light DODGE RAM 1500 GAS 2004 3.G Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 1500 GAS, Model: DODGE RAM 1500 GAS 2004 3.GPages: 429, PDF Size: 7.52 MB

Page 258 of 429

MMT In Gasoline

MMT is a manganese-containing metallic additive that is

blended into some gasoline to increase octane. Gasolines

blended with MMT provide no performance advantage

beyond gasolines of the same octane number without

MMT. Gasolines blended with MMT reduce spark plug

life and reduce emission system performance. We recom-

mend that gasolines free of MMT be used in your vehicle.

The MMT content of gasoline may not be indicated on

the gasoline pump; therefore, you should ask your gaso-

line retailer whether or not his/her gasoline contains

MMT.

It is even more important to look for gasolines without

MMT in Canada because MMT can be used at levels

higher than allowed in the United States. MMT is pro-

hibited in Federal and California reformulated gasolines.

Sulfur In Gasoline

If you live in the northeast United States, your vehicle

may have been designed to meet California low emission

standards with Cleaner-Burning California reformulated

gasoline with low sulfur. If such fuels are not available in

states adopting California emission standards, your ve-

hicles will operate satisfactorily on fuels meeting federal

specifications, but emission control system performance

may be adversely affected. Gasoline sold outside of

California is permitted to have higher sulfur levels which

may affect the performance of the vehicle's catalytic

converter. This may cause the Check Engine or Service

Engine Soon light to illuminate. We recommend that you

try a different brand of unleaded gasoline having lower

sulfur to determine if the problem is fuel related prior to

returning your vehicle to an authorized dealer for ser-

vice.

258 STARTING AND OPERATING

Page 259 of 429

CAUTION!

If the Check Engine or Service Engine Soon light is

flashing, immediate service is required; see onboard

diagnostics system section.

Materials Added To Fuel

All gasolines sold in the United States are required to

contain effective detergent additives. Use of additional

detergents or other additives is not needed under normal

conditions and would result in unnecessary cost. There-

fore, you should not have to add anything to the fuel.

ADDING FUEL

NOTE:If fuel is poured from a portable container, the

container should have a flexible nozzle long enough to

extend into the fuel filler tube.

CAUTION!

To avoid fuel spillage and overfilling, do not ªtop

offº the fuel tank after filling.

NOTE:When the fuel nozzle ªclicksº or shuts off, the

fuel tank is full.

NOTE:Tighten the gas cap until you hear a ªclickingº

sound. This is an indication that the gas cap is properly

tightened. Make sure that the gas cap is tightened each

time the vehicle is refueled.

WARNING!

A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle or on a

truck bed. You could be burned. Always place gas

containers on the ground while filling.

STARTING AND OPERATING 259

5

Page 261 of 429

Fuel System Cautions

CAUTION!

Follow these guidelines to maintain your vehicle's

performance:

²The use of leaded gas is prohibited by Federal law.

Using leaded gasoline can impair engine performance,

damage the emission control system, and could result

in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully loaded

vehicle when the humidity is low and the temperature

is high, use a premium unleaded fuel to help prevent

spark knock. If spark knock persists, lighten the load,

or engine piston damage may result.

²The use of fuel additives which are now being sold as

octane enhancers is not recommended. Many of these

products contain high concentrations of methanol.

Fuel system damage or vehicle performance problems

resulting from the use of such fuels or additives is not

the responsibility of the manufacturer and may not be

covered under the New Vehicle Warranty.

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

STARTING AND OPERATING 261

5

Page 273 of 429

2500/3500 Models

²

The Axles on 2500/3500 Modelsare trailer tow ready

andDO NOT REQUIREany special axle lubes or

additives.

Trailer Towing Recommendations

²

All trailer hitches should be professionally installed on

your vehicle.

²Safety chains must always be used between your

vehicle and trailer.

²Donotinterconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible

personal injury. An electrically±actuated electric trailer

brake controller is recommended.

²Trailer brakes are recommended for trailers over 1000

lbs (454 kg) and are required for trailers in excess of

2,000 lbs (907 kg)

²Use an approved wiring harness connector on the

trailer. Standard equipment on all RAM pickup mod-

els provides a 4-way trailer tow connector located

under the bumper. This connector contains the follow-

ing vehicle circuits: park/tail lamps, left stop/turn

lamp, right stop/turn lamp, and ground. With the

optional Trailer Tow Prep package a 7-way connector

is provided with the following additional circuits:

backup lamp, trailer battery and electric brake.

NOTE:Connect trailer lighting and brakes using factory

harnesses only. Do not cut or splice wiring to the brake

circuits.

STARTING AND OPERATING 273

5

Page 275 of 429

Connecting Trailer Lighting And Electric Trailer

Brakes

NOTE:A 4-way trailer tow connector, located behind

the bumper, is standard equipment on all Ram pickup

models. This connector contains the following vehicle

circuits: park/tail lamps, left stop/turn lamp, right stop/

turn lamp, and ground. With the optional Trailer Tow

Prep package a 7-way connector is also provided with the

following additional circuits: backup lamp, trailer battery

and electric brake.

NOTE:There is also a 4±way connector located under

the instrument panel, located to the left of the brake

pedal that is used for the electric brake. This connector

contains the following vehicle circuits; power ground,

battery, stop lamp switch and electric brake feed. The

4±way is optional with the trailer tow prep package.

CAUTION!

Adding lights or electrical devices to the headlamp/

park lamp circuit can be accomplished by connecting

to the standard 4-way trailer tow connector located

behind the rear bumper. The maximum current ca-

pacity for the park lamp circuit should not exceed 15

amps total (a typical park lamp bulb can draw from

0.5 to 1.0 amperes of current).

No connections can be made to the headlamp switch

itself, because it is not designed for high current

applications. Connections to the headlamp switch

will cause the exterior lights to malfunction.

STARTING AND OPERATING 275

5

Page 276 of 429

CAUTION!

Connect trailer lighting and brakes using factory

harnesses only. Do not cut or splice wiring to the

brake circuits. Use an approved wiring harness con-

nector on the trailer.

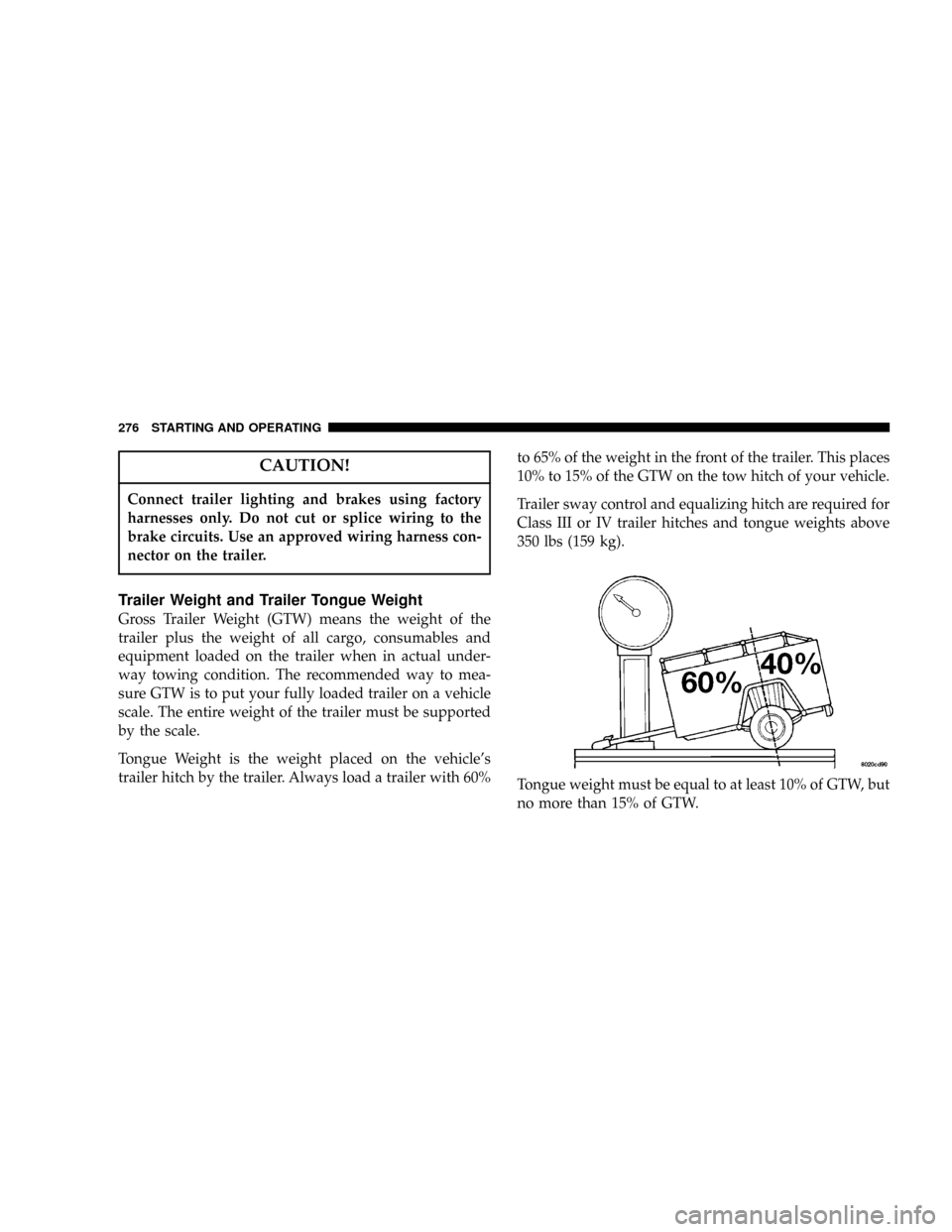

Trailer Weight and Trailer Tongue Weight

Gross Trailer Weight (GTW) means the weight of the

trailer plus the weight of all cargo, consumables and

equipment loaded on the trailer when in actual under-

way towing condition. The recommended way to mea-

sure GTW is to put your fully loaded trailer on a vehicle

scale. The entire weight of the trailer must be supported

by the scale.

Tongue Weight is the weight placed on the vehicle's

trailer hitch by the trailer. Always load a trailer with 60%to 65% of the weight in the front of the trailer. This places

10% to 15% of the GTW on the tow hitch of your vehicle.

Trailer sway control and equalizing hitch are required for

Class III or IV trailer hitches and tongue weights above

350 lbs (159 kg).

Tongue weight must be equal to at least 10% of GTW, but

no more than 15% of GTW.

276 STARTING AND OPERATING

Page 279 of 429

²Air ConditioningÐturn it off temporarily.

²Hilly TerrainÐTurn overdrive off.

See Cooling System Operating information in the Service

and Maintenance section of this manual for more infor-

mation.

Automatic Transmission Oil Temperature Warning

Light

All vehicles with automatic transmissions are equipped

with a transmission sump oil temperature sensor and

warning light. If elevated transmission temperatures are

encountered, the engine controller will select the most

desirable gear until the transmission temperatures are

reduced. If transmission oil temperatures continue to

rise, a warning light located in the instrument cluster will

illuminate. If this should occur, stop the vehicle, shift to

Neutral, and run the engine at idle or faster until the light

goes off.

Towing With An Automatic Transmission

Vehicles equipped with an automatic transmission may

shift into and out of Overdrive, or a lower gear, when

driving in hilly areas, when heavily loaded, or when

towing into heavy winds.

When this condition occurs, select TOW/HAUL mode or

shift into a lower gear to prevent excessive transmission

wear and/or overheating, and to provide better engine

braking.

NOTE:Do not exceed the following RPM while manu-

ally downshifting:

²5800 rpm with 3.7L engines.

²5800 rpm with 4.7L engines.

²5600 rpm with 5.7L engines.

STARTING AND OPERATING 279

5

Page 281 of 429

2004 BODY BUILDER'S GUIDE. See your dealer, installer

or snowplow manufacture for this information. There are

unique electrical systems that must be connected to

properly assure operator safety and prevent overloading

vehicle systems that would void the vehicle warranty.

WARNING!

Attaching a snowplow to this vehicle could ad-

versely affect performance of the airbag system in an

accident. Do not expect that the airbag will perform

as described earlier in this manual

CAUTION!

The ªLamp Outº indicator could illuminate if exte-

rior lamps are not properly installed.

Before plowing

²

Check the hydraulic system for leaks and proper fluid

level.

²Check the mounting bolts and nuts for proper tight-

ness.

²Check the runners and cutting edge for excessive wear.

The cutting edge should be 1/4 to 1/2 inch (6.4 mm

to13 mm) above ground in snow plowing position.

²Check that snowplow lighting is connected and func-

tioning properly.

Snowplow Model Prep Package Availability

For Detailed Information Visit www.dodge.com or refer

to the 2004 Dodge Truck Body Builders Guide.

1. The 1500 models are NOT available for snowplow

applications.

STARTING AND OPERATING 281

5

Page 288 of 429

7. After shift is completed and the Neutral (N) light

comes on release Neutral (N) button.

8. Start engine.

9. Shift automatic transmission into Reverse (R).

10. Release brake pedal for five seconds and ensure that

there is no vehicle movement.

11. Repeat steps 9 and 10 with the transmission in Drive

(D).

12. Shut engine OFF and place ignition key to the

unlocked OFF position.

13. Shift automatic transmission into Park (P).

14. Apply parking brake.

15. Attach vehicle to tow vehicle with tow bar.

16. Release parking brake.NOTE:Items 1 through 5 are requirements that must be

met prior to depressing the Neutral (N) selection button,

and must continue to be met until the 4 seconds elaspes

and the shift has been completed. If any of these require-

ments (with the exception of 3 - Key ON) are not met

prior to depressing the Neutral (N) button or are no

longer met during the 4 second timer, then the Neutral

(N) indicator light will flash continuously until all re-

quirements are met or until the Neutral (N) button is

released.

NOTE:The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key in not ON, the shift will not take place and no

position indicator lights will be on or flashing.

NOTE:Flashing neutral (N) position indicator light

indicates that shift requirements have not been met.

288 STARTING AND OPERATING

Page 289 of 429

CAUTION!

Damage to the transmission may occur if the trans-

mission is shifted into Park (P) with the transfer case

in Neutral (N) and the engine RUNNING. With the

transfer case in Neutral (N) ensure that the engine is

OFF prior to shifting the transmission into Park (P).

Returning to Normal Operation Ð Electronic Shift

Transfer Case

Use the following procedure to prepare your vehicle for

normal usage.

1. Bring vehicle to a complete stop.

2. Shut OFF the engine.

3. Place ignition key in the ON position.

4. Depress the brake pedal.5. Shift automatic transmission to Neutral (N) or depress

clutch on manual transmission.

6. Using the point of a ballpoint pen or similar object,

depress the recessed transfer case Neutral (N) button for

1 second.

7. After the Neutral (N) indicator light turns off release

the Neutral (N) button.

8. After the Neutral (N) button has been released the

transfer case will shift to the position identified by the

selector switch.

9. Shift automatic transmission into P (Park).

NOTE:Items 1 through 5 are requirements that must be

met prior to depressing the Neutral (N) selection button,

and must continue to be met until 1 second elapses and

the shift has been completed. If any of these requirements

(with the exception of 3 - key ON) are not met prior to

depressing the Neutral (N) button or are no longer met

STARTING AND OPERATING 289

5