DODGE RAM 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: RAM, Model: DODGE RAM 1999Pages: 1691, PDF Size: 40.34 MB

Page 681 of 1691

using ridge reamer. DO NOT remove an excessive amount of material.

Ensure ridge is completely removed.

PISTON & CONNECTING ROD REMOVAL

Note top of piston. Some pistons may contain a notch, arrow

or be marked "FRONT". Piston must be installed in proper direction to

prevent damage with valve operation.

Check that connecting rod and cap are numbered for cylinder

location and which side of cylinder block the number faces. Proper cap

and connecting rod must be installed together. Connecting rod cap must

be installed on connecting rod in proper direction to ensure bearing

lock procedure. Mark connecting rod and cap if necessary. Pistons must

be installed in original location.

Remove cap retaining nuts or bolts. Remove bearing cap.

Install stud protectors on connecting rod bolts. This protects

cylinder walls from scoring during removal. Ensure proper removal of

ridge. Push piston and connecting rod from cylinder. Connecting rod

boss can be tapped with a wooden dowel or hammer handle to aid in

removal.

PISTON & CONNECTING ROD

Disassembly

Using ring expander, remove piston rings. Remove piston pin

retaining rings (if equipped). On pressed type piston pins, special

fixtures and procedures according to manufacturer must be used to

remove piston pins. Follow manufacturer's recommendations to avoid

piston distortion or breakage.

Cleaning

Remove all carbon and varnish from piston. Pistons and

connecting rods may be cleaned in cold type chemical tank. Using ring

groove cleaner, clean all deposits from ring grooves. Ensure all

deposits are cleaned from ring grooves to prevent ring breakage or

sticking. DO NOT attempt to clean pistons using wire brush.

Inspection

Inspect pistons for nicks, scoring, cracks or damage in ring

areas. Connecting rod should be checked for cracks using Magnaflux

procedure. Piston diameter must be measured in manufacturers specified

area.

Using telescopic gauge and micrometer, measure piston pin

bore of piston in 2 areas, 90 degrees apart. This is done to check

diameter and out-of-round.

Install proper bearing cap on connecting rod. Ensure bearing

cap is installed in proper location. Tighten bolts or nuts to

specification. Using inside micrometer, measure inside diameter in 2

areas, 90 degrees apart.

Connecting rod I.D. and out-of-round must be within

specification. Measure piston pin bore I.D. and piston pin O.D. All

components must be within specification. Subtract piston pin diameter

from piston pin bore in piston and connecting rod to determine proper

fit.

Connecting rod length must be measured from center of

crankshaft journal inside diameter to center of piston pin bushing

using proper caliper. Connecting rods must be the same length.

Connecting rods should be checked on an alignment fixture for bent or

twisted condition. Replace all components which are damaged or not

within specification.

PISTON & CYLINDER BORE FIT

Page 682 of 1691

Ensure cylinder is checked for taper, out-of-round and

properly honed prior to checking piston and cylinder bore fit. See

CYLINDER BLOCK in this article. Using dial bore gauge, measure

cylinder bore. Measure piston at right angle to piston pin in center

of piston skirt area. Subtract piston diameter from cylinder bore

diameter. The difference is piston-to-cylinder clearance. Clearance

must be within specification. Mark piston for proper cylinder

location.

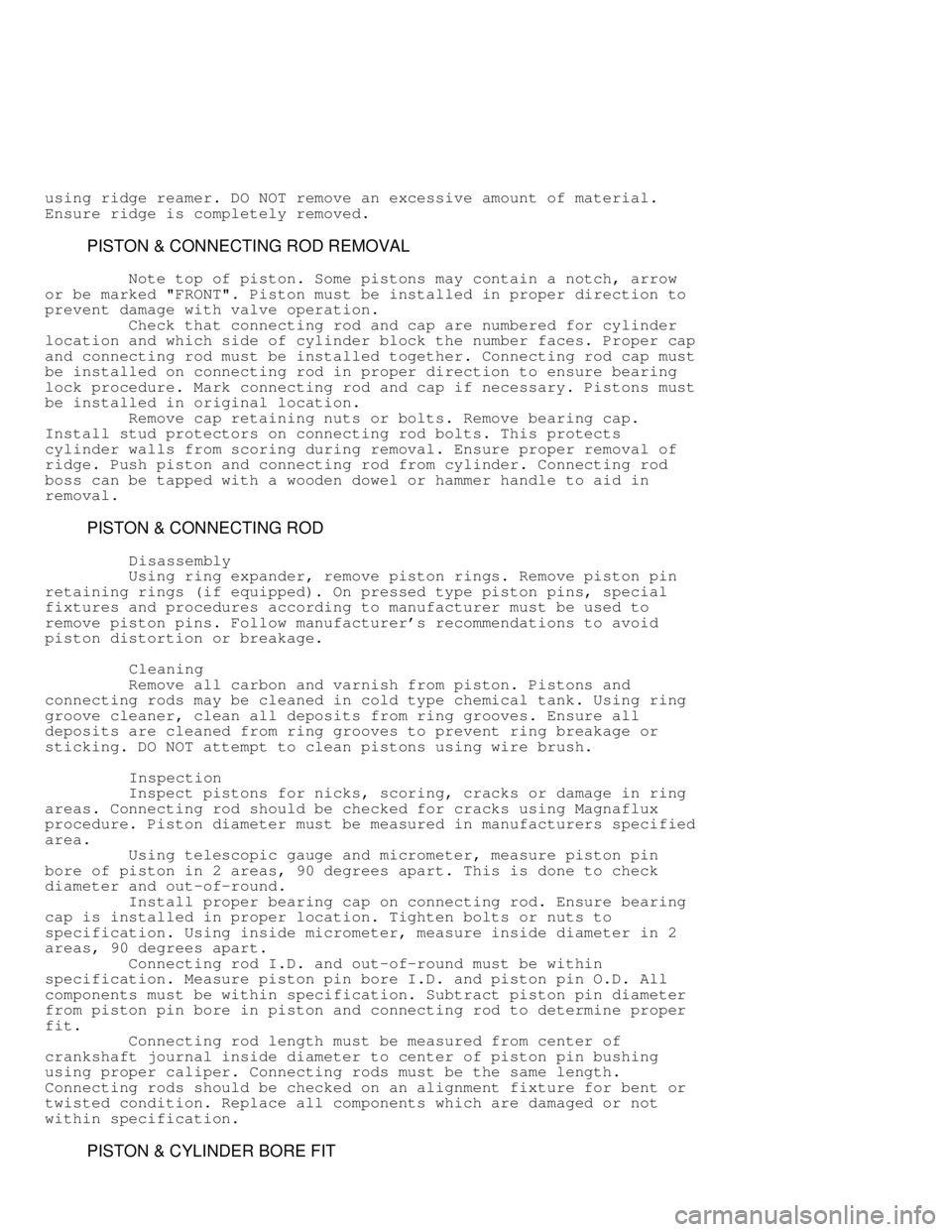

ASSEMBLING PISTON & CONNECTING ROD

Install proper fitted piston on connecting rod for proper

cylinder. Ensure piston marking on top of piston marked is in

correspondence with connecting rod and cap number. See Fig. 14.

Fig. 14: Piston Pin Installation - Typical

This Graphic For General Information Only

Lubricate piston pin and install in connecting rod. Ensure

piston pin retainers are fully seated (if equipped). On pressed type

piston pins, follow manufacturer's recommended procedure to avoid

distortion or breakage.

CHECKING PISTON RING CLEARANCES

Page 683 of 1691

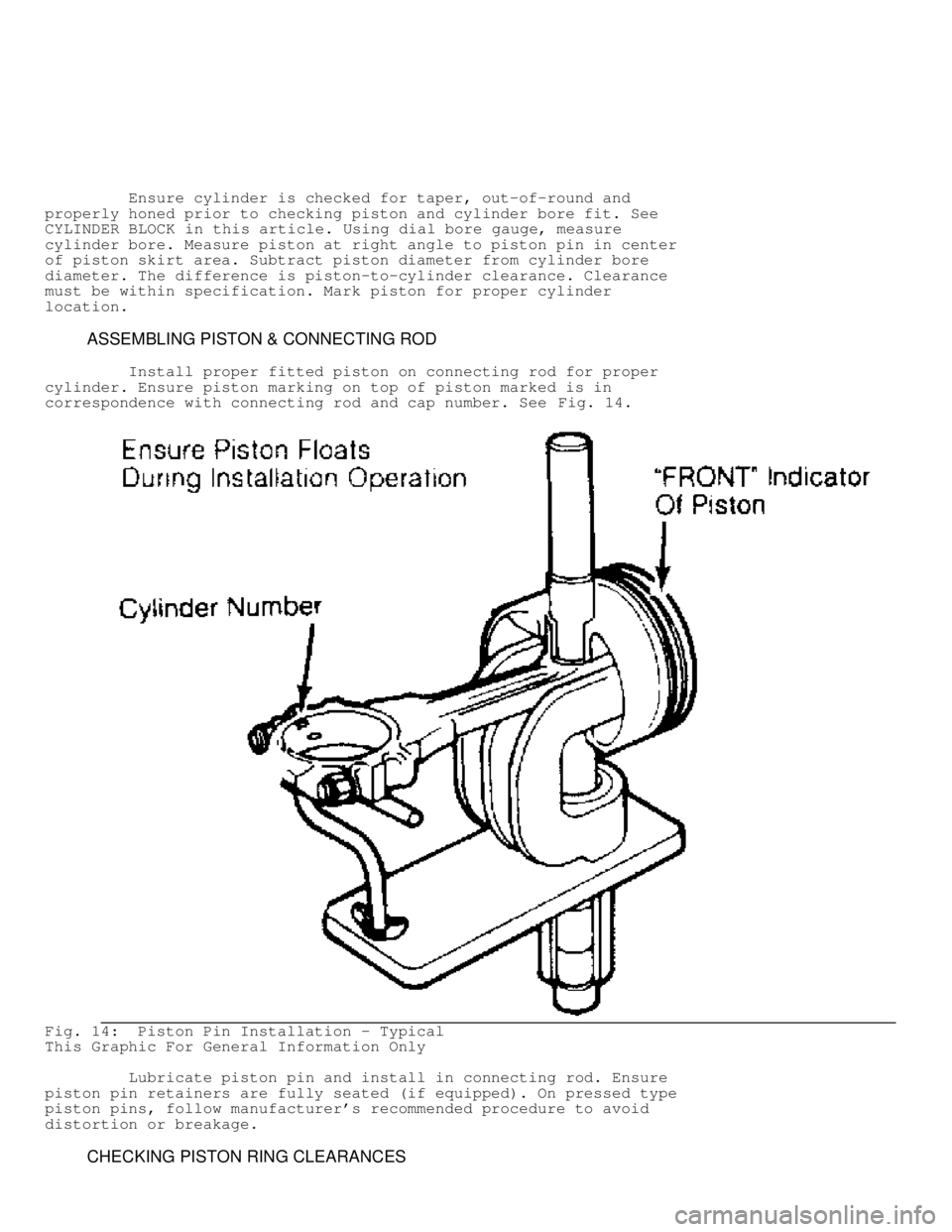

Piston rings must be checked for side clearance and end gap.

To check end gap, install piston ring in cylinder which it is to be

installed. Using an inverted piston, push ring to bottom of cylinder

in smallest cylinder diameter.

Using feeler gauge, check ring end gap. See Fig. 15. Piston

ring end gap must be within specification. Ring breakage will occur

with insufficient ring end gap.

On some manufacturers, insufficient ring end gap may be

corrected by using a fine file while other manufacturers recommend

using another ring set. Mark rings for proper cylinder installation

after checking end gap.

Fig. 15: Checking Piston Ring End Gap - Typical

This Graphic For General Information Only

For checking side clearance, install rings on piston. Using

feeler gauge, measure clearance between piston ring and piston ring

land. Check side clearance in several areas around piston. Side

clearance must be within specification.

If side clearance is excessive, piston ring grooves can be

machined to accept oversized piston rings (if available). Normal

practice is to replace piston.

Page 684 of 1691

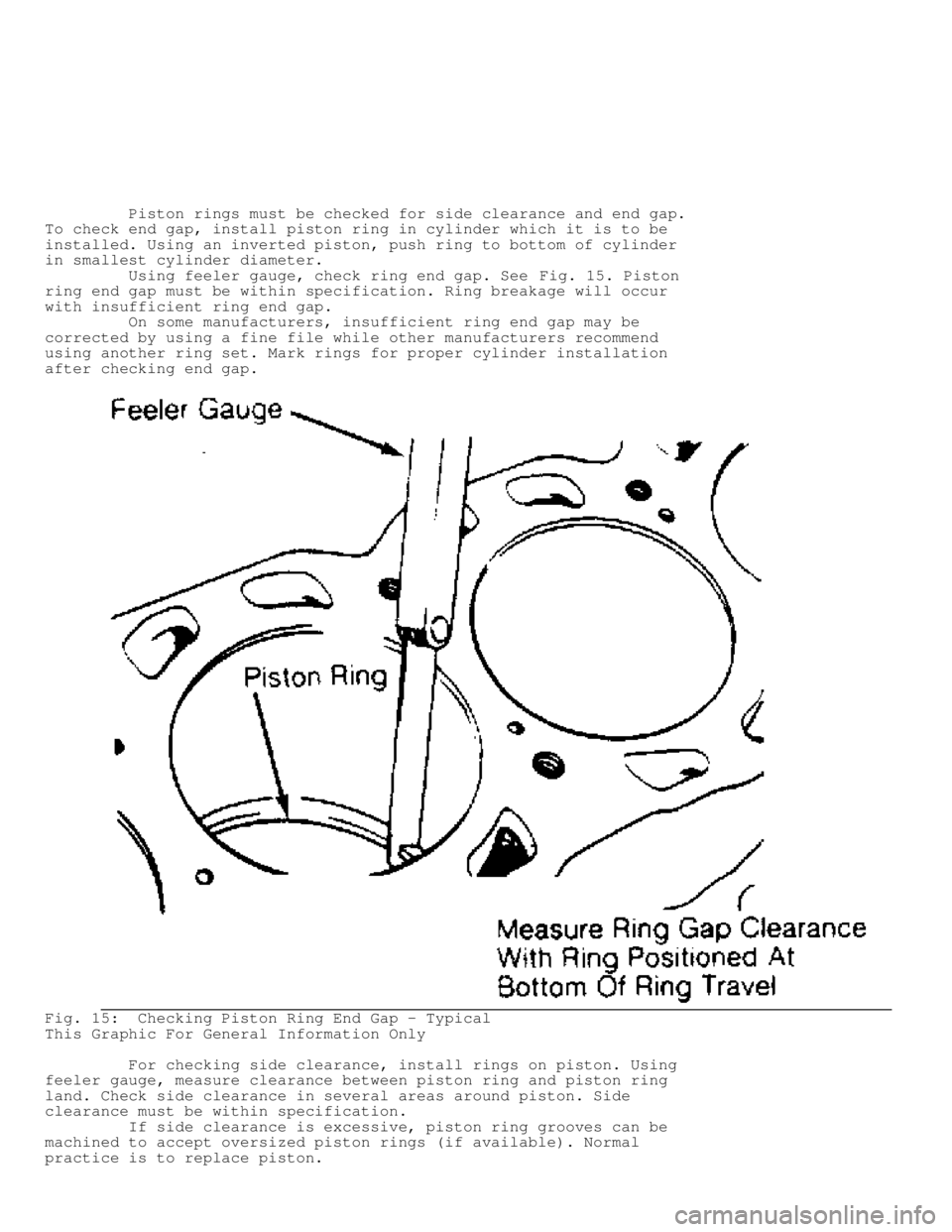

PISTON & CONNECTING ROD INSTALLATION

Cylinders must be honed prior to piston installation. See

CYLINDER HONING under CYLINDER BLOCK in this article.

Install upper connecting rod bearings. Lubricate upper

bearings with engine oil. Install lower bearings in rod caps. Ensure

bearing tabs are properly seated. Position piston ring gaps according

to manufacturers recommendations. See Fig. 16. Lubricate pistons,

rings and cylinder walls.

Fig. 16: Typical Piston Ring End Gap Positioning - Typical

This Graphic For General Information Only

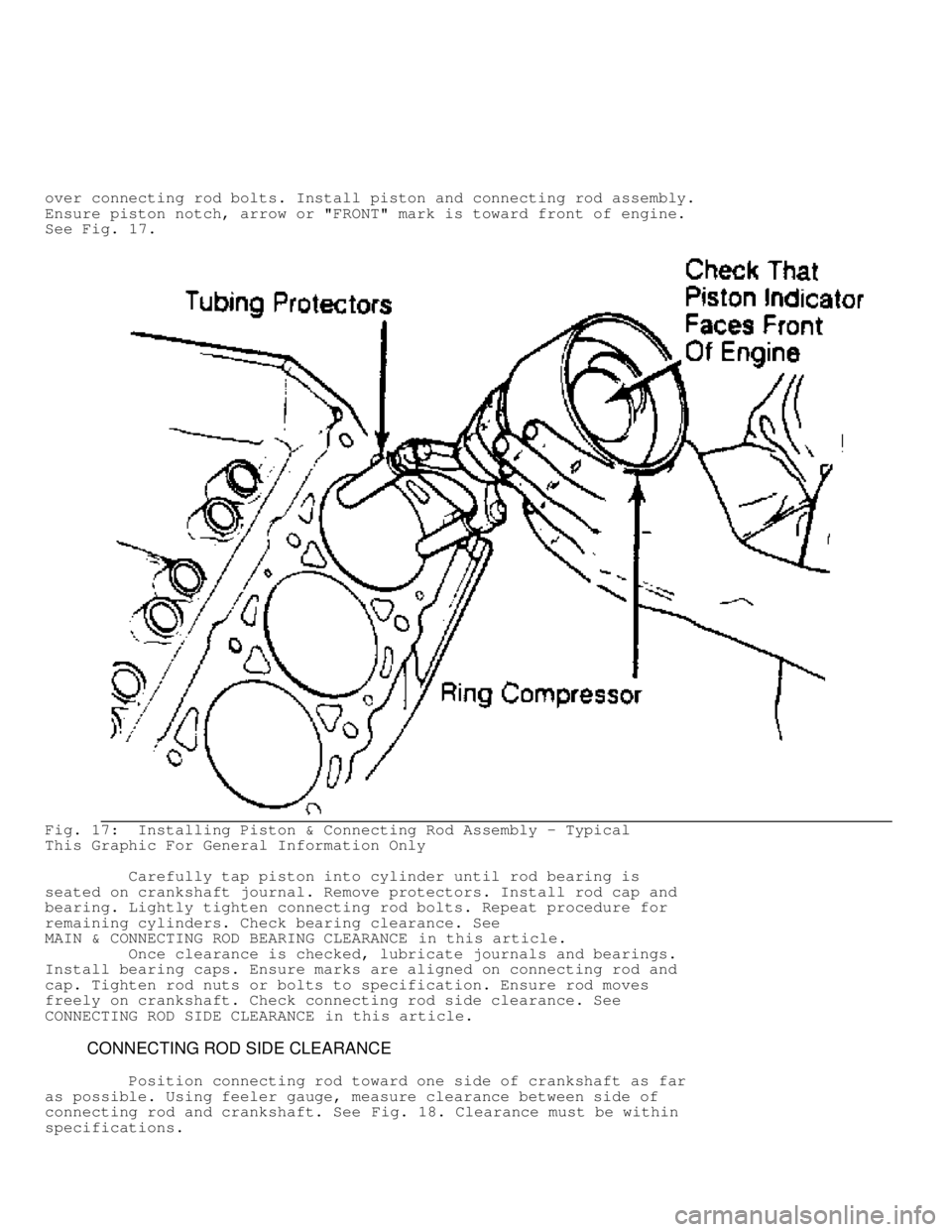

Install ring compressor. Use care not to rotate piston rings.

Compress rings with ring compressor. Install plastic tubing protectors

Page 685 of 1691

over connecting rod bolts. Install piston and connecting rod assembly.

Ensure piston notch, arrow or "FRONT" mark is toward front of engine.

See Fig. 17 .

Fig. 17: Installing Piston & Connecting Rod Assembly - Typical

This Graphic For General Information Only

Carefully tap piston into cylinder until rod bearing is

seated on crankshaft journal. Remove protectors. Install rod cap and

bearing. Lightly tighten connecting rod bolts. Repeat procedure for

remaining cylinders. Check bearing clearance. See

MAIN & CONNECTING ROD BEARING CLEARANCE in this article.

Once clearance is checked, lubricate journals and bearings.

Install bearing caps. Ensure marks are aligned on connecting rod and

cap. Tighten rod nuts or bolts to specification. Ensure rod moves

freely on crankshaft. Check connecting rod side clearance. See

CONNECTING ROD SIDE CLEARANCE in this article.

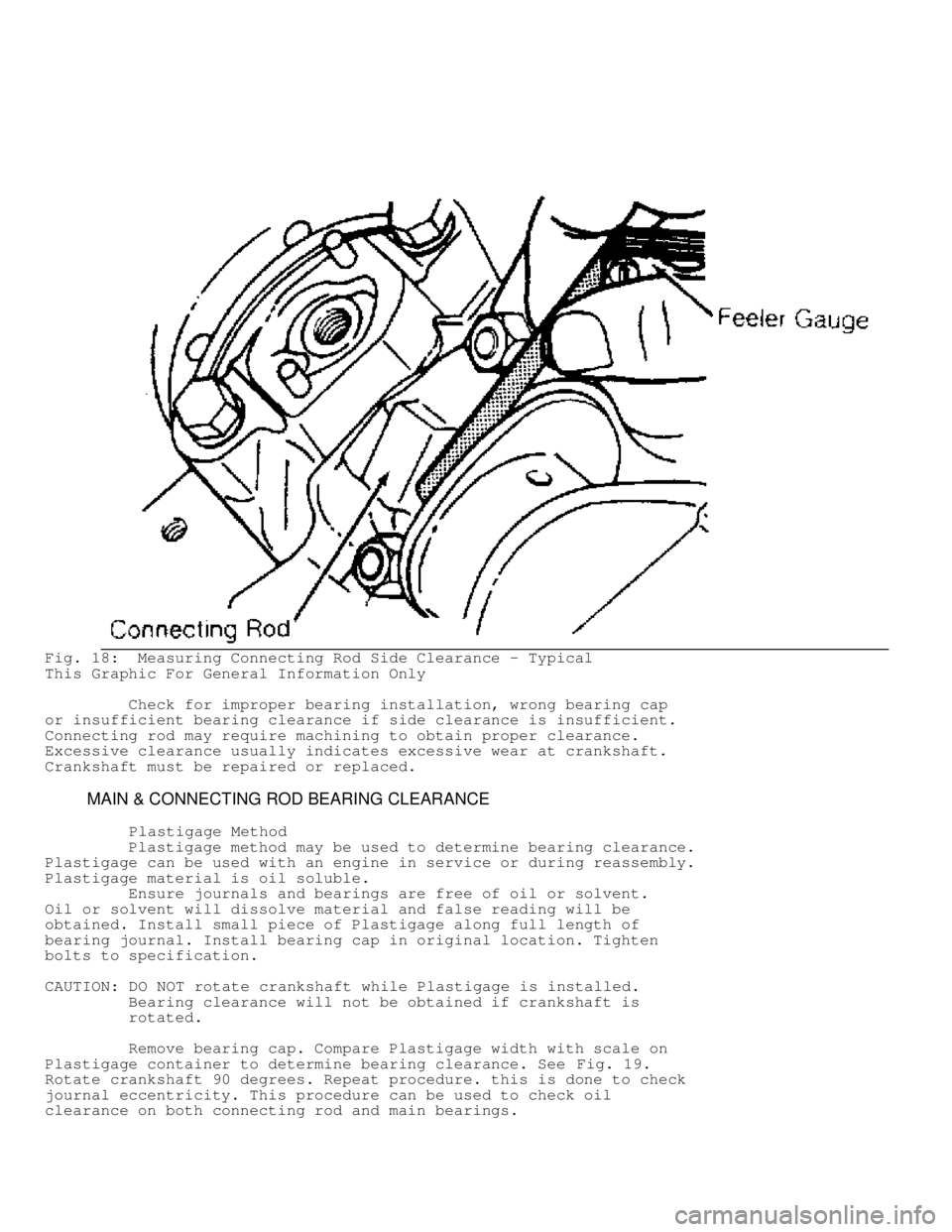

CONNECTING ROD SIDE CLEARANCE

Position connecting rod toward one side of crankshaft as far

as possible. Using feeler gauge, measure clearance between side of

connecting rod and crankshaft. See Fig. 18. Clearance must be within

specifications.

Page 686 of 1691

Fig. 18: Measuring Connecting Rod Side Clearance - Typical

This Graphic For General Information Only

Check for improper bearing installation, wrong bearing cap

or insufficient bearing clearance if side clearance is insufficient.

Connecting rod may require machining to obtain proper clearance.

Excessive clearance usually indicates excessive wear at crankshaft.

Crankshaft must be repaired or replaced.

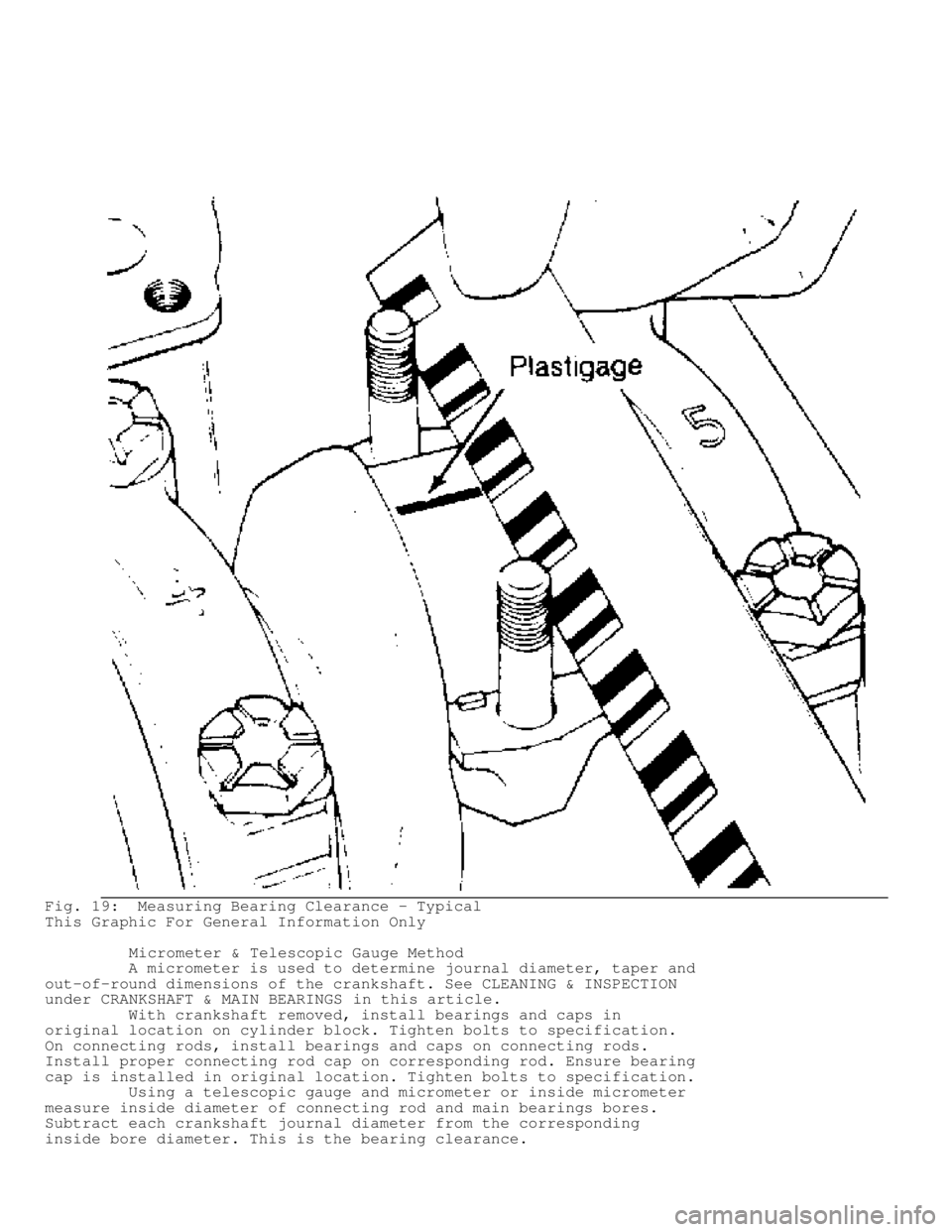

MAIN & CONNECTING ROD BEARING CLEARANCE

Plastigage Method

Plastigage method may be used to determine bearing clearance.

Plastigage can be used with an engine in service or during reassembly.

Plastigage material is oil soluble.

Ensure journals and bearings are free of oil or solvent.

Oil or solvent will dissolve material and false reading will be

obtained. Install small piece of Plastigage along full length of

bearing journal. Install bearing cap in original location. Tighten

bolts to specification.

CAUTION: DO NOT rotate crankshaft while Plastigage is installed.

Bearing clearance will not be obtained if crankshaft is

rotated.

Remove bearing cap. Compare Plastigage width with scale on

Plastigage container to determine bearing clearance. See Fig. 19.

Rotate crankshaft 90 degrees. Repeat procedure. this is done to check

journal eccentricity. This procedure can be used to check oil

clearance on both connecting rod and main bearings.

Page 687 of 1691

Fig. 19: Measuring Bearing Clearance - Typical

This Graphic For General Information Only

Micrometer & Telescopic Gauge Method

A micrometer is used to determine journal diameter, taper and

out-of-round dimensions of the crankshaft. See CLEANING & INSPECTION

under CRANKSHAFT & MAIN BEARINGS in this article.

With crankshaft removed, install bearings and caps in

original location on cylinder block. Tighten bolts to specification.

On connecting rods, install bearings and caps on connecting rods.

Install proper connecting rod cap on corresponding rod. Ensure bearing

cap is installed in original location. Tighten bolts to specification.

Using a telescopic gauge and micrometer or inside micrometer

measure inside diameter of connecting rod and main bearings bores.

Subtract each crankshaft journal diameter from the corresponding

inside bore diameter. This is the bearing clearance.

Page 688 of 1691

CRANKSHAFT & MAIN BEARINGS

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

REMOVAL

Ensure all main bearing caps are marked for location on

cylinder block. Some main bearing caps have an arrow stamped on it

which must face front of engine. Remove main bearing cap bolts. Remove

main bearing caps. Carefully remove crankshaft. Use care not to bind

crankshaft in cylinder block during removal.

CLEANING & INSPECTION

Thoroughly clean crankshaft using solvent. Dry with

compressed air. Ensure all oil passages are clear and free of sludge,

rust, dirt, and metal chips.

Inspect crankshaft for scoring and nicks. Inspect crankshaft

for cracks using Magnaflux procedure. Inspect rear seal area for

grooving or damage. Inspect bolt hole threads for damage. If pilot

bearing or bushing is used, check pilot bearing or bushing fit in

crankshaft. Inspect crankshaft gear for damaged or cracked teeth.

Replace gear if damaged. Check that oil passage plugs are tight (if

equipped).

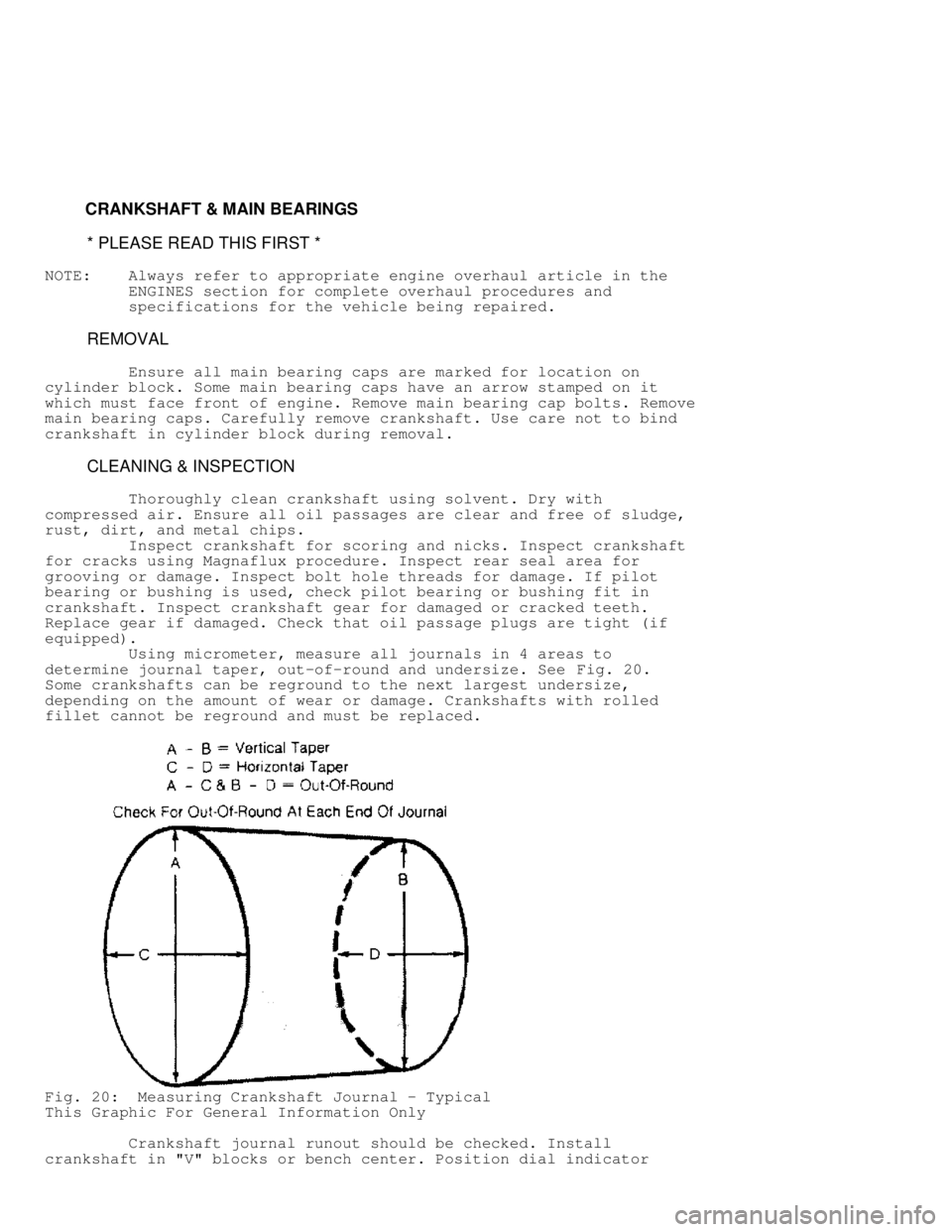

Using micrometer, measure all journals in 4 areas to

determine journal taper, out-of-round and undersize. See Fig. 20.

Some crankshafts can be reground to the next largest undersize,

depending on the amount of wear or damage. Crankshafts with rolled

fillet cannot be reground and must be replaced.

Fig. 20: Measuring Crankshaft Journal - Typical

This Graphic For General Information Only

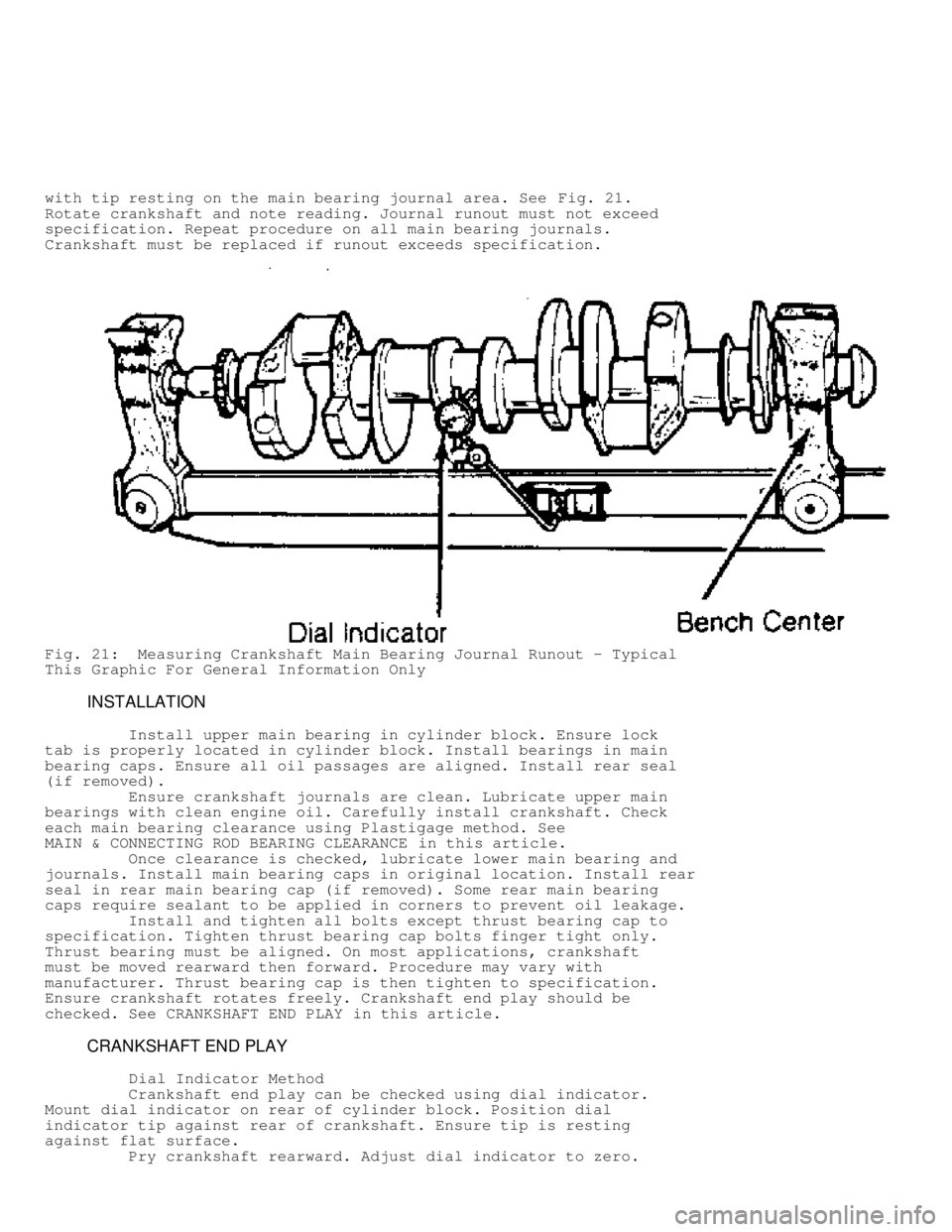

Crankshaft journal runout should be checked. Install

crankshaft in "V" blocks or bench center. Position dial indicator

Page 689 of 1691

with tip resting on the main bearing journal area. See Fig. 21.

Rotate crankshaft and note reading. Journal runout must not exceed

specification. Repeat procedure on all main bearing journals.

Crankshaft must be replaced if runout exceeds specification.

Fig. 21: Measuring Crankshaft Main Bearing Journal Runout - Typical

This Graphic For General Information Only

INSTALLATION

Install upper main bearing in cylinder block. Ensure lock

tab is properly located in cylinder block. Install bearings in main

bearing caps. Ensure all oil passages are aligned. Install rear seal

(if removed).

Ensure crankshaft journals are clean. Lubricate upper main

bearings with clean engine oil. Carefully install crankshaft. Check

each main bearing clearance using Plastigage method. See

MAIN & CONNECTING ROD BEARING CLEARANCE in this article.

Once clearance is checked, lubricate lower main bearing and

journals. Install main bearing caps in original location. Install rear

seal in rear main bearing cap (if removed). Some rear main bearing

caps require sealant to be applied in corners to prevent oil leakage.

Install and tighten all bolts except thrust bearing cap to

specification. Tighten thrust bearing cap bolts finger tight only.

Thrust bearing must be aligned. On most applications, crankshaft

must be moved rearward then forward. Procedure may vary with

manufacturer. Thrust bearing cap is then tighten to specification.

Ensure crankshaft rotates freely. Crankshaft end play should be

checked. See CRANKSHAFT END PLAY in this article.

CRANKSHAFT END PLAY

Dial Indicator Method

Crankshaft end play can be checked using dial indicator.

Mount dial indicator on rear of cylinder block. Position dial

indicator tip against rear of crankshaft. Ensure tip is resting

against flat surface.

Pry crankshaft rearward. Adjust dial indicator to zero.

Page 690 of 1691

Pry crankshaft forward and note reading. Crankshaft end play must be

within specification. If end play is not within specification, check

for faulty thrust bearing installation or worn crankshaft. Some

applications offer oversized thrust bearings.

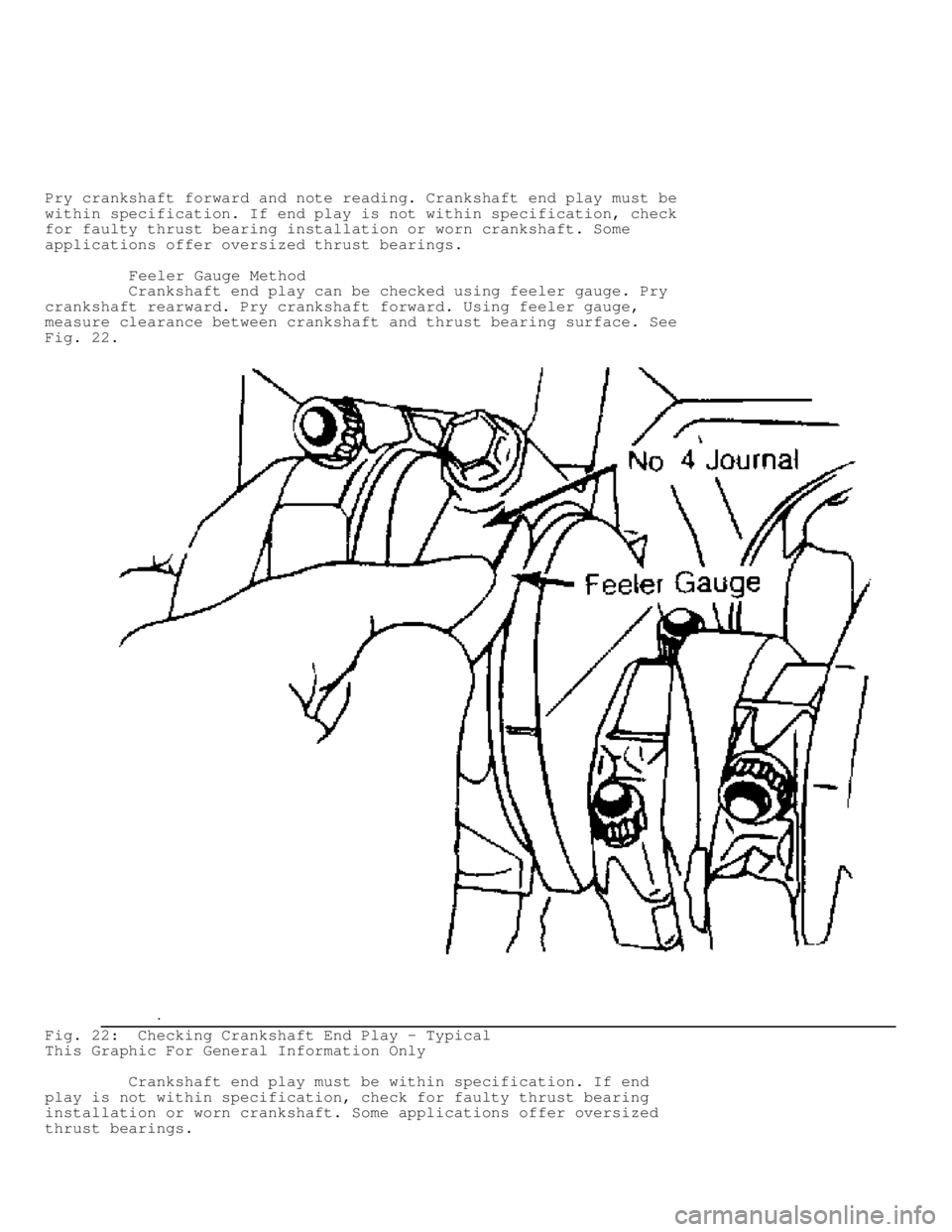

Feeler Gauge Method

Crankshaft end play can be checked using feeler gauge. Pry

crankshaft rearward. Pry crankshaft forward. Using feeler gauge,

measure clearance between crankshaft and thrust bearing surface. See

Fig. 22 .

Fig. 22: Checking Crankshaft End Play - Typical

This Graphic For General Information Only

Crankshaft end play must be within specification. If end

play is not within specification, check for faulty thrust bearing

installation or worn crankshaft. Some applications offer oversized

thrust bearings.