ignition DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1156 of 2889

DIAGNOSIS AND TESTINGÐCYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise, the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/SPARK PLUG -

REMOVAL).

(3) Secure the throttle in the wide-open position.

(4) Disconnect the ignition coil.

(5) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(6) Record the compression pressure on the third

revolution. Continue the test for the remaining cylin-

ders.

(Refer to 9 - ENGINE - SPECIFICATIONS) for the

correct engine compression pressures.

DIAGNOSIS AND TESTINGÐCYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing)

²Leaks between adjacent cylinders or into water

jacket²Any causes for combustion/compression pressure

loss

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM HOT COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn OFF the

engine.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedure on each cylinder accord-

ing to the tester manufacturer's instructions. While

testing, listen for pressurized air escaping through

the throttle body, tailpipe or oil filler cap opening.

Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to CYLINDER COMBUSTION PRESSURE

LEAKAGE DIAGNOSIS CHART below

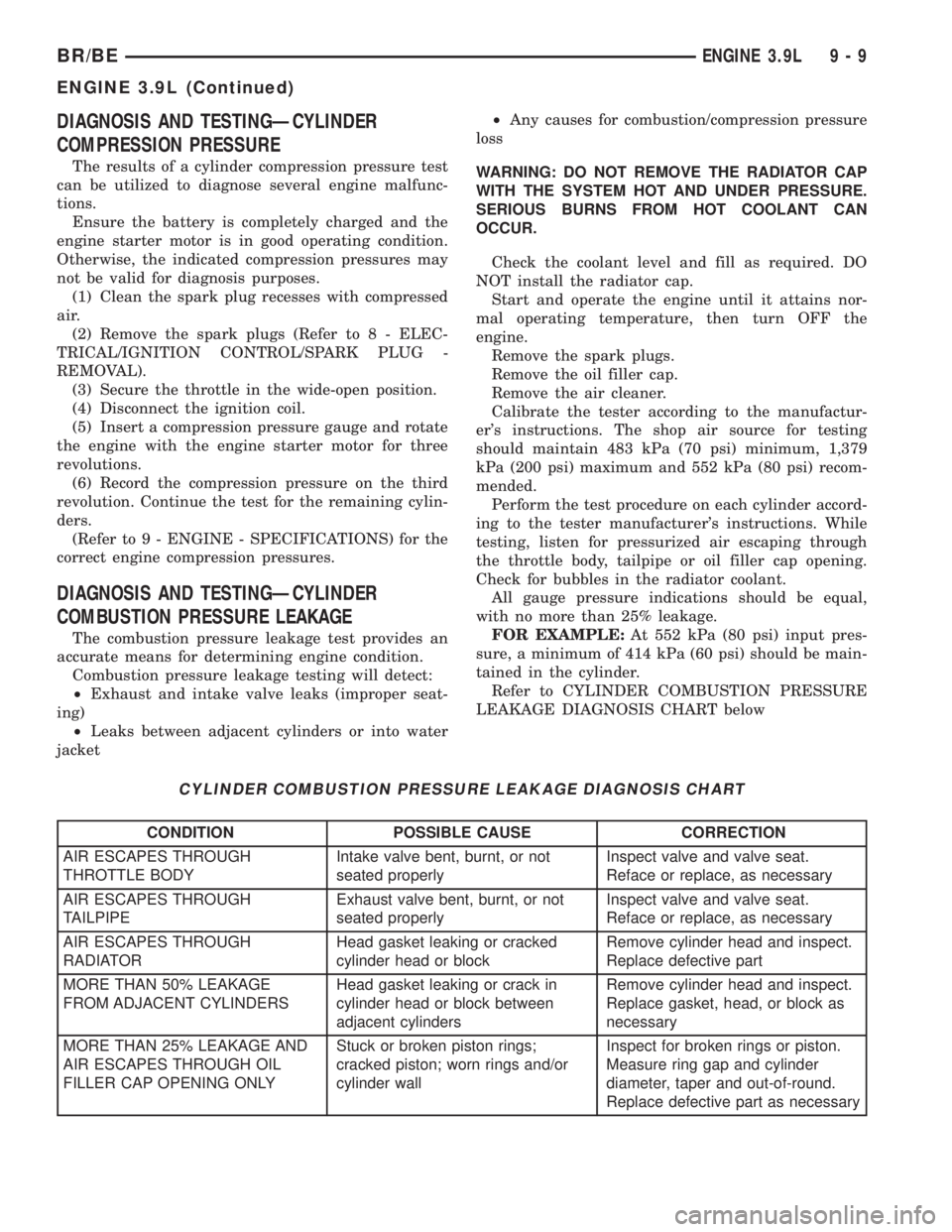

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

BR/BEENGINE 3.9L 9 - 9

ENGINE 3.9L (Continued)

Page 1169 of 2889

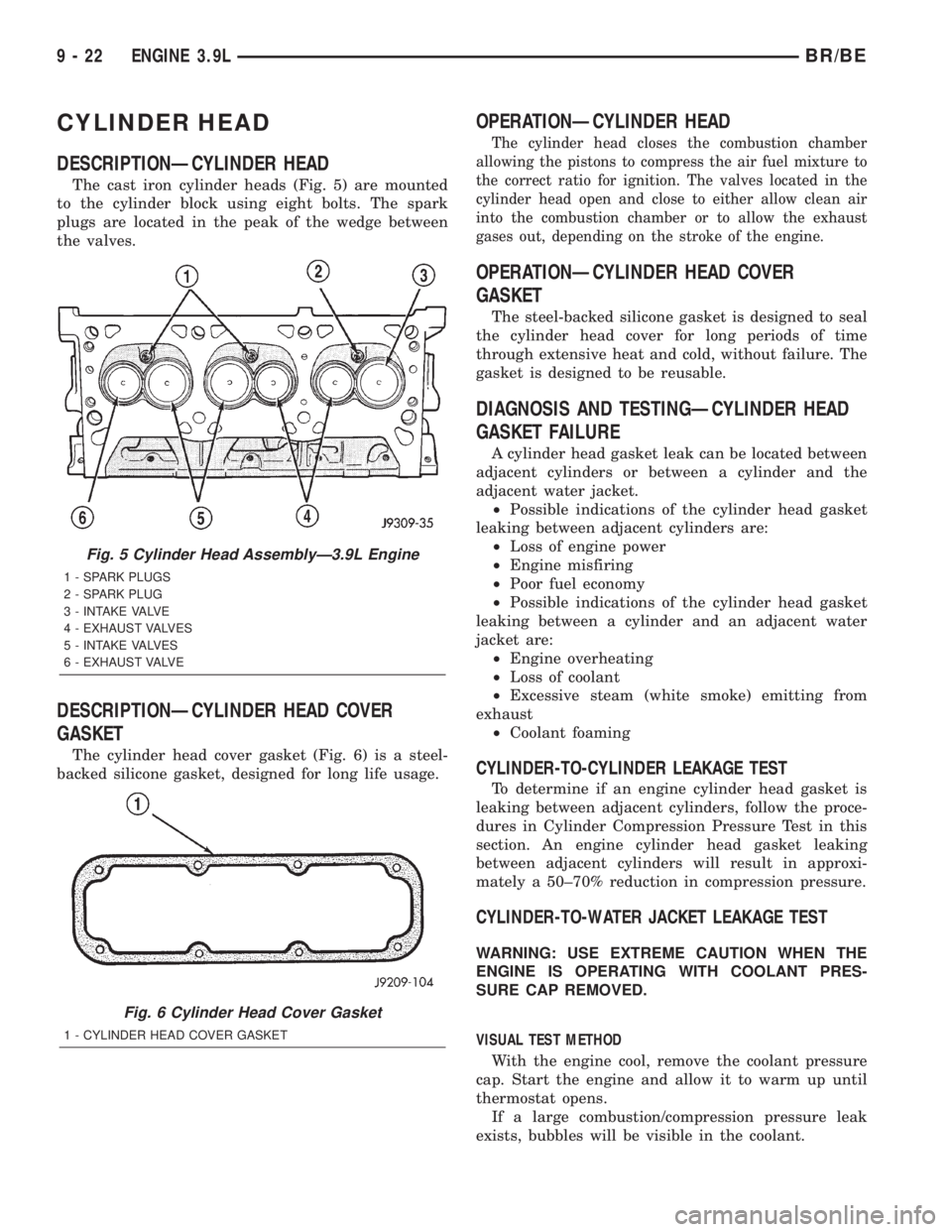

CYLINDER HEAD

DESCRIPTIONÐCYLINDER HEAD

The cast iron cylinder heads (Fig. 5) are mounted

to the cylinder block using eight bolts. The spark

plugs are located in the peak of the wedge between

the valves.

DESCRIPTIONÐCYLINDER HEAD COVER

GASKET

The cylinder head cover gasket (Fig. 6) is a steel-

backed silicone gasket, designed for long life usage.

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture to

the correct ratio for ignition. The valves located in the

cylinder head open and close to either allow clean air

into the combustion chamber or to allow the exhaust

gases out, depending on the stroke of the engine.

OPERATIONÐCYLINDER HEAD COVER

GASKET

The steel-backed silicone gasket is designed to seal

the cylinder head cover for long periods of time

through extensive heat and cold, without failure. The

gasket is designed to be reusable.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

Fig. 5 Cylinder Head AssemblyÐ3.9L Engine

1 - SPARK PLUGS

2 - SPARK PLUG

3 - INTAKE VALVE

4 - EXHAUST VALVES

5 - INTAKE VALVES

6 - EXHAUST VALVE

Fig. 6 Cylinder Head Cover Gasket

1 - CYLINDER HEAD COVER GASKET

9 - 22 ENGINE 3.9LBR/BE

Page 1176 of 2889

Bearing Mount Adhesive. Plug should be 54.0 to 57.7

mm (2-1/8 to 2-5/16 in.) from bottom of the block.

CAMSHAFT & BEARINGS (IN

BLOCK)

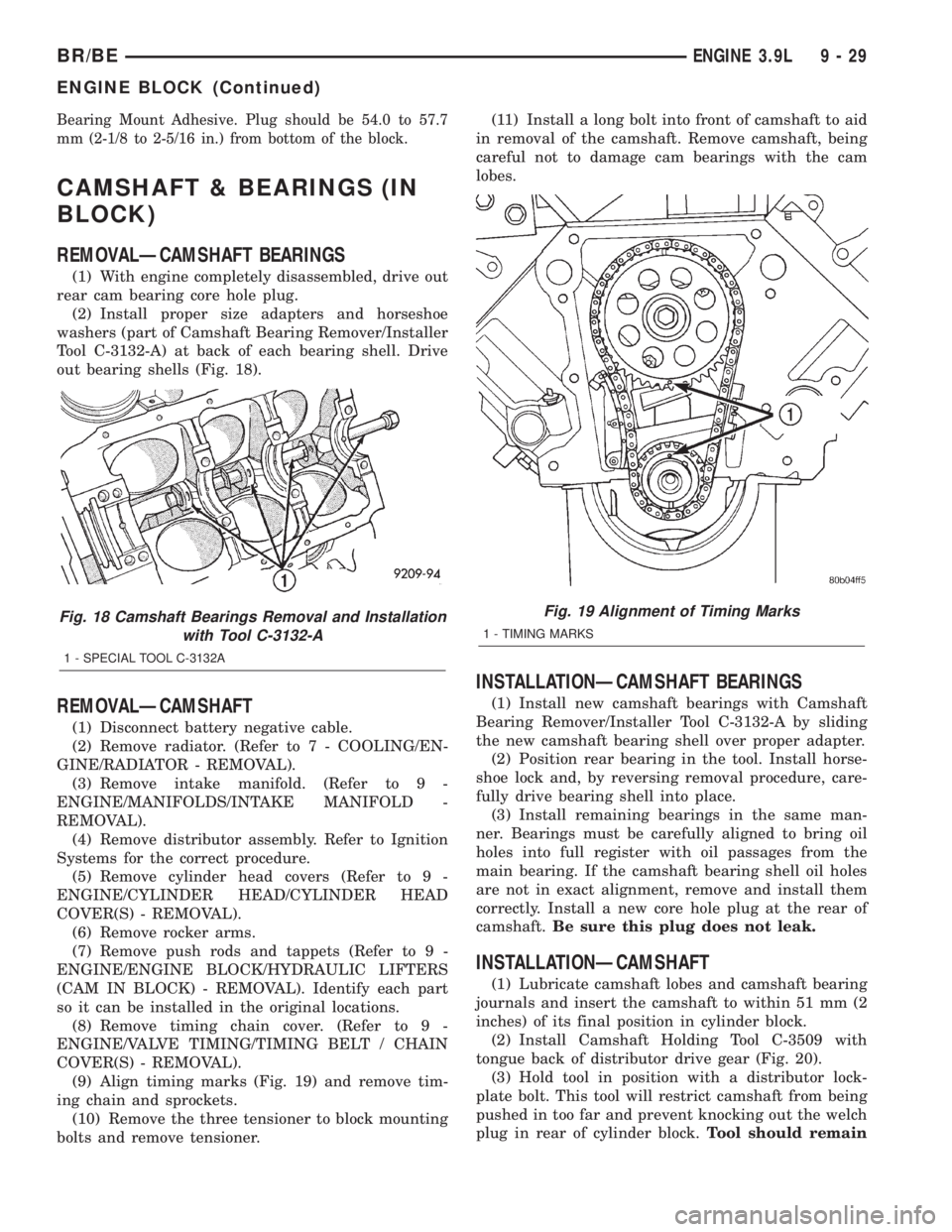

REMOVALÐCAMSHAFT BEARINGS

(1) With engine completely disassembled, drive out

rear cam bearing core hole plug.

(2) Install proper size adapters and horseshoe

washers (part of Camshaft Bearing Remover/Installer

Tool C-3132-A) at back of each bearing shell. Drive

out bearing shells (Fig. 18).

REMOVALÐCAMSHAFT

(1) Disconnect battery negative cable.

(2) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(3) Remove intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(4) Remove distributor assembly. Refer to Ignition

Systems for the correct procedure.

(5) Remove cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(6) Remove rocker arms.

(7) Remove push rods and tappets (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC LIFTERS

(CAM IN BLOCK) - REMOVAL). Identify each part

so it can be installed in the original locations.

(8) Remove timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Align timing marks (Fig. 19) and remove tim-

ing chain and sprockets.

(10) Remove the three tensioner to block mounting

bolts and remove tensioner.(11) Install a long bolt into front of camshaft to aid

in removal of the camshaft. Remove camshaft, being

careful not to damage cam bearings with the cam

lobes.

INSTALLATIONÐCAMSHAFT BEARINGS

(1) Install new camshaft bearings with Camshaft

Bearing Remover/Installer Tool C-3132-A by sliding

the new camshaft bearing shell over proper adapter.

(2) Position rear bearing in the tool. Install horse-

shoe lock and, by reversing removal procedure, care-

fully drive bearing shell into place.

(3) Install remaining bearings in the same man-

ner. Bearings must be carefully aligned to bring oil

holes into full register with oil passages from the

main bearing. If the camshaft bearing shell oil holes

are not in exact alignment, remove and install them

correctly. Install a new core hole plug at the rear of

camshaft.Be sure this plug does not leak.

INSTALLATIONÐCAMSHAFT

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft to within 51 mm (2

inches) of its final position in cylinder block.

(2) Install Camshaft Holding Tool C-3509 with

tongue back of distributor drive gear (Fig. 20).

(3) Hold tool in position with a distributor lock-

plate bolt. This tool will restrict camshaft from being

pushed in too far and prevent knocking out the welch

plug in rear of cylinder block.Tool should remain

Fig. 18 Camshaft Bearings Removal and Installation

with Tool C-3132-A

1 - SPECIAL TOOL C-3132A

Fig. 19 Alignment of Timing Marks

1 - TIMING MARKS

BR/BEENGINE 3.9L 9 - 29

ENGINE BLOCK (Continued)

Page 1208 of 2889

DIAGNOSIS AND TESTING-ENGINE DIAGNOSIS

- INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING - Preformance) or (Refer to 9 - ENGINE - DIAG-

NOSIS AND TESTING - Mechanical). Refer to 14 -

FUEL SYSTEM for fuel system diagnosis.Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Lash Adjuster (Tappet) Noise Diagnosis

²Engine Oil Leak Inspection

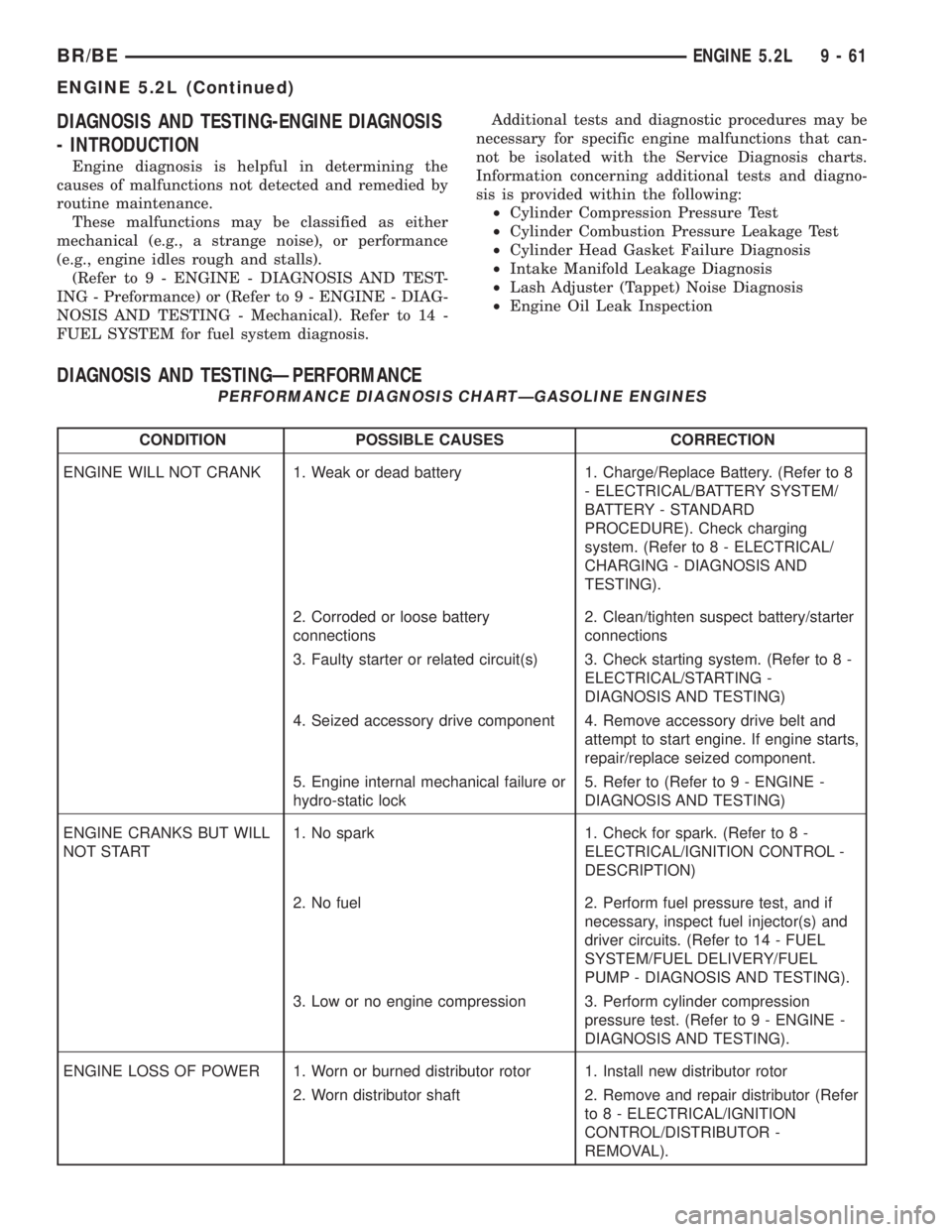

DIAGNOSIS AND TESTINGÐPERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to 8

- ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD

PROCEDURE). Check charging

system. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND

TESTING).

2. Corroded or loose battery

connections2. Clean/tighten suspect battery/starter

connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8 -

ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Seized accessory drive component 4. Remove accessory drive belt and

attempt to start engine. If engine starts,

repair/replace seized component.

5. Engine internal mechanical failure or

hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT WILL

NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL

PUMP - DIAGNOSIS AND TESTING).

3. Low or no engine compression 3. Perform cylinder compression

pressure test. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor (Refer

to 8 - ELECTRICAL/IGNITION

CONTROL/DISTRIBUTOR -

REMOVAL).

BR/BEENGINE 5.2L 9 - 61

ENGINE 5.2L (Continued)

Page 1209 of 2889

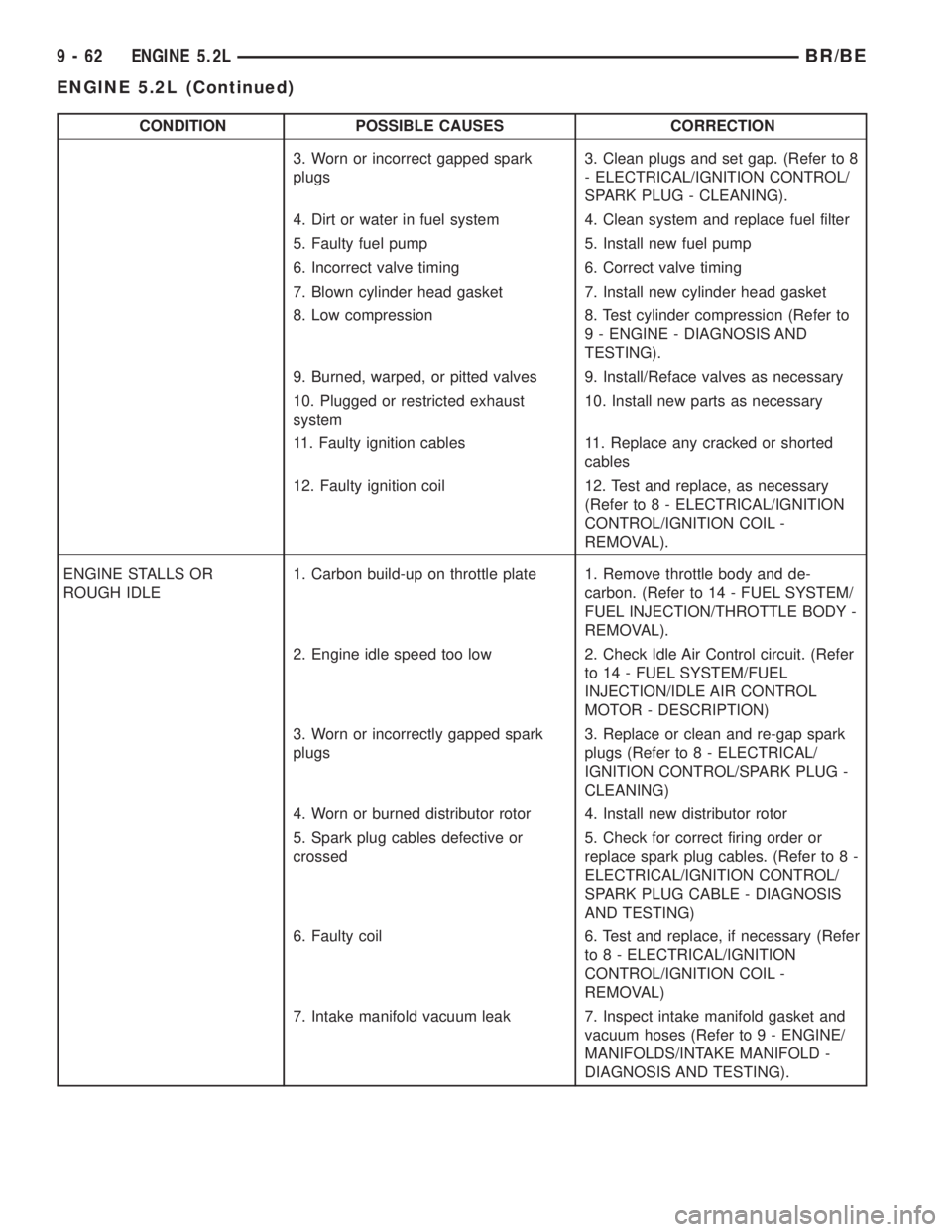

CONDITION POSSIBLE CAUSES CORRECTION

3. Worn or incorrect gapped spark

plugs3. Clean plugs and set gap. (Refer to 8

- ELECTRICAL/IGNITION CONTROL/

SPARK PLUG - CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression (Refer to

9 - ENGINE - DIAGNOSIS AND

TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust

system10. Install new parts as necessary

11. Faulty ignition cables 11. Replace any cracked or shorted

cables

12. Faulty ignition coil 12. Test and replace, as necessary

(Refer to 8 - ELECTRICAL/IGNITION

CONTROL/IGNITION COIL -

REMOVAL).

ENGINE STALLS OR

ROUGH IDLE1. Carbon build-up on throttle plate 1. Remove throttle body and de-

carbon. (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/THROTTLE BODY -

REMOVAL).

2. Engine idle speed too low 2. Check Idle Air Control circuit. (Refer

to 14 - FUEL SYSTEM/FUEL

INJECTION/IDLE AIR CONTROL

MOTOR - DESCRIPTION)

3. Worn or incorrectly gapped spark

plugs3. Replace or clean and re-gap spark

plugs (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING)

4. Worn or burned distributor rotor 4. Install new distributor rotor

5. Spark plug cables defective or

crossed5. Check for correct firing order or

replace spark plug cables. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG CABLE - DIAGNOSIS

AND TESTING)

6. Faulty coil 6. Test and replace, if necessary (Refer

to 8 - ELECTRICAL/IGNITION

CONTROL/IGNITION COIL -

REMOVAL)

7. Intake manifold vacuum leak 7. Inspect intake manifold gasket and

vacuum hoses (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING).

9 - 62 ENGINE 5.2LBR/BE

ENGINE 5.2L (Continued)

Page 1210 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE MISSES ON

ACCELERATION1. Worn or incorrectly gapped spark

plugs1. Replace spark plugs or clean and

set gap. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING)

2. Spark plug cables defective or

crossed2. Replace or rewire secondary ignition

cables. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

CABLE - REMOVAL)

3. Dirt in fuel system 3. Clean fuel system

4. Burned, warped or pitted valves 4. Install new valves

5. Faulty coil 5. Test and replace as necessary

(Refer to 8 - ELECTRICAL/IGNITION

CONTROL/IGNITION COIL -

REMOVAL)

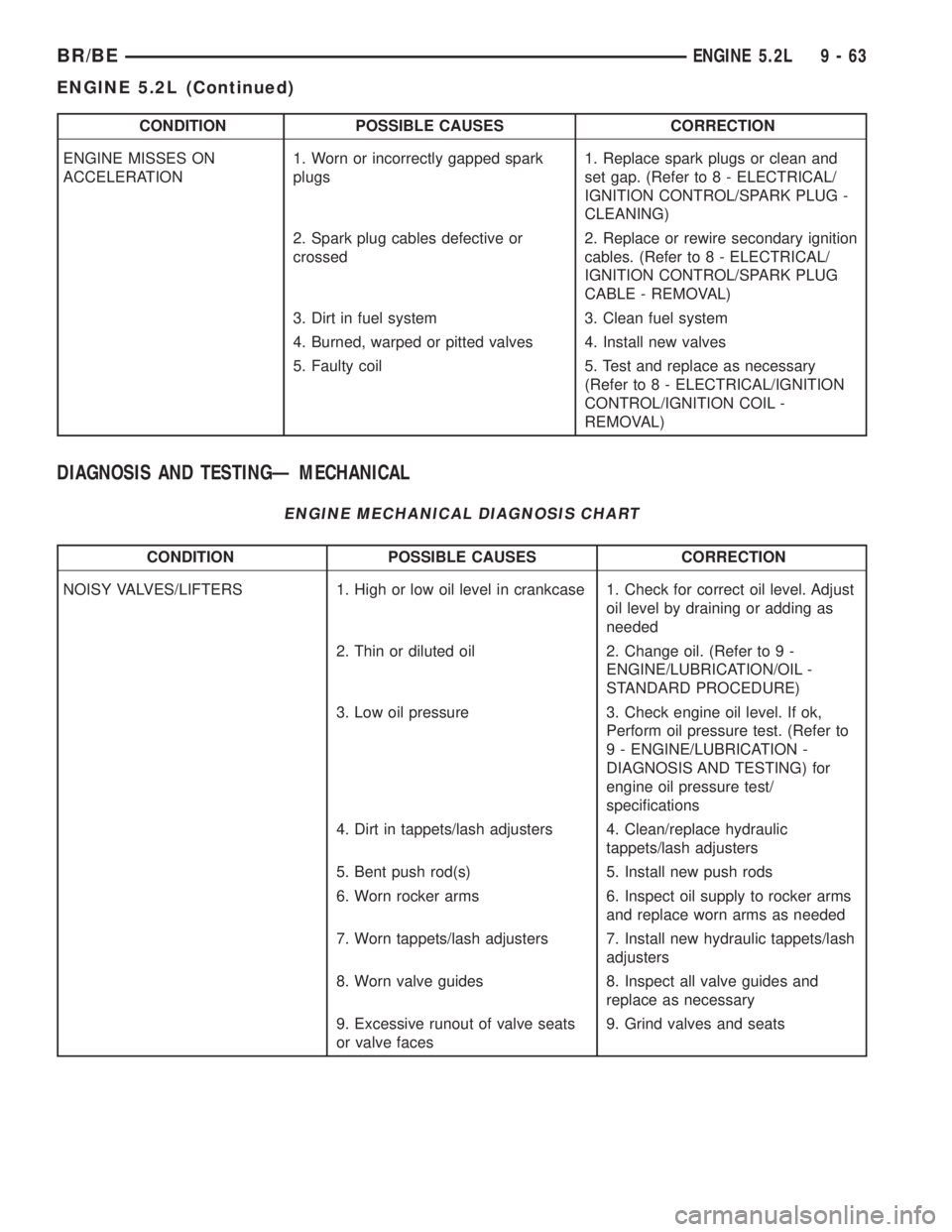

DIAGNOSIS AND TESTINGÐ MECHANICAL

ENGINE MECHANICAL DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES/LIFTERS 1. High or low oil level in crankcase 1. Check for correct oil level. Adjust

oil level by draining or adding as

needed

2. Thin or diluted oil 2. Change oil. (Refer to 9 -

ENGINE/LUBRICATION/OIL -

STANDARD PROCEDURE)

3. Low oil pressure 3. Check engine oil level. If ok,

Perform oil pressure test. (Refer to

9 - ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING) for

engine oil pressure test/

specifications

4. Dirt in tappets/lash adjusters 4. Clean/replace hydraulic

tappets/lash adjusters

5. Bent push rod(s) 5. Install new push rods

6. Worn rocker arms 6. Inspect oil supply to rocker arms

and replace worn arms as needed

7. Worn tappets/lash adjusters 7. Install new hydraulic tappets/lash

adjusters

8. Worn valve guides 8. Inspect all valve guides and

replace as necessary

9. Excessive runout of valve seats

or valve faces9. Grind valves and seats

BR/BEENGINE 5.2L 9 - 63

ENGINE 5.2L (Continued)

Page 1214 of 2889

DIAGNOSIS AND TESTINGÐCYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise, the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/SPARK PLUG -

REMOVAL).

(3) Secure the throttle in the wide-open position.

(4) Disconnect the ignition coil.

(5) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(6) Record the compression pressure on the third

revolution. Continue the test for the remaining cylin-

ders.

(Refer to 9 - ENGINE - SPECIFICATIONS) for the

correct engine compression pressures.

DIAGNOSIS AND TESTINGÐCYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing)

²Leaks between adjacent cylinders or into water

jacket²Any causes for combustion/compression pressure

loss

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM HOT COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn OFF the

engine.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedure on each cylinder accord-

ing to the tester manufacturer's instructions. While

testing, listen for pressurized air escaping through

the throttle body, tailpipe or oil filler cap opening.

Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to CYLINDER COMBUSTION PRESSURE

LEAKAGE DIAGNOSIS CHART below

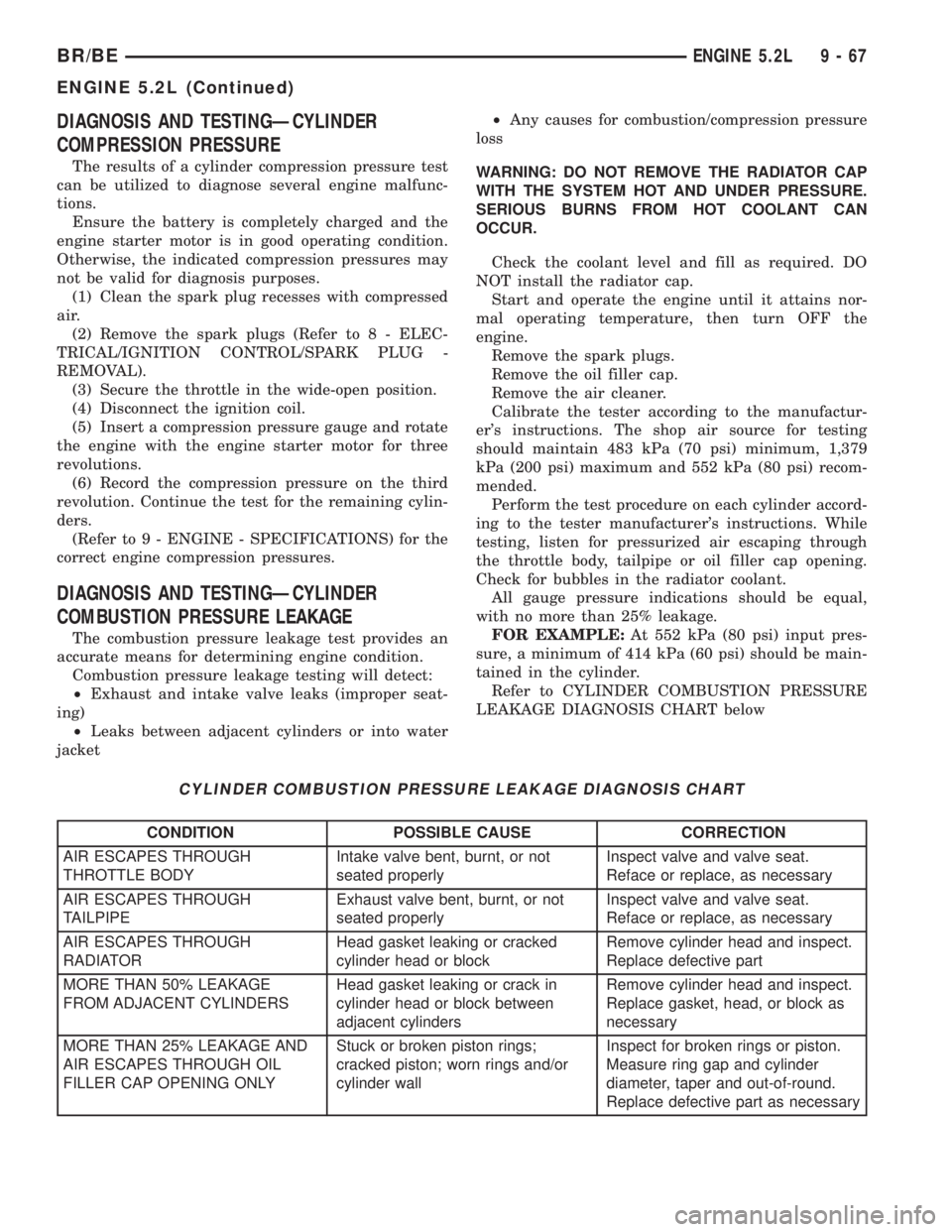

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

BR/BEENGINE 5.2L 9 - 67

ENGINE 5.2L (Continued)

Page 1226 of 2889

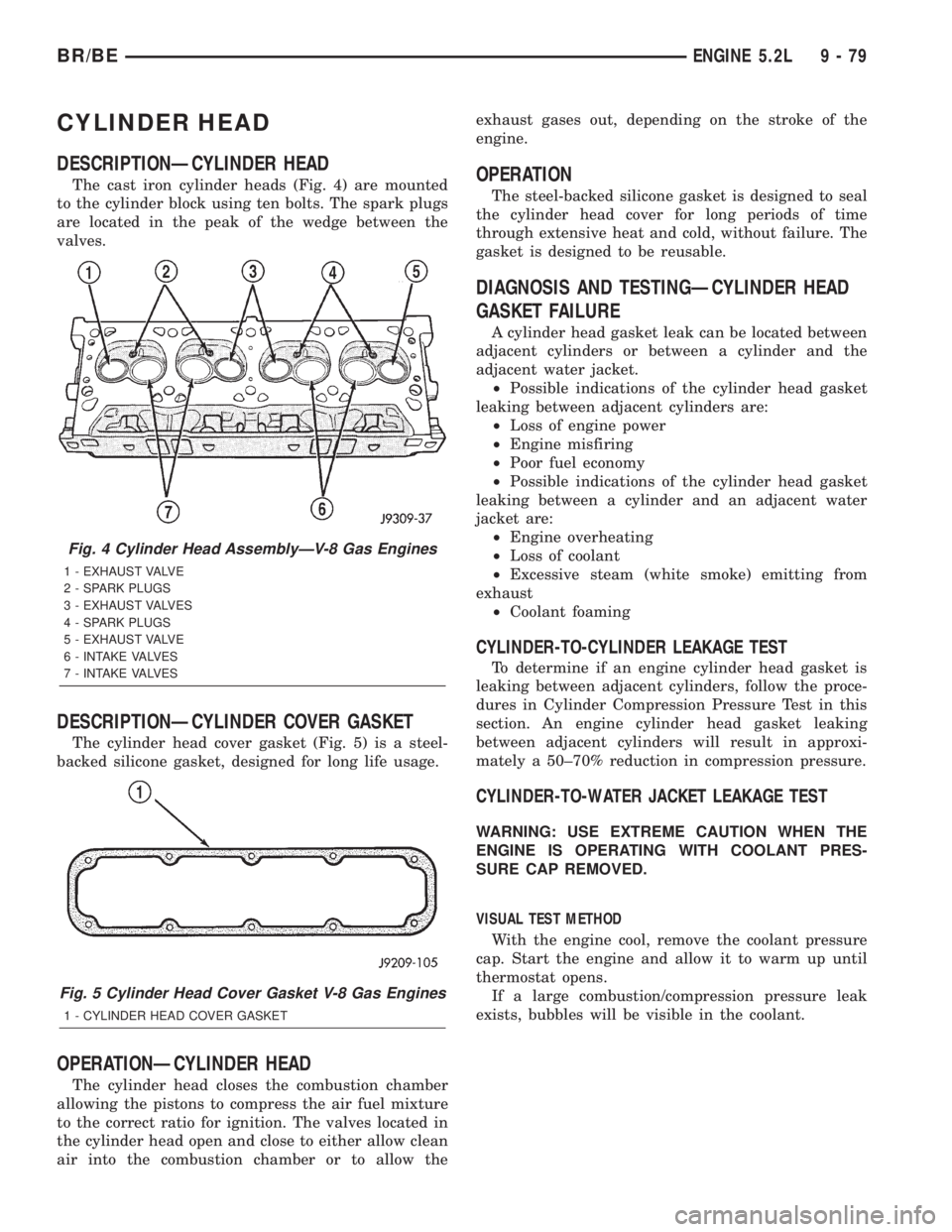

CYLINDER HEAD

DESCRIPTIONÐCYLINDER HEAD

The cast iron cylinder heads (Fig. 4) are mounted

to the cylinder block using ten bolts. The spark plugs

are located in the peak of the wedge between the

valves.

DESCRIPTIONÐCYLINDER COVER GASKET

The cylinder head cover gasket (Fig. 5) is a steel-

backed silicone gasket, designed for long life usage.

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture

to the correct ratio for ignition. The valves located in

the cylinder head open and close to either allow clean

air into the combustion chamber or to allow theexhaust gases out, depending on the stroke of the

engine.

OPERATION

The steel-backed silicone gasket is designed to seal

the cylinder head cover for long periods of time

through extensive heat and cold, without failure. The

gasket is designed to be reusable.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

Fig. 4 Cylinder Head AssemblyÐV-8 Gas Engines

1 - EXHAUST VALVE

2 - SPARK PLUGS

3 - EXHAUST VALVES

4 - SPARK PLUGS

5 - EXHAUST VALVE

6 - INTAKE VALVES

7 - INTAKE VALVES

Fig. 5 Cylinder Head Cover Gasket V-8 Gas Engines

1 - CYLINDER HEAD COVER GASKET

BR/BEENGINE 5.2L 9 - 79

Page 1241 of 2889

(9) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, at bearing cap-to-block

joint to provide cap-to-block and oil pan sealing (Fig.

32). Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10)

Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLATION).

LOWER SEAL

(1) Clean the rear main cap mating surfaces

including the oil pan gasket groove.

(2) Carefully install a new upper seal. Refer to

UPPER SEALÐCRANKSHAFT INSTALLED.

(3) Lightly oil the new lower seal lips with engine

oil.

(4) Install a new lower seal in bearing cap with

the white paint facing the rear of engine.

(5) Apply 5 mm (0.20 in.) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 31). DO NOT over-apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

(6) To align the bearing cap, use cap slot, align-

ment dowel, and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than two times for proper engagement.

(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten the cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - INSTALLATION).

(9) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, at bearing cap-to-block

joint to provide cap to block and oil pan sealing.

Apply enough sealant so that a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10)

Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLATION).

DISTRIBUTOR BUSHING

REMOVAL

(1) Remove distributor (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/DISTRIBUTOR - REMOVAL).

(2) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

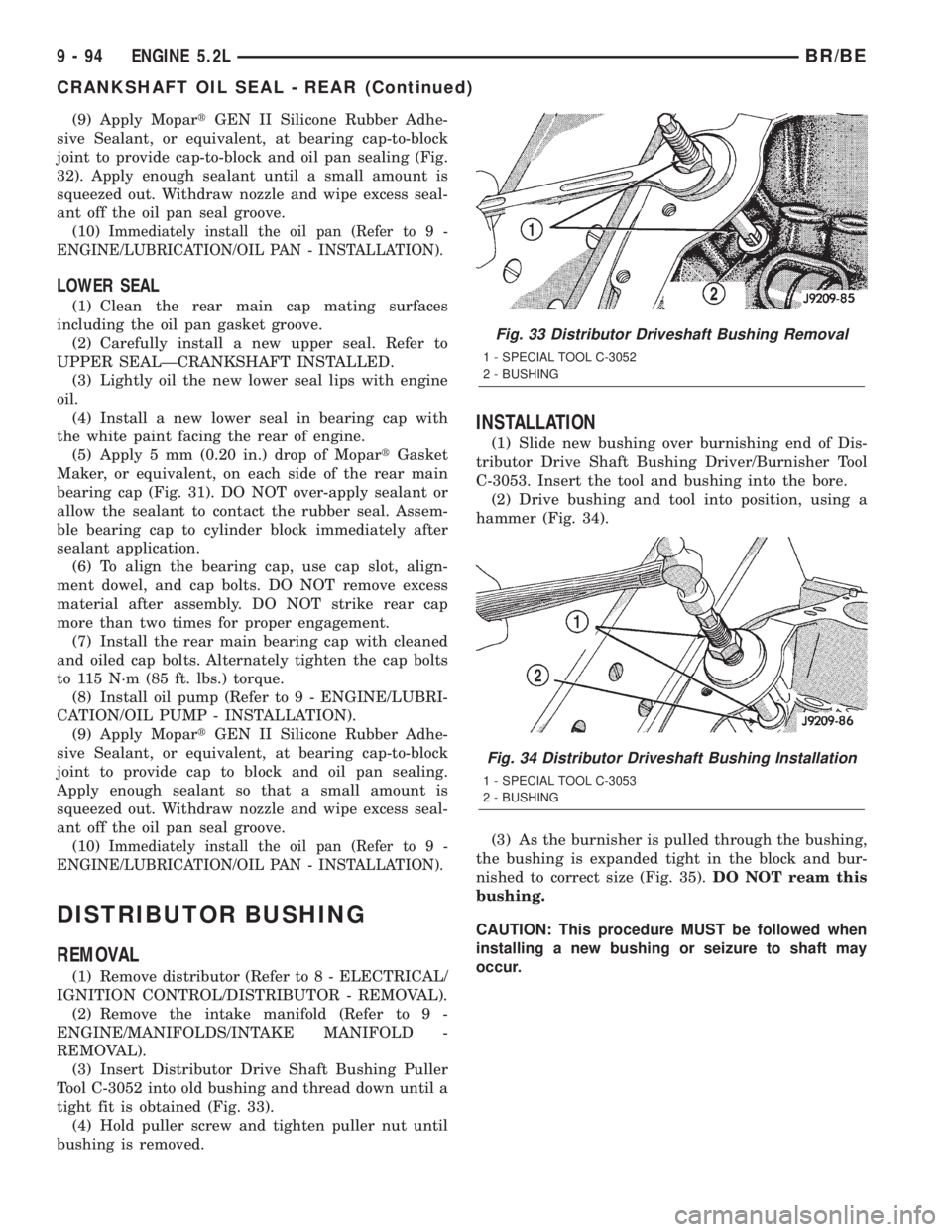

(3) Insert Distributor Drive Shaft Bushing Puller

Tool C-3052 into old bushing and thread down until a

tight fit is obtained (Fig. 33).

(4) Hold puller screw and tighten puller nut until

bushing is removed.

INSTALLATION

(1) Slide new bushing over burnishing end of Dis-

tributor Drive Shaft Bushing Driver/Burnisher Tool

C-3053. Insert the tool and bushing into the bore.

(2) Drive bushing and tool into position, using a

hammer (Fig. 34).

(3) As the burnisher is pulled through the bushing,

the bushing is expanded tight in the block and bur-

nished to correct size (Fig. 35).DO NOT ream this

bushing.

CAUTION: This procedure MUST be followed when

installing a new bushing or seizure to shaft may

occur.

Fig. 33 Distributor Driveshaft Bushing Removal

1 - SPECIAL TOOL C-3052

2 - BUSHING

Fig. 34 Distributor Driveshaft Bushing Installation

1 - SPECIAL TOOL C-3053

2 - BUSHING

9 - 94 ENGINE 5.2LBR/BE

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1242 of 2889

(4) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(5) Install the distributor (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/DISTRIBUTOR -

INSTALLATION).

HYDRAULIC LIFTERS (CAM IN

BLOCK)

DIAGNOSIS AND TESTINGÐHYDRAULIC

TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at

the pressure sending-unit. The pressure should be

between 207-552 kPa (30-80 psi) at 3,000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick. The oil level in the pan

should never be above the FULL mark or below the

ADD OIL mark on dipstick. Either of these two con-

ditions could be responsible for noisy tappets.

OIL LEVEL

HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the

engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the

hydraulic tappets by the oil pump causing them to

lose length and allow valves to seat noisily.LOW

Low oil level may allow oil pump to take in air.

When air is fed to the tappets, they lose length,

which allows valves to seat noisily. Any leaks on

intake side of oil pump through which air can be

drawn will create the same tappet action. Check the

lubrication system from the intake strainer to the

pump cover, including the relief valve retainer cap.

When tappet noise is due to aeration, it may be

intermittent or constant, and usually more than one

tappet will be noisy. When oil level and leaks have

been corrected, operate the engine at fast idle. Run

engine for a sufficient time to allow all of the air

inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger, or by the

plunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click is

caused by a tappet check valve not seating, or by for-

eign particles wedged between the plunger and the

tappet body. This will cause the plunger to stick in

the down position. This heavy click will be accompa-

nied by excessive clearance between the valve stem

and rocker arm as valve closes. In either case, tappet

assembly should be removed for inspection and clean-

ing.

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 36).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

Fig. 35 Burnishing Distributor Driveshaft Bushing

1 - SPECIAL TOOL C-3053

2 - BUSHING

BR/BEENGINE 5.2L 9 - 95

DISTRIBUTOR BUSHING (Continued)