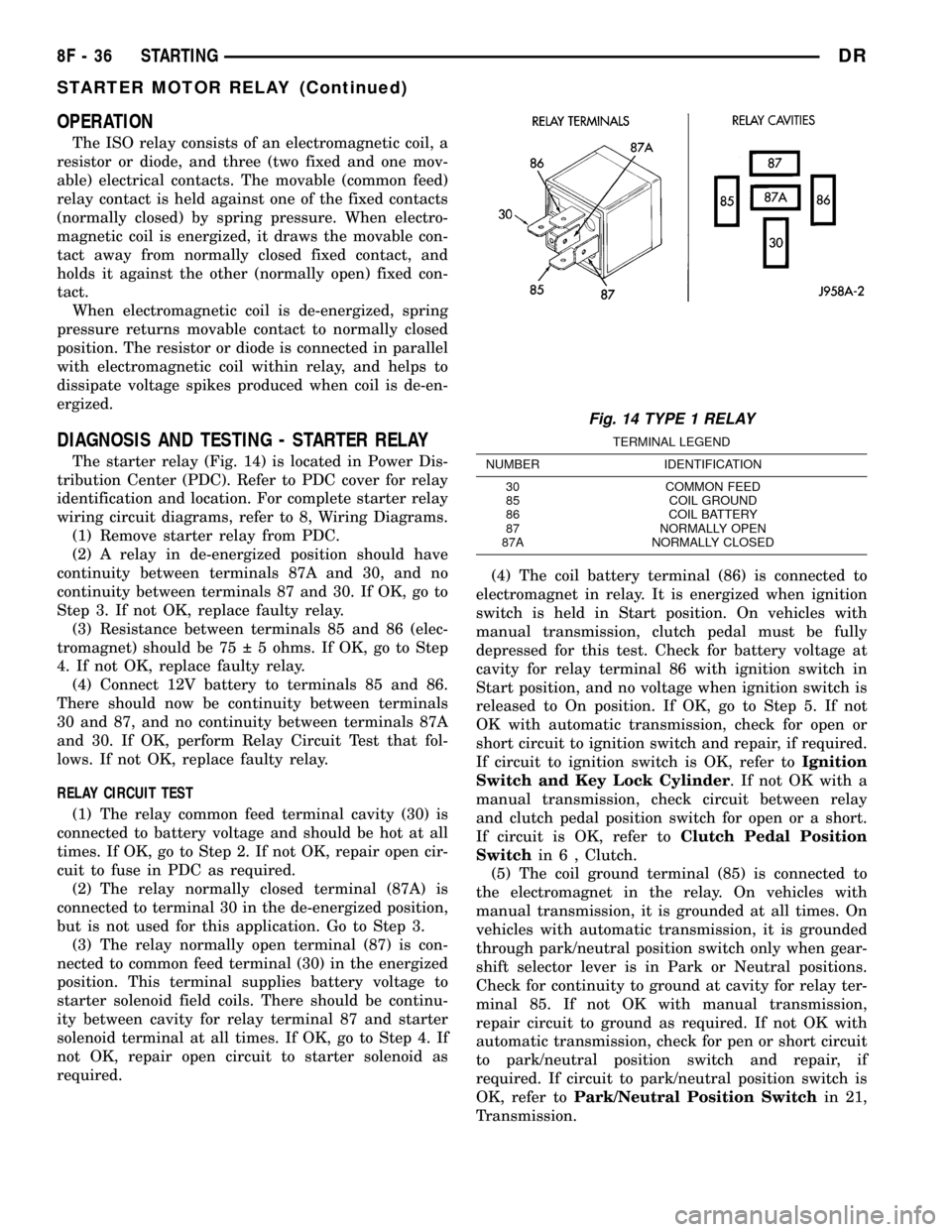

DIAGNOSIS AND TESTING - STARTER RELAY

The starter relay (Fig. 14) is located in Power Dis-

tribution Center (PDC). Refer to PDC cover for relay

identification and location. For complete starter relay

wiring circuit diagrams, refer to 8, Wiring Diagrams.

(1) Remove starter relay from PDC.

(2) A relay in de-energized position should have

continuity between terminals 87A and 30, and no

continuity between terminals 87 and 30. If OK, go to

Step 3. If not OK, replace faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace faulty relay.

(4) Connect 12V battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform Relay Circuit Test that fol-

lows. If not OK, replace faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair open cir-

cuit to fuse in PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to common feed terminal (30) in the energized

position. This terminal supplies battery voltage to

starter solenoid field coils. There should be continu-

ity between cavity for relay terminal 87 and starter

solenoid terminal at all times. If OK, go to Step 4. If

not OK, repair open circuit to starter solenoid as

required.(4) The coil battery terminal (86) is connected to

electromagnet in relay. It is energized when ignition

switch is held in Start position. On vehicles with

manual transmission, clutch pedal must be fully

depressed for this test. Check for battery voltage at

cavity for relay terminal 86 with ignition switch in

Start position, and no voltage when ignition switch is

released to On position. If OK, go to Step 5. If not

OK with automatic transmission, check for open or

short circuit to ignition switch and repair, if required.

If circuit to ignition switch is OK, refer toIgnition

Switch and Key Lock Cylinder. If not OK with a

manual transmission, check circuit between relay

and clutch pedal position switch for open or a short.

If circuit is OK, refer toClutch Pedal Position

Switchin 6 , Clutch.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. On vehicles with

manual transmission, it is grounded at all times. On

vehicles with automatic transmission, it is grounded

through park/neutral position switch only when gear-

shift selector lever is in Park or Neutral positions.

Check for continuity to ground at cavity for relay ter-

minal 85. If not OK with manual transmission,

repair circuit to ground as required. If not OK with

automatic transmission, check for pen or short circuit

to park/neutral position switch and repair, if

required. If circuit to park/neutral position switch is

OK, refer toPark/Neutral Position Switchin 21,

Transmission.

Fig. 14 TYPE 1 RELAY

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8F - 36 STARTINGDR

STARTER MOTOR RELAY (Continued)

Page 468 of 2627

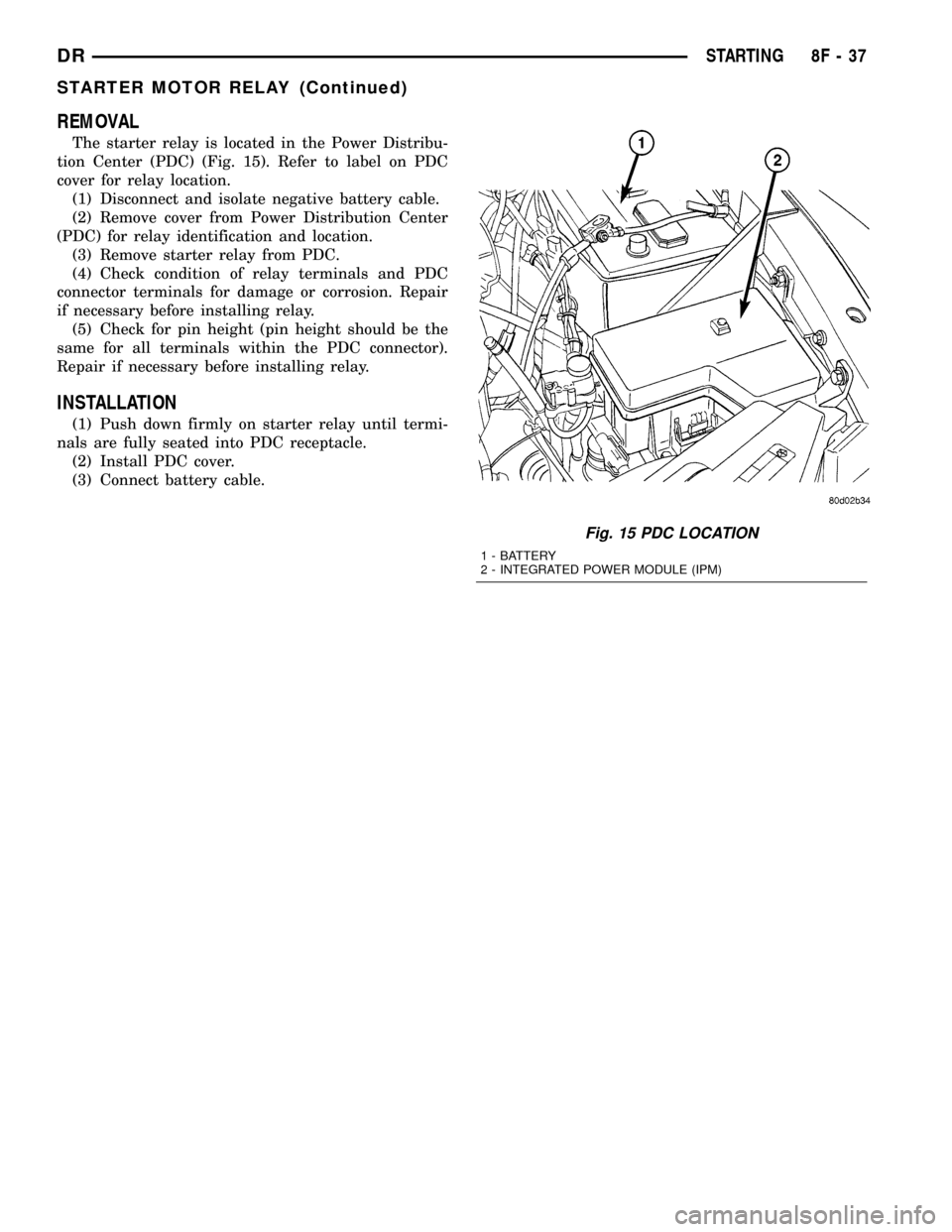

REMOVAL

The starter relay is located in the Power Distribu-

tion Center (PDC) (Fig. 15). Refer to label on PDC

cover for relay location.

(1) Disconnect and isolate negative battery cable.

(2) Remove cover from Power Distribution Center

(PDC) for relay identification and location.

(3) Remove starter relay from PDC.

(4) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(5) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

(1) Push down firmly on starter relay until termi-

nals are fully seated into PDC receptacle.

(2) Install PDC cover.

(3) Connect battery cable.

Fig. 15 PDC LOCATION

1 - BATTERY

2 - INTEGRATED POWER MODULE (IPM)

DRSTARTING 8F - 37

STARTER MOTOR RELAY (Continued)

Page 471 of 2627

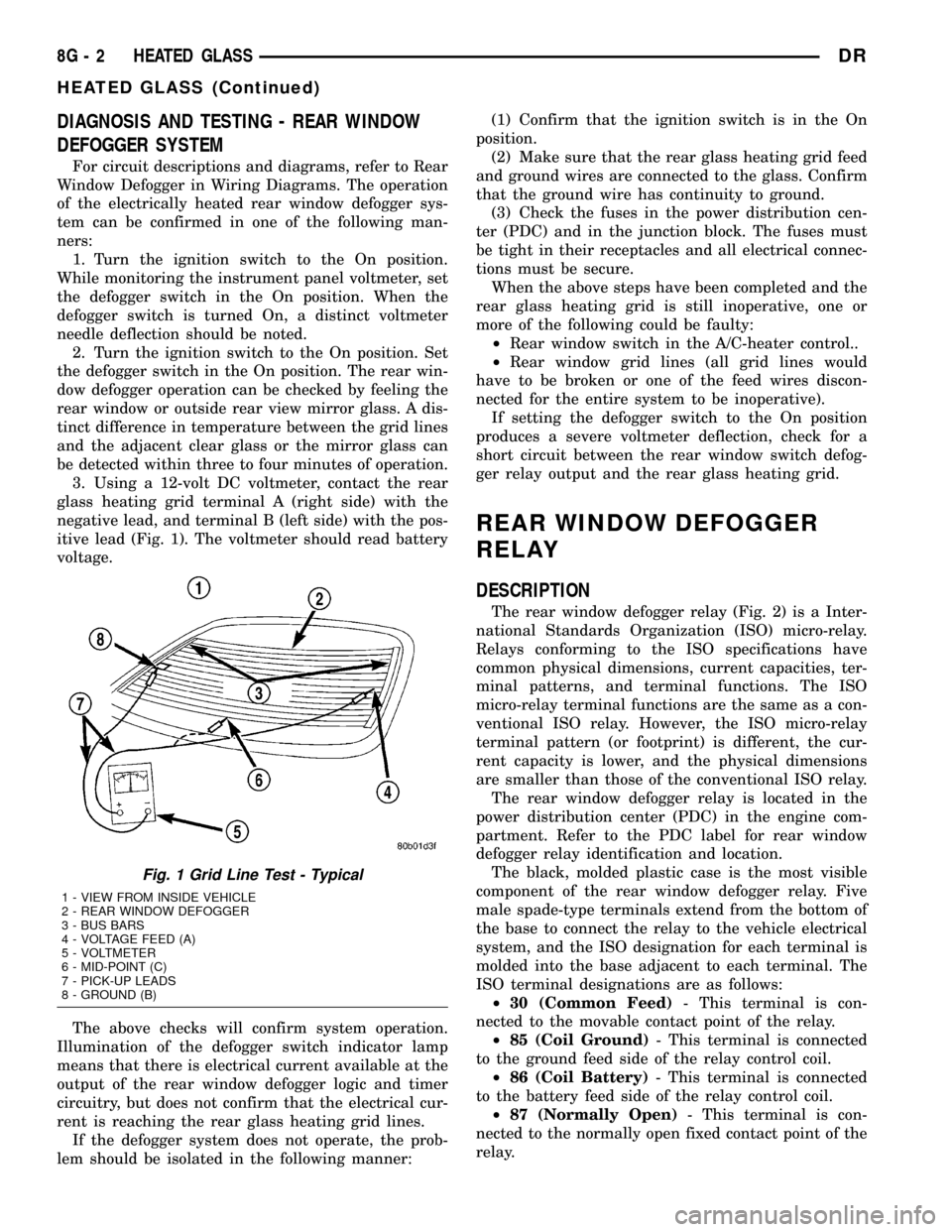

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SYSTEM

For circuit descriptions and diagrams, refer to Rear

Window Defogger in Wiring Diagrams. The operation

of the electrically heated rear window defogger sys-

tem can be confirmed in one of the following man-

ners:

1. Turn the ignition switch to the On position.

While monitoring the instrument panel voltmeter, set

the defogger switch in the On position. When the

defogger switch is turned On, a distinct voltmeter

needle deflection should be noted.

2. Turn the ignition switch to the On position. Set

the defogger switch in the On position. The rear win-

dow defogger operation can be checked by feeling the

rear window or outside rear view mirror glass. A dis-

tinct difference in temperature between the grid lines

and the adjacent clear glass or the mirror glass can

be detected within three to four minutes of operation.

3. Using a 12-volt DC voltmeter, contact the rear

glass heating grid terminal A (right side) with the

negative lead, and terminal B (left side) with the pos-

itive lead (Fig. 1). The voltmeter should read battery

voltage.

The above checks will confirm system operation.

Illumination of the defogger switch indicator lamp

means that there is electrical current available at the

output of the rear window defogger logic and timer

circuitry, but does not confirm that the electrical cur-

rent is reaching the rear glass heating grid lines.

If the defogger system does not operate, the prob-

lem should be isolated in the following manner:(1) Confirm that the ignition switch is in the On

position.

(2) Make sure that the rear glass heating grid feed

and ground wires are connected to the glass. Confirm

that the ground wire has continuity to ground.

(3) Check the fuses in the power distribution cen-

ter (PDC) and in the junction block. The fuses must

be tight in their receptacles and all electrical connec-

tions must be secure.

When the above steps have been completed and the

rear glass heating grid is still inoperative, one or

more of the following could be faulty:

²Rear window switch in the A/C-heater control..

²Rear window grid lines (all grid lines would

have to be broken or one of the feed wires discon-

nected for the entire system to be inoperative).

If setting the defogger switch to the On position

produces a severe voltmeter deflection, check for a

short circuit between the rear window switch defog-

ger relay output and the rear glass heating grid.

REAR WINDOW DEFOGGER

RELAY

DESCRIPTION

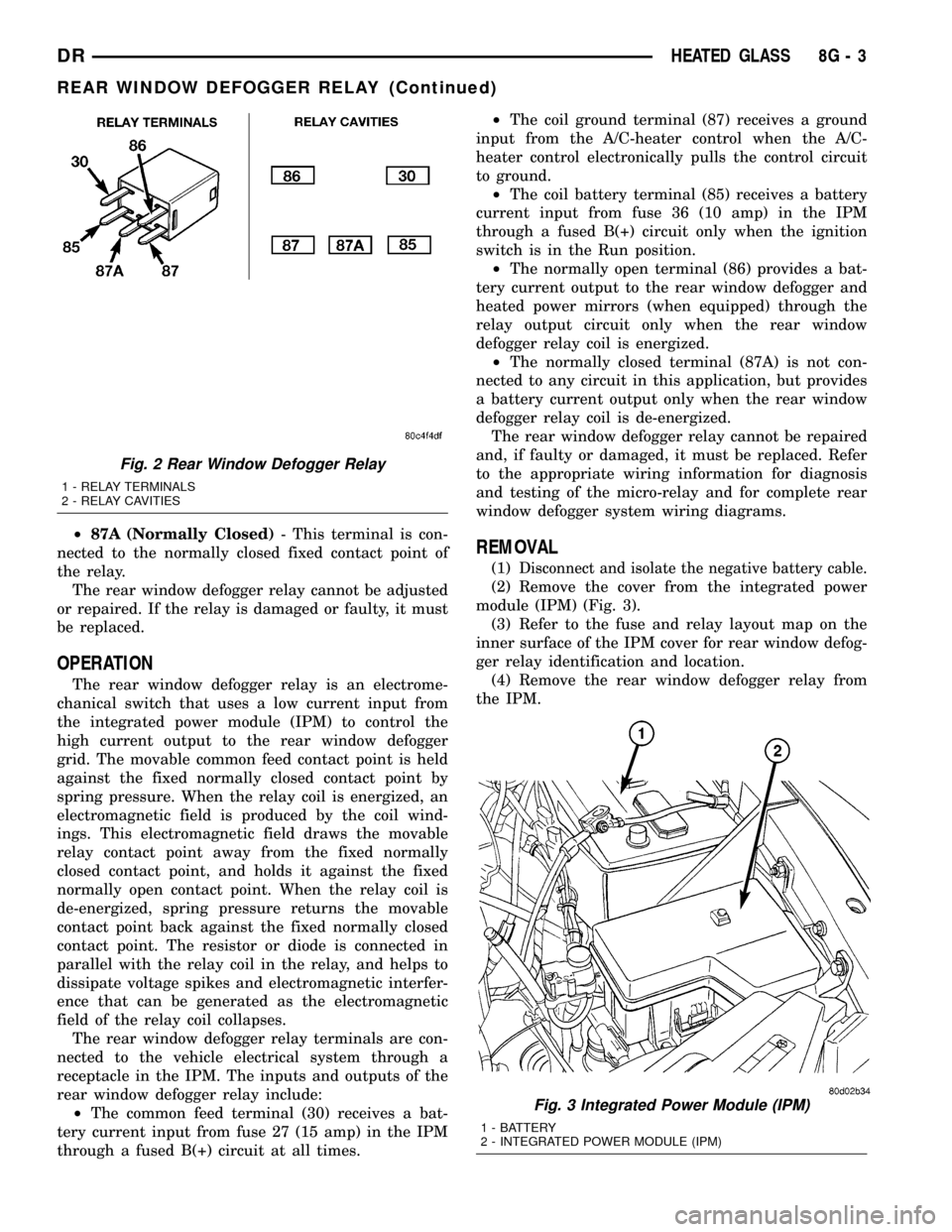

The rear window defogger relay (Fig. 2) is a Inter-

national Standards Organization (ISO) micro-relay.

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The ISO

micro-relay terminal functions are the same as a con-

ventional ISO relay. However, the ISO micro-relay

terminal pattern (or footprint) is different, the cur-

rent capacity is lower, and the physical dimensions

are smaller than those of the conventional ISO relay.

The rear window defogger relay is located in the

power distribution center (PDC) in the engine com-

partment. Refer to the PDC label for rear window

defogger relay identification and location.

The black, molded plastic case is the most visible

component of the rear window defogger relay. Five

male spade-type terminals extend from the bottom of

the base to connect the relay to the vehicle electrical

system, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

Fig. 1 Grid Line Test - Typical

1 - VIEW FROM INSIDE VEHICLE

2 - REAR WINDOW DEFOGGER

3 - BUS BARS

4 - VOLTAGE FEED (A)

5 - VOLTMETER

6 - MID-POINT (C)

7 - PICK-UP LEADS

8 - GROUND (B)

8G - 2 HEATED GLASSDR

HEATED GLASS (Continued)

Page 472 of 2627

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The rear window defogger relay cannot be adjusted

or repaired. If the relay is damaged or faulty, it must

be replaced.

OPERATION

The rear window defogger relay is an electrome-

chanical switch that uses a low current input from

the integrated power module (IPM) to control the

high current output to the rear window defogger

grid. The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The rear window defogger relay terminals are con-

nected to the vehicle electrical system through a

receptacle in the IPM. The inputs and outputs of the

rear window defogger relay include:

²The common feed terminal (30) receives a bat-

tery current input from fuse 27 (15 amp) in the IPM

through a fused B(+) circuit at all times.²The coil ground terminal (87) receives a ground

input from the A/C-heater control when the A/C-

heater control electronically pulls the control circuit

to ground.

²The coil battery terminal (85) receives a battery

current input from fuse 36 (10 amp) in the IPM

through a fused B(+) circuit only when the ignition

switch is in the Run position.

²The normally open terminal (86) provides a bat-

tery current output to the rear window defogger and

heated power mirrors (when equipped) through the

relay output circuit only when the rear window

defogger relay coil is energized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the rear window

defogger relay coil is de-energized.

The rear window defogger relay cannot be repaired

and, if faulty or damaged, it must be replaced. Refer

to the appropriate wiring information for diagnosis

and testing of the micro-relay and for complete rear

window defogger system wiring diagrams.

REMOVAL

(1)Disconnect and isolate the negative battery cable.

(2) Remove the cover from the integrated power

module (IPM) (Fig. 3).

(3) Refer to the fuse and relay layout map on the

inner surface of the IPM cover for rear window defog-

ger relay identification and location.

(4) Remove the rear window defogger relay from

the IPM.

Fig. 2 Rear Window Defogger Relay

1 - RELAY TERMINALS

2 - RELAY CAVITIES

Fig. 3 Integrated Power Module (IPM)

1 - BATTERY

2 - INTEGRATED POWER MODULE (IPM)

DRHEATED GLASS 8G - 3

REAR WINDOW DEFOGGER RELAY (Continued)