belt DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1597 of 2889

CONDITION POSSIBLE CAUSE CORRECTION

VEHICLE PULLS OR LEADS TO

ONE SIDE.1. Tire Pressure. 1. Adjust tire pressure.

2. Radial tire lead. 2. Rotate tires.

3. Brakes dragging. 3. Repair as necessary.

4. Wheel alignment. 4. Align front end.

DIAGNOSIS AND TESTING - POWER STEERING

FLOW AND PRESSURE

The following procedure is used to test the opera-

tion of the power steering system on the vehicle. This

test will provide the flow rate of the power steering

pump along with the maximum relief pressure. Per-

form test any time a power steering system problem

is present. This test will determine if the power

steering pump or power steering gear is not function-

ing properly. The following pressure and flow test is

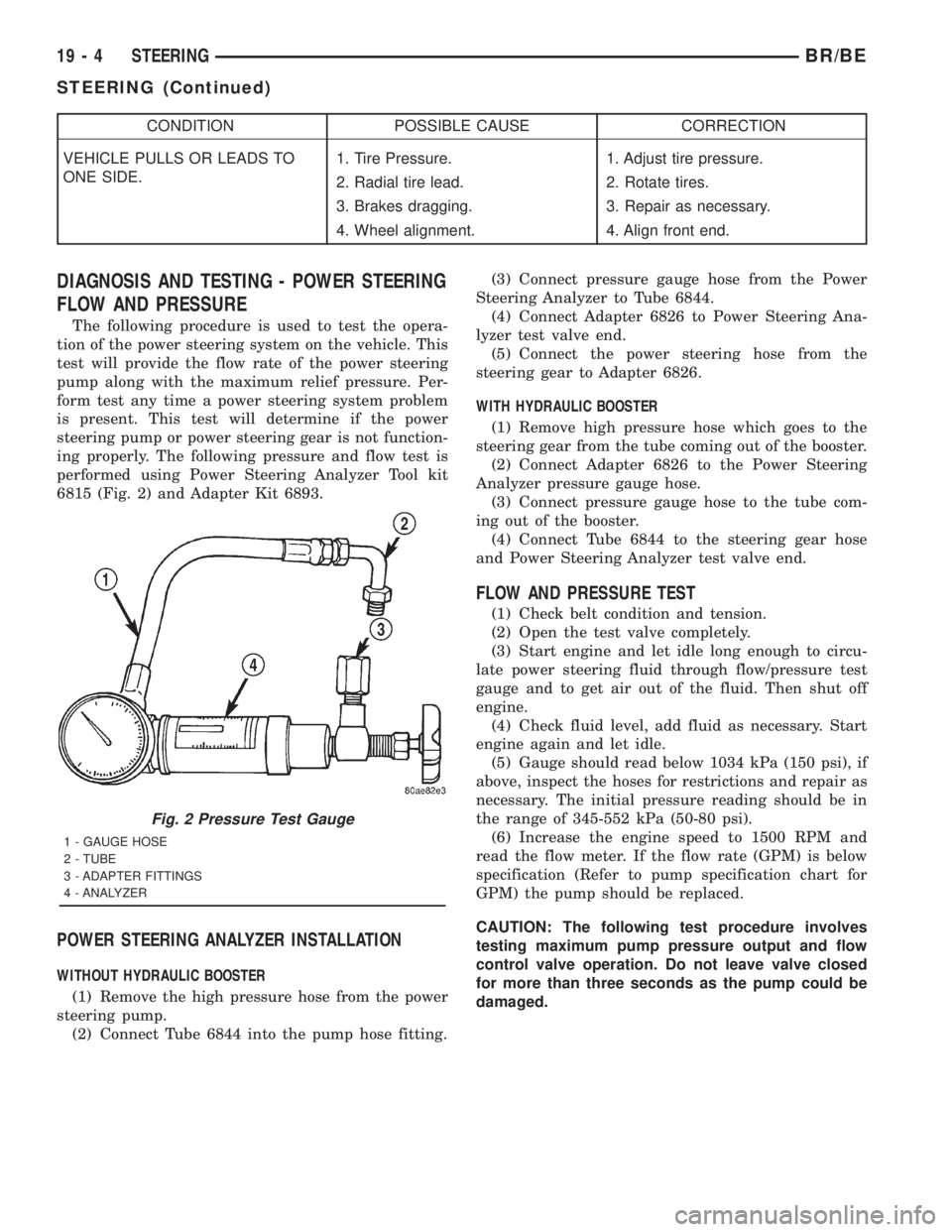

performed using Power Steering Analyzer Tool kit

6815 (Fig. 2) and Adapter Kit 6893.

POWER STEERING ANALYZER INSTALLATION

WITHOUT HYDRAULIC BOOSTER

(1) Remove the high pressure hose from the power

steering pump.

(2) Connect Tube 6844 into the pump hose fitting.(3) Connect pressure gauge hose from the Power

Steering Analyzer to Tube 6844.

(4) Connect Adapter 6826 to Power Steering Ana-

lyzer test valve end.

(5) Connect the power steering hose from the

steering gear to Adapter 6826.

WITH HYDRAULIC BOOSTER

(1) Remove high pressure hose which goes to the

steering gear from the tube coming out of the booster.

(2) Connect Adapter 6826 to the Power Steering

Analyzer pressure gauge hose.

(3) Connect pressure gauge hose to the tube com-

ing out of the booster.

(4) Connect Tube 6844 to the steering gear hose

and Power Steering Analyzer test valve end.

FLOW AND PRESSURE TEST

(1) Check belt condition and tension.

(2) Open the test valve completely.

(3) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

gauge and to get air out of the fluid. Then shut off

engine.

(4) Check fluid level, add fluid as necessary. Start

engine again and let idle.

(5) Gauge should read below 1034 kPa (150 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure reading should be in

the range of 345-552 kPa (50-80 psi).

(6) Increase the engine speed to 1500 RPM and

read the flow meter. If the flow rate (GPM) is below

specification (Refer to pump specification chart for

GPM) the pump should be replaced.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than three seconds as the pump could be

damaged.

Fig. 2 Pressure Test Gauge

1 - GAUGE HOSE

2 - TUBE

3 - ADAPTER FITTINGS

4 - ANALYZER

19 - 4 STEERINGBR/BE

STEERING (Continued)

Page 1624 of 2889

PUMP

TABLE OF CONTENTS

page page

PUMP

DESCRIPTION...........................31

OPERATION.............................31

DIAGNOSIS AND TESTING.................31

PUMP LEAKAGE.......................31

STANDARD PROCEDURE..................31

POWER STEERING PUMP - INITIAL

OPERATION...........................31

FLUSHING POWER STEERING SYSTEM.....32

REMOVAL..............................33

INSTALLATION...........................35SPECIAL TOOLS.........................36

PULLEY

REMOVAL..............................36

INSTALLATION...........................36

HOSES - PRESSURE

DESCRIPTION...........................37

OPERATION.............................37

HOSES - RETURN

DESCRIPTION...........................37

OPERATION.............................37

PUMP

DESCRIPTION

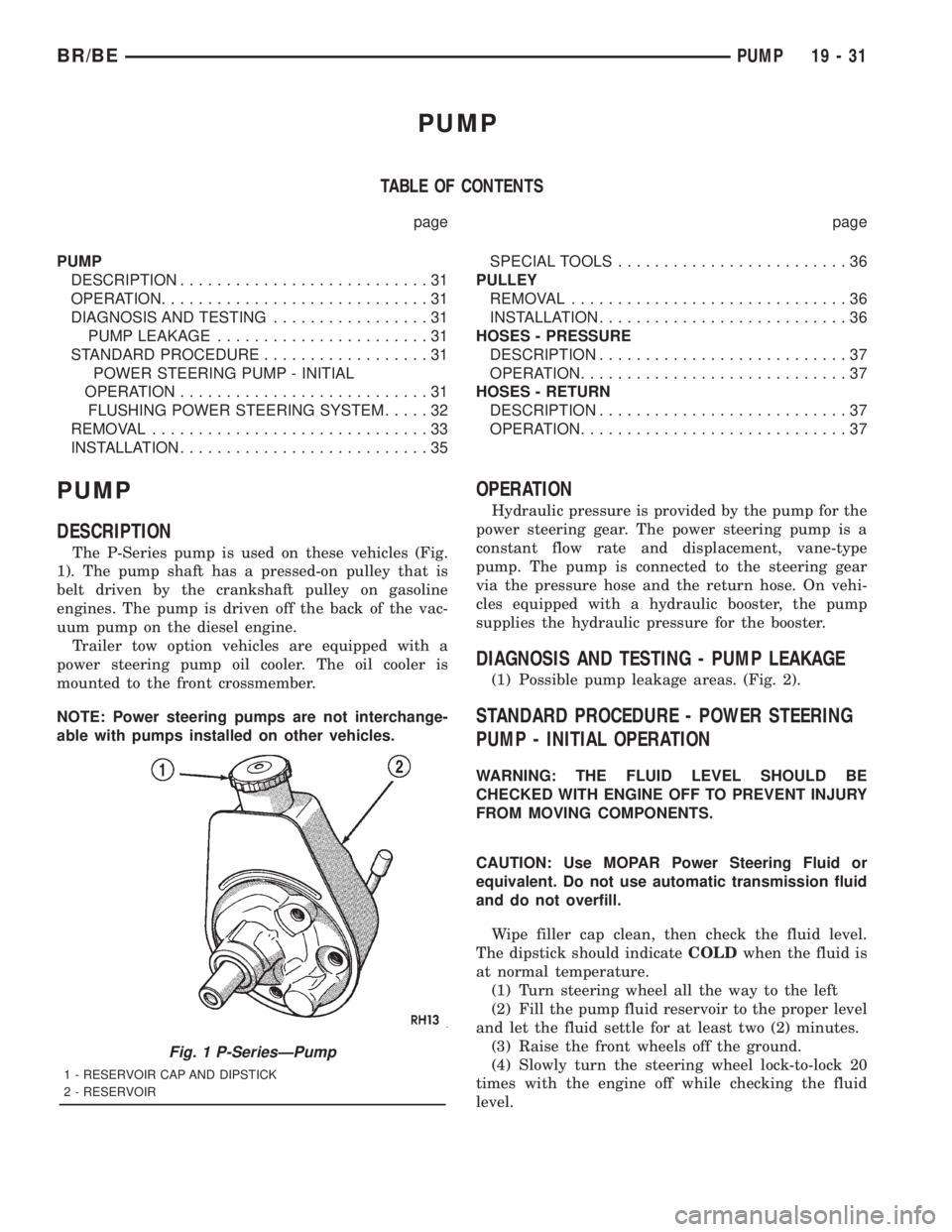

The P-Series pump is used on these vehicles (Fig.

1). The pump shaft has a pressed-on pulley that is

belt driven by the crankshaft pulley on gasoline

engines. The pump is driven off the back of the vac-

uum pump on the diesel engine.

Trailer tow option vehicles are equipped with a

power steering pump oil cooler. The oil cooler is

mounted to the front crossmember.

NOTE: Power steering pumps are not interchange-

able with pumps installed on other vehicles.

OPERATION

Hydraulic pressure is provided by the pump for the

power steering gear. The power steering pump is a

constant flow rate and displacement, vane-type

pump. The pump is connected to the steering gear

via the pressure hose and the return hose. On vehi-

cles equipped with a hydraulic booster, the pump

supplies the hydraulic pressure for the booster.

DIAGNOSIS AND TESTING - PUMP LEAKAGE

(1) Possible pump leakage areas. (Fig. 2).

STANDARD PROCEDURE - POWER STEERING

PUMP - INITIAL OPERATION

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature.

(1) Turn steering wheel all the way to the left

(2) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes.

(3) Raise the front wheels off the ground.

(4) Slowly turn the steering wheel lock-to-lock 20

times with the engine off while checking the fluid

level.

Fig. 1 P-SeriesÐPump

1 - RESERVOIR CAP AND DIPSTICK

2 - RESERVOIR

BR/BEPUMP 19 - 31

Page 1626 of 2889

(8) Fill the system with fluid and perform Steering

Pump Initial Operation, (Refer to 19 - STEERING/

PUMP - STANDARD PROCEDURE).

(9) Start the engine and run it for fifteen minutes

then stop the engine.

(10) Remove the return line/lines from the pump

and plug the pump port/ports.

(11) Pour fresh fluid into the reservoir and check

the draining fluid for contamination. If the fluid is

still contaminated, disassemble and clean the steer-

ing gear and flush the system again.

(12) Install the return line/lines and perform

Steering Pump Initial Operation, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

REMOVAL - GASOLINE ENGINE

(1) Remove the serpentine drive belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL) OR (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - REMOVAL).

(2) Remove the hoses from the power steering

pump and cap the fittings.

(3) Remove battery ground cable and unthread

stud from cylinder head, do not remove from bracket.

(4) Loosen upper bracket bolt and remove the

lower bracket to engine block bolts.

(5) Pivot the pump assembly past the coolant tube.

(6) Remove the upper stud and remove upper bolt

from cylinder head.

(7) Remove steering pump and mounting bracket

from engine as an assembly.

(8) Remove the pump pulley with Puller C-4333, to

access pump attaching bolts, (Refer to 19 - STEER-

ING/PUMP/PULLEY - REMOVAL).

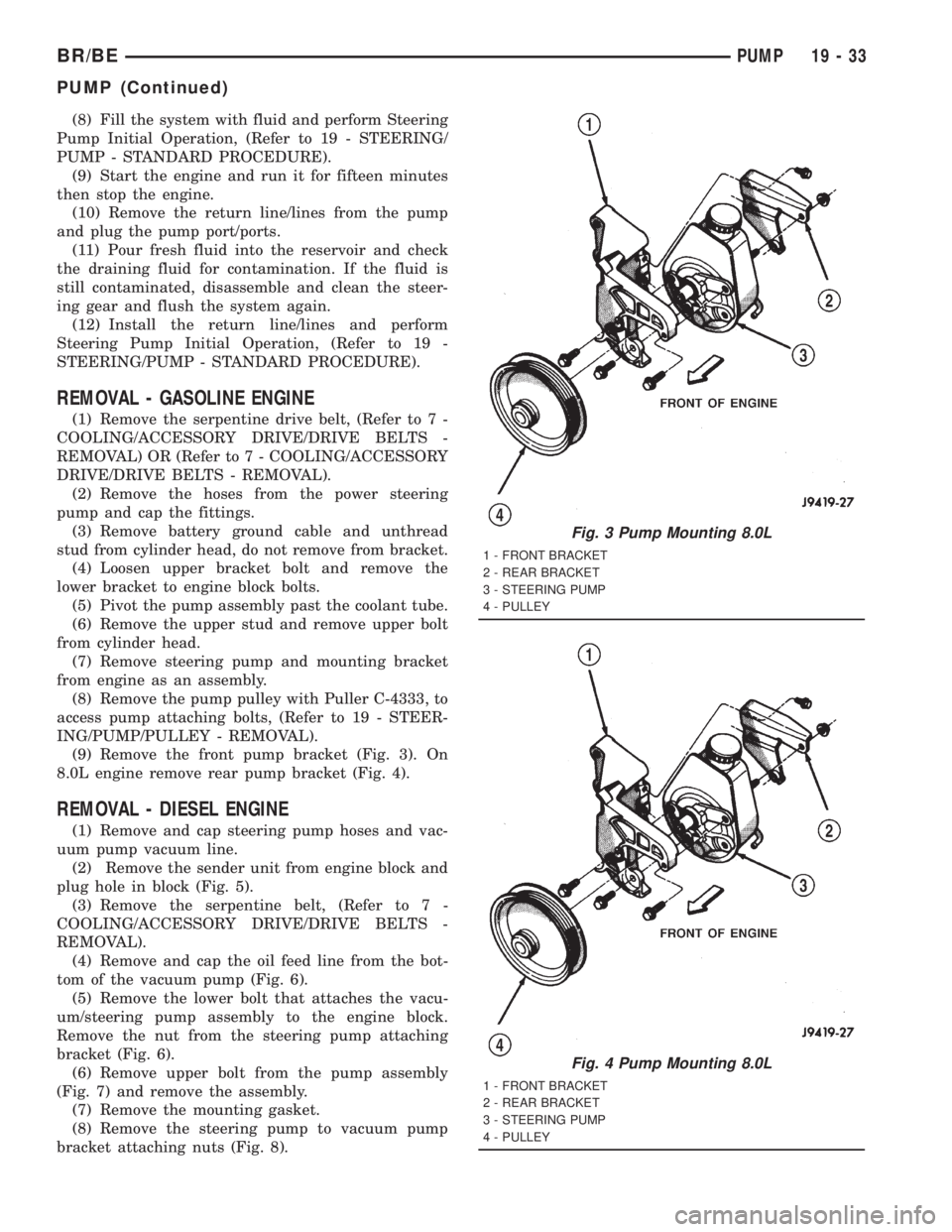

(9) Remove the front pump bracket (Fig. 3). On

8.0L engine remove rear pump bracket (Fig. 4).

REMOVAL - DIESEL ENGINE

(1) Remove and cap steering pump hoses and vac-

uum pump vacuum line.

(2) Remove the sender unit from engine block and

plug hole in block (Fig. 5).

(3) Remove the serpentine belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove and cap the oil feed line from the bot-

tom of the vacuum pump (Fig. 6).

(5) Remove the lower bolt that attaches the vacu-

um/steering pump assembly to the engine block.

Remove the nut from the steering pump attaching

bracket (Fig. 6).

(6) Remove upper bolt from the pump assembly

(Fig. 7) and remove the assembly.

(7) Remove the mounting gasket.

(8) Remove the steering pump to vacuum pump

bracket attaching nuts (Fig. 8).

Fig. 3 Pump Mounting 8.0L

1 - FRONT BRACKET

2 - REAR BRACKET

3 - STEERING PUMP

4 - PULLEY

Fig. 4 Pump Mounting 8.0L

1 - FRONT BRACKET

2 - REAR BRACKET

3 - STEERING PUMP

4 - PULLEY

BR/BEPUMP 19 - 33

PUMP (Continued)

Page 1628 of 2889

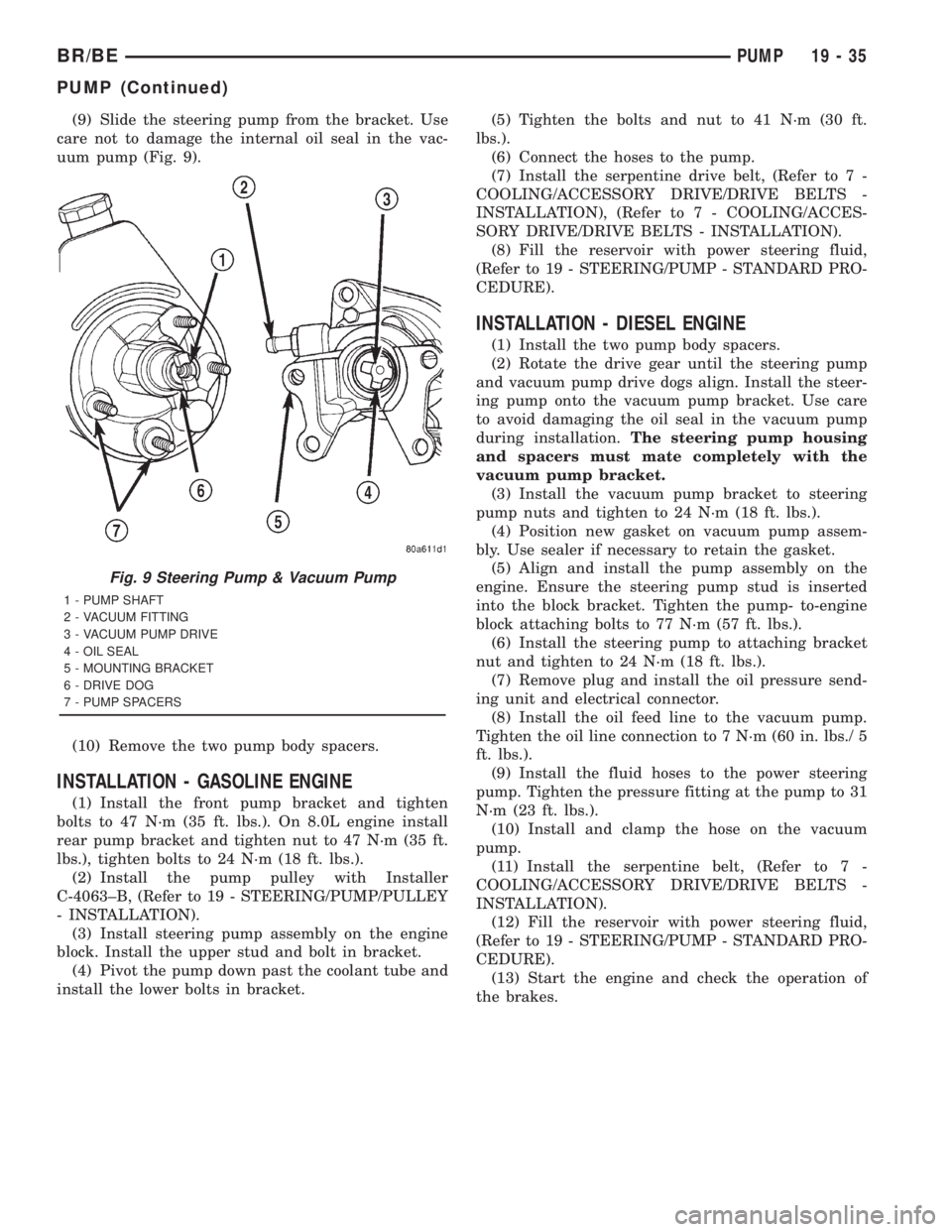

(9) Slide the steering pump from the bracket. Use

care not to damage the internal oil seal in the vac-

uum pump (Fig. 9).

(10) Remove the two pump body spacers.

INSTALLATION - GASOLINE ENGINE

(1) Install the front pump bracket and tighten

bolts to 47 N´m (35 ft. lbs.). On 8.0L engine install

rear pump bracket and tighten nut to 47 N´m (35 ft.

lbs.), tighten bolts to 24 N´m (18 ft. lbs.).

(2) Install the pump pulley with Installer

C-4063±B, (Refer to 19 - STEERING/PUMP/PULLEY

- INSTALLATION).

(3) Install steering pump assembly on the engine

block. Install the upper stud and bolt in bracket.

(4) Pivot the pump down past the coolant tube and

install the lower bolts in bracket.(5) Tighten the bolts and nut to 41 N´m (30 ft.

lbs.).

(6) Connect the hoses to the pump.

(7) Install the serpentine drive belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION), (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - INSTALLATION).

(8) Fill the reservoir with power steering fluid,

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE).

INSTALLATION - DIESEL ENGINE

(1) Install the two pump body spacers.

(2) Rotate the drive gear until the steering pump

and vacuum pump drive dogs align. Install the steer-

ing pump onto the vacuum pump bracket. Use care

to avoid damaging the oil seal in the vacuum pump

during installation.The steering pump housing

and spacers must mate completely with the

vacuum pump bracket.

(3) Install the vacuum pump bracket to steering

pump nuts and tighten to 24 N´m (18 ft. lbs.).

(4) Position new gasket on vacuum pump assem-

bly. Use sealer if necessary to retain the gasket.

(5) Align and install the pump assembly on the

engine. Ensure the steering pump stud is inserted

into the block bracket. Tighten the pump- to-engine

block attaching bolts to 77 N´m (57 ft. lbs.).

(6) Install the steering pump to attaching bracket

nut and tighten to 24 N´m (18 ft. lbs.).

(7) Remove plug and install the oil pressure send-

ing unit and electrical connector.

(8) Install the oil feed line to the vacuum pump.

Tighten the oil line connection to 7 N´m (60 in. lbs./ 5

ft. lbs.).

(9) Install the fluid hoses to the power steering

pump. Tighten the pressure fitting at the pump to 31

N´m (23 ft. lbs.).

(10) Install and clamp the hose on the vacuum

pump.

(11) Install the serpentine belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(12) Fill the reservoir with power steering fluid,

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE).

(13) Start the engine and check the operation of

the brakes.

Fig. 9 Steering Pump & Vacuum Pump

1 - PUMP SHAFT

2 - VACUUM FITTING

3 - VACUUM PUMP DRIVE

4 - OIL SEAL

5 - MOUNTING BRACKET

6 - DRIVE DOG

7 - PUMP SPACERS

BR/BEPUMP 19 - 35

PUMP (Continued)

Page 1629 of 2889

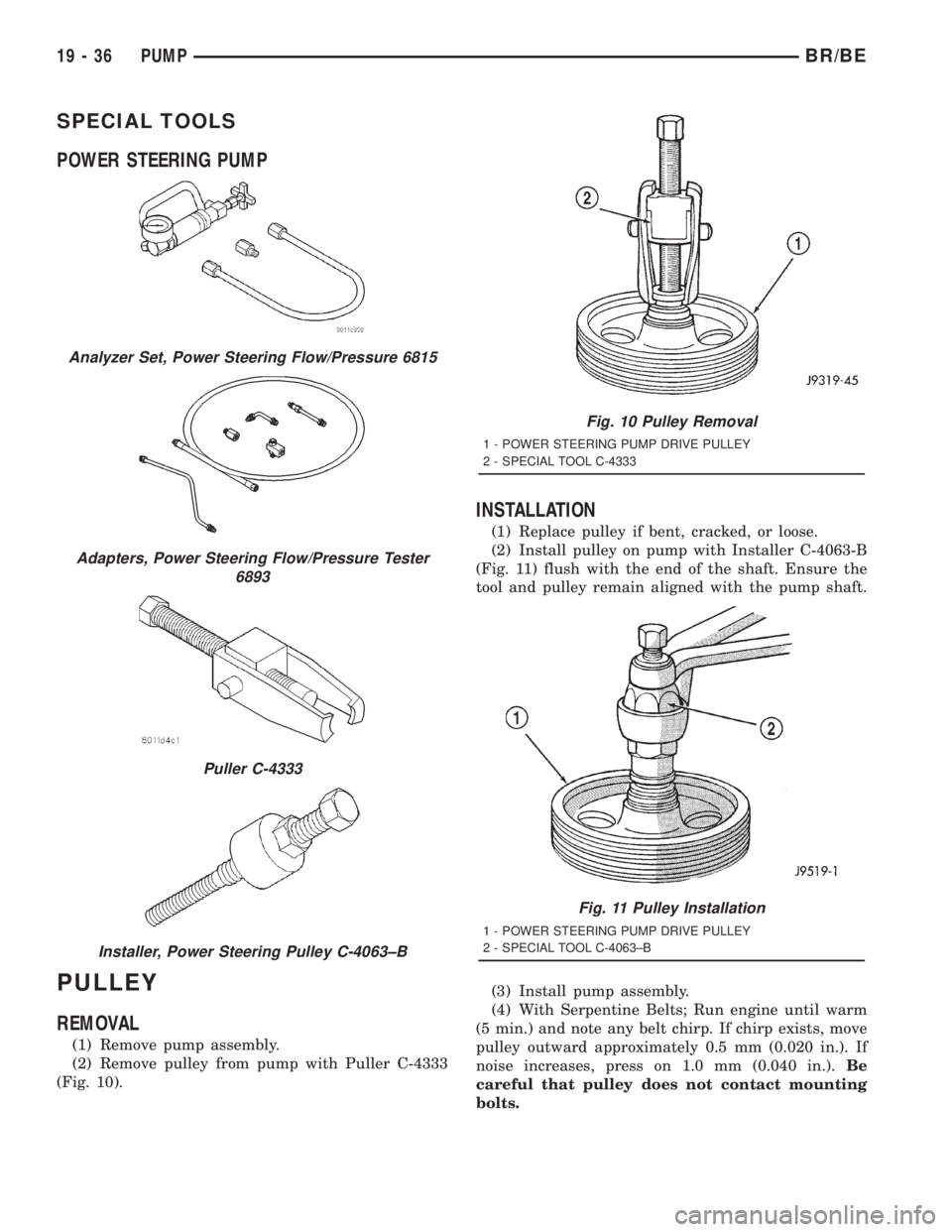

SPECIAL TOOLS

POWER STEERING PUMP

PULLEY

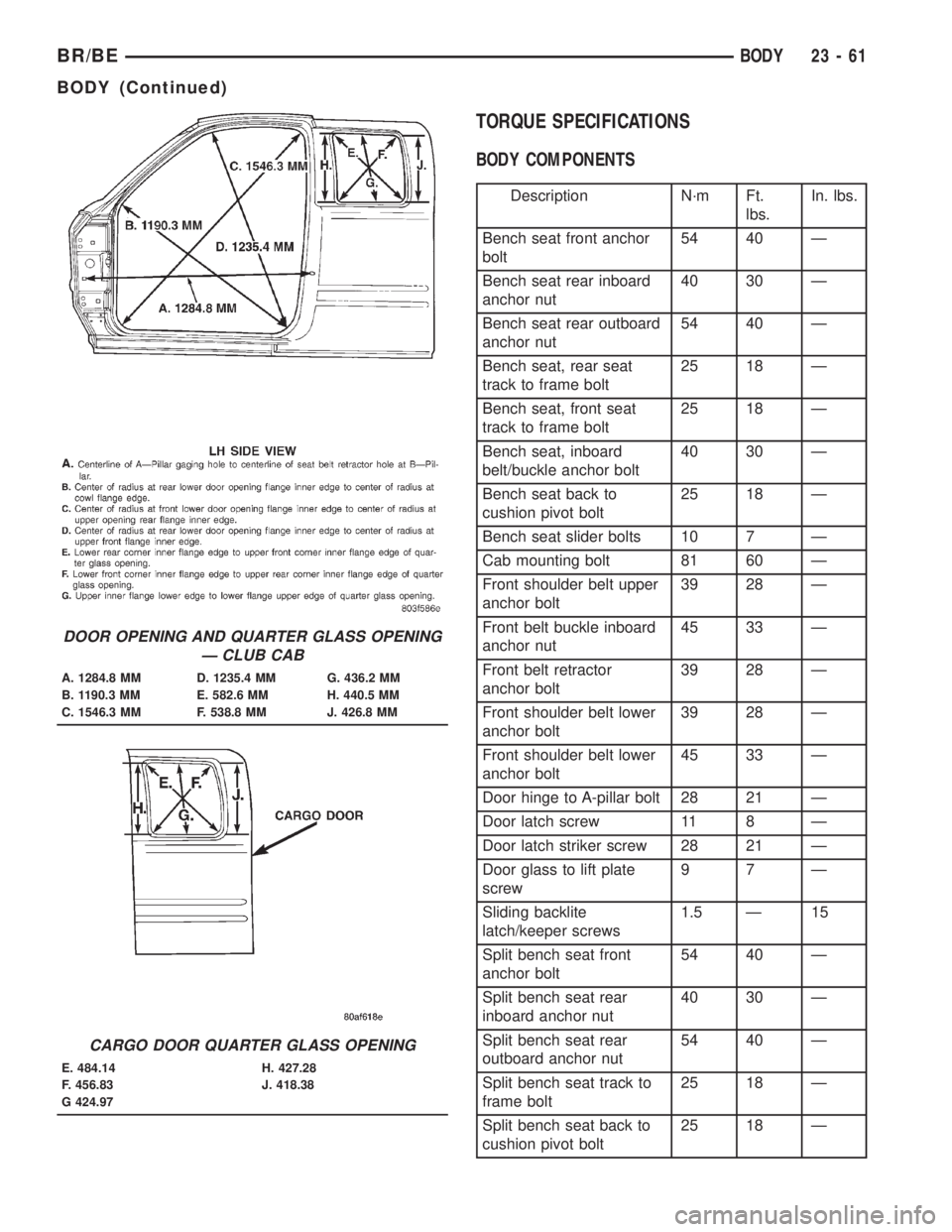

REMOVAL

(1) Remove pump assembly.

(2) Remove pulley from pump with Puller C-4333

(Fig. 10).

INSTALLATION

(1) Replace pulley if bent, cracked, or loose.

(2) Install pulley on pump with Installer C-4063-B

(Fig. 11) flush with the end of the shaft. Ensure the

tool and pulley remain aligned with the pump shaft.

(3) Install pump assembly.

(4) With Serpentine Belts; Run engine until warm

(5 min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0 mm (0.040 in.).Be

careful that pulley does not contact mounting

bolts.

Analyzer Set, Power Steering Flow/Pressure 6815

Adapters, Power Steering Flow/Pressure Tester

6893

Puller C-4333

Installer, Power Steering Pulley C-4063±B

Fig. 10 Pulley Removal

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL C-4333

Fig. 11 Pulley Installation

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL C-4063±B

19 - 36 PUMPBR/BE

Page 2634 of 2889

TORQUE SPECIFICATIONS

BODY COMPONENTS

Description N´m Ft.

lbs.In. lbs.

Bench seat front anchor

bolt54 40 Ð

Bench seat rear inboard

anchor nut40 30 Ð

Bench seat rear outboard

anchor nut54 40 Ð

Bench seat, rear seat

track to frame bolt25 18 Ð

Bench seat, front seat

track to frame bolt25 18 Ð

Bench seat, inboard

belt/buckle anchor bolt40 30 Ð

Bench seat back to

cushion pivot bolt25 18 Ð

Bench seat slider bolts 10 7 Ð

Cab mounting bolt 81 60 Ð

Front shoulder belt upper

anchor bolt39 28 Ð

Front belt buckle inboard

anchor nut45 33 Ð

Front belt retractor

anchor bolt39 28 Ð

Front shoulder belt lower

anchor bolt39 28 Ð

Front shoulder belt lower

anchor bolt45 33 Ð

Door hinge to A-pillar bolt 28 21 Ð

Door latch screw 11 8 Ð

Door latch striker screw 28 21 Ð

Door glass to lift plate

screw97Ð

Sliding backlite

latch/keeper screws1.5 Ð 15

Split bench seat front

anchor bolt54 40 Ð

Split bench seat rear

inboard anchor nut40 30 Ð

Split bench seat rear

outboard anchor nut54 40 Ð

Split bench seat track to

frame bolt25 18 Ð

Split bench seat back to

cushion pivot bolt25 18 Ð

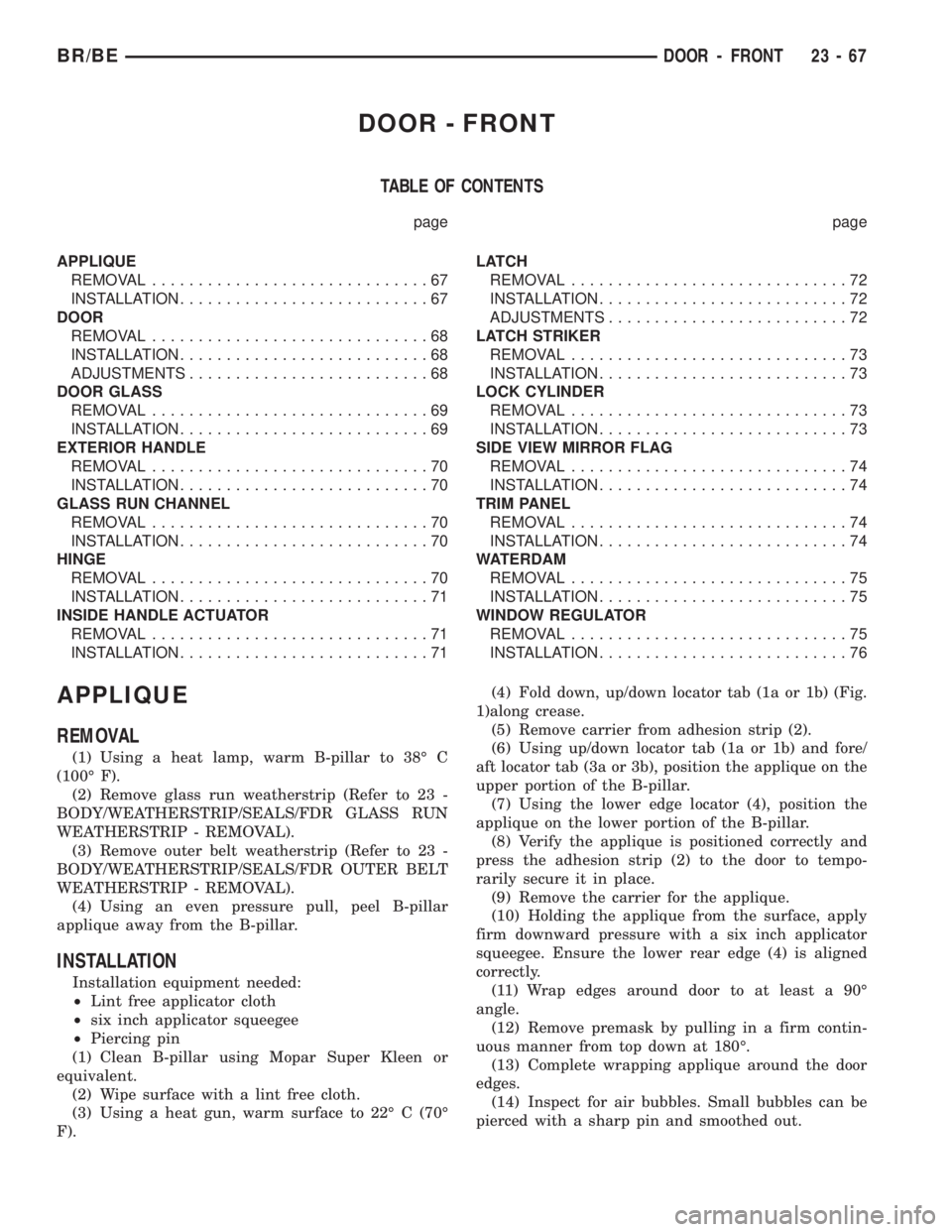

DOOR OPENING AND QUARTER GLASS OPENING

Ð CLUB CAB

A. 1284.8 MM D. 1235.4 MM G. 436.2 MM

B. 1190.3 MM E. 582.6 MM H. 440.5 MM

C. 1546.3 MM F. 538.8 MM J. 426.8 MM

CARGO DOOR QUARTER GLASS OPENING

E. 484.14 H. 427.28

F. 456.83 J. 418.38

G 424.97

BR/BEBODY 23 - 61

BODY (Continued)

Page 2640 of 2889

DOOR - FRONT

TABLE OF CONTENTS

page page

APPLIQUE

REMOVAL..............................67

INSTALLATION...........................67

DOOR

REMOVAL..............................68

INSTALLATION...........................68

ADJUSTMENTS..........................68

DOOR GLASS

REMOVAL..............................69

INSTALLATION...........................69

EXTERIOR HANDLE

REMOVAL..............................70

INSTALLATION...........................70

GLASS RUN CHANNEL

REMOVAL..............................70

INSTALLATION...........................70

HINGE

REMOVAL..............................70

INSTALLATION...........................71

INSIDE HANDLE ACTUATOR

REMOVAL..............................71

INSTALLATION...........................71LATCH

REMOVAL..............................72

INSTALLATION...........................72

ADJUSTMENTS..........................72

LATCH STRIKER

REMOVAL..............................73

INSTALLATION...........................73

LOCK CYLINDER

REMOVAL..............................73

INSTALLATION...........................73

SIDE VIEW MIRROR FLAG

REMOVAL..............................74

INSTALLATION...........................74

TRIM PANEL

REMOVAL..............................74

INSTALLATION...........................74

WATERDAM

REMOVAL..............................75

INSTALLATION...........................75

WINDOW REGULATOR

REMOVAL..............................75

INSTALLATION...........................76

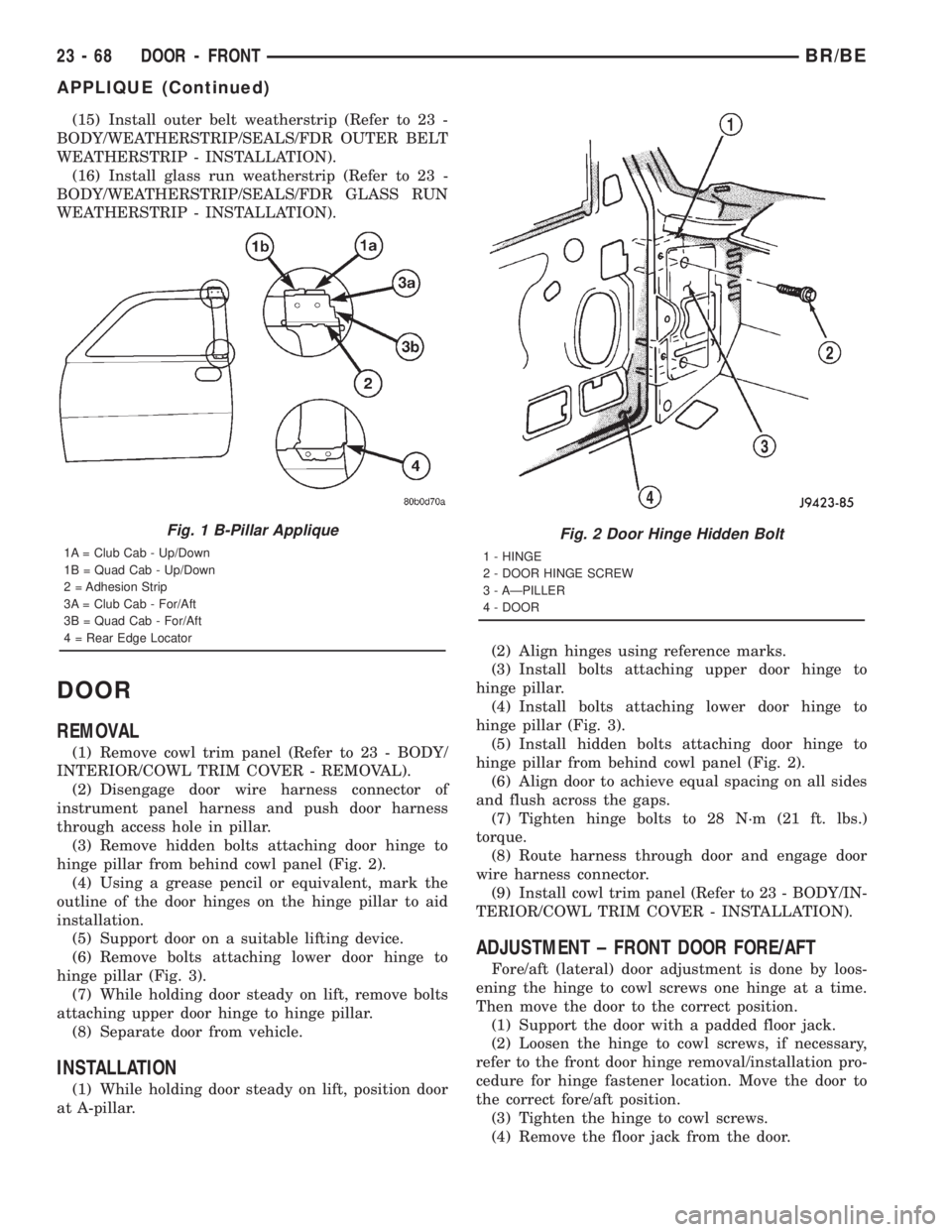

APPLIQUE

REMOVAL

(1) Using a heat lamp, warm B-pillar to 38É C

(100É F).

(2) Remove glass run weatherstrip (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR GLASS RUN

WEATHERSTRIP - REMOVAL).

(3) Remove outer belt weatherstrip (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR OUTER BELT

WEATHERSTRIP - REMOVAL).

(4) Using an even pressure pull, peel B-pillar

applique away from the B-pillar.

INSTALLATION

Installation equipment needed:

²Lint free applicator cloth

²six inch applicator squeegee

²Piercing pin

(1) Clean B-pillar using Mopar Super Kleen or

equivalent.

(2) Wipe surface with a lint free cloth.

(3) Using a heat gun, warm surface to 22É C (70É

F).(4) Fold down, up/down locator tab (1a or 1b) (Fig.

1)along crease.

(5) Remove carrier from adhesion strip (2).

(6) Using up/down locator tab (1a or 1b) and fore/

aft locator tab (3a or 3b), position the applique on the

upper portion of the B-pillar.

(7) Using the lower edge locator (4), position the

applique on the lower portion of the B-pillar.

(8) Verify the applique is positioned correctly and

press the adhesion strip (2) to the door to tempo-

rarily secure it in place.

(9) Remove the carrier for the applique.

(10) Holding the applique from the surface, apply

firm downward pressure with a six inch applicator

squeegee. Ensure the lower rear edge (4) is aligned

correctly.

(11) Wrap edges around door to at least a 90É

angle.

(12) Remove premask by pulling in a firm contin-

uous manner from top down at 180É.

(13) Complete wrapping applique around the door

edges.

(14) Inspect for air bubbles. Small bubbles can be

pierced with a sharp pin and smoothed out.

BR/BEDOOR - FRONT 23 - 67

Page 2641 of 2889

(15) Install outer belt weatherstrip (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR OUTER BELT

WEATHERSTRIP - INSTALLATION).

(16) Install glass run weatherstrip (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR GLASS RUN

WEATHERSTRIP - INSTALLATION).

DOOR

REMOVAL

(1) Remove cowl trim panel (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - REMOVAL).

(2) Disengage door wire harness connector of

instrument panel harness and push door harness

through access hole in pillar.

(3) Remove hidden bolts attaching door hinge to

hinge pillar from behind cowl panel (Fig. 2).

(4) Using a grease pencil or equivalent, mark the

outline of the door hinges on the hinge pillar to aid

installation.

(5) Support door on a suitable lifting device.

(6) Remove bolts attaching lower door hinge to

hinge pillar (Fig. 3).

(7) While holding door steady on lift, remove bolts

attaching upper door hinge to hinge pillar.

(8) Separate door from vehicle.

INSTALLATION

(1) While holding door steady on lift, position door

at A-pillar.(2) Align hinges using reference marks.

(3) Install bolts attaching upper door hinge to

hinge pillar.

(4) Install bolts attaching lower door hinge to

hinge pillar (Fig. 3).

(5) Install hidden bolts attaching door hinge to

hinge pillar from behind cowl panel (Fig. 2).

(6) Align door to achieve equal spacing on all sides

and flush across the gaps.

(7) Tighten hinge bolts to 28 N´m (21 ft. lbs.)

torque.

(8) Route harness through door and engage door

wire harness connector.

(9) Install cowl trim panel (Refer to 23 - BODY/IN-

TERIOR/COWL TRIM COVER - INSTALLATION).

ADJUSTMENT ± FRONT DOOR FORE/AFT

Fore/aft (lateral) door adjustment is done by loos-

ening the hinge to cowl screws one hinge at a time.

Then move the door to the correct position.

(1) Support the door with a padded floor jack.

(2) Loosen the hinge to cowl screws, if necessary,

refer to the front door hinge removal/installation pro-

cedure for hinge fastener location. Move the door to

the correct fore/aft position.

(3) Tighten the hinge to cowl screws.

(4) Remove the floor jack from the door.

Fig. 1 B-Pillar Applique

1A = Club Cab - Up/Down

1B = Quad Cab - Up/Down

2 = Adhesion Strip

3A = Club Cab - For/Aft

3B = Quad Cab - For/Aft

4 = Rear Edge Locator

Fig. 2 Door Hinge Hidden Bolt

1 - HINGE

2 - DOOR HINGE SCREW

3 - AÐPILLER

4 - DOOR

23 - 68 DOOR - FRONTBR/BE

APPLIQUE (Continued)

Page 2642 of 2889

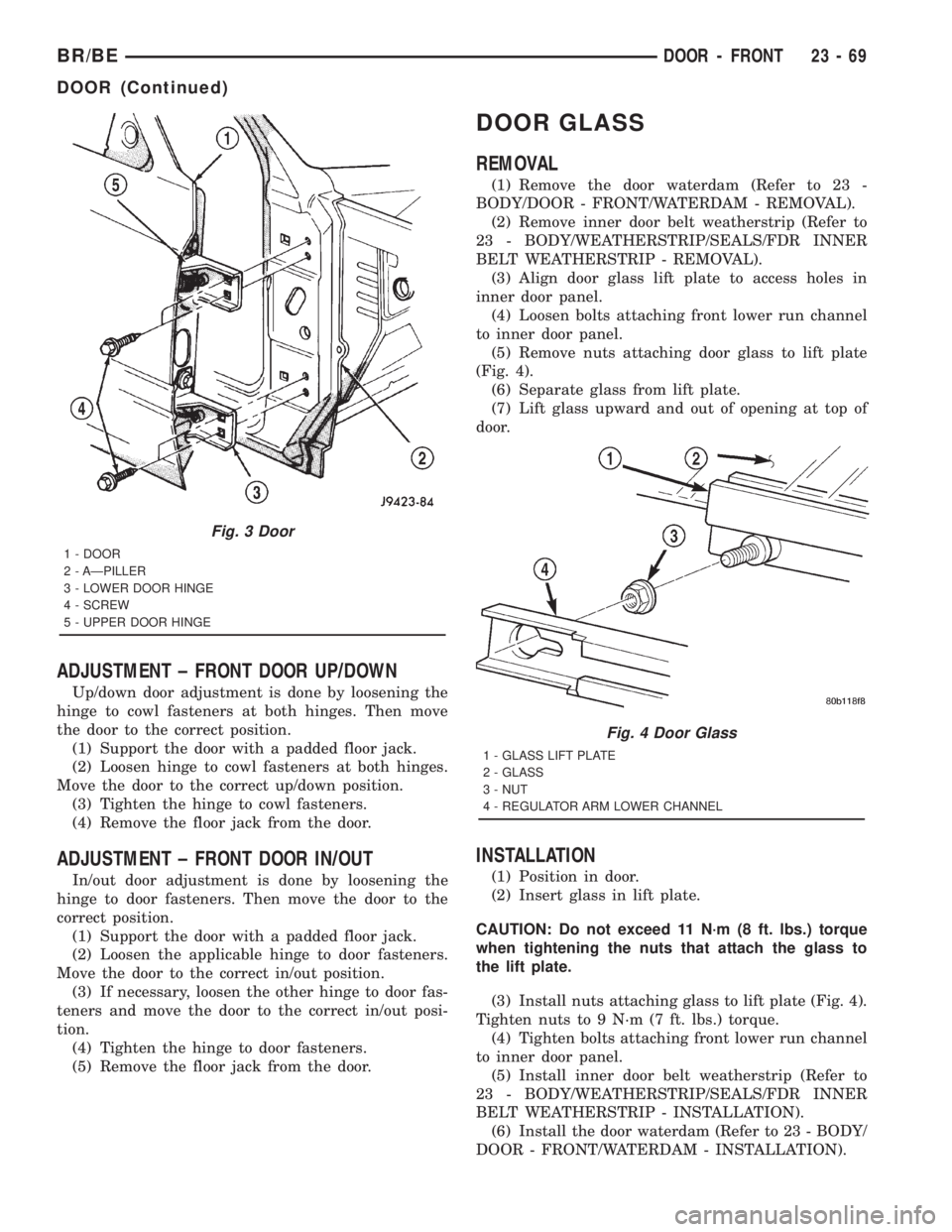

ADJUSTMENT ± FRONT DOOR UP/DOWN

Up/down door adjustment is done by loosening the

hinge to cowl fasteners at both hinges. Then move

the door to the correct position.

(1) Support the door with a padded floor jack.

(2) Loosen hinge to cowl fasteners at both hinges.

Move the door to the correct up/down position.

(3) Tighten the hinge to cowl fasteners.

(4) Remove the floor jack from the door.

ADJUSTMENT ± FRONT DOOR IN/OUT

In/out door adjustment is done by loosening the

hinge to door fasteners. Then move the door to the

correct position.

(1) Support the door with a padded floor jack.

(2) Loosen the applicable hinge to door fasteners.

Move the door to the correct in/out position.

(3) If necessary, loosen the other hinge to door fas-

teners and move the door to the correct in/out posi-

tion.

(4) Tighten the hinge to door fasteners.

(5) Remove the floor jack from the door.

DOOR GLASS

REMOVAL

(1) Remove the door waterdam (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Remove inner door belt weatherstrip (Refer to

23 - BODY/WEATHERSTRIP/SEALS/FDR INNER

BELT WEATHERSTRIP - REMOVAL).

(3) Align door glass lift plate to access holes in

inner door panel.

(4) Loosen bolts attaching front lower run channel

to inner door panel.

(5) Remove nuts attaching door glass to lift plate

(Fig. 4).

(6) Separate glass from lift plate.

(7) Lift glass upward and out of opening at top of

door.

INSTALLATION

(1) Position in door.

(2) Insert glass in lift plate.

CAUTION: Do not exceed 11 N´m (8 ft. lbs.) torque

when tightening the nuts that attach the glass to

the lift plate.

(3) Install nuts attaching glass to lift plate (Fig. 4).

Tighten nuts to 9 N´m (7 ft. lbs.) torque.

(4) Tighten bolts attaching front lower run channel

to inner door panel.

(5) Install inner door belt weatherstrip (Refer to

23 - BODY/WEATHERSTRIP/SEALS/FDR INNER

BELT WEATHERSTRIP - INSTALLATION).

(6) Install the door waterdam (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION).

Fig. 3 Door

1 - DOOR

2 - AÐPILLER

3 - LOWER DOOR HINGE

4 - SCREW

5 - UPPER DOOR HINGE

Fig. 4 Door Glass

1 - GLASS LIFT PLATE

2 - GLASS

3 - NUT

4 - REGULATOR ARM LOWER CHANNEL

BR/BEDOOR - FRONT 23 - 69

DOOR (Continued)

Page 2677 of 2889

INSTRUMENT PANEL SYSTEM

TABLE OF CONTENTS

page page

INSTRUMENT PANEL SYSTEM

DESCRIPTION..........................104

OPERATION............................105

REMOVAL.............................106

INSTALLATION..........................107

ASH RECEIVER

REMOVAL.............................108

INSTALLATION..........................109

CLUSTER BEZEL

REMOVAL.............................109

INSTALLATION..........................110

CUBBY BIN

REMOVAL.............................110

INSTALLATION..........................110

CUP HOLDER

REMOVAL.............................110

INSTALLATION..........................111

GLOVE BOX

REMOVAL.............................112DISASSEMBLY..........................112

ASSEMBLY.............................112

INSTALLATION..........................113

GLOVE BOX LATCH STRIKER

REMOVAL.............................113

INSTALLATION..........................113

GLOVE BOX OPENING UPPER TRIM

REMOVAL.............................114

INSTALLATION..........................114

INSTRUMENT PANEL TOP COVER

REMOVAL.............................114

INSTALLATION..........................115

STEERING COLUMN OPENING COVER

REMOVAL.............................115

INSTALLATION..........................116

STORAGE BIN

REMOVAL.............................116

INSTALLATION..........................116

INSTRUMENT PANEL SYSTEM

DESCRIPTION

The instrument panel is located at the front of the

passenger compartment. This instrument panel is

molded from a blend of various plastics that are

mechanically attached to the vehicle. Colors are

molded into the plastic components to minimize

appearance degradation from scratches or abrasions.

The panel components are internally ribbed and riv-

eted to steel reinforcements for additional structural

integrity and dimensional stability. The instrument

panel surface components are designed to deform

upon impact without breaking. This type of construc-

tion provides improved energy absorption which, in

conjunction with the dual airbags and seat belts,

helps to improve occupant protection.

The top of the instrument panel is secured to the

top of the dash panel near the base of the windshield

using screws. An end bracket integral to each end of

the instrument panel structure is secured to each

cowl side inner panel with a screw. A stamped metal

bracket supports the center of the instrument panel

by securing it to the top of the floor panel transmis-

sion tunnel below the instrument panel with screws.

The instrument cluster, radio, heater-air conditioner

control, passenger airbag, glove box, electrical junc-

tion block, Central Timer Module (CTM), accessoryswitches, ash receiver, cigar lighter, accessory power

outlet, park brake release handle, inside hood release

handle, as well as numerous other components are

secured to and supported by this unit.

The instrument panel for this vehicle includes the

following major features:

²Cluster Bezel- This molded plastic bezel is

secured with snap clips to the instrument panel sup-

porting structure. It trims out the edges of the head-

lamp switch, instrument cluster, radio, heater-air

conditioner controls, passenger airbag on-off switch,

and the heated seat switches on vehicles so equipped.

On vehicles without the heated seat option, a small

storage cubby bin is provided in the cluster bezel.

This bezel also incorporates three completely adjust-

able panel outlets for the climate control system, and

fills the opening between the instrument cluster and

the top of the steering column where it passes

through the instrument panel.

²Cup Holder/Storage Bin- Vehicles equipped

with an automatic transmission feature a latching

fold-down, adjustable cup holder located on the lower

instrument panel between the glove box and the ash

receiver. Vehicles equipped with a manual transmis-

sion have a lighted storage bin on the instrument

panel in place of the cup holder.

²Glove Box- The hinged bin-type glove box in

the passenger side of the instrument panel features a

recessed paddle-operated latch handle. Three molded

23 - 104 INSTRUMENT PANEL SYSTEMBR/BE