belt DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2714 of 2889

(6) Install seat tracks. (Refer to 23 - BODY/

SEATS/SEAT TRACK - SPLIT BENCH - INSTALLA-

TION)

QUAD CAB

(1) Position the cover on the cushion.

(2) Engage the hog rings attaching the cushion

cover to the cushion frame.

(3) Engage the hook and loop fasteners.

(4) Engage the electrical connectors for the heated

seat grid, if equipped.

(5) Engage the J-straps attaching the cushion

cover to the cushion frame.

(6) Install seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - INSTALLATION)

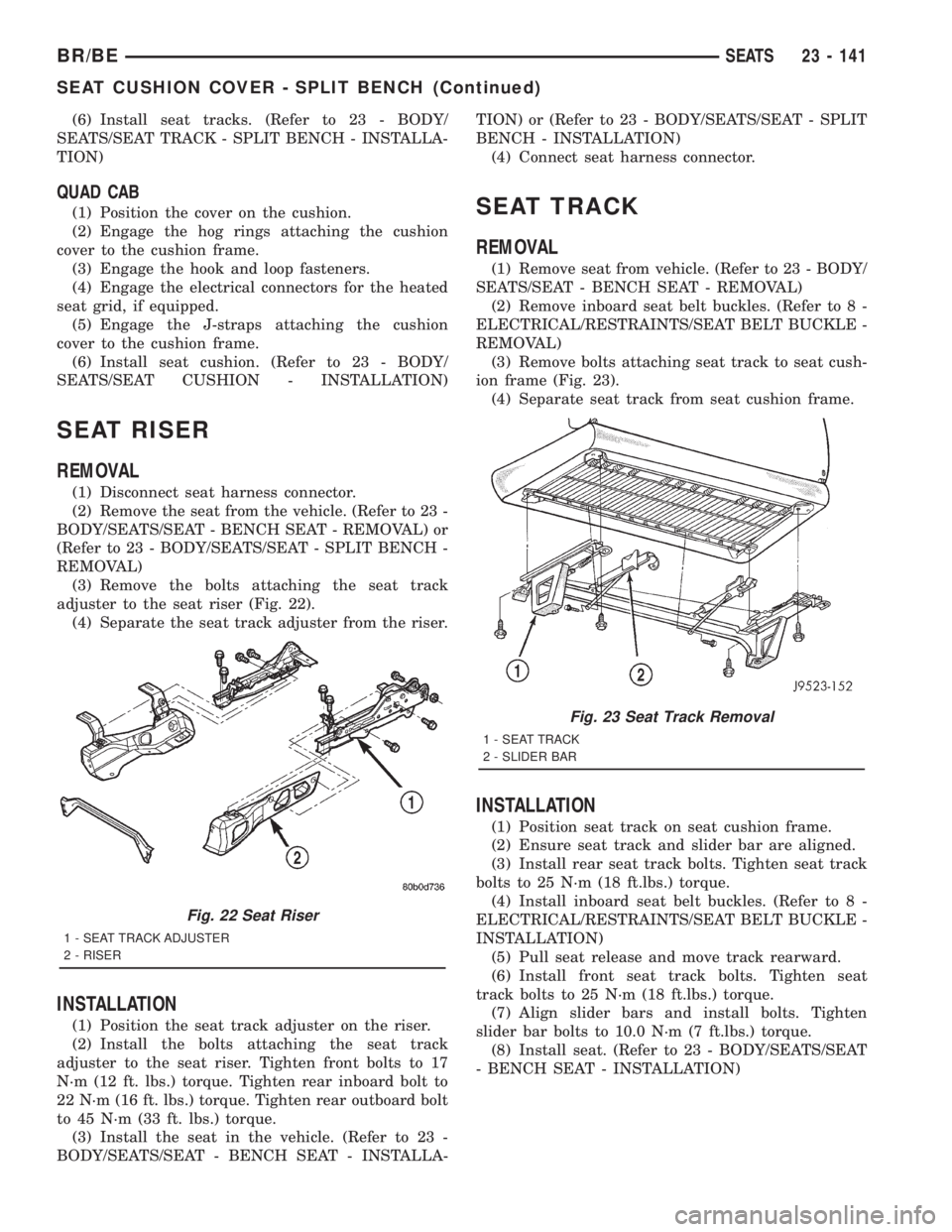

SEAT RISER

REMOVAL

(1) Disconnect seat harness connector.

(2) Remove the seat from the vehicle. (Refer to 23 -

BODY/SEATS/SEAT - BENCH SEAT - REMOVAL) or

(Refer to 23 - BODY/SEATS/SEAT - SPLIT BENCH -

REMOVAL)

(3) Remove the bolts attaching the seat track

adjuster to the seat riser (Fig. 22).

(4) Separate the seat track adjuster from the riser.

INSTALLATION

(1) Position the seat track adjuster on the riser.

(2) Install the bolts attaching the seat track

adjuster to the seat riser. Tighten front bolts to 17

N´m (12 ft. lbs.) torque. Tighten rear inboard bolt to

22 N´m (16 ft. lbs.) torque. Tighten rear outboard bolt

to 45 N´m (33 ft. lbs.) torque.

(3) Install the seat in the vehicle. (Refer to 23 -

BODY/SEATS/SEAT - BENCH SEAT - INSTALLA-TION) or (Refer to 23 - BODY/SEATS/SEAT - SPLIT

BENCH - INSTALLATION)

(4) Connect seat harness connector.

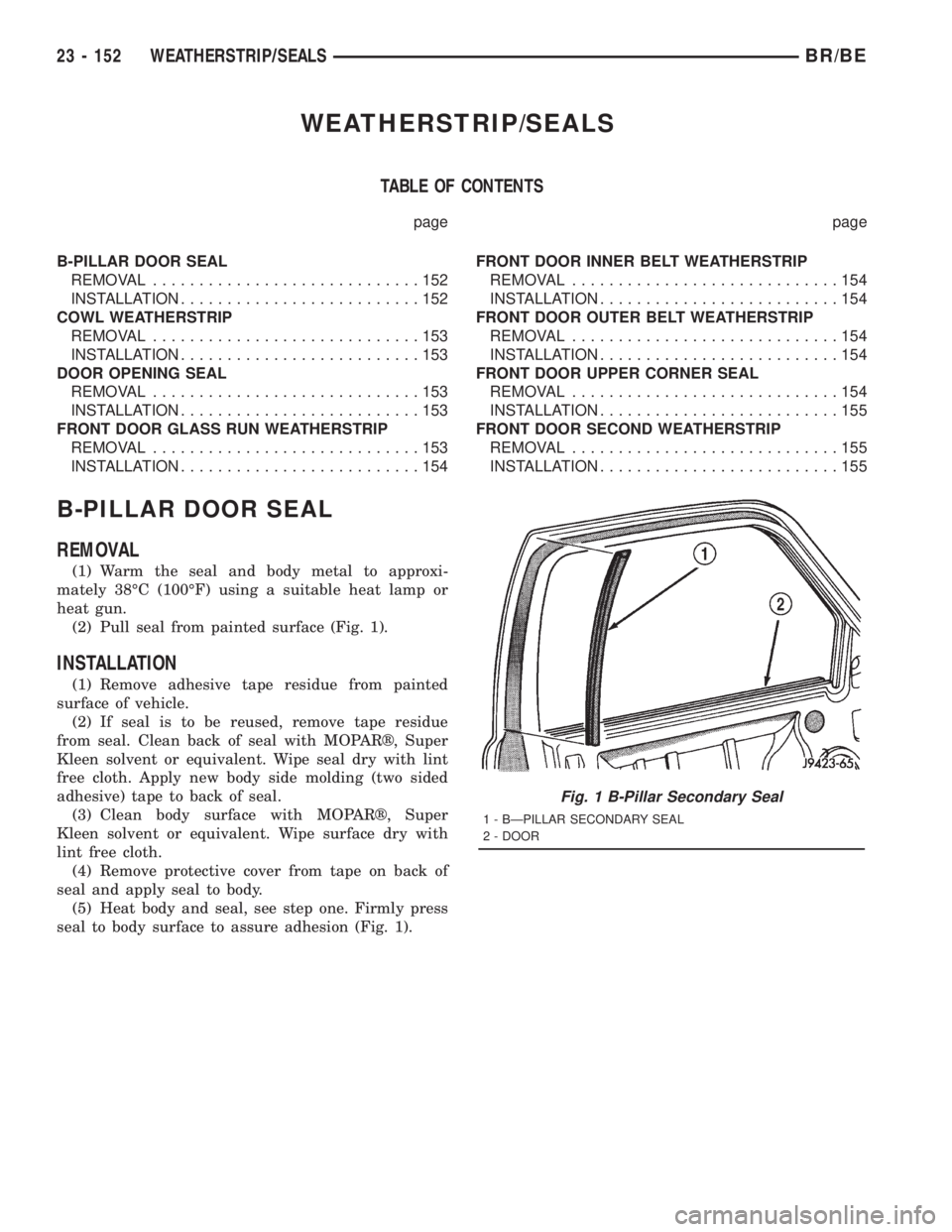

SEAT TRACK

REMOVAL

(1) Remove seat from vehicle. (Refer to 23 - BODY/

SEATS/SEAT - BENCH SEAT - REMOVAL)

(2) Remove inboard seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT BUCKLE -

REMOVAL)

(3) Remove bolts attaching seat track to seat cush-

ion frame (Fig. 23).

(4) Separate seat track from seat cushion frame.

INSTALLATION

(1) Position seat track on seat cushion frame.

(2) Ensure seat track and slider bar are aligned.

(3) Install rear seat track bolts. Tighten seat track

bolts to 25 N´m (18 ft.lbs.) torque.

(4) Install inboard seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT BUCKLE -

INSTALLATION)

(5) Pull seat release and move track rearward.

(6) Install front seat track bolts. Tighten seat

track bolts to 25 N´m (18 ft.lbs.) torque.

(7) Align slider bars and install bolts. Tighten

slider bar bolts to 10.0 N´m (7 ft.lbs.) torque.

(8) Install seat. (Refer to 23 - BODY/SEATS/SEAT

- BENCH SEAT - INSTALLATION)

Fig. 22 Seat Riser

1 - SEAT TRACK ADJUSTER

2 - RISER

Fig. 23 Seat Track Removal

1 - SEAT TRACK

2 - SLIDER BAR

BR/BESEATS 23 - 141

SEAT CUSHION COVER - SPLIT BENCH (Continued)

Page 2725 of 2889

WEATHERSTRIP/SEALS

TABLE OF CONTENTS

page page

B-PILLAR DOOR SEAL

REMOVAL.............................152

INSTALLATION..........................152

COWL WEATHERSTRIP

REMOVAL.............................153

INSTALLATION..........................153

DOOR OPENING SEAL

REMOVAL.............................153

INSTALLATION..........................153

FRONT DOOR GLASS RUN WEATHERSTRIP

REMOVAL.............................153

INSTALLATION..........................154FRONT DOOR INNER BELT WEATHERSTRIP

REMOVAL.............................154

INSTALLATION..........................154

FRONT DOOR OUTER BELT WEATHERSTRIP

REMOVAL.............................154

INSTALLATION..........................154

FRONT DOOR UPPER CORNER SEAL

REMOVAL.............................154

INSTALLATION..........................155

FRONT DOOR SECOND WEATHERSTRIP

REMOVAL.............................155

INSTALLATION..........................155

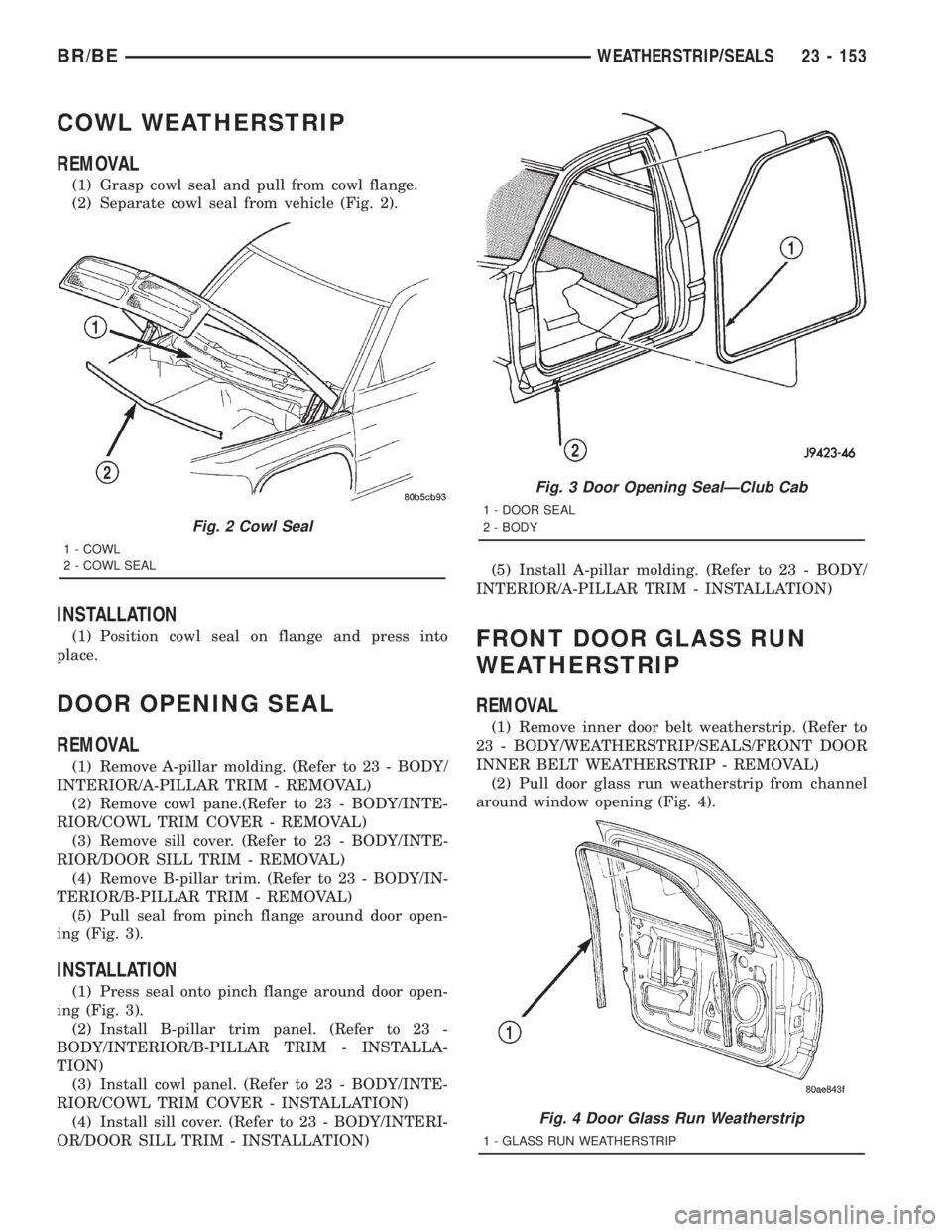

B-PILLAR DOOR SEAL

REMOVAL

(1) Warm the seal and body metal to approxi-

mately 38ÉC (100ÉF) using a suitable heat lamp or

heat gun.

(2) Pull seal from painted surface (Fig. 1).

INSTALLATION

(1) Remove adhesive tape residue from painted

surface of vehicle.

(2) If seal is to be reused, remove tape residue

from seal. Clean back of seal with MOPARž, Super

Kleen solvent or equivalent. Wipe seal dry with lint

free cloth. Apply new body side molding (two sided

adhesive) tape to back of seal.

(3) Clean body surface with MOPARž, Super

Kleen solvent or equivalent. Wipe surface dry with

lint free cloth.

(4) Remove protective cover from tape on back of

seal and apply seal to body.

(5) Heat body and seal, see step one. Firmly press

seal to body surface to assure adhesion (Fig. 1).

Fig. 1 B-Pillar Secondary Seal

1 - BÐPILLAR SECONDARY SEAL

2 - DOOR

23 - 152 WEATHERSTRIP/SEALSBR/BE

Page 2726 of 2889

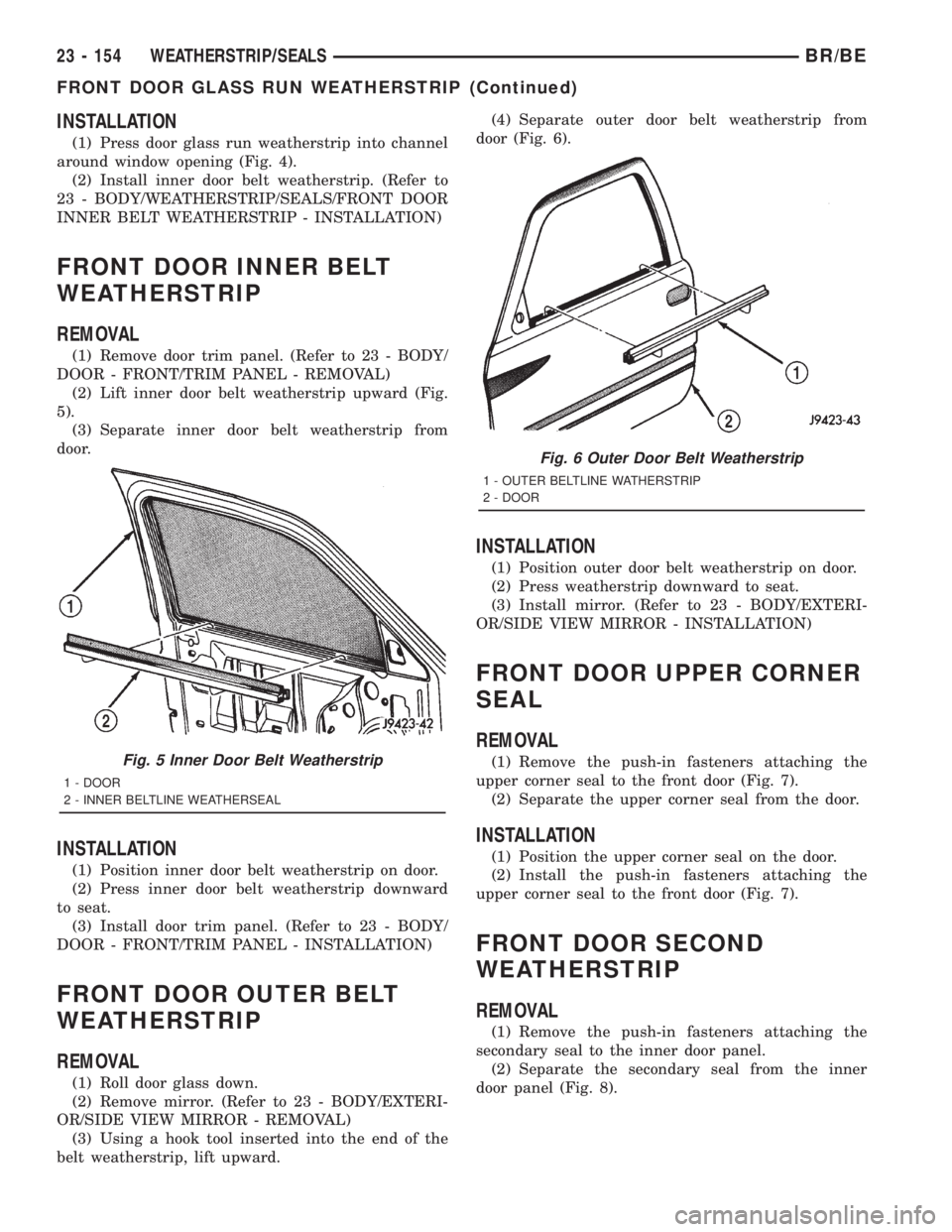

COWL WEATHERSTRIP

REMOVAL

(1) Grasp cowl seal and pull from cowl flange.

(2) Separate cowl seal from vehicle (Fig. 2).

INSTALLATION

(1) Position cowl seal on flange and press into

place.

DOOR OPENING SEAL

REMOVAL

(1) Remove A-pillar molding. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL)

(2) Remove cowl pane.(Refer to 23 - BODY/INTE-

RIOR/COWL TRIM COVER - REMOVAL)

(3) Remove sill cover. (Refer to 23 - BODY/INTE-

RIOR/DOOR SILL TRIM - REMOVAL)

(4) Remove B-pillar trim. (Refer to 23 - BODY/IN-

TERIOR/B-PILLAR TRIM - REMOVAL)

(5) Pull seal from pinch flange around door open-

ing (Fig. 3).

INSTALLATION

(1) Press seal onto pinch flange around door open-

ing (Fig. 3).

(2) Install B-pillar trim panel. (Refer to 23 -

BODY/INTERIOR/B-PILLAR TRIM - INSTALLA-

TION)

(3) Install cowl panel. (Refer to 23 - BODY/INTE-

RIOR/COWL TRIM COVER - INSTALLATION)

(4) Install sill cover. (Refer to 23 - BODY/INTERI-

OR/DOOR SILL TRIM - INSTALLATION)(5) Install A-pillar molding. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - INSTALLATION)

FRONT DOOR GLASS RUN

WEATHERSTRIP

REMOVAL

(1) Remove inner door belt weatherstrip. (Refer to

23 - BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - REMOVAL)

(2) Pull door glass run weatherstrip from channel

around window opening (Fig. 4).

Fig. 2 Cowl Seal

1 - COWL

2 - COWL SEAL

Fig. 3 Door Opening SealÐClub Cab

1 - DOOR SEAL

2 - BODY

Fig. 4 Door Glass Run Weatherstrip

1 - GLASS RUN WEATHERSTRIP

BR/BEWEATHERSTRIP/SEALS 23 - 153

Page 2727 of 2889

INSTALLATION

(1) Press door glass run weatherstrip into channel

around window opening (Fig. 4).

(2) Install inner door belt weatherstrip. (Refer to

23 - BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - INSTALLATION)

FRONT DOOR INNER BELT

WEATHERSTRIP

REMOVAL

(1) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Lift inner door belt weatherstrip upward (Fig.

5).

(3) Separate inner door belt weatherstrip from

door.

INSTALLATION

(1) Position inner door belt weatherstrip on door.

(2) Press inner door belt weatherstrip downward

to seat.

(3) Install door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

FRONT DOOR OUTER BELT

WEATHERSTRIP

REMOVAL

(1) Roll door glass down.

(2) Remove mirror. (Refer to 23 - BODY/EXTERI-

OR/SIDE VIEW MIRROR - REMOVAL)

(3) Using a hook tool inserted into the end of the

belt weatherstrip, lift upward.(4) Separate outer door belt weatherstrip from

door (Fig. 6).

INSTALLATION

(1) Position outer door belt weatherstrip on door.

(2) Press weatherstrip downward to seat.

(3) Install mirror. (Refer to 23 - BODY/EXTERI-

OR/SIDE VIEW MIRROR - INSTALLATION)

FRONT DOOR UPPER CORNER

SEAL

REMOVAL

(1) Remove the push-in fasteners attaching the

upper corner seal to the front door (Fig. 7).

(2) Separate the upper corner seal from the door.

INSTALLATION

(1) Position the upper corner seal on the door.

(2) Install the push-in fasteners attaching the

upper corner seal to the front door (Fig. 7).

FRONT DOOR SECOND

WEATHERSTRIP

REMOVAL

(1) Remove the push-in fasteners attaching the

secondary seal to the inner door panel.

(2) Separate the secondary seal from the inner

door panel (Fig. 8).

Fig. 5 Inner Door Belt Weatherstrip

1 - DOOR

2 - INNER BELTLINE WEATHERSEAL

Fig. 6 Outer Door Belt Weatherstrip

1 - OUTER BELTLINE WATHERSTRIP

2 - DOOR

23 - 154 WEATHERSTRIP/SEALSBR/BE

FRONT DOOR GLASS RUN WEATHERSTRIP (Continued)

Page 2734 of 2889

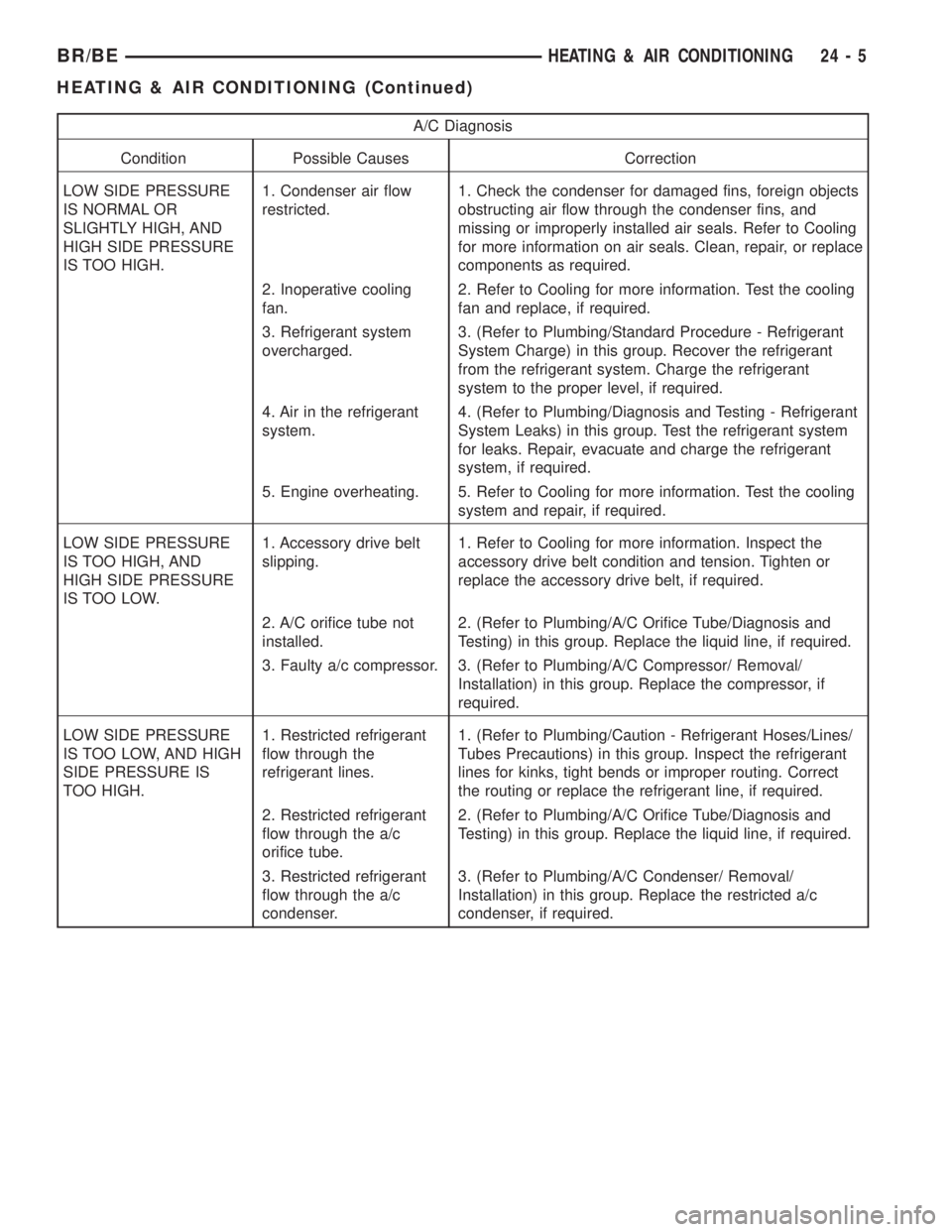

A/C Diagnosis

Condition Possible Causes Correction

LOW SIDE PRESSURE

IS NORMAL OR

SLIGHTLY HIGH, AND

HIGH SIDE PRESSURE

IS TOO HIGH.1. Condenser air flow

restricted.1. Check the condenser for damaged fins, foreign objects

obstructing air flow through the condenser fins, and

missing or improperly installed air seals. Refer to Cooling

for more information on air seals. Clean, repair, or replace

components as required.

2. Inoperative cooling

fan.2. Refer to Cooling for more information. Test the cooling

fan and replace, if required.

3. Refrigerant system

overcharged.3. (Refer to Plumbing/Standard Procedure - Refrigerant

System Charge) in this group. Recover the refrigerant

from the refrigerant system. Charge the refrigerant

system to the proper level, if required.

4. Air in the refrigerant

system.4. (Refer to Plumbing/Diagnosis and Testing - Refrigerant

System Leaks) in this group. Test the refrigerant system

for leaks. Repair, evacuate and charge the refrigerant

system, if required.

5. Engine overheating. 5. Refer to Cooling for more information. Test the cooling

system and repair, if required.

LOW SIDE PRESSURE

IS TOO HIGH, AND

HIGH SIDE PRESSURE

IS TOO LOW.1. Accessory drive belt

slipping.1. Refer to Cooling for more information. Inspect the

accessory drive belt condition and tension. Tighten or

replace the accessory drive belt, if required.

2. A/C orifice tube not

installed.2. (Refer to Plumbing/A/C Orifice Tube/Diagnosis and

Testing) in this group. Replace the liquid line, if required.

3. Faulty a/c compressor. 3. (Refer to Plumbing/A/C Compressor/ Removal/

Installation) in this group. Replace the compressor, if

required.

LOW SIDE PRESSURE

IS TOO LOW, AND HIGH

SIDE PRESSURE IS

TOO HIGH.1. Restricted refrigerant

flow through the

refrigerant lines.1. (Refer to Plumbing/Caution - Refrigerant Hoses/Lines/

Tubes Precautions) in this group. Inspect the refrigerant

lines for kinks, tight bends or improper routing. Correct

the routing or replace the refrigerant line, if required.

2. Restricted refrigerant

flow through the a/c

orifice tube.2. (Refer to Plumbing/A/C Orifice Tube/Diagnosis and

Testing) in this group. Replace the liquid line, if required.

3. Restricted refrigerant

flow through the a/c

condenser.3. (Refer to Plumbing/A/C Condenser/ Removal/

Installation) in this group. Replace the restricted a/c

condenser, if required.

BR/BEHEATING & AIR CONDITIONING 24 - 5

HEATING & AIR CONDITIONING (Continued)

Page 2735 of 2889

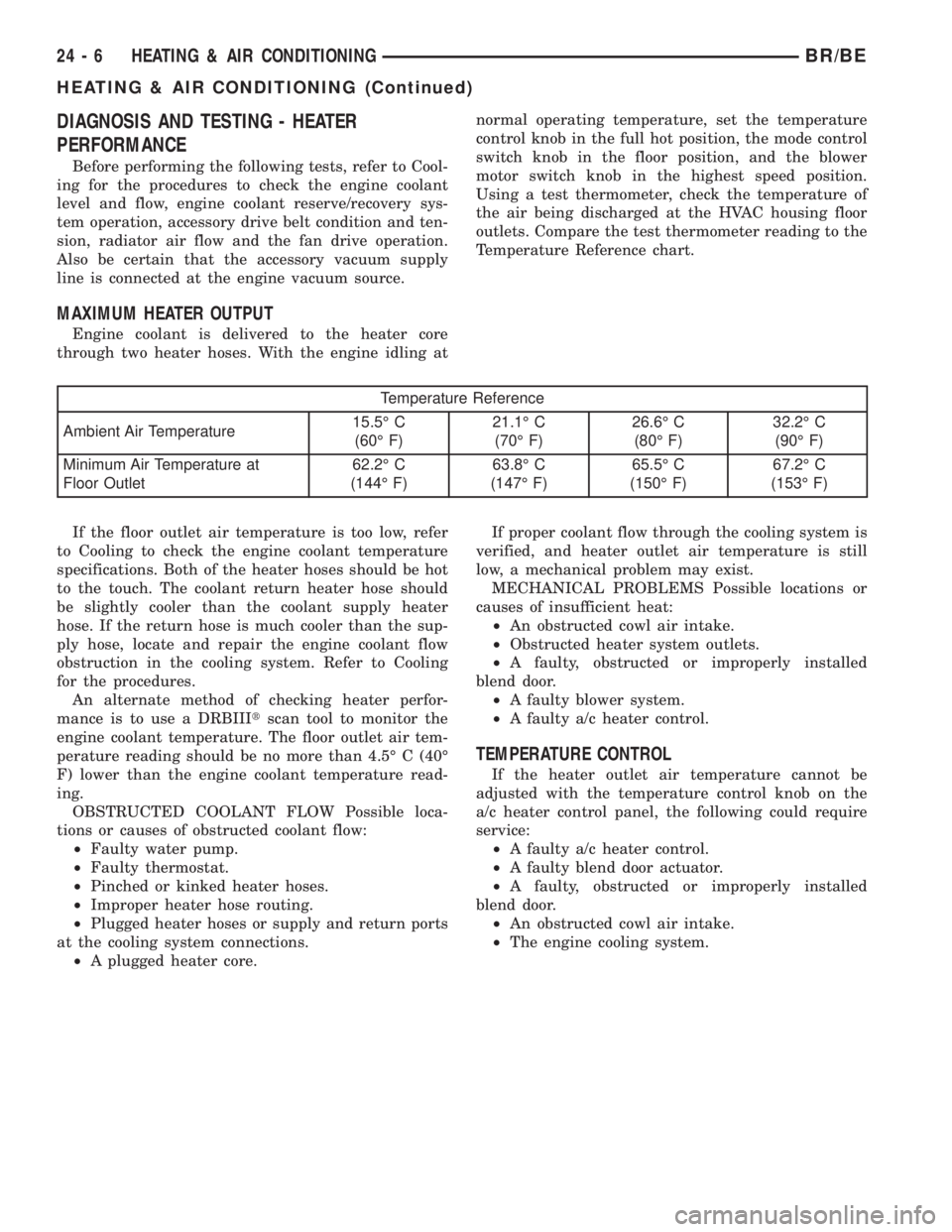

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE

Before performing the following tests, refer to Cool-

ing for the procedures to check the engine coolant

level and flow, engine coolant reserve/recovery sys-

tem operation, accessory drive belt condition and ten-

sion, radiator air flow and the fan drive operation.

Also be certain that the accessory vacuum supply

line is connected at the engine vacuum source.

MAXIMUM HEATER OUTPUT

Engine coolant is delivered to the heater core

through two heater hoses. With the engine idling atnormal operating temperature, set the temperature

control knob in the full hot position, the mode control

switch knob in the floor position, and the blower

motor switch knob in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged at the HVAC housing floor

outlets. Compare the test thermometer reading to the

Temperature Reference chart.

Temperature Reference

Ambient Air Temperature15.5É C

(60É F)21.1É C

(70É F)26.6É C

(80É F)32.2É C

(90É F)

Minimum Air Temperature at

Floor Outlet62.2É C

(144É F)63.8É C

(147É F)65.5É C

(150É F)67.2É C

(153É F)

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

An alternate method of checking heater perfor-

mance is to use a DRBIIItscan tool to monitor the

engine coolant temperature. The floor outlet air tem-

perature reading should be no more than 4.5É C (40É

F) lower than the engine coolant temperature read-

ing.

OBSTRUCTED COOLANT FLOW Possible loca-

tions or causes of obstructed coolant flow:

²Faulty water pump.

²Faulty thermostat.

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS Possible locations or

causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A faulty, obstructed or improperly installed

blend door.

²A faulty blower system.

²A faulty a/c heater control.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob on the

a/c heater control panel, the following could require

service:

²A faulty a/c heater control.

²A faulty blend door actuator.

²A faulty, obstructed or improperly installed

blend door.

²An obstructed cowl air intake.

²The engine cooling system.

24 - 6 HEATING & AIR CONDITIONINGBR/BE

HEATING & AIR CONDITIONING (Continued)

Page 2736 of 2889

Heater Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

INSUFFICIENT HEATER

OUTPUT.1. Incorrect engine

coolant level.1. Check the engine coolant level. Refer to Cooling for

the procedures.

2. Air trapped in engine

cooling system.2. Check the operation of the coolant reserve/recovery

system. Refer to Cooling for the procedures.

3. Incorrect engine

coolant temperature.3. Check the performance and operation of the engine

cooling system including: thermostat, water pump, fan

drive, accessory drive belt, coolant flow (plugged radiator

or heater core, plugged or kinked coolant hoses), air flow

(missing or improperly installed radiator air seals or fan

shroud). Refer to Cooling for the procedures.

4. Blend door actuator

inoperative or defective.4. (Refer to Controls/Blend Door Actuator) in this group.

5. Blend door not

operating properly.5. Check for a damaged, obstructed or improperly

installed blend door or seals. (Refer to Controls/Blend

Door Actuator) in this group.

6. Insufficient air flow

through heater housing.6. Remove foreign material or obstructions from cowl air

intake.

7. Improper blower motor

operation.7. (Refer to Distribution/Blower Motor/ Diagnosis and

Testing) in this group.

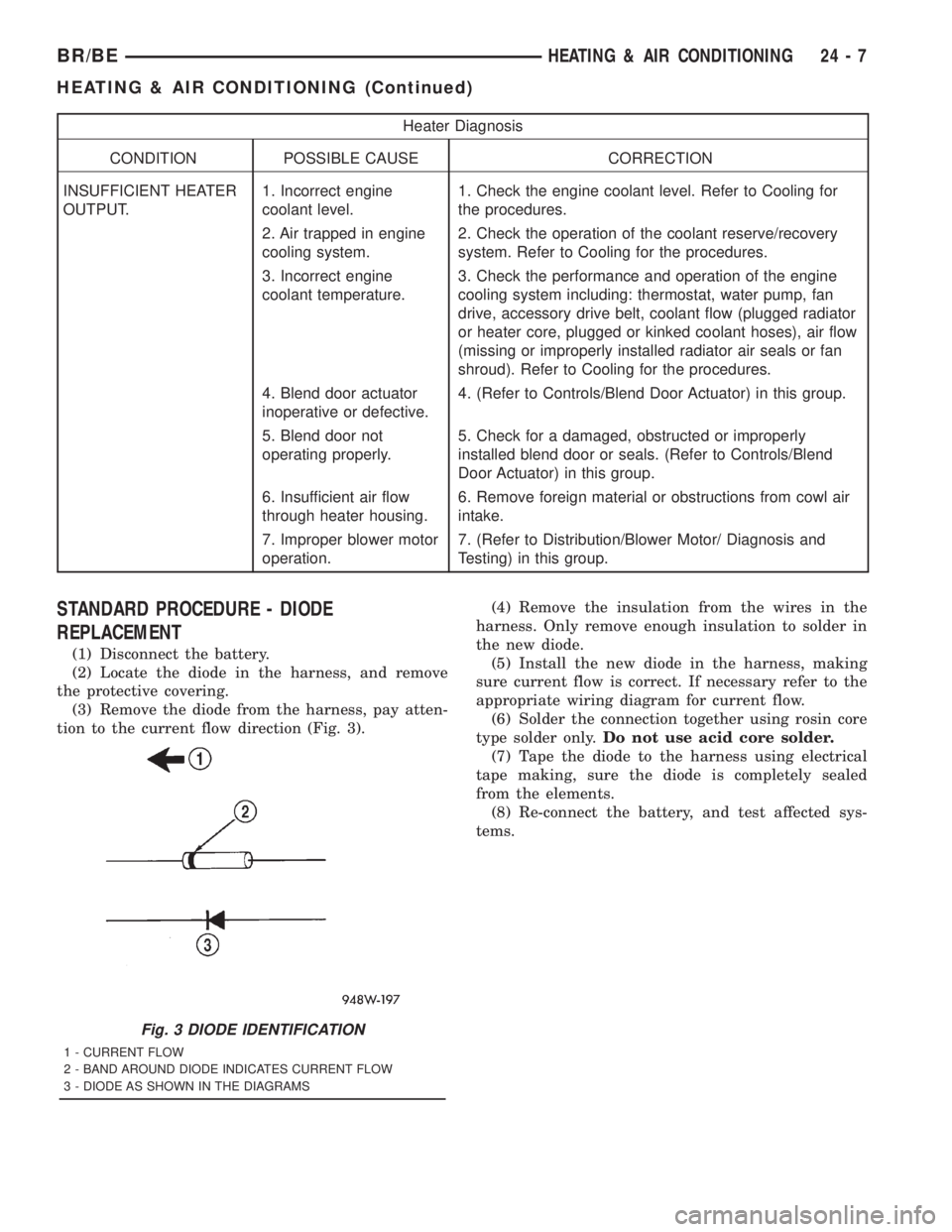

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect the battery.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 3).(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery, and test affected sys-

tems.

Fig. 3 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

BR/BEHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 2742 of 2889

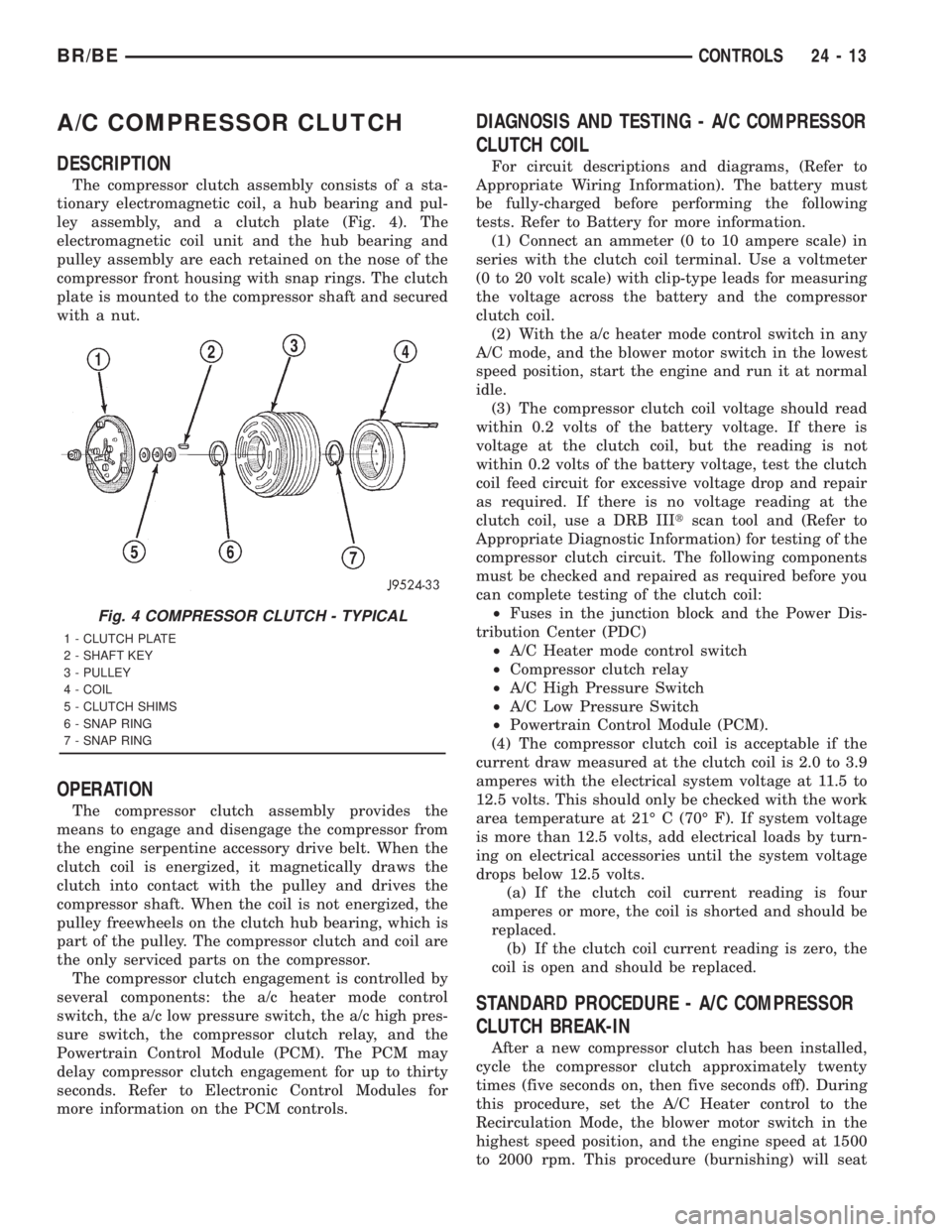

A/C COMPRESSOR CLUTCH

DESCRIPTION

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil, a hub bearing and pul-

ley assembly, and a clutch plate (Fig. 4). The

electromagnetic coil unit and the hub bearing and

pulley assembly are each retained on the nose of the

compressor front housing with snap rings. The clutch

plate is mounted to the compressor shaft and secured

with a nut.

OPERATION

The compressor clutch assembly provides the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch into contact with the pulley and drives the

compressor shaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is

part of the pulley. The compressor clutch and coil are

the only serviced parts on the compressor.

The compressor clutch engagement is controlled by

several components: the a/c heater mode control

switch, the a/c low pressure switch, the a/c high pres-

sure switch, the compressor clutch relay, and the

Powertrain Control Module (PCM). The PCM may

delay compressor clutch engagement for up to thirty

seconds. Refer to Electronic Control Modules for

more information on the PCM controls.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). The battery must

be fully-charged before performing the following

tests. Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the a/c heater mode control switch in any

A/C mode, and the blower motor switch in the lowest

speed position, start the engine and run it at normal

idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRB IIItscan tool and (Refer to

Appropriate Diagnostic Information) for testing of the

compressor clutch circuit. The following components

must be checked and repaired as required before you

can complete testing of the clutch coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C Heater mode control switch

²Compressor clutch relay

²A/C High Pressure Switch

²A/C Low Pressure Switch

²Powertrain Control Module (PCM).

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

STANDARD PROCEDURE - A/C COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C Heater control to the

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

Fig. 4 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY

3 - PULLEY

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

BR/BECONTROLS 24 - 13

Page 2748 of 2889

tom of the a/c heater control panel. Refer to Heated

Mirrors for more information on this feature.

The heater-only or a/c heater control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The control knobs and the illumi-

nation lamps are available for service replacement.

DIAGNOSIS AND TESTING - A/C HEATER

CONTROL

Satisfactory heater and air conditioner perfor-

mance depends upon proper operation and adjust-

ment of all operating controls and refrigeration

system components. For circuit descriptions and dia-

grams, (Refer to Appropriate Wiring Information).

These inspections, tests, and adjustments should be

used to locate the cause of a malfunction.

Operation must be tested as described in the fol-

lowing sequence:

(1) Inspect and adjust the serpentine drive belt.

Refer to Cooling for the procedures.

(2) Start the engine and hold the idle speed at

1,300 rpm.

(3) On vehicles with air conditioning, turn the

temperature control knob to the extreme counter-

clockwise (Cool) position, and set the mode control

switch knob to the Bi-Level (A/C) position. The out-

side (recirculation) air door should be open to outside

air. If not OK, (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS - DIAGNOSIS AND TEST-

ING - VACUUM SYSTEM).

(4) Open the vehicle windows. Test the blower

motor operation in all speeds. If not OK, (Refer to 24

- HEATING & AIR CONDITIONING/DISTRIBU-

TION/BLOWER MOTOR - DIAGNOSIS AND TEST-

ING).

(5) On vehicles with air conditioning, the compres-

sor should be running and the air conditioning sys-

tem in operation unless the ambient air temperature

is below about -1É C (30É F). If not OK, (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE).

(6) Check the mode control switch operation. The

heater and air conditioner systems should respond as

described in the owner's manual in the vehicle glove

box to each mode selected. Reduce the engine speed

to normal idle. The vacuum will be high at low idle

and the vacuum actuators should respond quickly. If

not OK, (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - DIAGNOSIS AND TEST-

ING - VACUUM SYSTEM).

(7) If the vacuum tests, and the electrical compo-

nent and circuit tests reveal no problems, disassem-

ble the HVAC housing to inspect for mechanical

misalignment or binding of the mode doors. (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION/HVAC HOUSING - DISASSEMBLY)

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the instrument panel near the

driver side of the floor panel transmission tunnel and

unplug the a/c heater control to HVAC housing vac-

uum harness connector.

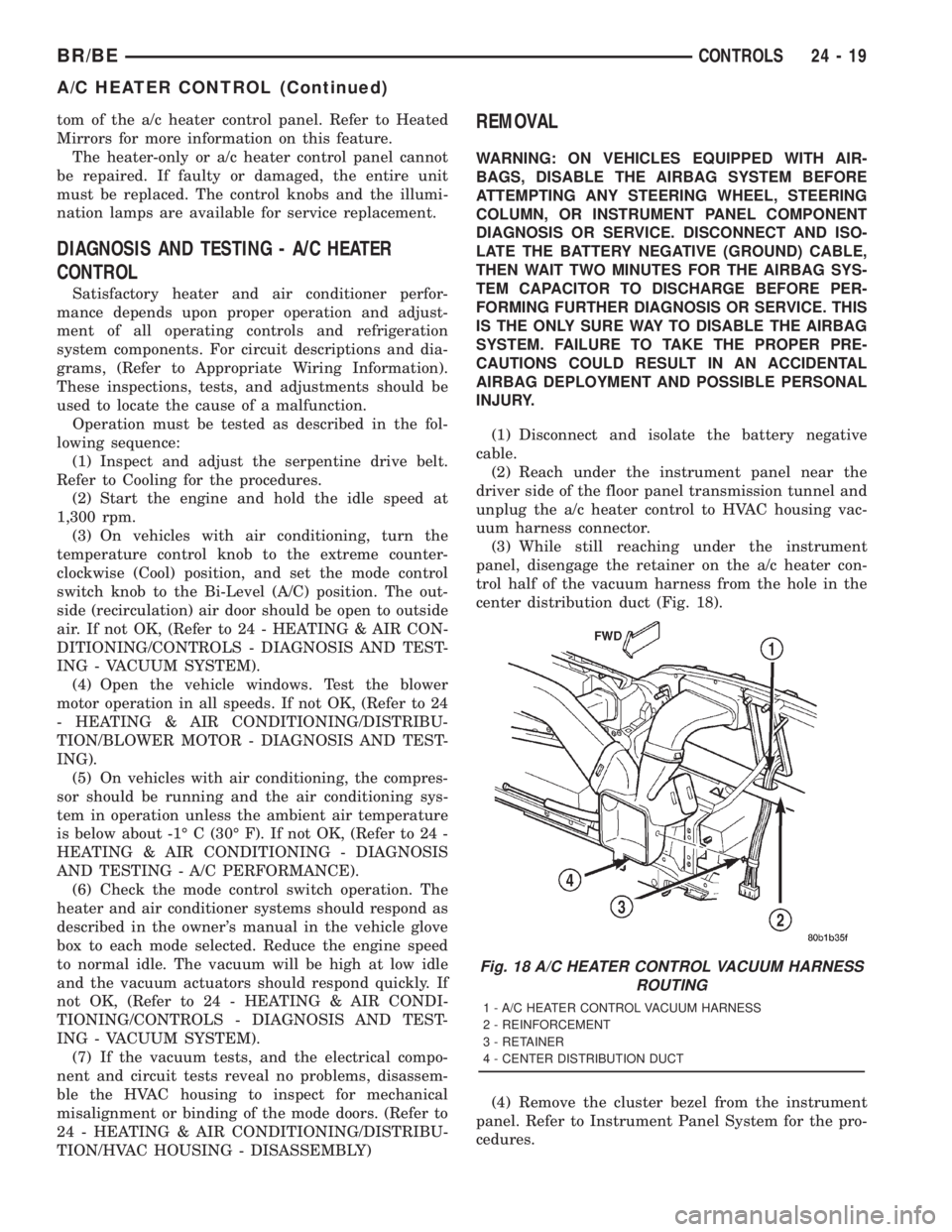

(3) While still reaching under the instrument

panel, disengage the retainer on the a/c heater con-

trol half of the vacuum harness from the hole in the

center distribution duct (Fig. 18).

(4) Remove the cluster bezel from the instrument

panel. Refer to Instrument Panel System for the pro-

cedures.

Fig. 18 A/C HEATER CONTROL VACUUM HARNESS

ROUTING

1 - A/C HEATER CONTROL VACUUM HARNESS

2 - REINFORCEMENT

3 - RETAINER

4 - CENTER DISTRIBUTION DUCT

BR/BECONTROLS 24 - 19

A/C HEATER CONTROL (Continued)

Page 2775 of 2889

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

After the refrigerant system has been tested for

leaks and evacuated, a refrigerant charge can be

injected into the system. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - SPECIFICA-

TIONS - CHARGE CAPACITY)

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to charge the refrigerant system with R-134a

refrigerant. Refer to the operating instructions sup-

plied by the equipment manufacturer for proper care

and use of this equipment.

SPECIFICATIONS

SPECIFICATIONS

The R-134a refrigerant system charge capacity for

this vehicle is: 0.907 kilograms (32 ounces).

A/C COMPRESSOR

DESCRIPTION - A/C COMPRESSOR

The air conditioning system uses a Sanden

SD7H15 seven cylinder, reciprocating wobble plate-

type compressor on all models. This compressor has a

fixed displacement of 150 cubic centimeters (9.375

cubic inches), and has both the suction and discharge

ports located on the cylinder head. A label identifying

the use of R-134a refrigerant is located on the com-

pressor.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor cylinder head, which is at the rear of the

compressor. This mechanical valve is designed to

vent refrigerant from the system to protect against

damage to the compressor and other system compo-

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION - A/C COMPRESSOR

The compressor is driven by the engine through an

electric clutch, drive pulley and belt arrangement.

The compressor is lubricated by refrigerant oil that iscirculated throughout the refrigerant system with the

refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes with

a minimum discharge pressure of 2756 kPa (400 psi)

is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean the valve is faulty.

The high pressure relief valve is a factory-cali-

brated unit. The valve cannot be adjusted or

repaired, and must not be removed or otherwise dis-

turbed. The valve is only serviced as a part of the

compressor assembly.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine temperature, and any

other special conditions. Noises that develop during

air conditioning operation can often be misleading.

For example: What sounds like a failed front bearing

or connecting rod, may be caused by loose bolts, nuts,

mounting brackets, or a loose compressor clutch

assembly.

Drive belts are speed sensitive. At different engine

speeds and depending upon belt tension, belts can

develop noises that are mistaken for a compressor

noise. Improper belt tension can cause a misleading

noise when the compressor clutch is engaged, which

may not occur when the compressor clutch is disen-

gaged. Check the serpentine drive belt condition and

tension as described in Cooling before beginning this

procedure.

(1) Select a quiet area for testing. Duplicate the

complaint conditions as much as possible. Switch the

compressor on and off several times to clearly iden-

tify the compressor noise. Listen to the compressor

while the clutch is engaged and disengaged. Probe

24 - 46 PLUMBINGBR/BE

PLUMBING (Continued)