sensor DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2566 of 2627

OPERATION

OPERATION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

problem is repaired or ceases to exist, the PCM can-

cels the code after 40 warm-up cycles. Diagnostic

trouble codes that affect vehicle emissions illuminate

the Malfunction Indicator Lamp (MIL). The MIL is

displayed as an engine icon (graphic) on the instru-

ment panel. Refer to Malfunction Indicator Lamp in

this section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example,assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

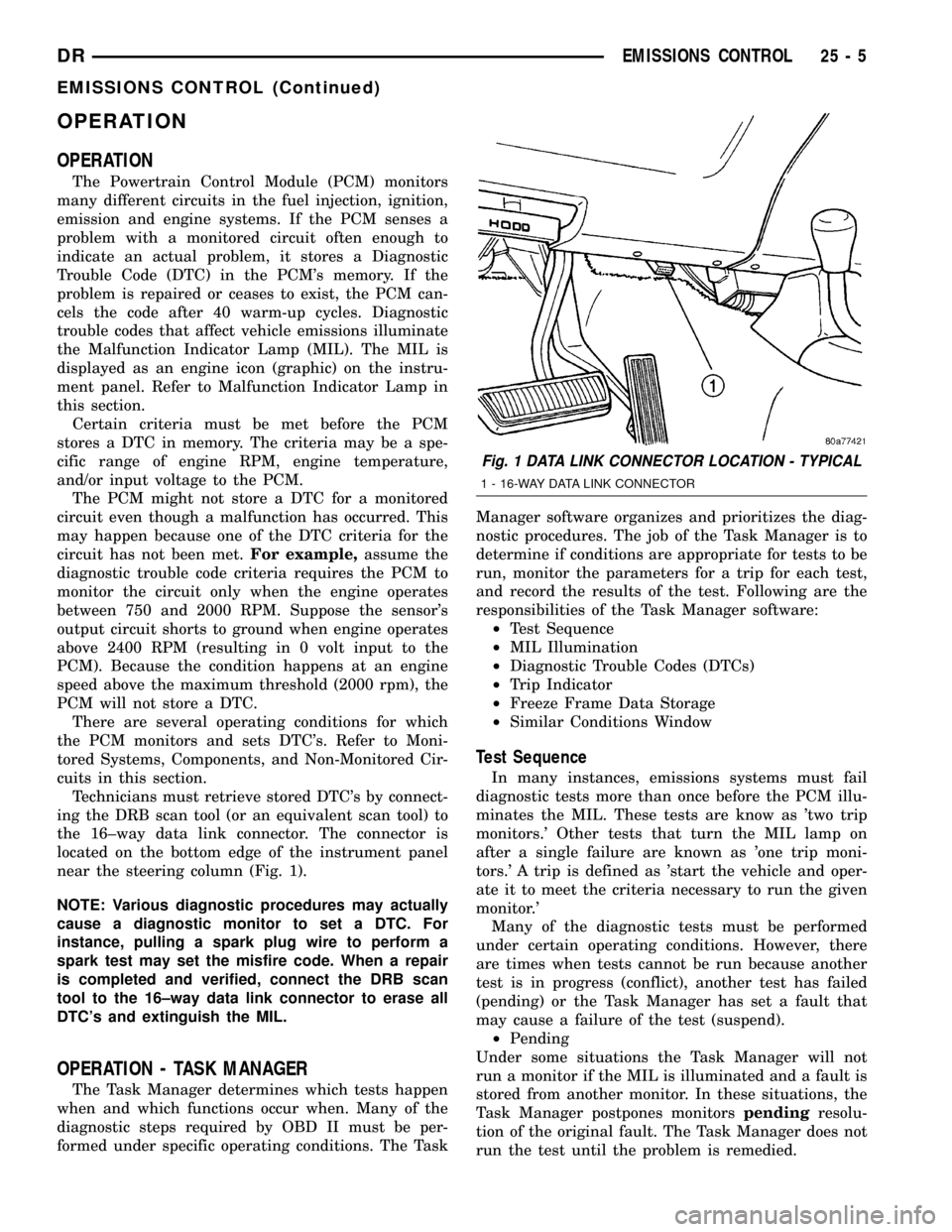

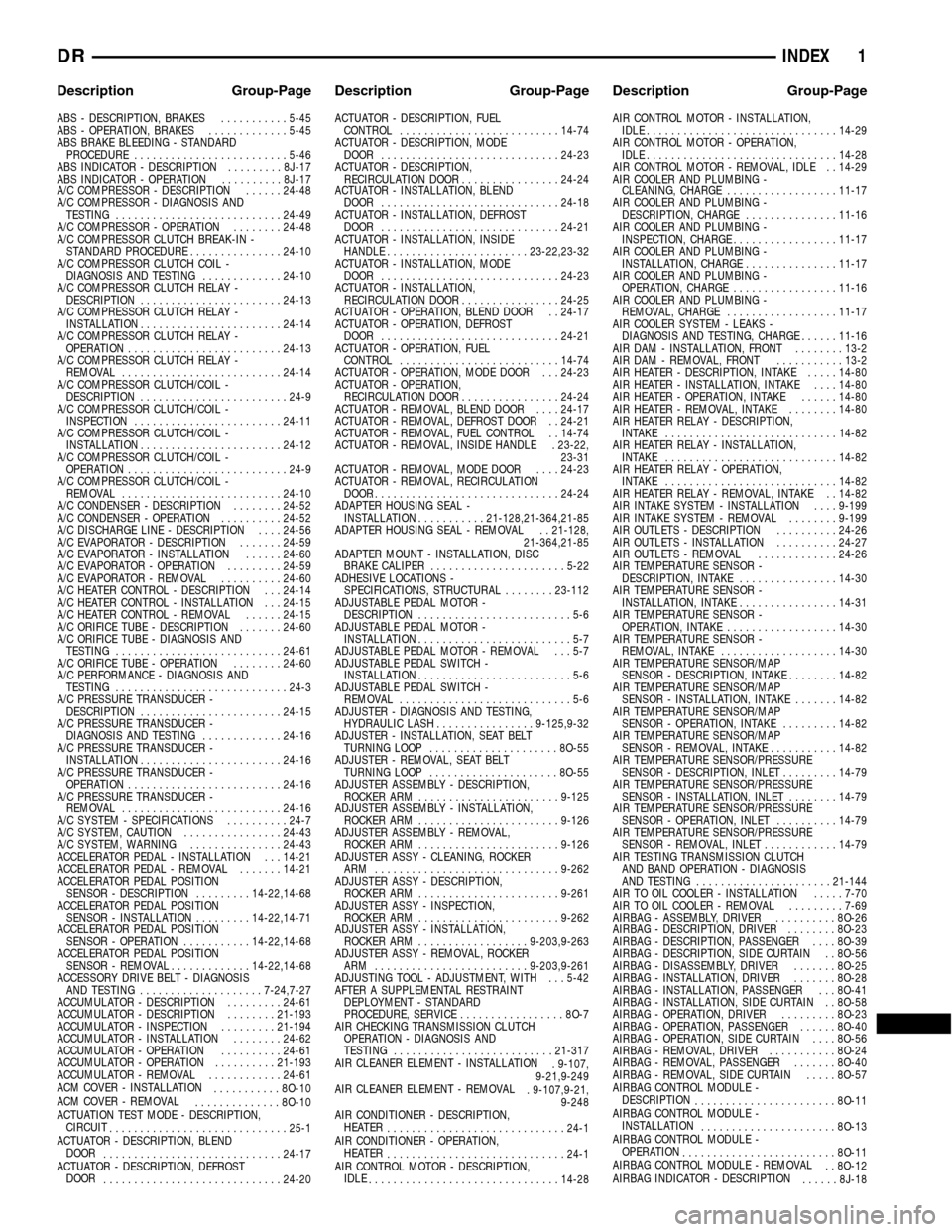

Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector. The connector is

located on the bottom edge of the instrument panel

near the steering column (Fig. 1).

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, connect the DRB scan

tool to the 16±way data link connector to erase all

DTC's and extinguish the MIL.

OPERATION - TASK MANAGER

The Task Manager determines which tests happen

when and which functions occur when. Many of the

diagnostic steps required by OBD II must be per-

formed under specific operating conditions. The TaskManager software organizes and prioritizes the diag-

nostic procedures. The job of the Task Manager is to

determine if conditions are appropriate for tests to be

run, monitor the parameters for a trip for each test,

and record the results of the test. Following are the

responsibilities of the Task Manager software:

²Test Sequence

²MIL Illumination

²Diagnostic Trouble Codes (DTCs)

²Trip Indicator

²Freeze Frame Data Storage

²Similar Conditions Window

Test Sequence

In many instances, emissions systems must fail

diagnostic tests more than once before the PCM illu-

minates the MIL. These tests are know as 'two trip

monitors.' Other tests that turn the MIL lamp on

after a single failure are known as 'one trip moni-

tors.' A trip is defined as 'start the vehicle and oper-

ate it to meet the criteria necessary to run the given

monitor.'

Many of the diagnostic tests must be performed

under certain operating conditions. However, there

are times when tests cannot be run because another

test is in progress (conflict), another test has failed

(pending) or the Task Manager has set a fault that

may cause a failure of the test (suspend).

²Pending

Under some situations the Task Manager will not

run a monitor if the MIL is illuminated and a fault is

stored from another monitor. In these situations, the

Task Manager postpones monitorspendingresolu-

tion of the original fault. The Task Manager does not

run the test until the problem is remedied.

Fig. 1 DATA LINK CONNECTOR LOCATION - TYPICAL

1 - 16-WAY DATA LINK CONNECTOR

DREMISSIONS CONTROL 25 - 5

EMISSIONS CONTROL (Continued)

Page 2567 of 2627

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is in

progress, the Task Manager does not run the EGR

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precis diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the EGR monitor, the

Task Manager may still run the EGR Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the EGR system is actu-

ally failing or if an Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

25 - 6 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2568 of 2627

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.

²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfireWarm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC and

Freeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for two

trip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-

lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

DREMISSIONS CONTROL 25 - 7

EMISSIONS CONTROL (Continued)

Page 2569 of 2627

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²Upstream O2S VoltsÐ A live reading of the

Oxygen Sensor to indicate its performance. For

example, stuck lean, stuck rich, etc.

²SCW Time in Window (Similar Conditions

Window Time in Window)Ð A timer used by the

PCM that indicates that, after all Similar Conditions

have been met, if there has been enough good engine

running time in the SCW without failure detected.

This timer is used to increment a Good Trip.

²Fuel System Good Trip CounterÐATrip

Counter used to turn OFF the MIL for Fuel System

DTCs. To increment a Fuel System Good Trip, the

engine must be in the Similar Conditions Window,

Adaptive Memory Factor must be less than cali-

brated threshold and the Adaptive Memory Factor

must stay below that threshold for a calibrated

amount of time.

²Test Done This TripÐ Indicates that the

monitor has already been run and completed during

the current trip.

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Misfire OccurredÐ

The stored MAP reading at the time of failure.

Informs the user at what engine load the failure

occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Misfire OccurredÐ The stored

RPM reading at the time of failure. Informs the user

at what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²200 Rev CounterÐ Counts 0±100 720 degree

cycles.²SCW Cat 200 Rev CounterÐ Counts when in

similar conditions.

²SCW FTP 1000 Rev CounterÐ Counts 0±4

when in similar conditions.

²Misfire Good Trip CounterÐ Counts up to

three to turn OFF the MIL.

²Misfire DataÐ Data collected during test.

²Test Done This TripÐ Indicates YES when the

test is done.

OPERATION - NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

causing driveability problems. The PCM might not

store diagnostic trouble codes for these conditions.

However, problems with these systems may cause the

PCM to store diagnostic trouble codes for other sys-

tems or components.EXAMPLE:a fuel pressure

problem will not register a fault directly, but could

cause a rich/lean condition or misfire. This could

cause the PCM to store an oxygen sensor or misfire

diagnostic trouble code

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system, although it may set a fuel

system fault.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

25 - 8 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2570 of 2627

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

DREMISSIONS CONTROL 25 - 9

EMISSIONS CONTROL (Continued)

Page 2588 of 2627

INDEX

ABS - DESCRIPTION, BRAKES...........5-45

ABS - OPERATION, BRAKES.............5-45

ABS BRAKE BLEEDING - STANDARD

PROCEDURE.........................5-46

ABS INDICATOR - DESCRIPTION.........8J-17

ABS INDICATOR - OPERATION..........8J-17

A/C COMPRESSOR - DESCRIPTION......24-48

A/C COMPRESSOR - DIAGNOSIS AND

TESTING...........................24-49

A/C COMPRESSOR - OPERATION........24-48

A/C COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-10

A/C COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-10

A/C COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-13

A/C COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-14

A/C COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-13

A/C COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-14

A/C COMPRESSOR CLUTCH/COIL -

DESCRIPTION........................24-9

A/C COMPRESSOR CLUTCH/COIL -

INSPECTION........................24-11

A/C COMPRESSOR CLUTCH/COIL -

INSTALLATION.......................24-12

A/C COMPRESSOR CLUTCH/COIL -

OPERATION..........................24-9

A/C COMPRESSOR CLUTCH/COIL -

REMOVAL..........................24-10

A/C CONDENSER - DESCRIPTION........24-52

A/C CONDENSER - OPERATION..........24-52

A/C DISCHARGE LINE - DESCRIPTION....24-56

A/C EVAPORATOR - DESCRIPTION.......24-59

A/C EVAPORATOR - INSTALLATION......24-60

A/C EVAPORATOR - OPERATION.........24-59

A/C EVAPORATOR - REMOVAL..........24-60

A/C HEATER CONTROL - DESCRIPTION . . . 24-14

A/C HEATER CONTROL - INSTALLATION . . . 24-15

A/C HEATER CONTROL - REMOVAL......24-15

A/C ORIFICE TUBE - DESCRIPTION.......24-60

A/C ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-61

A/C ORIFICE TUBE - OPERATION........24-60

A/C PERFORMANCE - DIAGNOSIS AND

TESTING............................24-3

A/C PRESSURE TRANSDUCER -

DESCRIPTION.......................24-15

A/C PRESSURE TRANSDUCER -

DIAGNOSIS AND TESTING.............24-16

A/C PRESSURE TRANSDUCER -

INSTALLATION.......................24-16

A/C PRESSURE TRANSDUCER -

OPERATION.........................24-16

A/C PRESSURE TRANSDUCER -

REMOVAL..........................24-16

A/C SYSTEM - SPECIFICATIONS..........24-7

A/C SYSTEM, CAUTION................24-43

A/C SYSTEM, WARNING...............24-43

ACCELERATOR PEDAL - INSTALLATION . . . 14-21

ACCELERATOR PEDAL - REMOVAL.......14-21

ACCELERATOR PEDAL POSITION

SENSOR - DESCRIPTION.........14-22,14-68

ACCELERATOR PEDAL POSITION

SENSOR - INSTALLATION.........14-22,14-71

ACCELERATOR PEDAL POSITION

SENSOR - OPERATION...........14-22,14-68

ACCELERATOR PEDAL POSITION

SENSOR - REMOVAL.............14-22,14-68

ACCESSORY DRIVE BELT - DIAGNOSIS

AND TESTING....................7-24,7-27

ACCUMULATOR - DESCRIPTION.........24-61

ACCUMULATOR - DESCRIPTION........21-193

ACCUMULATOR - INSPECTION.........21-194

ACCUMULATOR - INSTALLATION........24-62

ACCUMULATOR - OPERATION..........24-61

ACCUMULATOR - OPERATION..........21-193

ACCUMULATOR - REMOVAL............24-61

ACM COVER - INSTALLATION

...........8O-10

ACM COVER - REMOVAL

..............8O-10

ACTUATION TEST MODE - DESCRIPTION,

CIRCUIT

.............................25-1

ACTUATOR - DESCRIPTION, BLEND

DOOR

.............................24-17

ACTUATOR - DESCRIPTION, DEFROST

DOOR

.............................24-20ACTUATOR - DESCRIPTION, FUEL

CONTROL..........................14-74

ACTUATOR - DESCRIPTION, MODE

DOOR.............................24-23

ACTUATOR - DESCRIPTION,

RECIRCULATION DOOR................24-24

ACTUATOR - INSTALLATION, BLEND

DOOR.............................24-18

ACTUATOR - INSTALLATION, DEFROST

DOOR.............................24-21

ACTUATOR - INSTALLATION, INSIDE

HANDLE.......................23-22,23-32

ACTUATOR - INSTALLATION, MODE

DOOR.............................24-23

ACTUATOR - INSTALLATION,

RECIRCULATION DOOR................24-25

ACTUATOR - OPERATION, BLEND DOOR . . 24-17

ACTUATOR - OPERATION, DEFROST

DOOR.............................24-21

ACTUATOR - OPERATION, FUEL

CONTROL..........................14-74

ACTUATOR - OPERATION, MODE DOOR . . . 24-23

ACTUATOR - OPERATION,

RECIRCULATION DOOR................24-24

ACTUATOR - REMOVAL, BLEND DOOR....24-17

ACTUATOR - REMOVAL, DEFROST DOOR . . 24-21

ACTUATOR - REMOVAL, FUEL CONTROL . . 14-74

ACTUATOR - REMOVAL, INSIDE HANDLE . 23-22,

23-31

ACTUATOR - REMOVAL, MODE DOOR....24-23

ACTUATOR - REMOVAL, RECIRCULATION

DOOR...............................24-24

ADAPTER HOUSING SEAL -

INSTALLATION...........21-128,21-364,21-85

ADAPTER HOUSING SEAL - REMOVAL . . 21-128,

21-364,21-85

ADAPTER MOUNT - INSTALLATION, DISC

BRAKE CALIPER......................5-22

ADHESIVE LOCATIONS -

SPECIFICATIONS, STRUCTURAL........23-112

ADJUSTABLE PEDAL MOTOR -

DESCRIPTION.........................5-6

ADJUSTABLE PEDAL MOTOR -

INSTALLATION.........................5-7

ADJUSTABLE PEDAL MOTOR - REMOVAL . . . 5-7

ADJUSTABLE PEDAL SWITCH -

INSTALLATION.........................5-6

ADJUSTABLE PEDAL SWITCH -

REMOVAL............................5-6

ADJUSTER - DIAGNOSIS AND TESTING,

HYDRAULIC LASH................9-125,9-32

ADJUSTER - INSTALLATION, SEAT BELT

TURNING LOOP.....................8O-55

ADJUSTER - REMOVAL, SEAT BELT

TURNING LOOP.....................8O-55

ADJUSTER ASSEMBLY - DESCRIPTION,

ROCKER ARM.......................9-125

ADJUSTER ASSEMBLY - INSTALLATION,

ROCKER ARM.......................9-126

ADJUSTER ASSEMBLY - REMOVAL,

ROCKER ARM.......................9-126

ADJUSTER ASSY - CLEANING, ROCKER

ARM ..............................9-262

ADJUSTER ASSY - DESCRIPTION,

ROCKER ARM.......................9-261

ADJUSTER ASSY - INSPECTION,

ROCKER ARM.......................9-262

ADJUSTER ASSY - INSTALLATION,

ROCKER ARM..................9-203,9-263

ADJUSTER ASSY - REMOVAL, ROCKER

ARM .........................9-203,9-261

ADJUSTING TOOL - ADJUSTMENT, WITH . . . 5-42

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE.................8O-7

AIR CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING..........................21-317

AIR CLEANER ELEMENT - INSTALLATION

. 9-107,

9-21,9-249

AIR CLEANER ELEMENT - REMOVAL

. 9-107,9-21,

9-248

AIR CONDITIONER - DESCRIPTION,

HEATER

.............................24-1

AIR CONDITIONER - OPERATION,

HEATER

.............................24-1

AIR CONTROL MOTOR - DESCRIPTION,

IDLE

...............................14-28AIR CONTROL MOTOR - INSTALLATION,

IDLE...............................14-29

AIR CONTROL MOTOR - OPERATION,

IDLE...............................14-28

AIR CONTROL MOTOR - REMOVAL, IDLE . . 14-29

AIR COOLER AND PLUMBING -

CLEANING, CHARGE..................11-17

AIR COOLER AND PLUMBING -

DESCRIPTION, CHARGE...............11-16

AIR COOLER AND PLUMBING -

INSPECTION, CHARGE.................11-17

AIR COOLER AND PLUMBING -

INSTALLATION, CHARGE...............11-17

AIR COOLER AND PLUMBING -

OPERATION, CHARGE.................11-16

AIR COOLER AND PLUMBING -

REMOVAL, CHARGE..................11-17

AIR COOLER SYSTEM - LEAKS -

DIAGNOSIS AND TESTING, CHARGE......11-16

AIR DAM - INSTALLATION, FRONT........13-2

AIR DAM - REMOVAL, FRONT...........13-2

AIR HEATER - DESCRIPTION, INTAKE.....14-80

AIR HEATER - INSTALLATION, INTAKE....14-80

AIR HEATER - OPERATION, INTAKE......14-80

AIR HEATER - REMOVAL, INTAKE........14-80

AIR HEATER RELAY - DESCRIPTION,

INTAKE ............................14-82

AIR HEATER RELAY - INSTALLATION,

INTAKE ............................14-82

AIR HEATER RELAY - OPERATION,

INTAKE ............................14-82

AIR HEATER RELAY - REMOVAL, INTAKE . . 14-82

AIR INTAKE SYSTEM - INSTALLATION....9-199

AIR INTAKE SYSTEM - REMOVAL........9-199

AIR OUTLETS - DESCRIPTION..........24-26

AIR OUTLETS - INSTALLATION..........24-27

AIR OUTLETS - REMOVAL.............24-26

AIR TEMPERATURE SENSOR -

DESCRIPTION, INTAKE................14-30

AIR TEMPERATURE SENSOR -

INSTALLATION, INTAKE................14-31

AIR TEMPERATURE SENSOR -

OPERATION, INTAKE..................14-30

AIR TEMPERATURE SENSOR -

REMOVAL, INTAKE...................14-30

AIR TEMPERATURE SENSOR/MAP

SENSOR - DESCRIPTION, INTAKE........14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - INSTALLATION, INTAKE.......14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - OPERATION, INTAKE.........14-82

AIR TEMPERATURE SENSOR/MAP

SENSOR - REMOVAL, INTAKE...........14-82

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - DESCRIPTION, INLET.........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - INSTALLATION, INLET........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - OPERATION, INLET..........14-79

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - REMOVAL, INLET............14-79

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION - DIAGNOSIS

AND TESTING......................21-144

AIR TO OIL COOLER - INSTALLATION.....7-70

AIR TO OIL COOLER - REMOVAL.........7-69

AIRBAG - ASSEMBLY, DRIVER..........8O-26

AIRBAG - DESCRIPTION, DRIVER........8O-23

AIRBAG - DESCRIPTION, PASSENGER....8O-39

AIRBAG - DESCRIPTION, SIDE CURTAIN . . 8O-56

AIRBAG - DISASSEMBLY, DRIVER.......8O-25

AIRBAG - INSTALLATION, DRIVER.......8O-28

AIRBAG - INSTALLATION, PASSENGER . . . 8O-41

AIRBAG - INSTALLATION, SIDE CURTAIN . . 8O-58

AIRBAG - OPERATION, DRIVER.........8O-23

AIRBAG - OPERATION, PASSENGER......8O-40

AIRBAG - OPERATION, SIDE CURTAIN....8O-56

AIRBAG - REMOVAL, DRIVER...........8O-24

AIRBAG - REMOVAL, PASSENGER.......8O-40

AIRBAG - REMOVAL, SIDE CURTAIN.....8O-57

AIRBAG CONTROL MODULE -

DESCRIPTION

.......................8O-11

AIRBAG CONTROL MODULE -

INSTALLATION

......................8O-13

AIRBAG CONTROL MODULE -

OPERATION

.........................8O-11

AIRBAG CONTROL MODULE - REMOVAL

. . 8O-12

AIRBAG INDICATOR - DESCRIPTION

......8J-18

DRINDEX 1

Description Group-Page Description Group-Page Description Group-Page

Page 2589 of 2627

AIRBAG INDICATOR - OPERATION.......8J-18

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-42

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-44

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-43

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-43

AJAR INDICATOR - DESCRIPTION, DOOR . . 8J-23

AJAR INDICATOR - OPERATION, DOOR . . . 8J-23

AJAR SWITCH - DESCRIPTION, DOOR....8L-27

AJAR SWITCH - OPERATION, DOOR......8L-27

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURE.................2-5

ALIGNMENT, SPECIAL TOOLS - WHEEL.....2-7

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD PROCEDURE........21-158,21-318

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-10

AMBIENT TEMP SENSOR - OPERATION . . 8M-10

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS AND TESTING.............8M-10

AMBIENT TEMPERATURE SENSOR

CIRCUIT - DIAGNOSIS AND TESTING....8M-10

AMPLIFIER - DESCRIPTION.............8A-3

AMPLIFIER - INSTALLATION.............8A-4

AMPLIFIER - OPERATION...............8A-3

AMPLIFIER - REMOVAL................8A-3

ANCHOR - DESCRIPTION, CHILD

RESTRAINT.........................8O-15

ANCHOR - INSTALLATION, CHILD

RESTRAINT.........................8O-18

ANCHOR - OPERATION, CHILD

RESTRAINT.........................8O-17

ANCHOR - REMOVAL, CHILD RESTRAINT . 8O-17

ANCHOR & RIGHT OUTBOARD -

INSTALLATION, CENTER...............8O-50

ANCHOR & RIGHT OUTBOARD -

REMOVAL, CENTER...................8O-49

ANTENNA - NAVIGATION -

INSTALLATION.......................8A-6

ANTENNA - NAVIGATION - REMOVAL......8A-6

ANTENNA BODY & CABLE -

DESCRIPTION........................8A-4

ANTENNA BODY & CABLE -

INSTALLATION.......................8A-6

ANTENNA BODY & CABLE - OPERATION . . . 8A-4

ANTENNA BODY & CABLE - REMOVAL.....8A-6

ANTENNA BODY AND CABLE -

DIAGNOSIS AND TESTING..............8A-4

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL..................8A-7

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL..................8A-7

ANTILOCK - DIAGNOSIS AND TESTING,

REAR WHEEL........................5-48

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER

........................8E-3

ANTILOCK BRAKE - OPERATION,

CONTROLLER

........................8E-3

ANTILOCK BRAKE - REMOVAL,

CONTROLLER

........................8E-3

A-PILLAR TRIM/GRAB HANDLE -

INSTALLATION

.......................23-63

A-PILLAR TRIM/GRAB HANDLE -

REMOVAL

..........................23-63

A-PILLAR WEATHERSTRIP RETAINER -

INSTALLATION

.......................23-91

A-PILLAR WEATHERSTRIP RETAINER -

REMOVAL

..........................23-91

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL

........9-137,9-209,9-65

ARM / ADJUSTER ASSEMBLY -

DESCRIPTION, ROCKER

...............9-125

ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER

...............9-126

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER

..................9-126

ARM / ADJUSTER ASSY - CLEANING,

ROCKER

............................9-262

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER

............................9-261ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-262

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER..........9-203,9-263

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER......................9-203,9-261

ARM - DESCRIPTION, ROCKER......9-31,9-37

ARM - DESCRIPTION, WIPER...........8R-17

ARM - INSTALLATION, LOWER

SUSPENSION.........................2-38

ARM - INSTALLATION, PITMAN.........19-37

ARM - INSTALLATION, ROCKER..........9-31

ARM - INSTALLATION, UPPER CONTROL . . . 2-28

ARM - INSTALLATION, WIPER..........8R-18

ARM - OPERATION, WIPER............8R-18

ARM - REMOVAL, LOWER SUSPENSION . . . 2-38

ARM - REMOVAL, PITMAN.............19-36

ARM - REMOVAL, ROCKER..........9-31,9-37

ARM - REMOVAL, UPPER CONTROL......2-28

ARM - REMOVAL, WIPER..............8R-18

ARM BUSHINGS - 2WD (LD) -

INSTALLATION, LOWER CONTROL........2-15

ARM BUSHINGS - 2WD (LD) -

REMOVAL, LOWER CONTROL............2-13

ARM BUSHINGS - 4WD (LD) -

INSTALLATION, LOWER CONTROL........2-14

ARM BUSHINGS - 4WD (LD) -

REMOVAL, LOWER CONTROL............2-13

ARMREST / SEAT BACK - INSTALLATION,

CENTER.............................23-77

ARMREST / SEAT BACK - REMOVAL,

CENTER............................23-76

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-5

ASD SENSE - PCM INPUT - OPERATION....8I-5

ASH RECEIVER - INSTALLATION.........23-51

ASH RECEIVER - REMOVAL............23-50

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-1

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-11

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-12

AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION.......................8O-14

AUTOMATIC LOCKING RETRACTOR -

OPERATION.........................8O-14

AUTOMATIC TRANSMISSION -

45RFE/545RFE - DESCRIPTION.........21-312

AUTOMATIC TRANSMISSION -

45RFE/545RFE - OPERATION...........21-313

AUTOMATIC TRANSMISSION - 48RE -

DESCRIPTION......................21-132

AUTOMATIC TRANSMISSION - 48RE -

OPERATION........................21-134

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING......21-140,21-314

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-4

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-5

AUXILIARY SPRING BUMPERS (3500) -

INSTALLATION........................2-43

AUXILIARY SPRING BUMPERS (3500) -

REMOVAL...........................2-43

AXLE - 10 1/2 AA - ADJUSTMENTS,

REAR..............................3-116

AXLE - 10 1/2 AA - DIAGNOSIS AND

TESTING, REAR......................3-112

AXLE - 10 1/2 AA - INSTALLATION,

REAR..............................3-116

AXLE - 10 1/2 AA - REMOVAL, REAR.....3-115

AXLE - 10 1/2 AA - SPECIAL TOOLS,

REAR..............................3-120

AXLE - 10 1/2 AA - SPECIFICATIONS,

REAR

..............................3-120

AXLE - 11 1/2 AA - ADJUSTMENTS,

REAR

..............................3-144

AXLE - 11 1/2 AA - DIAGNOSIS AND

TESTING, REAR

......................3-140

AXLE - 11 1/2 AA - INSTALLATION,

REAR

..............................3-144

AXLE - 11 1/2 AA - REMOVAL, REAR

.....3-143AXLE - 11 1/2 AA - SPECIAL TOOLS,

REAR..............................3-148

AXLE - 11 1/2 AA - SPECIFICATIONS,

REAR..............................3-148

AXLE - 9 1/4 - ADJUSTMENTS, REAR.....3-83

AXLE - 9 1/4 - DIAGNOSIS AND

TESTING, REAR.......................3-80

AXLE - 9 1/4 - INSTALLATION, REAR......3-83

AXLE - 9 1/4 - REMOVAL, REAR..........3-83

AXLE - 9 1/4 - SPECIAL TOOLS, REAR.....3-90

AXLE - 9 1/4 - SPECIFICATIONS, REAR....3-90

AXLE - 9 1/4 AA - ADJUSTMENTS,

FRONT..............................3-59

AXLE - 9 1/4 AA - DIAGNOSIS AND

TESTING, FRONT......................3-54

AXLE - 9 1/4 AA - INSTALLATION,

FRONT..............................3-58

AXLE - 9 1/4 AA - REMOVAL, FRONT......3-57

AXLE - 9 1/4 AA - SPECIAL TOOLS,

FRONT..............................3-64

AXLE - 9 1/4 AA - SPECIFICATIONS,

FRONT..............................3-63

AXLE - C205F - ADJUSTMENTS, FRONT....3-32

AXLE - C205F - DIAGNOSIS AND

TESTING, FRONT......................3-27

AXLE - C205F - INSTALLATION, FRONT....3-31

AXLE - C205F - REMOVAL, FRONT........3-31

AXLE - C205F - SPECIAL TOOLS, FRONT . . . 3-40

AXLE - C205F - SPECIFICATIONS, FRONT . . . 3-39

AXLE - DESCRIPTION.....................0-4

AXLE BEARINGS - INSTALLATION . . 3-125,3-153,

3-44,3-95

AXLE BEARINGS - REMOVAL . . 3-125,3-152,3-43,

3-95

AXLE SHAFT SEALS - INSTALLATION . 3-43,3-70,

3-94

AXLE SHAFT SEALS - REMOVAL . 3-43,3-69,3-94

AXLE SHAFTS - ASSEMBLY.............3-69

AXLE SHAFTS - DISASSEMBLY...........3-68

AXLE SHAFTS - INSTALLATION....3-124,3-152,

3-43,3-69,3-94

AXLE SHAFTS - REMOVAL....3-124,3-152,3-43,

3-67,3-93

BACK - INSTALLATION, CENTER

ARMREST / SEAT....................23-77

BACK - REAR - INSTALLATION, SEAT.....23-83

BACK - REAR - REMOVAL, SEAT........23-83

BACK - REMOVAL, CENTER ARMREST /

SEAT ..............................23-76

BACK CUSHION / COVER - FRONT -

INSTALLATION, SEAT.................23-82

BACK CUSHION / COVER - FRONT -

REMOVAL, SEAT.....................23-82

BACK CUSHION / COVER - REAR -

INSTALLATION, SEAT.................23-84

BACK CUSHION / COVER - REAR -

REMOVAL, SEAT.....................23-84

BACK HINGE - INSTALLATION, CENTER

SEAT ..............................23-79

BACK HINGE - REMOVAL, CENTER SEAT . . 23-78

BACK INERTIA HINGE COVER -

INSTALLATION, CENTER SEAT..........23-77

BACK INERTIA HINGE COVER -

REMOVAL, CENTER SEAT..............23-77

BACK LID - INSTALLATION, CENTER

SEAT ..............................23-79

BACK LID - REMOVAL, CENTER SEAT....23-79

BACK PANEL TRIM - INSTALLATION,

REAR CAB..........................23-69

BACK PANEL TRIM - REMOVAL, REAR

CAB

...............................23-68

BACK REAR - FOOTMANS LOOP

BRACKETS - INSTALLATION, SEAT

.......23-85

BACK REAR - FOOTMANS LOOP

BRACKETS - REMOVAL, SEAT

...........23-85

BACKLITE - INSTALLATION

.............23-86

BACKLITE - REMOVAL

.................23-86

BACKLITE VENT GLASS - INSTALLATION

. . 23-87

BACKLITE VENT GLASS - REMOVAL

......23-87

BACKUP LAMP SWITCH - DESCRIPTION

. . . 8L-8

BACKUP LAMP SWITCH - DIAGNOSIS

AND TESTING

........................8L-8

BACKUP LAMP SWITCH - OPERATION

.....8L-8

BALANCE - STANDARD PROCEDURE,

TIRE AND WHEEL

.....................22-4

BALANCE SHAFT - INSTALLATION

........9-80

BALANCE SHAFT - REMOVAL

............9-80

2 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2590 of 2627

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.........................2-19,2-34

BALL JOINT - DIAGNOSIS AND TESTING,

UPPER..........................2-27,2-36

BALL JOINT - INSTALLATION, LOWER . 2-20,2-35

BALL JOINT - INSTALLATION, UPPER.....2-36

BALL JOINT - REMOVAL, LOWER.....2-19,2-35

BALL JOINT - REMOVAL, UPPER.........2-36

BAND OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING

TRANSMISSION CLUTCH.............21-144

BANDS - ADJUSTMENT...............21-195

BANDS - DESCRIPTION...............21-194

BANDS - OPERATION................21-194

BAR - DESCRIPTION, STABILIZER........2-24

BAR - DESCRIPTION, TORSION..........2-26

BAR - INSTALLATION, STABILIZER....2-25,2-40

BAR - INSTALLATION, TORSION..........2-27

BAR - INSTALLATION, TRACK...........19-38

BAR - OPERATION, STABILIZER..........2-25

BAR - OPERATION, TORSION............2-26

BAR - REMOVAL, STABILIZER.......2-25,2-39

BAR - REMOVAL, TORSION.............2-26

BAR - REMOVAL, TRACK..............19-38

BAR CROSS MEMBER BUSHING -

INSTALLATION, TORSION...............2-15

BAR CROSSMEMBER BUSHING -

REMOVAL, TORSION...................2-13

BASE BRAKE, SPECIFICATIONS...........5-10

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING.............................5-2

BASE BRAKES, SPECIAL TOOLS...........5-5

BASECOAT/CLEARCOAT FINISH -

DESCRIPTION.......................23-73

BATTERIES - STANDARD PROCEDURE,

RKE TRANSMITTER...................8N-8

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-7

BATTERY CABLES - DESCRIPTION.......8F-14

BATTERY CABLES - DIAGNOSIS AND

TESTING...........................8F-15

BATTERY CABLES - INSTALLATION.......8F-17

BATTERY CABLES - OPERATION.........8F-15

BATTERY CABLES - REMOVAL..........8F-16

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-8

BATTERY HOLDDOWN - DESCRIPTION....8F-14

BATTERY HOLDDOWN - INSTALLATION . . . 8F-14

BATTERY HOLDDOWN - OPERATION.....8F-14

BATTERY HOLDDOWN - REMOVAL.......8F-14

BATTERY SYSTEM - CLEANING...........8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-5

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM - SPECIFICATIONS......8F-6

BATTERY SYSTEM SPECIAL TOOLS,

SPECIAL TOOLS......................8F-7

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-21

BATTERY TEMPERATURE SENSOR -

INSTALLATION.......................8F-21

BATTERY TEMPERATURE SENSOR -

OPERATION.........................8F-21

BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-21

BATTERY TESTER - STANDARD

PROCEDURE, USING MICRO 420........8F-12

BATTERY TRAY - DESCRIPTION.........8F-17

BATTERY TRAY - INSTALLATION.........8F-18

BATTERY TRAY - OPERATION...........8F-17

BATTERY TRAY - REMOVAL............8F-17

BEAM INDICATOR - DESCRIPTION, HIGH . . 8J-28

BEAM INDICATOR - OPERATION, HIGH....8J-28

BEARING - ADJUSTMENTS, CENTER.......3-9

BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT MAIN . . 9-134,9-207

BEARING - INSTALLATION, CENTER........3-9

BEARING - INSTALLATION, CLUTCH

RELEASE............................6-10

BEARING - INSTALLATION, HUB

..........2-32

BEARING - INSTALLATION, OUTPUT

SHAFT FRONT

......................21-216

BEARING - INSTALLATION, OUTPUT

SHAFT REAR

.......................21-217

BEARING - INSTALLATION, PILOT

........6-12

BEARING - REMOVAL, CENTER

...........3-9BEARING - REMOVAL, CLUTCH RELEASE . . . 6-9

BEARING - REMOVAL, HUB.............2-31

BEARING - REMOVAL, OUTPUT SHAFT

FRONT............................21-216

BEARING - REMOVAL, OUTPUT SHAFT

REAR.............................21-216

BEARING - REMOVAL, PILOT............6-11

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD........9-272

BEARING CLEARANCE - STANDARD

PROCEDURE, MAIN...................9-274

BEARING FITTING - STANDARD

PROCEDURE, CONNECTING ROD........9-129

BEARING FITTING, STANDARD

PROCEDURE - CONNECTING ROD........9-49

BEARING FITTING, STANDARD

PROCEDURE - MAIN...................9-44

BEARINGS - INSPECTION, CRANKSHAFT

MAIN.........................9-135,9-208

BEARINGS - INSTALLATION, AXLE . . 3-125,3-153,

3-44,3-95

BEARINGS - INSTALLATION, CAMSHAFT . . 9-271

BEARINGS - INSTALLATION,

DIFFERENTIAL CASE . . . 3-106,3-134,3-161,3-48,

3-75

BEARINGS - REMOVAL, AXLE . 3-125,3-152,3-43,

3-95

BEARINGS - REMOVAL, CAMSHAFT......9-268

BEARINGS - REMOVAL, DIFFERENTIAL

CASE............3-105,3-134,3-161,3-48,3-75

BELT - 3.7L / 4.7L - INSTALLATION,

DRIVE................................7-26

BELT - 3.7L / 4.7L - REMOVAL, DRIVE.....7-26

BELT - 5.9L DIESEL - INSTALLATION,

DRIVE..............................7-29

BELT - 5.9L DIESEL - REMOVAL, DRIVE....7-29

BELT / CHAIN COVER(S) -

INSTALLATION, TIMING...........9-171,9-81

BELT / CHAIN COVER(S) - REMOVAL,

TIMING........................9-170,9-81

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE................7-24,7-27

BELT - INSTALLATION, FRONT CENTER

SEAT ..............................8O-31

BELT - REMOVAL, FRONT CENTER SEAT . . 8O-30

BELT & RETRACTOR - INSTALLATION,

FRONT CENTER SEAT.................8O-29

BELT & RETRACTOR - INSTALLATION,

REAR CENTER SEAT..................8O-45

BELT & RETRACTOR - INSTALLATION,

REAR OUTBOARD SEAT...............8O-47

BELT & RETRACTOR - REMOVAL, FRONT

CENTER SEAT.......................8O-29

BELT & RETRACTOR - REMOVAL, REAR

CENTER SEAT.......................8O-44

BELT & RETRACTOR - REMOVAL, REAR

OUTBOARD SEAT....................8O-46

BELT BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT....................8O-38

BELT BUCKLE - REMOVAL, FRONT

OUTBOARD SEAT....................8O-37

BELT MOLDING - INSTALLATION, FRONT

DOOR INNER........................23-93

BELT MOLDING - INSTALLATION, FRONT

DOOR OUTER.......................23-93

BELT MOLDING - INSTALLATION, REAR

DOOR INNER........................23-94

BELT MOLDING - INSTALLATION, REAR

DOOR OUTER.......................23-94

BELT MOLDING - REMOVAL, FRONT

DOOR INNER........................23-93

BELT MOLDING - REMOVAL, FRONT

DOOR OUTER.......................23-92

BELT MOLDING - REMOVAL, REAR

DOOR INNER........................23-94

BELT MOLDING - REMOVAL, REAR

DOOR OUTER.......................23-93

BELT SWITCH - DESCRIPTION, SEAT.....8O-51

BELT SWITCH - DIAGNOSIS AND

TESTING, SEAT

......................8O-51

BELT SWITCH - OPERATION, SEAT

.......8O-51

BELT TENSION REDUCER -

DESCRIPTION, SEAT

..................8O-53

BELT TENSION REDUCER - DIAGNOSIS

AND TESTING, SEAT

..................8O-54

BELT TENSION REDUCER - OPERATION,

SEAT

..............................8O-54BELT TENSIONER - 3.7L / 4.7L -

DESCRIPTION........................7-21

BELT TENSIONER - 3.7L / 4.7L -

INSTALLATION........................7-22

BELT TENSIONER - 3.7L / 4.7L -

OPERATION..........................7-21

BELT TENSIONER - 3.7L / 4.7L -

REMOVAL...........................7-21

BELT TENSIONER - 5.9L DIESEL -

DESCRIPTION........................7-23

BELT TENSIONER - 5.9L DIESEL -

INSTALLATION........................7-24

BELT TENSIONER - 5.9L DIESEL -

OPERATION..........................7-23

BELT TENSIONER - 5.9L DIESEL -

REMOVAL...........................7-23

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-52

BELT TENSIONER - OPERATION, SEAT....8O-53

BELT TENSIONER-5.7L - DESCRIPTION....7-22

BELT TENSIONER-5.7L - INSTALLATION....7-23

BELT TENSIONER-5.7L - OPERATION......7-22

BELT TENSIONER-5.7L - REMOVAL.......7-22

BELT TURNING LOOP ADJUSTER -

INSTALLATION, SEAT.................8O-55

BELT TURNING LOOP ADJUSTER -

REMOVAL, SEAT.....................8O-55

BELT/CHAIN AND SPROCKETS -

INSPECTION, TIMING.............9-174,9-84

BELT/CHAIN AND SPROCKETS -

INSTALLATION, TIMING...........9-176,9-85

BELT/CHAIN AND SPROCKETS -

REMOVAL, TIMING.................9-172,9-83

BEZEL - INSTALLATION, CLUSTER.......23-49

BEZEL - INSTALLATION, INSTRUMENT

PANEL CENTER......................23-57

BEZEL - INSTALLATION, INSTRUMENT

PANEL DRIVER SIDE..................23-58

BEZEL - INSTALLATION, INSTRUMENT

PANEL HEADLAMP SWITCH............23-56

BEZEL - REMOVAL, CLUSTER...........23-49

BEZEL - REMOVAL, INSTRUMENT PANEL

CENTER............................23-57

BEZEL - REMOVAL, INSTRUMENT PANEL

DRIVER SIDE........................23-58

BEZEL - REMOVAL, INSTRUMENT PANEL

HEADLAMP SWITCH..................23-56

BIN - INSTALLATION, STORAGE.........23-61

BIN - INSTALLATION, UNDER SEAT

STORAGE...........................23-80

BIN - REMOVAL, STORAGE.............23-61

BIN - REMOVAL, UNDER SEAT STORAGE . . 23-80

BIN COVERING - INSTALLATION, UNDER

SEAT STORAGE......................23-80

BIN COVERING - REMOVAL, UNDER

SEAT STORAGE......................23-80

BIN LATCH - INSTALLATION, UNDER

SEAT STORAGE......................23-80

BIN LATCH - REMOVAL, UNDER SEAT

STORAGE...........................23-80

BIN LID - INSTALLATION, UNDER SEAT

STORAGE...........................23-80

BIN LID - REMOVAL, UNDER SEAT

STORAGE...........................23-80

BLADE - DESCRIPTION, WIPER.........8R-18

BLADE - INSTALLATION, WIPER.........8R-20

BLADE - OPERATION, WIPER...........8R-19

BLADE - REMOVAL, WIPER............8R-19

BLEEDING - STANDARD PROCEDURE......5-31

BLEEDING - STANDARD PROCEDURE,

ABS BRAKE..........................5-46

BLEEDING - STANDARD PROCEDURE,

MANUAL.............................5-5

BLEEDING - STANDARD PROCEDURE,

MASTER CYLINDER...................5-26

BLEEDING - STANDARD PROCEDURE,

PRESSURE...........................5-5

BLEND DOOR - INSTALLATION..........24-27

BLEND DOOR - REMOVAL.............24-27

BLEND DOOR ACTUATOR -

DESCRIPTION.......................24-17

BLEND DOOR ACTUATOR -

INSTALLATION.......................24-18

BLEND DOOR ACTUATOR - OPERATION

. . . 24-17

BLEND DOOR ACTUATOR - REMOVAL

....24-17

BLOCK - CLEANING, ENGINE

. . 9-128,9-205,9-39

BLOCK - DESCRIPTION, BLOWER

MOTOR RESISTOR

...................24-18

BLOCK - DESCRIPTION, ENGINE

.....9-128,9-38

DRINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 2592 of 2627

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF..........21-201,21-366

BUSHING - INSTALLATION.............19-19

BUSHING - INSTALLATION, TORSION

BAR CROSS MEMBER..................2-15

BUSHING - REMOVAL.................19-19

BUSHING - REMOVAL, TORSION BAR

CROSSMEMBER......................2-13

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING................21-440

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING................21-440

BUSHINGS - 2WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-15

BUSHINGS - 2WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-13

BUSHINGS - 4WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-14

BUSHINGS - 4WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-13

BUSHINGS - INSTALLATION.............2-43

BUSHINGS - REMOVAL.................2-43

BUZZ, SQUEAK & RATTLE - STANDARD

PROCEDURE........................23-11

BYPASS - DESCRIPTION, WATER PUMP . . . 7-59

BYPASS - OPERATION, WATER PUMP.....7-60

C205F - ADJUSTMENTS, FRONT AXLE.....3-32

C205F - DIAGNOSIS AND TESTING,

FRONT AXLE.........................3-27

C205F - INSTALLATION, FRONT AXLE.....3-31

C205F - REMOVAL, FRONT AXLE...........3-31

C205F - SPECIAL TOOLS, FRONT AXLE....3-40

C205F - SPECIFICATIONS, FRONT AXLE....3-39

CAB - INSTALLATION, QUAD......8O-36,8O-61

CAB - INSTALLATION, STANDARD . . 8O-35,8O-61

CAB - REMOVAL, QUAD..........8O-33,8O-60

CAB - REMOVAL, STANDARD......8O-32,8O-59

CAB BACK PANEL TRIM -

INSTALLATION, REAR.................23-69

CAB BACK PANEL TRIM - REMOVAL,

REAR..............................23-68

CAB CLEARANCE LAMP - INSTALLATION . . 8L-12

CAB CLEARANCE LAMP - REMOVAL.....8L-11

CABLE - ADJUSTMENTS, THROTTLE

VALVE ............................21-254

CABLE - DESCRIPTION.................8P-4

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, SPARK PLUG.....8I-21

CABLE - DESCRIPTION, THROTTLE

VALVE ............................21-253

CABLE - DIAGNOSIS AND TESTING,

ANTENNA BODY......................8A-4

CABLE - DIAGNOSIS AND TESTING,

GEARSHIFT..................21-210,21-368

CABLE - INSTALLATION................8P-5

CABLE - INSTALLATION, ANTENNA BODY . . 8A-6

CABLE - INSTALLATION, CHECK.........23-15

CABLE - INSTALLATION, FRONT

PARKING BRAKE......................5-38

CABLE - INSTALLATION, GEARSHIFT....21-211,

21-370

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-7

CABLE - INSTALLATION, LEFT REAR......5-39

CABLE - INSTALLATION, REAR PARK

BRAKE..............................5-38

CABLE - INSTALLATION, RIGHT REAR.....5-38

CABLE - INSTALLATION, SPARK PLUG....8I-22

CABLE - INSTALLATION, THROTTLE

CONTROL.....................14-40,14-84

CABLE - OPERATION...................8P-4

CABLE - OPERATION, ANTENNA BODY

.....8A-4

CABLE - OPERATION, SPARK PLUG

.......8I-21

CABLE - REMOVAL

....................8P-4

CABLE - REMOVAL, ANTENNA BODY

......8A-6

CABLE - REMOVAL, CHECK

.............23-15

CABLE - REMOVAL, FRONT PARKING

BRAKE

..............................5-36

CABLE - REMOVAL, GEARSHIFT

. . 21-210,21-369

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA

...........................8A-7

CABLE - REMOVAL, LEFT REAR

..........5-38

CABLE - REMOVAL, REAR PARK BRAKE

. . . 5-37

CABLE - REMOVAL, RIGHT REAR

.........5-37

CABLE - REMOVAL, SPARK PLUG

........8I-22

CABLE - REMOVAL, THROTTLE

CONTROL

.....................14-38,14-83CABLE, ADJUSTMENTS - GEARSHIFT . . . 21-212,

21-370

CABLE RESISTANCE, SPECIFICATIONS -

SPARK PLUG.........................8I-4

CABLE ROUTING, 5.7L V-8 ENGINE -

FIRING ORDER........................8I-4

CABLE/HANDLE ASSEMBLY -

INSTALLATION, LATCH RELEASE........23-47

CABLE/HANDLE ASSEMBLY - REMOVAL,

LATCH RELEASE.....................23-47

CABLES - DESCRIPTION, BATTERY.......8F-14

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-15

CABLES - INSTALLATION, BATTERY......8F-17

CABLES - OPERATION, BATTERY........8F-15

CABLES - REMOVAL, BATTERY..........8F-16

CALIBRATION - STANDARD PROCEDURE,

COMPASS...........................8M-3

CALIPER ADAPTER MOUNT -

INSTALLATION, DISC BRAKE............5-22

CALIPERS - DESCRIPTION, DISC BRAKE . . . 5-16

CALIPERS - OPERATION, DISC BRAKE.....5-16

CAM BORE REPAIR - STANDARD

PROCEDURE........................9-267

CAMBER AND CASTER ADJUSTMENT -

STANDARD PROCEDURE.................2-4

CAMBER, CASTER AND TOE

ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

CAM/OVERDRIVE PISTON RETAINER -

ASSEMBLY, OVERRUNNING CLUTCH....21-237

CAM/OVERDRIVE PISTON RETAINER -

CLEANING, OVERRUNNING CLUTCH.....21-236

CAM/OVERDRIVE PISTON RETAINER -

DESCRIPTION, OVERRUNNING CLUTCH . . 21-236

CAM/OVERDRIVE PISTON RETAINER -

DISASSEMBLY, OVERRUNNING

CLUTCH...........................21-236

CAM/OVERDRIVE PISTON RETAINER -

INSPECTION, OVERRUNNING CLUTCH . . . 21-237

CAM/OVERDRIVE PISTON RETAINER -

OPERATION, OVERRUNNING CLUTCH....21-236

CAMSHAFT - INSTALLATION.......9-206,9-271

CAMSHAFT - REMOVAL..........9-205,9-268

CAMSHAFT BEARINGS - INSTALLATION . . . 9-271

CAMSHAFT BEARINGS - REMOVAL......9-268

CAMSHAFT CORE HOLE PLUG -

INSTALLATION.......................9-206

CAMSHAFT CORE HOLE PLUG -

REMOVAL..........................9-205

CAMSHAFT POSITION SENSOR -

DESCRIPTION.......................14-71

CAMSHAFT POSITION SENSOR -

DESCRIPTION.........................8I-7

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................14-72

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................8I-10

CAMSHAFT POSITION SENSOR -

OPERATION.........................14-71

CAMSHAFT POSITION SENSOR -

OPERATION..........................8I-7

CAMSHAFT POSITION SENSOR -

REMOVAL..........................14-72

CAMSHAFT POSITION SENSOR -

REMOVAL............................8I-9

CAMSHAFT(S) - DESCRIPTION.......9-25,9-35

CAMSHAFT(S) - INSTALLATION......9-27,9-36

CAMSHAFT(S) - LEFT - DESCRIPTION....9-114

CAMSHAFT(S) - LEFT - INSTALLATION....9-116

CAMSHAFT(S) - LEFT - REMOVAL.......9-115

CAMSHAFT(S) - REMOVAL..........9-25,9-35

CAMSHAFT(S) - RIGHT - DESCRIPTION . . . 9-119

CAMSHAFT(S) - RIGHT - INSTALLATION . . 9-120

CAMSHAFT(S) - RIGHT - REMOVAL......9-119

CANISTER - DESCRIPTION, VAPOR......25-22

CANISTER - INSTALLATION, VAPOR......25-22

CANISTER - OPERATION, VAPOR........25-22

CANISTER - REMOVAL, VAPOR..........25-22

CAP - DESCRIPTION, FUEL FILLER.......25-13

CAP - DESCRIPTION, RADIATOR

PRESSURE

..........................7-57

CAP - DIAGNOSIS AND TESTING,

RADIATOR

...........................7-58

CAP - OPERATION, FUEL FILLER

........25-13

CAP - OPERATION, RADIATOR

PRESSURE

..........................7-58

CAPACITIES, SPECIFICATIONS - FLUID

......0-5CAPACITOR - DESCRIPTION, IGNITION

COIL...............................8I-21

CAPACITOR - INSTALLATION, IGNITION

COIL...............................8I-21

CAPACITOR - OPERATION, IGNITION

COIL...............................8I-21

CAPACITOR - REMOVAL, IGNITION COIL . . . 8I-21

CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING, RADIATOR.....7-58

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, DOUBLE...................3-17

CARDAN UNIVERSAL JOINTS -

DISASSEMBLY, DOUBLE................3-16

CARGO BOX - INSTALLATION...........23-37

CARGO BOX - INSTALLATION, WITH.....8L-22,

8L-23,8L-24,8L-7,8L-9

CARGO BOX - INSTALLATION, WITHOUT . . 8L-22,

8L-23,8L-24,8L-8,8L-9

CARGO BOX - REMOVAL...............23-37

CARGO BOX - REMOVAL, WITH....8L-22,8L-24,

8L-7,8L-9

CARGO BOX - REMOVAL, WITHOUT.....8L-22,

8L-23,8L-24,8L-7,8L-9

CARGO BOX - TIE DOWN -

INSTALLATION.......................23-38

CARGO BOX - TIE DOWN - REMOVAL....23-38

CARGO LAMP INDICATOR -

DESCRIPTION.......................8J-20

CARGO LAMP INDICATOR - OPERATION . . 8J-20

CARPETS AND FLOOR MATS -

INSTALLATION.......................23-65

CARPETS AND FLOOR MATS - REMOVAL . . . 23-65

CASCADE OVERFLOW VALVE -

DESCRIPTION.......................14-66

CASCADE OVERFLOW VALVE -

OPERATION.........................14-66

CASE - DESCRIPTION, TRANSFER.........0-4

CASE - NV241 GENII - ASSEMBLY,

TRANSFER.........................21-428

CASE - NV241 GENII - CLEANING,

TRANSFER.........................21-426

CASE - NV241 GENII - DESCRIPTION,

TRANSFER.........................21-415

CASE - NV241 GENII - DIAGNOSIS AND

TESTING, TRANSFER.................21-416

CASE - NV241 GENII - DISASSEMBLY,

TRANSFER.........................21-417

CASE - NV241 GENII - INSPECTION,

TRANSFER.........................21-426

CASE - NV241 GENII - INSTALLATION,

TRANSFER.........................21-438

CASE - NV241 GENII - OPERATION,

TRANSFER.........................21-415

CASE - NV241 GENII - REMOVAL,

TRANSFER.........................21-417

CASE - NV243 - ASSEMBLY, TRANSFER . . 21-496

CASE - NV243 - CLEANING, TRANSFER . . 21-493

CASE - NV243 - DESCRIPTION,

TRANSFER.........................21-482

CASE - NV243 - DIAGNOSIS AND

TESTING, TRANSFER.................21-483

CASE - NV243 - DISASSEMBLY,

TRANSFER.........................21-484

CASE - NV243 - INSPECTION, TRANSFER . 21-493

CASE - NV243 - INSTALLATION,

TRANSFER.........................21-505

CASE - NV243 - OPERATION, TRANSFER . 21-483

CASE - NV243 - REMOVAL, TRANSFER . . 21-484

CASE - NV244 - DIAGNOSIS AND

TESTING, TRANSFER.................21-513

CASE - NV244 GENII - ASSEMBLY,

TRANSFER.........................21-525

CASE - NV244 GENII - CLEANING,

TRANSFER.........................21-523

CASE - NV244 GENII - DESCRIPTION,

TRANSFER.........................21-512

CASE - NV244 GENII - DISASSEMBLY,

TRANSFER.........................21-514

CASE - NV244 GENII - INSPECTION,

TRANSFER.........................21-523

CASE - NV244 GENII - INSTALLATION,

TRANSFER

.........................21-534

CASE - NV244 GENII - OPERATION,

TRANSFER

.........................21-513

CASE - NV244 GENII - REMOVAL,

TRANSFER

.........................21-514

CASE - NV271 - ASSEMBLY, TRANSFER

. . 21-461

CASE - NV271 - CLEANING, TRANSFER

. . 21-459

DRINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2593 of 2627

CASE - NV271 - DESCRIPTION,

TRANSFER.........................21-447

CASE - NV271 - DIAGNOSIS AND

TESTING, TRANSFER.................21-448

CASE - NV271 - DISASSEMBLY,

TRANSFER.........................21-450

CASE - NV271 - INSPECTION, TRANSFER . 21-459

CASE - NV271 - INSTALLATION,

TRANSFER.........................21-473

CASE - NV271 - OPERATION, TRANSFER . 21-448

CASE - NV271 - REMOVAL, TRANSFER . . 21-450

CASE - NV273 - ASSEMBLY, TRANSFER . . 21-556

CASE - NV273 - CLEANING, TRANSFER . . 21-554

CASE - NV273 - DESCRIPTION,

TRANSFER.........................21-542

CASE - NV273 - DIAGNOSIS AND

TESTING, TRANSFER.................21-543

CASE - NV273 - DISASSEMBLY,

TRANSFER.........................21-544

CASE - NV273 - INSPECTION, TRANSFER . 21-554

CASE - NV273 - INSTALLATION,

TRANSFER.........................21-568

CASE - NV273 - OPERATION, TRANSFER . 21-543

CASE - NV273 - REMOVAL, TRANSFER . . 21-544

CASE BEARINGS - INSTALLATION,

DIFFERENTIAL.....3-106,3-134,3-161,3-48,3-75

CASE BEARINGS - REMOVAL,

DIFFERENTIAL.....3-105,3-134,3-161,3-48,3-75

CASE CONTROL MODULE -

DESCRIPTION, TRANSFER.............8E-16

CASE CONTROL MODULE - OPERATION,

TRANSFER..........................8E-16

CASE, NV241 GENII - TRANSFER.......21-438

CASE, NV241/NV243 - TRANSFER......21-439

CASE, NV243 - TRANSFER......21-505,21-506

CASE, NV244 GENII - TRANSFER.......21-535

CASE, NV271 - TRANSFER............21-473

CASE NV271/NV273, SPECIAL TOOLS -

TRANSFER...................21-474,21-569

CASE, NV273 - TRANSFER............21-568

CASE SKID PLATE - INSTALLATION,

TRANSFER..........................13-26

CASE SKID PLATE - REMOVAL,

TRANSFER..........................13-26

CASTER ADJUSTMENT - STANDARD

PROCEDURE, CAMBER..................2-4

CASTER AND TOE ADJUSTMENT -

STANDARD PROCEDURE, CAMBER........2-4

CATALYTIC CONVERTER - DESCRIPTION . . . 11-6

CATALYTIC CONVERTER - OPERATION.....11-6

CATCH - INSTALLATION, LATCH STRIKER

/ SECONDARY.......................23-48

CATCH - REMOVAL, LATCH STRIKER /

SECONDARY........................23-47

CAUTION - A/C SYSTEM...............24-43

CAUTION, HALF SHAFT.................3-20

CAUTION, INTERIOR..................23-62

CENTER - DESCRIPTION, ELECTRONIC

VEHICLE INFO.......................8M-7

CENTER - DIAGNOSIS AND TESTING,

ELECTRONIC VEHICLE INFORMATION.....8M-8

CENTER - INSTALLATION, ELECTRONIC

VEHICLE INFO.......................8M-9

CENTER & LEFT OUTBOARD -

INSTALLATION......................8O-50

CENTER & LEFT OUTBOARD - REMOVAL

. . 8O-48

CENTER - OPERATION, ELECTRONIC

VEHICLE INFO

.......................8M-7

CENTER - REMOVAL, ELECTRONIC

VEHICLE INFO

.......................8M-9

CENTER ANCHOR & RIGHT OUTBOARD -

INSTALLATION

......................8O-50

CENTER ANCHOR & RIGHT OUTBOARD -

REMOVAL

..........................8O-49

CENTER ARMREST / SEAT BACK -

INSTALLATION

.......................23-77

CENTER ARMREST / SEAT BACK -

REMOVAL

..........................23-76

CENTER BEARING - ADJUSTMENTS

........3-9

CENTER BEARING - INSTALLATION

........3-9

CENTER BEARING - REMOVAL

............3-9

CENTER BEZEL - INSTALLATION,

INSTRUMENT PANEL

..................23-57

CENTER BEZEL - REMOVAL,

INSTRUMENT PANEL

..................23-57

CENTER HIGH MOUNTED STOP LAMP -

INSTALLATION

.......................8L-11CENTER HIGH MOUNTED STOP LAMP -

REMOVAL..........................8L-11

CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION.................8L-11

CENTER HIGH MOUNTED STOP LAMP

UNIT - REMOVAL....................8L-11

CENTER PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC VEHICLE

INFORMATION.......................8M-8

CENTER SEAT - INSTALLATION..........23-76

CENTER SEAT - REMOVAL.............23-75

CENTER SEAT BACK HINGE -

INSTALLATION.......................23-79

CENTER SEAT BACK HINGE - REMOVAL . . . 23-78

CENTER SEAT BACK INERTIA HINGE

COVER - INSTALLATION...............23-77

CENTER SEAT BACK INERTIA HINGE

COVER - REMOVAL...................23-77

CENTER SEAT BACK LID - INSTALLATION . 23-79

CENTER SEAT BACK LID - REMOVAL.....23-79

CENTER SEAT BELT - INSTALLATION,

FRONT.............................8O-31

CENTER SEAT BELT - REMOVAL, FRONT . . 8O-30

CENTER SEAT BELT & RETRACTOR -

INSTALLATION, FRONT................8O-29

CENTER SEAT BELT & RETRACTOR -

INSTALLATION, REAR.................8O-45

CENTER SEAT BELT & RETRACTOR -

REMOVAL, FRONT....................8O-29

CENTER SEAT BELT & RETRACTOR -

REMOVAL, REAR....................8O-44

CENTER SEAT CUSHION - INSTALLATION . . . 23-79

CENTER SEAT CUSHION - REMOVAL.....23-79

CENTER SEAT CUSHION COVER -

INSTALLATION.......................23-79

CENTER SEAT CUSHION COVER -

REMOVAL..........................23-79

CENTERING - STANDARD PROCEDURE,

CLOCKSPRING......................8O-19

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE.........................Intro.-11

CHAIN COVER(S) - INSTALLATION,

TIMING BELT....................9-171,9-81

CHAIN COVER(S) - REMOVAL, TIMING

BELT ..........................9-170,9-81

CHAIN WEAR - STANDARD PROCEDURE,

MEASURING TIMING..................9-167

CHAIN WEAR, STANDARD PROCEDURE -

MEASURING TIMING...................9-77

CHAIN/TENSIONER - DESCRIPTION,

TIMING............................9-229

CHAIN/TENSIONER - OPERATION,

TIMING............................9-229

CHANNEL - INSTALLATION, GLASS RUN . . 23-22,

23-31

CHANNEL - REMOVAL, GLASS RUN . 23-21,23-30

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-47

CHARGE AIR COOLER AND PLUMBING -

CLEANING..........................11-17

CHARGE AIR COOLER AND PLUMBING -

DESCRIPTION.......................11-16

CHARGE AIR COOLER AND PLUMBING -

INSPECTION........................11-17

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION.......................11-17

CHARGE AIR COOLER AND PLUMBING -

OPERATION

.........................11-16

CHARGE AIR COOLER AND PLUMBING -

REMOVAL

..........................11-17

CHARGE AIR COOLER SYSTEM - LEAKS

- DIAGNOSIS AND TESTING

............11-16

CHARGING - DESCRIPTION

.............8F-19

CHARGING - OPERATION

..............8F-19

CHARGING - STANDARD PROCEDURE,

BATTERY

............................8F-8

CHARGING SYSTEM - DIAGNOSIS AND

TESTING

...........................8F-19

CHARGING SYSTEM - SPECIFICATIONS,

TORQUE - GENERATOR

................8F-20

CHART - SPECIFICATIONS, TORQUE

........5-8

CHART, SPECIFICATIONS - TORQUE

.......5-46

CHART, SPECIFICATIONS - TORQUE

.....19-19,

19-23,19-35,19-42

CHART, SPECIFICATIONS - TORQUE

. . 2-10,2-29,

2-42

CHART, SPECIFICATIONS - TORQUE

......22-13CHARTS - DIAGNOSIS AND TESTING,

DIAGNOSIS........................21-145

CHARTS - DIAGNOSIS AND TESTING,

SMOKE DIAGNOSIS...................9-236

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL......................7-17

CHECK - STANDARD PROCEDURE, FLUID

LEVEL......................21-202,21-366

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME.....................21-387

CHECK CABLE - INSTALLATION.........23-15

CHECK CABLE - REMOVAL.............23-15

CHECK GAUGES INDICATOR -

DESCRIPTION.......................8J-21

CHECK GAUGES INDICATOR -

OPERATION.........................8J-21

CHECK VALVE - DESCRIPTION...........8R-7

CHECK VALVE - INSTALLATION..........8R-8

CHECK VALVE - OPERATION.............8R-8

CHECK VALVE - REMOVAL..............8R-8

CHILD RESTRAINT ANCHOR -

DESCRIPTION.......................8O-15

CHILD RESTRAINT ANCHOR -

INSTALLATION......................8O-18

CHILD RESTRAINT ANCHOR -

OPERATION.........................8O-17

CHILD RESTRAINT ANCHOR - REMOVAL . . 8O-17

CHIME WARNING SYSTEM -

DESCRIPTION........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING........................8B-3

CHIME WARNING SYSTEM - OPERATION . . . 8B-1

CIGAR LIGHTER OUTLET -

DESCRIPTION.....................8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR......8M-10

CIRCUIT - OPERATION, FUEL DRAIN.....14-67

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-1

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-10

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-11

CIRCUITS - OPERATION, NON-

MONITORED.........................25-8

CLAMPS - DESCRIPTION, HOSE...........7-3

CLAMPS - OPERATION, HOSE.............7-5

CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-272

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-274

CLEARANCE LAMP - INSTALLATION, CAB . 8L-12

CLEARANCE LAMP - REMOVAL, CAB.....8L-11

CLOCKSPRING - DESCRIPTION.........8O-18

CLOCKSPRING - INSTALLATION.........8O-21

CLOCKSPRING - OPERATION...........8O-19

CLOCKSPRING - REMOVAL............8O-20

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-15

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-10

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-14

CLUSTER - INSTALLATION, INSTRUMENT . 8J-16

CLUSTER - OPERATION, INSTRUMENT.....8J-6

CLUSTER - REMOVAL, INSTRUMENT.....8J-14

CLUSTER BEZEL - INSTALLATION........23-49

CLUSTER BEZEL - REMOVAL...........23-49

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-52

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-52

CLUTCH - ASSEMBLY, FRONT..........21-207

CLUTCH - ASSEMBLY, LOW/REVERSE . . . 21-385

CLUTCH - ASSEMBLY, REAR

...........21-249

CLUTCH - CLEANING, LOW/REVERSE

....21-385

CLUTCH - CLEANING, REAR

...........21-248

CLUTCH - DESCRIPTION, FRONT

.......21-205

CLUTCH - DESCRIPTION, OVERDRIVE

. . . 21-217

6 INDEXDR

Description Group-Page Description Group-Page Description Group-Page