spark plugs replace DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 30 of 2889

²Inspect brake linings.

³Off-the-highway operation, trailer towing snow

plowing, prolonged operation with heavy loading,

especially in hot weather require the more frequent

transmission service indicated with an ³ in Schedule

ªBº. Perform these services if the vehicle is usually

operated under these conditions.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

DESCRIPTION - HEAVY DUTY ENGINE

(FEDERAL ONLY ± 2500 8.0L HD AND 3500

5.9L& 8.0L MODELS) MAINTENANCE

SCHEDULES

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to. Use the schedule that best

describes these conditions.

ScheduleªAº, lists all the scheduled maintenance

to be performed under normal operating conditions

for Heavy Duty vehicles.

ScheduleªBº, lists maintenance recommended for

Heavy Duty vehicles operated under the conditions

listed at the beginning of that schedule.

²Where time and mileage are listed, follow the

interval that occurs first.

At Each Stop For Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

²Clean windshield and wiper blades as required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.

²Check fluid levels of coolant reservoir, power

steering and transmission and add as needed.

²Check all lights and all other electrical items for

correct operation.

²Inspect and clean wiper blades. Replace if

required.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses.

²Adjust rear brakes.

²Rotate the tires at each oil change interval

shown on schedule ªAº (6,000 Miles) or every other

interval shown on schedule ªBº (6,000 Miles).

²Check engine coolant level, hoses, and clamps.

²Lubricate steering linkage.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

FLUID FILL LOCATIONS AND LUBRICATION

POINTS

The fluid fill/check locations and lubrication points

are located in each applicable group.

HEAVY DUTY SCHEDULE ªAº

6,000 miles (10 000 km) or at 6 months

²Change engine oil.

²Replace engine oil filter.

12,000 Miles (19 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

²Inspect engine air cleaner element, replace

as necessary (8.0L only).

18,000 Miles (29 000 km) or at 18 months

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings

²Inspect front wheel bearings. Clean and repack,

if required (4x4).

24,000 Miles (38 000 km) or at 24 months

²Change engine oil.

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

30,000 Miles (48 000 km) or at 30 months

²Change engine oil.

²Replace engine oil filter.

²Replace spark plugs.

36,000 Miles (58 000 km) or at 36 months

²Change engine oil.

²Replace engine oil filter.

BR/BELUBRICATION & MAINTENANCE 0 - 17

MAINTENANCE SCHEDULES (Continued)

Page 31 of 2889

²Drain and refill transfer case fluid.

²Inspect brake linings.

²Flush and replace engine coolant at 36 months,

regardless of mileage.

²Inspect front wheel bearings. Clean and repack,

if required (4x4).

²Inspect engine air cleaner element, replace

as necessary (8.0L only).

42,000 Miles (67 000 km) or at 42 months

²Change engine oil.

²Replace engine oil filter.

48,000 Miles (77 000 km) or at 48 months)

²Change engine oil.

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

²Flush and replace engine coolant if not done at

36 months.

54,000 Miles (86 000 km) or at 54 months

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

²Inspect front wheel bearings. Clean and repack,

if required (4x4).

60,000 Miles (96 000 km) or at 60 months

²Change engine oil.

²Replace engine oil filter.

²Replace ignition cables.

²Replace PCV valve (5.9L).*

²Replace distributor cap and rotor (5.9L

only).

²Replace spark plugs.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

²Inspect engine air cleaner element, replace

as necessary (8.0L only).

66,000 Miles (106 000 km) or at 66 months

²Change engine oil.

²Replace engine oil filter.

72,000 Miles (115 000 km) or at 72 months

²Change engine oil.

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Drain and refill transfer case fluid.

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Inspect front wheel bearings. Clean and repack,

if required (all).

²Inspect brake linings.

78,000 Miles (125 000 km) or at 78 months

²Change engine oil.

²Replace engine oil filter.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

82,500 Miles (132 000 km) or at 82 months

²Replace oxygen sensor (5.9L only).*

84,000 Miles (134 000 km) or at 84 months

²Change engine oil.

²Replace engine oil filter.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

²Inspect engine air cleaner element, replace

as necessary (8.0L only).

90,000 Miles (144 000 km) or at 90 months

²Change engine oil.

²Replace engine oil filter.

²Replace spark plugs.

²Inspect brake linings.

²Inspect front wheel bearings. Clean and repack,

if required (4x4).

96,000 Miles (154 000 km) or at 96 months

²Change engine oil.

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

102,000 Miles (163 000 km) or at 102 months

²Change engine oil.

²Replace engine oil filter.

108,000 Miles (173 000 km) or at 108 months

²Change engine oil.

²Replace engine oil filter.

²Drain and refill transfer case fluid.

²Inspect brake linings.

0 - 18 LUBRICATION & MAINTENANCEBR/BE

MAINTENANCE SCHEDULES (Continued)

Page 32 of 2889

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

²Inspect front wheel bearings. Clean and repack,

if required (4x4).

²Inspect engine air cleaner element, replace

as necessary (8.0L only).

*Requires Service Reminder Indicator Light. If so

equipped, these parts are to be replaced at the indi-

cated mileage or when the service reminder indicator

light remains on continuously with the key in the

ªONº position, whichever occurs first.

HEAVY DUTY SCHEDULE ªBº

Follow this schedule if the vehicle is usually oper-

ated under one or more of the following conditions.

²Frequent short trips driving less than 5 miles

(8km)

²Frequent driving in dusty conditions

²Frequent trailer towing

²Extensive idling

²More than 50% of the driving is at sustained

high speeds during hot weather, above 90ÉF (32ÉC)

3,000 Miles (5 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

6,000 Miles (10 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

9,000 Miles (14 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x2).

12,000 Miles (19 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect engine air cleaner element and air

pump filter, replace as necessary.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.³

²Change rear axle fluid.

²Change front axle fluid (4x4).

²Inspect brake linings.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

15,000 Miles (24 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

18,000 Miles (29 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

²Inspect front wheel bearings (4x2).

²Drain and refill transfer case fluid every 18,000

miles (4x4).

21,000 Miles (34 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

24,000 Miles (38 000 km)

²Change engine oil

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Change rear axle fluid.

²Change front axle fluid (4x4).

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

²Inspect brake linings.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

27,000 Miles (43 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x2).

30,000 Miles (48 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect PCV valve, replace as necessary

(5.9L).

²Replace spark plugs.

²Inspect front wheel bearings (4x4).

BR/BELUBRICATION & MAINTENANCE 0 - 19

MAINTENANCE SCHEDULES (Continued)

Page 33 of 2889

33,000 Miles (53 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

36,000 Miles (58 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect engine air cleaner element and air

pump filter, replace as necessary.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.³

²Drain and refill transfer case (4x4).

²Change rear axle fluid.

²Change front axle fluid (4x4).

²Inspect brake linings.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

²Inspect front wheel bearings (4x2).

39,000 Miles (62 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

42,000 Miles (67 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

45,000 Miles (72 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x2).

²Flush and replace engine coolant (36 months).

48,000 Miles (77 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Change rear axle fluid.

²Change front axle fluid (4x4).

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Inspect front wheel bearings. Clean and repack,

if required (4x2).²Inspect brake linings.

²Flush and replace engine coolant.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

²Drain and refill transfer case fluid every 18,000

miles (4x4).

51,000 Miles (82 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

54,000 Miles (86 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

²Inspect front wheel bearings (4x2).

²Drain and refill transfer case (4x4).

57,000 Miles (91 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

60,000 Miles (96 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect engine air cleaner element and air

pump filter, replace as necessary.

²Replace PCV valve (5.9L).*

²Replace distributor cap and rotor (5.9L).

²Replace ignition cables.

²Replace spark plugs.

²Clean EGR passages (5.9L if so equipped).*

²Replace EGR valve (5.9L if so equipped).*

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.³

²Change rear axle fluid.

²Change front axle fluid (4x4).

²Inspect brake linings.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

63,000 Miles (101 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x2).

0 - 20 LUBRICATION & MAINTENANCEBR/BE

MAINTENANCE SCHEDULES (Continued)

Page 34 of 2889

66,000 Miles (106 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

69,000 Miles (110 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

72, 000 Miles (115 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Drain and refill transfer case fluid (4x4).

²Change rear axle fluid.

²Change front axle fluid (4x4).

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

²Inspect brake linings.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

²Inspect front wheel bearings (4x2).

75,000 Miles (120 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

78,000 Miles (125 000 km)

²Change engine oil.

²Replace engine oil filter.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) since last change.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

81,000 Miles (130 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x2).

82,500 Miles (132 000 km)

²Replace oxygen sensor (5.9L only).*

84,000 Miles (134 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect engine air cleaner element and air

pump filter, replace as necessary.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.³

²Change rear axle fluid.

²Change front axle fluid (4x4).

²Inspect brake linings.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

87,000 Miles (139 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

90,000 Miles (144 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect PCV valve, replace as necessary

(5.9L).

²Replace spark plugs.

²Inspect front wheel bearings (4x4).

²Inspect front wheel bearings (4x2).

²Drain and refill transfer case fluid (4x4).

93,000 Miles (149 000 km)

²Change engine oil.

²Replace engine oil filter.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

96,000 Miles (154 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace engine air cleaner element and air

pump filter.

²Drain and refill automatic transmission fluid.

Replace filter and adjust bands.

²Change rear axle fluid.

²Change front axle fluid (4x4).

²Clean and lubricate crankcase inlet air filter

(5.9L).

²Inspect front wheel bearings. Clean and repack,

if required (4x2).

²Inspect brake linings.

²Lubricate tie rod ends every 3,000 miles (5 000

km).

²Inspect front wheel bearings (4x4).

BR/BELUBRICATION & MAINTENANCE 0 - 21

MAINTENANCE SCHEDULES (Continued)

Page 436 of 2889

²Wiper motor.

If the source of RFI or EMI noise is identified as a

component on the vehicle (i.e., generator, blower

motor, etc.), the ground path for that component

should be checked. If excessive resistance is found in

any ground circuit, clean, tighten, or repair the

ground circuits or connections to ground as required

before considering any component replacement.

For service and inspection of secondary ignition

components, refer to Electrical, Ignition Control.

Inspect the following secondary ignition system com-

ponents:

²Distributor cap and rotor

²Ignition coil

²Spark plugs

²Spark plug wire routing and condition.

Reroute the spark plug wires or replace the faulty

components as required.

If the source of the RFI or EMI noise is identified

as two-way mobile radio or telephone equipment,

check the equipment installation for the following:

²Power connections should be made directly to

the battery, and fused as closely to the battery as

possible.

²The antenna should be mounted on the roof or

toward the rear of the vehicle. Remember that mag-

netic antenna mounts on the roof panel can adversely

affect the operation of an overhead console compass,

if the vehicle is so equipped.

²The antenna cable should be fully shielded coax-

ial cable, should be as short as is practical, and

should be routed away from the factory-installed

vehicle wire harnesses whenever possible.

²The antenna and cable must be carefully

matched to ensure a low Standing Wave Ratio

(SWR).

Fleet vehicles are available with an extra-cost RFI-

suppressed Powertrain Control Module (PCM). This

unit reduces interference generated by the PCM on

some radio frequencies used in two-way radio com-

munications. However, this unit will not resolve com-

plaints of RFI in the commercial AM or FM radio

frequency ranges.

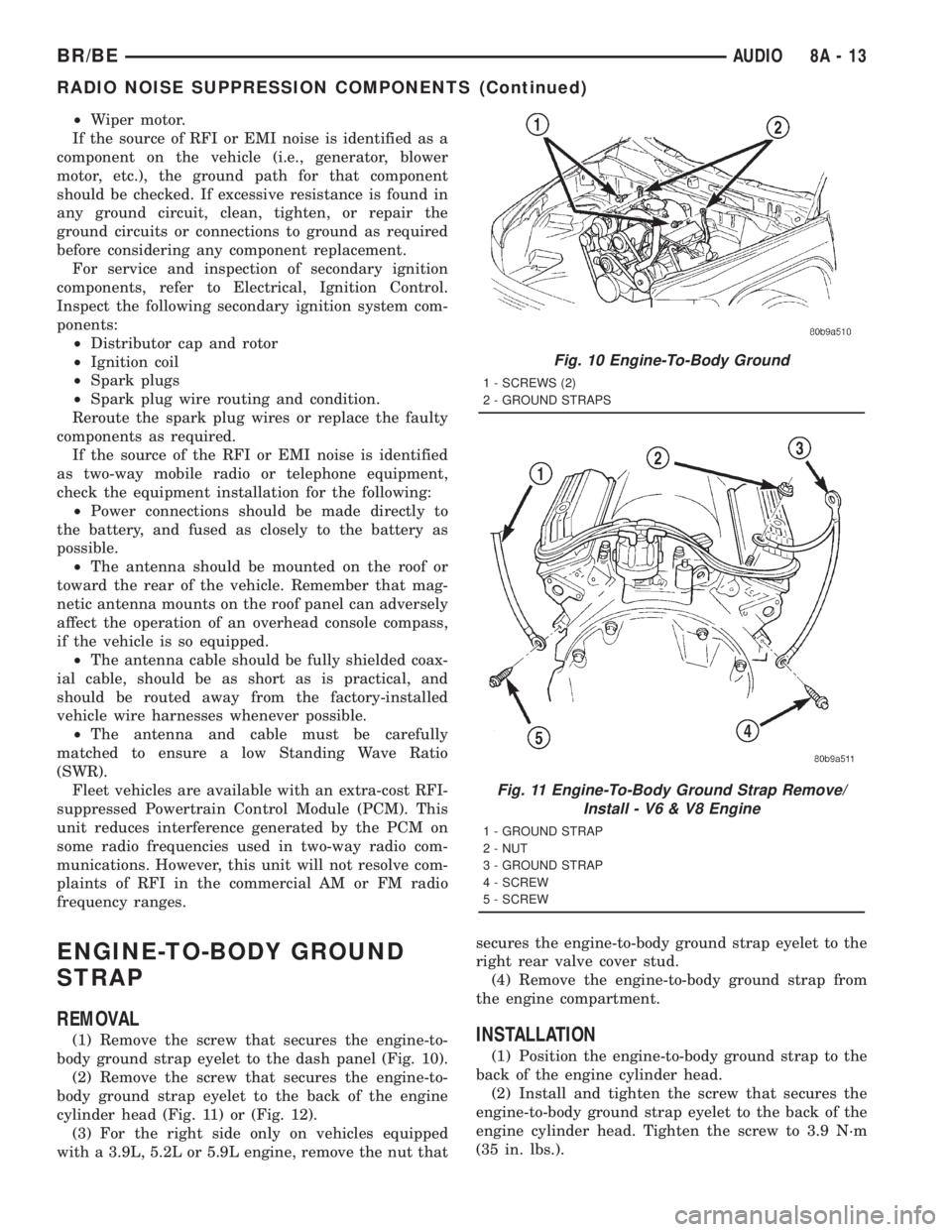

ENGINE-TO-BODY GROUND

STRAP

REMOVAL

(1) Remove the screw that secures the engine-to-

body ground strap eyelet to the dash panel (Fig. 10).

(2) Remove the screw that secures the engine-to-

body ground strap eyelet to the back of the engine

cylinder head (Fig. 11) or (Fig. 12).

(3) For the right side only on vehicles equipped

with a 3.9L, 5.2L or 5.9L engine, remove the nut thatsecures the engine-to-body ground strap eyelet to the

right rear valve cover stud.

(4) Remove the engine-to-body ground strap from

the engine compartment.INSTALLATION

(1) Position the engine-to-body ground strap to the

back of the engine cylinder head.

(2) Install and tighten the screw that secures the

engine-to-body ground strap eyelet to the back of the

engine cylinder head. Tighten the screw to 3.9 N´m

(35 in. lbs.).

Fig. 10 Engine-To-Body Ground

1 - SCREWS (2)

2 - GROUND STRAPS

Fig. 11 Engine-To-Body Ground Strap Remove/

Install - V6 & V8 Engine

1 - GROUND STRAP

2 - NUT

3 - GROUND STRAP

4 - SCREW

5 - SCREW

BR/BEAUDIO 8A - 13

RADIO NOISE SUPPRESSION COMPONENTS (Continued)

Page 553 of 2889

SPARK PLUG

DESCRIPTION

The 3.9L V-6 and 5.2L/5.9L V-8 engines use resis-

tor type spark plugs. The 8.0L V-10 engine uses

inductive type spark plugs.

Spark plug resistance values range from 6,000 to

20,000 ohms (when checked with at least a 1000 volt

spark plug tester).Do not use an ohmmeter to

check the resistance values of the spark plugs.

Inaccurate readings will result.

OPERATION

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.

Always use the recommended torque when tighten-

ing spark plugs. Incorrect torque can distort the

spark plug and change plug gap. It can also pull the

plug threads and do possible damage to both the

spark plug and the cylinder head.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A sin-gle plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O, Lubrication and Maintenance

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled. Also refer to Spark Plug Conditions.

CAUTION: Never use a motorized wire wheel brush

to clean the spark plugs. Metallic deposits will

remain on the spark plug insulator and will cause

plug misfire.

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

(Fig. 29). There will not be evidence of electrode

burning. Gap growth will not average more than

approximately 0.025 mm (.001 in) per 3200 km (2000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes

filed, have the gap set and then be installed.

Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

causes the entire tip of the spark plug to be coated

with a rust colored deposit. This rust color can be

misdiagnosed as being caused by coolant in the com-

bustion chamber. Spark plug performance may be

affected by MMT deposits.

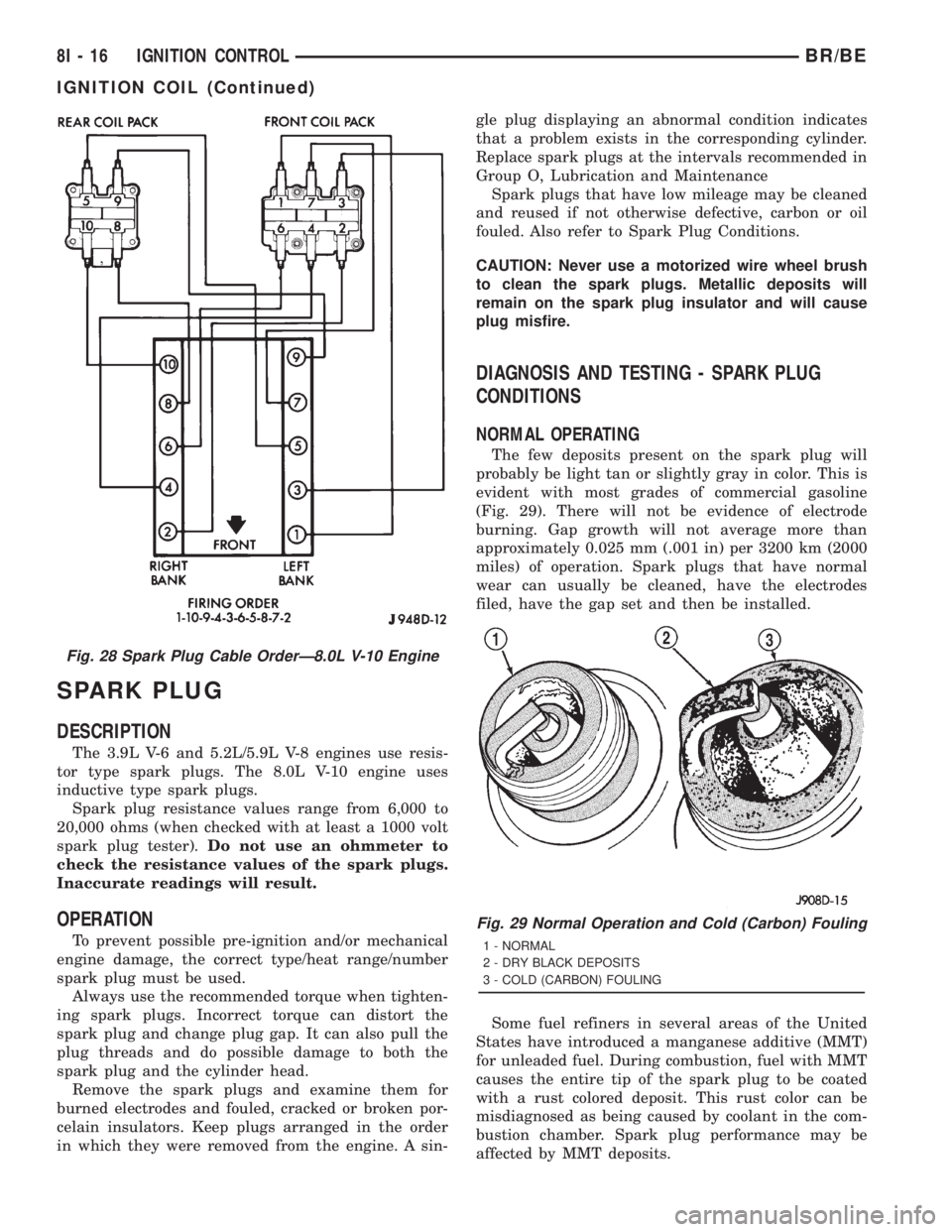

Fig. 28 Spark Plug Cable OrderÐ8.0L V-10 Engine

Fig. 29 Normal Operation and Cold (Carbon) Fouling

1 - NORMAL

2 - DRY BLACK DEPOSITS

3 - COLD (CARBON) FOULING

8I - 16 IGNITION CONTROLBR/BE

IGNITION COIL (Continued)

Page 555 of 2889

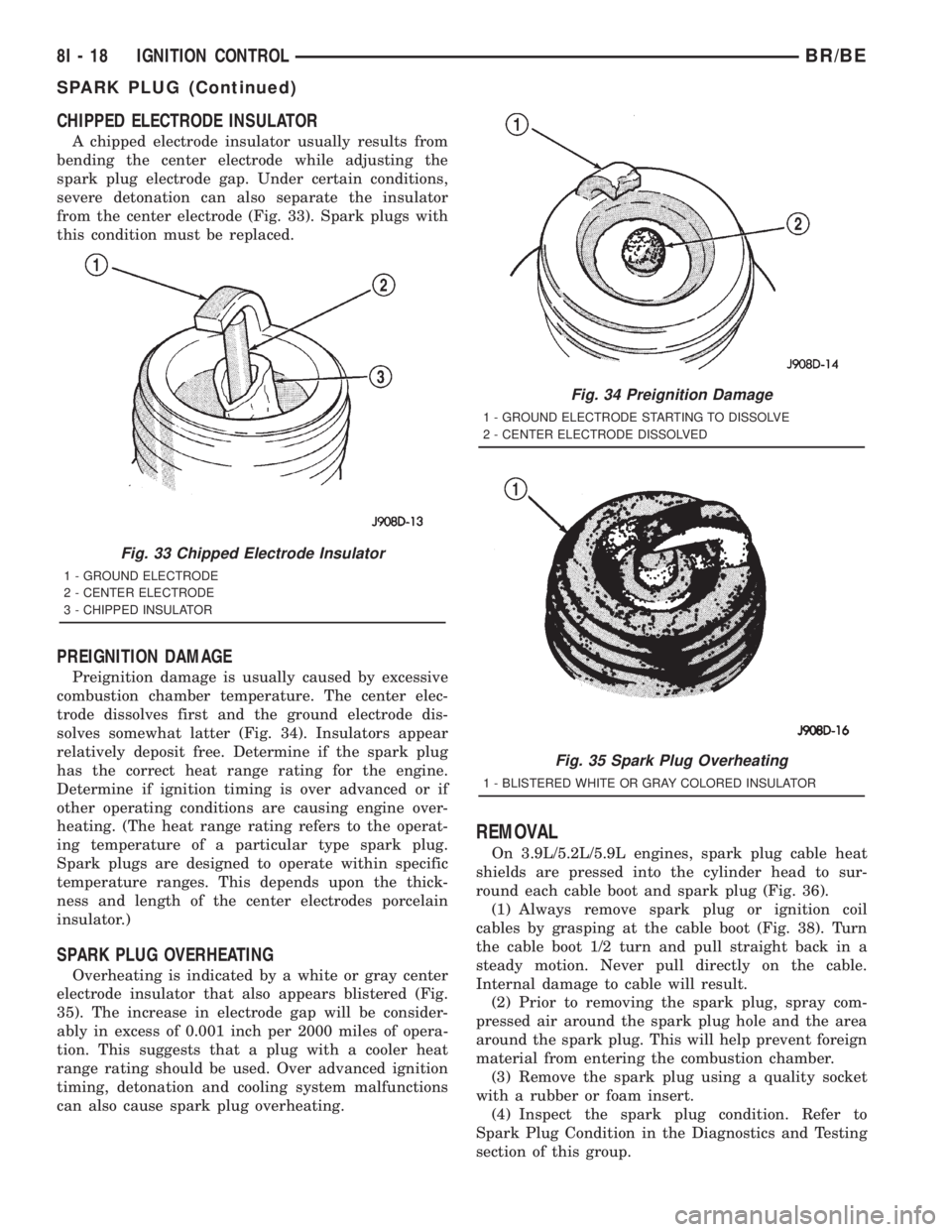

CHIPPED ELECTRODE INSULATOR

A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation can also separate the insulator

from the center electrode (Fig. 33). Spark plugs with

this condition must be replaced.

PREIGNITION DAMAGE

Preignition damage is usually caused by excessive

combustion chamber temperature. The center elec-

trode dissolves first and the ground electrode dis-

solves somewhat latter (Fig. 34). Insulators appear

relatively deposit free. Determine if the spark plug

has the correct heat range rating for the engine.

Determine if ignition timing is over advanced or if

other operating conditions are causing engine over-

heating. (The heat range rating refers to the operat-

ing temperature of a particular type spark plug.

Spark plugs are designed to operate within specific

temperature ranges. This depends upon the thick-

ness and length of the center electrodes porcelain

insulator.)

SPARK PLUG OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

35). The increase in electrode gap will be consider-

ably in excess of 0.001 inch per 2000 miles of opera-

tion. This suggests that a plug with a cooler heat

range rating should be used. Over advanced ignition

timing, detonation and cooling system malfunctions

can also cause spark plug overheating.

REMOVAL

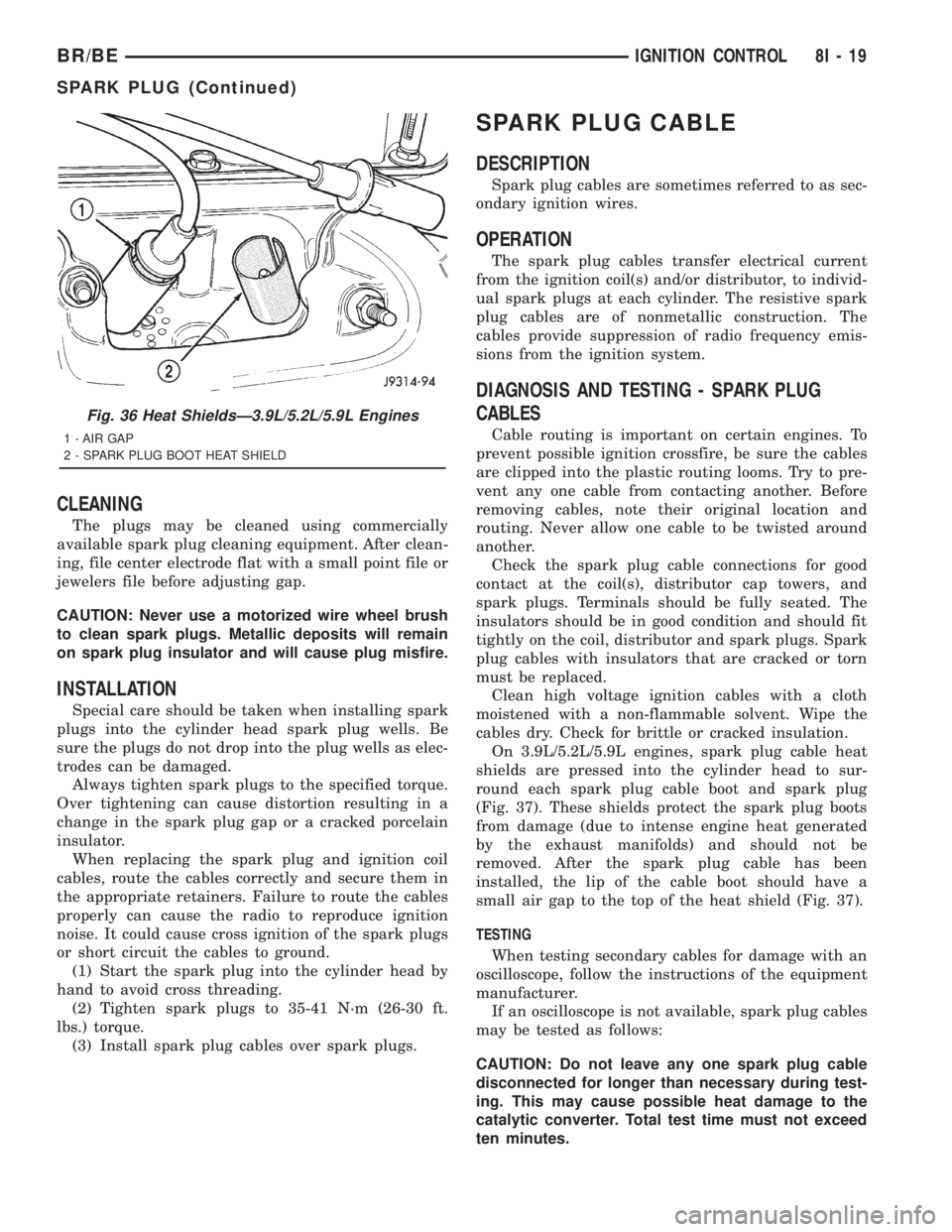

On 3.9L/5.2L/5.9L engines, spark plug cable heat

shields are pressed into the cylinder head to sur-

round each cable boot and spark plug (Fig. 36).

(1) Always remove spark plug or ignition coil

cables by grasping at the cable boot (Fig. 38). Turn

the cable boot 1/2 turn and pull straight back in a

steady motion. Never pull directly on the cable.

Internal damage to cable will result.

(2) Prior to removing the spark plug, spray com-

pressed air around the spark plug hole and the area

around the spark plug. This will help prevent foreign

material from entering the combustion chamber.

(3) Remove the spark plug using a quality socket

with a rubber or foam insert.

(4) Inspect the spark plug condition. Refer to

Spark Plug Condition in the Diagnostics and Testing

section of this group.

Fig. 33 Chipped Electrode Insulator

1 - GROUND ELECTRODE

2 - CENTER ELECTRODE

3 - CHIPPED INSULATOR

Fig. 34 Preignition Damage

1 - GROUND ELECTRODE STARTING TO DISSOLVE

2 - CENTER ELECTRODE DISSOLVED

Fig. 35 Spark Plug Overheating

1 - BLISTERED WHITE OR GRAY COLORED INSULATOR

8I - 18 IGNITION CONTROLBR/BE

SPARK PLUG (Continued)

Page 556 of 2889

CLEANING

The plugs may be cleaned using commercially

available spark plug cleaning equipment. After clean-

ing, file center electrode flat with a small point file or

jewelers file before adjusting gap.

CAUTION: Never use a motorized wire wheel brush

to clean spark plugs. Metallic deposits will remain

on spark plug insulator and will cause plug misfire.

INSTALLATION

Special care should be taken when installing spark

plugs into the cylinder head spark plug wells. Be

sure the plugs do not drop into the plug wells as elec-

trodes can be damaged.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap or a cracked porcelain

insulator.

When replacing the spark plug and ignition coil

cables, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise. It could cause cross ignition of the spark plugs

or short circuit the cables to ground.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten spark plugs to 35-41 N´m (26-30 ft.

lbs.) torque.

(3) Install spark plug cables over spark plugs.

SPARK PLUG CABLE

DESCRIPTION

Spark plug cables are sometimes referred to as sec-

ondary ignition wires.

OPERATION

The spark plug cables transfer electrical current

from the ignition coil(s) and/or distributor, to individ-

ual spark plugs at each cylinder. The resistive spark

plug cables are of nonmetallic construction. The

cables provide suppression of radio frequency emis-

sions from the ignition system.

DIAGNOSIS AND TESTING - SPARK PLUG

CABLES

Cable routing is important on certain engines. To

prevent possible ignition crossfire, be sure the cables

are clipped into the plastic routing looms. Try to pre-

vent any one cable from contacting another. Before

removing cables, note their original location and

routing. Never allow one cable to be twisted around

another.

Check the spark plug cable connections for good

contact at the coil(s), distributor cap towers, and

spark plugs. Terminals should be fully seated. The

insulators should be in good condition and should fit

tightly on the coil, distributor and spark plugs. Spark

plug cables with insulators that are cracked or torn

must be replaced.

Clean high voltage ignition cables with a cloth

moistened with a non-flammable solvent. Wipe the

cables dry. Check for brittle or cracked insulation.

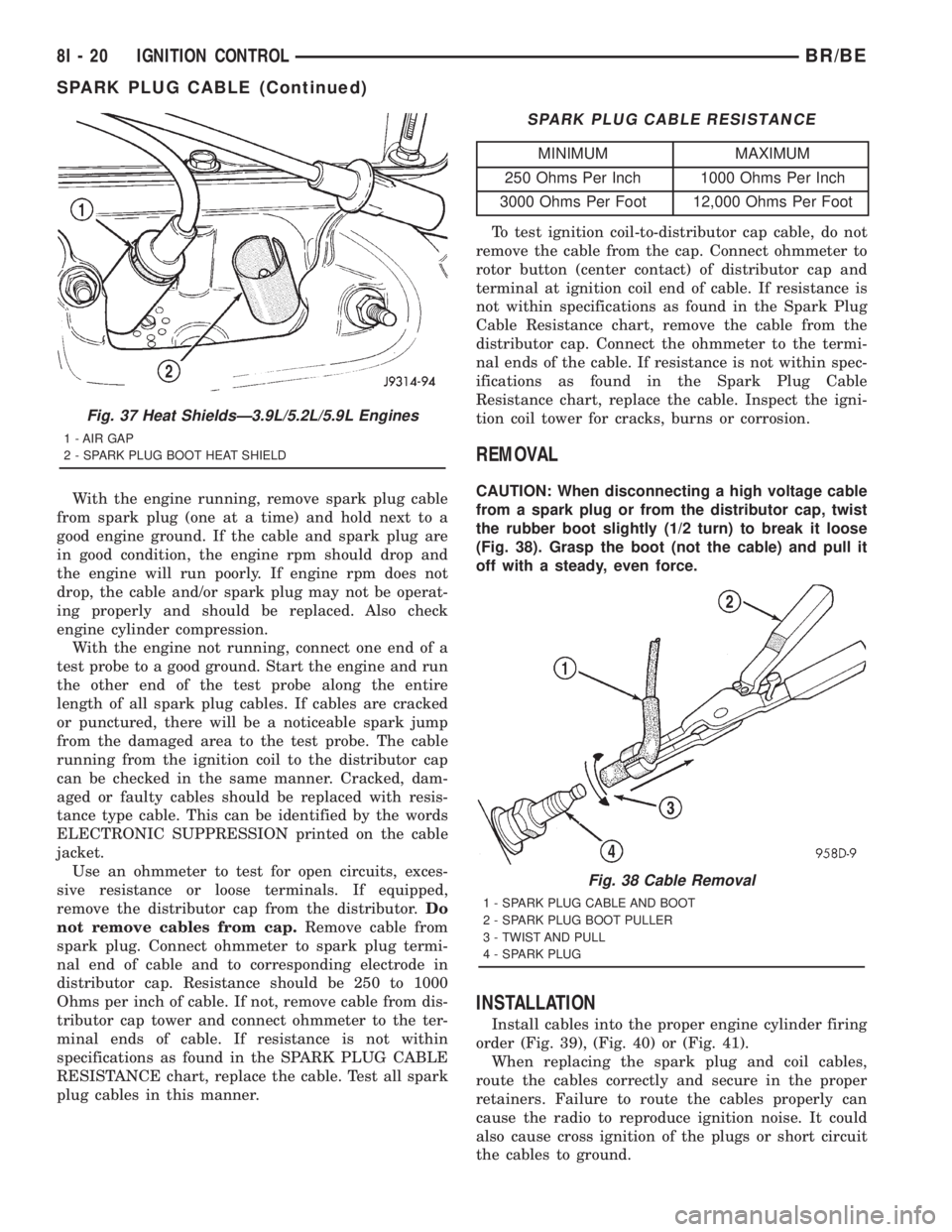

On 3.9L/5.2L/5.9L engines, spark plug cable heat

shields are pressed into the cylinder head to sur-

round each spark plug cable boot and spark plug

(Fig. 37). These shields protect the spark plug boots

from damage (due to intense engine heat generated

by the exhaust manifolds) and should not be

removed. After the spark plug cable has been

installed, the lip of the cable boot should have a

small air gap to the top of the heat shield (Fig. 37).

TESTING

When testing secondary cables for damage with an

oscilloscope, follow the instructions of the equipment

manufacturer.

If an oscilloscope is not available, spark plug cables

may be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected for longer than necessary during test-

ing. This may cause possible heat damage to the

catalytic converter. Total test time must not exceed

ten minutes.

Fig. 36 Heat ShieldsÐ3.9L/5.2L/5.9L Engines

1 - AIR GAP

2 - SPARK PLUG BOOT HEAT SHIELD

BR/BEIGNITION CONTROL 8I - 19

SPARK PLUG (Continued)

Page 557 of 2889

With the engine running, remove spark plug cable

from spark plug (one at a time) and hold next to a

good engine ground. If the cable and spark plug are

in good condition, the engine rpm should drop and

the engine will run poorly. If engine rpm does not

drop, the cable and/or spark plug may not be operat-

ing properly and should be replaced. Also check

engine cylinder compression.

With the engine not running, connect one end of a

test probe to a good ground. Start the engine and run

the other end of the test probe along the entire

length of all spark plug cables. If cables are cracked

or punctured, there will be a noticeable spark jump

from the damaged area to the test probe. The cable

running from the ignition coil to the distributor cap

can be checked in the same manner. Cracked, dam-

aged or faulty cables should be replaced with resis-

tance type cable. This can be identified by the words

ELECTRONIC SUPPRESSION printed on the cable

jacket.

Use an ohmmeter to test for open circuits, exces-

sive resistance or loose terminals. If equipped,

remove the distributor cap from the distributor.Do

not remove cables from cap.Remove cable from

spark plug. Connect ohmmeter to spark plug termi-

nal end of cable and to corresponding electrode in

distributor cap. Resistance should be 250 to 1000

Ohms per inch of cable. If not, remove cable from dis-

tributor cap tower and connect ohmmeter to the ter-

minal ends of cable. If resistance is not within

specifications as found in the SPARK PLUG CABLE

RESISTANCE chart, replace the cable. Test all spark

plug cables in this manner.

SPARK PLUG CABLE RESISTANCE

MINIMUM MAXIMUM

250 Ohms Per Inch 1000 Ohms Per Inch

3000 Ohms Per Foot 12,000 Ohms Per Foot

To test ignition coil-to-distributor cap cable, do not

remove the cable from the cap. Connect ohmmeter to

rotor button (center contact) of distributor cap and

terminal at ignition coil end of cable. If resistance is

not within specifications as found in the Spark Plug

Cable Resistance chart, remove the cable from the

distributor cap. Connect the ohmmeter to the termi-

nal ends of the cable. If resistance is not within spec-

ifications as found in the Spark Plug Cable

Resistance chart, replace the cable. Inspect the igni-

tion coil tower for cracks, burns or corrosion.

REMOVAL

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose

(Fig. 38). Grasp the boot (not the cable) and pull it

off with a steady, even force.

INSTALLATION

Install cables into the proper engine cylinder firing

order (Fig. 39), (Fig. 40) or (Fig. 41).

When replacing the spark plug and coil cables,

route the cables correctly and secure in the proper

retainers. Failure to route the cables properly can

cause the radio to reproduce ignition noise. It could

also cause cross ignition of the plugs or short circuit

the cables to ground.

Fig. 37 Heat ShieldsÐ3.9L/5.2L/5.9L Engines

1 - AIR GAP

2 - SPARK PLUG BOOT HEAT SHIELD

Fig. 38 Cable Removal

1 - SPARK PLUG CABLE AND BOOT

2 - SPARK PLUG BOOT PULLER

3 - TWIST AND PULL

4 - SPARK PLUG

8I - 20 IGNITION CONTROLBR/BE

SPARK PLUG CABLE (Continued)