ignition DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1091 of 2889

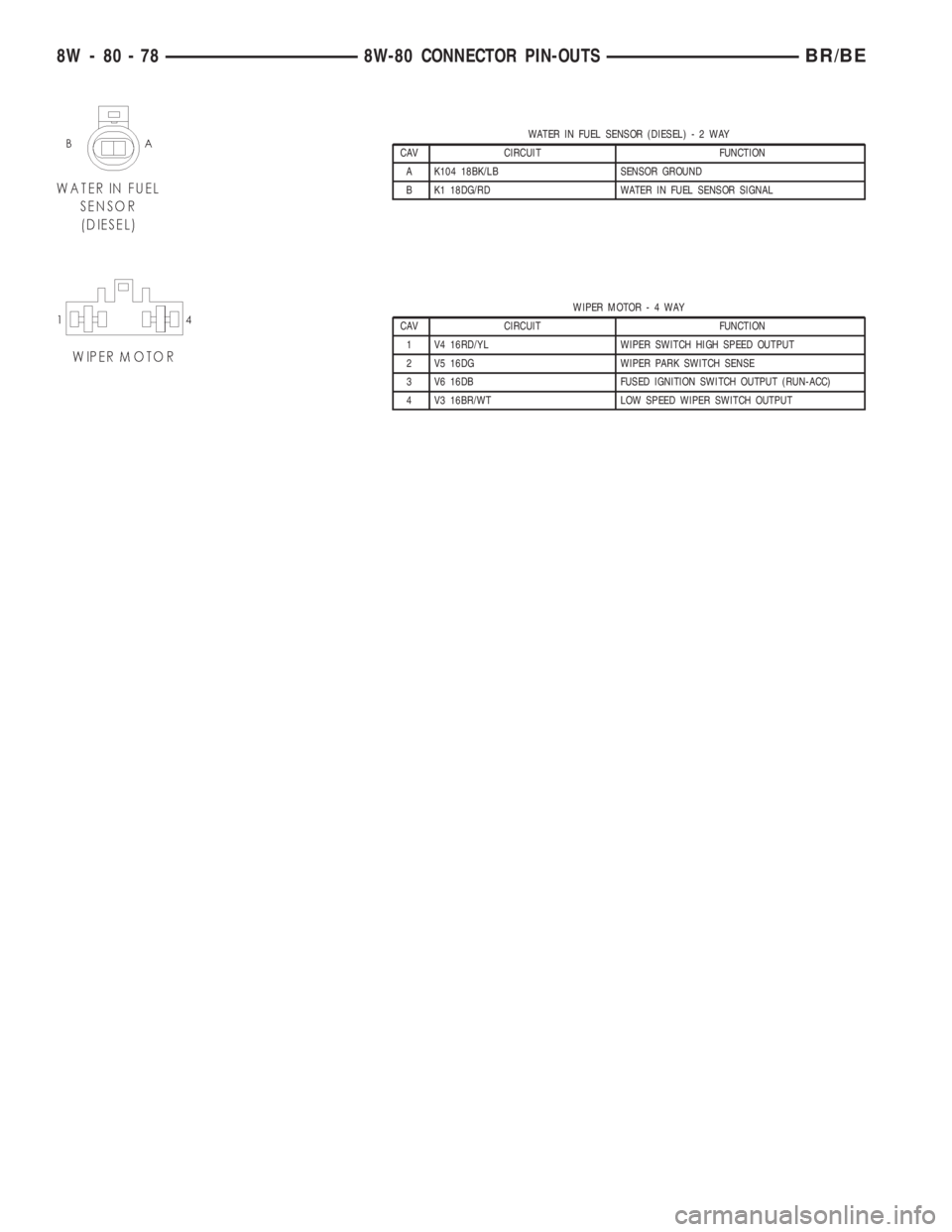

WATER IN FUEL SENSOR (DIESEL)-2WAY

CAV CIRCUIT FUNCTION

A K104 18BK/LB SENSOR GROUND

B K1 18DG/RD WATER IN FUEL SENSOR SIGNAL

WIPER MOTOR-4WAY

CAV CIRCUIT FUNCTION

1 V4 16RD/YL WIPER SWITCH HIGH SPEED OUTPUT

2 V5 16DG WIPER PARK SWITCH SENSE

3 V6 16DB FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

4 V3 16BR/WT LOW SPEED WIPER SWITCH OUTPUT

8W - 80 - 78 8W-80 CONNECTOR PIN-OUTSBR/BE

Page 1095 of 2889

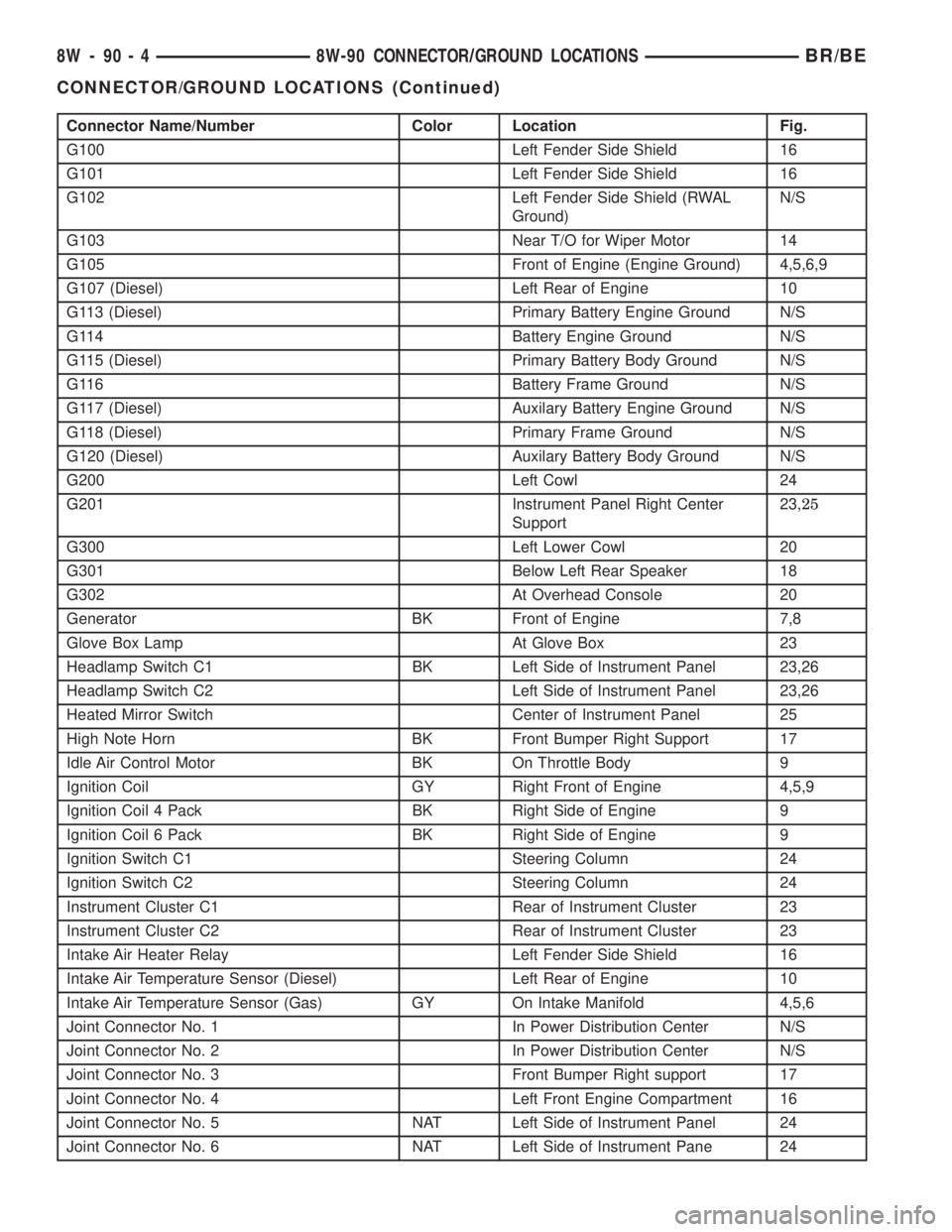

Connector Name/Number Color Location Fig.

G100 Left Fender Side Shield 16

G101 Left Fender Side Shield 16

G102 Left Fender Side Shield (RWAL

Ground)N/S

G103 Near T/O for Wiper Motor 14

G105 Front of Engine (Engine Ground) 4,5,6,9

G107 (Diesel) Left Rear of Engine 10

G113 (Diesel) Primary Battery Engine Ground N/S

G114 Battery Engine Ground N/S

G115 (Diesel) Primary Battery Body Ground N/S

G116 Battery Frame Ground N/S

G117 (Diesel) Auxilary Battery Engine Ground N/S

G118 (Diesel) Primary Frame Ground N/S

G120 (Diesel) Auxilary Battery Body Ground N/S

G200 Left Cowl 24

G201 Instrument Panel Right Center

Support23,25

G300 Left Lower Cowl 20

G301 Below Left Rear Speaker 18

G302 At Overhead Console 20

Generator BK Front of Engine 7,8

Glove Box Lamp At Glove Box 23

Headlamp Switch C1 BK Left Side of Instrument Panel 23,26

Headlamp Switch C2 Left Side of Instrument Panel 23,26

Heated Mirror Switch Center of Instrument Panel 25

High Note Horn BK Front Bumper Right Support 17

Idle Air Control Motor BK On Throttle Body 9

Ignition Coil GY Right Front of Engine 4,5,9

Ignition Coil 4 Pack BK Right Side of Engine 9

Ignition Coil 6 Pack BK Right Side of Engine 9

Ignition Switch C1 Steering Column 24

Ignition Switch C2 Steering Column 24

Instrument Cluster C1 Rear of Instrument Cluster 23

Instrument Cluster C2 Rear of Instrument Cluster 23

Intake Air Heater Relay Left Fender Side Shield 16

Intake Air Temperature Sensor (Diesel) Left Rear of Engine 10

Intake Air Temperature Sensor (Gas) GY On Intake Manifold 4,5,6

Joint Connector No. 1 In Power Distribution Center N/S

Joint Connector No. 2 In Power Distribution Center N/S

Joint Connector No. 3 Front Bumper Right support 17

Joint Connector No. 4 Left Front Engine Compartment 16

Joint Connector No. 5 NAT Left Side of Instrument Panel 24

Joint Connector No. 6 NAT Left Side of Instrument Pane 24

8W - 90 - 4 8W-90 CONNECTOR/GROUND LOCATIONSBR/BE

CONNECTOR/GROUND LOCATIONS (Continued)

Page 1105 of 2889

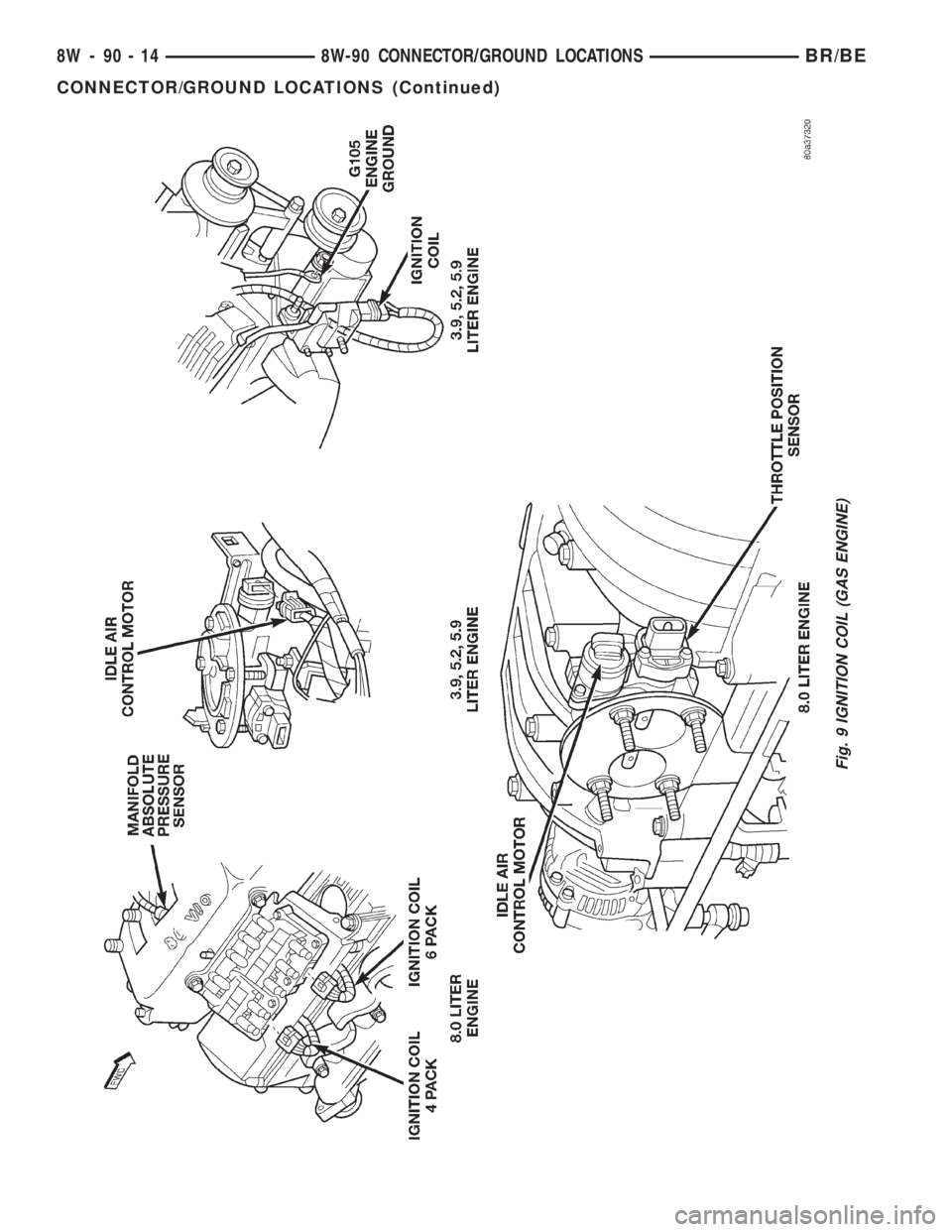

Fig. 9 IGNITION COIL (GAS ENGINE)

8W - 90 - 14 8W-90 CONNECTOR/GROUND LOCATIONSBR/BE

CONNECTOR/GROUND LOCATIONS (Continued)

Page 1137 of 2889

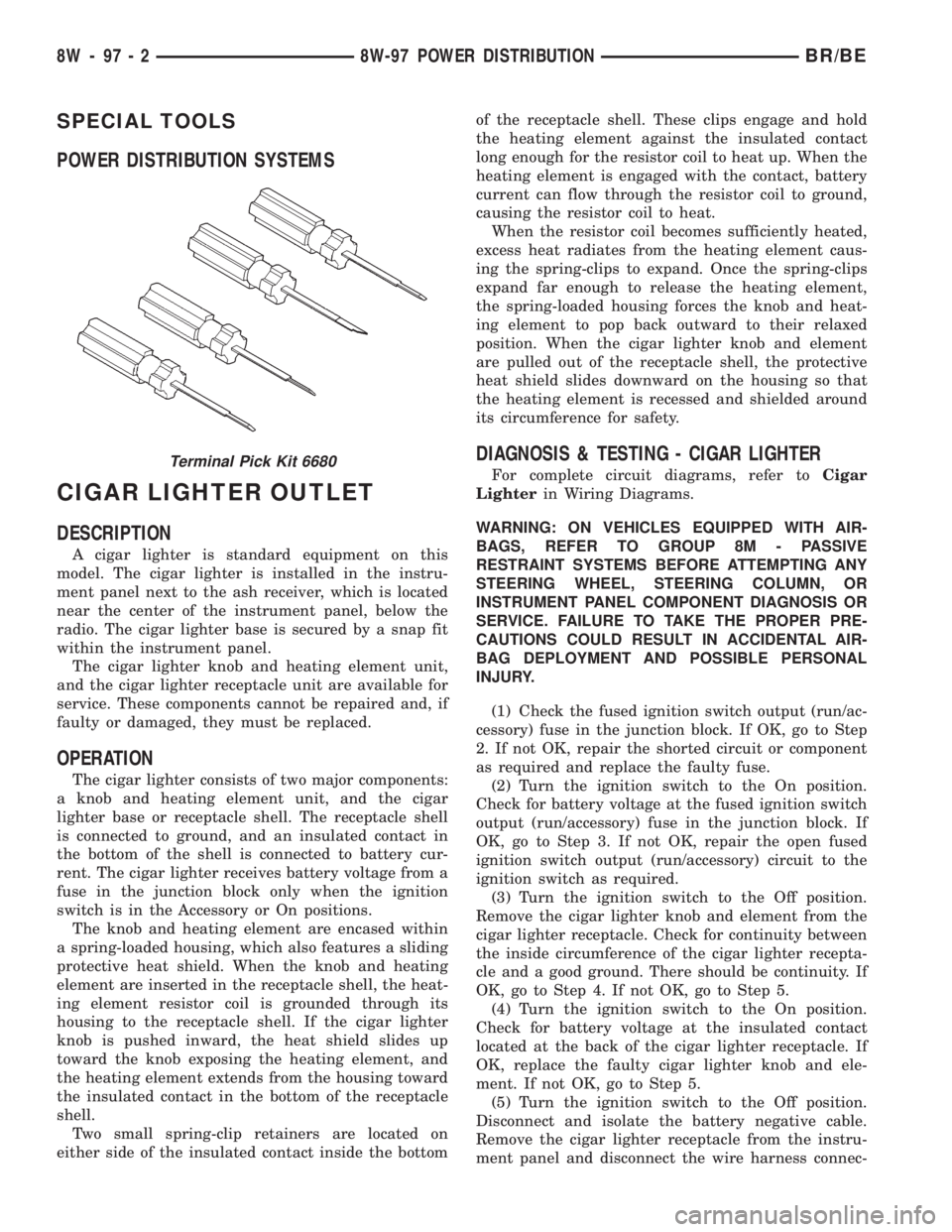

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

CIGAR LIGHTER OUTLET

DESCRIPTION

A cigar lighter is standard equipment on this

model. The cigar lighter is installed in the instru-

ment panel next to the ash receiver, which is located

near the center of the instrument panel, below the

radio. The cigar lighter base is secured by a snap fit

within the instrument panel.

The cigar lighter knob and heating element unit,

and the cigar lighter receptacle unit are available for

service. These components cannot be repaired and, if

faulty or damaged, they must be replaced.

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or receptacle shell. The receptacle shell

is connected to ground, and an insulated contact in

the bottom of the shell is connected to battery cur-

rent. The cigar lighter receives battery voltage from a

fuse in the junction block only when the ignition

switch is in the Accessory or On positions.

The knob and heating element are encased within

a spring-loaded housing, which also features a sliding

protective heat shield. When the knob and heating

element are inserted in the receptacle shell, the heat-

ing element resistor coil is grounded through its

housing to the receptacle shell. If the cigar lighter

knob is pushed inward, the heat shield slides up

toward the knob exposing the heating element, and

the heating element extends from the housing toward

the insulated contact in the bottom of the receptacle

shell.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottomof the receptacle shell. These clips engage and hold

the heating element against the insulated contact

long enough for the resistor coil to heat up. When the

heating element is engaged with the contact, battery

current can flow through the resistor coil to ground,

causing the resistor coil to heat.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element caus-

ing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heat-

ing element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the receptacle shell, the protective

heat shield slides downward on the housing so that

the heating element is recessed and shielded around

its circumference for safety.

DIAGNOSIS & TESTING - CIGAR LIGHTER

For complete circuit diagrams, refer toCigar

Lighterin Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run/ac-

cessory) fuse in the junction block. If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/accessory) fuse in the junction block. If

OK, go to Step 3. If not OK, repair the open fused

ignition switch output (run/accessory) circuit to the

ignition switch as required.

(3) Turn the ignition switch to the Off position.

Remove the cigar lighter knob and element from the

cigar lighter receptacle. Check for continuity between

the inside circumference of the cigar lighter recepta-

cle and a good ground. There should be continuity. If

OK, go to Step 4. If not OK, go to Step 5.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the insulated contact

located at the back of the cigar lighter receptacle. If

OK, replace the faulty cigar lighter knob and ele-

ment. If not OK, go to Step 5.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the cigar lighter receptacle from the instru-

ment panel and disconnect the wire harness connec-Terminal Pick Kit 6680

8W - 97 - 2 8W-97 POWER DISTRIBUTIONBR/BE

Page 1138 of 2889

tor. Check for continuity between the ground circuit

cavity of the cigar lighter wire harness connector and

a good ground. There should be continuity. If OK, go

to Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run/ac-

cessory) circuit cavity of the cigar lighter wire har-

ness connector. If OK, replace the faulty cigar lighter

receptacle. If not OK, repair the open fused ignition

switch output (run/accessory) circuit to the junction

block fuse as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

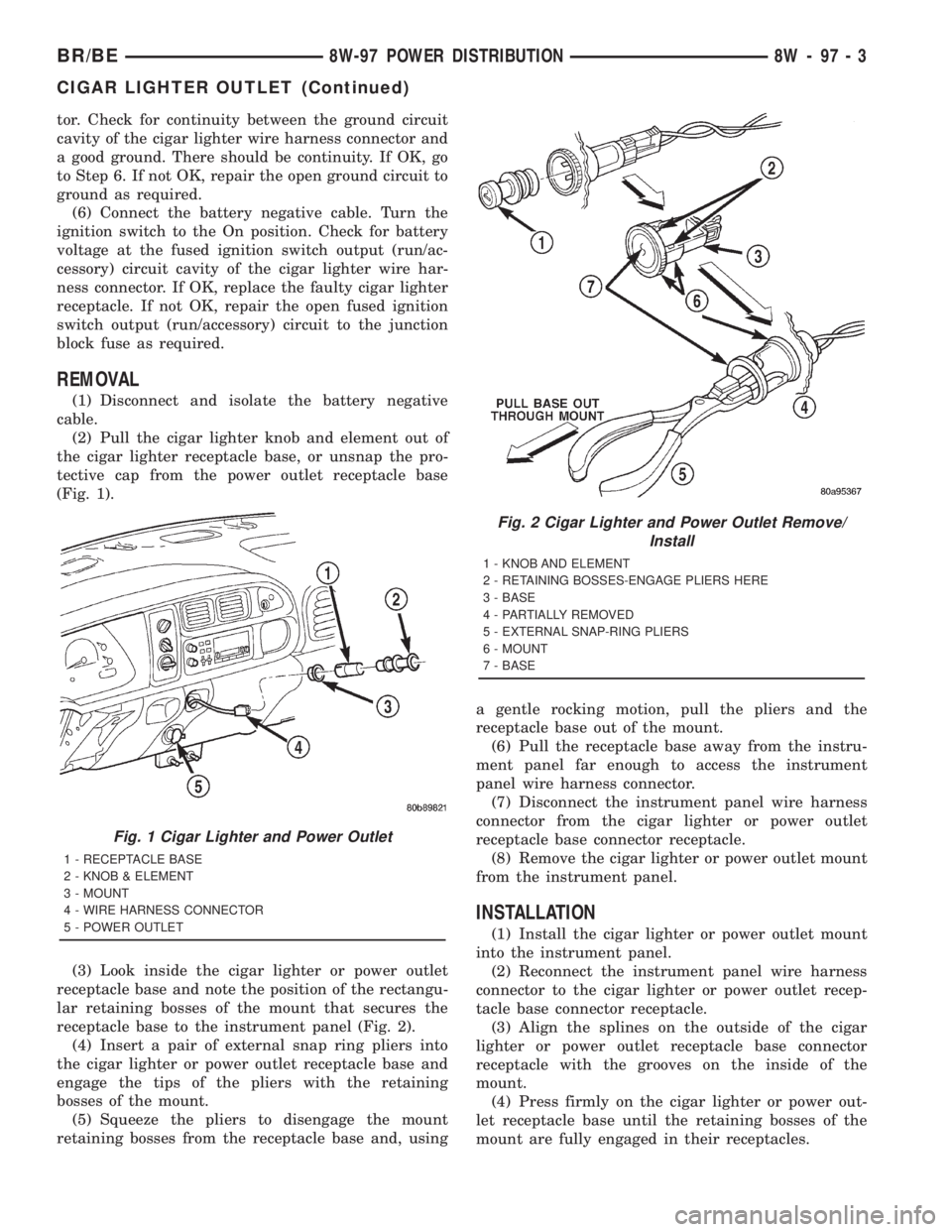

(2) Pull the cigar lighter knob and element out of

the cigar lighter receptacle base, or unsnap the pro-

tective cap from the power outlet receptacle base

(Fig. 1).

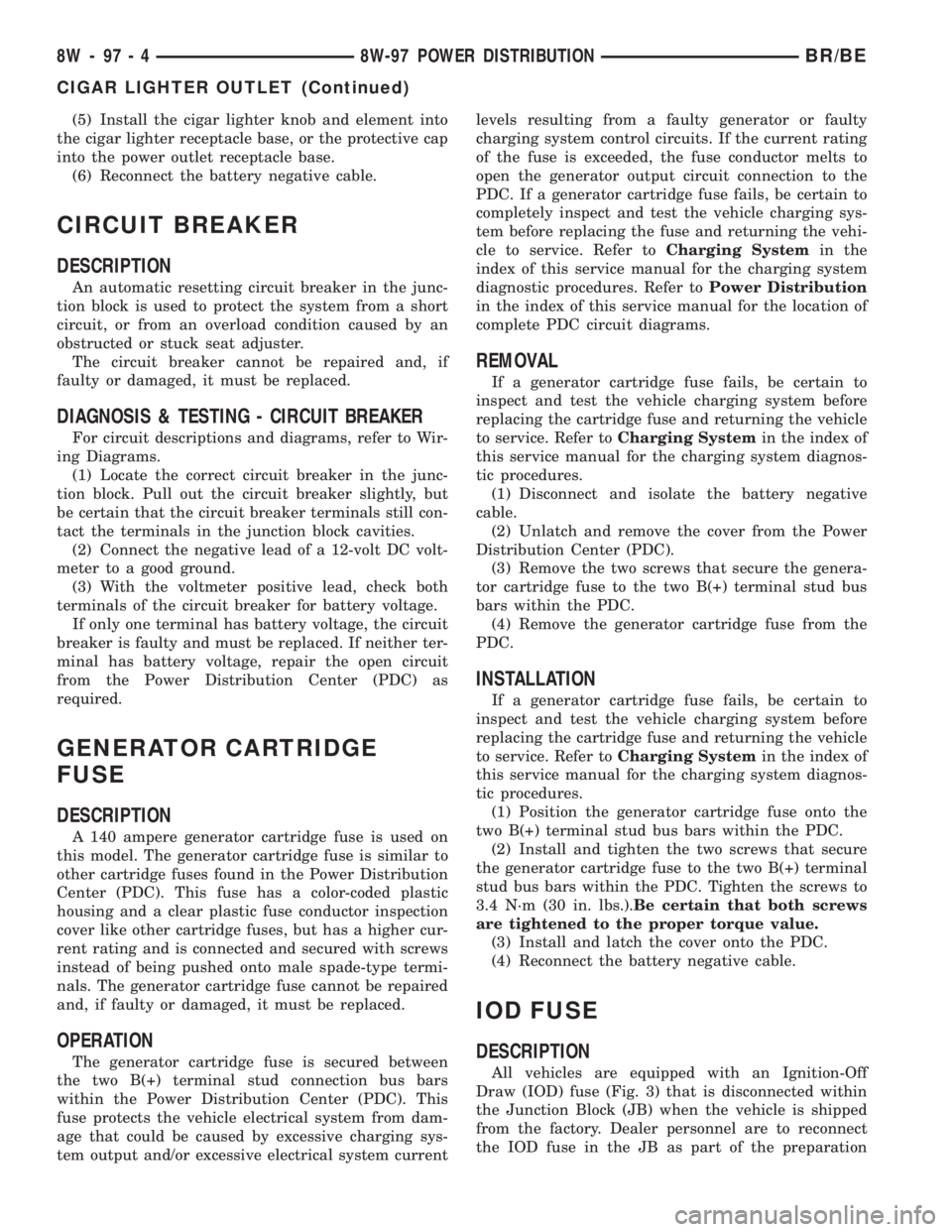

(3) Look inside the cigar lighter or power outlet

receptacle base and note the position of the rectangu-

lar retaining bosses of the mount that secures the

receptacle base to the instrument panel (Fig. 2).

(4) Insert a pair of external snap ring pliers into

the cigar lighter or power outlet receptacle base and

engage the tips of the pliers with the retaining

bosses of the mount.

(5) Squeeze the pliers to disengage the mount

retaining bosses from the receptacle base and, usinga gentle rocking motion, pull the pliers and the

receptacle base out of the mount.

(6) Pull the receptacle base away from the instru-

ment panel far enough to access the instrument

panel wire harness connector.

(7) Disconnect the instrument panel wire harness

connector from the cigar lighter or power outlet

receptacle base connector receptacle.

(8) Remove the cigar lighter or power outlet mount

from the instrument panel.

INSTALLATION

(1) Install the cigar lighter or power outlet mount

into the instrument panel.

(2) Reconnect the instrument panel wire harness

connector to the cigar lighter or power outlet recep-

tacle base connector receptacle.

(3) Align the splines on the outside of the cigar

lighter or power outlet receptacle base connector

receptacle with the grooves on the inside of the

mount.

(4) Press firmly on the cigar lighter or power out-

let receptacle base until the retaining bosses of the

mount are fully engaged in their receptacles.

Fig. 1 Cigar Lighter and Power Outlet

1 - RECEPTACLE BASE

2 - KNOB & ELEMENT

3 - MOUNT

4 - WIRE HARNESS CONNECTOR

5 - POWER OUTLET

Fig. 2 Cigar Lighter and Power Outlet Remove/

Install

1 - KNOB AND ELEMENT

2 - RETAINING BOSSES-ENGAGE PLIERS HERE

3 - BASE

4 - PARTIALLY REMOVED

5 - EXTERNAL SNAP-RING PLIERS

6 - MOUNT

7 - BASE

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 3

CIGAR LIGHTER OUTLET (Continued)

Page 1139 of 2889

(5) Install the cigar lighter knob and element into

the cigar lighter receptacle base, or the protective cap

into the power outlet receptacle base.

(6) Reconnect the battery negative cable.

CIRCUIT BREAKER

DESCRIPTION

An automatic resetting circuit breaker in the junc-

tion block is used to protect the system from a short

circuit, or from an overload condition caused by an

obstructed or stuck seat adjuster.

The circuit breaker cannot be repaired and, if

faulty or damaged, it must be replaced.

DIAGNOSIS & TESTING - CIRCUIT BREAKER

For circuit descriptions and diagrams, refer to Wir-

ing Diagrams.

(1) Locate the correct circuit breaker in the junc-

tion block. Pull out the circuit breaker slightly, but

be certain that the circuit breaker terminals still con-

tact the terminals in the junction block cavities.

(2) Connect the negative lead of a 12-volt DC volt-

meter to a good ground.

(3) With the voltmeter positive lead, check both

terminals of the circuit breaker for battery voltage.

If only one terminal has battery voltage, the circuit

breaker is faulty and must be replaced. If neither ter-

minal has battery voltage, repair the open circuit

from the Power Distribution Center (PDC) as

required.

GENERATOR CARTRIDGE

FUSE

DESCRIPTION

A 140 ampere generator cartridge fuse is used on

this model. The generator cartridge fuse is similar to

other cartridge fuses found in the Power Distribution

Center (PDC). This fuse has a color-coded plastic

housing and a clear plastic fuse conductor inspection

cover like other cartridge fuses, but has a higher cur-

rent rating and is connected and secured with screws

instead of being pushed onto male spade-type termi-

nals. The generator cartridge fuse cannot be repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The generator cartridge fuse is secured between

the two B(+) terminal stud connection bus bars

within the Power Distribution Center (PDC). This

fuse protects the vehicle electrical system from dam-

age that could be caused by excessive charging sys-

tem output and/or excessive electrical system currentlevels resulting from a faulty generator or faulty

charging system control circuits. If the current rating

of the fuse is exceeded, the fuse conductor melts to

open the generator output circuit connection to the

PDC. If a generator cartridge fuse fails, be certain to

completely inspect and test the vehicle charging sys-

tem before replacing the fuse and returning the vehi-

cle to service. Refer toCharging Systemin the

index of this service manual for the charging system

diagnostic procedures. Refer toPower Distribution

in the index of this service manual for the location of

complete PDC circuit diagrams.

REMOVAL

If a generator cartridge fuse fails, be certain to

inspect and test the vehicle charging system before

replacing the cartridge fuse and returning the vehicle

to service. Refer toCharging Systemin the index of

this service manual for the charging system diagnos-

tic procedures.

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Power

Distribution Center (PDC).

(3) Remove the two screws that secure the genera-

tor cartridge fuse to the two B(+) terminal stud bus

bars within the PDC.

(4) Remove the generator cartridge fuse from the

PDC.

INSTALLATION

If a generator cartridge fuse fails, be certain to

inspect and test the vehicle charging system before

replacing the cartridge fuse and returning the vehicle

to service. Refer toCharging Systemin the index of

this service manual for the charging system diagnos-

tic procedures.

(1) Position the generator cartridge fuse onto the

two B(+) terminal stud bus bars within the PDC.

(2) Install and tighten the two screws that secure

the generator cartridge fuse to the two B(+) terminal

stud bus bars within the PDC. Tighten the screws to

3.4 N´m (30 in. lbs.).Be certain that both screws

are tightened to the proper torque value.

(3) Install and latch the cover onto the PDC.

(4) Reconnect the battery negative cable.

IOD FUSE

DESCRIPTION

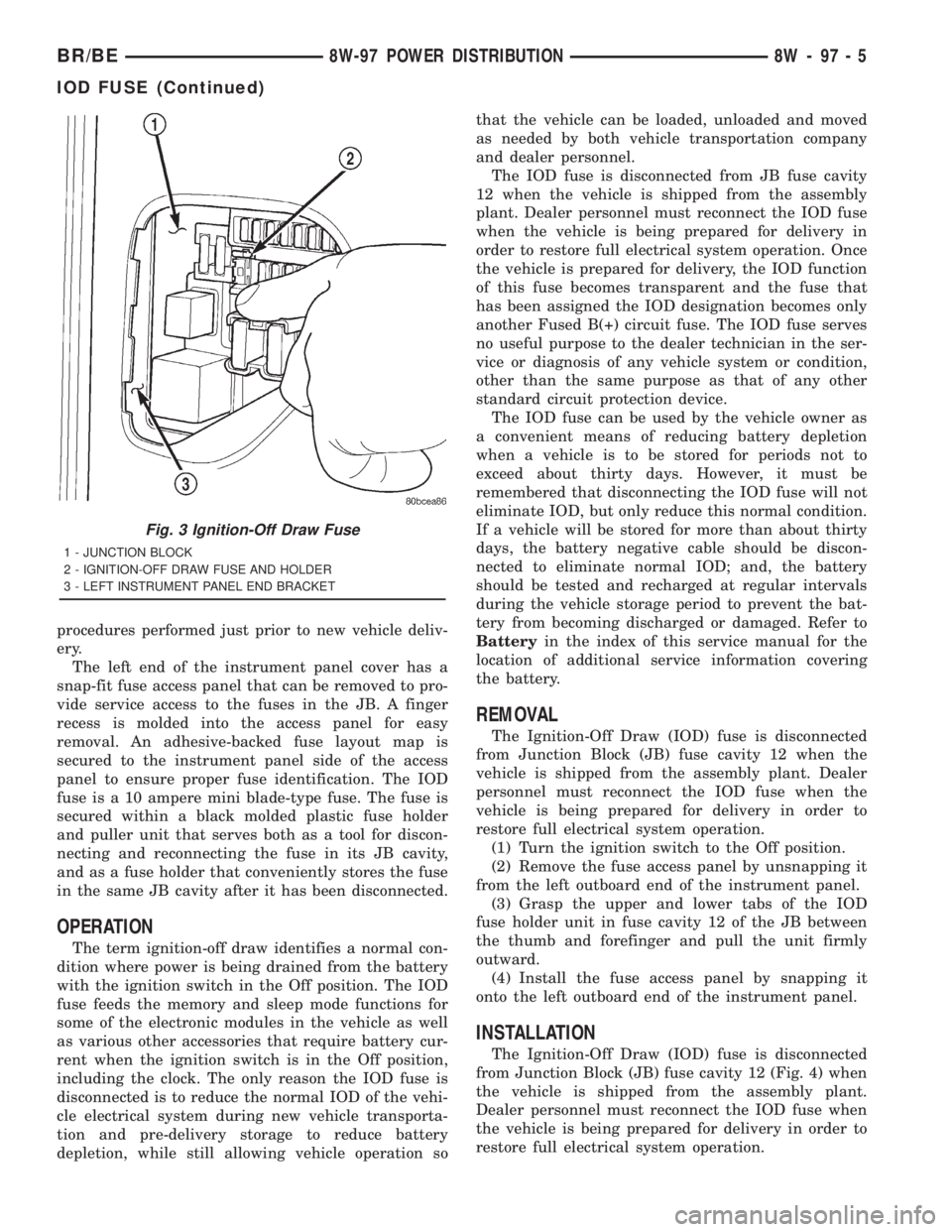

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse (Fig. 3) that is disconnected within

the Junction Block (JB) when the vehicle is shipped

from the factory. Dealer personnel are to reconnect

the IOD fuse in the JB as part of the preparation

8W - 97 - 4 8W-97 POWER DISTRIBUTIONBR/BE

CIGAR LIGHTER OUTLET (Continued)

Page 1140 of 2889

procedures performed just prior to new vehicle deliv-

ery.

The left end of the instrument panel cover has a

snap-fit fuse access panel that can be removed to pro-

vide service access to the fuses in the JB. A finger

recess is molded into the access panel for easy

removal. An adhesive-backed fuse layout map is

secured to the instrument panel side of the access

panel to ensure proper fuse identification. The IOD

fuse is a 10 ampere mini blade-type fuse. The fuse is

secured within a black molded plastic fuse holder

and puller unit that serves both as a tool for discon-

necting and reconnecting the fuse in its JB cavity,

and as a fuse holder that conveniently stores the fuse

in the same JB cavity after it has been disconnected.

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position,

including the clock. The only reason the IOD fuse is

disconnected is to reduce the normal IOD of the vehi-

cle electrical system during new vehicle transporta-

tion and pre-delivery storage to reduce battery

depletion, while still allowing vehicle operation sothat the vehicle can be loaded, unloaded and moved

as needed by both vehicle transportation company

and dealer personnel.

The IOD fuse is disconnected from JB fuse cavity

12 when the vehicle is shipped from the assembly

plant. Dealer personnel must reconnect the IOD fuse

when the vehicle is being prepared for delivery in

order to restore full electrical system operation. Once

the vehicle is prepared for delivery, the IOD function

of this fuse becomes transparent and the fuse that

has been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that disconnecting the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged. Refer to

Batteryin the index of this service manual for the

location of additional service information covering

the battery.

REMOVAL

The Ignition-Off Draw (IOD) fuse is disconnected

from Junction Block (JB) fuse cavity 12 when the

vehicle is shipped from the assembly plant. Dealer

personnel must reconnect the IOD fuse when the

vehicle is being prepared for delivery in order to

restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) Remove the fuse access panel by unsnapping it

from the left outboard end of the instrument panel.

(3) Grasp the upper and lower tabs of the IOD

fuse holder unit in fuse cavity 12 of the JB between

the thumb and forefinger and pull the unit firmly

outward.

(4) Install the fuse access panel by snapping it

onto the left outboard end of the instrument panel.

INSTALLATION

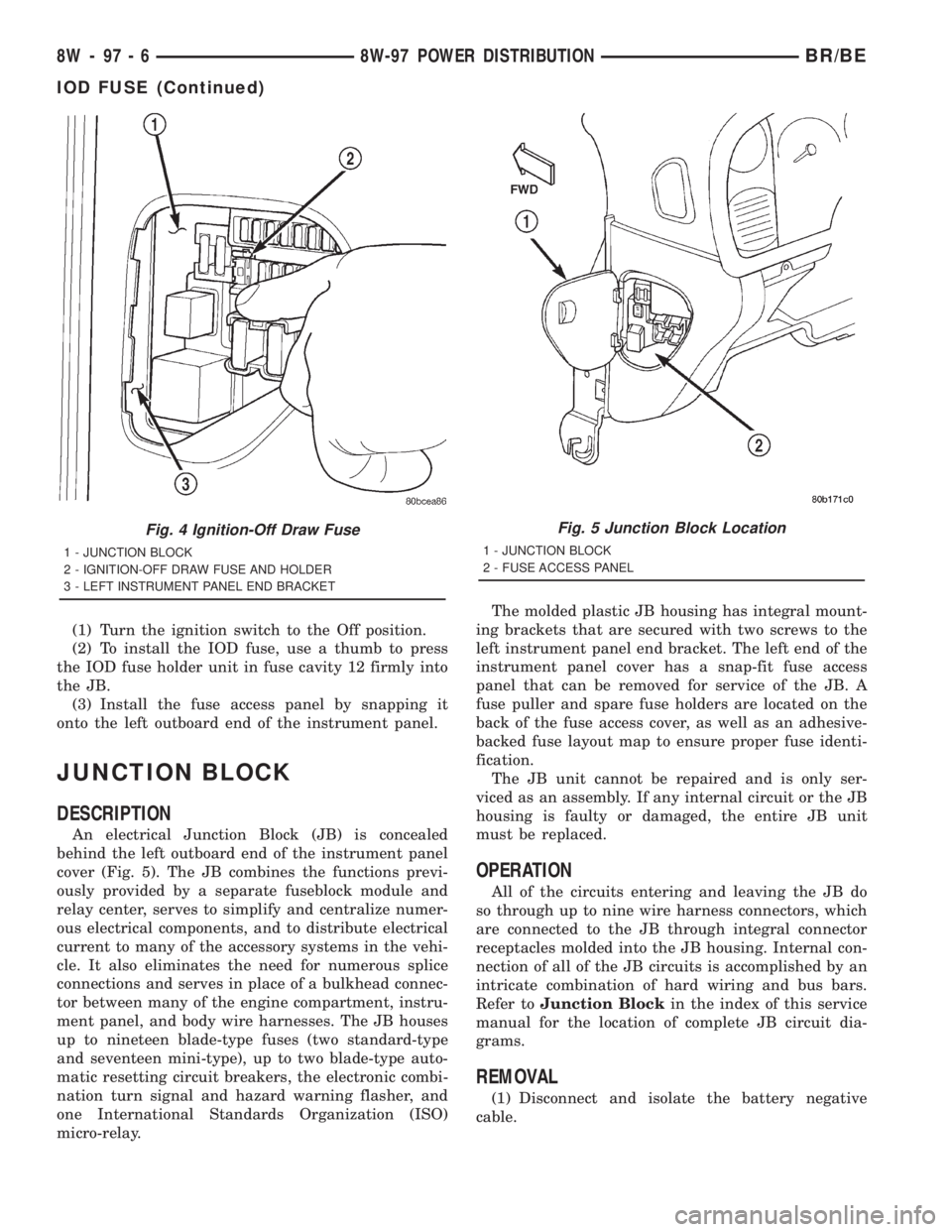

The Ignition-Off Draw (IOD) fuse is disconnected

from Junction Block (JB) fuse cavity 12 (Fig. 4) when

the vehicle is shipped from the assembly plant.

Dealer personnel must reconnect the IOD fuse when

the vehicle is being prepared for delivery in order to

restore full electrical system operation.

Fig. 3 Ignition-Off Draw Fuse

1 - JUNCTION BLOCK

2 - IGNITION-OFF DRAW FUSE AND HOLDER

3 - LEFT INSTRUMENT PANEL END BRACKET

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 5

IOD FUSE (Continued)

Page 1141 of 2889

(1) Turn the ignition switch to the Off position.

(2) To install the IOD fuse, use a thumb to press

the IOD fuse holder unit in fuse cavity 12 firmly into

the JB.

(3) Install the fuse access panel by snapping it

onto the left outboard end of the instrument panel.

JUNCTION BLOCK

DESCRIPTION

An electrical Junction Block (JB) is concealed

behind the left outboard end of the instrument panel

cover (Fig. 5). The JB combines the functions previ-

ously provided by a separate fuseblock module and

relay center, serves to simplify and centralize numer-

ous electrical components, and to distribute electrical

current to many of the accessory systems in the vehi-

cle. It also eliminates the need for numerous splice

connections and serves in place of a bulkhead connec-

tor between many of the engine compartment, instru-

ment panel, and body wire harnesses. The JB houses

up to nineteen blade-type fuses (two standard-type

and seventeen mini-type), up to two blade-type auto-

matic resetting circuit breakers, the electronic combi-

nation turn signal and hazard warning flasher, and

one International Standards Organization (ISO)

micro-relay.The molded plastic JB housing has integral mount-

ing brackets that are secured with two screws to the

left instrument panel end bracket. The left end of the

instrument panel cover has a snap-fit fuse access

panel that can be removed for service of the JB. A

fuse puller and spare fuse holders are located on the

back of the fuse access cover, as well as an adhesive-

backed fuse layout map to ensure proper fuse identi-

fication.

The JB unit cannot be repaired and is only ser-

viced as an assembly. If any internal circuit or the JB

housing is faulty or damaged, the entire JB unit

must be replaced.

OPERATION

All of the circuits entering and leaving the JB do

so through up to nine wire harness connectors, which

are connected to the JB through integral connector

receptacles molded into the JB housing. Internal con-

nection of all of the JB circuits is accomplished by an

intricate combination of hard wiring and bus bars.

Refer toJunction Blockin the index of this service

manual for the location of complete JB circuit dia-

grams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 4 Ignition-Off Draw Fuse

1 - JUNCTION BLOCK

2 - IGNITION-OFF DRAW FUSE AND HOLDER

3 - LEFT INSTRUMENT PANEL END BRACKET

Fig. 5 Junction Block Location

1 - JUNCTION BLOCK

2 - FUSE ACCESS PANEL

8W - 97 - 6 8W-97 POWER DISTRIBUTIONBR/BE

IOD FUSE (Continued)

Page 1151 of 2889

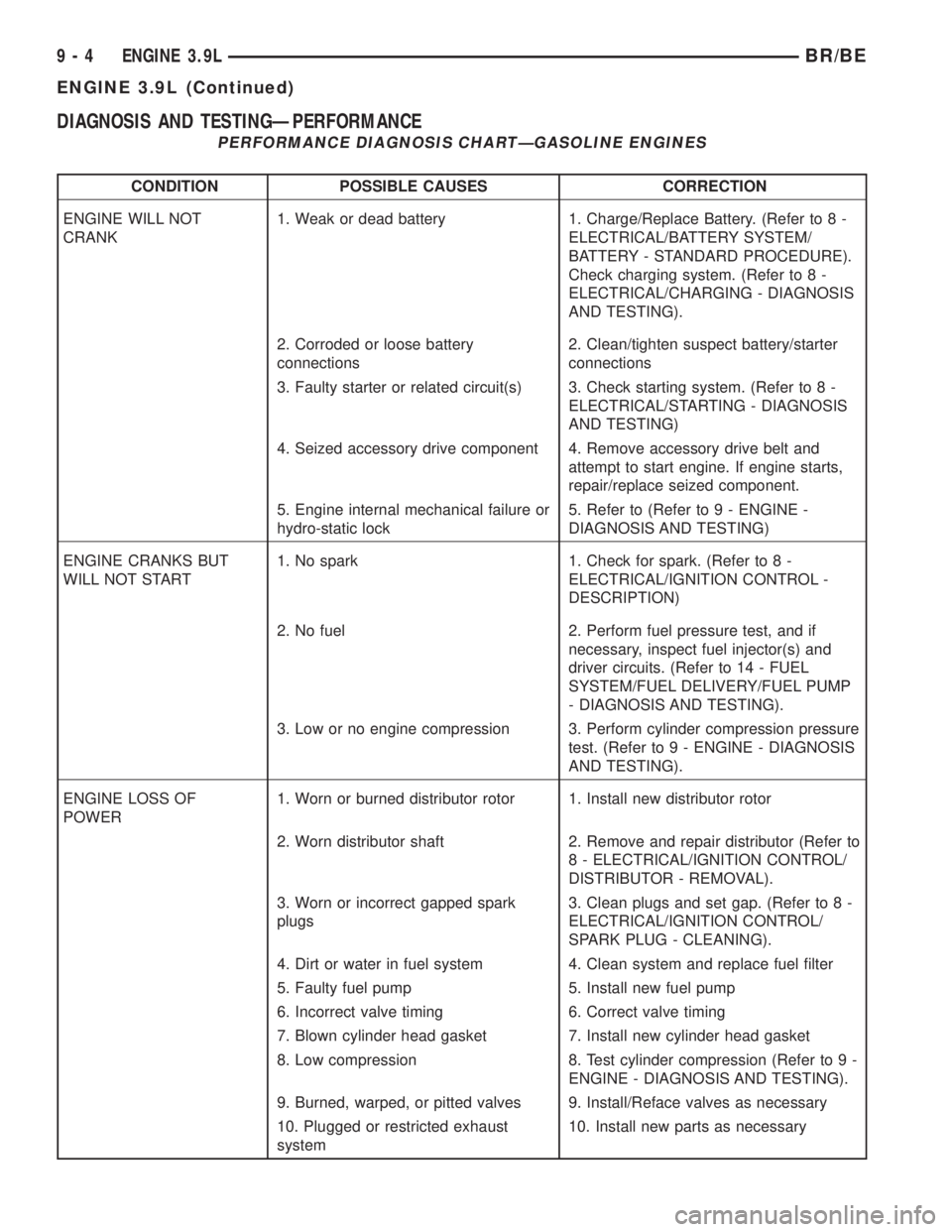

DIAGNOSIS AND TESTINGÐPERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT

CRANK1. Weak or dead battery 1. Charge/Replace Battery. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE).

Check charging system. (Refer to 8 -

ELECTRICAL/CHARGING - DIAGNOSIS

AND TESTING).

2. Corroded or loose battery

connections2. Clean/tighten suspect battery/starter

connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8 -

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING)

4. Seized accessory drive component 4. Remove accessory drive belt and

attempt to start engine. If engine starts,

repair/replace seized component.

5. Engine internal mechanical failure or

hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT

WILL NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL PUMP

- DIAGNOSIS AND TESTING).

3. Low or no engine compression 3. Perform cylinder compression pressure

test. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING).

ENGINE LOSS OF

POWER1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor (Refer to

8 - ELECTRICAL/IGNITION CONTROL/

DISTRIBUTOR - REMOVAL).

3. Worn or incorrect gapped spark

plugs3. Clean plugs and set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG - CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust

system10. Install new parts as necessary

9 - 4 ENGINE 3.9LBR/BE

ENGINE 3.9L (Continued)

Page 1152 of 2889

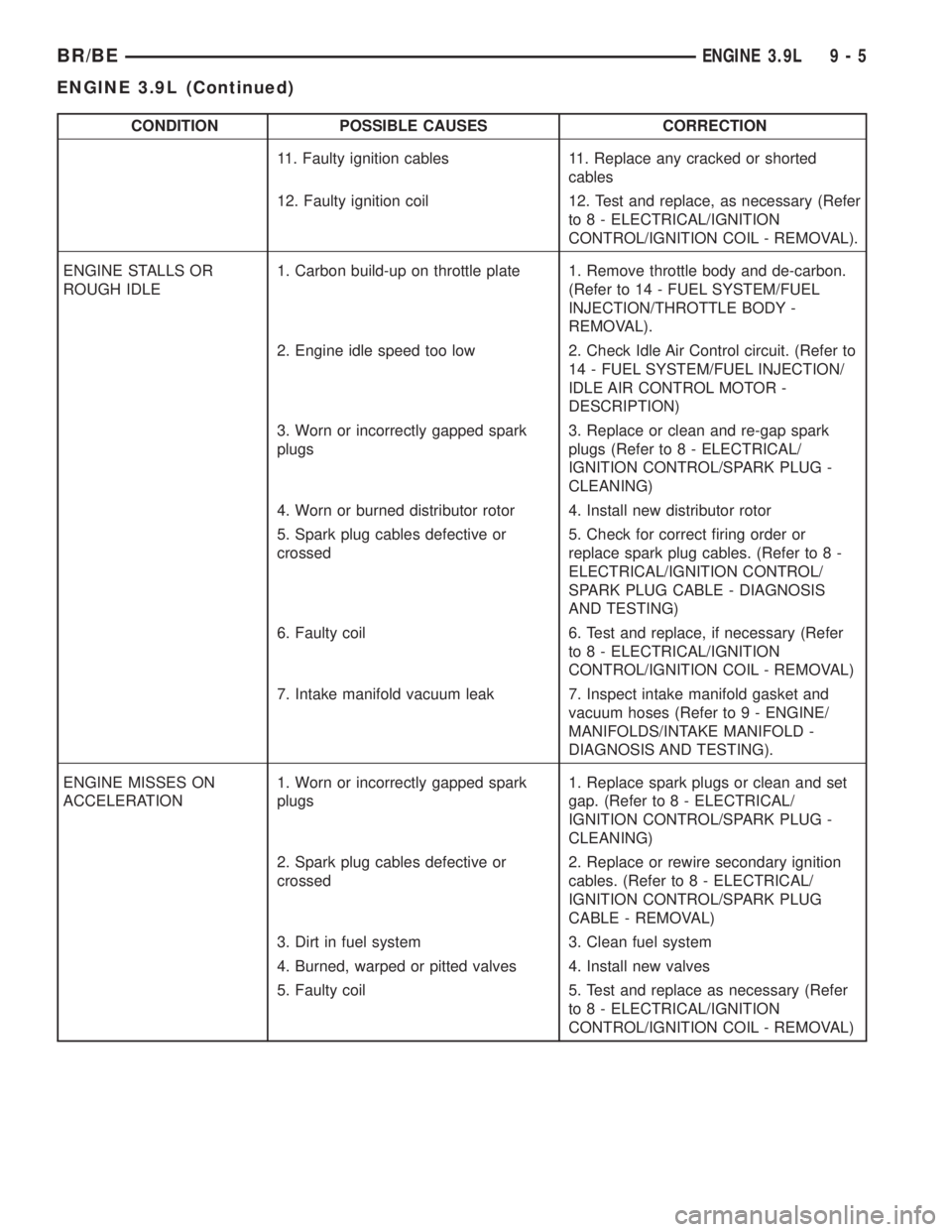

CONDITION POSSIBLE CAUSES CORRECTION

11. Faulty ignition cables 11. Replace any cracked or shorted

cables

12. Faulty ignition coil 12. Test and replace, as necessary (Refer

to 8 - ELECTRICAL/IGNITION

CONTROL/IGNITION COIL - REMOVAL).

ENGINE STALLS OR

ROUGH IDLE1. Carbon build-up on throttle plate 1. Remove throttle body and de-carbon.

(Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/THROTTLE BODY -

REMOVAL).

2. Engine idle speed too low 2. Check Idle Air Control circuit. (Refer to

14 - FUEL SYSTEM/FUEL INJECTION/

IDLE AIR CONTROL MOTOR -

DESCRIPTION)

3. Worn or incorrectly gapped spark

plugs3. Replace or clean and re-gap spark

plugs (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING)

4. Worn or burned distributor rotor 4. Install new distributor rotor

5. Spark plug cables defective or

crossed5. Check for correct firing order or

replace spark plug cables. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG CABLE - DIAGNOSIS

AND TESTING)

6. Faulty coil 6. Test and replace, if necessary (Refer

to 8 - ELECTRICAL/IGNITION

CONTROL/IGNITION COIL - REMOVAL)

7. Intake manifold vacuum leak 7. Inspect intake manifold gasket and

vacuum hoses (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING).

ENGINE MISSES ON

ACCELERATION1. Worn or incorrectly gapped spark

plugs1. Replace spark plugs or clean and set

gap. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING)

2. Spark plug cables defective or

crossed2. Replace or rewire secondary ignition

cables. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

CABLE - REMOVAL)

3. Dirt in fuel system 3. Clean fuel system

4. Burned, warped or pitted valves 4. Install new valves

5. Faulty coil 5. Test and replace as necessary (Refer

to 8 - ELECTRICAL/IGNITION

CONTROL/IGNITION COIL - REMOVAL)

BR/BEENGINE 3.9L 9 - 5

ENGINE 3.9L (Continued)