DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 171 of 2889

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install differential pinion and thrust washers.

(3) Install the pinion shaft.

(4) Align the hole in the pinion shaft with the hole

in the differential case and install the pinion shaft

lock screw.

(5) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

(1) Apply a coating of hypoid gear lubricant to the

differential bearings, bearing cups, and threaded

adjusters. A dab of grease can be used to keep the

adjusters in position. Carefully position the assem-

bled differential case in the housing.

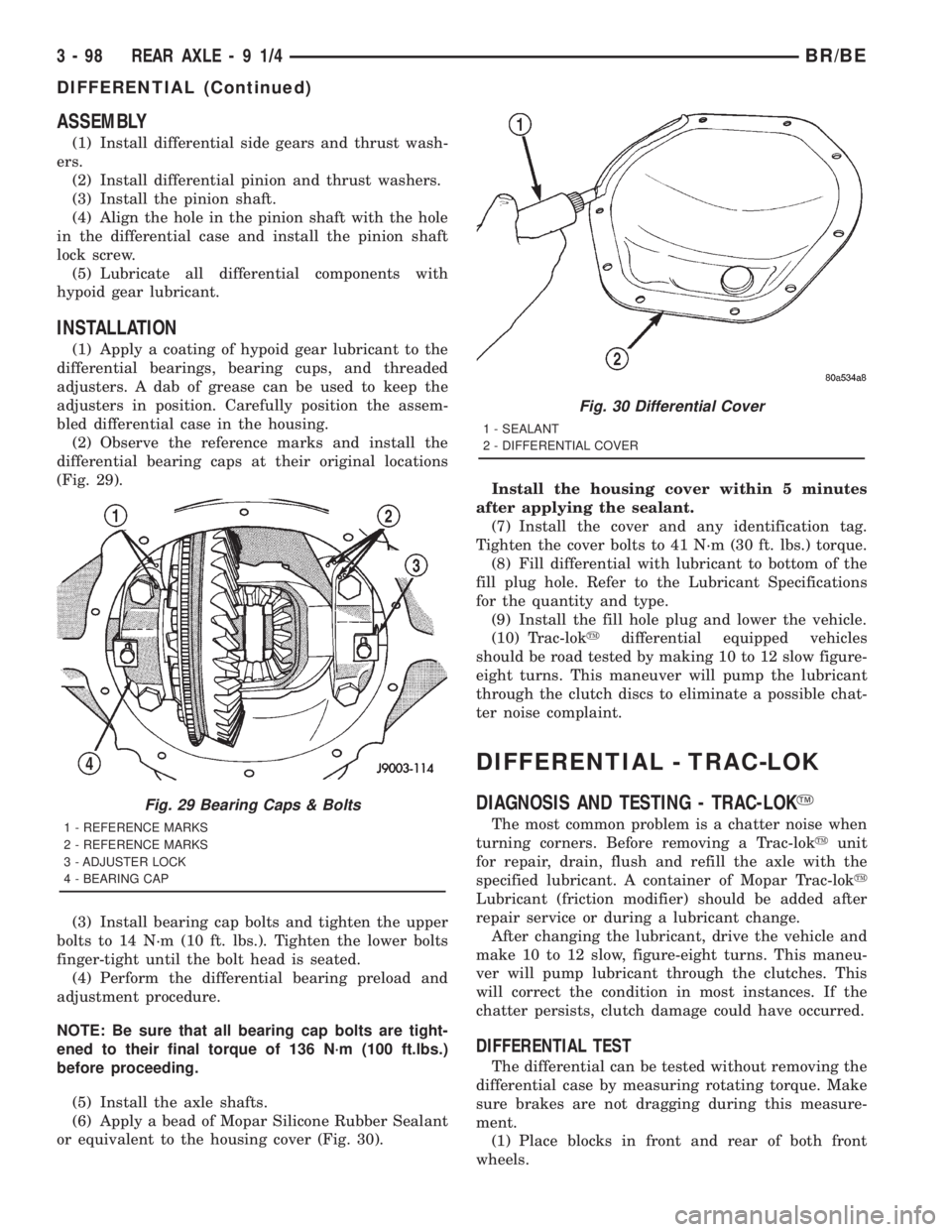

(2) Observe the reference marks and install the

differential bearing caps at their original locations

(Fig. 29).

(3) Install bearing cap bolts and tighten the upper

bolts to 14 N´m (10 ft. lbs.). Tighten the lower bolts

finger-tight until the bolt head is seated.

(4) Perform the differential bearing preload and

adjustment procedure.

NOTE: Be sure that all bearing cap bolts are tight-

ened to their final torque of 136 N´m (100 ft.lbs.)

before proceeding.

(5) Install the axle shafts.

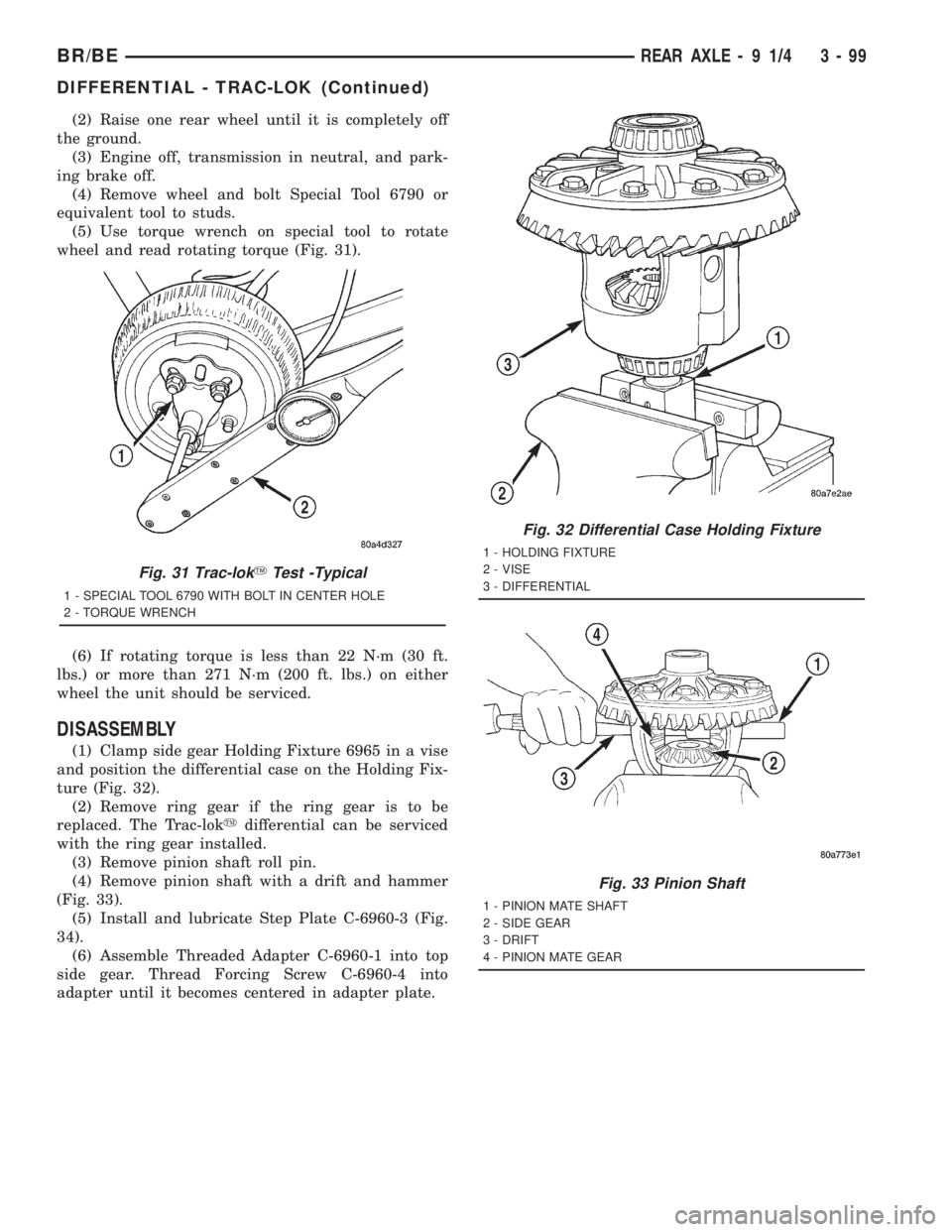

(6) Apply a bead of Mopar Silicone Rubber Sealant

or equivalent to the housing cover (Fig. 30).Install the housing cover within 5 minutes

after applying the sealant.

(7) Install the cover and any identification tag.

Tighten the cover bolts to 41 N´m (30 ft. lbs.) torque.

(8) Fill differential with lubricant to bottom of the

fill plug hole. Refer to the Lubricant Specifications

for the quantity and type.

(9) Install the fill hole plug and lower the vehicle.

(10) Trac-lokydifferential equipped vehicles

should be road tested by making 10 to 12 slow figure-

eight turns. This maneuver will pump the lubricant

through the clutch discs to eliminate a possible chat-

ter noise complaint.

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKY

The most common problem is a chatter noise when

turning corners. Before removing a Trac-lokyunit

for repair, drain, flush and refill the axle with the

specified lubricant. A container of Mopar Trac-loky

Lubricant (friction modifier) should be added after

repair service or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

Fig. 29 Bearing Caps & Bolts

1 - REFERENCE MARKS

2 - REFERENCE MARKS

3 - ADJUSTER LOCK

4 - BEARING CAP

Fig. 30 Differential Cover

1 - SEALANT

2 - DIFFERENTIAL COVER

3 - 98 REAR AXLE-91/4BR/BE

DIFFERENTIAL (Continued)

Page 172 of 2889

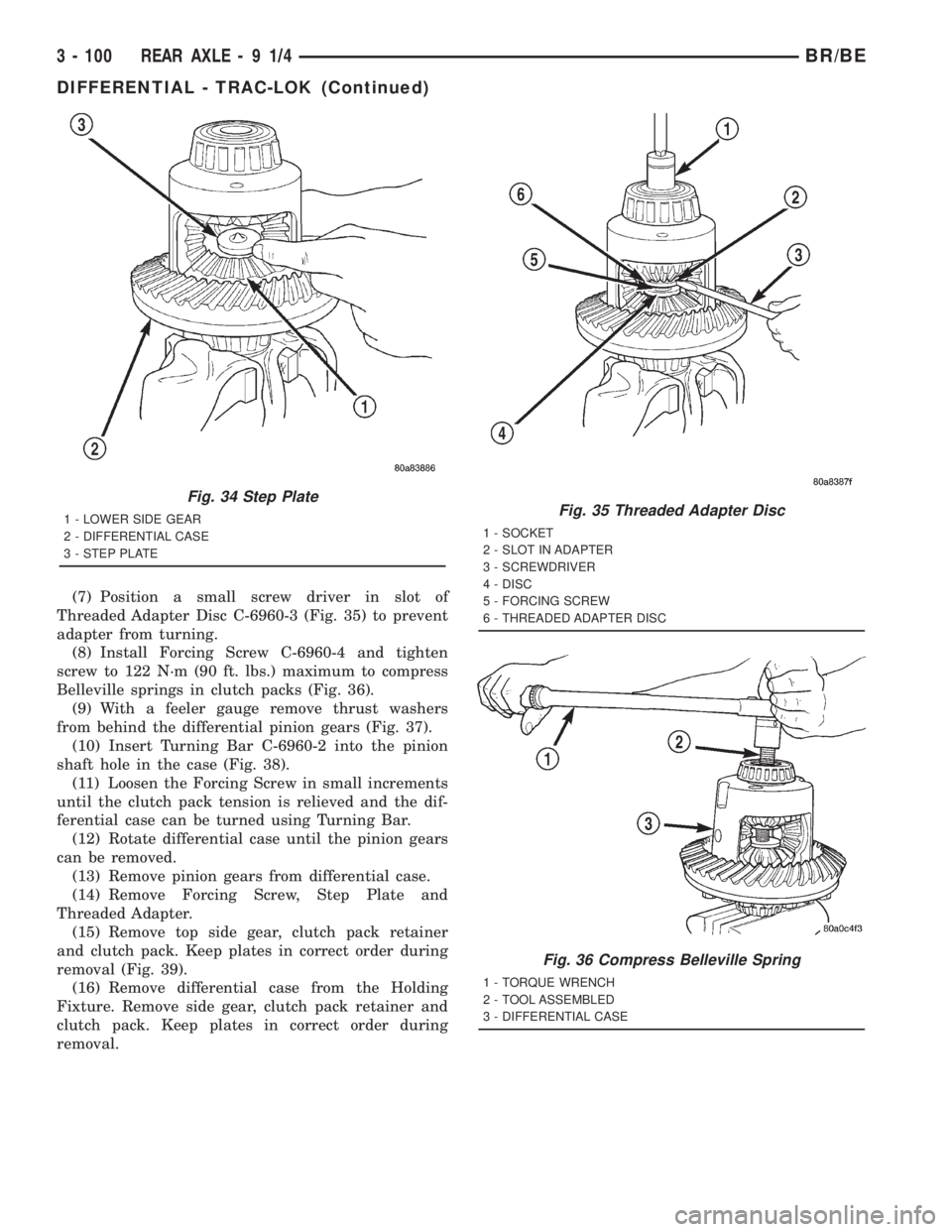

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 31).

(6) If rotating torque is less than 22 N´m (30 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

DISASSEMBLY

(1) Clamp side gear Holding Fixture 6965 in a vise

and position the differential case on the Holding Fix-

ture (Fig. 32).

(2) Remove ring gear if the ring gear is to be

replaced. The Trac-lokydifferential can be serviced

with the ring gear installed.

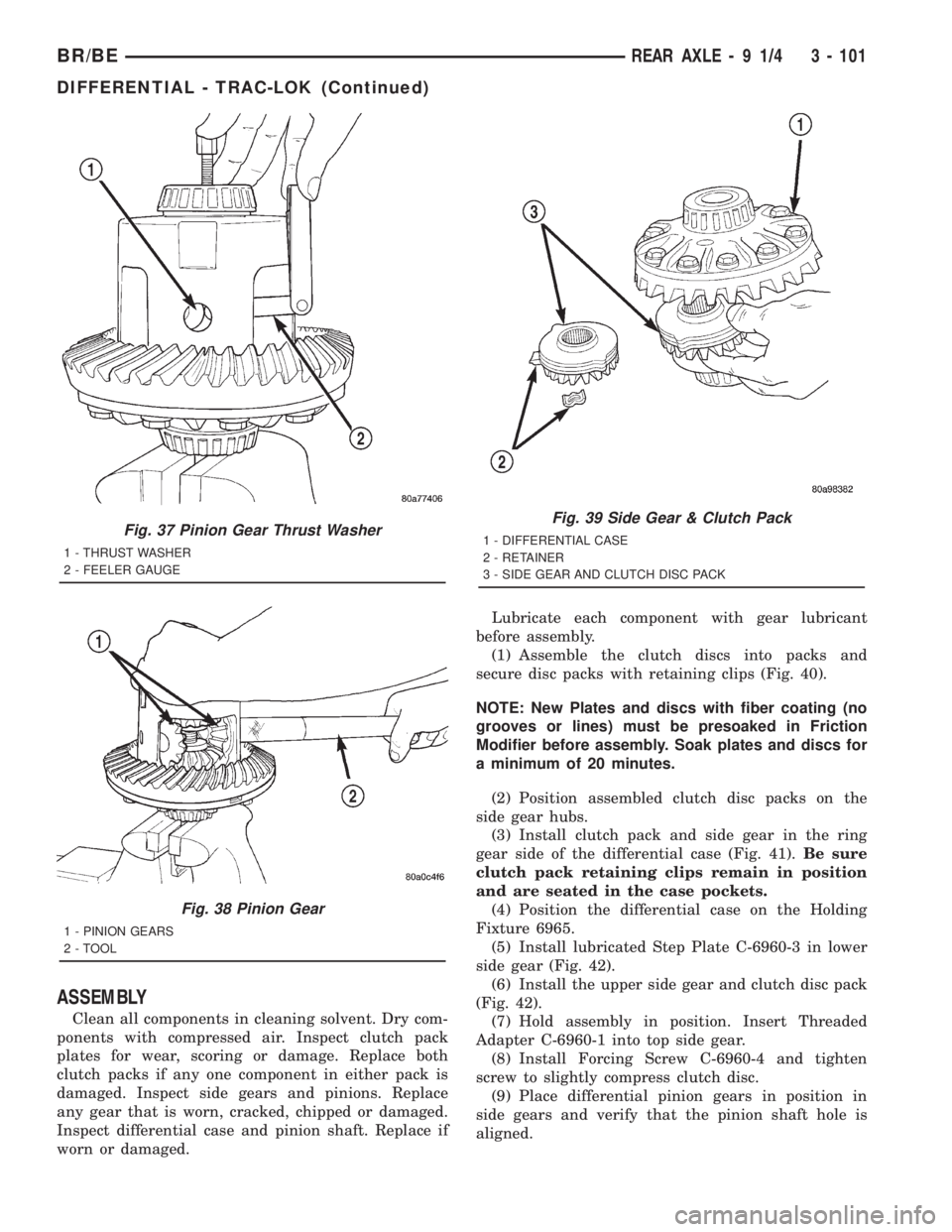

(3) Remove pinion shaft roll pin.

(4) Remove pinion shaft with a drift and hammer

(Fig. 33).

(5) Install and lubricate Step Plate C-6960-3 (Fig.

34).

(6) Assemble Threaded Adapter C-6960-1 into top

side gear. Thread Forcing Screw C-6960-4 into

adapter until it becomes centered in adapter plate.

Fig. 31 Trac-lokYTest -Typical

1 - SPECIAL TOOL 6790 WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 32 Differential Case Holding Fixture

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

Fig. 33 Pinion Shaft

1 - PINION MATE SHAFT

2 - SIDE GEAR

3 - DRIFT

4 - PINION MATE GEAR

BR/BEREAR AXLE - 9 1/4 3 - 99

DIFFERENTIAL - TRAC-LOK (Continued)

Page 173 of 2889

(7) Position a small screw driver in slot of

Threaded Adapter Disc C-6960-3 (Fig. 35) to prevent

adapter from turning.

(8) Install Forcing Screw C-6960-4 and tighten

screw to 122 N´m (90 ft. lbs.) maximum to compress

Belleville springs in clutch packs (Fig. 36).

(9) With a feeler gauge remove thrust washers

from behind the differential pinion gears (Fig. 37).

(10) Insert Turning Bar C-6960-2 into the pinion

shaft hole in the case (Fig. 38).

(11) Loosen the Forcing Screw in small increments

until the clutch pack tension is relieved and the dif-

ferential case can be turned using Turning Bar.

(12) Rotate differential case until the pinion gears

can be removed.

(13) Remove pinion gears from differential case.

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

(15) Remove top side gear, clutch pack retainer

and clutch pack. Keep plates in correct order during

removal (Fig. 39).

(16) Remove differential case from the Holding

Fixture. Remove side gear, clutch pack retainer and

clutch pack. Keep plates in correct order during

removal.

Fig. 34 Step Plate

1 - LOWER SIDE GEAR

2 - DIFFERENTIAL CASE

3 - STEP PLATEFig. 35 Threaded Adapter Disc

1 - SOCKET

2 - SLOT IN ADAPTER

3 - SCREWDRIVER

4 - DISC

5 - FORCING SCREW

6 - THREADED ADAPTER DISC

Fig. 36 Compress Belleville Spring

1 - TORQUE WRENCH

2 - TOOL ASSEMBLED

3 - DIFFERENTIAL CASE

3 - 100 REAR AXLE-91/4BR/BE

DIFFERENTIAL - TRAC-LOK (Continued)

Page 174 of 2889

ASSEMBLY

Clean all components in cleaning solvent. Dry com-

ponents with compressed air. Inspect clutch pack

plates for wear, scoring or damage. Replace both

clutch packs if any one component in either pack is

damaged. Inspect side gears and pinions. Replace

any gear that is worn, cracked, chipped or damaged.

Inspect differential case and pinion shaft. Replace if

worn or damaged.Lubricate each component with gear lubricant

before assembly.

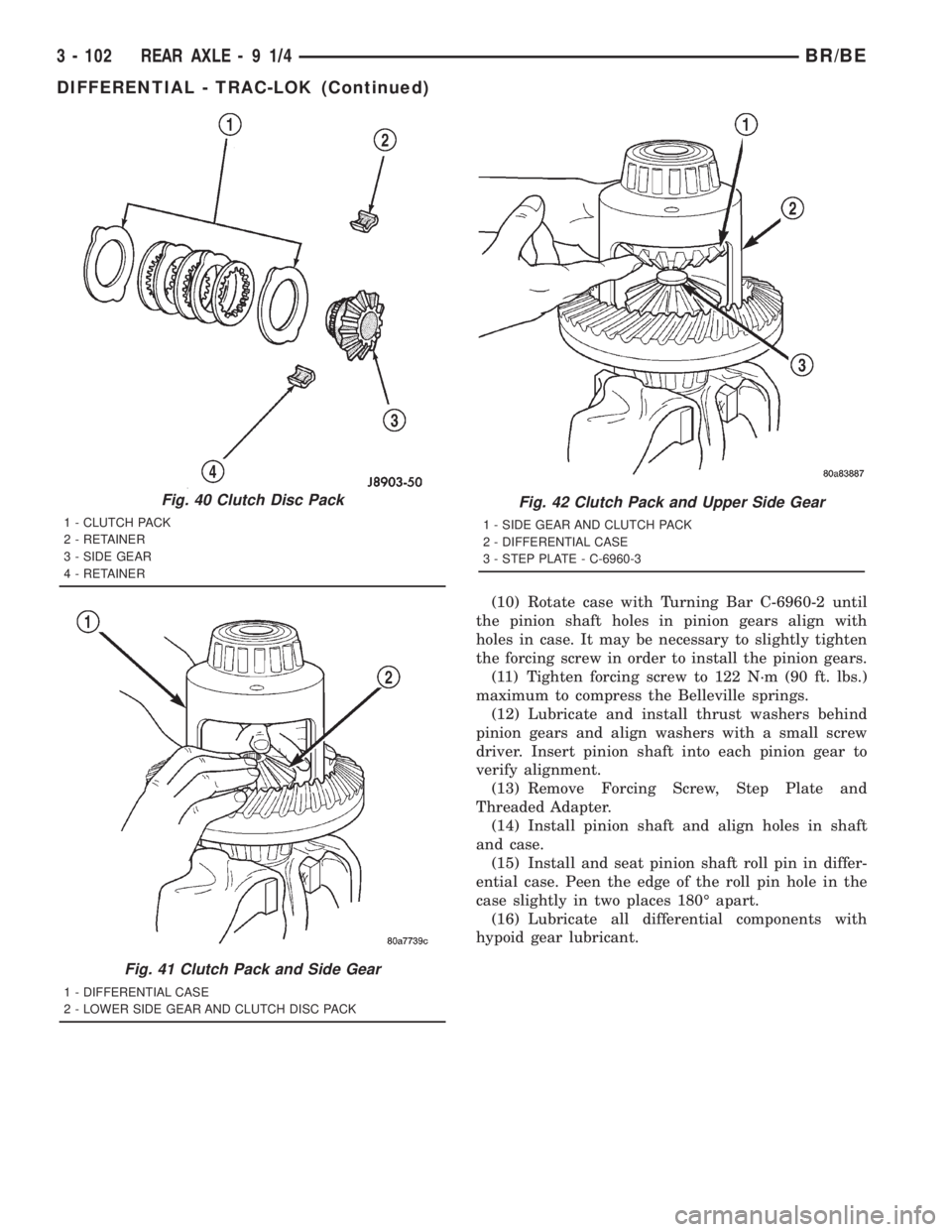

(1) Assemble the clutch discs into packs and

secure disc packs with retaining clips (Fig. 40).

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.

(2) Position assembled clutch disc packs on the

side gear hubs.

(3) Install clutch pack and side gear in the ring

gear side of the differential case (Fig. 41).Be sure

clutch pack retaining clips remain in position

and are seated in the case pockets.

(4) Position the differential case on the Holding

Fixture 6965.

(5) Install lubricated Step Plate C-6960-3 in lower

side gear (Fig. 42).

(6) Install the upper side gear and clutch disc pack

(Fig. 42).

(7) Hold assembly in position. Insert Threaded

Adapter C-6960-1 into top side gear.

(8) Install Forcing Screw C-6960-4 and tighten

screw to slightly compress clutch disc.

(9) Place differential pinion gears in position in

side gears and verify that the pinion shaft hole is

aligned.

Fig. 37 Pinion Gear Thrust Washer

1 - THRUST WASHER

2 - FEELER GAUGE

Fig. 38 Pinion Gear

1 - PINION GEARS

2 - TOOL

Fig. 39 Side Gear & Clutch Pack

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

BR/BEREAR AXLE - 9 1/4 3 - 101

DIFFERENTIAL - TRAC-LOK (Continued)

Page 175 of 2889

(10) Rotate case with Turning Bar C-6960-2 until

the pinion shaft holes in pinion gears align with

holes in case. It may be necessary to slightly tighten

the forcing screw in order to install the pinion gears.

(11) Tighten forcing screw to 122 N´m (90 ft. lbs.)

maximum to compress the Belleville springs.

(12) Lubricate and install thrust washers behind

pinion gears and align washers with a small screw

driver. Insert pinion shaft into each pinion gear to

verify alignment.

(13) Remove Forcing Screw, Step Plate and

Threaded Adapter.

(14) Install pinion shaft and align holes in shaft

and case.

(15) Install and seat pinion shaft roll pin in differ-

ential case. Peen the edge of the roll pin hole in the

case slightly in two places 180É apart.

(16) Lubricate all differential components with

hypoid gear lubricant.

Fig. 40 Clutch Disc Pack

1 - CLUTCH PACK

2 - RETAINER

3 - SIDE GEAR

4 - RETAINER

Fig. 41 Clutch Pack and Side Gear

1 - DIFFERENTIAL CASE

2 - LOWER SIDE GEAR AND CLUTCH DISC PACK

Fig. 42 Clutch Pack and Upper Side Gear

1 - SIDE GEAR AND CLUTCH PACK

2 - DIFFERENTIAL CASE

3 - STEP PLATE - C-6960-3

3 - 102 REAR AXLE-91/4BR/BE

DIFFERENTIAL - TRAC-LOK (Continued)

Page 176 of 2889

DIFFERENTIAL CASE

BEARINGS

REMOVAL

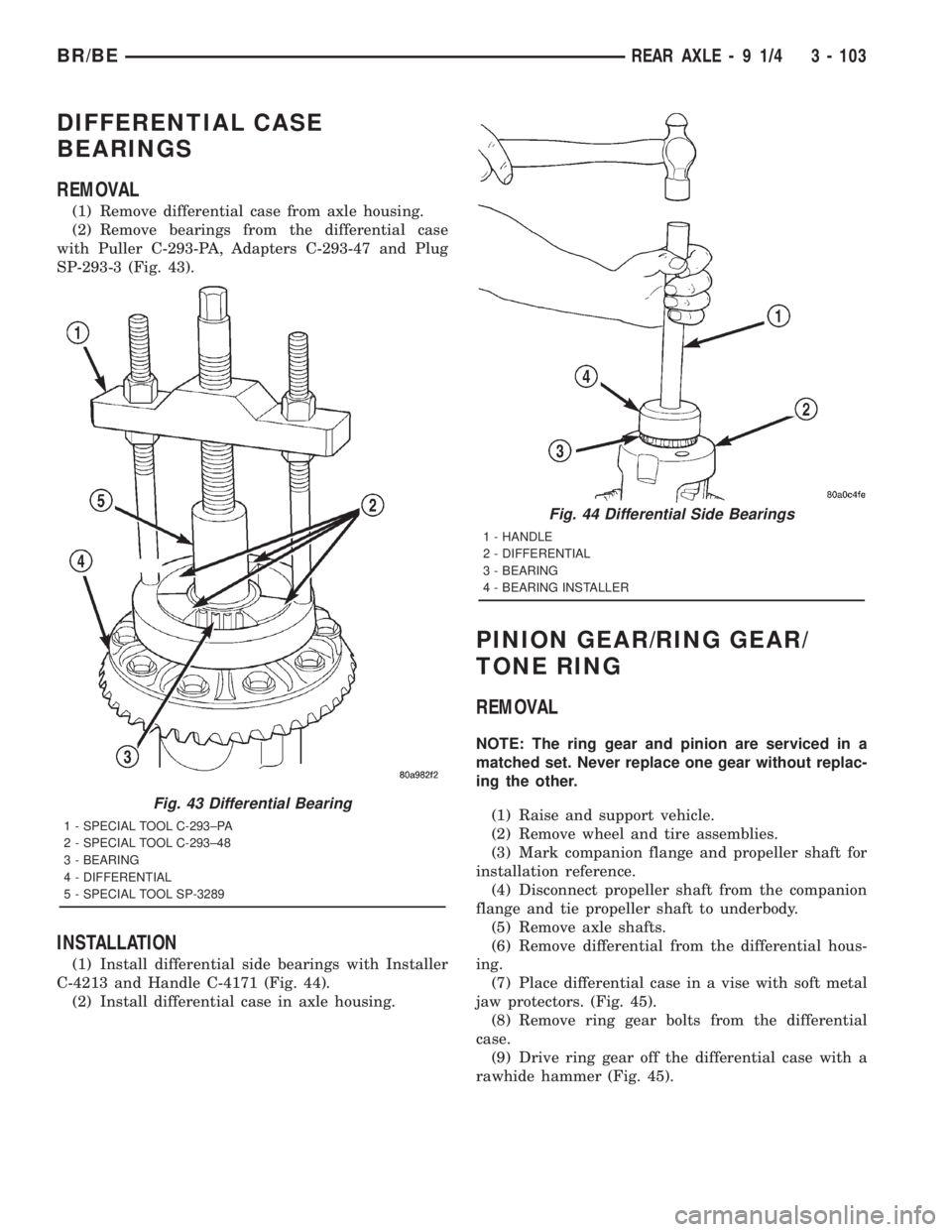

(1) Remove differential case from axle housing.

(2) Remove bearings from the differential case

with Puller C-293-PA, Adapters C-293-47 and Plug

SP-293-3 (Fig. 43).

INSTALLATION

(1) Install differential side bearings with Installer

C-4213 and Handle C-4171 (Fig. 44).

(2) Install differential case in axle housing.

PINION GEAR/RING GEAR/

TONE RING

REMOVAL

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one gear without replac-

ing the other.

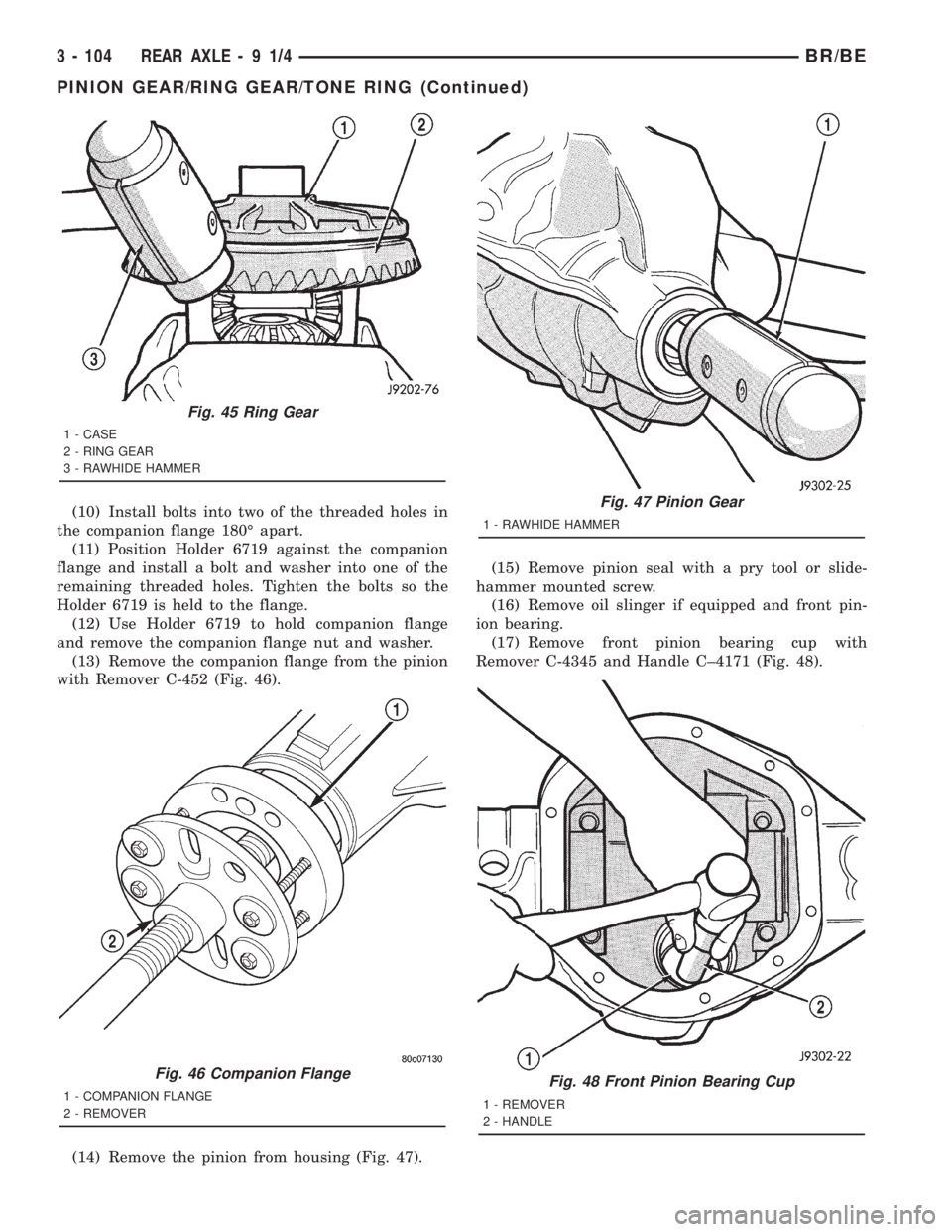

(1) Raise and support vehicle.

(2) Remove wheel and tire assemblies.

(3) Mark companion flange and propeller shaft for

installation reference.

(4) Disconnect propeller shaft from the companion

flange and tie propeller shaft to underbody.

(5) Remove axle shafts.

(6) Remove differential from the differential hous-

ing.

(7) Place differential case in a vise with soft metal

jaw protectors. (Fig. 45).

(8) Remove ring gear bolts from the differential

case.

(9) Drive ring gear off the differential case with a

rawhide hammer (Fig. 45).

Fig. 43 Differential Bearing

1 - SPECIAL TOOL C-293±PA

2 - SPECIAL TOOL C-293±48

3 - BEARING

4 - DIFFERENTIAL

5 - SPECIAL TOOL SP-3289

Fig. 44 Differential Side Bearings

1 - HANDLE

2 - DIFFERENTIAL

3 - BEARING

4 - BEARING INSTALLER

BR/BEREAR AXLE - 9 1/4 3 - 103

Page 177 of 2889

(10) Install bolts into two of the threaded holes in

the companion flange 180É apart.

(11) Position Holder 6719 against the companion

flange and install a bolt and washer into one of the

remaining threaded holes. Tighten the bolts so the

Holder 6719 is held to the flange.

(12) Use Holder 6719 to hold companion flange

and remove the companion flange nut and washer.

(13) Remove the companion flange from the pinion

with Remover C-452 (Fig. 46).

(14) Remove the pinion from housing (Fig. 47).(15) Remove pinion seal with a pry tool or slide-

hammer mounted screw.

(16) Remove oil slinger if equipped and front pin-

ion bearing.

(17) Remove front pinion bearing cup with

Remover C-4345 and Handle C±4171 (Fig. 48).

Fig. 45 Ring Gear

1 - CASE

2 - RING GEAR

3 - RAWHIDE HAMMER

Fig. 46 Companion Flange

1 - COMPANION FLANGE

2 - REMOVER

Fig. 47 Pinion Gear

1 - RAWHIDE HAMMER

Fig. 48 Front Pinion Bearing Cup

1 - REMOVER

2 - HANDLE

3 - 104 REAR AXLE-91/4BR/BE

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 178 of 2889

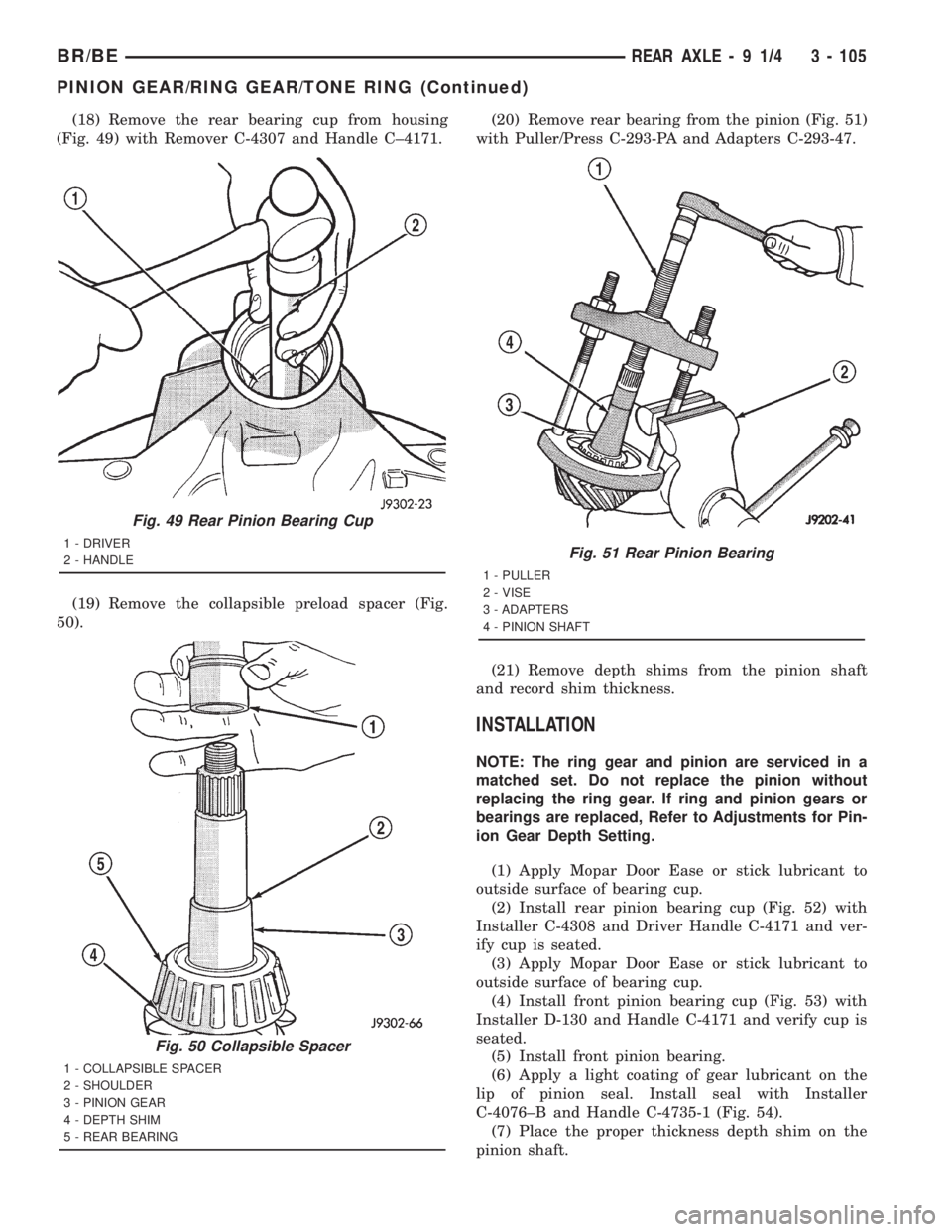

(18) Remove the rear bearing cup from housing

(Fig. 49) with Remover C-4307 and Handle C±4171.

(19) Remove the collapsible preload spacer (Fig.

50).(20) Remove rear bearing from the pinion (Fig. 51)

with Puller/Press C-293-PA and Adapters C-293-47.

(21) Remove depth shims from the pinion shaft

and record shim thickness.

INSTALLATION

NOTE: The ring gear and pinion are serviced in a

matched set. Do not replace the pinion without

replacing the ring gear. If ring and pinion gears or

bearings are replaced, Refer to Adjustments for Pin-

ion Gear Depth Setting.

(1) Apply Mopar Door Ease or stick lubricant to

outside surface of bearing cup.

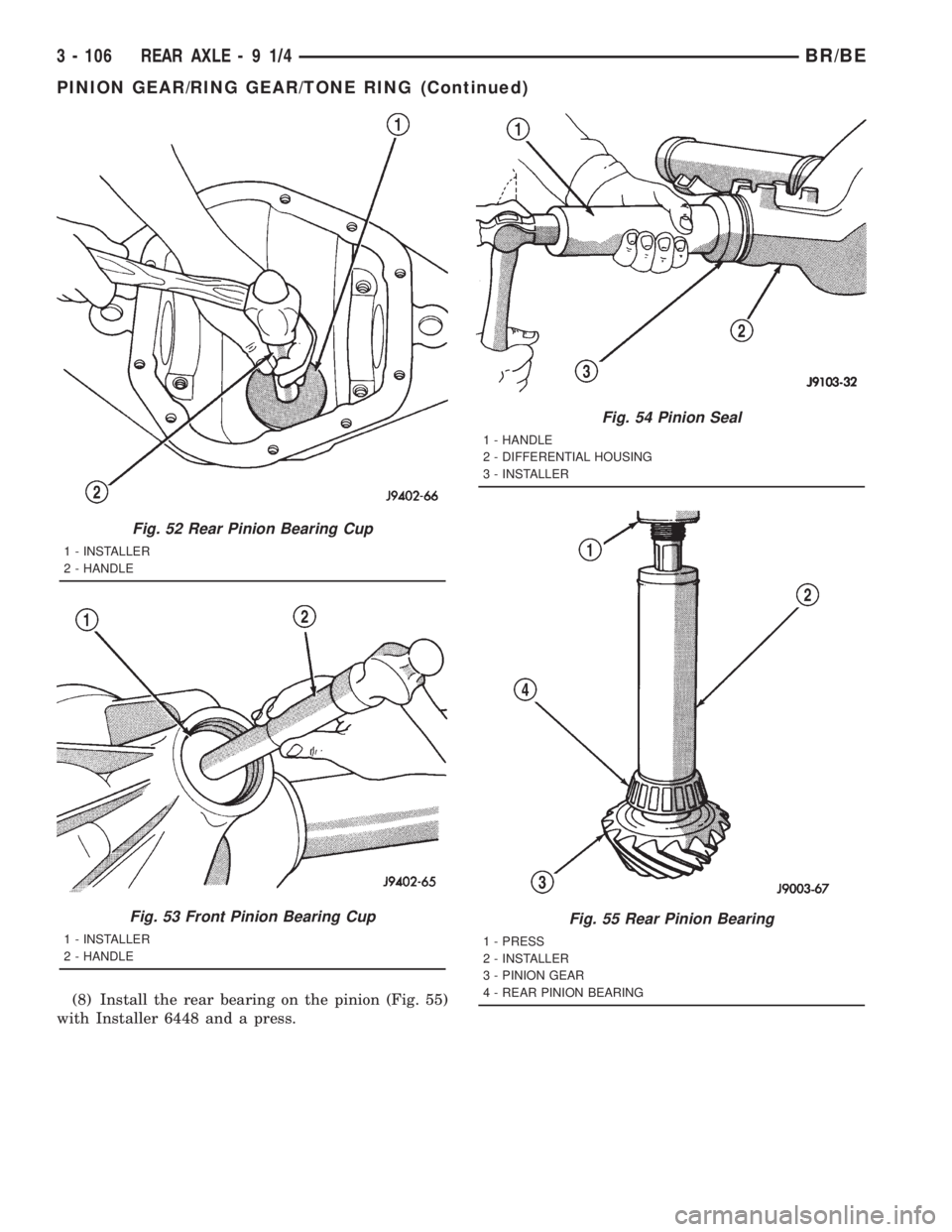

(2) Install rear pinion bearing cup (Fig. 52) with

Installer C-4308 and Driver Handle C-4171 and ver-

ify cup is seated.

(3) Apply Mopar Door Ease or stick lubricant to

outside surface of bearing cup.

(4) Install front pinion bearing cup (Fig. 53) with

Installer D-130 and Handle C-4171 and verify cup is

seated.

(5) Install front pinion bearing.

(6) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with Installer

C-4076±B and Handle C-4735-1 (Fig. 54).

(7) Place the proper thickness depth shim on the

pinion shaft.

Fig. 49 Rear Pinion Bearing Cup

1 - DRIVER

2 - HANDLE

Fig. 50 Collapsible Spacer

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION GEAR

4 - DEPTH SHIM

5 - REAR BEARING

Fig. 51 Rear Pinion Bearing

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - PINION SHAFT

BR/BEREAR AXLE - 9 1/4 3 - 105

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 179 of 2889

(8) Install the rear bearing on the pinion (Fig. 55)

with Installer 6448 and a press.

Fig. 52 Rear Pinion Bearing Cup

1 - INSTALLER

2 - HANDLE

Fig. 53 Front Pinion Bearing Cup

1 - INSTALLER

2 - HANDLE

Fig. 54 Pinion Seal

1 - HANDLE

2 - DIFFERENTIAL HOUSING

3 - INSTALLER

Fig. 55 Rear Pinion Bearing

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - REAR PINION BEARING

3 - 106 REAR AXLE-91/4BR/BE

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 180 of 2889

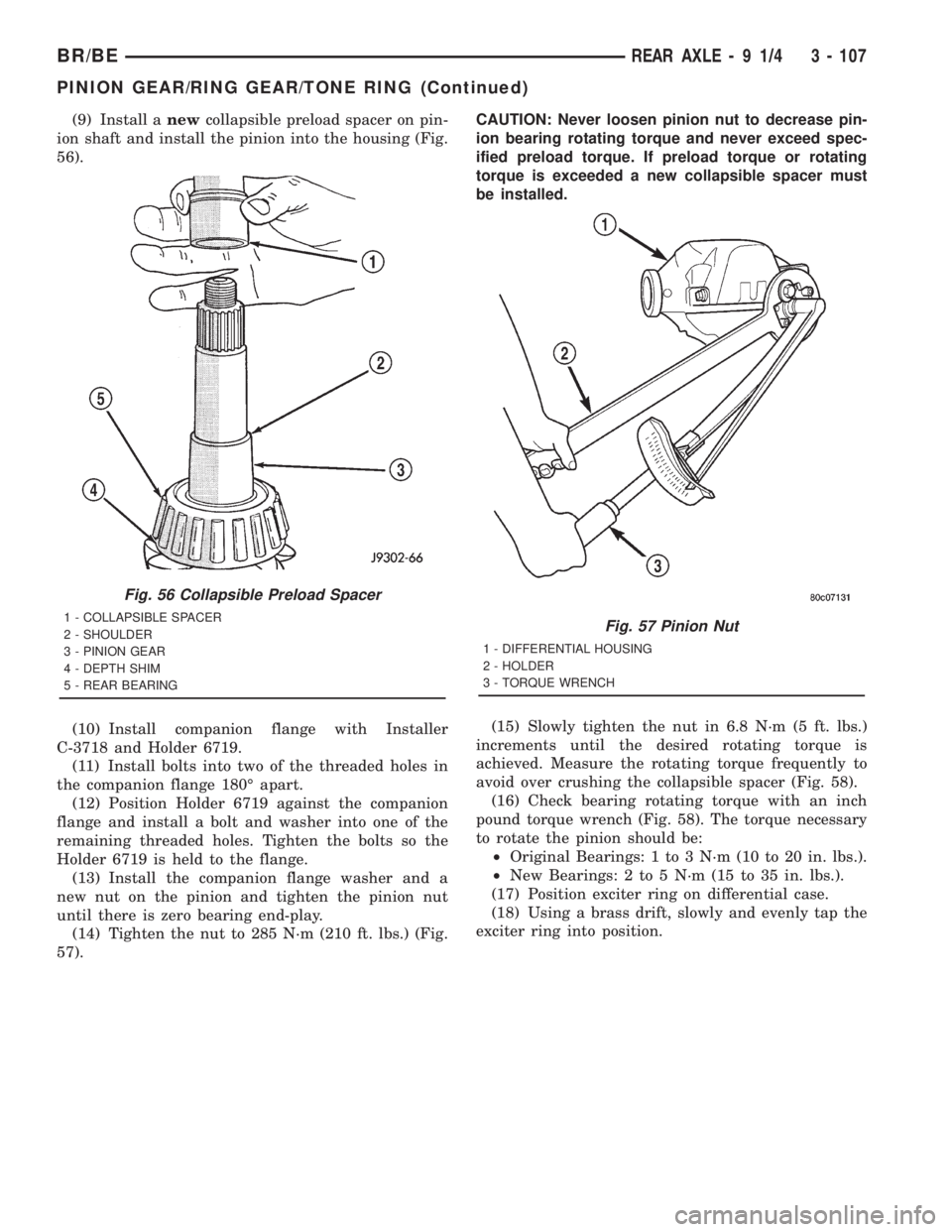

(9) Install anewcollapsible preload spacer on pin-

ion shaft and install the pinion into the housing (Fig.

56).

(10) Install companion flange with Installer

C-3718 and Holder 6719.

(11) Install bolts into two of the threaded holes in

the companion flange 180É apart.

(12) Position Holder 6719 against the companion

flange and install a bolt and washer into one of the

remaining threaded holes. Tighten the bolts so the

Holder 6719 is held to the flange.

(13) Install the companion flange washer and a

new nut on the pinion and tighten the pinion nut

until there is zero bearing end-play.

(14) Tighten the nut to 285 N´m (210 ft. lbs.) (Fig.

57).CAUTION: Never loosen pinion nut to decrease pin-

ion bearing rotating torque and never exceed spec-

ified preload torque. If preload torque or rotating

torque is exceeded a new collapsible spacer must

be installed.

(15) Slowly tighten the nut in 6.8 N´m (5 ft. lbs.)

increments until the desired rotating torque is

achieved. Measure the rotating torque frequently to

avoid over crushing the collapsible spacer (Fig. 58).

(16) Check bearing rotating torque with an inch

pound torque wrench (Fig. 58). The torque necessary

to rotate the pinion should be:

²Original Bearings: 1 to 3 N´m (10 to 20 in. lbs.).

²New Bearings: 2 to 5 N´m (15 to 35 in. lbs.).

(17) Position exciter ring on differential case.

(18) Using a brass drift, slowly and evenly tap the

exciter ring into position.

Fig. 56 Collapsible Preload Spacer

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION GEAR

4 - DEPTH SHIM

5 - REAR BEARINGFig. 57 Pinion Nut

1 - DIFFERENTIAL HOUSING

2 - HOLDER

3 - TORQUE WRENCH

BR/BEREAR AXLE - 9 1/4 3 - 107

PINION GEAR/RING GEAR/TONE RING (Continued)