Heat DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 712 of 2889

(6) From under left front wheel opening, remove 2

forward battery tray nuts (Fig. 9).

(7) Remove 2 nuts and 2 bolts holding battery tray

to vehicle (Fig. 10).

(8) Disconnect servo cable at throttle body. Refer to

Servo Cable Removal/Installation in this group.(9) Position battery tray up far enough for access

to speed control servo electrical connector and vac-

uum line.

(10) Disconnect electrical connector and vacuum

line at servo.

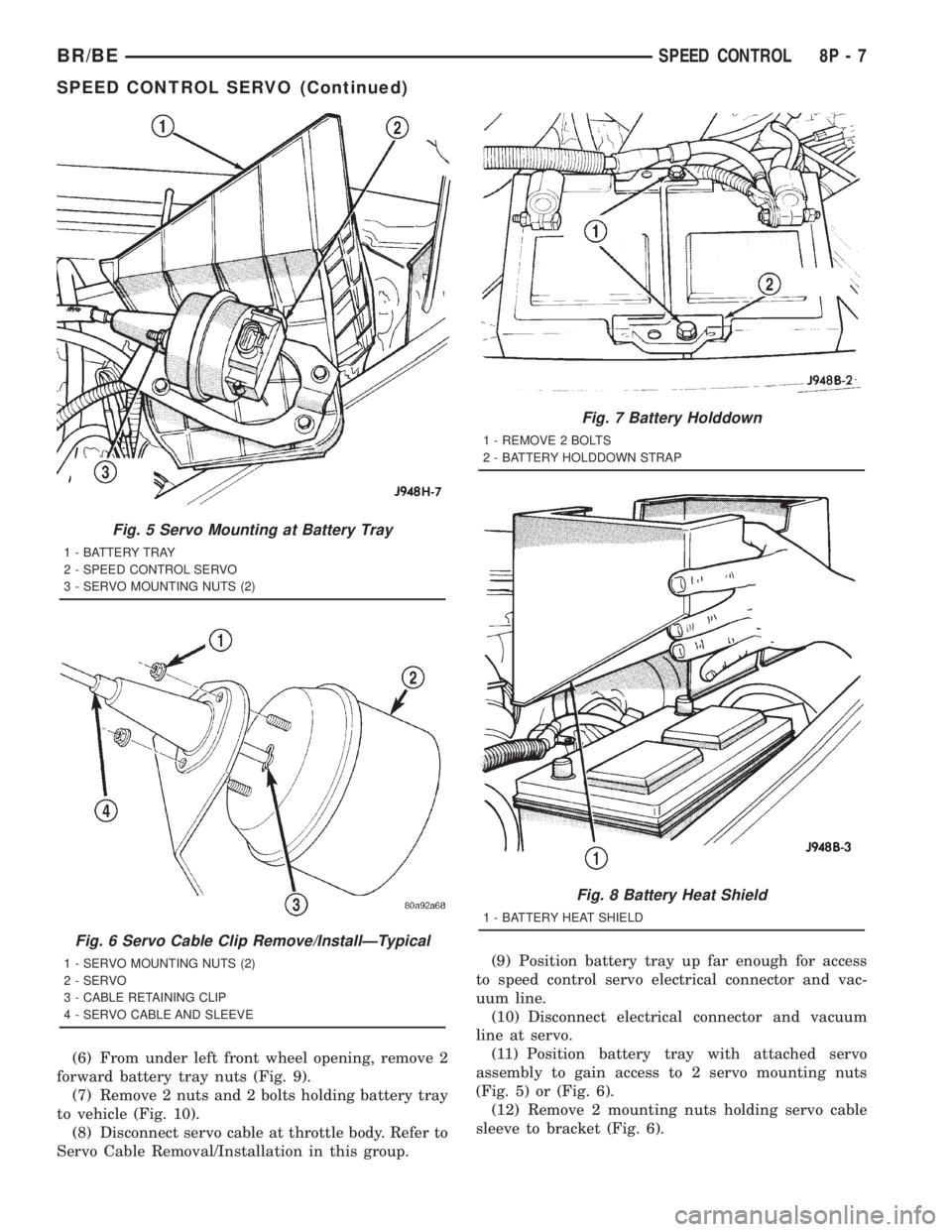

(11) Position battery tray with attached servo

assembly to gain access to 2 servo mounting nuts

(Fig. 5) or (Fig. 6).

(12) Remove 2 mounting nuts holding servo cable

sleeve to bracket (Fig. 6).

Fig. 5 Servo Mounting at Battery Tray

1 - BATTERY TRAY

2 - SPEED CONTROL SERVO

3 - SERVO MOUNTING NUTS (2)

Fig. 6 Servo Cable Clip Remove/InstallÐTypical

1 - SERVO MOUNTING NUTS (2)

2 - SERVO

3 - CABLE RETAINING CLIP

4 - SERVO CABLE AND SLEEVE

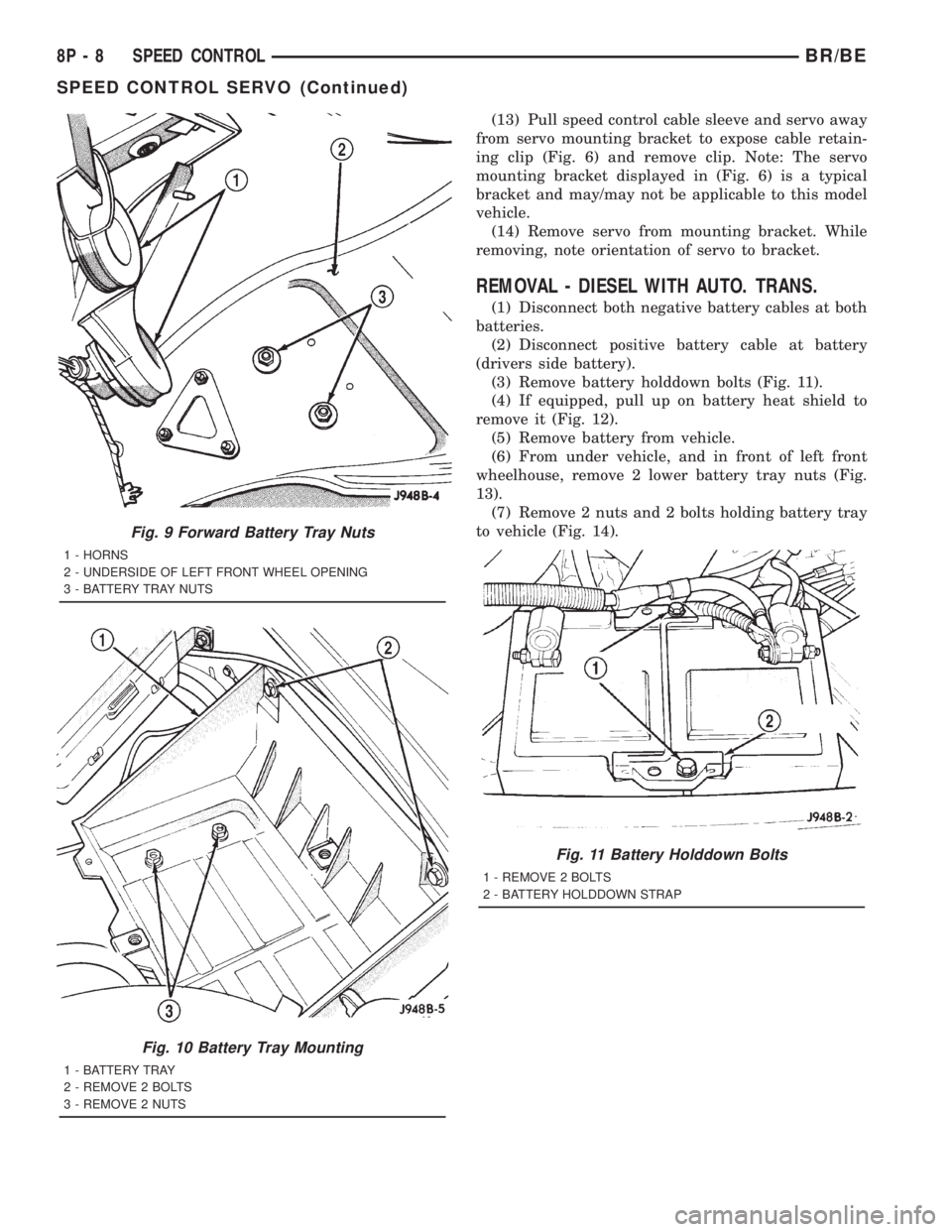

Fig. 7 Battery Holddown

1 - REMOVE 2 BOLTS

2 - BATTERY HOLDDOWN STRAP

Fig. 8 Battery Heat Shield

1 - BATTERY HEAT SHIELD

BR/BESPEED CONTROL 8P - 7

SPEED CONTROL SERVO (Continued)

Page 713 of 2889

(13) Pull speed control cable sleeve and servo away

from servo mounting bracket to expose cable retain-

ing clip (Fig. 6) and remove clip. Note: The servo

mounting bracket displayed in (Fig. 6) is a typical

bracket and may/may not be applicable to this model

vehicle.

(14) Remove servo from mounting bracket. While

removing, note orientation of servo to bracket.

REMOVAL - DIESEL WITH AUTO. TRANS.

(1) Disconnect both negative battery cables at both

batteries.

(2) Disconnect positive battery cable at battery

(drivers side battery).

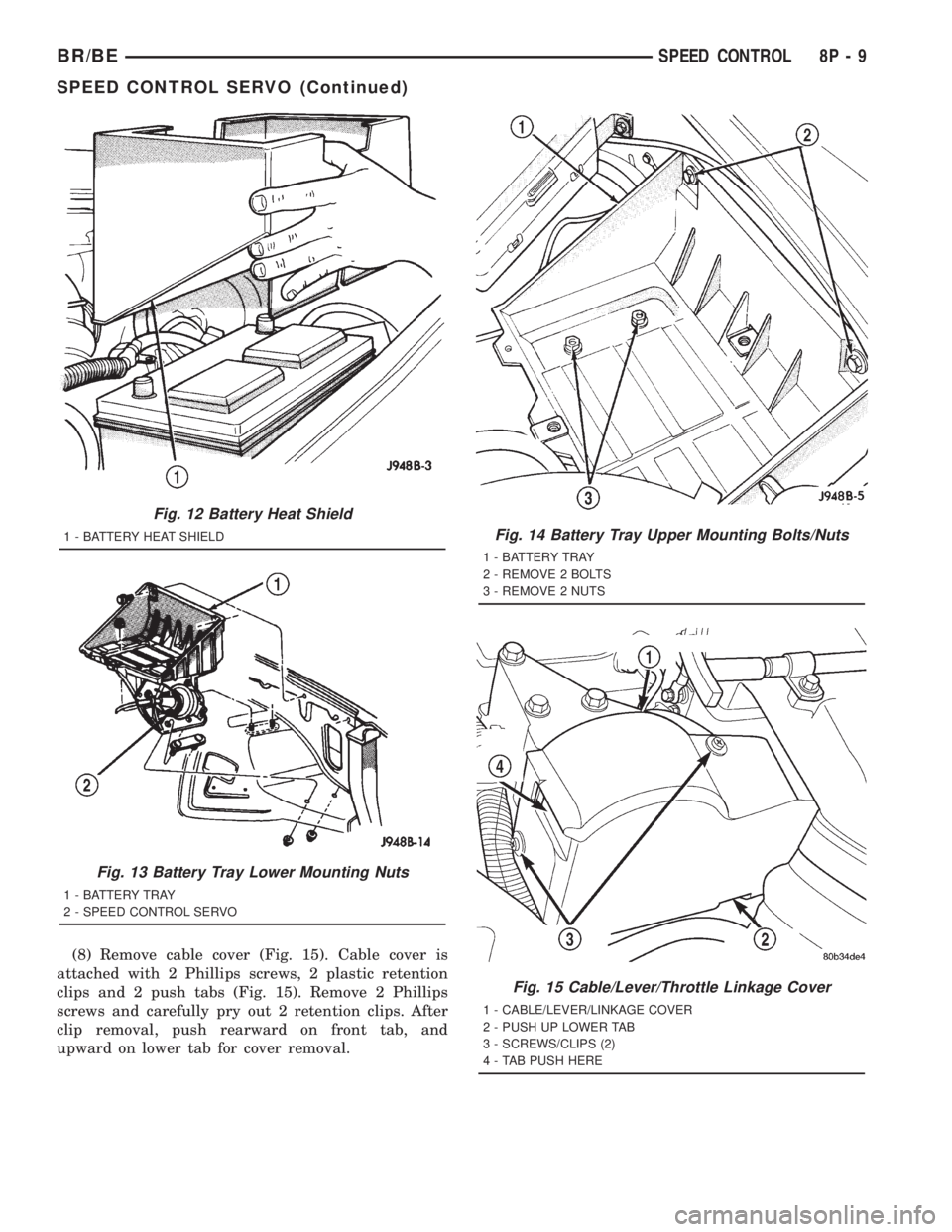

(3) Remove battery holddown bolts (Fig. 11).

(4) If equipped, pull up on battery heat shield to

remove it (Fig. 12).

(5) Remove battery from vehicle.

(6) From under vehicle, and in front of left front

wheelhouse, remove 2 lower battery tray nuts (Fig.

13).

(7) Remove 2 nuts and 2 bolts holding battery tray

to vehicle (Fig. 14).

Fig. 9 Forward Battery Tray Nuts

1 - HORNS

2 - UNDERSIDE OF LEFT FRONT WHEEL OPENING

3 - BATTERY TRAY NUTS

Fig. 10 Battery Tray Mounting

1 - BATTERY TRAY

2 - REMOVE 2 BOLTS

3 - REMOVE 2 NUTS

Fig. 11 Battery Holddown Bolts

1 - REMOVE 2 BOLTS

2 - BATTERY HOLDDOWN STRAP

8P - 8 SPEED CONTROLBR/BE

SPEED CONTROL SERVO (Continued)

Page 714 of 2889

(8) Remove cable cover (Fig. 15). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 15). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.

Fig. 12 Battery Heat Shield

1 - BATTERY HEAT SHIELD

Fig. 13 Battery Tray Lower Mounting Nuts

1 - BATTERY TRAY

2 - SPEED CONTROL SERVO

Fig. 14 Battery Tray Upper Mounting Bolts/Nuts

1 - BATTERY TRAY

2 - REMOVE 2 BOLTS

3 - REMOVE 2 NUTS

Fig. 15 Cable/Lever/Throttle Linkage Cover

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

BR/BESPEED CONTROL 8P - 9

SPEED CONTROL SERVO (Continued)

Page 716 of 2889

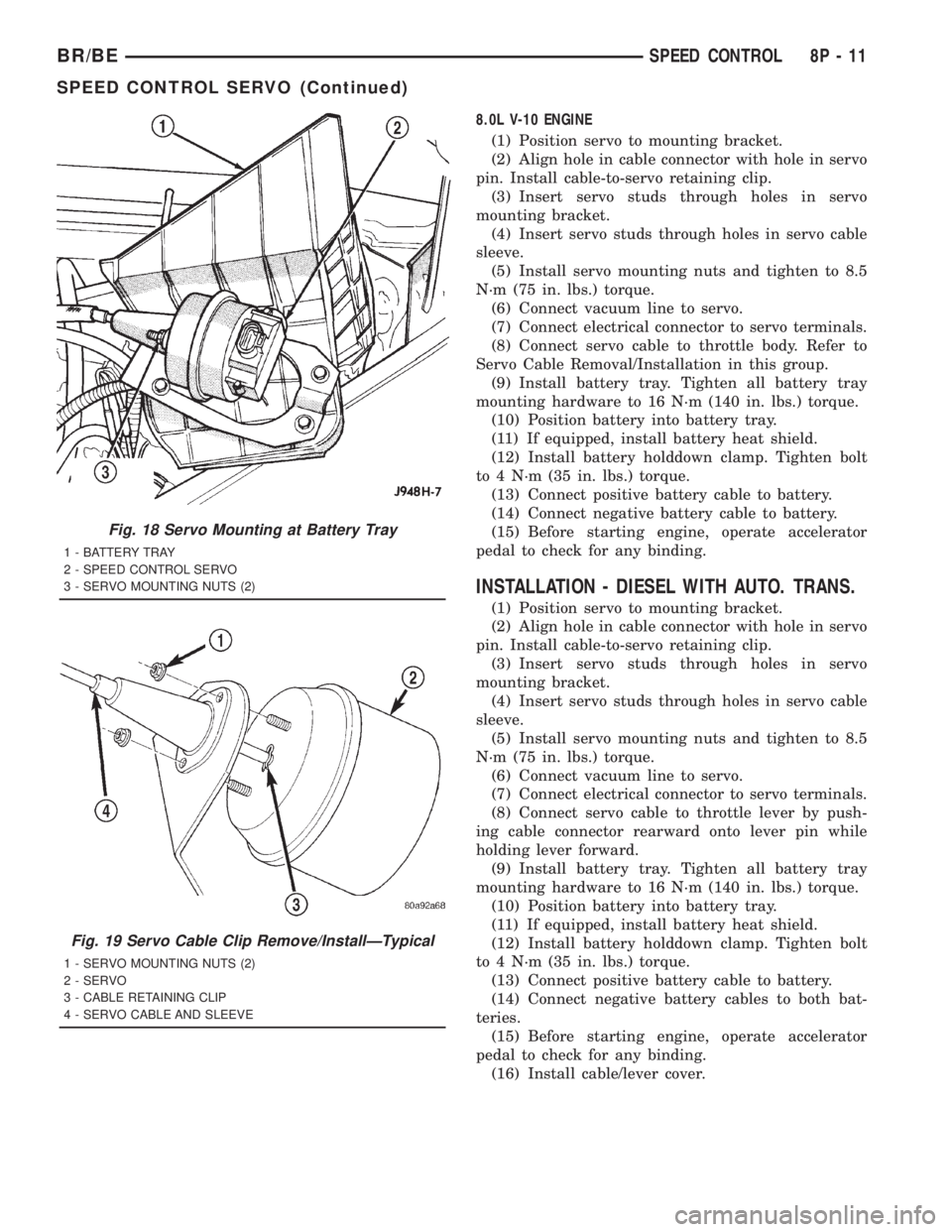

8.0L V-10 ENGINE

(1) Position servo to mounting bracket.

(2) Align hole in cable connector with hole in servo

pin. Install cable-to-servo retaining clip.

(3) Insert servo studs through holes in servo

mounting bracket.

(4) Insert servo studs through holes in servo cable

sleeve.

(5) Install servo mounting nuts and tighten to 8.5

N´m (75 in. lbs.) torque.

(6) Connect vacuum line to servo.

(7) Connect electrical connector to servo terminals.

(8) Connect servo cable to throttle body. Refer to

Servo Cable Removal/Installation in this group.

(9) Install battery tray. Tighten all battery tray

mounting hardware to 16 N´m (140 in. lbs.) torque.

(10) Position battery into battery tray.

(11) If equipped, install battery heat shield.

(12) Install battery holddown clamp. Tighten bolt

to 4 N´m (35 in. lbs.) torque.

(13) Connect positive battery cable to battery.

(14) Connect negative battery cable to battery.

(15) Before starting engine, operate accelerator

pedal to check for any binding.

INSTALLATION - DIESEL WITH AUTO. TRANS.

(1) Position servo to mounting bracket.

(2) Align hole in cable connector with hole in servo

pin. Install cable-to-servo retaining clip.

(3) Insert servo studs through holes in servo

mounting bracket.

(4) Insert servo studs through holes in servo cable

sleeve.

(5) Install servo mounting nuts and tighten to 8.5

N´m (75 in. lbs.) torque.

(6) Connect vacuum line to servo.

(7) Connect electrical connector to servo terminals.

(8) Connect servo cable to throttle lever by push-

ing cable connector rearward onto lever pin while

holding lever forward.

(9) Install battery tray. Tighten all battery tray

mounting hardware to 16 N´m (140 in. lbs.) torque.

(10) Position battery into battery tray.

(11) If equipped, install battery heat shield.

(12) Install battery holddown clamp. Tighten bolt

to 4 N´m (35 in. lbs.) torque.

(13) Connect positive battery cable to battery.

(14) Connect negative battery cables to both bat-

teries.

(15) Before starting engine, operate accelerator

pedal to check for any binding.

(16) Install cable/lever cover.

Fig. 18 Servo Mounting at Battery Tray

1 - BATTERY TRAY

2 - SPEED CONTROL SERVO

3 - SERVO MOUNTING NUTS (2)

Fig. 19 Servo Cable Clip Remove/InstallÐTypical

1 - SERVO MOUNTING NUTS (2)

2 - SERVO

3 - CABLE RETAINING CLIP

4 - SERVO CABLE AND SLEEVE

BR/BESPEED CONTROL 8P - 11

SPEED CONTROL SERVO (Continued)

Page 718 of 2889

²If the actual speed is not within 20 mph of the

set speedThe previous disengagement conditions are

programmed for added safety.

Once the speed control has been disengaged,

depressing the ACCEL switch restores the vehicle to

the target speed that was stored in the ECM's RAM.

NOTE: Depressing the OFF switch will erase the set

speed stored in the ECM's RAM.

If, while the speed control is engaged, the driver

wishes to increase vehicle speed, the ECM is pro-

grammed for an acceleration feature. With the

ACCEL switch held closed, the vehicle accelerates

slowly to the desired speed. The new target speed is

stored in the ECM's RAM when the ACCEL switch is

released. The ECM also has a9tap-up9feature in

which vehicle speed increases at a rate of approxi-

mately 2 mph for each momentary switch activation

of the ACCEL switch.

The ECM also provides a means to decelerate with-

out disengaging speed control. To decelerate from an

existing recorded target speed, depress and hold the

COAST switch until the desired speed is reached.

Then release the switch. The ON, OFF switch oper-

ates two components: the ECM's ON, OFF input, and

the battery voltage to the brake switch, which powers

the speed control servo.

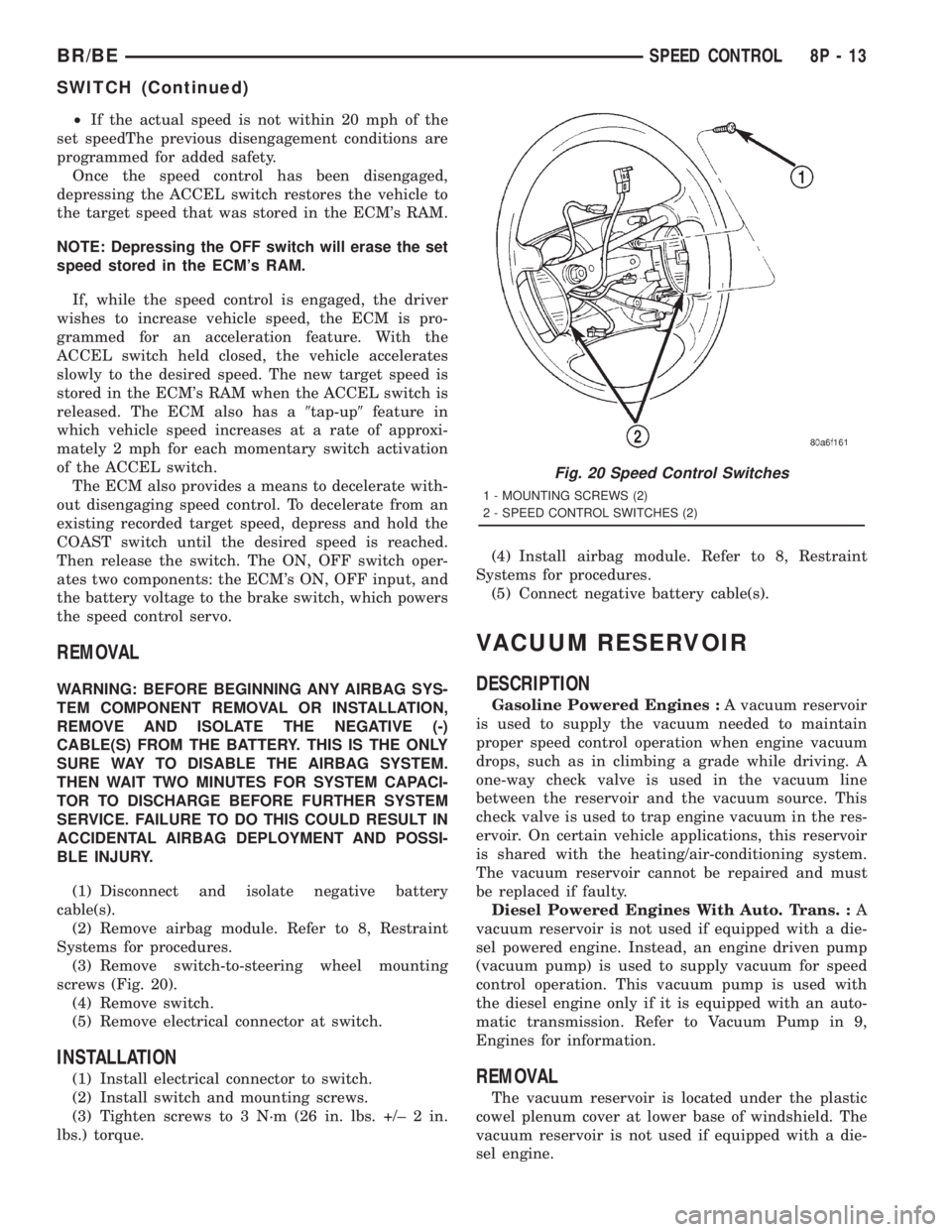

REMOVAL

WARNING: BEFORE BEGINNING ANY AIRBAG SYS-

TEM COMPONENT REMOVAL OR INSTALLATION,

REMOVE AND ISOLATE THE NEGATIVE (-)

CABLE(S) FROM THE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIRBAG SYSTEM.

THEN WAIT TWO MINUTES FOR SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE FURTHER SYSTEM

SERVICE. FAILURE TO DO THIS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE INJURY.

(1) Disconnect and isolate negative battery

cable(s).

(2) Remove airbag module. Refer to 8, Restraint

Systems for procedures.

(3) Remove switch-to-steering wheel mounting

screws (Fig. 20).

(4) Remove switch.

(5) Remove electrical connector at switch.

INSTALLATION

(1) Install electrical connector to switch.

(2) Install switch and mounting screws.

(3) Tighten screws to 3 N´m (26 in. lbs. +/± 2 in.

lbs.) torque.(4) Install airbag module. Refer to 8, Restraint

Systems for procedures.

(5) Connect negative battery cable(s).

VACUUM RESERVOIR

DESCRIPTION

Gasoline Powered Engines :A vacuum reservoir

is used to supply the vacuum needed to maintain

proper speed control operation when engine vacuum

drops, such as in climbing a grade while driving. A

one-way check valve is used in the vacuum line

between the reservoir and the vacuum source. This

check valve is used to trap engine vacuum in the res-

ervoir. On certain vehicle applications, this reservoir

is shared with the heating/air-conditioning system.

The vacuum reservoir cannot be repaired and must

be replaced if faulty.

Diesel Powered Engines With Auto. Trans. :A

vacuum reservoir is not used if equipped with a die-

sel powered engine. Instead, an engine driven pump

(vacuum pump) is used to supply vacuum for speed

control operation. This vacuum pump is used with

the diesel engine only if it is equipped with an auto-

matic transmission. Refer to Vacuum Pump in 9,

Engines for information.

REMOVAL

The vacuum reservoir is located under the plastic

cowel plenum cover at lower base of windshield. The

vacuum reservoir is not used if equipped with a die-

sel engine.

Fig. 20 Speed Control Switches

1 - MOUNTING SCREWS (2)

2 - SPEED CONTROL SWITCHES (2)

BR/BESPEED CONTROL 8P - 13

SWITCH (Continued)

Page 724 of 2889

WIPERS/WASHERS

TABLE OF CONTENTS

page page

WIPERS/WASHERS

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................3

WIPER & WASHER SYSTEM...............3

CLEANING...............................6

INSPECTION.............................6

WASHER FLUID LEVEL SWITCH

DESCRIPTION............................7

OPERATION.............................7

REMOVAL...............................8

INSTALLATION............................8

WASHER HOSES/TUBES

DESCRIPTION............................8

OPERATION.............................8

WASHER NOZZLE

DESCRIPTION............................9

OPERATION.............................9

REMOVAL...............................9

INSTALLATION............................9

WASHER PUMP/MOTOR

DESCRIPTION............................9

OPERATION.............................9

REMOVAL..............................10

INSTALLATION...........................10

WASHER RESERVOIR

DESCRIPTION...........................10OPERATION.............................10

REMOVAL..............................10

INSTALLATION...........................11

WIPER ARM

DESCRIPTION...........................11

OPERATION.............................12

REMOVAL..............................12

INSTALLATION...........................12

WIPER BLADE

DESCRIPTION...........................12

OPERATION.............................13

REMOVAL..............................13

INSTALLATION...........................13

WIPER MODULE

DESCRIPTION...........................14

OPERATION.............................14

REMOVAL..............................14

INSTALLATION...........................15

WIPER RELAY

DESCRIPTION...........................15

OPERATION.............................15

DIAGNOSIS AND TESTING.................16

WIPER RELAY.........................16

REMOVAL..............................17

INSTALLATION...........................17

WIPERS/WASHERS

DESCRIPTION

An electrically operated intermittent wiper and

washer system is standard factory-installed safety

equipment on this model. The wiper and washer sys-

tem includes the following major components, which

are described in further detail elsewhere in this ser-

vice information:

²Central Timer Module- The Central Timer

Module (CTM) is located under the driver side end of

the instrument panel, inboard of the instrument

panel steering column opening. A base version of the

CTM is used on base models of this vehicle. The base

version of the CTM combines the functions of a

chime module and an intermittent wipe module in a

single unit. The high-line version of the CTM is used

on high-line vehicles. The high-line CTM provides all

of the functions of the base version of the CTM, but

also is used to control and integrate many additionalelectronic functions and features included on high-

line models. The premium version of the CTM is the

same as the high-line version, but is used only on

models equipped with the heated seat option. The

high-line and premium versions of the CTM contain

integrated circuitry, a central processing unit and the

programming to provide all of the proper wiper and

washer system features based upon the monitored

inputs. The high-line and premium CTM circuitry

monitors hard wired switch inputs, as well as mes-

sage inputs received from other vehicle electronic

modules on the Chrysler Collision Detection (CCD)

data bus network. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/BODY CONTROL/

CENTRAL TIMER MODULE - DESCRIPTION).

²Multi-Function Switch- The multi-function

switch is secured to the left side of the steering col-

umn, just below the steering wheel. Only the control

stalk for the multi-function switch is visible, the

remainder of the switch is concealed beneath the

steering column shrouds. The multi-function switch

BR/BEWIPERS/WASHERS 8R - 1

Page 742 of 2889

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

JUNCTION BLOCK.................... 8W-12-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1INTERIOR LIGHTING.................. 8W-44-1

CENTRAL TIMER MODULE............. 8W-45-1

AUDIO SYSTEM..................... 8W-47-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND LOCATIONS...... 8W-90-1

SPLICE LOCATIONS.................. 8W-95-1

POWER DISTRIBUTION............... 8W-97-1 BR/BEWIRING 8W - 1

Page 755 of 2889

WIRE

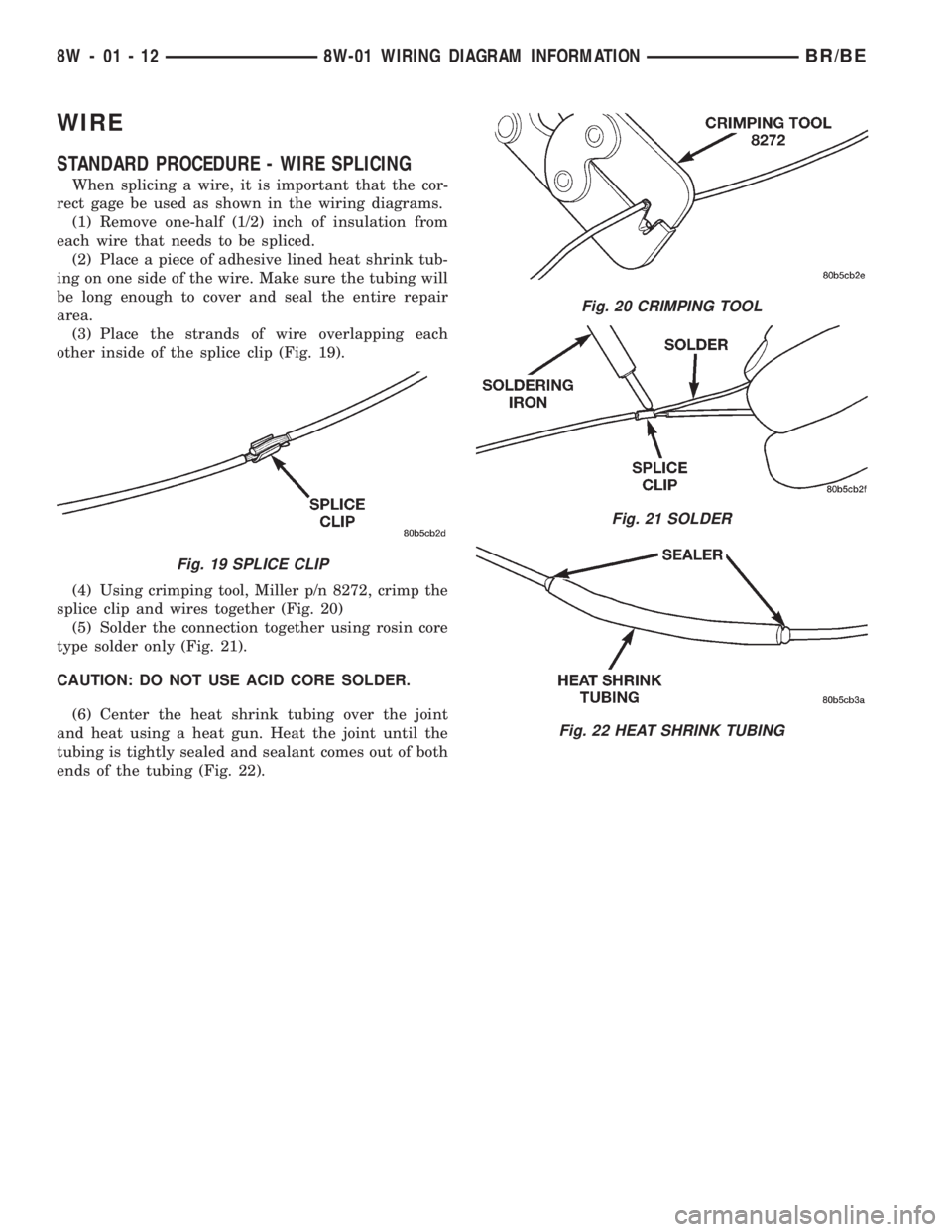

STANDARD PROCEDURE - WIRE SPLICING

When splicing a wire, it is important that the cor-

rect gage be used as shown in the wiring diagrams.

(1) Remove one-half (1/2) inch of insulation from

each wire that needs to be spliced.

(2) Place a piece of adhesive lined heat shrink tub-

ing on one side of the wire. Make sure the tubing will

be long enough to cover and seal the entire repair

area.

(3) Place the strands of wire overlapping each

other inside of the splice clip (Fig. 19).

(4) Using crimping tool, Miller p/n 8272, crimp the

splice clip and wires together (Fig. 20)

(5) Solder the connection together using rosin core

type solder only (Fig. 21).

CAUTION: DO NOT USE ACID CORE SOLDER.

(6) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing (Fig. 22).

Fig. 19 SPLICE CLIP

Fig. 20 CRIMPING TOOL

Fig. 21 SOLDER

Fig. 22 HEAT SHRINK TUBING

8W - 01 - 12 8W-01 WIRING DIAGRAM INFORMATIONBR/BE

Page 756 of 2889

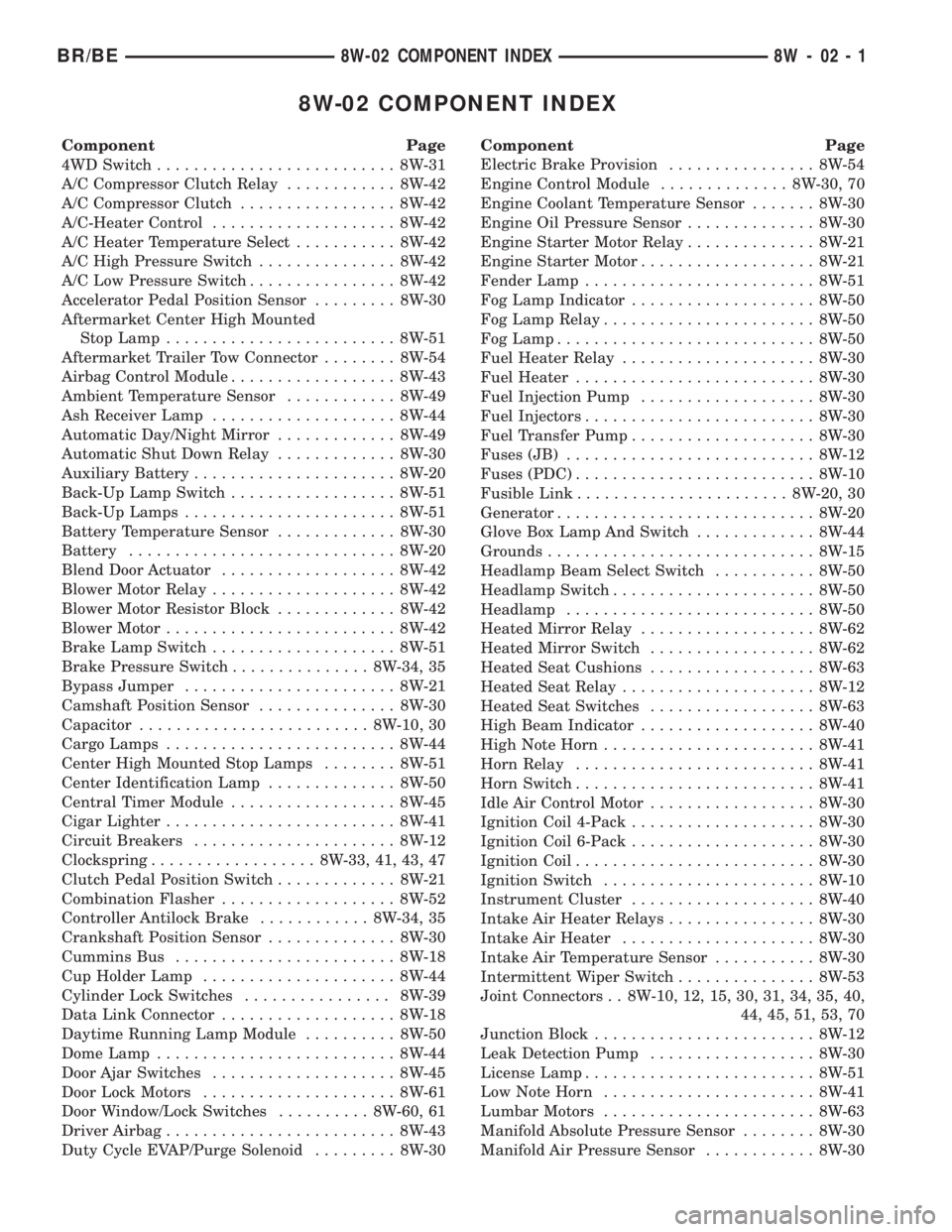

8W-02 COMPONENT INDEX

Component Page

4WD Switch.......................... 8W-31

A/C Compressor Clutch Relay............ 8W-42

A/C Compressor Clutch................. 8W-42

A/C-Heater Control.................... 8W-42

A/C Heater Temperature Select........... 8W-42

A/C High Pressure Switch............... 8W-42

A/C Low Pressure Switch................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Aftermarket Center High Mounted

Stop Lamp......................... 8W-51

Aftermarket Trailer Tow Connector........ 8W-54

Airbag Control Module.................. 8W-43

Ambient Temperature Sensor............ 8W-49

Ash Receiver Lamp.................... 8W-44

Automatic Day/Night Mirror............. 8W-49

Automatic Shut Down Relay............. 8W-30

Auxiliary Battery...................... 8W-20

Back-Up Lamp Switch.................. 8W-51

Back-Up Lamps....................... 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Actuator................... 8W-42

Blower Motor Relay.................... 8W-42

Blower Motor Resistor Block............. 8W-42

Blower Motor......................... 8W-42

Brake Lamp Switch.................... 8W-51

Brake Pressure Switch............... 8W-34, 35

Bypass Jumper....................... 8W-21

Camshaft Position Sensor............... 8W-30

Capacitor......................... 8W-10, 30

Cargo Lamps......................... 8W-44

Center High Mounted Stop Lamps........ 8W-51

Center Identification Lamp.............. 8W-50

Central Timer Module.................. 8W-45

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Clutch Pedal Position Switch............. 8W-21

Combination Flasher................... 8W-52

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cummins Bus........................ 8W-18

Cup Holder Lamp..................... 8W-44

Cylinder Lock Switches................ 8W-39

Data Link Connector................... 8W-18

Daytime Running Lamp Module.......... 8W-50

Dome Lamp.......................... 8W-44

Door Ajar Switches.................... 8W-45

Door Lock Motors..................... 8W-61

Door Window/Lock Switches.......... 8W-60, 61

Driver Airbag......................... 8W-43

Duty Cycle EVAP/Purge Solenoid......... 8W-30Component Page

Electric Brake Provision................ 8W-54

Engine Control Module.............. 8W-30, 70

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor Relay.............. 8W-21

Engine Starter Motor................... 8W-21

Fender Lamp......................... 8W-51

Fog Lamp Indicator.................... 8W-50

Fog Lamp Relay....................... 8W-50

Fog Lamp............................ 8W-50

Fuel Heater Relay..................... 8W-30

Fuel Heater.......................... 8W-30

Fuel Injection Pump................... 8W-30

Fuel Injectors......................... 8W-30

Fuel Transfer Pump.................... 8W-30

Fuses (JB)........................... 8W-12

Fuses (PDC).......................... 8W-10

Fusible Link....................... 8W-20, 30

Generator............................ 8W-20

Glove Box Lamp And Switch............. 8W-44

Grounds............................. 8W-15

Headlamp Beam Select Switch........... 8W-50

Headlamp Switch...................... 8W-50

Headlamp........................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Mirror Switch.................. 8W-62

Heated Seat Cushions.................. 8W-63

Heated Seat Relay..................... 8W-12

Heated Seat Switches.................. 8W-63

High Beam Indicator................... 8W-40

High Note Horn....................... 8W-41

Horn Relay.......................... 8W-41

Horn Switch.......................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Coil 4-Pack.................... 8W-30

Ignition Coil 6-Pack.................... 8W-30

Ignition Coil.......................... 8W-30

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Intake Air Heater Relays................ 8W-30

Intake Air Heater..................... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intermittent Wiper Switch............... 8W-53

Joint Connectors . . 8W-10, 12, 15, 30, 31, 34, 35, 40,

44, 45, 51, 53, 70

Junction Block........................ 8W-12

Leak Detection Pump.................. 8W-30

License Lamp......................... 8W-51

Low Note Horn....................... 8W-41

Lumbar Motors....................... 8W-63

Manifold Absolute Pressure Sensor........ 8W-30

Manifold Air Pressure Sensor............ 8W-30

BR/BE8W-02 COMPONENT INDEX 8W - 02 - 1

Page 757 of 2889

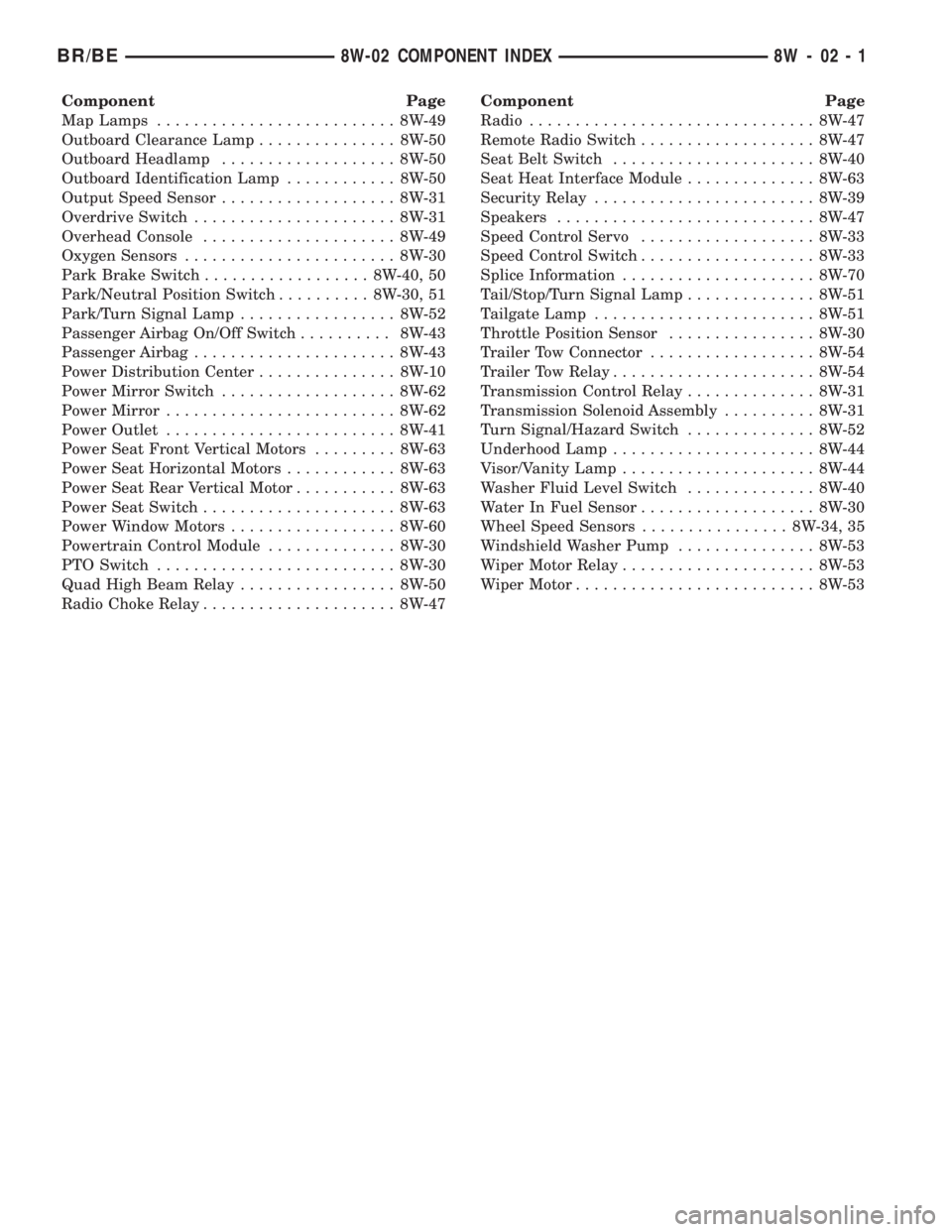

Component Page

Map Lamps.......................... 8W-49

Outboard Clearance Lamp............... 8W-50

Outboard Headlamp................... 8W-50

Outboard Identification Lamp............ 8W-50

Output Speed Sensor................... 8W-31

Overdrive Switch...................... 8W-31

Overhead Console..................... 8W-49

Oxygen Sensors....................... 8W-30

Park Brake Switch.................. 8W-40, 50

Park/Neutral Position Switch.......... 8W-30, 51

Park/Turn Signal Lamp................. 8W-52

Passenger Airbag On/Off Switch.......... 8W-43

Passenger Airbag...................... 8W-43

Power Distribution Center............... 8W-10

Power Mirror Switch................... 8W-62

Power Mirror......................... 8W-62

Power Outlet......................... 8W-41

Power Seat Front Vertical Motors......... 8W-63

Power Seat Horizontal Motors............ 8W-63

Power Seat Rear Vertical Motor........... 8W-63

Power Seat Switch..................... 8W-63

Power Window Motors.................. 8W-60

Powertrain Control Module.............. 8W-30

PTO Switch.......................... 8W-30

Quad High Beam Relay................. 8W-50

Radio Choke Relay..................... 8W-47Component Page

Radio............................... 8W-47

Remote Radio Switch................... 8W-47

Seat Belt Switch...................... 8W-40

Seat Heat Interface Module.............. 8W-63

Security Relay........................ 8W-39

Speakers............................ 8W-47

Speed Control Servo................... 8W-33

Speed Control Switch................... 8W-33

Splice Information..................... 8W-70

Tail/Stop/Turn Signal Lamp.............. 8W-51

Tailgate Lamp........................ 8W-51

Throttle Position Sensor................ 8W-30

Trailer Tow Connector.................. 8W-54

Trailer Tow Relay...................... 8W-54

Transmission Control Relay.............. 8W-31

Transmission Solenoid Assembly.......... 8W-31

Turn Signal/Hazard Switch.............. 8W-52

Underhood Lamp...................... 8W-44

Visor/Vanity Lamp..................... 8W-44

Washer Fluid Level Switch.............. 8W-40

Water In Fuel Sensor................... 8W-30

Wheel Speed Sensors................ 8W-34, 35

Windshield Washer Pump............... 8W-53

Wiper Motor Relay..................... 8W-53

Wiper Motor.......................... 8W-53

BR/BE8W-02 COMPONENT INDEX 8W - 02 - 1