flat tire DODGE RAM 2001 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2569 of 2889

DIAGNOSIS AND TESTING - TIRE NOISE OR

VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.

To find out if tires are causing the noise or vibra-

tion, drive the vehicle over a smooth road at varying

speeds. Note the noise level during acceleration and

deceleration. The engine, differential and exhaust

noises will change as speed varies, while the tire

noise will usually remain constant.

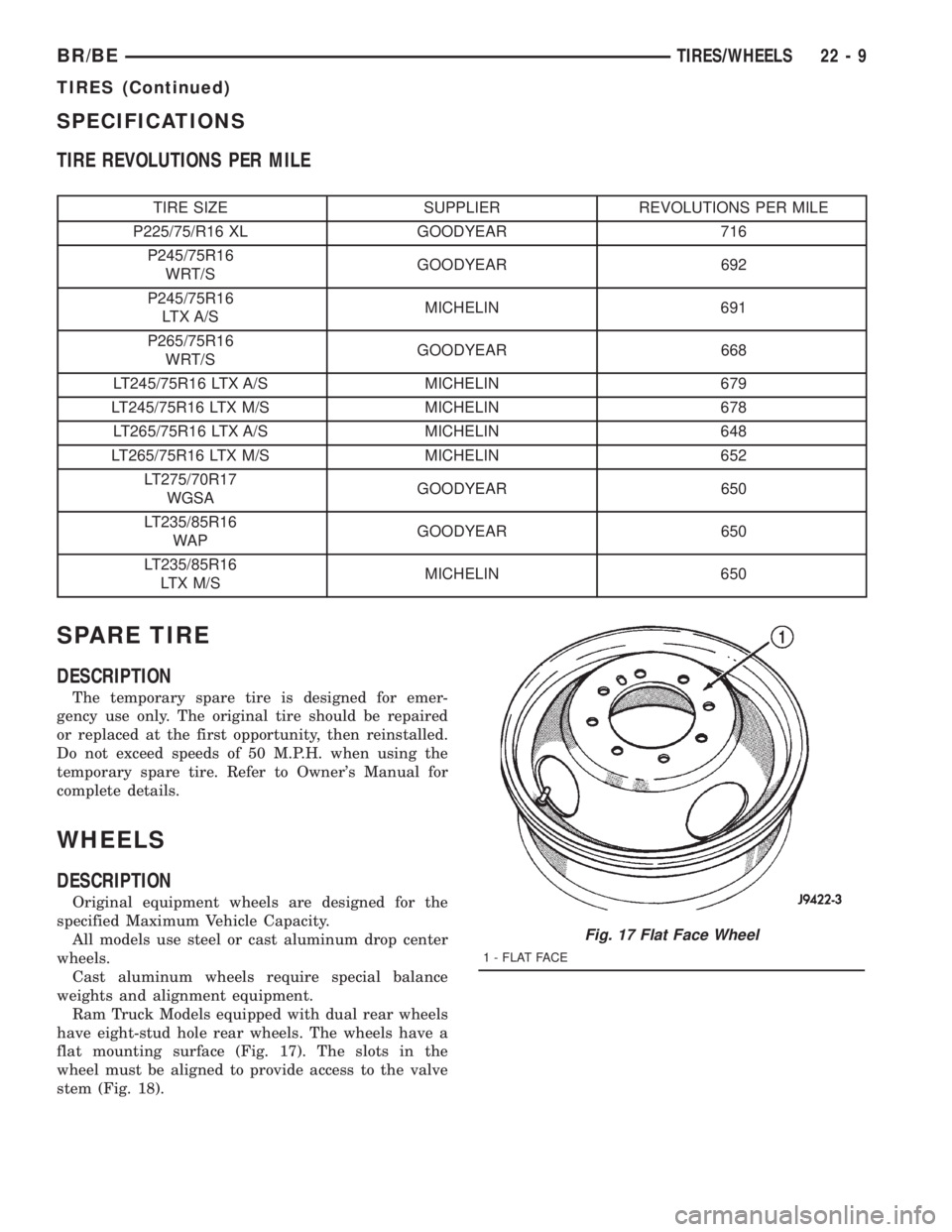

STANDARD PROCEDURES - REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 16). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before removing the tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and tighten to proper

torque specification, (Refer to 22 - TIRES/WHEELS/

WHEELS - SPECIFICATIONS).

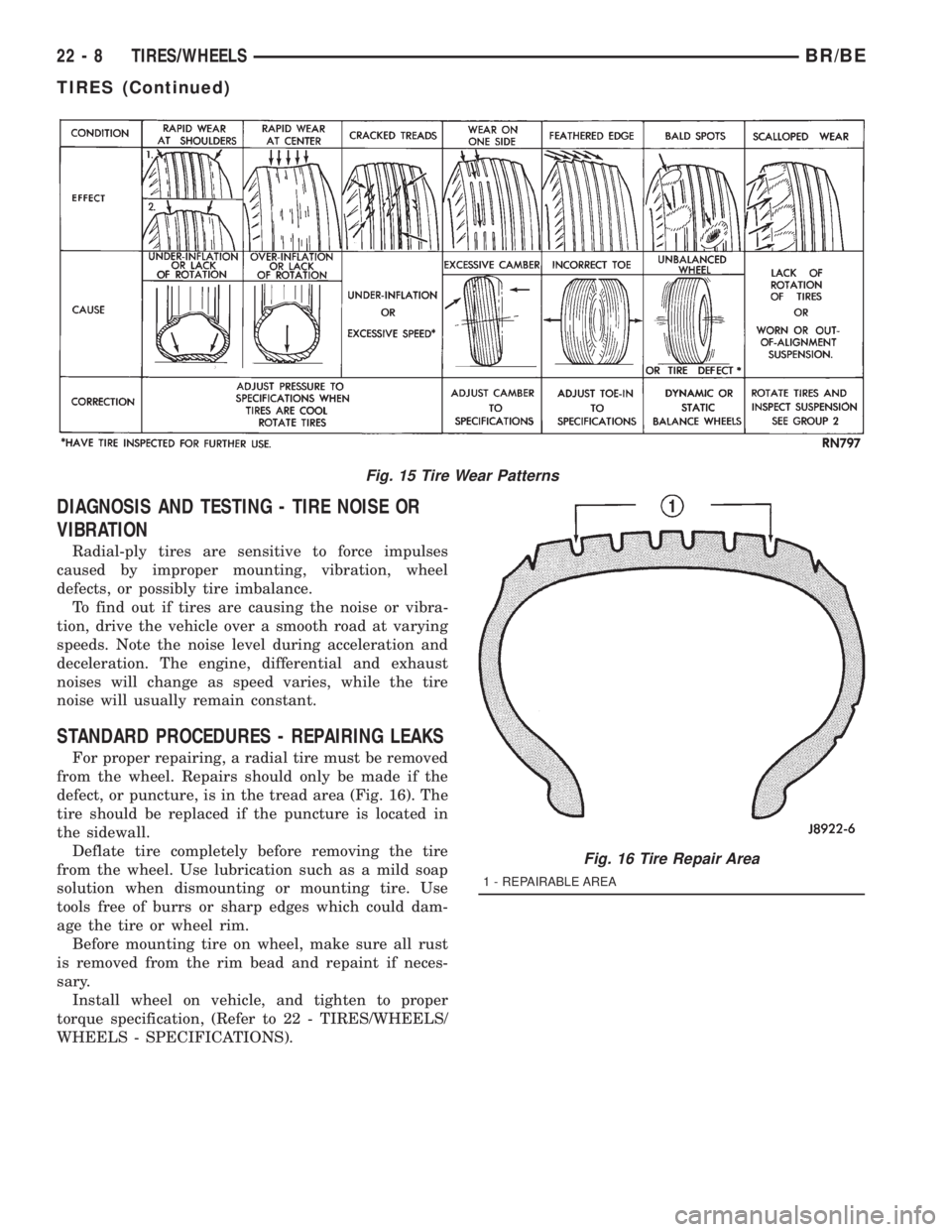

Fig. 15 Tire Wear Patterns

Fig. 16 Tire Repair Area

1 - REPAIRABLE AREA

22 - 8 TIRES/WHEELSBR/BE

TIRES (Continued)

Page 2570 of 2889

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE

TIRE SIZE SUPPLIER REVOLUTIONS PER MILE

P225/75/R16 XL GOODYEAR 716

P245/75R16

WRT/SGOODYEAR 692

P245/75R16

LTX A/SMICHELIN 691

P265/75R16

WRT/SGOODYEAR 668

LT245/75R16 LTX A/S MICHELIN 679

LT245/75R16 LTX M/S MICHELIN 678

LT265/75R16 LTX A/S MICHELIN 648

LT265/75R16 LTX M/S MICHELIN 652

LT275/70R17

WGSAGOODYEAR 650

LT235/85R16

WAPGOODYEAR 650

LT235/85R16

LTX M/SMICHELIN 650

SPARE TIRE

DESCRIPTION

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M.P.H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

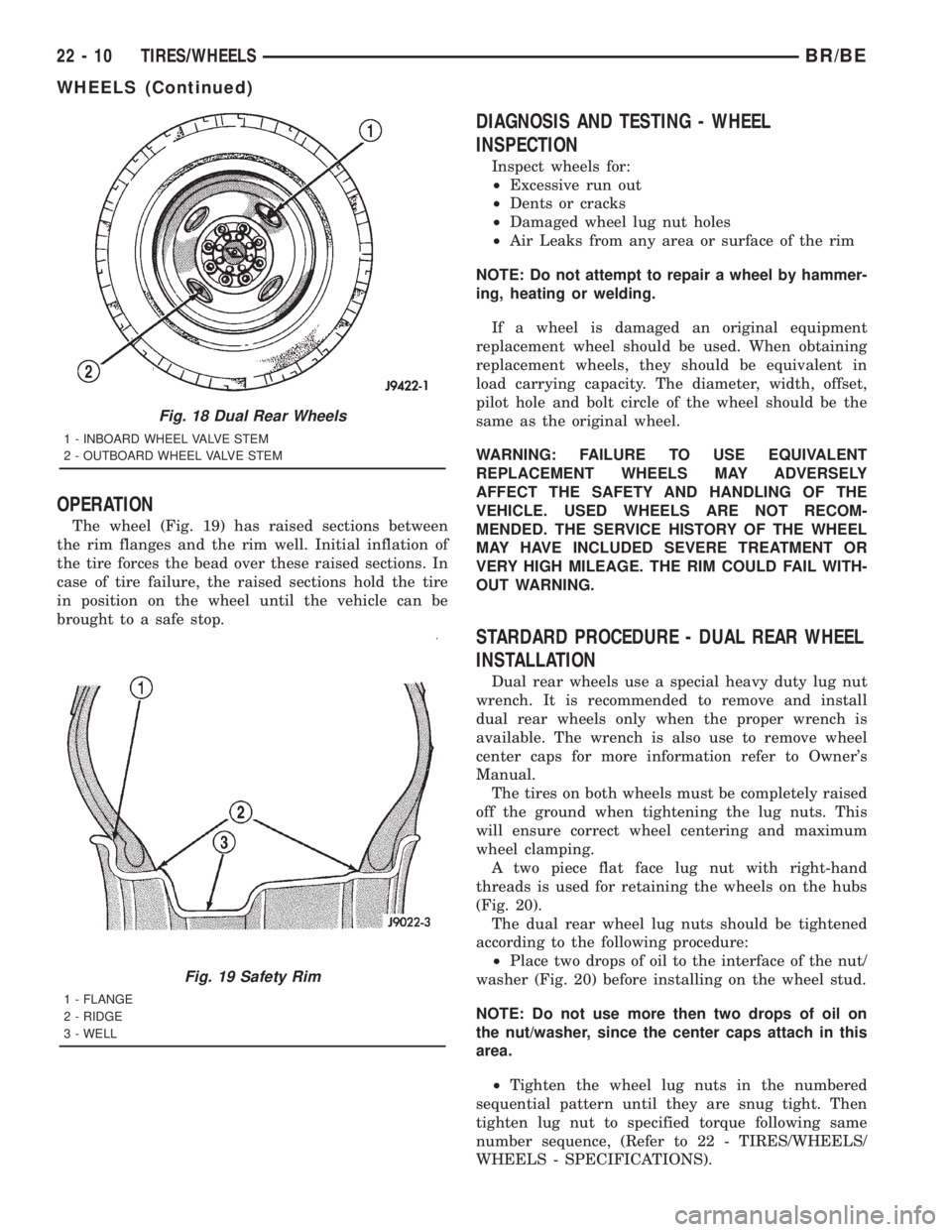

WHEELS

DESCRIPTION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or cast aluminum drop center

wheels.

Cast aluminum wheels require special balance

weights and alignment equipment.

Ram Truck Models equipped with dual rear wheels

have eight-stud hole rear wheels. The wheels have a

flat mounting surface (Fig. 17). The slots in the

wheel must be aligned to provide access to the valve

stem (Fig. 18).

Fig. 17 Flat Face Wheel

1 - FLAT FACE

BR/BETIRES/WHEELS 22 - 9

TIRES (Continued)

Page 2571 of 2889

OPERATION

The wheel (Fig. 19) has raised sections between

the rim flanges and the rim well. Initial inflation of

the tire forces the bead over these raised sections. In

case of tire failure, the raised sections hold the tire

in position on the wheel until the vehicle can be

brought to a safe stop.

DIAGNOSIS AND TESTING - WHEEL

INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE. USED WHEELS ARE NOT RECOM-

MENDED. THE SERVICE HISTORY OF THE WHEEL

MAY HAVE INCLUDED SEVERE TREATMENT OR

VERY HIGH MILEAGE. THE RIM COULD FAIL WITH-

OUT WARNING.

STARDARD PROCEDURE - DUAL REAR WHEEL

INSTALLATION

Dual rear wheels use a special heavy duty lug nut

wrench. It is recommended to remove and install

dual rear wheels only when the proper wrench is

available. The wrench is also use to remove wheel

center caps for more information refer to Owner's

Manual.

The tires on both wheels must be completely raised

off the ground when tightening the lug nuts. This

will ensure correct wheel centering and maximum

wheel clamping.

A two piece flat face lug nut with right-hand

threads is used for retaining the wheels on the hubs

(Fig. 20).

The dual rear wheel lug nuts should be tightened

according to the following procedure:

²Place two drops of oil to the interface of the nut/

washer (Fig. 20) before installing on the wheel stud.

NOTE: Do not use more then two drops of oil on

the nut/washer, since the center caps attach in this

area.

²Tighten the wheel lug nuts in the numbered

sequential pattern until they are snug tight. Then

tighten lug nut to specified torque following same

number sequence, (Refer to 22 - TIRES/WHEELS/

WHEELS - SPECIFICATIONS).

Fig. 18 Dual Rear Wheels

1 - INBOARD WHEEL VALVE STEM

2 - OUTBOARD WHEEL VALVE STEM

Fig. 19 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

22 - 10 TIRES/WHEELSBR/BE

WHEELS (Continued)

Page 2573 of 2889

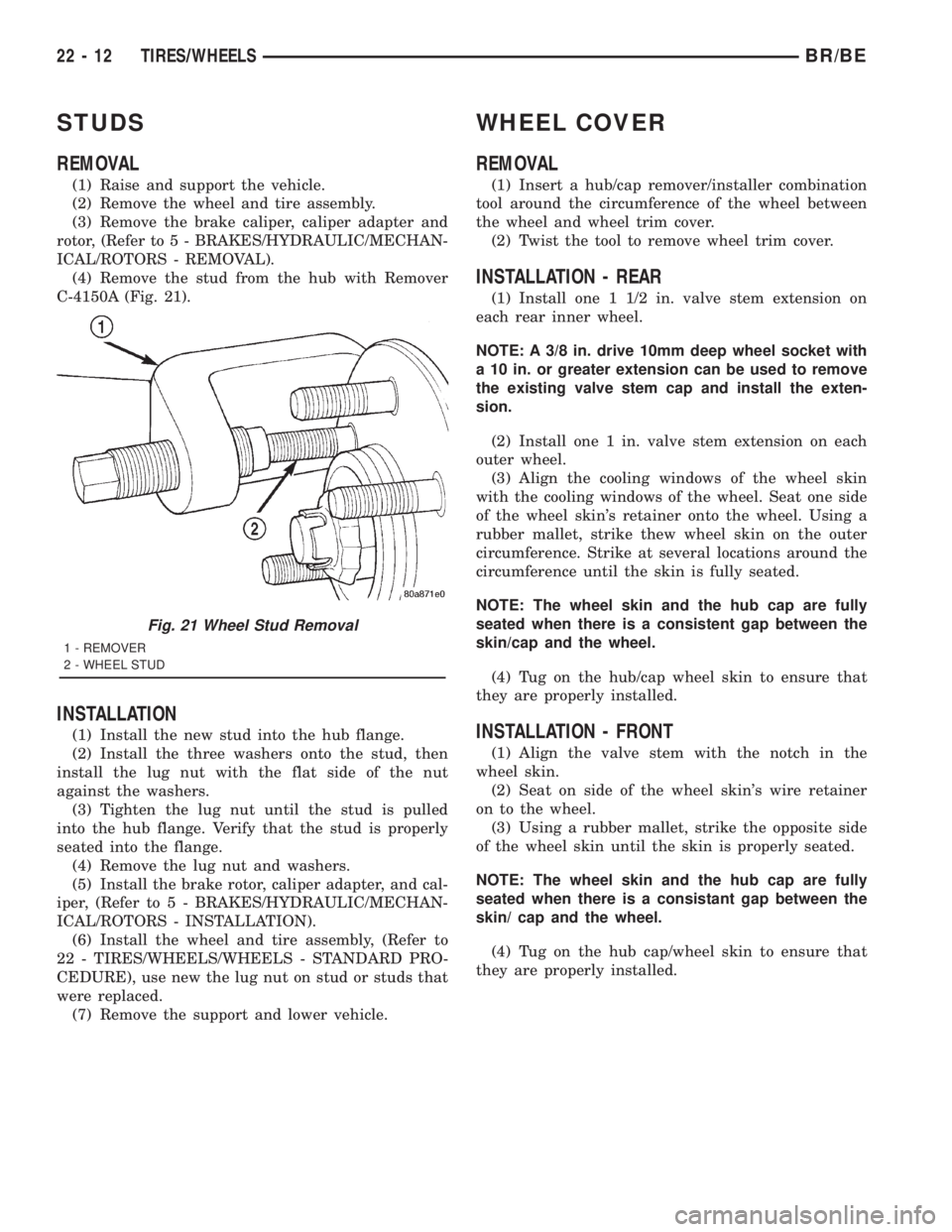

STUDS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake caliper, caliper adapter and

rotor, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove the stud from the hub with Remover

C-4150A (Fig. 21).

INSTALLATION

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and cal-

iper, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - INSTALLATION).

(6) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE), use new the lug nut on stud or studs that

were replaced.

(7) Remove the support and lower vehicle.

WHEEL COVER

REMOVAL

(1) Insert a hub/cap remover/installer combination

tool around the circumference of the wheel between

the wheel and wheel trim cover.

(2) Twist the tool to remove wheel trim cover.

INSTALLATION - REAR

(1) Install one 1 1/2 in. valve stem extension on

each rear inner wheel.

NOTE: A 3/8 in. drive 10mm deep wheel socket with

a 10 in. or greater extension can be used to remove

the existing valve stem cap and install the exten-

sion.

(2) Install one 1 in. valve stem extension on each

outer wheel.

(3) Align the cooling windows of the wheel skin

with the cooling windows of the wheel. Seat one side

of the wheel skin's retainer onto the wheel. Using a

rubber mallet, strike thew wheel skin on the outer

circumference. Strike at several locations around the

circumference until the skin is fully seated.

NOTE: The wheel skin and the hub cap are fully

seated when there is a consistent gap between the

skin/cap and the wheel.

(4) Tug on the hub/cap wheel skin to ensure that

they are properly installed.

INSTALLATION - FRONT

(1) Align the valve stem with the notch in the

wheel skin.

(2) Seat on side of the wheel skin's wire retainer

on to the wheel.

(3) Using a rubber mallet, strike the opposite side

of the wheel skin until the skin is properly seated.

NOTE: The wheel skin and the hub cap are fully

seated when there is a consistant gap between the

skin/ cap and the wheel.

(4) Tug on the hub cap/wheel skin to ensure that

they are properly installed.

Fig. 21 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

22 - 12 TIRES/WHEELSBR/BE

Page 2845 of 2889

STANDARD PROCEDURE - PRE DELIVERY

STORAGE

(1) If possible, store vehicles indoors, in clean, dry

places. If vehicles must be stored outdoors:

²Try to avoid storage locations that are near any

obvious sources of industrial or environmental con-

tamination (e.g., trees, factories, steam or vapor

vents, railroad tracks, etc.)

²Maintain tight security to help prevent pilferage

and vandalism, and inspect each vehicle regularly to

check for such damage

²If the vehicle must be parked on an incline, park

it with the front end higher than the rear; this will

prevent ªhydrostatic lockº caused by fuel draining

into the engine

²Rinse the vehicle at least once a week. Snow

should be washed away more often, since it can trap

harmful contaminants. Dry all horizontal surfaces

(2) The IOD fuse should be removed in order to

prevent battery drain and possible damage.

(3) Check the vehicle's coolant and anti-freeze pro-

tection.

(4) Check the vehicle's battery at least once a

month for a proper charge (at least 12.4 volts).

Charge the battery if necessary. This will help pre-

vent freezing and deterioration.

(5) Check the vehicle's tires and inflate them to

their maximum recommended levels. Move the vehi-

cles periodically to avoid ªflatspottingº the tires.

(6) Do not engage the parking brake; keep it in the

OFF position.

(7) Keep all windows closed, all doors locked, and

all trim covers intact and in place.

(8) Do not use chalks, crayons or any marker con-

taining abrasives on painted, plated or glass sur-

faces.

(9) Always use seat covers when moving a vehicle.

PROGRAMMABLE

ELECTRONIC FEATURES

DESCRIPTION

The programming of electronic features applies to

specific DaimlerChrysler Corporation vehicles. Not

all vehicles are equipped with these electronic fea-

tures, and not all vehicles equipped with electronic

features have all the available features. Programma-

ble electronic features are subject to change and may

be added or deleted from specific vehicle models.

(1) The programmable electronic features that may

be provided on the vehicle are:

²Rolling Power Door Locks

²Horn Chirp (When Doors Locked With Remote

Keyless Entry)²Headlamp Flash (When Doors Locked or

Unlocked With Remote Keyless Entry)

²Low Fuel Chime

²Remote Keyless Entry Door Unlock Sequence

²Headlights On Automatically With Wipers

²Turn Signal Chime

²12V Power Outlet

²Remote Unlock

²Remote Linked To Memory

²Headlamp Delay

²Service Interval

²Easy Exit Seat

(2) Programming any of the above features is to be

performed prior to vehicle delivery to the customer,

depending on customer preference.

NOTE: For all vehicles except Caravan/Town and

Country, the programming must be performed using

the DRB IIITscan tool. On Caravan/Town and Coun-

try vehicles the features can be programmed using

the DRB IIITscan tool or by button pushing

sequences. The customer can perform program-

ming, if desired, by following the instructions out-

lined in the owner manual.

OPERATION

NOTE: The programmable features provided on

vehicles need to be explained to the customer at

the time of sale. The customer's preferences con-

cerning the features should be noted and pro-

grammed accordingly during predelivery.

NOTE: When using the DRB IIITscan tool to enable/

disable any programmable electronic features, go to

the main menu item #9 on the DRB IIITscan tool.

This is ªCustomer Preferencesº. You must choose

ªCustomer Preferencesº on the main menu to pro-

gram the desired features.

ROLLING POWER DOOR LOCKS

With this feature enabled, the vehicle's door lock-

ing mechanisms automatically lock when the vehicle

reaches approximately 24 Km/h (15 mph).

HORN CHIRP

NOTE: This feature can be enabled with or without

the headlamp flash feature.

The horn chirp function is a feature that can be

enabled or disabled on vehicles equipped with

30 - 20 NEW VEHICLE PREPARATIONBR/BE

PRE DELIVERY STORAGE (Continued)