DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1561 of 2889

the fuel injection pump and the fuel injectors. Also

refer to High-Pressure Fuel Lines Description/Opera-

tion.

DESCRIPTIONÐHIGH PRESSURE FUEL LINES

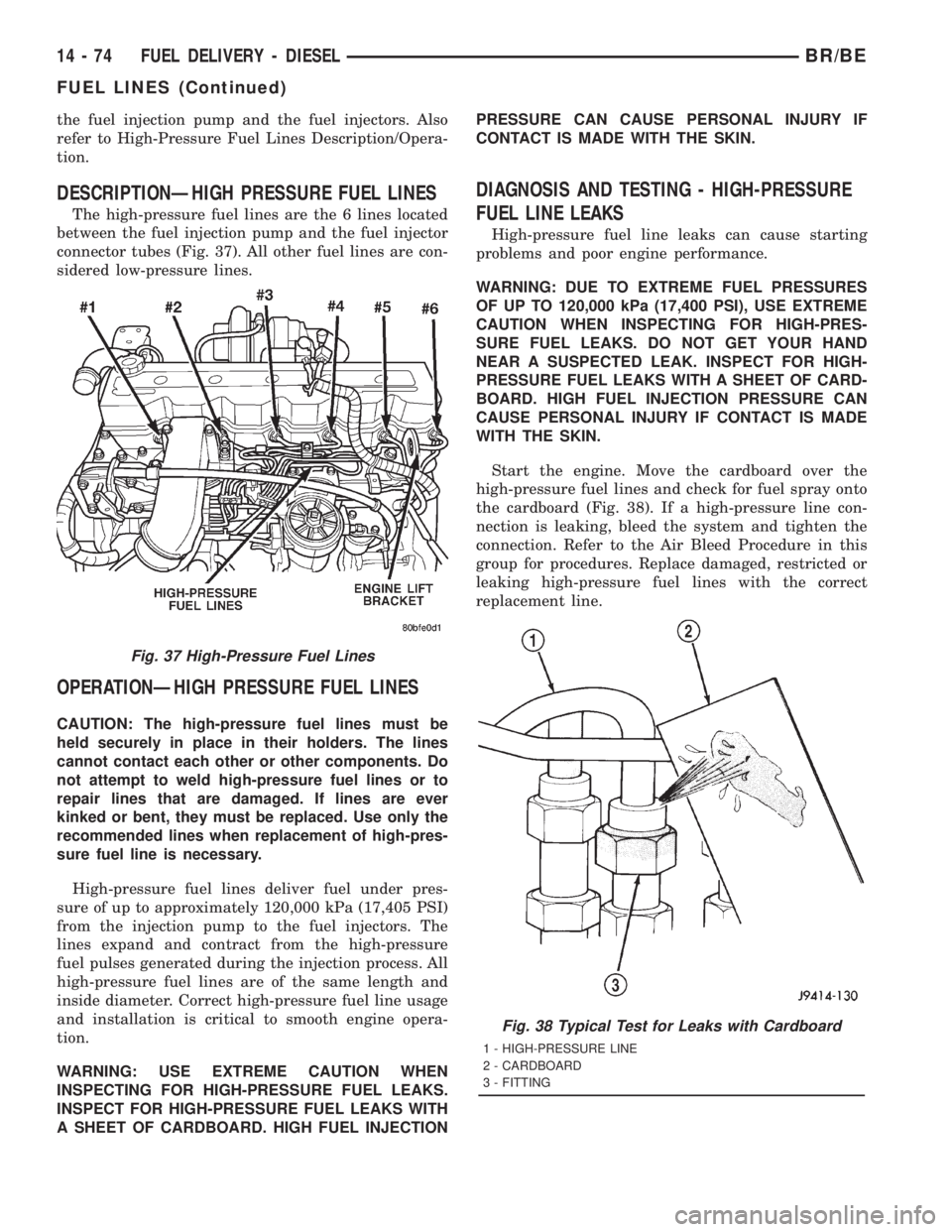

The high-pressure fuel lines are the 6 lines located

between the fuel injection pump and the fuel injector

connector tubes (Fig. 37). All other fuel lines are con-

sidered low-pressure lines.

OPERATIONÐHIGH PRESSURE FUEL LINES

CAUTION: The high-pressure fuel lines must be

held securely in place in their holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. If lines are ever

kinked or bent, they must be replaced. Use only the

recommended lines when replacement of high-pres-

sure fuel line is necessary.

High-pressure fuel lines deliver fuel under pres-

sure of up to approximately 120,000 kPa (17,405 PSI)

from the injection pump to the fuel injectors. The

lines expand and contract from the high-pressure

fuel pulses generated during the injection process. All

high-pressure fuel lines are of the same length and

inside diameter. Correct high-pressure fuel line usage

and installation is critical to smooth engine opera-

tion.

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH-PRESSURE FUEL LEAKS.

INSPECT FOR HIGH-PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTIONPRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

DIAGNOSIS AND TESTING - HIGH-PRESSURE

FUEL LINE LEAKS

High-pressure fuel line leaks can cause starting

problems and poor engine performance.

WARNING: DUE TO EXTREME FUEL PRESSURES

OF UP TO 120,000 kPa (17,400 PSI), USE EXTREME

CAUTION WHEN INSPECTING FOR HIGH-PRES-

SURE FUEL LEAKS. DO NOT GET YOUR HAND

NEAR A SUSPECTED LEAK. INSPECT FOR HIGH-

PRESSURE FUEL LEAKS WITH A SHEET OF CARD-

BOARD. HIGH FUEL INJECTION PRESSURE CAN

CAUSE PERSONAL INJURY IF CONTACT IS MADE

WITH THE SKIN.

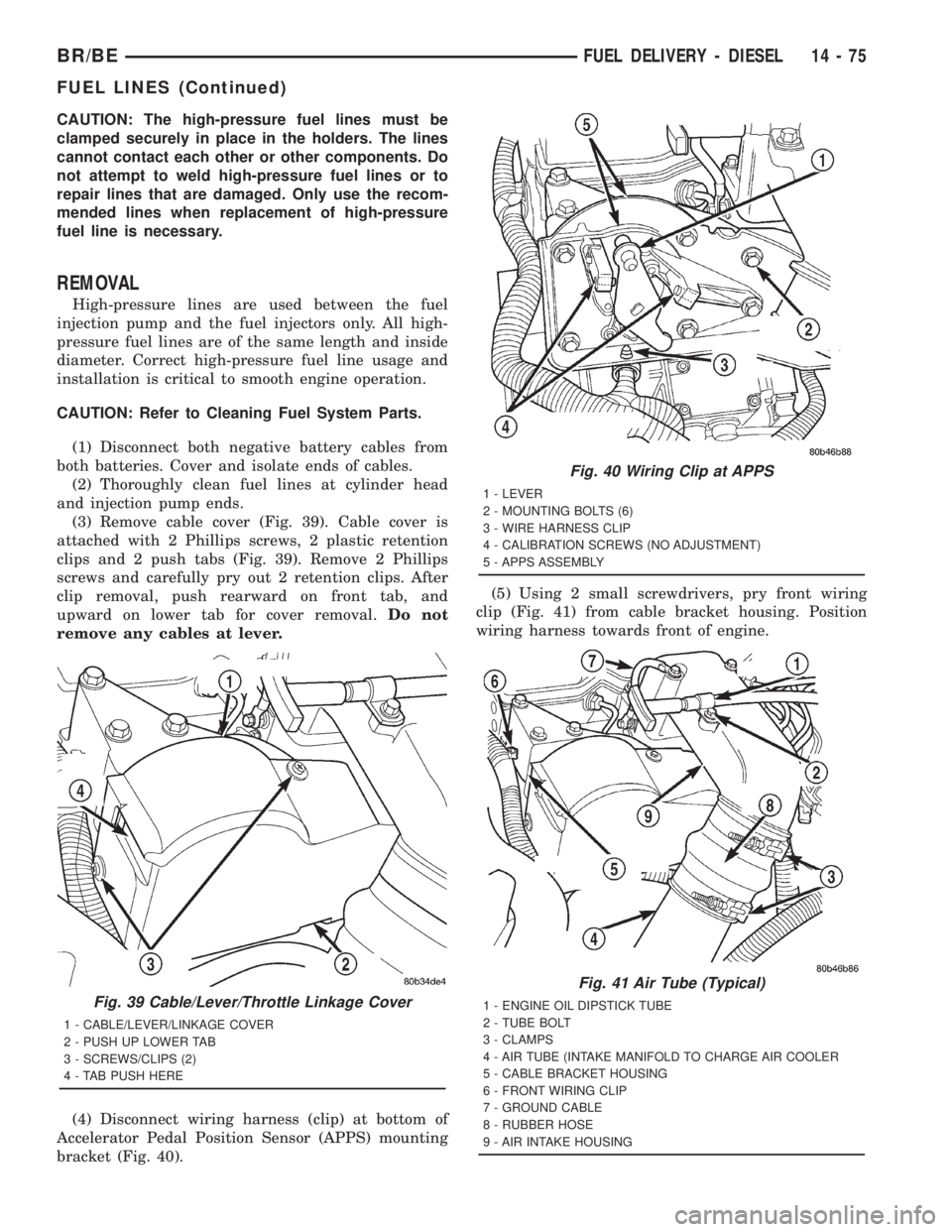

Start the engine. Move the cardboard over the

high-pressure fuel lines and check for fuel spray onto

the cardboard (Fig. 38). If a high-pressure line con-

nection is leaking, bleed the system and tighten the

connection. Refer to the Air Bleed Procedure in this

group for procedures. Replace damaged, restricted or

leaking high-pressure fuel lines with the correct

replacement line.

Fig. 37 High-Pressure Fuel Lines

Fig. 38 Typical Test for Leaks with Cardboard

1 - HIGH-PRESSURE LINE

2 - CARDBOARD

3 - FITTING

14 - 74 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)

Page 1562 of 2889

CAUTION: The high-pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high-pressure

fuel line is necessary.

REMOVAL

High-pressure lines are used between the fuel

injection pump and the fuel injectors only. All high-

pressure fuel lines are of the same length and inside

diameter. Correct high-pressure fuel line usage and

installation is critical to smooth engine operation.

CAUTION: Refer to Cleaning Fuel System Parts.

(1) Disconnect both negative battery cables from

both batteries. Cover and isolate ends of cables.

(2) Thoroughly clean fuel lines at cylinder head

and injection pump ends.

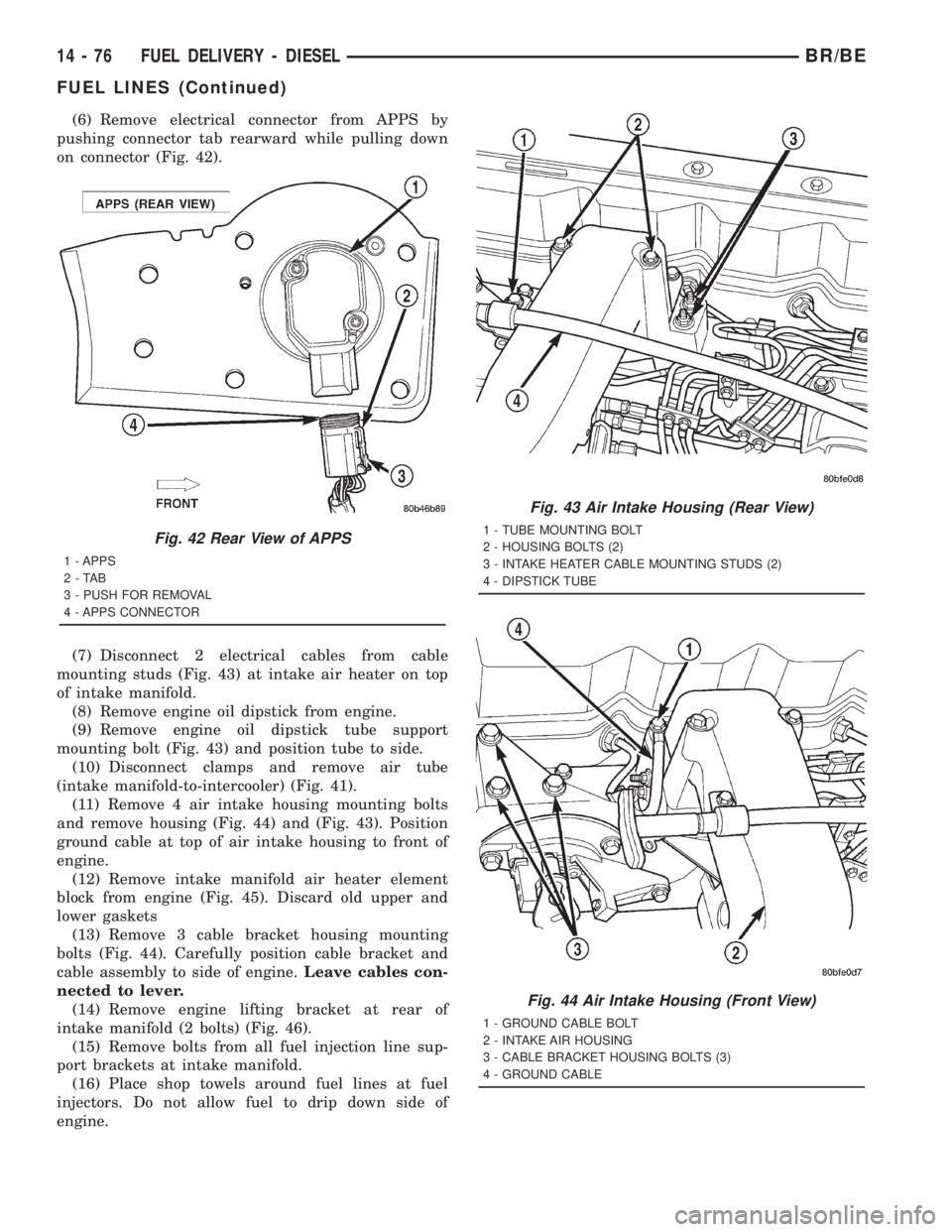

(3) Remove cable cover (Fig. 39). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 39). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.Do not

remove any cables at lever.

(4) Disconnect wiring harness (clip) at bottom of

Accelerator Pedal Position Sensor (APPS) mounting

bracket (Fig. 40).(5) Using 2 small screwdrivers, pry front wiring

clip (Fig. 41) from cable bracket housing. Position

wiring harness towards front of engine.

Fig. 39 Cable/Lever/Throttle Linkage Cover

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

Fig. 40 Wiring Clip at APPS

1 - LEVER

2 - MOUNTING BOLTS (6)

3 - WIRE HARNESS CLIP

4 - CALIBRATION SCREWS (NO ADJUSTMENT)

5 - APPS ASSEMBLY

Fig. 41 Air Tube (Typical)

1 - ENGINE OIL DIPSTICK TUBE

2 - TUBE BOLT

3 - CLAMPS

4 - AIR TUBE (INTAKE MANIFOLD TO CHARGE AIR COOLER

5 - CABLE BRACKET HOUSING

6 - FRONT WIRING CLIP

7 - GROUND CABLE

8 - RUBBER HOSE

9 - AIR INTAKE HOUSING

BR/BEFUEL DELIVERY - DIESEL 14 - 75

FUEL LINES (Continued)

Page 1563 of 2889

(6) Remove electrical connector from APPS by

pushing connector tab rearward while pulling down

on connector (Fig. 42).

(7) Disconnect 2 electrical cables from cable

mounting studs (Fig. 43) at intake air heater on top

of intake manifold.

(8) Remove engine oil dipstick from engine.

(9) Remove engine oil dipstick tube support

mounting bolt (Fig. 43) and position tube to side.

(10) Disconnect clamps and remove air tube

(intake manifold-to-intercooler) (Fig. 41).

(11) Remove 4 air intake housing mounting bolts

and remove housing (Fig. 44) and (Fig. 43). Position

ground cable at top of air intake housing to front of

engine.

(12) Remove intake manifold air heater element

block from engine (Fig. 45). Discard old upper and

lower gaskets

(13) Remove 3 cable bracket housing mounting

bolts (Fig. 44). Carefully position cable bracket and

cable assembly to side of engine.Leave cables con-

nected to lever.

(14) Remove engine lifting bracket at rear of

intake manifold (2 bolts) (Fig. 46).

(15) Remove bolts from all fuel injection line sup-

port brackets at intake manifold.

(16) Place shop towels around fuel lines at fuel

injectors. Do not allow fuel to drip down side of

engine.

Fig. 42 Rear View of APPS

1 - APPS

2-TAB

3 - PUSH FOR REMOVAL

4 - APPS CONNECTOR

Fig. 43 Air Intake Housing (Rear View)

1 - TUBE MOUNTING BOLT

2 - HOUSING BOLTS (2)

3 - INTAKE HEATER CABLE MOUNTING STUDS (2)

4 - DIPSTICK TUBE

Fig. 44 Air Intake Housing (Front View)

1 - GROUND CABLE BOLT

2 - INTAKE AIR HOUSING

3 - CABLE BRACKET HOUSING BOLTS (3)

4 - GROUND CABLE

14 - 76 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)

Page 1564 of 2889

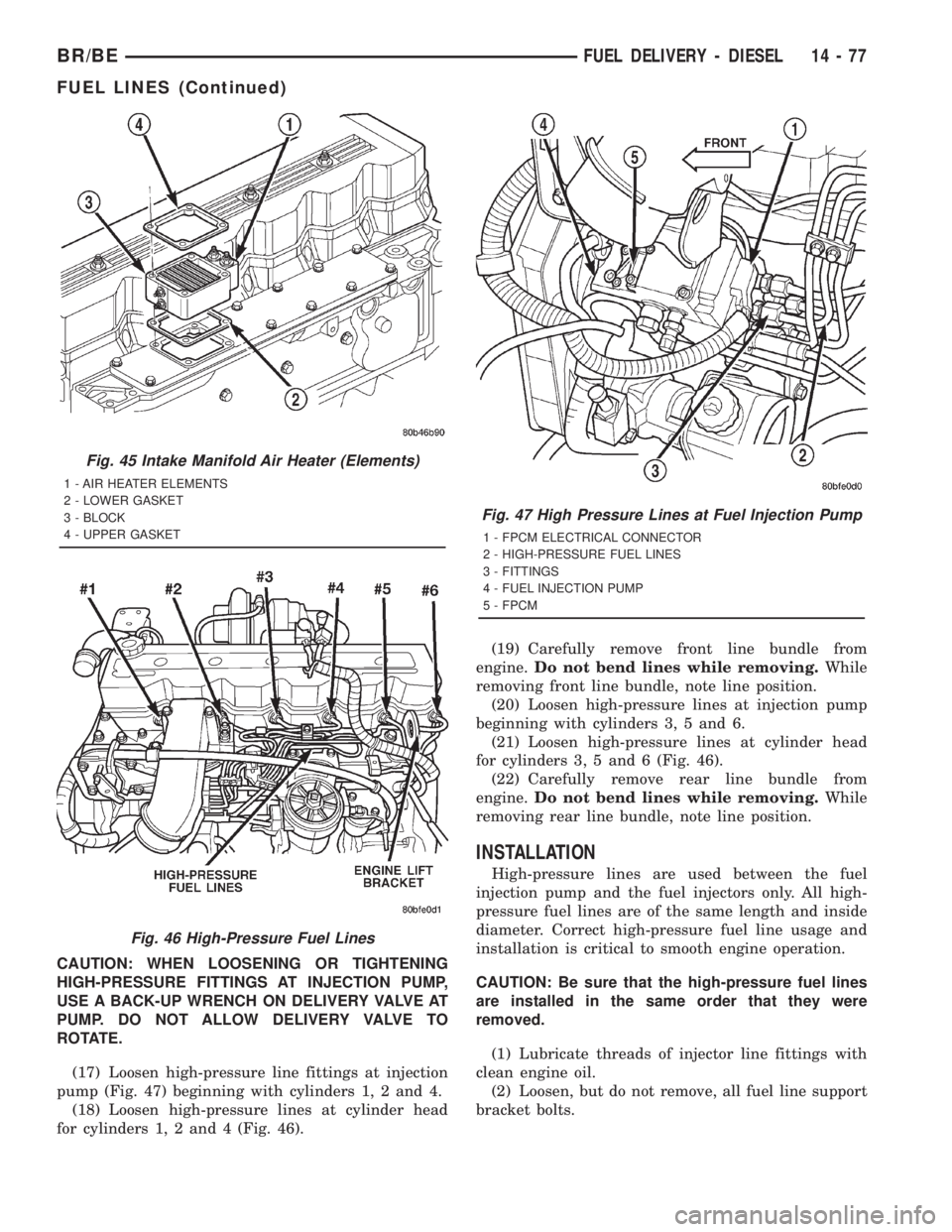

CAUTION: WHEN LOOSENING OR TIGHTENING

HIGH-PRESSURE FITTINGS AT INJECTION PUMP,

USE A BACK-UP WRENCH ON DELIVERY VALVE AT

PUMP. DO NOT ALLOW DELIVERY VALVE TO

ROTATE.

(17) Loosen high-pressure line fittings at injection

pump (Fig. 47) beginning with cylinders 1, 2 and 4.

(18) Loosen high-pressure lines at cylinder head

for cylinders 1, 2 and 4 (Fig. 46).(19) Carefully remove front line bundle from

engine.Do not bend lines while removing.While

removing front line bundle, note line position.

(20) Loosen high-pressure lines at injection pump

beginning with cylinders 3, 5 and 6.

(21) Loosen high-pressure lines at cylinder head

for cylinders 3, 5 and 6 (Fig. 46).

(22) Carefully remove rear line bundle from

engine.Do not bend lines while removing.While

removing rear line bundle, note line position.

INSTALLATION

High-pressure lines are used between the fuel

injection pump and the fuel injectors only. All high-

pressure fuel lines are of the same length and inside

diameter. Correct high-pressure fuel line usage and

installation is critical to smooth engine operation.

CAUTION: Be sure that the high-pressure fuel lines

are installed in the same order that they were

removed.

(1) Lubricate threads of injector line fittings with

clean engine oil.

(2) Loosen, but do not remove, all fuel line support

bracket bolts.

Fig. 45 Intake Manifold Air Heater (Elements)

1 - AIR HEATER ELEMENTS

2 - LOWER GASKET

3 - BLOCK

4 - UPPER GASKET

Fig. 46 High-Pressure Fuel Lines

Fig. 47 High Pressure Lines at Fuel Injection Pump

1 - FPCM ELECTRICAL CONNECTOR

2 - HIGH-PRESSURE FUEL LINES

3 - FITTINGS

4 - FUEL INJECTION PUMP

5 - FPCM

BR/BEFUEL DELIVERY - DIESEL 14 - 77

FUEL LINES (Continued)

Page 1565 of 2889

(3) Installrearinjection line bundle beginning

with cylinder head (fuel injector) connections, fol-

lowed by injection pump connections. Tighten all fit-

tings finger tight.

(4) Tighten fittings at fuel injector ends for cylin-

ders number 6 and 5 to 38 N´m (28 ft. lbs.) torque.

Do not tighten number 3 line at this time. It

will be tightened during bleeding procedure.

(5) Tighten 3 fittings at fuel injection pump ends

to 24 N´m (18 ft. lbs.) torque.

(6) Installfrontinjection line bundle beginning

with cylinder head (fuel injector) connections, fol-

lowed by injection pump connections. Tighten all fit-

tings finger tight.

(7) Tighten fitting at fuel injector end for cylinder

number 2 to 38 N´m (28 ft. lbs.) torque.Do not

tighten lines number 1 or 4 at this time. They

will be tightened during bleeding procedure.

(8) Tighten remaining 3 fittings at fuel injection

pump ends to 24 N´m (18 ft. lbs.) torque.

(9) Install fuel line support bracket bolts to intake

manifold and tighten to 24 N´m (18 ft. lbs.) torque.

CAUTION: Be sure fuel lines are not contacting

each other or any other component. Noise will

result.

(10) Install engine lifting bracket at rear of intake

manifold. Tighten 2 bolts to 77 N´m (57 ft. lbs.)

torque.

(11) Install cable bracket housing/cable assembly

and tighten 3 mounting bolts to 24 N´m (18 ft. lbs.)

torque.

(12) Clean any old gasket material below and

above intake manifold air heater element block. Also

clean mating areas at intake manifold and air intake

housing.

(13) Using new gaskets, position intake manifold

air heater element block to engine.

(14) Install air intake housing and position ground

cable. Install 4 mounting bolts and tighten to 24 N´m

(18 ft. lbs.) torque.

(15) Install air tube (intake manifold-to-charge air

cooler) (Fig. 41). Tighten clamps to 8 N´m (72 in. lbs.)

torque.

(16) Install engine oil dipstick tube support mount-

ing bolt and tighten to 24 N´m (18 ft. lbs.) torque.

(17) Install engine oil dipstick to engine.

(18) Connect 2 electrical cables to cable mounting

studs.

(19) Connect electrical connector to bottom of

APPS by pushing connector upward until it snaps

into position.

(20) Connect wiring harness (clip) at bottom of

Accelerator Pedal Position Sensor (APPS) mounting

bracket (Fig. 40).(21) Connect front wiring clip (Fig. 41) to cable

bracket housing.

(22) Install cable cover (Fig. 39).

(23) Connect both negative battery cables to both

batteries.

(24) Bleed air from fuel system. Do this at fuel

injector ends of lines. Use cylinders numbers 1, 3 and

4 for bleeding . (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). After

bleeding, tighten fittings to 38 N´m (28 ft. lbs.)

torque.

(25) Check lines/fittings for leaks.

FUEL TANK

DESCRIPTION - DIESEL FUEL TANK

The fuel tank is similar to the tank used with gas-

oline powered models. The tank is equipped with a

separate fuel return line and a different fuel tank

module for diesel powered models. A fuel tank

mounted, electric fuel pump is not used with diesel

powered models. Refer to Fuel Tank Module for addi-

tional information.

For removal and installation procedures, refer to

Fuel Tank - Gasoline Engines.

FUEL TANK MODULE

DESCRIPTION

An electric fuel pump isnot usedin the fuel tank

module for diesel powered engines. Fuel is supplied

by the engine mounted fuel transfer pump and the

fuel injection pump.

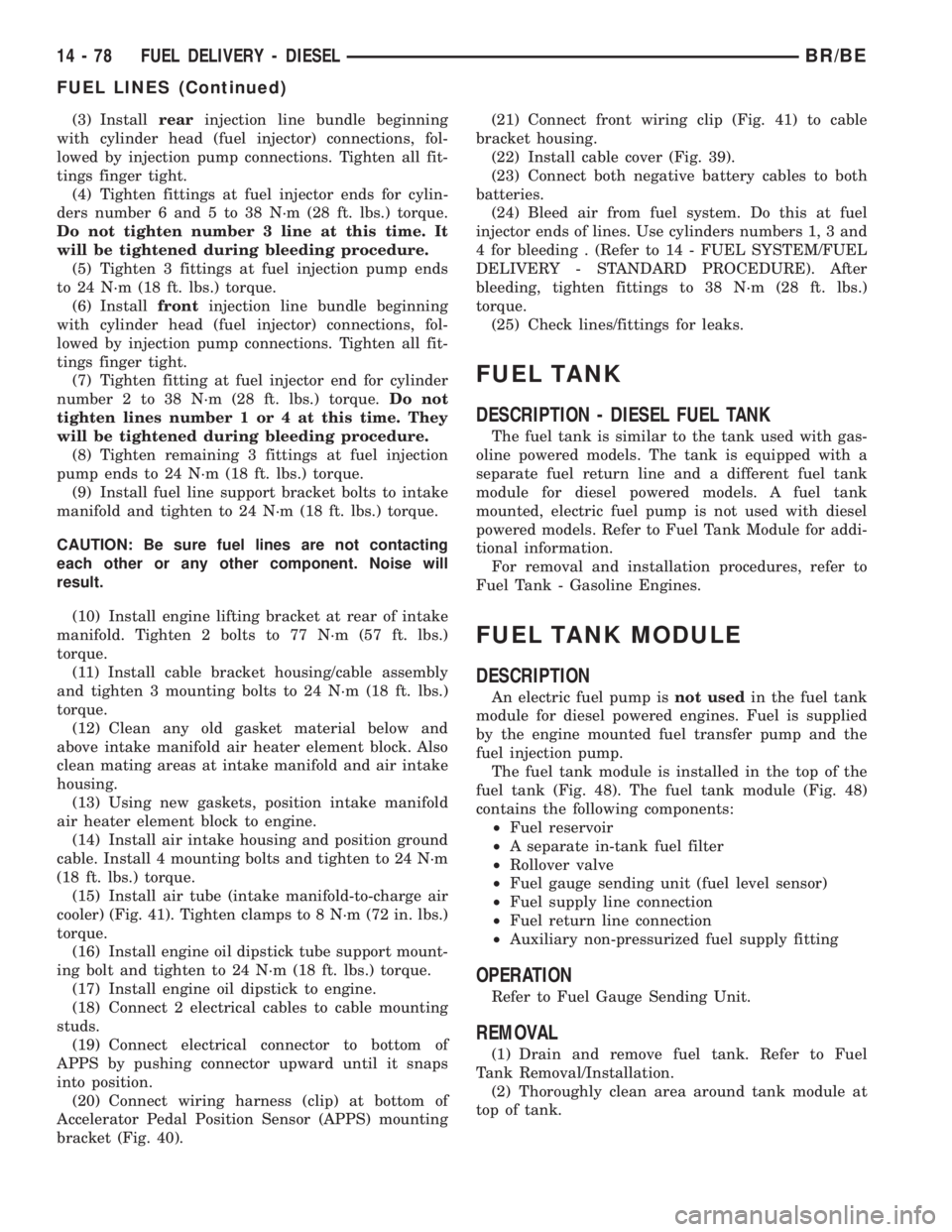

The fuel tank module is installed in the top of the

fuel tank (Fig. 48). The fuel tank module (Fig. 48)

contains the following components:

²Fuel reservoir

²A separate in-tank fuel filter

²Rollover valve

²Fuel gauge sending unit (fuel level sensor)

²Fuel supply line connection

²Fuel return line connection

²Auxiliary non-pressurized fuel supply fitting

OPERATION

Refer to Fuel Gauge Sending Unit.

REMOVAL

(1) Drain and remove fuel tank. Refer to Fuel

Tank Removal/Installation.

(2) Thoroughly clean area around tank module at

top of tank.

14 - 78 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)

Page 1566 of 2889

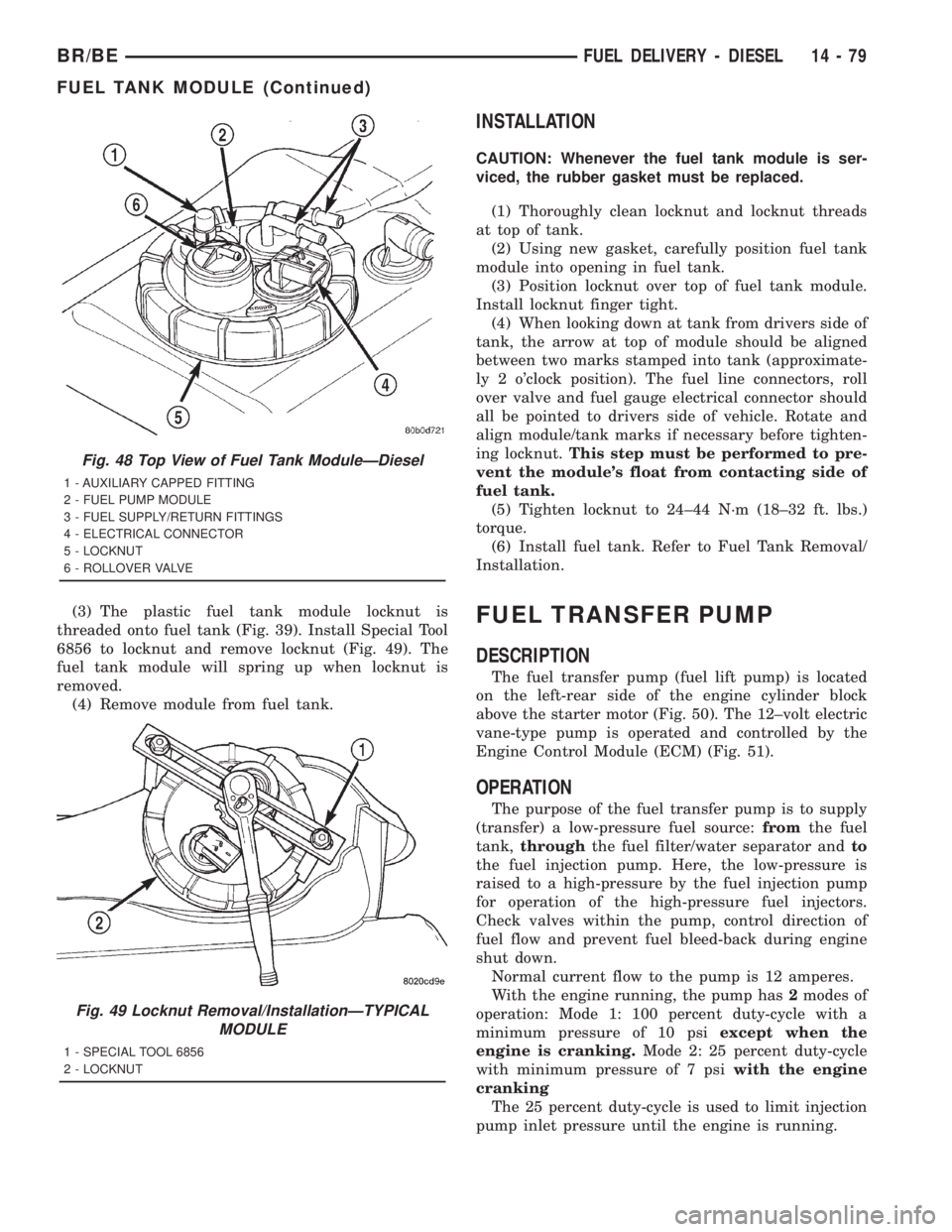

(3) The plastic fuel tank module locknut is

threaded onto fuel tank (Fig. 39). Install Special Tool

6856 to locknut and remove locknut (Fig. 49). The

fuel tank module will spring up when locknut is

removed.

(4) Remove module from fuel tank.

INSTALLATION

CAUTION: Whenever the fuel tank module is ser-

viced, the rubber gasket must be replaced.

(1) Thoroughly clean locknut and locknut threads

at top of tank.

(2) Using new gasket, carefully position fuel tank

module into opening in fuel tank.

(3) Position locknut over top of fuel tank module.

Install locknut finger tight.

(4) When looking down at tank from drivers side of

tank, the arrow at top of module should be aligned

between two marks stamped into tank (approximate-

ly 2 o'clock position). The fuel line connectors, roll

over valve and fuel gauge electrical connector should

all be pointed to drivers side of vehicle. Rotate and

align module/tank marks if necessary before tighten-

ing locknut.This step must be performed to pre-

vent the module's float from contacting side of

fuel tank.

(5) Tighten locknut to 24±44 N´m (18±32 ft. lbs.)

torque.

(6) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

FUEL TRANSFER PUMP

DESCRIPTION

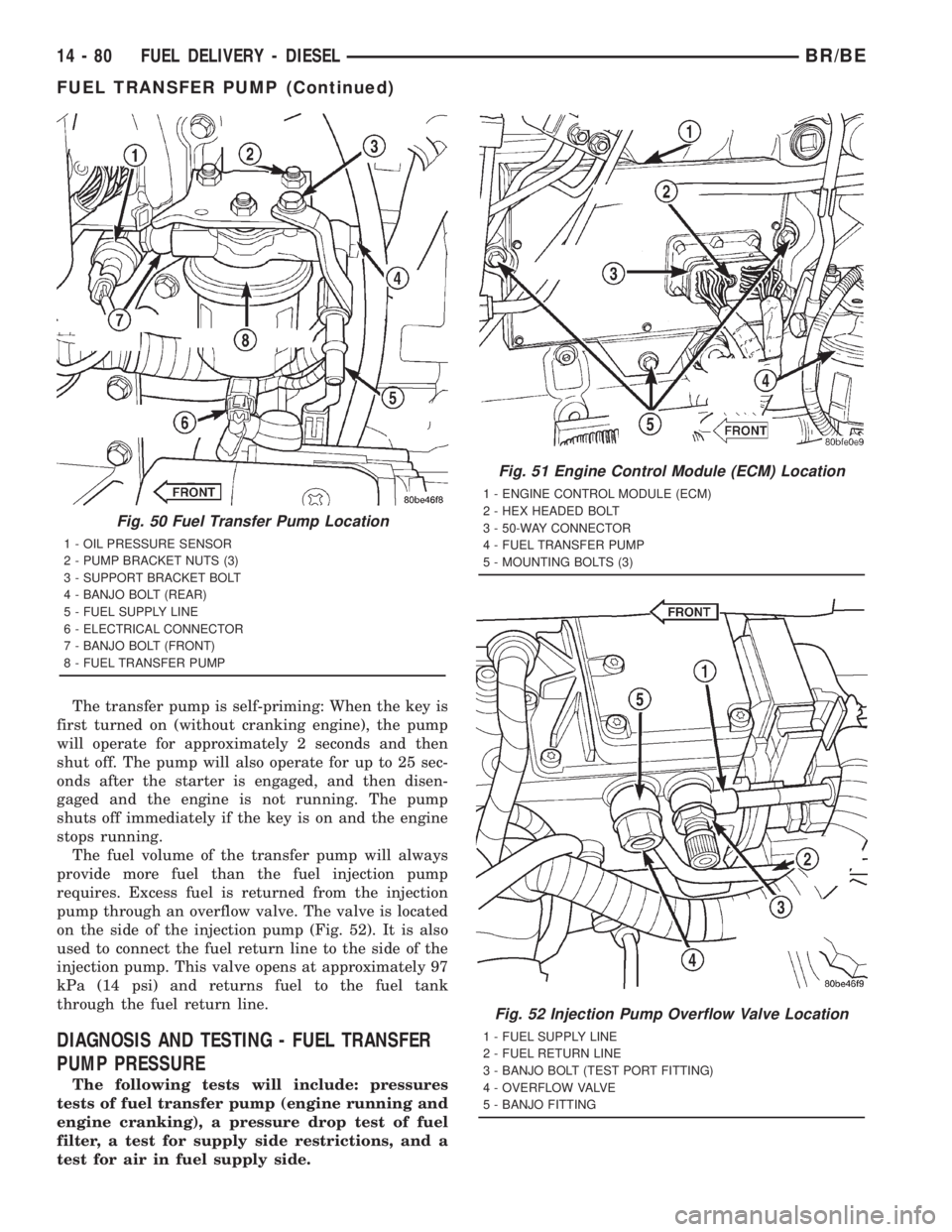

The fuel transfer pump (fuel lift pump) is located

on the left-rear side of the engine cylinder block

above the starter motor (Fig. 50). The 12±volt electric

vane-type pump is operated and controlled by the

Engine Control Module (ECM) (Fig. 51).

OPERATION

The purpose of the fuel transfer pump is to supply

(transfer) a low-pressure fuel source:fromthe fuel

tank,throughthe fuel filter/water separator andto

the fuel injection pump. Here, the low-pressure is

raised to a high-pressure by the fuel injection pump

for operation of the high-pressure fuel injectors.

Check valves within the pump, control direction of

fuel flow and prevent fuel bleed-back during engine

shut down.

Normal current flow to the pump is 12 amperes.

With the engine running, the pump has2modes of

operation: Mode 1: 100 percent duty-cycle with a

minimum pressure of 10 psiexcept when the

engine is cranking.Mode 2: 25 percent duty-cycle

with minimum pressure of 7 psiwith the engine

cranking

The 25 percent duty-cycle is used to limit injection

pump inlet pressure until the engine is running.

Fig. 48 Top View of Fuel Tank ModuleÐDiesel

1 - AUXILIARY CAPPED FITTING

2 - FUEL PUMP MODULE

3 - FUEL SUPPLY/RETURN FITTINGS

4 - ELECTRICAL CONNECTOR

5 - LOCKNUT

6 - ROLLOVER VALVE

Fig. 49 Locknut Removal/InstallationÐTYPICAL

MODULE

1 - SPECIAL TOOL 6856

2 - LOCKNUT

BR/BEFUEL DELIVERY - DIESEL 14 - 79

FUEL TANK MODULE (Continued)

Page 1567 of 2889

The transfer pump is self-priming: When the key is

first turned on (without cranking engine), the pump

will operate for approximately 2 seconds and then

shut off. The pump will also operate for up to 25 sec-

onds after the starter is engaged, and then disen-

gaged and the engine is not running. The pump

shuts off immediately if the key is on and the engine

stops running.

The fuel volume of the transfer pump will always

provide more fuel than the fuel injection pump

requires. Excess fuel is returned from the injection

pump through an overflow valve. The valve is located

on the side of the injection pump (Fig. 52). It is also

used to connect the fuel return line to the side of the

injection pump. This valve opens at approximately 97

kPa (14 psi) and returns fuel to the fuel tank

through the fuel return line.

DIAGNOSIS AND TESTING - FUEL TRANSFER

PUMP PRESSURE

The following tests will include: pressures

tests of fuel transfer pump (engine running and

engine cranking), a pressure drop test of fuel

filter, a test for supply side restrictions, and a

test for air in fuel supply side.

Fig. 50 Fuel Transfer Pump Location

1 - OIL PRESSURE SENSOR

2 - PUMP BRACKET NUTS (3)

3 - SUPPORT BRACKET BOLT

4 - BANJO BOLT (REAR)

5 - FUEL SUPPLY LINE

6 - ELECTRICAL CONNECTOR

7 - BANJO BOLT (FRONT)

8 - FUEL TRANSFER PUMP

Fig. 51 Engine Control Module (ECM) Location

1 - ENGINE CONTROL MODULE (ECM)

2 - HEX HEADED BOLT

3 - 50-WAY CONNECTOR

4 - FUEL TRANSFER PUMP

5 - MOUNTING BOLTS (3)

Fig. 52 Injection Pump Overflow Valve Location

1 - FUEL SUPPLY LINE

2 - FUEL RETURN LINE

3 - BANJO BOLT (TEST PORT FITTING)

4 - OVERFLOW VALVE

5 - BANJO FITTING

14 - 80 FUEL DELIVERY - DIESELBR/BE

FUEL TRANSFER PUMP (Continued)

Page 1568 of 2889

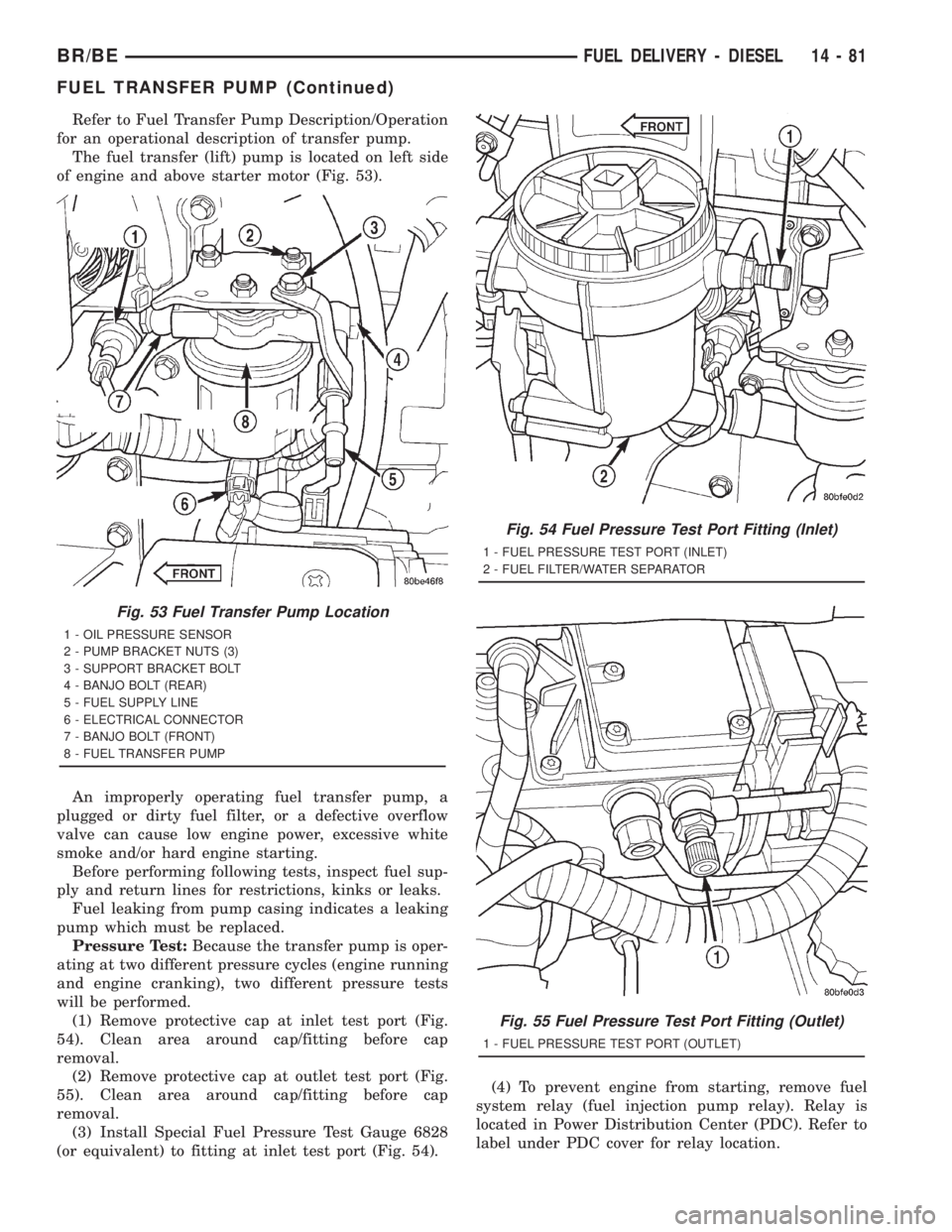

Refer to Fuel Transfer Pump Description/Operation

for an operational description of transfer pump.

The fuel transfer (lift) pump is located on left side

of engine and above starter motor (Fig. 53).

An improperly operating fuel transfer pump, a

plugged or dirty fuel filter, or a defective overflow

valve can cause low engine power, excessive white

smoke and/or hard engine starting.

Before performing following tests, inspect fuel sup-

ply and return lines for restrictions, kinks or leaks.

Fuel leaking from pump casing indicates a leaking

pump which must be replaced.

Pressure Test:Because the transfer pump is oper-

ating at two different pressure cycles (engine running

and engine cranking), two different pressure tests

will be performed.

(1) Remove protective cap at inlet test port (Fig.

54). Clean area around cap/fitting before cap

removal.

(2) Remove protective cap at outlet test port (Fig.

55). Clean area around cap/fitting before cap

removal.

(3) Install Special Fuel Pressure Test Gauge 6828

(or equivalent) to fitting at inlet test port (Fig. 54).(4) To prevent engine from starting, remove fuel

system relay (fuel injection pump relay). Relay is

located in Power Distribution Center (PDC). Refer to

label under PDC cover for relay location.

Fig. 53 Fuel Transfer Pump Location

1 - OIL PRESSURE SENSOR

2 - PUMP BRACKET NUTS (3)

3 - SUPPORT BRACKET BOLT

4 - BANJO BOLT (REAR)

5 - FUEL SUPPLY LINE

6 - ELECTRICAL CONNECTOR

7 - BANJO BOLT (FRONT)

8 - FUEL TRANSFER PUMP

Fig. 54 Fuel Pressure Test Port Fitting (Inlet)

1 - FUEL PRESSURE TEST PORT (INLET)

2 - FUEL FILTER/WATER SEPARATOR

Fig. 55 Fuel Pressure Test Port Fitting (Outlet)

1 - FUEL PRESSURE TEST PORT (OUTLET)

BR/BEFUEL DELIVERY - DIESEL 14 - 81

FUEL TRANSFER PUMP (Continued)

Page 1569 of 2889

(5) Using key, crank engine over while observing

gauge. Pressure should be 5±7 psi.

(6) Re-install fuel system relay to PDC.

(7) Start engine and record fuel pressure. Pressure

should be aminimumof 69 kPa (10 psi) at idle

speed.

(8) Because fuel pump relay was removed, a Diag-

nostic Trouble Code (DTC) may have been set. After

testing is completed, and relay has been installed,

use DRB scan tool to remove DTC.

Pressure Drop Test:

(9) Shut engine off and remove test gauge from

inlet port test fitting. Re-attach 6828 test gauge to

outlet port (Fig. 55). Start engine and record fuel

pressure. Pressure should not be more than 34 kPa

(5 psi) lower than inlet port pressure test. If so,

replace fuel filter.

Fuel Supply Restriction Test:

Due to very small vacuum specifications, the DRB

scan tool along with the Periphal Expansion Port

(PEP) Module and 0±15 psi transducer must be used.

(10) Verify transfer pump pressure is OK before

performing restriction test.

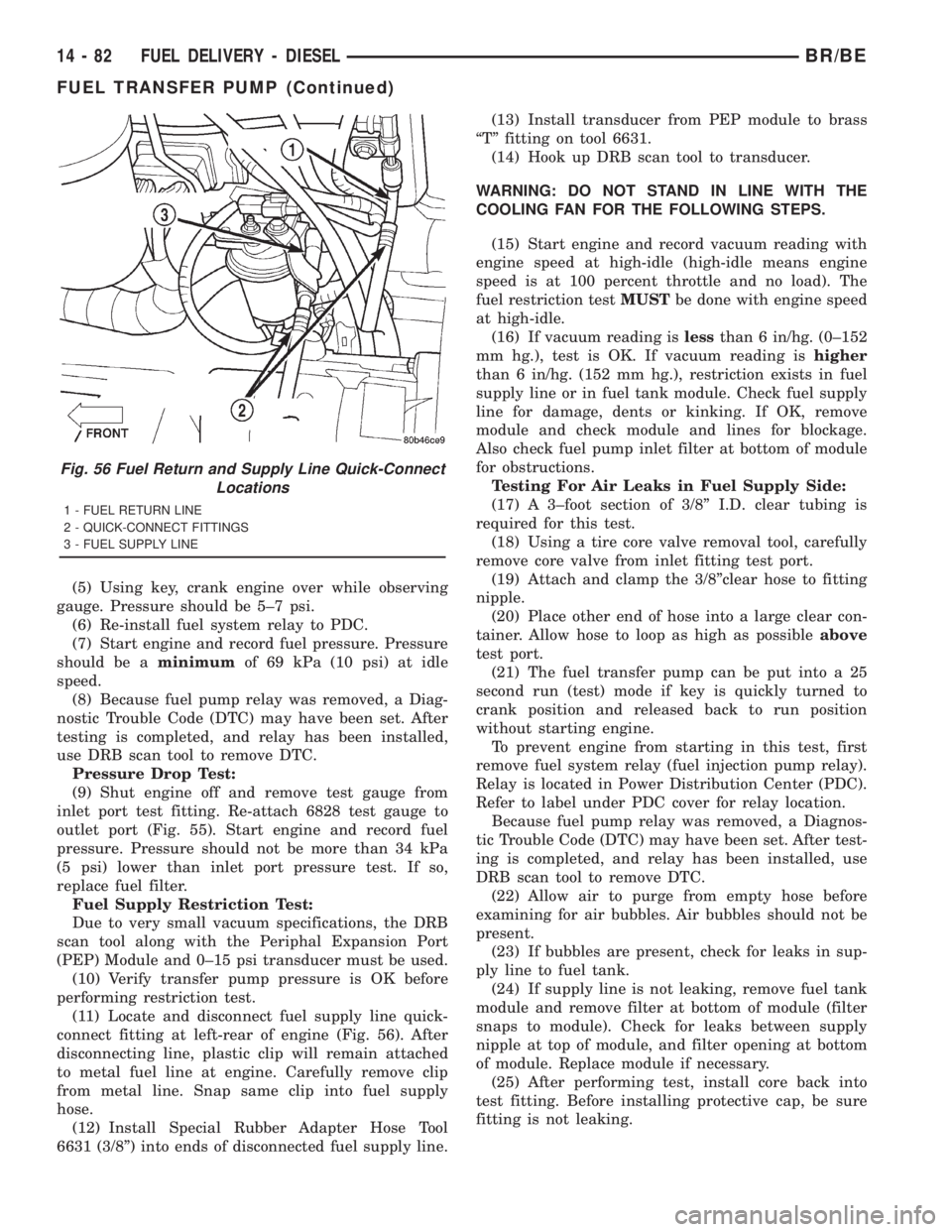

(11) Locate and disconnect fuel supply line quick-

connect fitting at left-rear of engine (Fig. 56). After

disconnecting line, plastic clip will remain attached

to metal fuel line at engine. Carefully remove clip

from metal line. Snap same clip into fuel supply

hose.

(12) Install Special Rubber Adapter Hose Tool

6631 (3/8º) into ends of disconnected fuel supply line.(13) Install transducer from PEP module to brass

ªTº fitting on tool 6631.

(14) Hook up DRB scan tool to transducer.

WARNING: DO NOT STAND IN LINE WITH THE

COOLING FAN FOR THE FOLLOWING STEPS.

(15) Start engine and record vacuum reading with

engine speed at high-idle (high-idle means engine

speed is at 100 percent throttle and no load). The

fuel restriction testMUSTbe done with engine speed

at high-idle.

(16) If vacuum reading islessthan 6 in/hg. (0±152

mm hg.), test is OK. If vacuum reading ishigher

than 6 in/hg. (152 mm hg.), restriction exists in fuel

supply line or in fuel tank module. Check fuel supply

line for damage, dents or kinking. If OK, remove

module and check module and lines for blockage.

Also check fuel pump inlet filter at bottom of module

for obstructions.

Testing For Air Leaks in Fuel Supply Side:

(17) A 3±foot section of 3/8º I.D. clear tubing is

required for this test.

(18) Using a tire core valve removal tool, carefully

remove core valve from inlet fitting test port.

(19) Attach and clamp the 3/8ºclear hose to fitting

nipple.

(20) Place other end of hose into a large clear con-

tainer. Allow hose to loop as high as possibleabove

test port.

(21) The fuel transfer pump can be put into a 25

second run (test) mode if key is quickly turned to

crank position and released back to run position

without starting engine.

To prevent engine from starting in this test, first

remove fuel system relay (fuel injection pump relay).

Relay is located in Power Distribution Center (PDC).

Refer to label under PDC cover for relay location.

Because fuel pump relay was removed, a Diagnos-

tic Trouble Code (DTC) may have been set. After test-

ing is completed, and relay has been installed, use

DRB scan tool to remove DTC.

(22) Allow air to purge from empty hose before

examining for air bubbles. Air bubbles should not be

present.

(23) If bubbles are present, check for leaks in sup-

ply line to fuel tank.

(24) If supply line is not leaking, remove fuel tank

module and remove filter at bottom of module (filter

snaps to module). Check for leaks between supply

nipple at top of module, and filter opening at bottom

of module. Replace module if necessary.

(25) After performing test, install core back into

test fitting. Before installing protective cap, be sure

fitting is not leaking.

Fig. 56 Fuel Return and Supply Line Quick-Connect

Locations

1 - FUEL RETURN LINE

2 - QUICK-CONNECT FITTINGS

3 - FUEL SUPPLY LINE

14 - 82 FUEL DELIVERY - DIESELBR/BE

FUEL TRANSFER PUMP (Continued)

Page 1570 of 2889

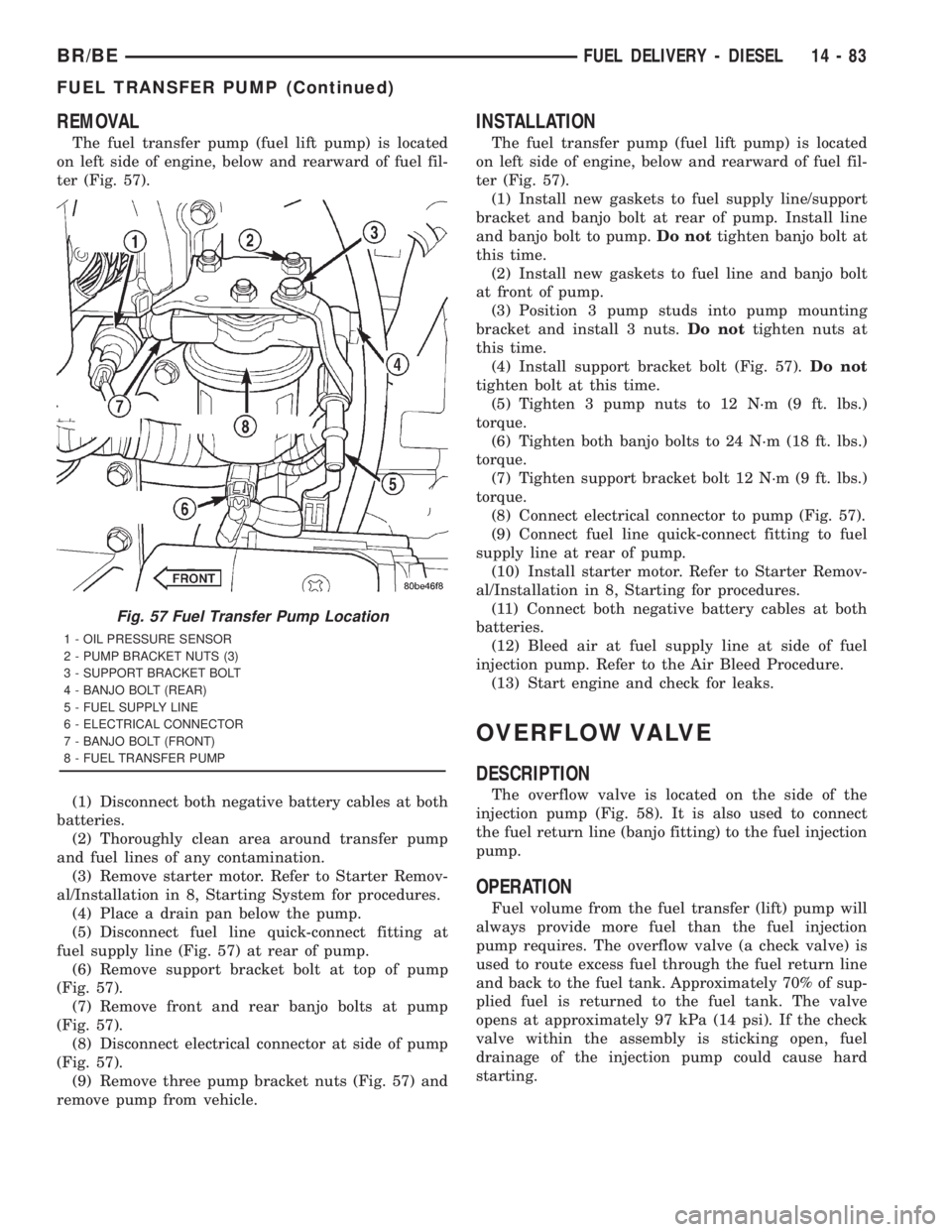

REMOVAL

The fuel transfer pump (fuel lift pump) is located

on left side of engine, below and rearward of fuel fil-

ter (Fig. 57).

(1) Disconnect both negative battery cables at both

batteries.

(2) Thoroughly clean area around transfer pump

and fuel lines of any contamination.

(3) Remove starter motor. Refer to Starter Remov-

al/Installation in 8, Starting System for procedures.

(4) Place a drain pan below the pump.

(5) Disconnect fuel line quick-connect fitting at

fuel supply line (Fig. 57) at rear of pump.

(6) Remove support bracket bolt at top of pump

(Fig. 57).

(7) Remove front and rear banjo bolts at pump

(Fig. 57).

(8) Disconnect electrical connector at side of pump

(Fig. 57).

(9) Remove three pump bracket nuts (Fig. 57) and

remove pump from vehicle.

INSTALLATION

The fuel transfer pump (fuel lift pump) is located

on left side of engine, below and rearward of fuel fil-

ter (Fig. 57).

(1) Install new gaskets to fuel supply line/support

bracket and banjo bolt at rear of pump. Install line

and banjo bolt to pump.Do nottighten banjo bolt at

this time.

(2) Install new gaskets to fuel line and banjo bolt

at front of pump.

(3) Position 3 pump studs into pump mounting

bracket and install 3 nuts.Do nottighten nuts at

this time.

(4) Install support bracket bolt (Fig. 57).Do not

tighten bolt at this time.

(5) Tighten 3 pump nuts to 12 N´m (9 ft. lbs.)

torque.

(6) Tighten both banjo bolts to 24 N´m (18 ft. lbs.)

torque.

(7) Tighten support bracket bolt 12 N´m (9 ft. lbs.)

torque.

(8) Connect electrical connector to pump (Fig. 57).

(9) Connect fuel line quick-connect fitting to fuel

supply line at rear of pump.

(10) Install starter motor. Refer to Starter Remov-

al/Installation in 8, Starting for procedures.

(11) Connect both negative battery cables at both

batteries.

(12) Bleed air at fuel supply line at side of fuel

injection pump. Refer to the Air Bleed Procedure.

(13) Start engine and check for leaks.

OVERFLOW VALVE

DESCRIPTION

The overflow valve is located on the side of the

injection pump (Fig. 58). It is also used to connect

the fuel return line (banjo fitting) to the fuel injection

pump.

OPERATION

Fuel volume from the fuel transfer (lift) pump will

always provide more fuel than the fuel injection

pump requires. The overflow valve (a check valve) is

used to route excess fuel through the fuel return line

and back to the fuel tank. Approximately 70% of sup-

plied fuel is returned to the fuel tank. The valve

opens at approximately 97 kPa (14 psi). If the check

valve within the assembly is sticking open, fuel

drainage of the injection pump could cause hard

starting.

Fig. 57 Fuel Transfer Pump Location

1 - OIL PRESSURE SENSOR

2 - PUMP BRACKET NUTS (3)

3 - SUPPORT BRACKET BOLT

4 - BANJO BOLT (REAR)

5 - FUEL SUPPLY LINE

6 - ELECTRICAL CONNECTOR

7 - BANJO BOLT (FRONT)

8 - FUEL TRANSFER PUMP

BR/BEFUEL DELIVERY - DIESEL 14 - 83

FUEL TRANSFER PUMP (Continued)