DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1521 of 2889

(25) Verify electrical harness is firmly connected to

rear wheel speed sensor. Verify rear wheel speed sen-

sor is firmly attached to rear axle with proper air

gap. Refer to 5, Brakes for information.

(26) If equipped with 4±wheel antilock brake sys-

tem, verify electrical harness is firmly connected to

each front wheel speed sensor. Verify both front

wheel speed sensors are firmly attached. Refer to 5,

Brakes for information.

(27) Verify that fuel pump/gauge sender unit wire

connector is firmly connected to harness connector.

(28) Inspect fuel hoses at fuel pump/gauge sender

unit for cracks or leaks.

(29) Inspect transmission torque convertor housing

(automatic transmission) or clutch housing (manual

transmission) for damage to timing ring on drive

plate/flywheel.

(30) Verify that battery cable and solenoid feed

wire connections to the starter solenoid are tight and

clean. Inspect for chaffed wires or wires rubbing up

against other components.

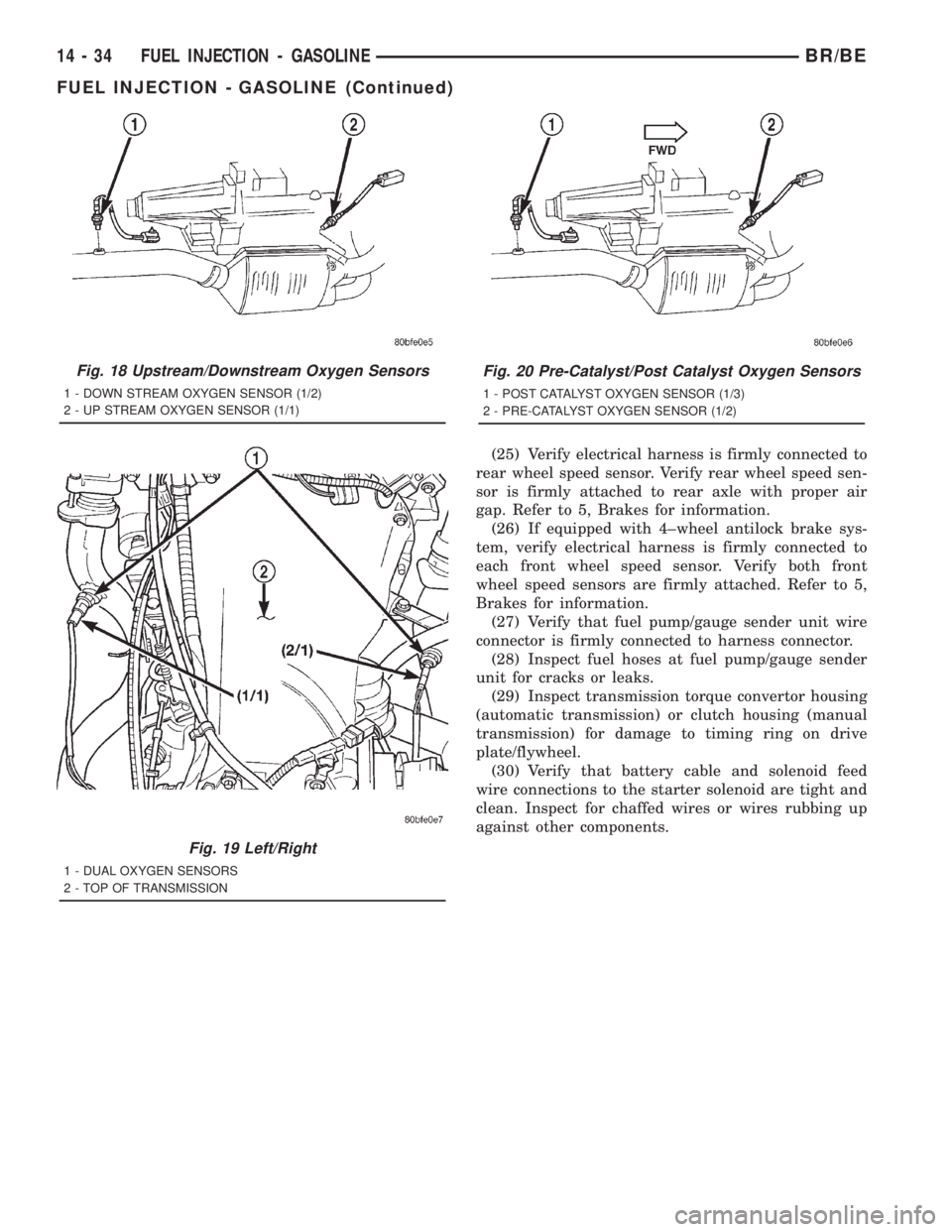

Fig. 18 Upstream/Downstream Oxygen Sensors

1 - DOWN STREAM OXYGEN SENSOR (1/2)

2 - UP STREAM OXYGEN SENSOR (1/1)

Fig. 19 Left/Right

1 - DUAL OXYGEN SENSORS

2 - TOP OF TRANSMISSION

Fig. 20 Pre-Catalyst/Post Catalyst Oxygen Sensors

1 - POST CATALYST OXYGEN SENSOR (1/3)

2 - PRE-CATALYST OXYGEN SENSOR (1/2)

14 - 34 FUEL INJECTION - GASOLINEBR/BE

FUEL INJECTION - GASOLINE (Continued)

Page 1522 of 2889

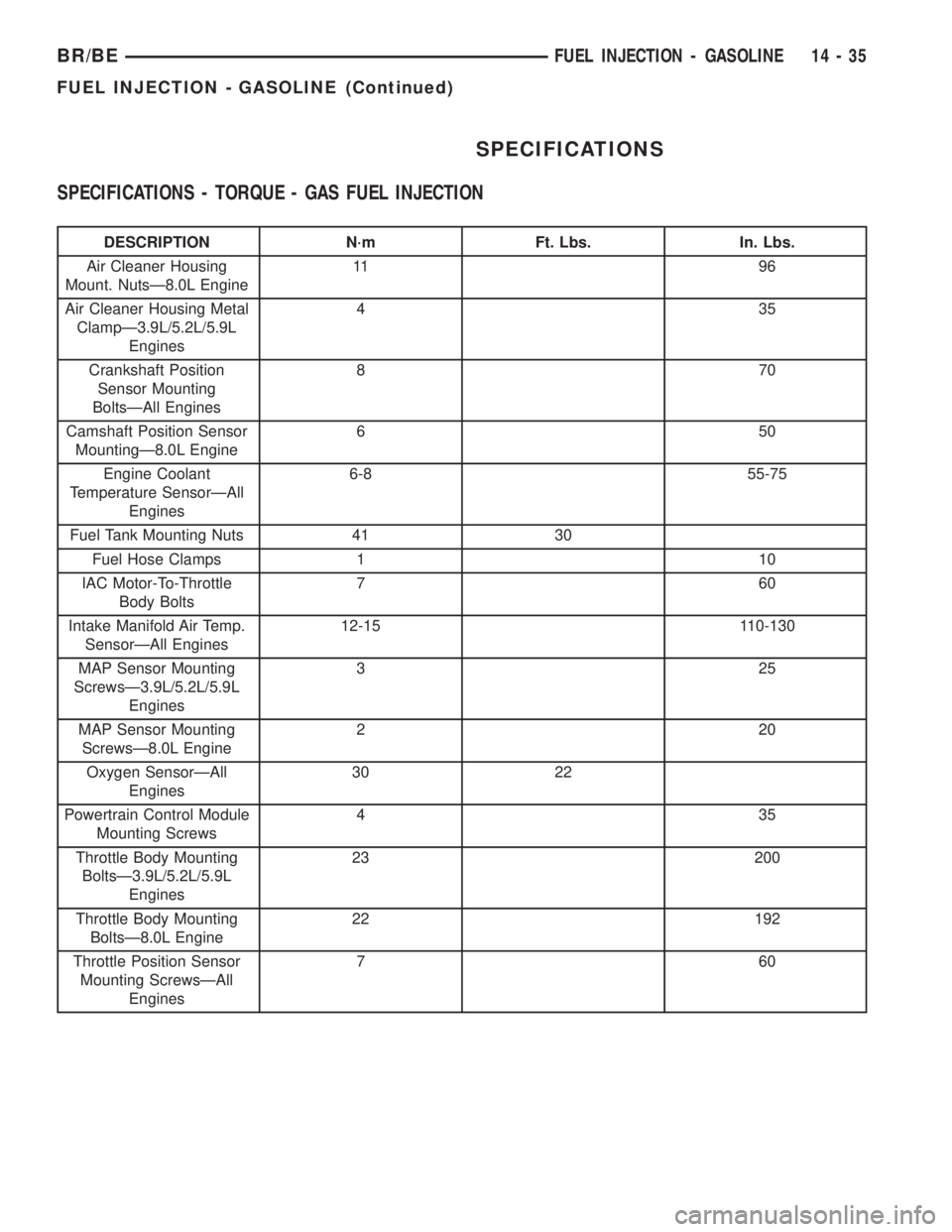

SPECIFICATIONS

SPECIFICATIONS - TORQUE - GAS FUEL INJECTION

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Air Cleaner Housing

Mount. NutsÐ8.0L Engine11 9 6

Air Cleaner Housing Metal

ClampÐ3.9L/5.2L/5.9L

Engines435

Crankshaft Position

Sensor Mounting

BoltsÐAll Engines870

Camshaft Position Sensor

MountingÐ8.0L Engine650

Engine Coolant

Temperature SensorÐAll

Engines6-8 55-75

Fuel Tank Mounting Nuts 41 30

Fuel Hose Clamps 1 10

IAC Motor-To-Throttle

Body Bolts760

Intake Manifold Air Temp.

SensorÐAll Engines12-15 110-130

MAP Sensor Mounting

ScrewsÐ3.9L/5.2L/5.9L

Engines325

MAP Sensor Mounting

ScrewsÐ8.0L Engine220

Oxygen SensorÐAll

Engines30 22

Powertrain Control Module

Mounting Screws435

Throttle Body Mounting

BoltsÐ3.9L/5.2L/5.9L

Engines23 200

Throttle Body Mounting

BoltsÐ8.0L Engine22 192

Throttle Position Sensor

Mounting ScrewsÐAll

Engines760

BR/BEFUEL INJECTION - GASOLINE 14 - 35

FUEL INJECTION - GASOLINE (Continued)

Page 1523 of 2889

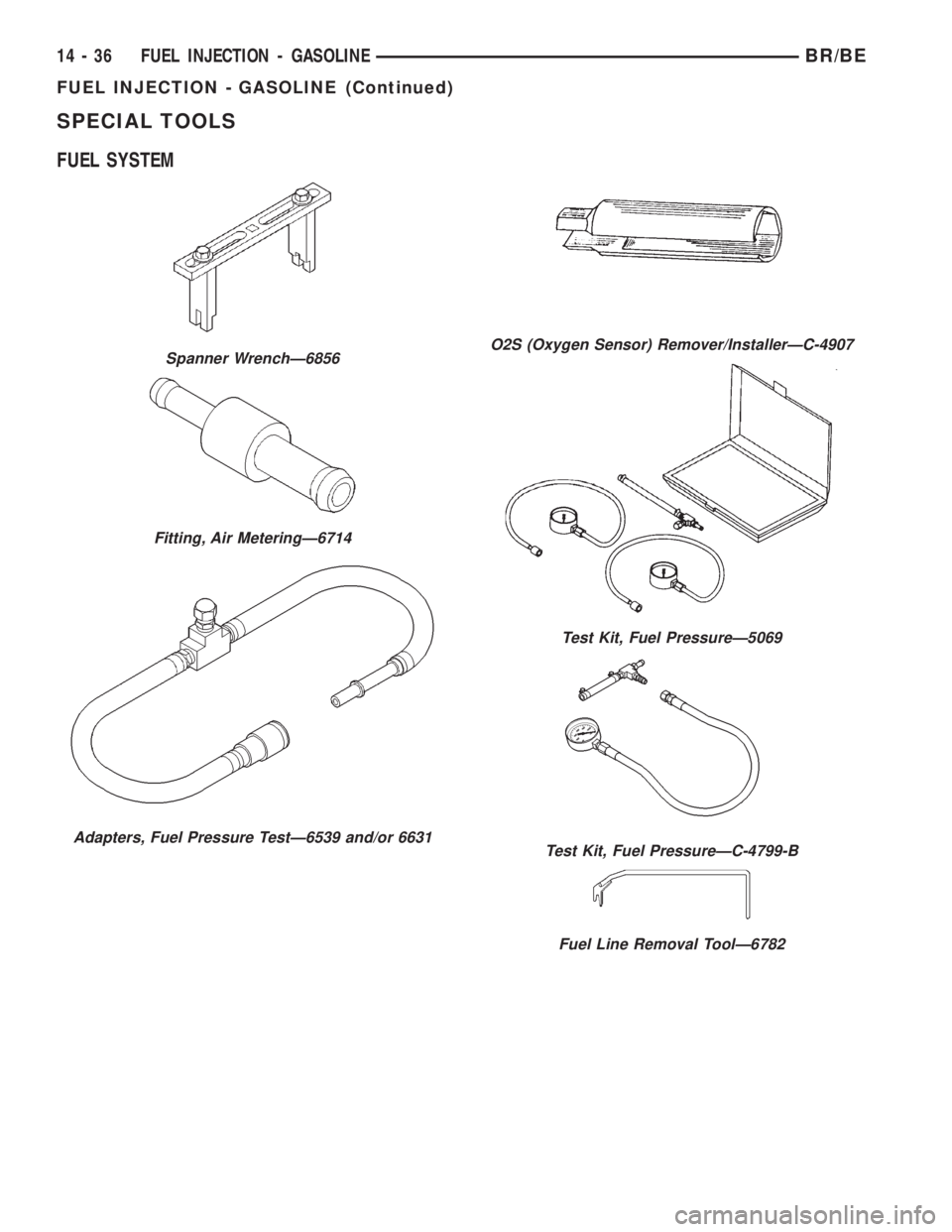

SPECIAL TOOLS

FUEL SYSTEM

Spanner WrenchÐ6856

Fitting, Air MeteringÐ6714

Adapters, Fuel Pressure TestÐ6539 and/or 6631

O2S (Oxygen Sensor) Remover/InstallerÐC-4907

Test Kit, Fuel PressureÐ5069

Test Kit, Fuel PressureÐC-4799-B

Fuel Line Removal ToolÐ6782

14 - 36 FUEL INJECTION - GASOLINEBR/BE

FUEL INJECTION - GASOLINE (Continued)

Page 1524 of 2889

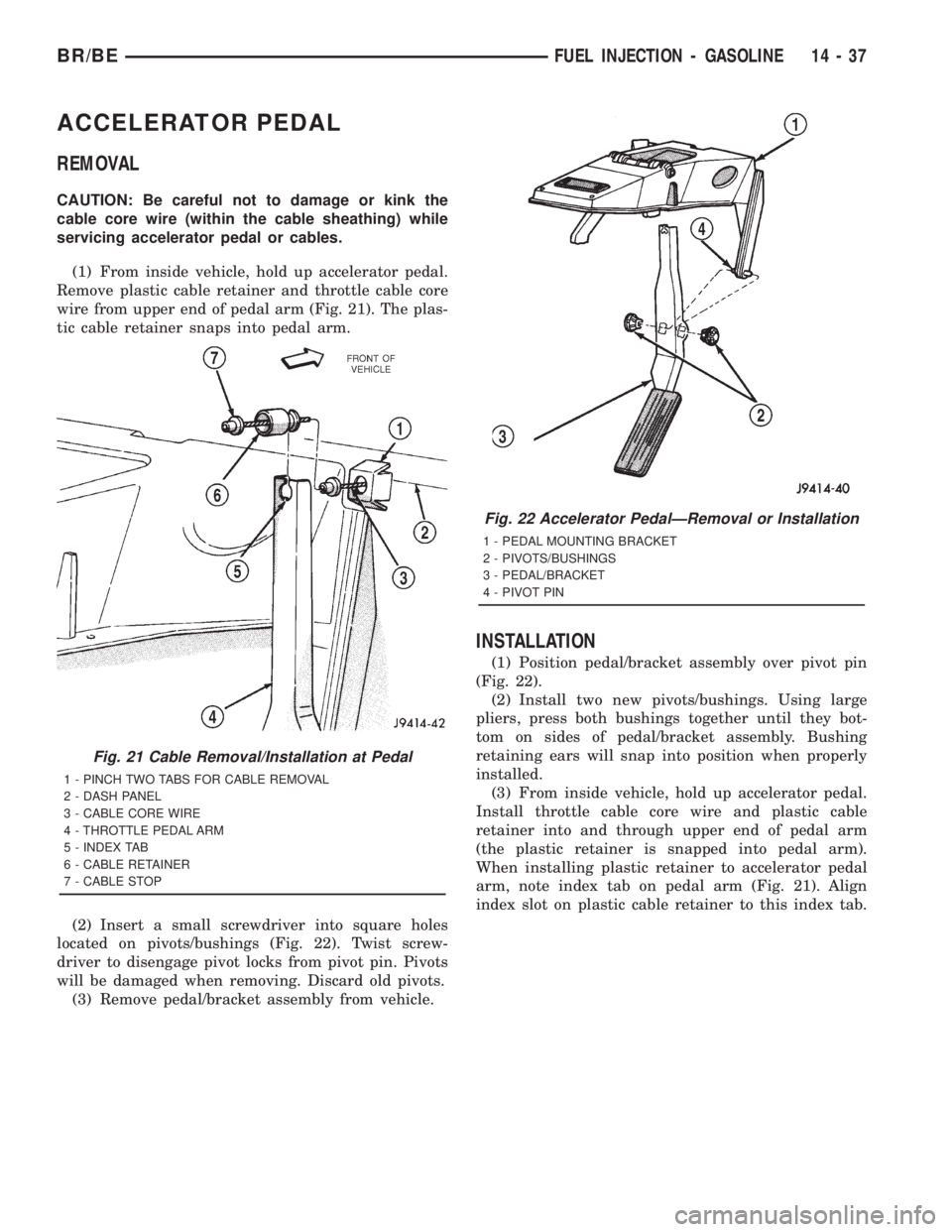

ACCELERATOR PEDAL

REMOVAL

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or cables.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer and throttle cable core

wire from upper end of pedal arm (Fig. 21). The plas-

tic cable retainer snaps into pedal arm.

(2) Insert a small screwdriver into square holes

located on pivots/bushings (Fig. 22). Twist screw-

driver to disengage pivot locks from pivot pin. Pivots

will be damaged when removing. Discard old pivots.

(3) Remove pedal/bracket assembly from vehicle.

INSTALLATION

(1) Position pedal/bracket assembly over pivot pin

(Fig. 22).

(2) Install two new pivots/bushings. Using large

pliers, press both bushings together until they bot-

tom on sides of pedal/bracket assembly. Bushing

retaining ears will snap into position when properly

installed.

(3) From inside vehicle, hold up accelerator pedal.

Install throttle cable core wire and plastic cable

retainer into and through upper end of pedal arm

(the plastic retainer is snapped into pedal arm).

When installing plastic retainer to accelerator pedal

arm, note index tab on pedal arm (Fig. 21). Align

index slot on plastic cable retainer to this index tab.

Fig. 21 Cable Removal/Installation at Pedal

1 - PINCH TWO TABS FOR CABLE REMOVAL

2 - DASH PANEL

3 - CABLE CORE WIRE

4 - THROTTLE PEDAL ARM

5 - INDEX TAB

6 - CABLE RETAINER

7 - CABLE STOP

Fig. 22 Accelerator PedalÐRemoval or Installation

1 - PEDAL MOUNTING BRACKET

2 - PIVOTS/BUSHINGS

3 - PEDAL/BRACKET

4 - PIVOT PIN

BR/BEFUEL INJECTION - GASOLINE 14 - 37

Page 1525 of 2889

CRANKSHAFT POSITION

SENSOR

DESCRIPTION - 3.9L

The Crankshaft Position (CKP) sensor is located

near the outer edge of the flywheel (starter ringear).

DESCRIPTION - 5.2L/5.9L

The Crankshaft Position (CKP) sensor is located

near the outer edge of the flywheel (starter ringear).

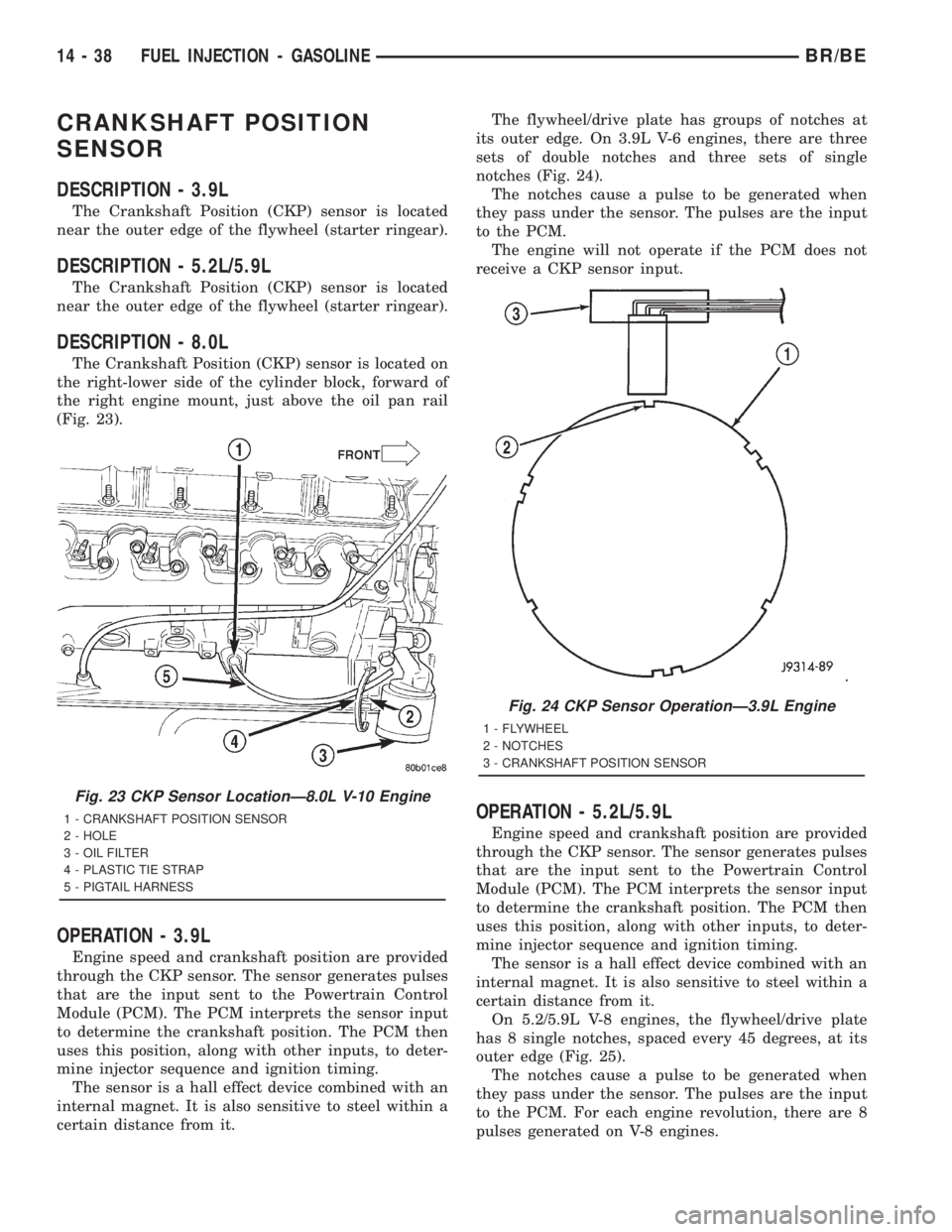

DESCRIPTION - 8.0L

The Crankshaft Position (CKP) sensor is located on

the right-lower side of the cylinder block, forward of

the right engine mount, just above the oil pan rail

(Fig. 23).

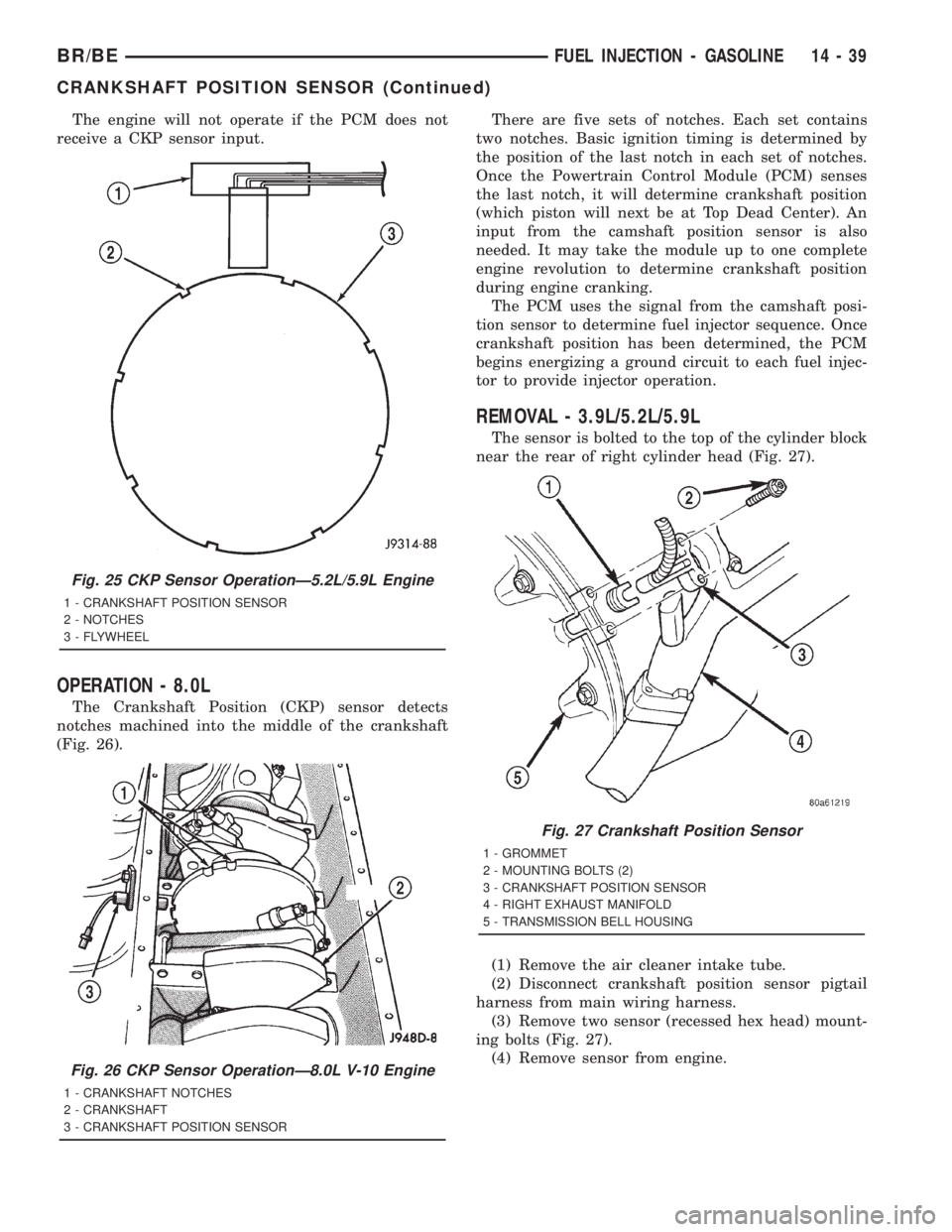

OPERATION - 3.9L

Engine speed and crankshaft position are provided

through the CKP sensor. The sensor generates pulses

that are the input sent to the Powertrain Control

Module (PCM). The PCM interprets the sensor input

to determine the crankshaft position. The PCM then

uses this position, along with other inputs, to deter-

mine injector sequence and ignition timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.The flywheel/drive plate has groups of notches at

its outer edge. On 3.9L V-6 engines, there are three

sets of double notches and three sets of single

notches (Fig. 24).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

The engine will not operate if the PCM does not

receive a CKP sensor input.

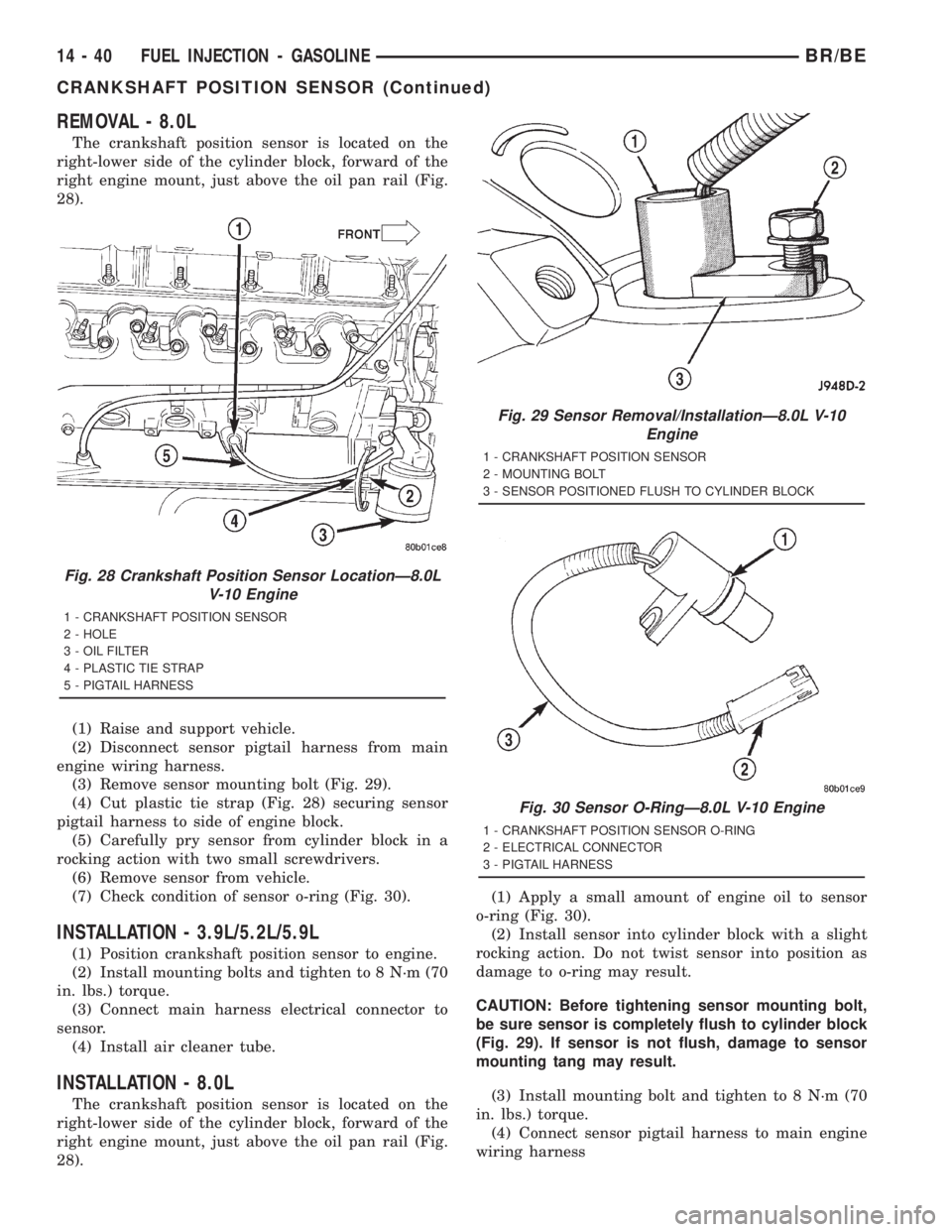

OPERATION - 5.2L/5.9L

Engine speed and crankshaft position are provided

through the CKP sensor. The sensor generates pulses

that are the input sent to the Powertrain Control

Module (PCM). The PCM interprets the sensor input

to determine the crankshaft position. The PCM then

uses this position, along with other inputs, to deter-

mine injector sequence and ignition timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On 5.2/5.9L V-8 engines, the flywheel/drive plate

has 8 single notches, spaced every 45 degrees, at its

outer edge (Fig. 25).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM. For each engine revolution, there are 8

pulses generated on V-8 engines.

Fig. 23 CKP Sensor LocationÐ8.0L V-10 Engine

1 - CRANKSHAFT POSITION SENSOR

2 - HOLE

3 - OIL FILTER

4 - PLASTIC TIE STRAP

5 - PIGTAIL HARNESS

Fig. 24 CKP Sensor OperationÐ3.9L Engine

1 - FLYWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

14 - 38 FUEL INJECTION - GASOLINEBR/BE

Page 1526 of 2889

The engine will not operate if the PCM does not

receive a CKP sensor input.

OPERATION - 8.0L

The Crankshaft Position (CKP) sensor detects

notches machined into the middle of the crankshaft

(Fig. 26).There are five sets of notches. Each set contains

two notches. Basic ignition timing is determined by

the position of the last notch in each set of notches.

Once the Powertrain Control Module (PCM) senses

the last notch, it will determine crankshaft position

(which piston will next be at Top Dead Center). An

input from the camshaft position sensor is also

needed. It may take the module up to one complete

engine revolution to determine crankshaft position

during engine cranking.

The PCM uses the signal from the camshaft posi-

tion sensor to determine fuel injector sequence. Once

crankshaft position has been determined, the PCM

begins energizing a ground circuit to each fuel injec-

tor to provide injector operation.

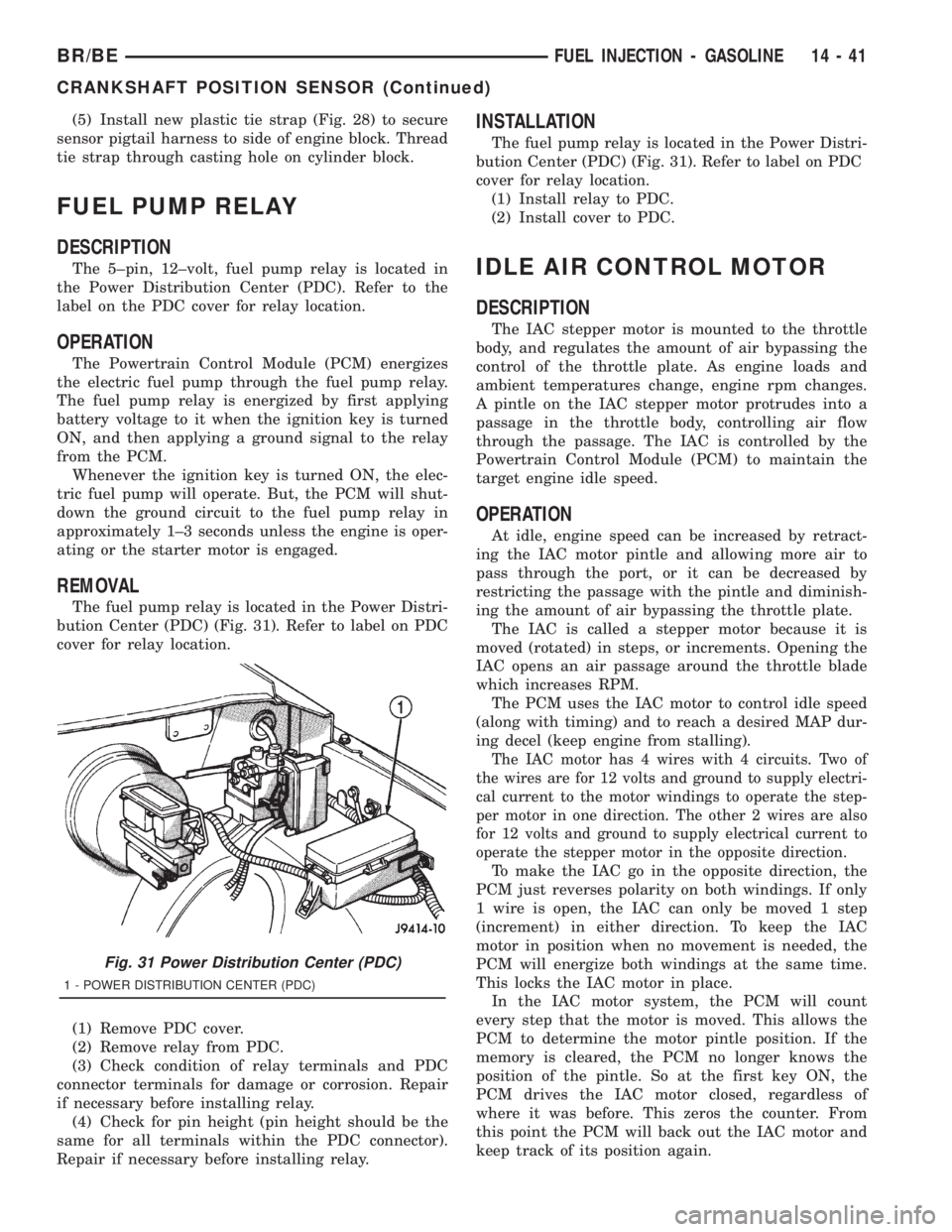

REMOVAL - 3.9L/5.2L/5.9L

The sensor is bolted to the top of the cylinder block

near the rear of right cylinder head (Fig. 27).

(1) Remove the air cleaner intake tube.

(2) Disconnect crankshaft position sensor pigtail

harness from main wiring harness.

(3) Remove two sensor (recessed hex head) mount-

ing bolts (Fig. 27).

(4) Remove sensor from engine.

Fig. 25 CKP Sensor OperationÐ5.2L/5.9L Engine

1 - CRANKSHAFT POSITION SENSOR

2 - NOTCHES

3 - FLYWHEEL

Fig. 26 CKP Sensor OperationÐ8.0L V-10 Engine

1 - CRANKSHAFT NOTCHES

2 - CRANKSHAFT

3 - CRANKSHAFT POSITION SENSOR

Fig. 27 Crankshaft Position Sensor

1 - GROMMET

2 - MOUNTING BOLTS (2)

3 - CRANKSHAFT POSITION SENSOR

4 - RIGHT EXHAUST MANIFOLD

5 - TRANSMISSION BELL HOUSING

BR/BEFUEL INJECTION - GASOLINE 14 - 39

CRANKSHAFT POSITION SENSOR (Continued)

Page 1527 of 2889

REMOVAL - 8.0L

The crankshaft position sensor is located on the

right-lower side of the cylinder block, forward of the

right engine mount, just above the oil pan rail (Fig.

28).

(1) Raise and support vehicle.

(2) Disconnect sensor pigtail harness from main

engine wiring harness.

(3) Remove sensor mounting bolt (Fig. 29).

(4) Cut plastic tie strap (Fig. 28) securing sensor

pigtail harness to side of engine block.

(5) Carefully pry sensor from cylinder block in a

rocking action with two small screwdrivers.

(6) Remove sensor from vehicle.

(7) Check condition of sensor o-ring (Fig. 30).

INSTALLATION - 3.9L/5.2L/5.9L

(1) Position crankshaft position sensor to engine.

(2) Install mounting bolts and tighten to 8 N´m (70

in. lbs.) torque.

(3) Connect main harness electrical connector to

sensor.

(4) Install air cleaner tube.

INSTALLATION - 8.0L

The crankshaft position sensor is located on the

right-lower side of the cylinder block, forward of the

right engine mount, just above the oil pan rail (Fig.

28).(1) Apply a small amount of engine oil to sensor

o-ring (Fig. 30).

(2) Install sensor into cylinder block with a slight

rocking action. Do not twist sensor into position as

damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder block

(Fig. 29). If sensor is not flush, damage to sensor

mounting tang may result.

(3) Install mounting bolt and tighten to 8 N´m (70

in. lbs.) torque.

(4) Connect sensor pigtail harness to main engine

wiring harness

Fig. 28 Crankshaft Position Sensor LocationÐ8.0L

V-10 Engine

1 - CRANKSHAFT POSITION SENSOR

2 - HOLE

3 - OIL FILTER

4 - PLASTIC TIE STRAP

5 - PIGTAIL HARNESS

Fig. 29 Sensor Removal/InstallationÐ8.0L V-10

Engine

1 - CRANKSHAFT POSITION SENSOR

2 - MOUNTING BOLT

3 - SENSOR POSITIONED FLUSH TO CYLINDER BLOCK

Fig. 30 Sensor O-RingÐ8.0L V-10 Engine

1 - CRANKSHAFT POSITION SENSOR O-RING

2 - ELECTRICAL CONNECTOR

3 - PIGTAIL HARNESS

14 - 40 FUEL INJECTION - GASOLINEBR/BE

CRANKSHAFT POSITION SENSOR (Continued)

Page 1528 of 2889

(5) Install new plastic tie strap (Fig. 28) to secure

sensor pigtail harness to side of engine block. Thread

tie strap through casting hole on cylinder block.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

REMOVAL

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 31). Refer to label on PDC

cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 31). Refer to label on PDC

cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

IDLE AIR CONTROL MOTOR

DESCRIPTION

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into a

passage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply electri-

cal current to the motor windings to operate the step-

per motor in one direction. The other 2 wires are also

for 12 volts and ground to supply electrical current to

operate the stepper motor in the opposite direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

Fig. 31 Power Distribution Center (PDC)

1 - POWER DISTRIBUTION CENTER (PDC)

BR/BEFUEL INJECTION - GASOLINE 14 - 41

CRANKSHAFT POSITION SENSOR (Continued)

Page 1529 of 2889

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

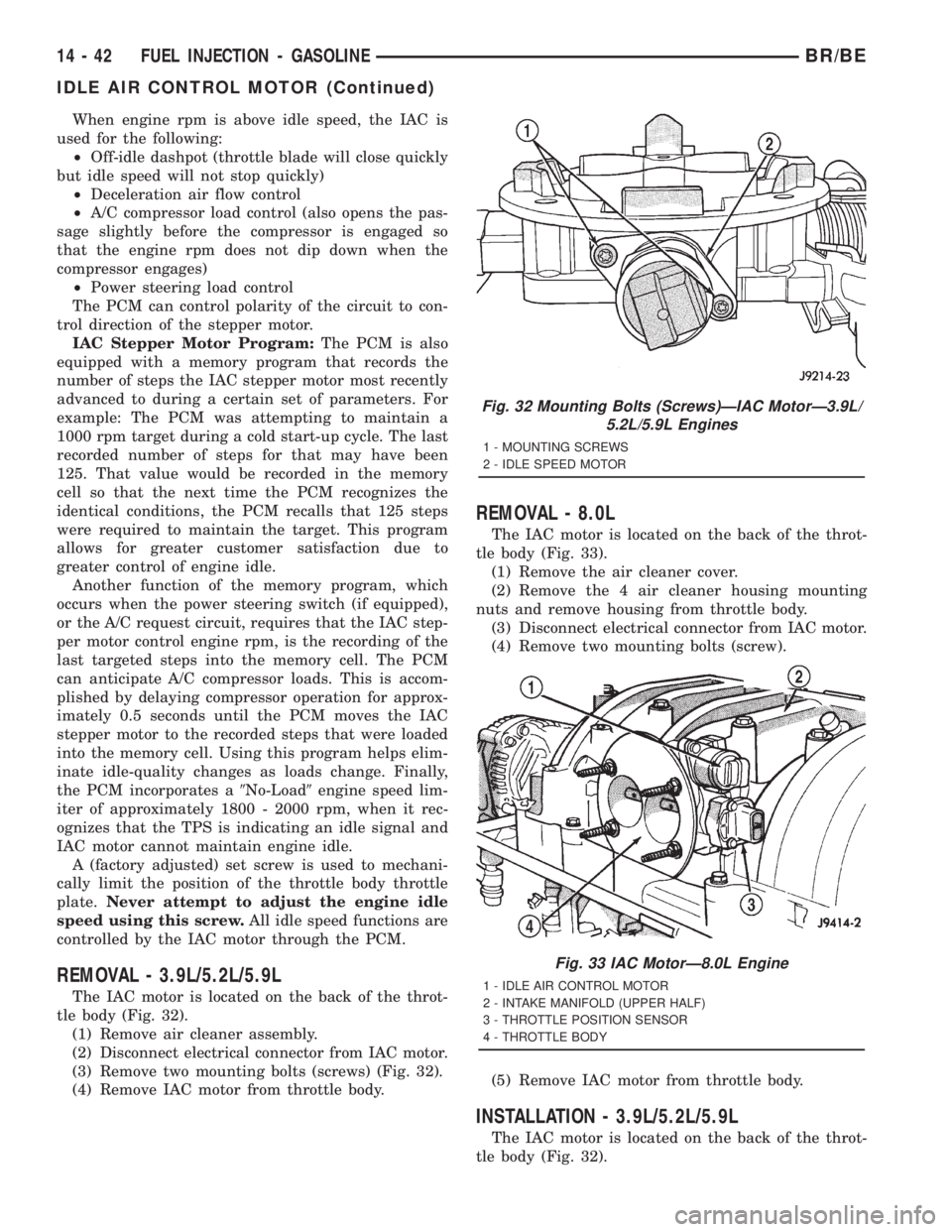

REMOVAL - 3.9L/5.2L/5.9L

The IAC motor is located on the back of the throt-

tle body (Fig. 32).

(1) Remove air cleaner assembly.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws) (Fig. 32).

(4) Remove IAC motor from throttle body.

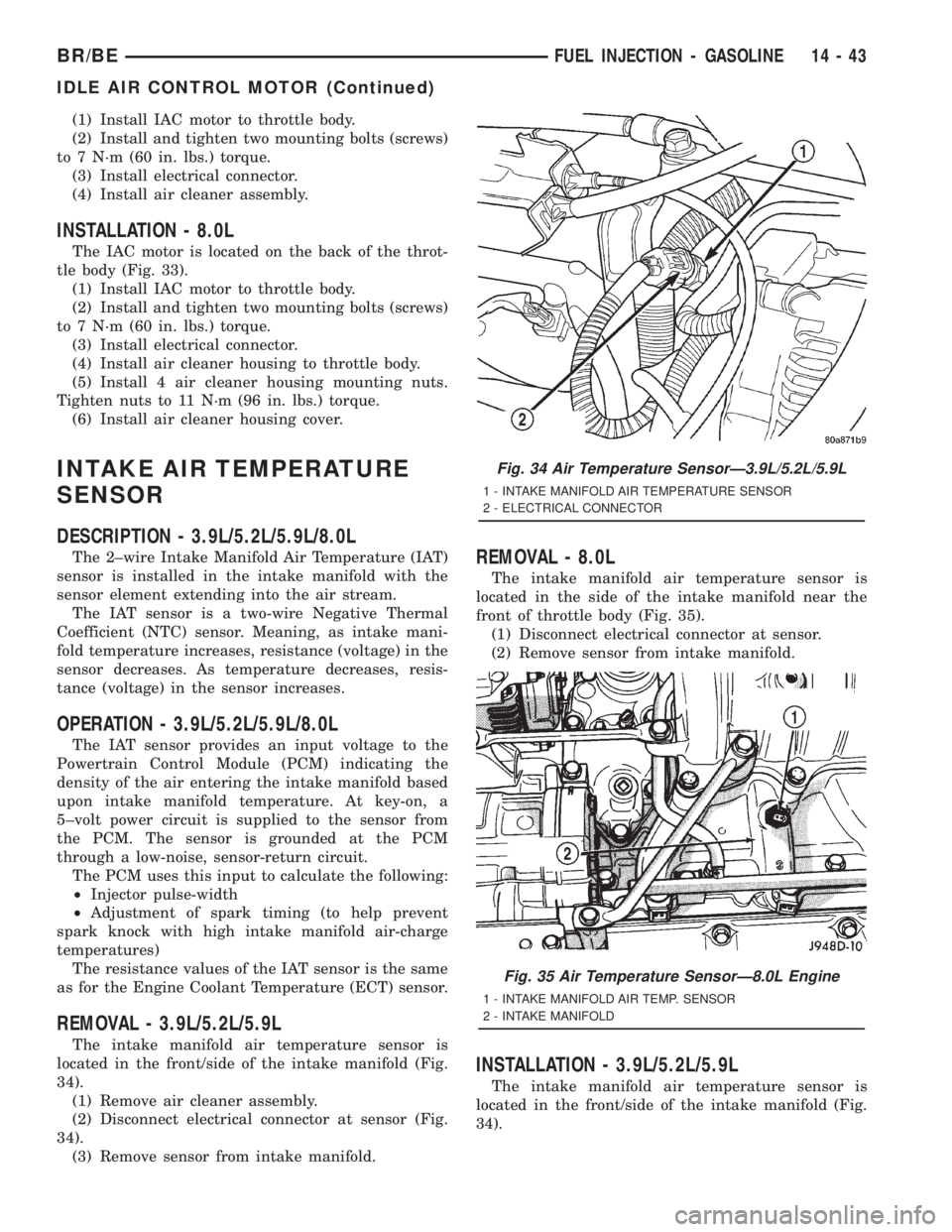

REMOVAL - 8.0L

The IAC motor is located on the back of the throt-

tle body (Fig. 33).

(1) Remove the air cleaner cover.

(2) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(3) Disconnect electrical connector from IAC motor.

(4) Remove two mounting bolts (screw).

(5) Remove IAC motor from throttle body.

INSTALLATION - 3.9L/5.2L/5.9L

The IAC motor is located on the back of the throt-

tle body (Fig. 32).

Fig. 32 Mounting Bolts (Screws)ÐIAC MotorÐ3.9L/

5.2L/5.9L Engines

1 - MOUNTING SCREWS

2 - IDLE SPEED MOTOR

Fig. 33 IAC MotorÐ8.0L Engine

1 - IDLE AIR CONTROL MOTOR

2 - INTAKE MANIFOLD (UPPER HALF)

3 - THROTTLE POSITION SENSOR

4 - THROTTLE BODY

14 - 42 FUEL INJECTION - GASOLINEBR/BE

IDLE AIR CONTROL MOTOR (Continued)

Page 1530 of 2889

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air cleaner assembly.

INSTALLATION - 8.0L

The IAC motor is located on the back of the throt-

tle body (Fig. 33).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air cleaner housing to throttle body.

(5) Install 4 air cleaner housing mounting nuts.

Tighten nuts to 11 N´m (96 in. lbs.) torque.

(6) Install air cleaner housing cover.

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION - 3.9L/5.2L/5.9L/8.0L

The 2±wire Intake Manifold Air Temperature (IAT)

sensor is installed in the intake manifold with the

sensor element extending into the air stream.

The IAT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as intake mani-

fold temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION - 3.9L/5.2L/5.9L/8.0L

The IAT sensor provides an input voltage to the

Powertrain Control Module (PCM) indicating the

density of the air entering the intake manifold based

upon intake manifold temperature. At key-on, a

5±volt power circuit is supplied to the sensor from

the PCM. The sensor is grounded at the PCM

through a low-noise, sensor-return circuit.

The PCM uses this input to calculate the following:

²Injector pulse-width

²Adjustment of spark timing (to help prevent

spark knock with high intake manifold air-charge

temperatures)

The resistance values of the IAT sensor is the same

as for the Engine Coolant Temperature (ECT) sensor.

REMOVAL - 3.9L/5.2L/5.9L

The intake manifold air temperature sensor is

located in the front/side of the intake manifold (Fig.

34).

(1) Remove air cleaner assembly.

(2) Disconnect electrical connector at sensor (Fig.

34).

(3) Remove sensor from intake manifold.

REMOVAL - 8.0L

The intake manifold air temperature sensor is

located in the side of the intake manifold near the

front of throttle body (Fig. 35).

(1) Disconnect electrical connector at sensor.

(2) Remove sensor from intake manifold.

INSTALLATION - 3.9L/5.2L/5.9L

The intake manifold air temperature sensor is

located in the front/side of the intake manifold (Fig.

34).

Fig. 34 Air Temperature SensorÐ3.9L/5.2L/5.9L

1 - INTAKE MANIFOLD AIR TEMPERATURE SENSOR

2 - ELECTRICAL CONNECTOR

Fig. 35 Air Temperature SensorÐ8.0L Engine

1 - INTAKE MANIFOLD AIR TEMP. SENSOR

2 - INTAKE MANIFOLD

BR/BEFUEL INJECTION - GASOLINE 14 - 43

IDLE AIR CONTROL MOTOR (Continued)