torque DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1422 of 2889

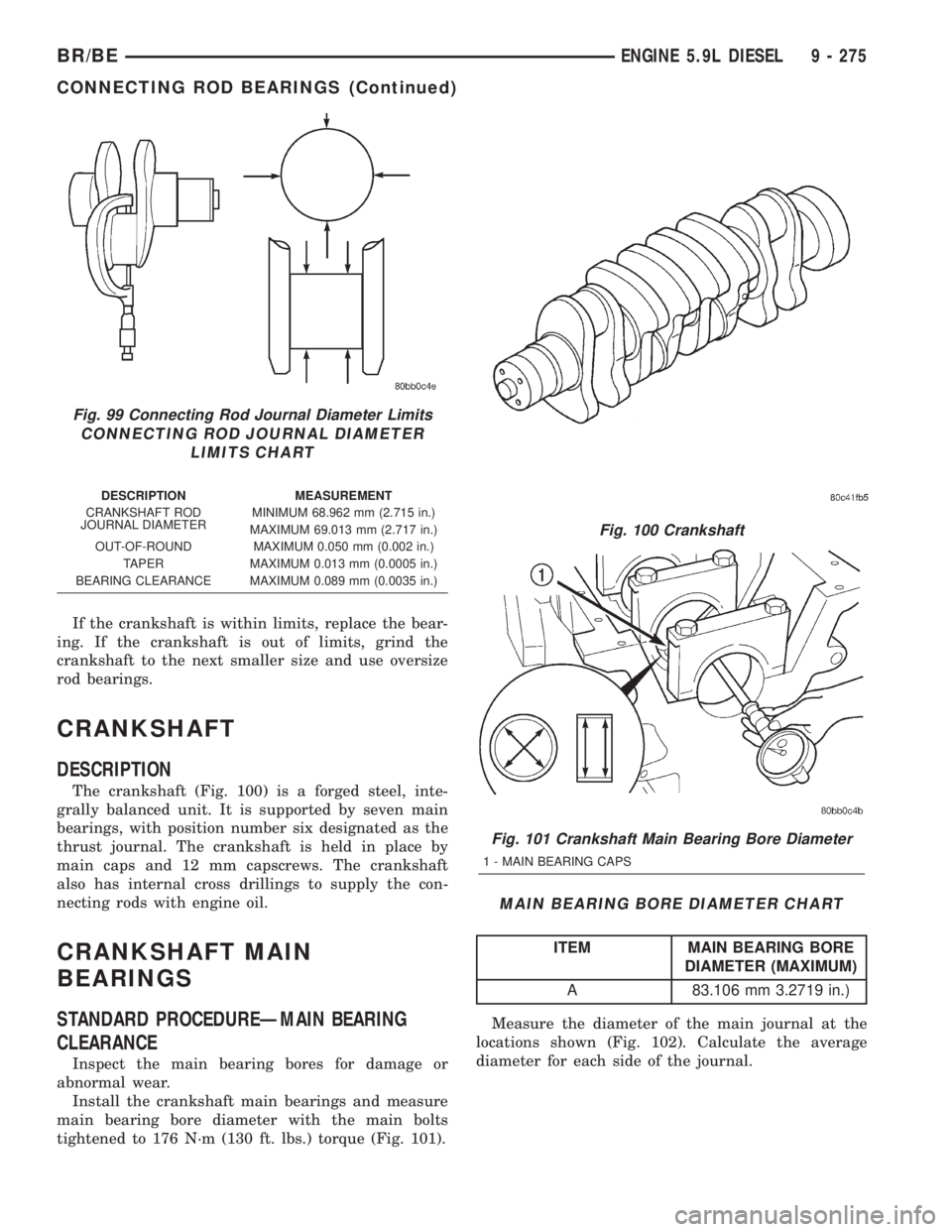

If the crankshaft is within limits, replace the bear-

ing. If the crankshaft is out of limits, grind the

crankshaft to the next smaller size and use oversize

rod bearings.

CRANKSHAFT

DESCRIPTION

The crankshaft (Fig. 100) is a forged steel, inte-

grally balanced unit. It is supported by seven main

bearings, with position number six designated as the

thrust journal. The crankshaft is held in place by

main caps and 12 mm capscrews. The crankshaft

also has internal cross drillings to supply the con-

necting rods with engine oil.

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐMAIN BEARING

CLEARANCE

Inspect the main bearing bores for damage or

abnormal wear.

Install the crankshaft main bearings and measure

main bearing bore diameter with the main bolts

tightened to 176 N´m (130 ft. lbs.) torque (Fig. 101).

MAIN BEARING BORE DIAMETER CHART

ITEM MAIN BEARING BORE

DIAMETER (MAXIMUM)

A 83.106 mm 3.2719 in.)

Measure the diameter of the main journal at the

locations shown (Fig. 102). Calculate the average

diameter for each side of the journal.

Fig. 99 Connecting Rod Journal Diameter Limits

CONNECTING ROD JOURNAL DIAMETER

LIMITS CHART

DESCRIPTION MEASUREMENT

CRANKSHAFT ROD

JOURNAL DIAMETERMINIMUM 68.962 mm (2.715 in.)

MAXIMUM 69.013 mm (2.717 in.)

OUT-OF-ROUND MAXIMUM 0.050 mm (0.002 in.)

TAPER MAXIMUM 0.013 mm (0.0005 in.)

BEARING CLEARANCE MAXIMUM 0.089 mm (0.0035 in.)

Fig. 100 Crankshaft

Fig. 101 Crankshaft Main Bearing Bore Diameter

1 - MAIN BEARING CAPS

BR/BEENGINE 5.9L DIESEL 9 - 275

CONNECTING ROD BEARINGS (Continued)

Page 1424 of 2889

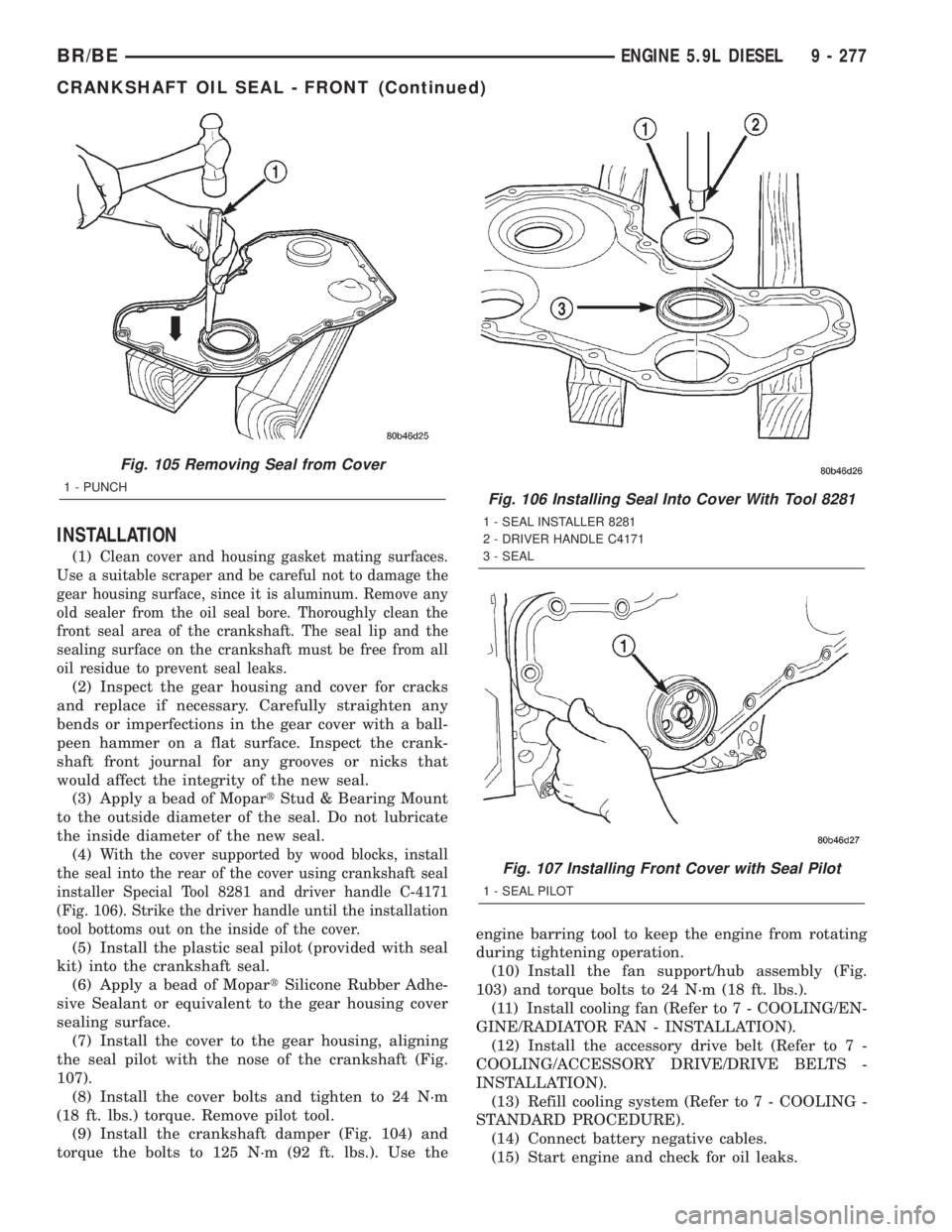

INSTALLATION

(1)Clean cover and housing gasket mating surfaces.

Use a suitable scraper and be careful not to damage the

gear housing surface, since it is aluminum. Remove any

old sealer from the oil seal bore. Thoroughly clean the

front seal area of the crankshaft. The seal lip and the

sealing surface on the crankshaft must be free from all

oil residue to prevent seal leaks.

(2) Inspect the gear housing and cover for cracks

and replace if necessary. Carefully straighten any

bends or imperfections in the gear cover with a ball-

peen hammer on a flat surface. Inspect the crank-

shaft front journal for any grooves or nicks that

would affect the integrity of the new seal.

(3) Apply a bead of MopartStud & Bearing Mount

to the outside diameter of the seal. Do not lubricate

the inside diameter of the new seal.

(4)

With the cover supported by wood blocks, install

the seal into the rear of the cover using crankshaft seal

installer Special Tool 8281 and driver handle C-4171

(Fig. 106). Strike the driver handle until the installation

tool bottoms out on the inside of the cover.

(5) Install the plastic seal pilot (provided with seal

kit) into the crankshaft seal.

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the cover to the gear housing, aligning

the seal pilot with the nose of the crankshaft (Fig.

107).

(8) Install the cover bolts and tighten to 24 N´m

(18 ft. lbs.) torque. Remove pilot tool.

(9) Install the crankshaft damper (Fig. 104) and

torque the bolts to 125 N´m (92 ft. lbs.). Use theengine barring tool to keep the engine from rotating

during tightening operation.

(10) Install the fan support/hub assembly (Fig.

103) and torque bolts to 24 N´m (18 ft. lbs.).

(11) Install cooling fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect battery negative cables.

(15) Start engine and check for oil leaks.

Fig. 105 Removing Seal from Cover

1 - PUNCHFig. 106 Installing Seal Into Cover With Tool 8281

1 - SEAL INSTALLER 8281

2 - DRIVER HANDLE C4171

3 - SEAL

Fig. 107 Installing Front Cover with Seal Pilot

1 - SEAL PILOT

BR/BEENGINE 5.9L DIESEL 9 - 277

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1425 of 2889

CRANKSHAFT OIL SEAL -

REAR

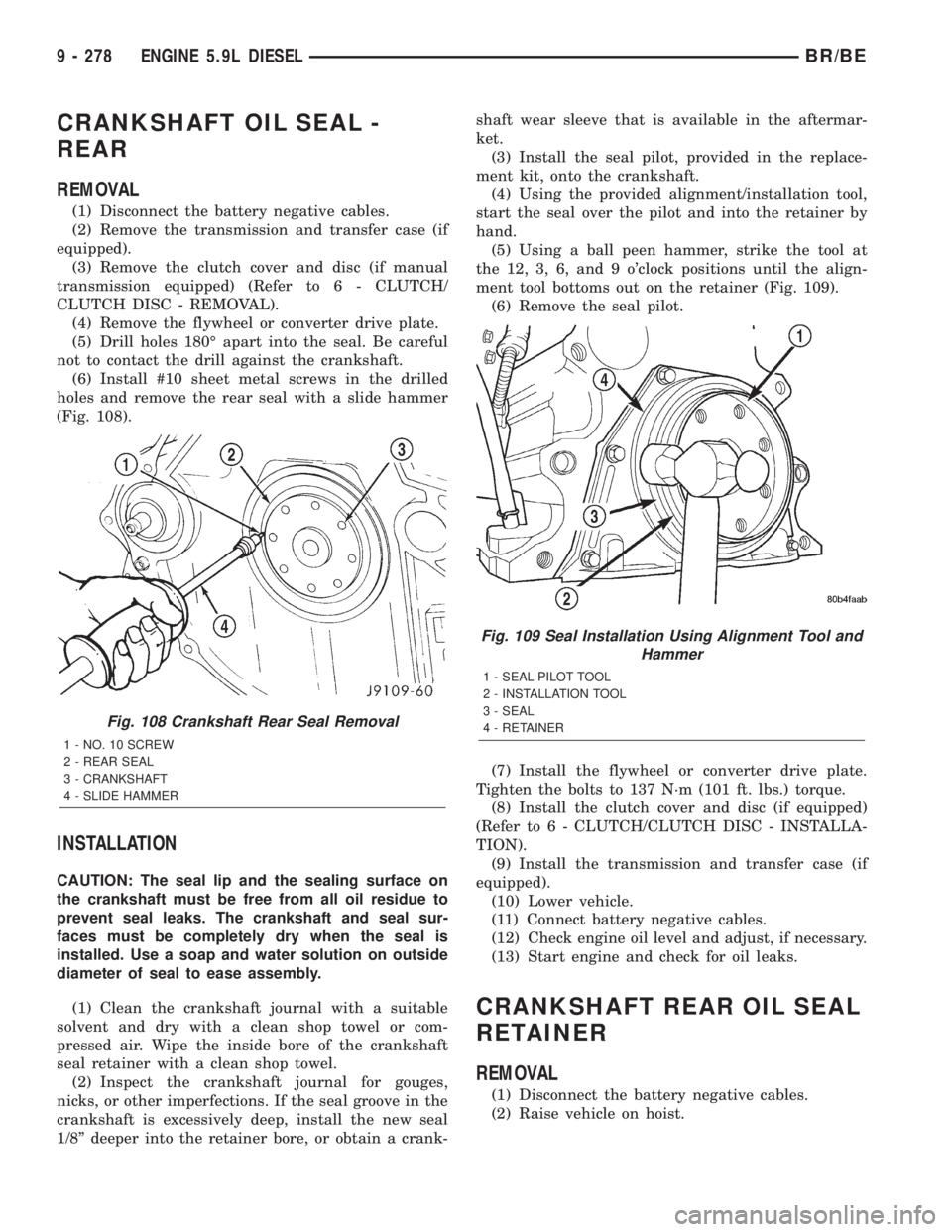

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the transmission and transfer case (if

equipped).

(3) Remove the clutch cover and disc (if manual

transmission equipped) (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

(4) Remove the flywheel or converter drive plate.

(5) Drill holes 180É apart into the seal. Be careful

not to contact the drill against the crankshaft.

(6) Install #10 sheet metal screws in the drilled

holes and remove the rear seal with a slide hammer

(Fig. 108).

INSTALLATION

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(1) Clean the crankshaft journal with a suitable

solvent and dry with a clean shop towel or com-

pressed air. Wipe the inside bore of the crankshaft

seal retainer with a clean shop towel.

(2) Inspect the crankshaft journal for gouges,

nicks, or other imperfections. If the seal groove in the

crankshaft is excessively deep, install the new seal

1/8º deeper into the retainer bore, or obtain a crank-shaft wear sleeve that is available in the aftermar-

ket.

(3) Install the seal pilot, provided in the replace-

ment kit, onto the crankshaft.

(4) Using the provided alignment/installation tool,

start the seal over the pilot and into the retainer by

hand.

(5) Using a ball peen hammer, strike the tool at

the 12, 3, 6, and 9 o'clock positions until the align-

ment tool bottoms out on the retainer (Fig. 109).

(6) Remove the seal pilot.

(7) Install the flywheel or converter drive plate.

Tighten the bolts to 137 N´m (101 ft. lbs.) torque.

(8) Install the clutch cover and disc (if equipped)

(Refer to 6 - CLUTCH/CLUTCH DISC - INSTALLA-

TION).

(9) Install the transmission and transfer case (if

equipped).

(10) Lower vehicle.

(11) Connect battery negative cables.

(12) Check engine oil level and adjust, if necessary.

(13) Start engine and check for oil leaks.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

Fig. 108 Crankshaft Rear Seal Removal

1 - NO. 10 SCREW

2 - REAR SEAL

3 - CRANKSHAFT

4 - SLIDE HAMMER

Fig. 109 Seal Installation Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

9 - 278 ENGINE 5.9L DIESELBR/BE

Page 1426 of 2889

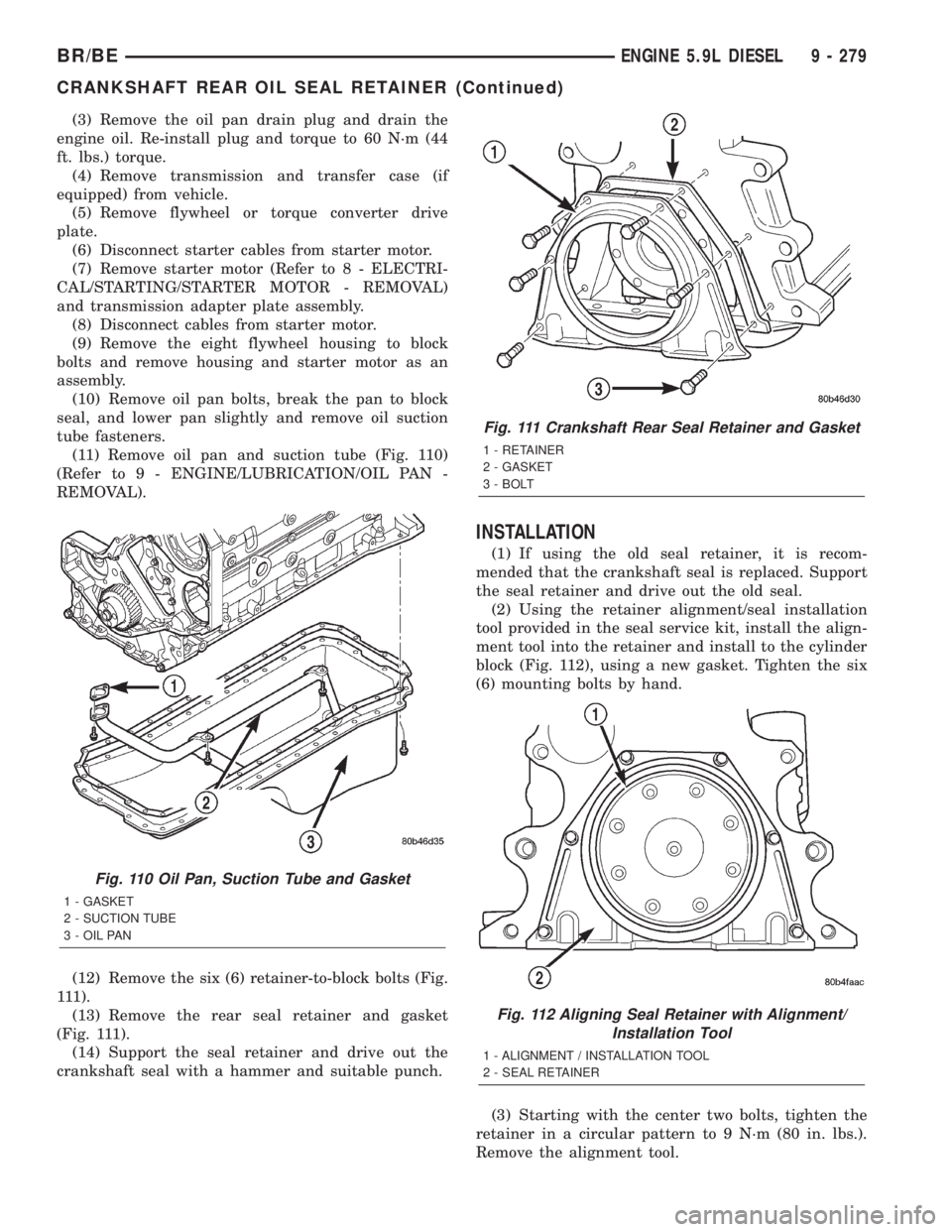

(3) Remove the oil pan drain plug and drain the

engine oil. Re-install plug and torque to 60 N´m (44

ft. lbs.) torque.

(4) Remove transmission and transfer case (if

equipped) from vehicle.

(5) Remove flywheel or torque converter drive

plate.

(6) Disconnect starter cables from starter motor.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(8) Disconnect cables from starter motor.

(9) Remove the eight flywheel housing to block

bolts and remove housing and starter motor as an

assembly.

(10) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(11) Remove oil pan and suction tube (Fig. 110)

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(12) Remove the six (6) retainer-to-block bolts (Fig.

111).

(13) Remove the rear seal retainer and gasket

(Fig. 111).

(14) Support the seal retainer and drive out the

crankshaft seal with a hammer and suitable punch.

INSTALLATION

(1) If using the old seal retainer, it is recom-

mended that the crankshaft seal is replaced. Support

the seal retainer and drive out the old seal.

(2) Using the retainer alignment/seal installation

tool provided in the seal service kit, install the align-

ment tool into the retainer and install to the cylinder

block (Fig. 112), using a new gasket. Tighten the six

(6) mounting bolts by hand.

(3) Starting with the center two bolts, tighten the

retainer in a circular pattern to 9 N´m (80 in. lbs.).

Remove the alignment tool.

Fig. 110 Oil Pan, Suction Tube and Gasket

1 - GASKET

2 - SUCTION TUBE

3 - OIL PAN

Fig. 111 Crankshaft Rear Seal Retainer and Gasket

1 - RETAINER

2 - GASKET

3 - BOLT

Fig. 112 Aligning Seal Retainer with Alignment/

Installation Tool

1 - ALIGNMENT / INSTALLATION TOOL

2 - SEAL RETAINER

BR/BEENGINE 5.9L DIESEL 9 - 279

CRANKSHAFT REAR OIL SEAL RETAINER (Continued)

Page 1427 of 2889

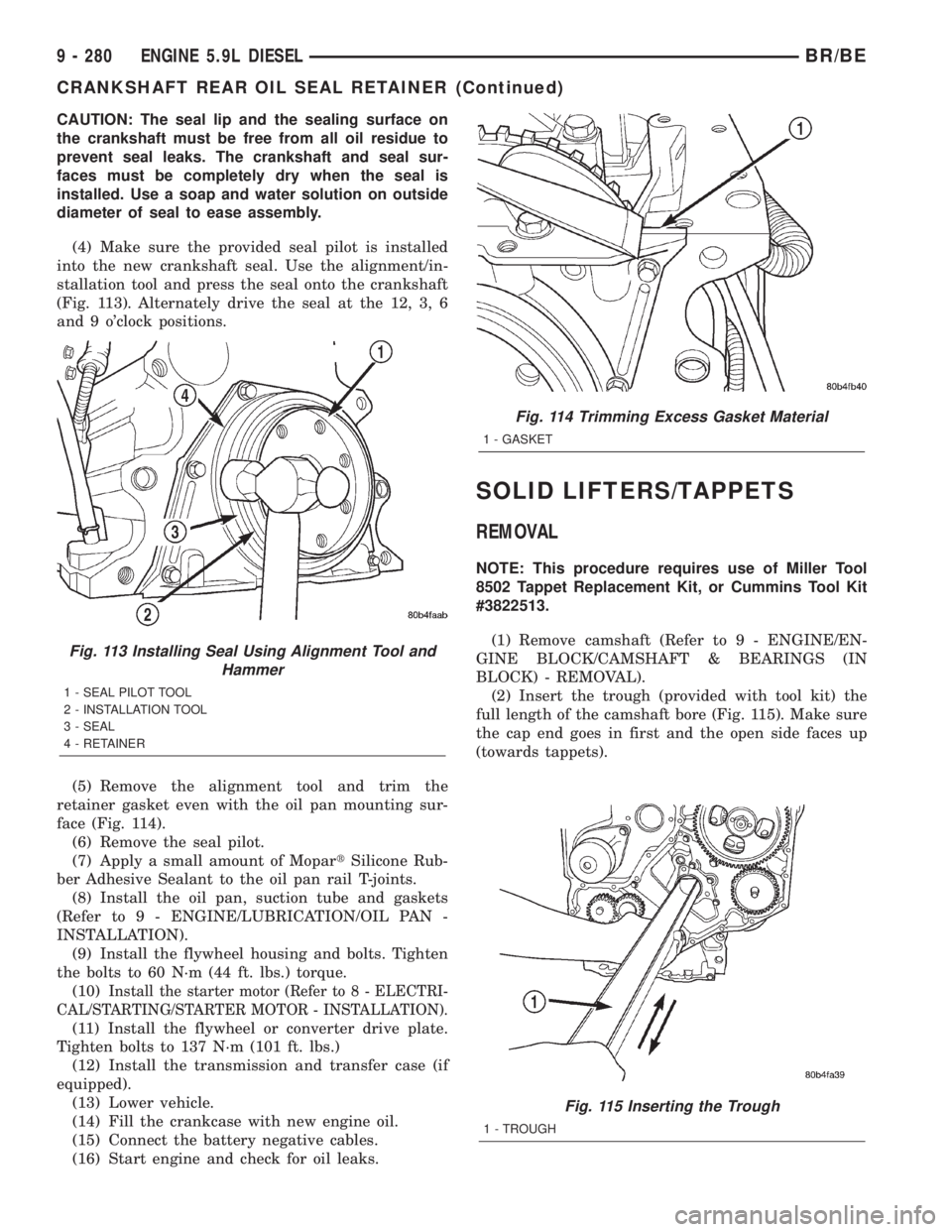

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(4) Make sure the provided seal pilot is installed

into the new crankshaft seal. Use the alignment/in-

stallation tool and press the seal onto the crankshaft

(Fig. 113). Alternately drive the seal at the 12, 3, 6

and 9 o'clock positions.

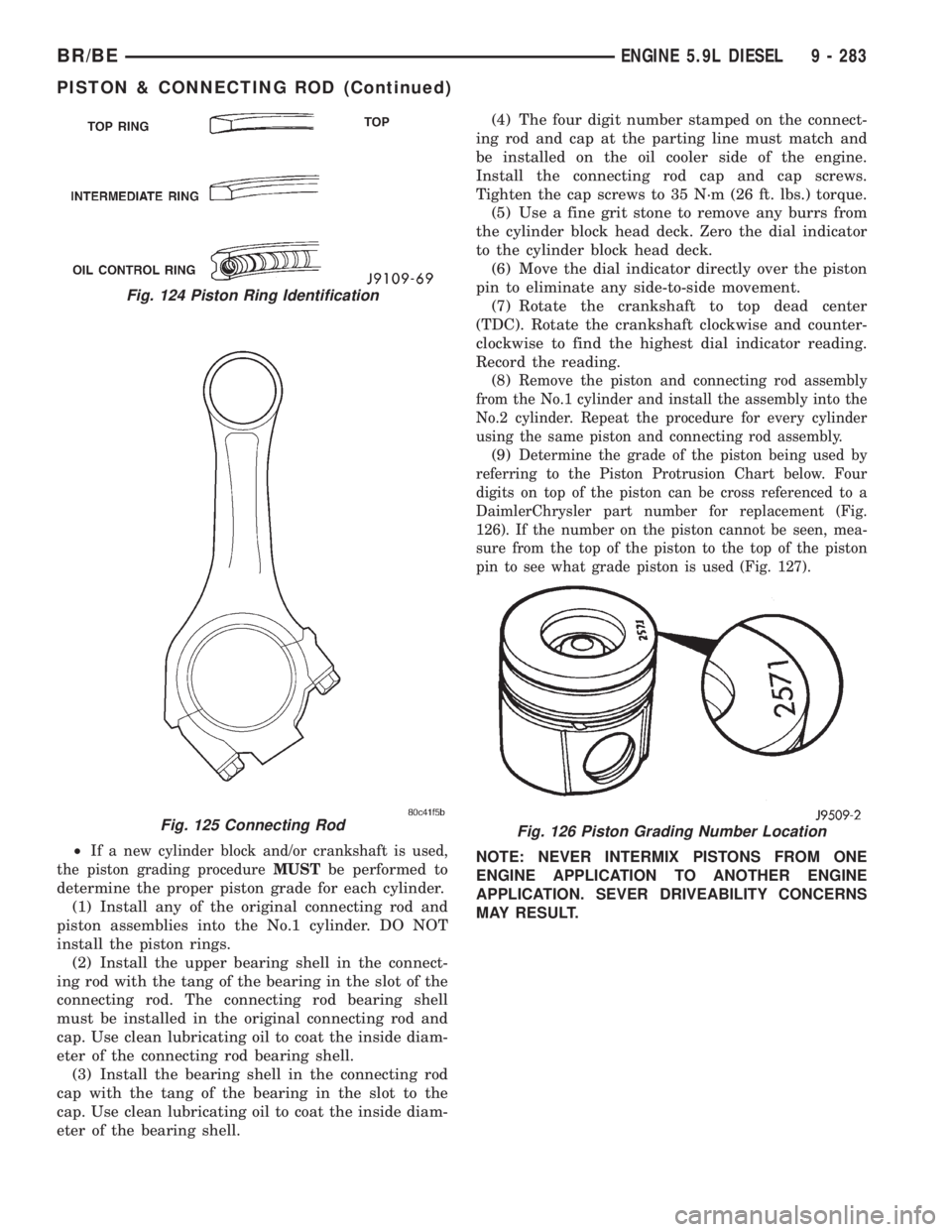

(5) Remove the alignment tool and trim the

retainer gasket even with the oil pan mounting sur-

face (Fig. 114).

(6) Remove the seal pilot.

(7) Apply a small amount of MopartSilicone Rub-

ber Adhesive Sealant to the oil pan rail T-joints.

(8) Install the oil pan, suction tube and gaskets

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

INSTALLATION).

(9) Install the flywheel housing and bolts. Tighten

the bolts to 60 N´m (44 ft. lbs.) torque.

(10)

Install the starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - INSTALLATION).

(11) Install the flywheel or converter drive plate.

Tighten bolts to 137 N´m (101 ft. lbs.)

(12) Install the transmission and transfer case (if

equipped).

(13) Lower vehicle.

(14) Fill the crankcase with new engine oil.

(15) Connect the battery negative cables.

(16) Start engine and check for oil leaks.

SOLID LIFTERS/TAPPETS

REMOVAL

NOTE: This procedure requires use of Miller Tool

8502 Tappet Replacement Kit, or Cummins Tool Kit

#3822513.

(1) Remove camshaft (Refer to 9 - ENGINE/EN-

GINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(2) Insert the trough (provided with tool kit) the

full length of the camshaft bore (Fig. 115). Make sure

the cap end goes in first and the open side faces up

(towards tappets).

Fig. 115 Inserting the Trough

1 - TROUGH

Fig. 113 Installing Seal Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

Fig. 114 Trimming Excess Gasket Material

1 - GASKET

9 - 280 ENGINE 5.9L DIESELBR/BE

CRANKSHAFT REAR OIL SEAL RETAINER (Continued)

Page 1430 of 2889

²If a new cylinder block and/or crankshaft is used,

the piston grading procedureMUST

be performed to

determine the proper piston grade for each cylinder.

(1) Install any of the original connecting rod and

piston assemblies into the No.1 cylinder. DO NOT

install the piston rings.

(2) Install the upper bearing shell in the connect-

ing rod with the tang of the bearing in the slot of the

connecting rod. The connecting rod bearing shell

must be installed in the original connecting rod and

cap. Use clean lubricating oil to coat the inside diam-

eter of the connecting rod bearing shell.

(3) Install the bearing shell in the connecting rod

cap with the tang of the bearing in the slot to the

cap. Use clean lubricating oil to coat the inside diam-

eter of the bearing shell.(4) The four digit number stamped on the connect-

ing rod and cap at the parting line must match and

be installed on the oil cooler side of the engine.

Install the connecting rod cap and cap screws.

Tighten the cap screws to 35 N´m (26 ft. lbs.) torque.

(5) Use a fine grit stone to remove any burrs from

the cylinder block head deck. Zero the dial indicator

to the cylinder block head deck.

(6) Move the dial indicator directly over the piston

pin to eliminate any side-to-side movement.

(7) Rotate the crankshaft to top dead center

(TDC). Rotate the crankshaft clockwise and counter-

clockwise to find the highest dial indicator reading.

Record the reading.

(8)

Remove the piston and connecting rod assembly

from the No.1 cylinder and install the assembly into the

No.2 cylinder. Repeat the procedure for every cylinder

using the same piston and connecting rod assembly.

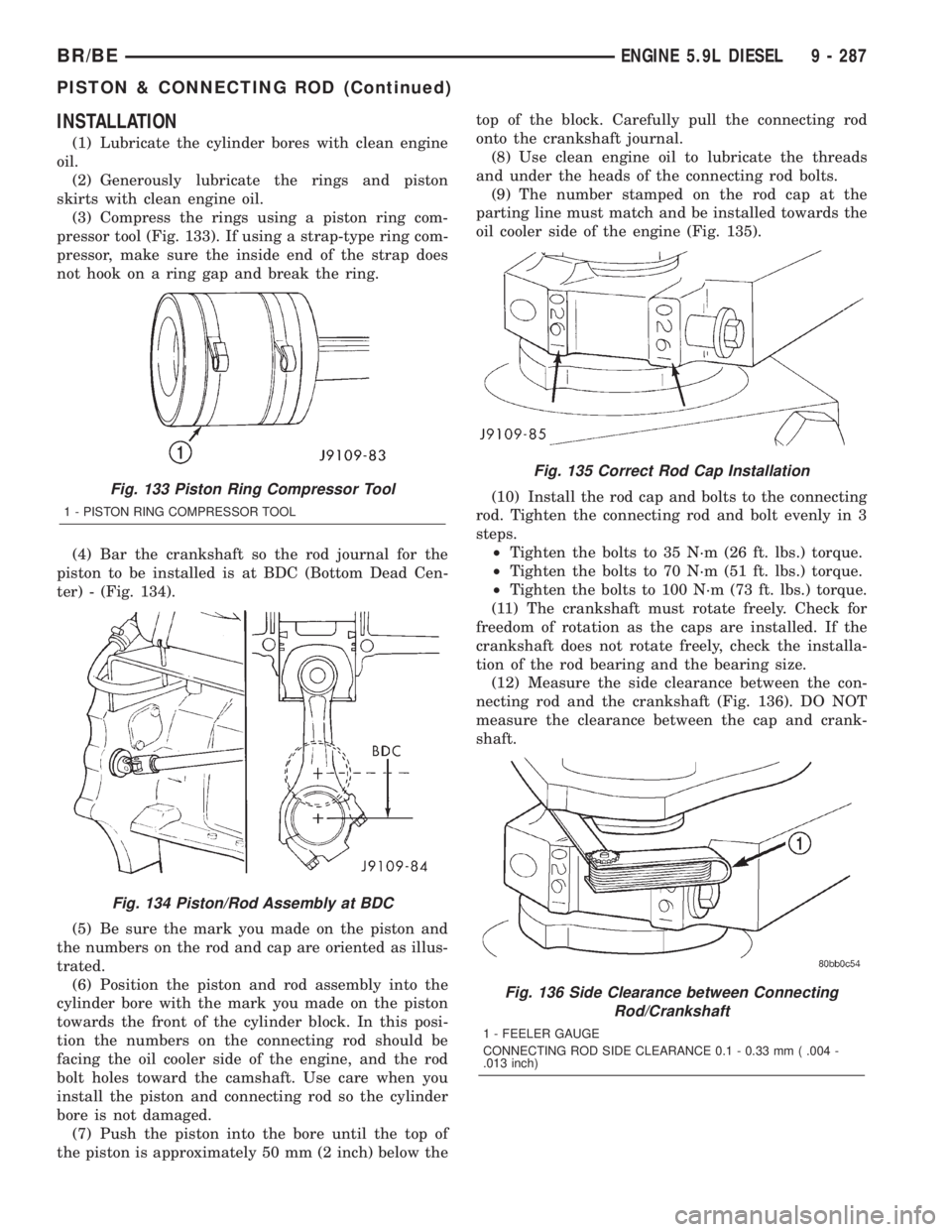

(9)Determine the grade of the piston being used by

referring to the Piston Protrusion Chart below. Four

digits on top of the piston can be cross referenced to a

DaimlerChrysler part number for replacement (Fig.

126). If the number on the piston cannot be seen, mea-

sure from the top of the piston to the top of the piston

pin to see what grade piston is used (Fig. 127).

NOTE: NEVER INTERMIX PISTONS FROM ONE

ENGINE APPLICATION TO ANOTHER ENGINE

APPLICATION. SEVER DRIVEABILITY CONCERNS

MAY RESULT.

Fig. 124 Piston Ring Identification

Fig. 125 Connecting RodFig. 126 Piston Grading Number Location

BR/BEENGINE 5.9L DIESEL 9 - 283

PISTON & CONNECTING ROD (Continued)

Page 1434 of 2889

INSTALLATION

(1) Lubricate the cylinder bores with clean engine

oil.

(2) Generously lubricate the rings and piston

skirts with clean engine oil.

(3) Compress the rings using a piston ring com-

pressor tool (Fig. 133). If using a strap-type ring com-

pressor, make sure the inside end of the strap does

not hook on a ring gap and break the ring.

(4) Bar the crankshaft so the rod journal for the

piston to be installed is at BDC (Bottom Dead Cen-

ter) - (Fig. 134).

(5) Be sure the mark you made on the piston and

the numbers on the rod and cap are oriented as illus-

trated.

(6) Position the piston and rod assembly into the

cylinder bore with the mark you made on the piston

towards the front of the cylinder block. In this posi-

tion the numbers on the connecting rod should be

facing the oil cooler side of the engine, and the rod

bolt holes toward the camshaft. Use care when you

install the piston and connecting rod so the cylinder

bore is not damaged.

(7) Push the piston into the bore until the top of

the piston is approximately 50 mm (2 inch) below thetop of the block. Carefully pull the connecting rod

onto the crankshaft journal.

(8) Use clean engine oil to lubricate the threads

and under the heads of the connecting rod bolts.

(9) The number stamped on the rod cap at the

parting line must match and be installed towards the

oil cooler side of the engine (Fig. 135).

(10) Install the rod cap and bolts to the connecting

rod. Tighten the connecting rod and bolt evenly in 3

steps.

²Tighten the bolts to 35 N´m (26 ft. lbs.) torque.

²Tighten the bolts to 70 N´m (51 ft. lbs.) torque.

²Tighten the bolts to 100 N´m (73 ft. lbs.) torque.

(11) The crankshaft must rotate freely. Check for

freedom of rotation as the caps are installed. If the

crankshaft does not rotate freely, check the installa-

tion of the rod bearing and the bearing size.

(12) Measure the side clearance between the con-

necting rod and the crankshaft (Fig. 136). DO NOT

measure the clearance between the cap and crank-

shaft.

Fig. 133 Piston Ring Compressor Tool

1 - PISTON RING COMPRESSOR TOOL

Fig. 134 Piston/Rod Assembly at BDC

Fig. 135 Correct Rod Cap Installation

Fig. 136 Side Clearance between Connecting

Rod/Crankshaft

1 - FEELER GAUGE

CONNECTING ROD SIDE CLEARANCE 0.1 - 0.33 mm ( .004 -

.013 inch)

BR/BEENGINE 5.9L DIESEL 9 - 287

PISTON & CONNECTING ROD (Continued)

Page 1436 of 2889

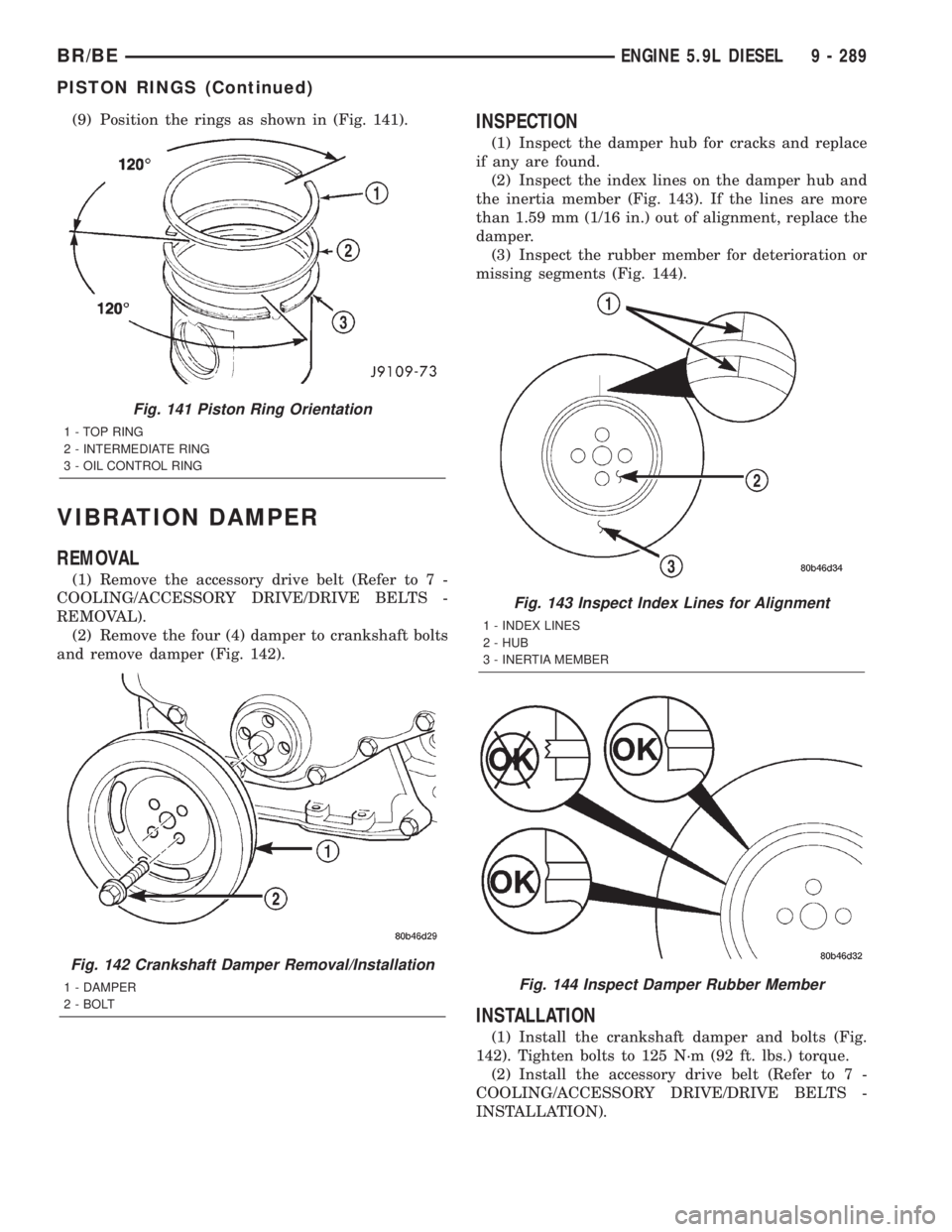

(9) Position the rings as shown in (Fig. 141).

VIBRATION DAMPER

REMOVAL

(1) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove the four (4) damper to crankshaft bolts

and remove damper (Fig. 142).

INSPECTION

(1) Inspect the damper hub for cracks and replace

if any are found.

(2) Inspect the index lines on the damper hub and

the inertia member (Fig. 143). If the lines are more

than 1.59 mm (1/16 in.) out of alignment, replace the

damper.

(3) Inspect the rubber member for deterioration or

missing segments (Fig. 144).

INSTALLATION

(1) Install the crankshaft damper and bolts (Fig.

142). Tighten bolts to 125 N´m (92 ft. lbs.) torque.

(2) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Fig. 141 Piston Ring Orientation

1 - TOP RING

2 - INTERMEDIATE RING

3 - OIL CONTROL RING

Fig. 142 Crankshaft Damper Removal/Installation

1 - DAMPER

2 - BOLT

Fig. 143 Inspect Index Lines for Alignment

1 - INDEX LINES

2 - HUB

3 - INERTIA MEMBER

Fig. 144 Inspect Damper Rubber Member

BR/BEENGINE 5.9L DIESEL 9 - 289

PISTON RINGS (Continued)

Page 1437 of 2889

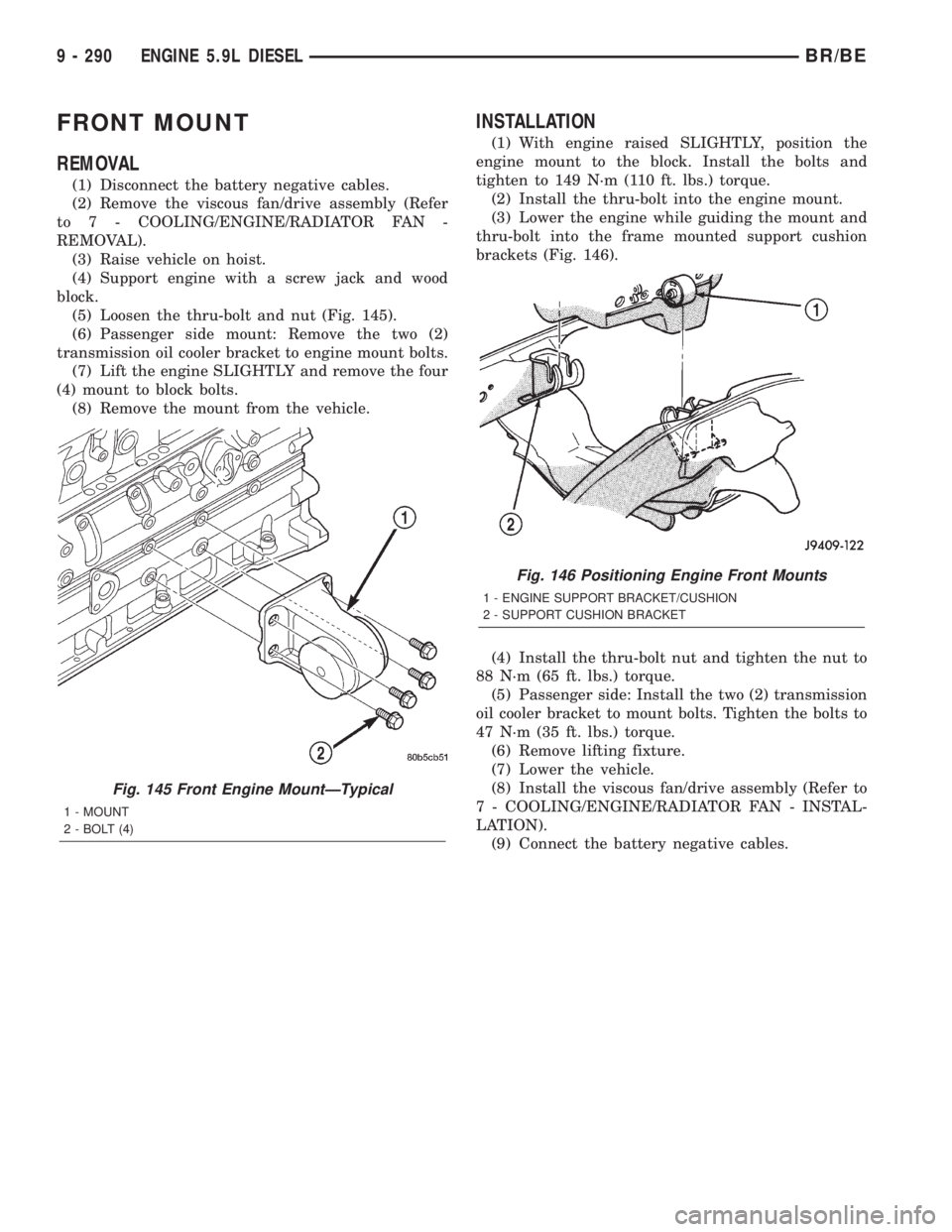

FRONT MOUNT

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the viscous fan/drive assembly (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(3) Raise vehicle on hoist.

(4) Support engine with a screw jack and wood

block.

(5) Loosen the thru-bolt and nut (Fig. 145).

(6) Passenger side mount: Remove the two (2)

transmission oil cooler bracket to engine mount bolts.

(7) Lift the engine SLIGHTLY and remove the four

(4) mount to block bolts.

(8) Remove the mount from the vehicle.

INSTALLATION

(1) With engine raised SLIGHTLY, position the

engine mount to the block. Install the bolts and

tighten to 149 N´m (110 ft. lbs.) torque.

(2) Install the thru-bolt into the engine mount.

(3) Lower the engine while guiding the mount and

thru-bolt into the frame mounted support cushion

brackets (Fig. 146).

(4) Install the thru-bolt nut and tighten the nut to

88 N´m (65 ft. lbs.) torque.

(5) Passenger side: Install the two (2) transmission

oil cooler bracket to mount bolts. Tighten the bolts to

47 N´m (35 ft. lbs.) torque.

(6) Remove lifting fixture.

(7) Lower the vehicle.

(8) Install the viscous fan/drive assembly (Refer to

7 - COOLING/ENGINE/RADIATOR FAN - INSTAL-

LATION).

(9) Connect the battery negative cables.

Fig. 145 Front Engine MountÐTypical

1 - MOUNT

2 - BOLT (4)

Fig. 146 Positioning Engine Front Mounts

1 - ENGINE SUPPORT BRACKET/CUSHION

2 - SUPPORT CUSHION BRACKET

9 - 290 ENGINE 5.9L DIESELBR/BE

Page 1438 of 2889

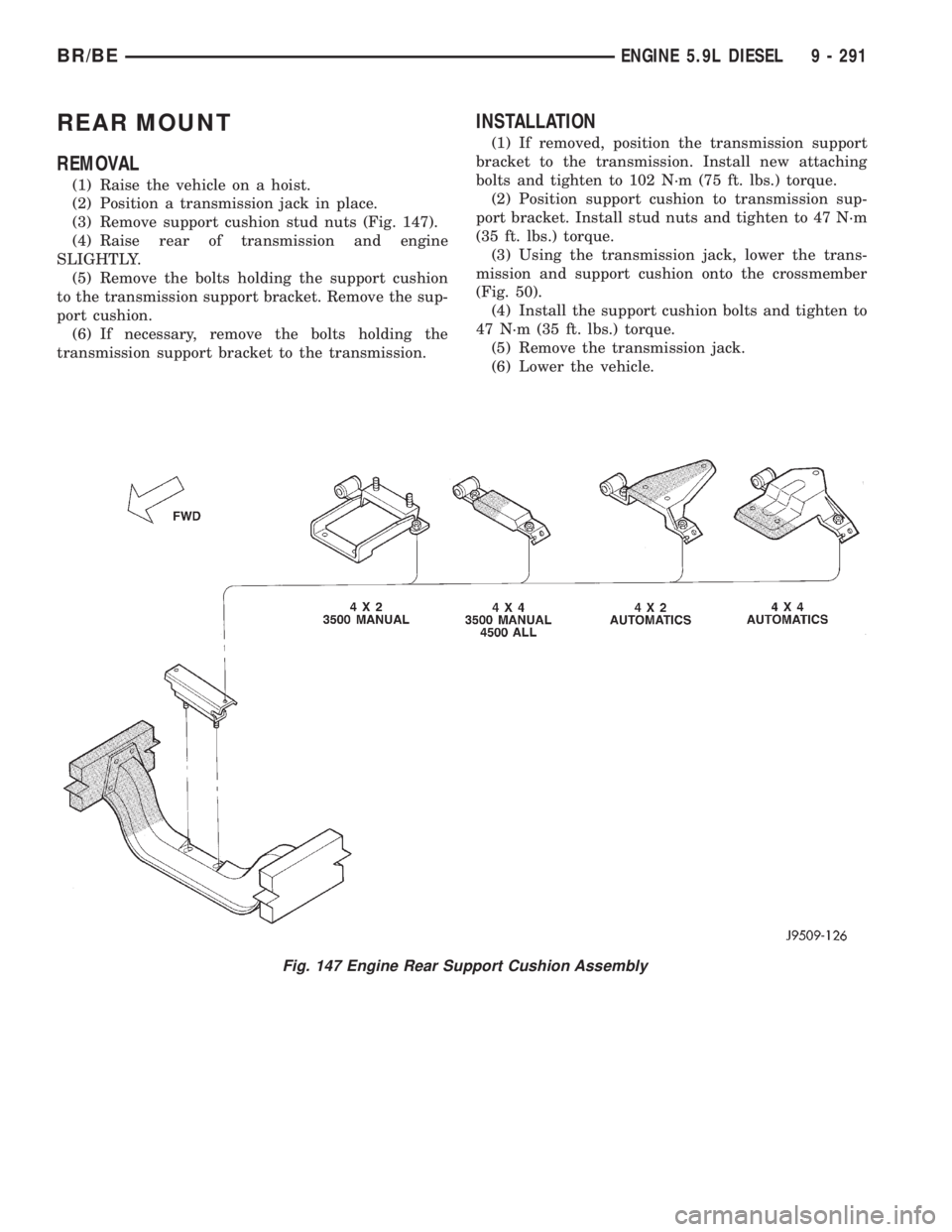

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Position a transmission jack in place.

(3) Remove support cushion stud nuts (Fig. 147).

(4) Raise rear of transmission and engine

SLIGHTLY.

(5) Remove the bolts holding the support cushion

to the transmission support bracket. Remove the sup-

port cushion.

(6) If necessary, remove the bolts holding the

transmission support bracket to the transmission.

INSTALLATION

(1) If removed, position the transmission support

bracket to the transmission. Install new attaching

bolts and tighten to 102 N´m (75 ft. lbs.) torque.

(2) Position support cushion to transmission sup-

port bracket. Install stud nuts and tighten to 47 N´m

(35 ft. lbs.) torque.

(3) Using the transmission jack, lower the trans-

mission and support cushion onto the crossmember

(Fig. 50).

(4) Install the support cushion bolts and tighten to

47 N´m (35 ft. lbs.) torque.

(5) Remove the transmission jack.

(6) Lower the vehicle.

Fig. 147 Engine Rear Support Cushion Assembly

BR/BEENGINE 5.9L DIESEL 9 - 291