Ignition cylinder DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1422 of 2627

AIR INTAKE SYSTEM

REMOVAL

Filter Element Only

Housing removal is not necessary for element (fil-

ter) replacement.

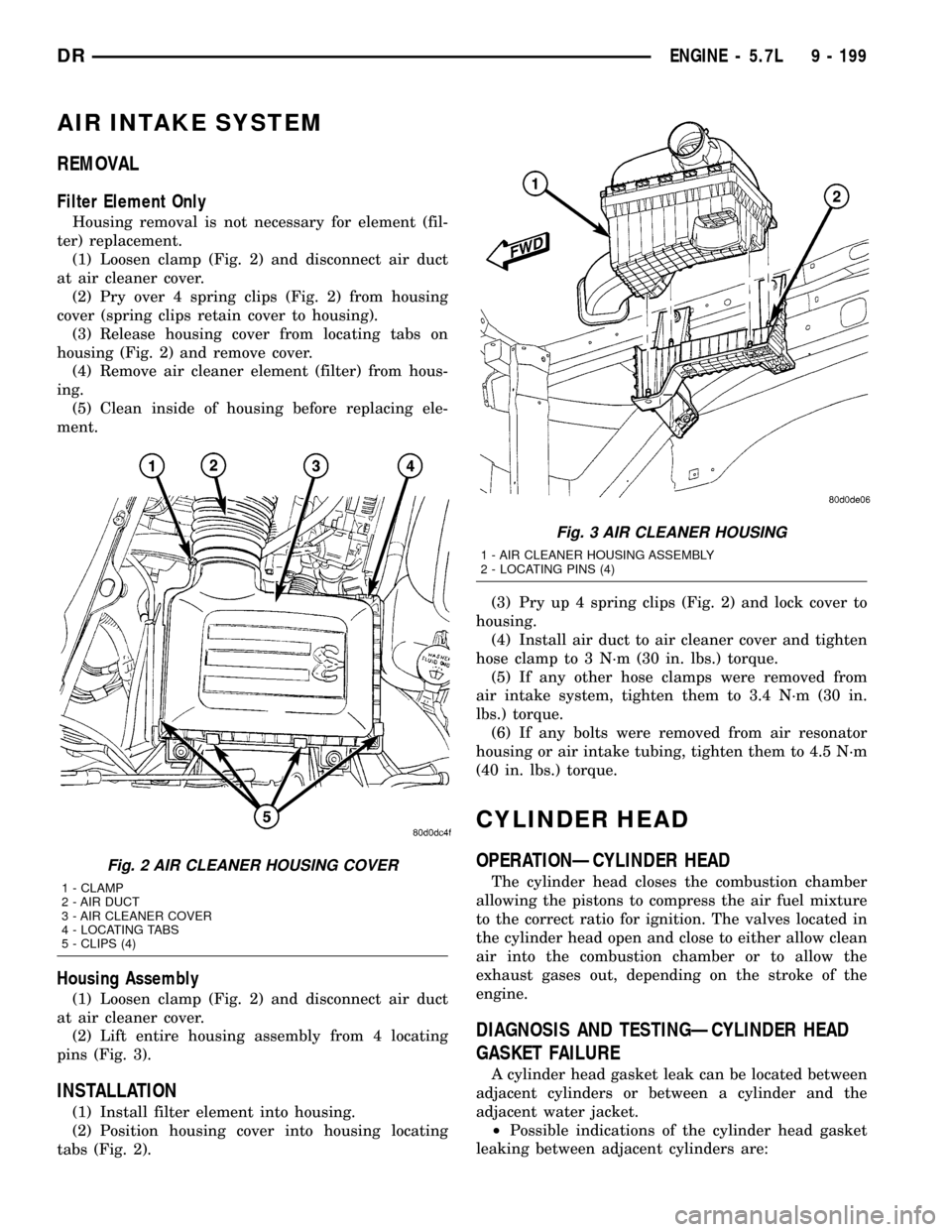

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 2) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 2) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

Housing Assembly

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Lift entire housing assembly from 4 locating

pins (Fig. 3).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 2).(3) Pry up 4 spring clips (Fig. 2) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture

to the correct ratio for ignition. The valves located in

the cylinder head open and close to either allow clean

air into the combustion chamber or to allow the

exhaust gases out, depending on the stroke of the

engine.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

Fig. 2 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 3 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

DRENGINE - 5.7L 9 - 199

Page 1424 of 2627

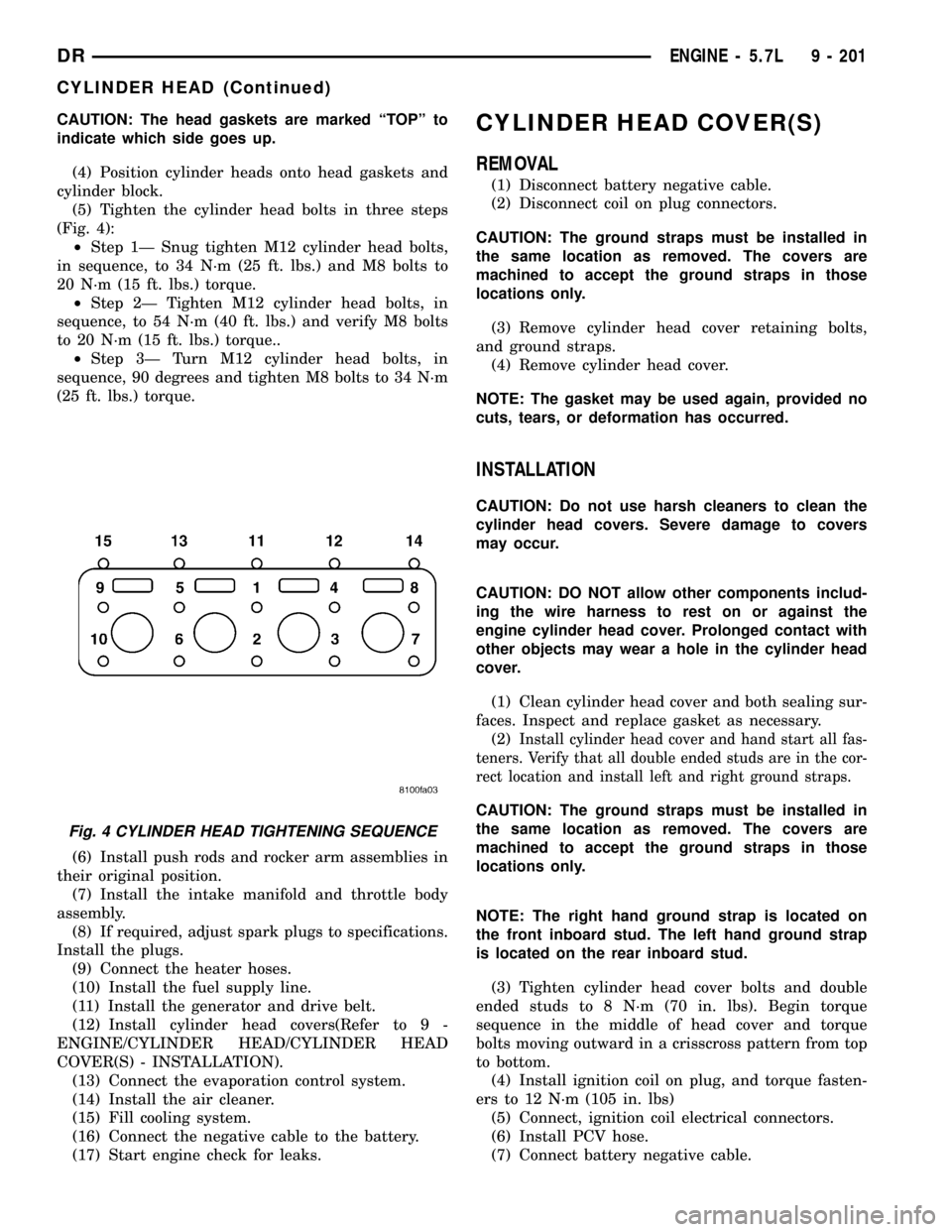

CAUTION: The head gaskets are marked ªTOPº to

indicate which side goes up.

(4) Position cylinder heads onto head gaskets and

cylinder block.

(5) Tighten the cylinder head bolts in three steps

(Fig. 4):

²Step 1Ð Snug tighten M12 cylinder head bolts,

in sequence, to 34 N´m (25 ft. lbs.) and M8 bolts to

20 N´m (15 ft. lbs.) torque.

²Step 2Ð Tighten M12 cylinder head bolts, in

sequence, to 54 N´m (40 ft. lbs.) and verify M8 bolts

to 20 N´m (15 ft. lbs.) torque..

²Step 3Ð Turn M12 cylinder head bolts, in

sequence, 90 degrees and tighten M8 bolts to 34 N´m

(25 ft. lbs.) torque.

(6) Install push rods and rocker arm assemblies in

their original position.

(7) Install the intake manifold and throttle body

assembly.

(8) If required, adjust spark plugs to specifications.

Install the plugs.

(9) Connect the heater hoses.

(10) Install the fuel supply line.

(11) Install the generator and drive belt.

(12) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(13) Connect the evaporation control system.

(14) Install the air cleaner.

(15) Fill cooling system.

(16) Connect the negative cable to the battery.

(17) Start engine check for leaks.CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect coil on plug connectors.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

(3) Remove cylinder head cover retaining bolts,

and ground straps.

(4) Remove cylinder head cover.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the

engine cylinder head cover. Prolonged contact with

other objects may wear a hole in the cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2)

Install cylinder head cover and hand start all fas-

teners. Verify that all double ended studs are in the cor-

rect location and install left and right ground straps.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

NOTE: The right hand ground strap is located on

the front inboard stud. The left hand ground strap

is located on the rear inboard stud.

(3) Tighten cylinder head cover bolts and double

ended studs to 8 N´m (70 in. lbs). Begin torque

sequence in the middle of head cover and torque

bolts moving outward in a crisscross pattern from top

to bottom.

(4) Install ignition coil on plug, and torque fasten-

ers to 12 N´m (105 in. lbs)

(5) Connect, ignition coil electrical connectors.

(6) Install PCV hose.

(7) Connect battery negative cable.

Fig. 4 CYLINDER HEAD TIGHTENING SEQUENCE

DRENGINE - 5.7L 9 - 201

CYLINDER HEAD (Continued)

Page 1427 of 2627

VALVE SPRINGS

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner assembly.

(3) Remove air intake resonator.

(4) Remove spark plug cables.

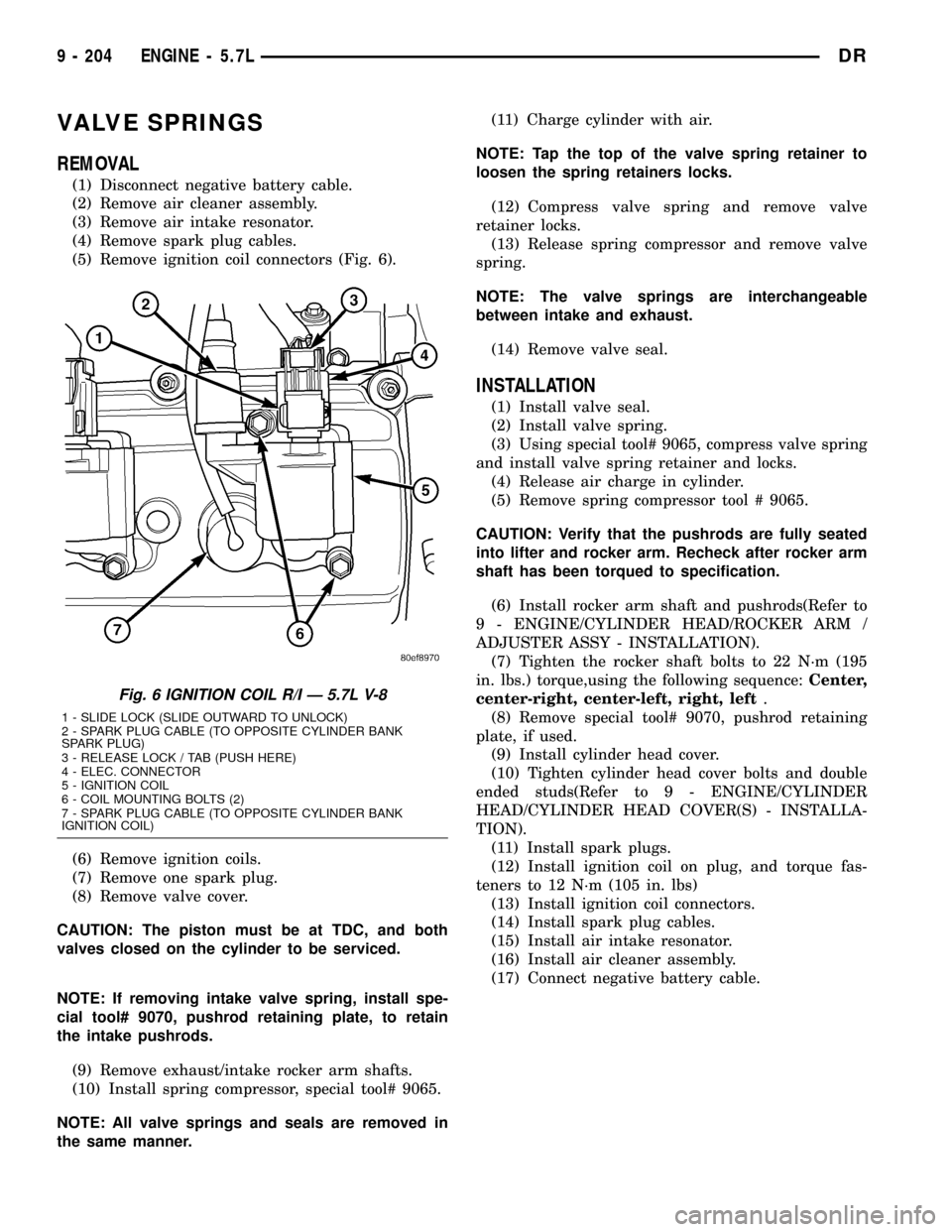

(5) Remove ignition coil connectors (Fig. 6).

(6) Remove ignition coils.

(7) Remove one spark plug.

(8) Remove valve cover.

CAUTION: The piston must be at TDC, and both

valves closed on the cylinder to be serviced.

NOTE: If removing intake valve spring, install spe-

cial tool# 9070, pushrod retaining plate, to retain

the intake pushrods.

(9) Remove exhaust/intake rocker arm shafts.

(10) Install spring compressor, special tool# 9065.

NOTE: All valve springs and seals are removed in

the same manner.(11) Charge cylinder with air.

NOTE: Tap the top of the valve spring retainer to

loosen the spring retainers locks.

(12) Compress valve spring and remove valve

retainer locks.

(13) Release spring compressor and remove valve

spring.

NOTE: The valve springs are interchangeable

between intake and exhaust.

(14) Remove valve seal.

INSTALLATION

(1) Install valve seal.

(2) Install valve spring.

(3) Using special tool# 9065, compress valve spring

and install valve spring retainer and locks.

(4) Release air charge in cylinder.

(5) Remove spring compressor tool # 9065.

CAUTION: Verify that the pushrods are fully seated

into lifter and rocker arm. Recheck after rocker arm

shaft has been torqued to specification.

(6) Install rocker arm shaft and pushrods(Refer to

9 - ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - INSTALLATION).

(7) Tighten the rocker shaft bolts to 22 N´m (195

in. lbs.) torque,using the following sequence:Center,

center-right, center-left, right, left.

(8) Remove special tool# 9070, pushrod retaining

plate, if used.

(9) Install cylinder head cover.

(10) Tighten cylinder head cover bolts and double

ended studs(Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

(11) Install spark plugs.

(12) Install ignition coil on plug, and torque fas-

teners to 12 N´m (105 in. lbs)

(13) Install ignition coil connectors.

(14) Install spark plug cables.

(15) Install air intake resonator.

(16) Install air cleaner assembly.

(17) Connect negative battery cable.

Fig. 6 IGNITION COIL R/I Ð 5.7L V-8

1 - SLIDE LOCK (SLIDE OUTWARD TO UNLOCK)

2 - SPARK PLUG CABLE (TO OPPOSITE CYLINDER BANK

SPARK PLUG)

3 - RELEASE LOCK / TAB (PUSH HERE)

4 - ELEC. CONNECTOR

5 - IGNITION COIL

6 - COIL MOUNTING BOLTS (2)

7 - SPARK PLUG CABLE (TO OPPOSITE CYLINDER BANK

IGNITION COIL)

9 - 204 ENGINE - 5.7LDR

Page 1582 of 2627

REMOVAL

3.7L V-6

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tubes (Fig. 18). Due to design

of tubes, it does not use any clamps. Never attempt

to install a clamping device of any kind to tubes.

When removing fuel rail assembly for any reason,

be careful not to bend or kink tubes.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove air resonator mounting bracket at

front of throttle body (2 bolts).

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove necessary vacuum lines at throttle

body.

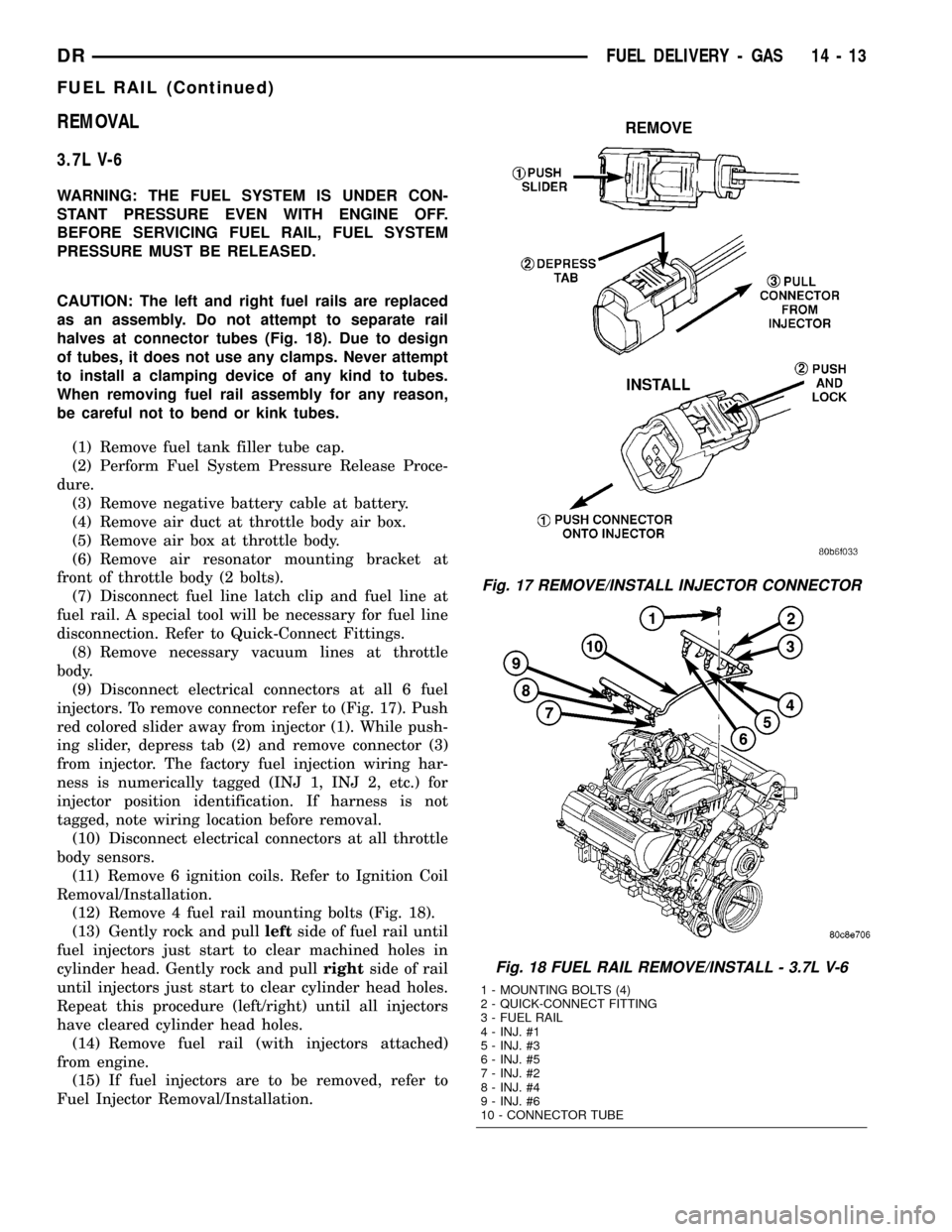

(9) Disconnect electrical connectors at all 6 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at all throttle

body sensors.

(11) Remove 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(12) Remove 4 fuel rail mounting bolts (Fig. 18).

(13) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pullrightside of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

Fig. 17 REMOVE/INSTALL INJECTOR CONNECTOR

Fig. 18 FUEL RAIL REMOVE/INSTALL - 3.7L V-6

1 - MOUNTING BOLTS (4)

2 - QUICK-CONNECT FITTING

3 - FUEL RAIL

4 - INJ. #1

5 - INJ. #3

6 - INJ. #5

7 - INJ. #2

8 - INJ. #4

9 - INJ. #6

10 - CONNECTOR TUBE

DRFUEL DELIVERY - GAS 14 - 13

FUEL RAIL (Continued)

Page 1583 of 2627

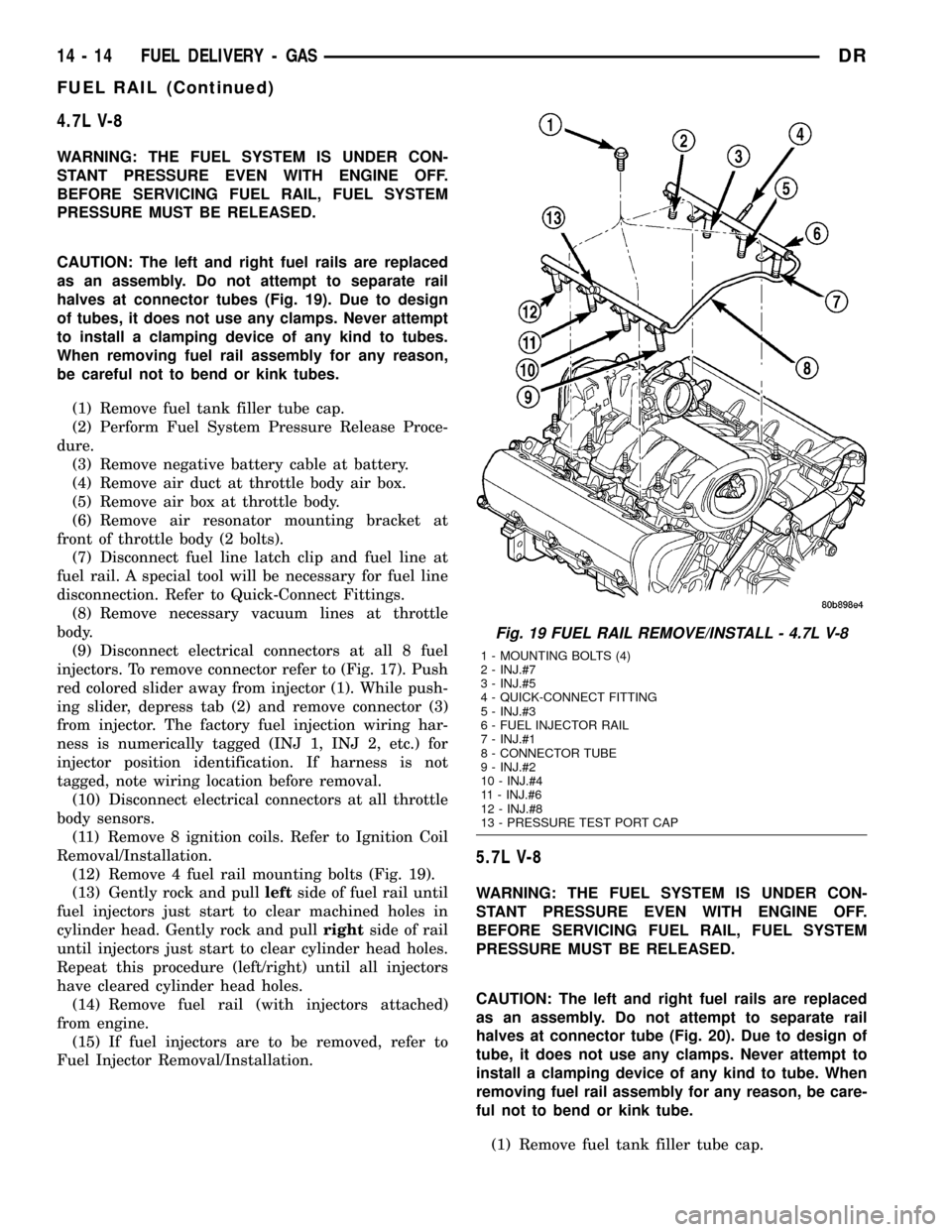

4.7L V-8

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tubes (Fig. 19). Due to design

of tubes, it does not use any clamps. Never attempt

to install a clamping device of any kind to tubes.

When removing fuel rail assembly for any reason,

be careful not to bend or kink tubes.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove air resonator mounting bracket at

front of throttle body (2 bolts).

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove necessary vacuum lines at throttle

body.

(9) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at all throttle

body sensors.

(11) Remove 8 ignition coils. Refer to Ignition Coil

Removal/Installation.

(12) Remove 4 fuel rail mounting bolts (Fig. 19).

(13) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pullrightside of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

5.7L V-8

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tube (Fig. 20). Due to design of

tube, it does not use any clamps. Never attempt to

install a clamping device of any kind to tube. When

removing fuel rail assembly for any reason, be care-

ful not to bend or kink tube.

(1) Remove fuel tank filler tube cap.

Fig. 19 FUEL RAIL REMOVE/INSTALL - 4.7L V-8

1 - MOUNTING BOLTS (4)

2 - INJ.#7

3 - INJ.#5

4 - QUICK-CONNECT FITTING

5 - INJ.#3

6 - FUEL INJECTOR RAIL

7 - INJ.#1

8 - CONNECTOR TUBE

9 - INJ.#2

10 - INJ.#4

11 - INJ.#6

12 - INJ.#8

13 - PRESSURE TEST PORT CAP

14 - 14 FUEL DELIVERY - GASDR

FUEL RAIL (Continued)

Page 1584 of 2627

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove flex tube (air cleaner housing to

engine).

(5) Remove air resonator box at throttle body.

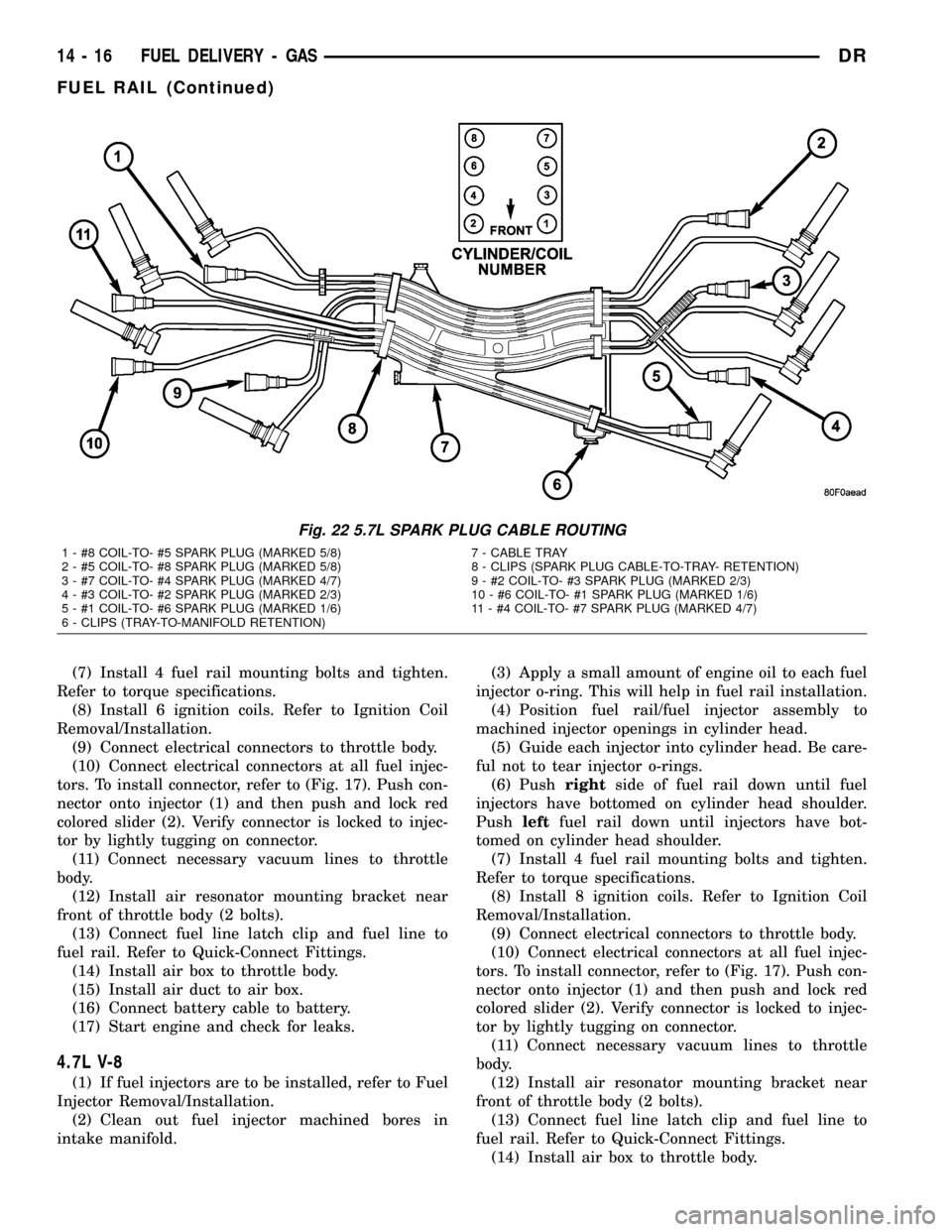

(6) Disconnect all spark plug cables from all spark

plugs and ignition coils. Do not remove cables from

cable routing tray. Note original cable positions while

removing (Fig. 22).

(7) Remove spark plug cable tray from engine by

releasing 4 retaining clips (Fig. 21). Remove tray and

cables from engine as an assembly.

(8) Disconnect electrical connectors at all 8 igni-

tion coils. Refer to Ignition Coil Removal/Installation.

(9) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(10) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(11) Disconnect electrical connectors at all throttle

body sensors.

(12) Remove 4 fuel rail mounting bolts and hold-

own clamps (Fig. 20).

(13) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

intake manifold. Gently rock and pullrightside of

rail until injectors just start to clear intake manifold

head holes. Repeat this procedure (left/right) until all

injectors have cleared machined holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

INSTALLATION

3.7L V-6

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

Fig. 20 5.7L FUEL RAIL

1 - FUEL RAIL

2 - MOUNTING BOLT

3 - HOLDOWN CLAMPS

4 - CONNECTOR TUBE

Fig. 21 5.7L SPARK PLUG CABLE ROUTING TRAY

1 - SPARK PLUG CABLES

2 - RETAINING CLIP

3 - SPARK PLUG CABLE ROUTING TRAY

DRFUEL DELIVERY - GAS 14 - 15

FUEL RAIL (Continued)

Page 1585 of 2627

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect necessary vacuum lines to throttle

body.

(12) Install air resonator mounting bracket near

front of throttle body (2 bolts).

(13) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(14) Install air box to throttle body.

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

4.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.

Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 8 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect necessary vacuum lines to throttle

body.

(12) Install air resonator mounting bracket near

front of throttle body (2 bolts).

(13) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(14) Install air box to throttle body.

Fig. 22 5.7L SPARK PLUG CABLE ROUTING

1 - #8 COIL-TO- #5 SPARK PLUG (MARKED 5/8) 7 - CABLE TRAY

2 - #5 COIL-TO- #8 SPARK PLUG (MARKED 5/8) 8 - CLIPS (SPARK PLUG CABLE-TO-TRAY- RETENTION)

3 - #7 COIL-TO- #4 SPARK PLUG (MARKED 4/7) 9 - #2 COIL-TO- #3 SPARK PLUG (MARKED 2/3)

4 - #3 COIL-TO- #2 SPARK PLUG (MARKED 2/3) 10 - #6 COIL-TO- #1 SPARK PLUG (MARKED 1/6)

5 - #1 COIL-TO- #6 SPARK PLUG (MARKED 1/6) 11 - #4 COIL-TO- #7 SPARK PLUG (MARKED 4/7)

6 - CLIPS (TRAY-TO-MANIFOLD RETENTION)

14 - 16 FUEL DELIVERY - GASDR

FUEL RAIL (Continued)

Page 1592 of 2627

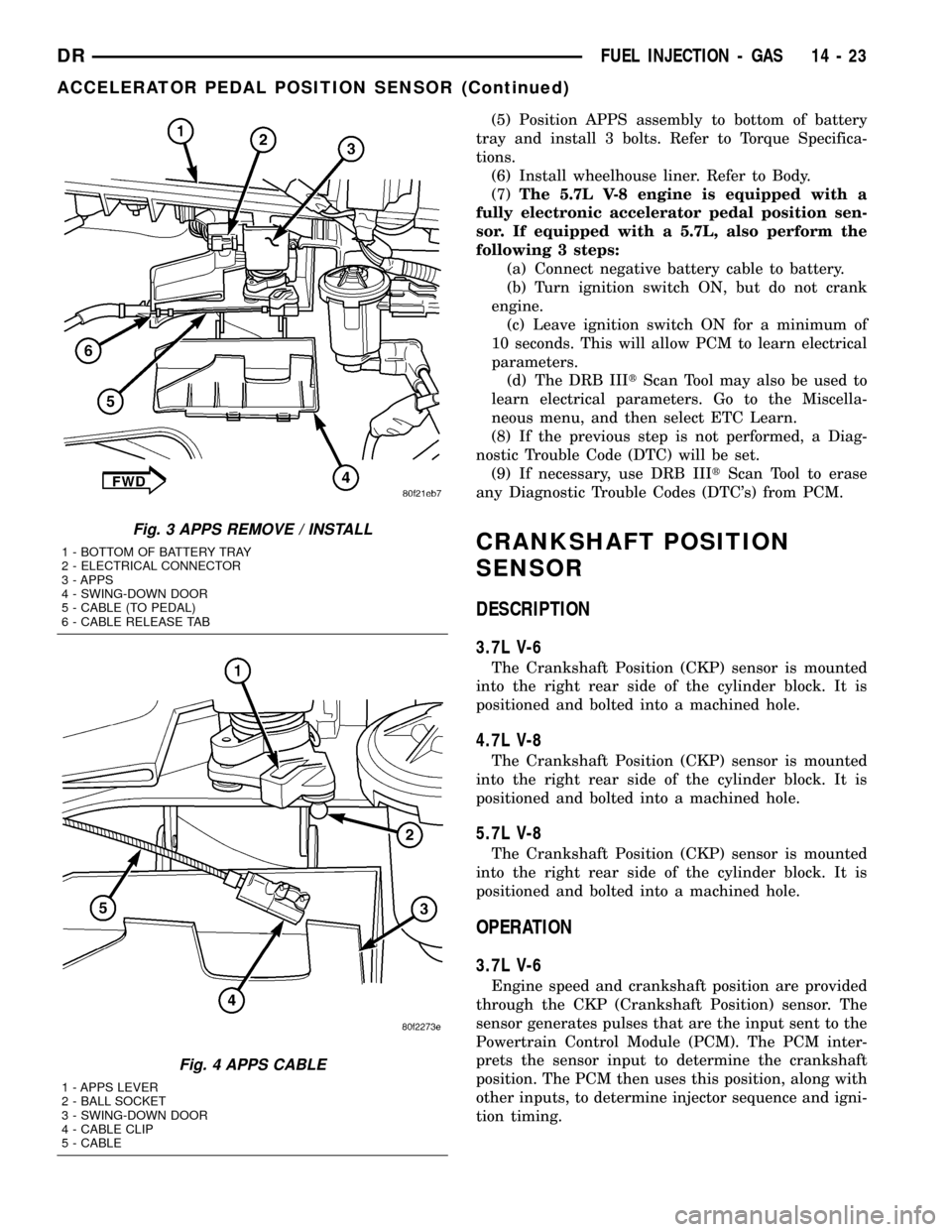

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7)The 5.7L V-8 engine is equipped with a

fully electronic accelerator pedal position sen-

sor. If equipped with a 5.7L, also perform the

following 3 steps:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(d) The DRB IIItScan Tool may also be used to

learn electrical parameters. Go to the Miscella-

neous menu, and then select ETC Learn.

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM inter-

prets the sensor input to determine the crankshaft

position. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

Fig. 3 APPS REMOVE / INSTALL

1 - BOTTOM OF BATTERY TRAY

2 - ELECTRICAL CONNECTOR

3 - APPS

4 - SWING-DOWN DOOR

5 - CABLE (TO PEDAL)

6 - CABLE RELEASE TAB

Fig. 4 APPS CABLE

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

DRFUEL INJECTION - GAS 14 - 23

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1596 of 2627

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

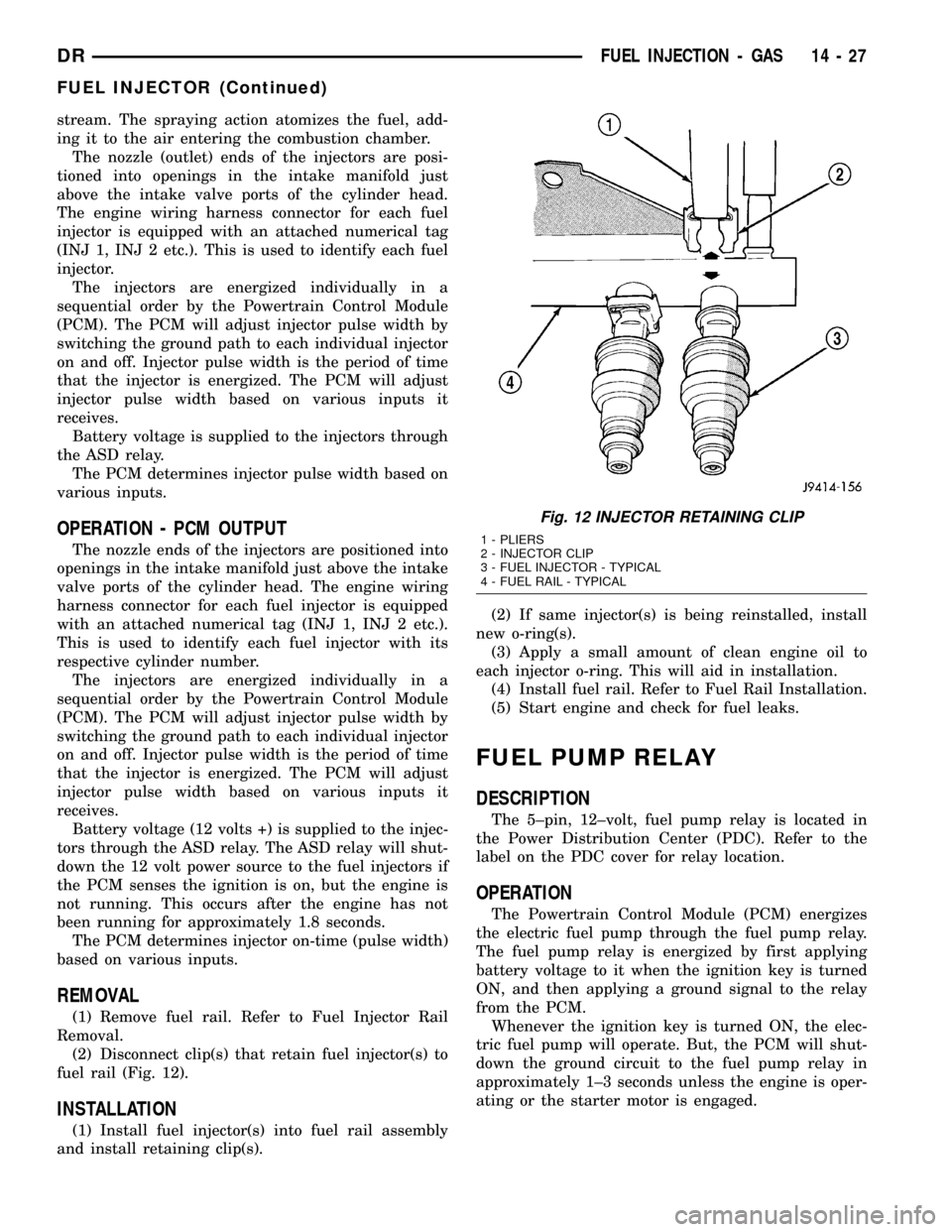

REMOVAL

(1) Remove fuel rail. Refer to Fuel Injector Rail

Removal.

(2) Disconnect clip(s) that retain fuel injector(s) to

fuel rail (Fig. 12).

INSTALLATION

(1) Install fuel injector(s) into fuel rail assembly

and install retaining clip(s).(2) If same injector(s) is being reinstalled, install

new o-ring(s).

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Install fuel rail. Refer to Fuel Rail Installation.

(5) Start engine and check for fuel leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

Fig. 12 INJECTOR RETAINING CLIP

1 - PLIERS

2 - INJECTOR CLIP

3 - FUEL INJECTOR - TYPICAL

4 - FUEL RAIL - TYPICAL

DRFUEL INJECTION - GAS 14 - 27

FUEL INJECTOR (Continued)

Page 1661 of 2627

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION..........................6

DIAGNOSIS AND TESTING - STEERING

COLUMN.............................7

REMOVAL.............................7

INSTALLATION..........................9

IGNITION SWITCH

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - IGNITION

SWITCH.............................9

REMOVAL.............................10

INSTALLATION.........................11

KEY-IN IGNITION SWITCH

DESCRIPTION.........................11

DIAGNOSIS AND TESTING - IGNITION

SWITCH AND KEY LOCK CYLINDER.......11

KEY CYLINDER

REMOVAL.............................12

INSTALLATION.........................12GEAR SHIFT LEVER

REMOVAL.............................12

INSTALLATION.........................12

UPPER STEERING COUPLING

REMOVAL.............................13

INSTALLATION.........................13

LOWER STEERING COUPLING

REMOVAL

REMOVAL - ALL LD & HD EXCEPT 4X4 HD . 14

REMOVAL - 4X4 HD...................14

INSTALLATION

INSTALLATION - ALL LD & HD EXCEPT 4X4

HD.................................14

INSTALLATION - 4X4 HD................15

STEERING WHEEL

REMOVAL.............................15

INSTALLATION.........................15

TILT LEVER KNOB RELEASE

REMOVAL.............................16

INSTALLATION.........................16

COLUMN

DESCRIPTION

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.

The tilt and standard column (Fig. 1) has been

designed to be serviced as an assembly; less wiring,

switches, shrouds, steering wheel, etc. Most steering

column components can be serviced without remov-

ing the steering column from the vehicle.

To service the steering wheel, switches or airbag,

refer to Restraints and follow all WARNINGS and

CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT INACCIDENTAL DEPLOYMENT OF THE AIRBAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COAT-

INGS AND ARE SPECIFICALLY DESIGNED FOR THE

AIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.

CAUTION: Do not hammer on steering column

shaft. This may cause damage to the shaft or bear-

ing.

CAUTION: Do not attempt to remove the pivot bolts

to disassemble the tilting mechanism. Do not

remove shaft lock plate or plate retainer. This will

damage the column.

CAUTION: Do not attempt to remove or modify the

park lock slider or link.

19 - 6 COLUMNDR