light DODGE RAM 1500 GAS 2004 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 1500 GAS, Model: DODGE RAM 1500 GAS 2004 3.GPages: 429, PDF Size: 7.52 MB

Page 343 of 429

directed on the container, aids cleaning action, reduces

the freezing point to avoid line clogging, and is not

harmful to paint or trim.

Exhaust System

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system.

Whenever a change is noticed in the sound of the exhaust

system, when exhaust fumes can be detected inside the

vehicle, or when the underside or rear of the vehicle is

damaged, have a competent mechanic inspect the com-

plete exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition,

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO) which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing CO, fol-

low the preceding safety tips.

Exhaust System Rubber Isolator and Loop-Type

Hanger Ð If Equipped

Inspect surfaces whenever the vehicle is hoisted for

rubber to metal separation or deep cracks. SLIGHT

CRACKING DUE TO WEATHERING DOES NOT AD-

VERSELY AFFECT PERFORMANCE. If, however, exces-

sively deep localized cracks are present, or any part of the

exhaust system abnormally contacts the underbody hard-

ware, the isolator and/or hanger should be replaced.

MAINTAINING YOUR VEHICLE 343

7

Page 354 of 429

CAUTION!

Be aware that if the fluid temperature is below 50ÉF

(10ÉC) it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough to

produce an accurate reading.

7. Check for leaks. Release parking brake.

To prevent dirt and water from entering the transmission

after checking or replenishing fluid, make certain that the

dipstick cap is properly reseated. It is normal for the

dipstick cap to spring back slightly from its fully seated

position, as long as its seal remains engaged in the

dipstick tube.

Selection Of Lubricant

Refer to Recommended Fluids, Lubricants and Genuine

Parts for correct fluid type. It is important that the

transmission fluid be maintained at the prescribed level

using the recommended fluid.

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturers recommended fluid will result in

more frequent fluid and filter changes. Refer to

Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

354 MAINTAINING YOUR VEHICLE

Page 355 of 429

Automatic Transmission Fluid and Filter Change

To obtain best performance and long life for automatic

transmissions, the manufacturer recommends that they

be given regular maintenance service by an Authorized

Dodge Dealer or Service Center.

It is important that proper lubricant is used in the

transmission. Refer to Recommended Fluids, Lubricants

and Genuine Parts for correct fluid type.

The fluid and filter(s) should be changed as specified in

the Maintenance Schedule (Section 8).

NOTE:If the transmission is disassembled for any

reason, the fluid and filter(s) should be changed.

Special Additives

The manufacturer strongly recommends against the ad-

dition of any additives to the transmission. Exception to

this policy is the use of special dyes to aid in detectingfluid leaks. The use of transmission sealers should be

avoided, since they may adversely affect seals.

Front Wheel Bearings

Front wheel bearings for all Dodge Ram Trucks are

sealed-for-life. They do not require greasing or seal

replacement. In some instances, these bearings will

ªpurgeº excess grease and the bearing will look slightly

wet. This is normal. Periodic inspection for excess play is

recommended.

Rear Wheel Bearings Ð Manufacturer's Axles

These bearings are normally considered permanently

lubricated. Cleaning and repacking is required only

when axle shafts are removed or in case of extreme water

or dust contamination.

MAINTAINING YOUR VEHICLE 355

7

Page 366 of 429

REPLACEMENT LIGHT BULBS

LIGHT BULBS Ð Inside Bulb No.

Overhead Console Lights............... TS212-2

Dome Light............................7679

All of the inside bulbs are brass or glass wedge base.

Aluminum base bulbs are not approved.

LIGHT BULBS Ð Outside Bulb No.

Back-Up..............................3057

Center High Mounted Stop Lamp............. 912

Fog Lamp...........................9006LL

Headlamp (Halogen)...................9007QL

Park & Turn Signal...................3157NAK

Rear License Plate Lamp................... 168

Rear Cargo Light......................... 912

Tail & Stop............................3057

Cab Clearance Lights...................... 168

Dual Rear Wheel Sidemarker Light............ 168

Dual Rear Wheel Tailgate ID Lights (3)......... 168

BULB REPLACEMENT

Headlight (Halogen)/Front Park and Turn Lights

CAUTION!

This is a halogen bulb. Avoid touching the glass

with your fingers. Reduced bulb life will result.

1. Remove the expanding fastener from the headlight

welt.

366 MAINTAINING YOUR VEHICLE

Page 368 of 429

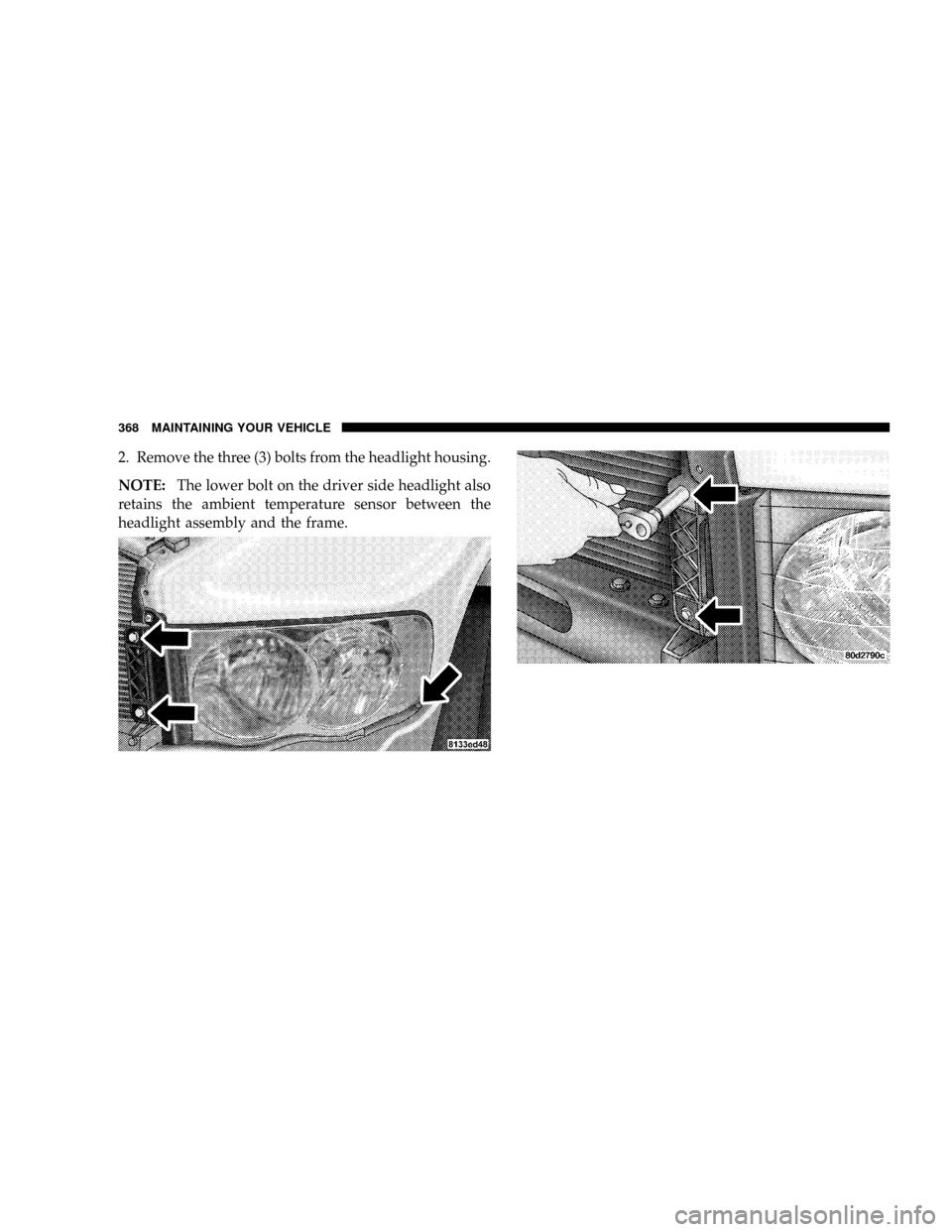

2. Remove the three (3) bolts from the headlight housing.

NOTE:The lower bolt on the driver side headlight also

retains the ambient temperature sensor between the

headlight assembly and the frame.

368 MAINTAINING YOUR VEHICLE

Page 369 of 429

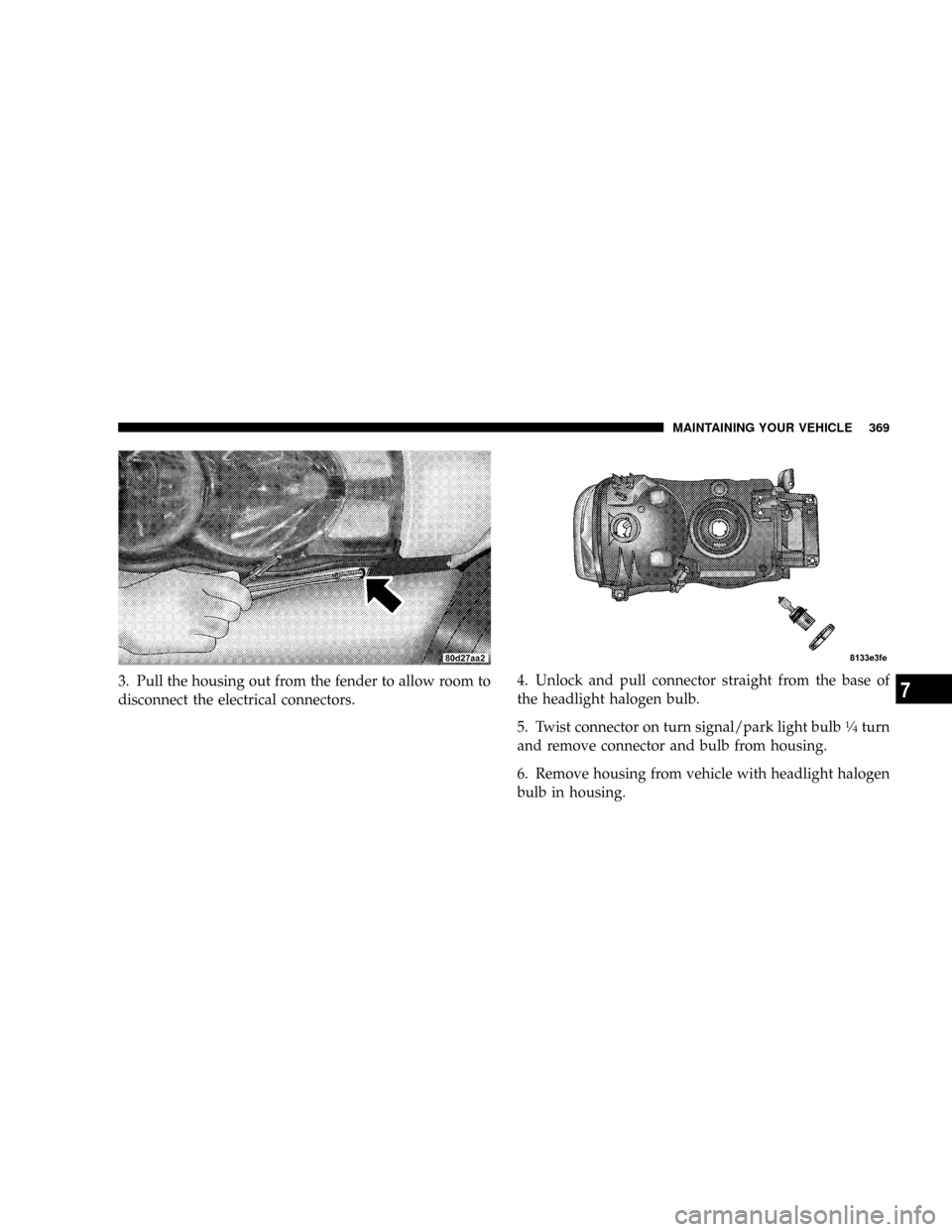

3. Pull the housing out from the fender to allow room to

disconnect the electrical connectors.4. Unlock and pull connector straight from the base of

the headlight halogen bulb.

5. Twist connector on turn signal/park light bulb

1¤4turn

and remove connector and bulb from housing.

6. Remove housing from vehicle with headlight halogen

bulb in housing.

MAINTAINING YOUR VEHICLE 369

7

Page 370 of 429

7. Twist collar on headlight halogen bulb1¤4turn and

remove headlight bulb from the housing.

8. Replace headlight or turn signal bulb. Do not touch

the headlight halogen bulb.

9. Reverse procedure for installation of bulbs and hous-

ing.

10. Tighten the outboard fastener first.

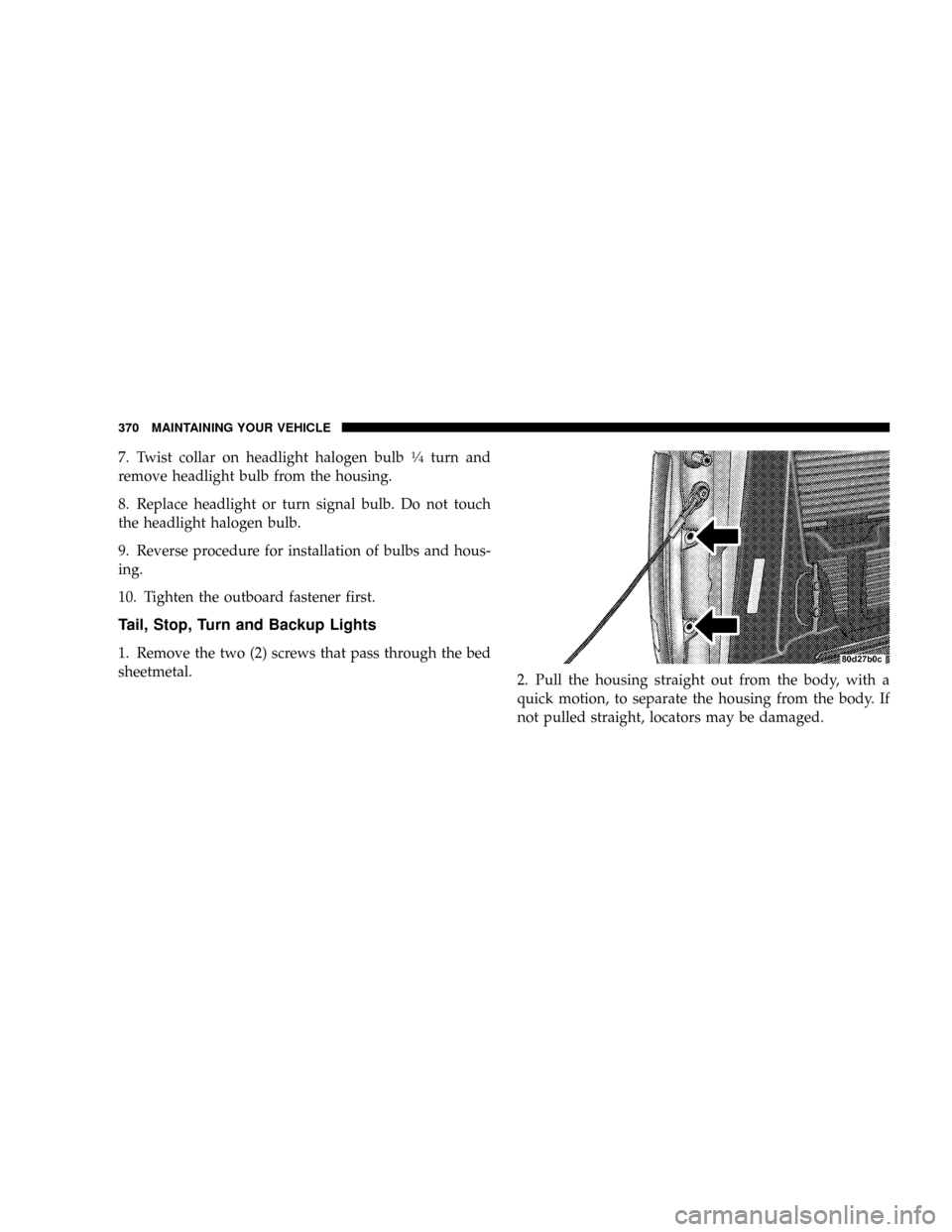

Tail, Stop, Turn and Backup Lights

1. Remove the two (2) screws that pass through the bed

sheetmetal.

2. Pull the housing straight out from the body, with a

quick motion, to separate the housing from the body. If

not pulled straight, locators may be damaged.

370 MAINTAINING YOUR VEHICLE

Page 372 of 429

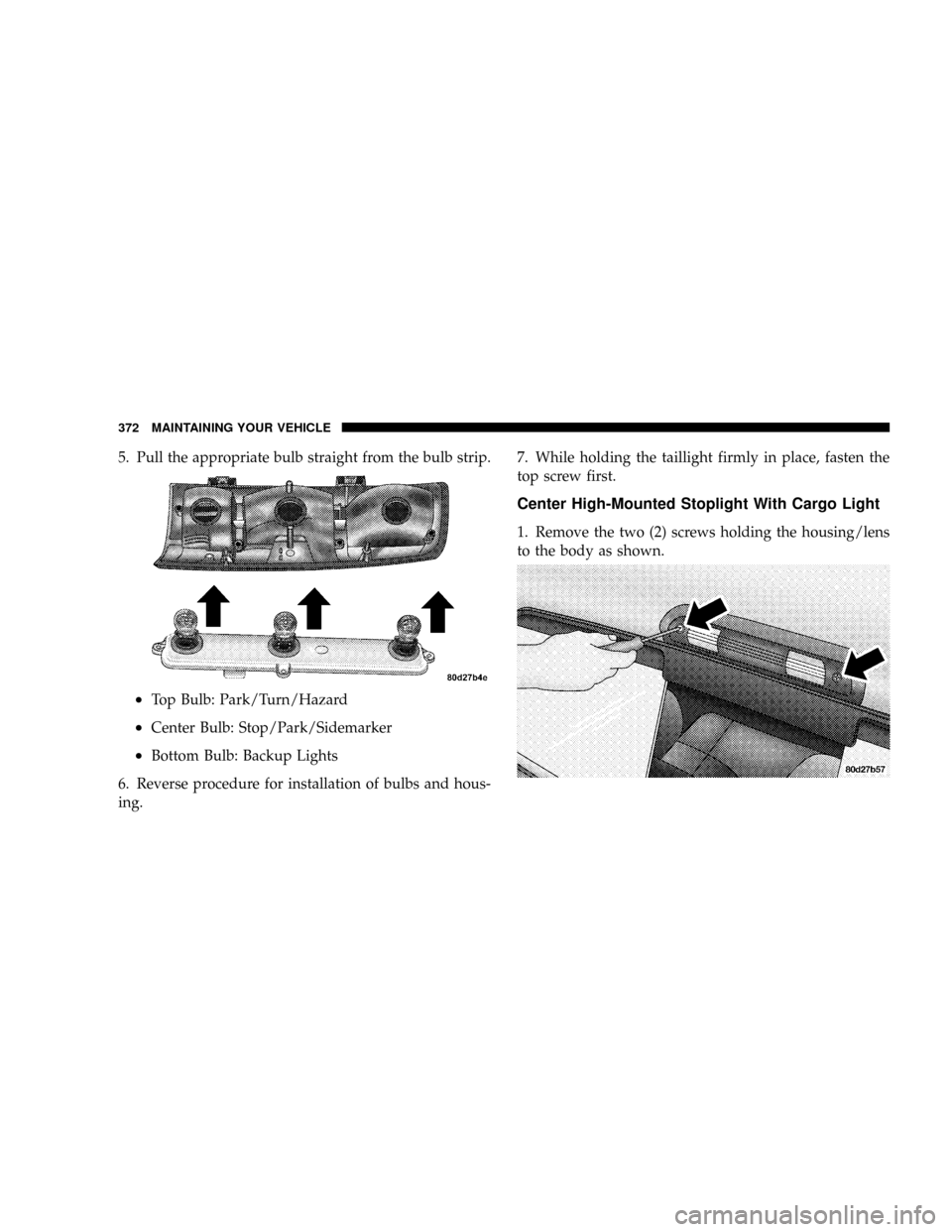

5. Pull the appropriate bulb straight from the bulb strip.

²Top Bulb: Park/Turn/Hazard

²Center Bulb: Stop/Park/Sidemarker

²Bottom Bulb: Backup Lights

6. Reverse procedure for installation of bulbs and hous-

ing.7. While holding the taillight firmly in place, fasten the

top screw first.

Center High-Mounted Stoplight With Cargo Light

1. Remove the two (2) screws holding the housing/lens

to the body as shown.

372 MAINTAINING YOUR VEHICLE

Page 374 of 429

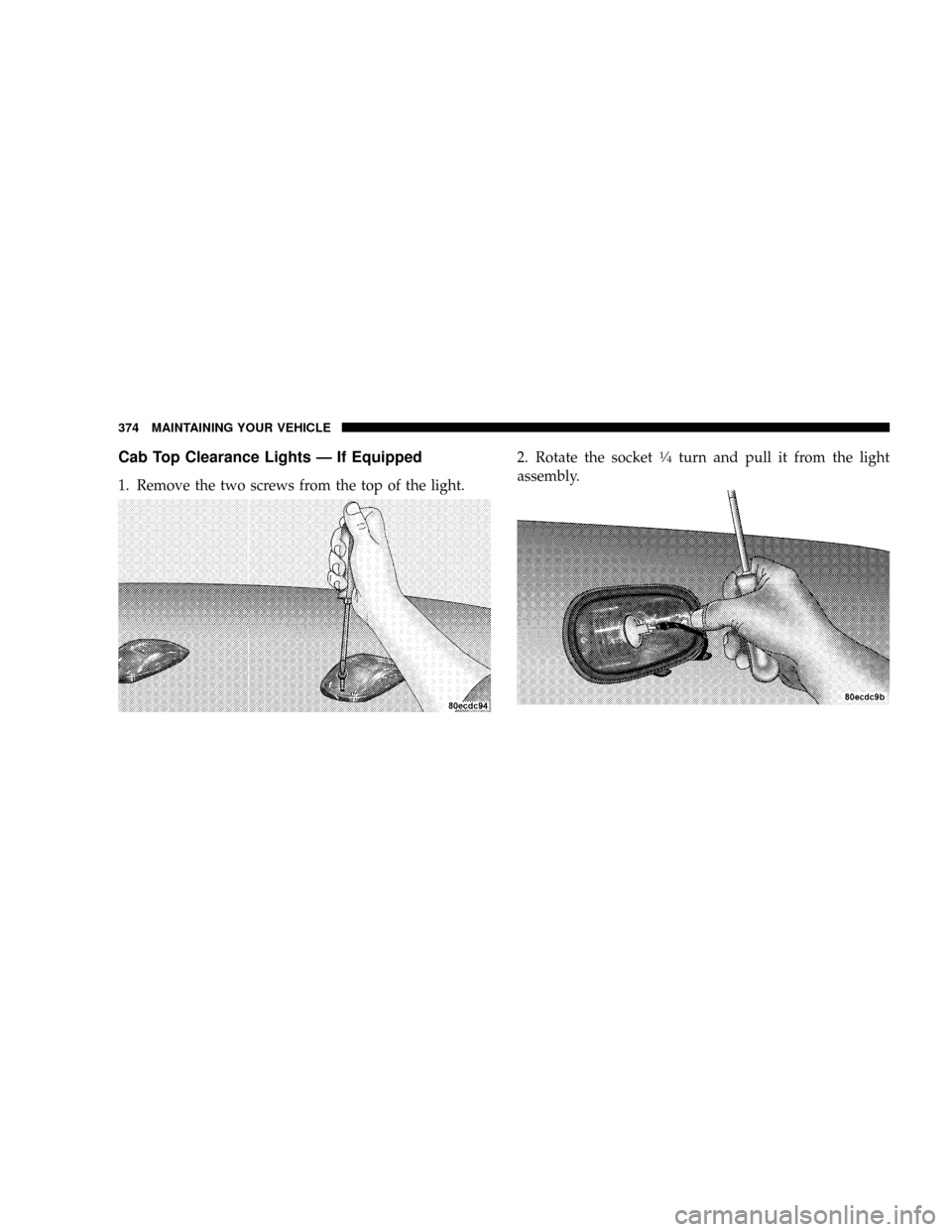

Cab Top Clearance Lights Ð If Equipped

1. Remove the two screws from the top of the light.2. Rotate the socket

1¤4turn and pull it from the light

assembly.

374 MAINTAINING YOUR VEHICLE

Page 375 of 429

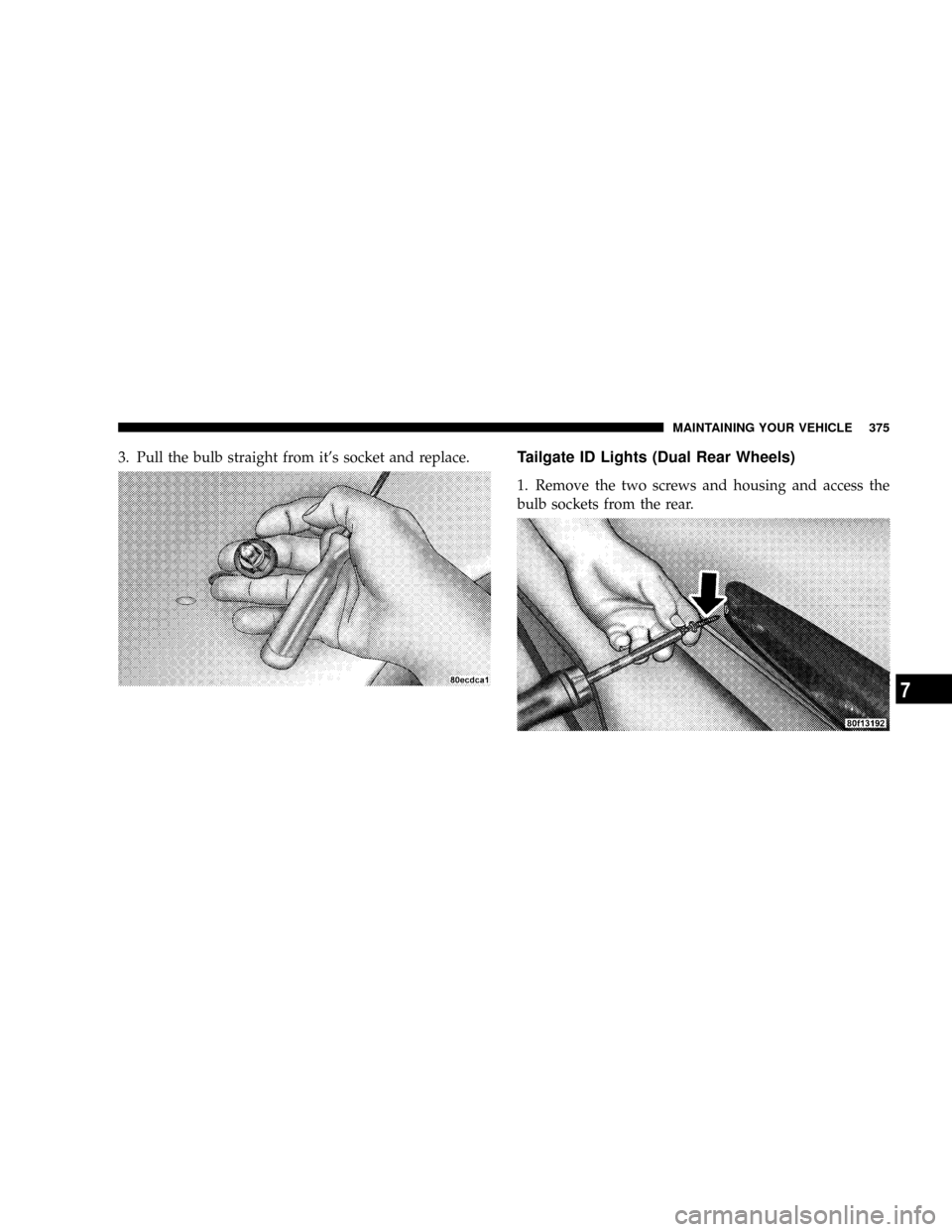

3. Pull the bulb straight from it's socket and replace.Tailgate ID Lights (Dual Rear Wheels)

1. Remove the two screws and housing and access the

bulb sockets from the rear.

MAINTAINING YOUR VEHICLE 375

7