flat tire DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 668 of 2889

PASSENGER POWER SEAT

SWITCH

DESCRIPTION

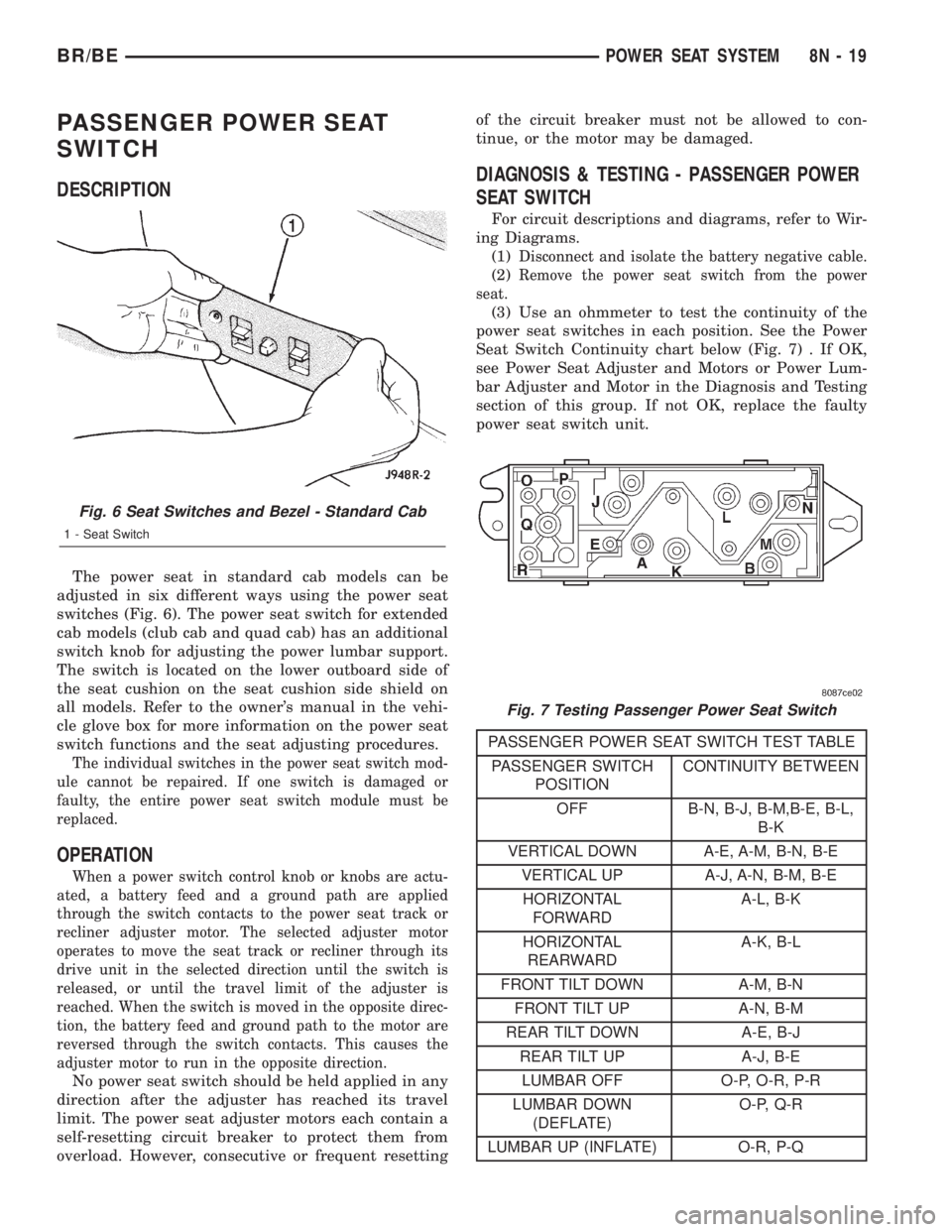

The power seat in standard cab models can be

adjusted in six different ways using the power seat

switches (Fig. 6). The power seat switch for extended

cab models (club cab and quad cab) has an additional

switch knob for adjusting the power lumbar support.

The switch is located on the lower outboard side of

the seat cushion on the seat cushion side shield on

all models. Refer to the owner's manual in the vehi-

cle glove box for more information on the power seat

switch functions and the seat adjusting procedures.

The individual switches in the power seat switch mod-

ule cannot be repaired. If one switch is damaged or

faulty, the entire power seat switch module must be

replaced.

OPERATION

When a power switch control knob or knobs are actu-

ated, a battery feed and a ground path are applied

through the switch contacts to the power seat track or

recliner adjuster motor. The selected adjuster motor

operates to move the seat track or recliner through its

drive unit in the selected direction until the switch is

released, or until the travel limit of the adjuster is

reached. When the switch is moved in the opposite direc-

tion, the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resettingof the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

DIAGNOSIS & TESTING - PASSENGER POWER

SEAT SWITCH

For circuit descriptions and diagrams, refer to Wir-

ing Diagrams.

(1)

Disconnect and isolate the battery negative cable.

(2)Remove the power seat switch from the power

seat.

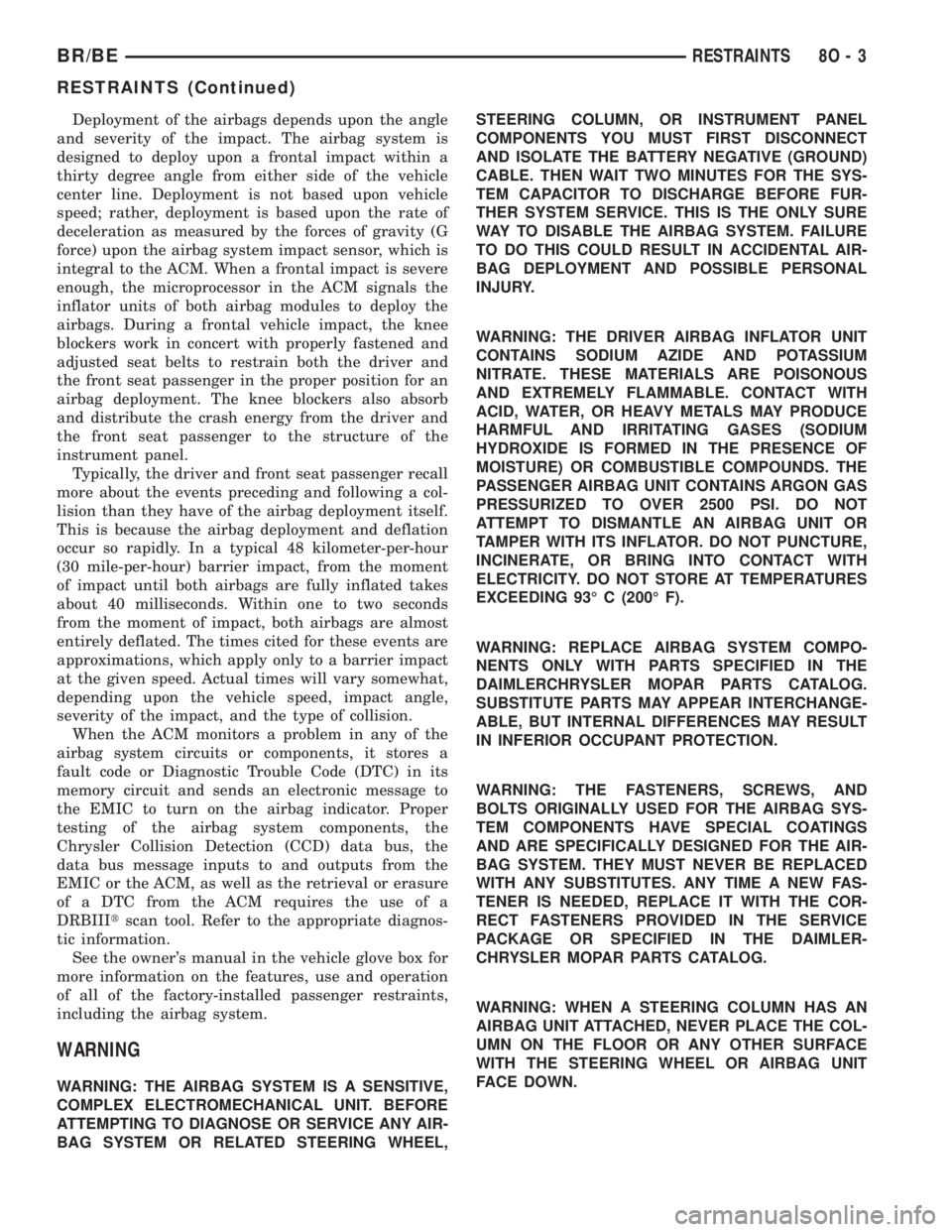

(3) Use an ohmmeter to test the continuity of the

power seat switches in each position. See the Power

Seat Switch Continuity chart below (Fig. 7) . If OK,

see Power Seat Adjuster and Motors or Power Lum-

bar Adjuster and Motor in the Diagnosis and Testing

section of this group. If not OK, replace the faulty

power seat switch unit.

PASSENGER POWER SEAT SWITCH TEST TABLE

PASSENGER SWITCH

POSITIONCONTINUITY BETWEEN

OFF B-N, B-J, B-M,B-E, B-L,

B-K

VERTICAL DOWN A-E, A-M, B-N, B-E

VERTICAL UP A-J, A-N, B-M, B-E

HORIZONTAL

FORWARDA-L, B-K

HORIZONTAL

REARWARDA-K, B-L

FRONT TILT DOWN A-M, B-N

FRONT TILT UP A-N, B-M

REAR TILT DOWN A-E, B-J

REAR TILT UP A-J, B-E

LUMBAR OFF O-P, O-R, P-R

LUMBAR DOWN

(DEFLATE)O-P, Q-R

LUMBAR UP (INFLATE) O-R, P-Q

Fig. 6 Seat Switches and Bezel - Standard Cab

1 - Seat Switch

Fig. 7 Testing Passenger Power Seat Switch

BR/BEPOWER SEAT SYSTEM 8N - 19

Page 678 of 2889

Deployment of the airbags depends upon the angle

and severity of the impact. The airbag system is

designed to deploy upon a frontal impact within a

thirty degree angle from either side of the vehicle

center line. Deployment is not based upon vehicle

speed; rather, deployment is based upon the rate of

deceleration as measured by the forces of gravity (G

force) upon the airbag system impact sensor, which is

integral to the ACM. When a frontal impact is severe

enough, the microprocessor in the ACM signals the

inflator units of both airbag modules to deploy the

airbags. During a frontal vehicle impact, the knee

blockers work in concert with properly fastened and

adjusted seat belts to restrain both the driver and

the front seat passenger in the proper position for an

airbag deployment. The knee blockers also absorb

and distribute the crash energy from the driver and

the front seat passenger to the structure of the

instrument panel.

Typically, the driver and front seat passenger recall

more about the events preceding and following a col-

lision than they have of the airbag deployment itself.

This is because the airbag deployment and deflation

occur so rapidly. In a typical 48 kilometer-per-hour

(30 mile-per-hour) barrier impact, from the moment

of impact until both airbags are fully inflated takes

about 40 milliseconds. Within one to two seconds

from the moment of impact, both airbags are almost

entirely deflated. The times cited for these events are

approximations, which apply only to a barrier impact

at the given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

airbag system circuits or components, it stores a

fault code or Diagnostic Trouble Code (DTC) in its

memory circuit and sends an electronic message to

the EMIC to turn on the airbag indicator. Proper

testing of the airbag system components, the

Chrysler Collision Detection (CCD) data bus, the

data bus message inputs to and outputs from the

EMIC or the ACM, as well as the retrieval or erasure

of a DTC from the ACM requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passenger restraints,

including the airbag system.

WARNING

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTROMECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY AIR-

BAG SYSTEM OR RELATED STEERING WHEEL,STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENTS YOU MUST FIRST DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE (GROUND)

CABLE. THEN WAIT TWO MINUTES FOR THE SYS-

TEM CAPACITOR TO DISCHARGE BEFORE FUR-

THER SYSTEM SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO DO THIS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE DRIVER AIRBAG INFLATOR UNIT

CONTAINS SODIUM AZIDE AND POTASSIUM

NITRATE. THESE MATERIALS ARE POISONOUS

AND EXTREMELY FLAMMABLE. CONTACT WITH

ACID, WATER, OR HEAVY METALS MAY PRODUCE

HARMFUL AND IRRITATING GASES (SODIUM

HYDROXIDE IS FORMED IN THE PRESENCE OF

MOISTURE) OR COMBUSTIBLE COMPOUNDS. THE

PASSENGER AIRBAG UNIT CONTAINS ARGON GAS

PRESSURIZED TO OVER 2500 PSI. DO NOT

ATTEMPT TO DISMANTLE AN AIRBAG UNIT OR

TAMPER WITH ITS INFLATOR. DO NOT PUNCTURE,

INCINERATE, OR BRING INTO CONTACT WITH

ELECTRICITY. DO NOT STORE AT TEMPERATURES

EXCEEDING 93É C (200É F).

WARNING: REPLACE AIRBAG SYSTEM COMPO-

NENTS ONLY WITH PARTS SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

SUBSTITUTE PARTS MAY APPEAR INTERCHANGE-

ABLE, BUT INTERNAL DIFFERENCES MAY RESULT

IN INFERIOR OCCUPANT PROTECTION.

WARNING: THE FASTENERS, SCREWS, AND

BOLTS ORIGINALLY USED FOR THE AIRBAG SYS-

TEM COMPONENTS HAVE SPECIAL COATINGS

AND ARE SPECIFICALLY DESIGNED FOR THE AIR-

BAG SYSTEM. THEY MUST NEVER BE REPLACED

WITH ANY SUBSTITUTES. ANY TIME A NEW FAS-

TENER IS NEEDED, REPLACE IT WITH THE COR-

RECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR SPECIFIED IN THE DAIMLER-

CHRYSLER MOPAR PARTS CATALOG.

WARNING: WHEN A STEERING COLUMN HAS AN

AIRBAG UNIT ATTACHED, NEVER PLACE THE COL-

UMN ON THE FLOOR OR ANY OTHER SURFACE

WITH THE STEERING WHEEL OR AIRBAG UNIT

FACE DOWN.

BR/BERESTRAINTS 8O - 3

RESTRAINTS (Continued)

Page 690 of 2889

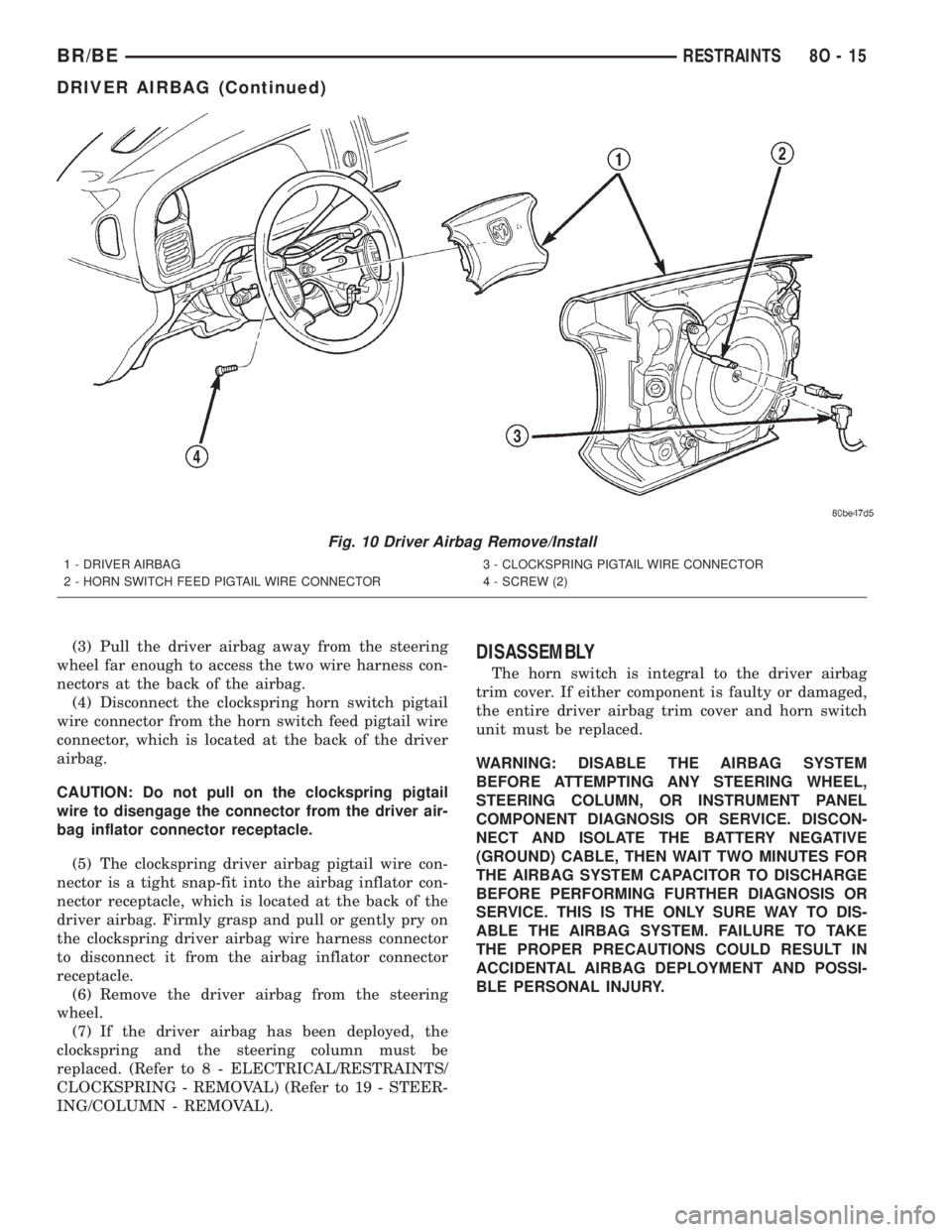

(3) Pull the driver airbag away from the steering

wheel far enough to access the two wire harness con-

nectors at the back of the airbag.

(4) Disconnect the clockspring horn switch pigtail

wire connector from the horn switch feed pigtail wire

connector, which is located at the back of the driver

airbag.

CAUTION: Do not pull on the clockspring pigtail

wire to disengage the connector from the driver air-

bag inflator connector receptacle.

(5) The clockspring driver airbag pigtail wire con-

nector is a tight snap-fit into the airbag inflator con-

nector receptacle, which is located at the back of the

driver airbag. Firmly grasp and pull or gently pry on

the clockspring driver airbag wire harness connector

to disconnect it from the airbag inflator connector

receptacle.

(6) Remove the driver airbag from the steering

wheel.

(7) If the driver airbag has been deployed, the

clockspring and the steering column must be

replaced. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL) (Refer to 19 - STEER-

ING/COLUMN - REMOVAL).DISASSEMBLY

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

the entire driver airbag trim cover and horn switch

unit must be replaced.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

Fig. 10 Driver Airbag Remove/Install

1 - DRIVER AIRBAG

2 - HORN SWITCH FEED PIGTAIL WIRE CONNECTOR3 - CLOCKSPRING PIGTAIL WIRE CONNECTOR

4 - SCREW (2)

BR/BERESTRAINTS 8O - 15

DRIVER AIRBAG (Continued)

Page 692 of 2889

ASSEMBLY

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

the entire driver airbag trim cover and horn switch

unit must be replaced.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

WARNING: THE HORN SWITCH IS INTEGRAL TO

THE DRIVER AIRBAG UNIT. SERVICE OF THIS UNIT

SHOULD BE PERFORMED ONLY BY DAIMLER-

CHRYSLER-TRAINED AND AUTHORIZED DEALER

SERVICE TECHNICIANS. FAILURE TO TAKE THE

PROPER PRECAUTIONS OR TO FOLLOW THE

PROPER PROCEDURES COULD RESULT IN ACCI-

DENTAL, INCOMPLETE, OR IMPROPER AIRBAG

DEPLOYMENT AND POSSIBLE OCCUPANT INJU-

RIES.

WARNING: USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.

WARNING: THE DRIVER AIRBAG TRIM COVER

MUST NEVER BE PAINTED. REPLACEMENT TRIM

COVERS ARE SERVICED IN THE ORIGINAL COL-

ORS. PAINT MAY CHANGE THE WAY IN WHICH THE

MATERIAL OF THE TRIM COVER RESPONDS TO AN

AIRBAG DEPLOYMENT. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN OCCUPANT

INJURIES UPON AIRBAG DEPLOYMENT.

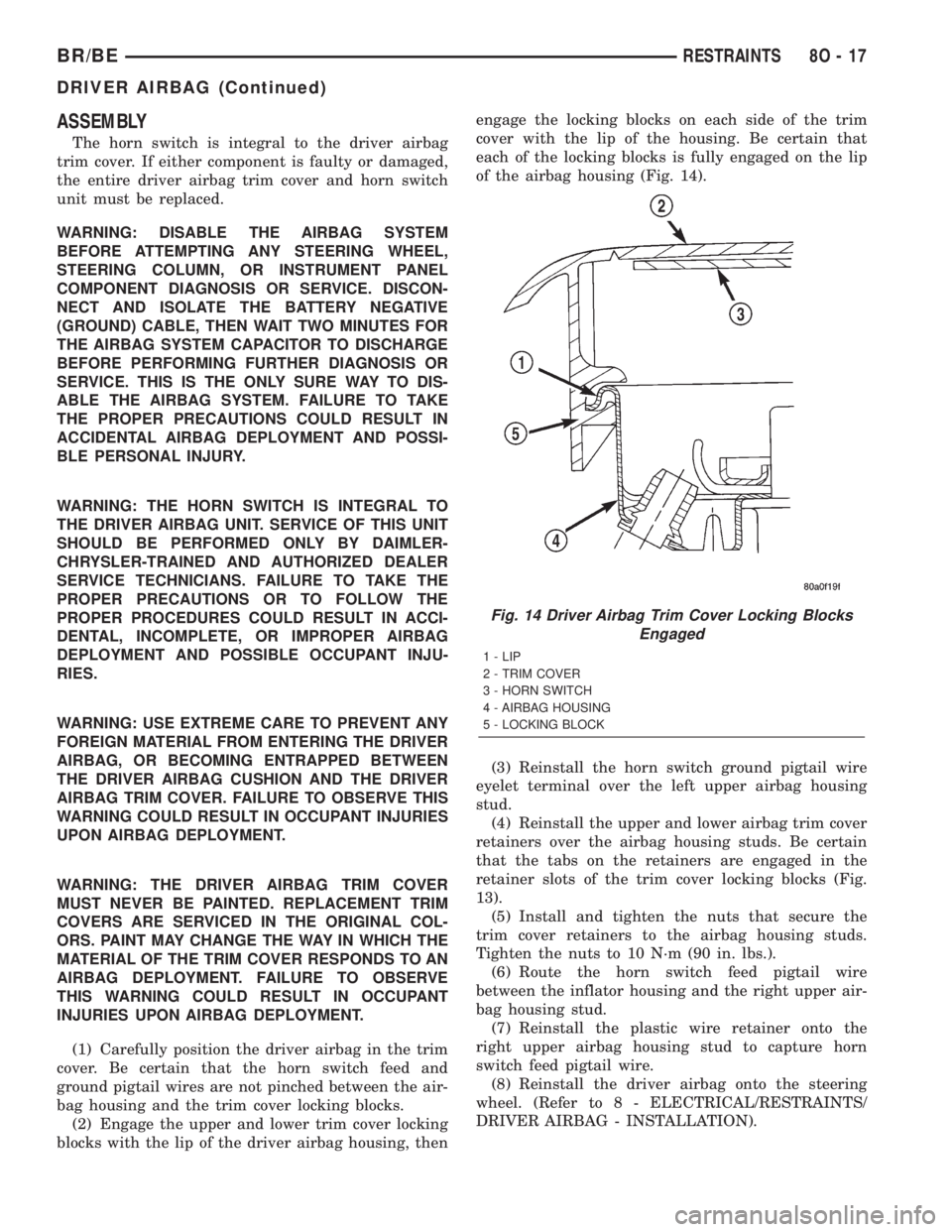

(1) Carefully position the driver airbag in the trim

cover. Be certain that the horn switch feed and

ground pigtail wires are not pinched between the air-

bag housing and the trim cover locking blocks.

(2) Engage the upper and lower trim cover locking

blocks with the lip of the driver airbag housing, thenengage the locking blocks on each side of the trim

cover with the lip of the housing. Be certain that

each of the locking blocks is fully engaged on the lip

of the airbag housing (Fig. 14).

(3) Reinstall the horn switch ground pigtail wire

eyelet terminal over the left upper airbag housing

stud.

(4) Reinstall the upper and lower airbag trim cover

retainers over the airbag housing studs. Be certain

that the tabs on the retainers are engaged in the

retainer slots of the trim cover locking blocks (Fig.

13).

(5) Install and tighten the nuts that secure the

trim cover retainers to the airbag housing studs.

Tighten the nuts to 10 N´m (90 in. lbs.).

(6) Route the horn switch feed pigtail wire

between the inflator housing and the right upper air-

bag housing stud.

(7) Reinstall the plastic wire retainer onto the

right upper airbag housing stud to capture horn

switch feed pigtail wire.

(8) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

Fig. 14 Driver Airbag Trim Cover Locking Blocks

Engaged

1 - LIP

2 - TRIM COVER

3 - HORN SWITCH

4 - AIRBAG HOUSING

5 - LOCKING BLOCK

BR/BERESTRAINTS 8O - 17

DRIVER AIRBAG (Continued)

Page 1883 of 2889

materials will adhere to component surfaces and

could restrict or block fluid passages after assembly.

INSPECTION

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac-

ing is flaking off. Replace the top and bottom pres-

sure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates are

also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston spring and wave spring if either

part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots. Replace the retainer if the grooves are worn or

damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft, if necessary, (Fig. 218) and (Fig.

219).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input

shaft into retainer (Fig. 220). Use a suitably sized

press tool to support retainer as close to input shaft

as possible.

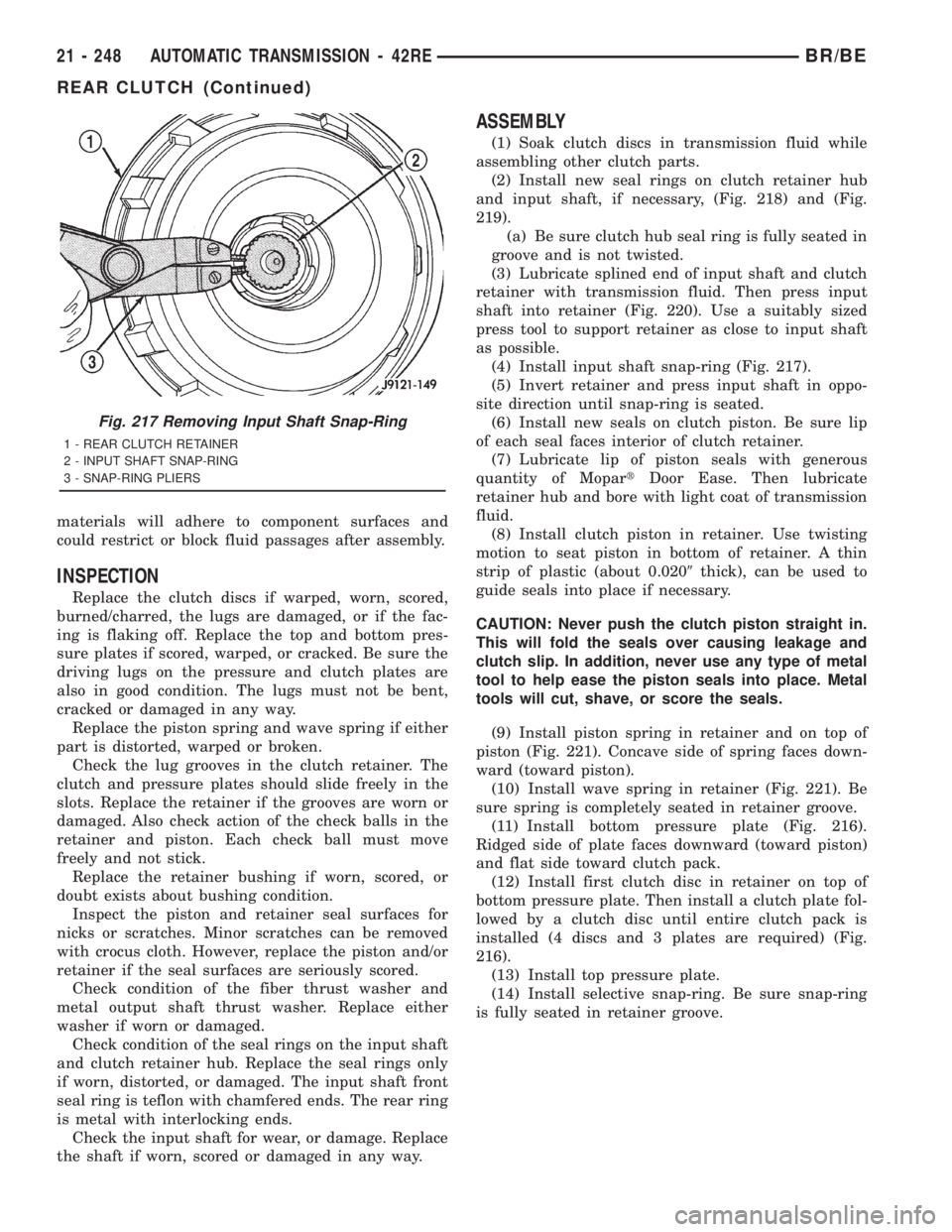

(4) Install input shaft snap-ring (Fig. 217).

(5) Invert retainer and press input shaft in oppo-

site direction until snap-ring is seated.

(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricate

retainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston (Fig. 221). Concave side of spring faces down-

ward (toward piston).

(10) Install wave spring in retainer (Fig. 221). Be

sure spring is completely seated in retainer groove.

(11) Install bottom pressure plate (Fig. 216).

Ridged side of plate faces downward (toward piston)

and flat side toward clutch pack.

(12) Install first clutch disc in retainer on top of

bottom pressure plate. Then install a clutch plate fol-

lowed by a clutch disc until entire clutch pack is

installed (4 discs and 3 plates are required) (Fig.

216).

(13) Install top pressure plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

Fig. 217 Removing Input Shaft Snap-Ring

1 - REAR CLUTCH RETAINER

2 - INPUT SHAFT SNAP-RING

3 - SNAP-RING PLIERS

21 - 248 AUTOMATIC TRANSMISSION - 42REBR/BE

REAR CLUTCH (Continued)

Page 2054 of 2889

INSPECTION

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac-

ing is flaking off. Replace the top and bottom pres-

sure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates are

also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston spring and wave spring if either

part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots. Replace the retainer if the grooves are worn or

damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft, if necessary, (Fig. 216) and (Fig.

217).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input

shaft into retainer (Fig. 218). Use a suitably sized

press tool to support retainer as close to input shaft

as possible.

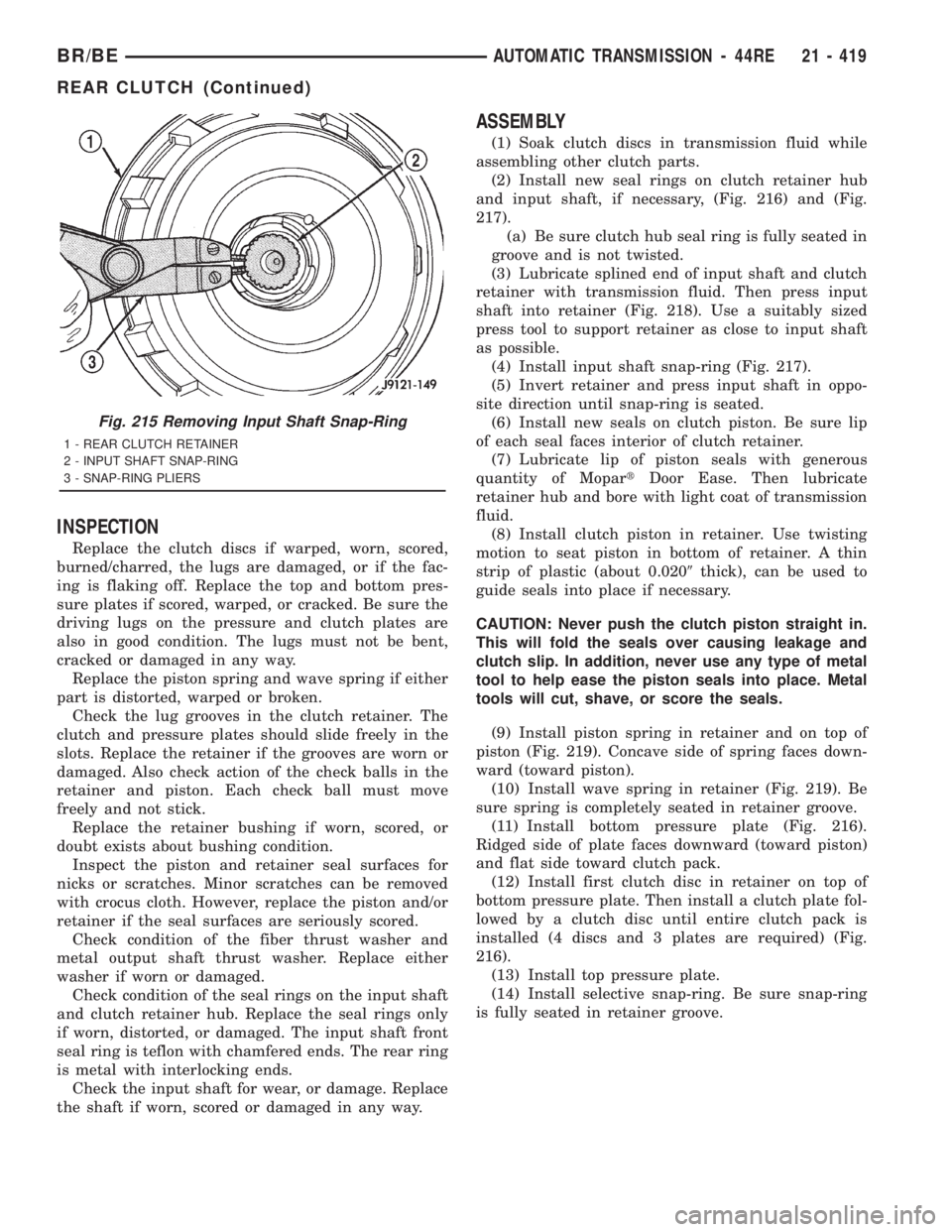

(4) Install input shaft snap-ring (Fig. 217).

(5) Invert retainer and press input shaft in oppo-

site direction until snap-ring is seated.

(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricate

retainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston (Fig. 219). Concave side of spring faces down-

ward (toward piston).

(10) Install wave spring in retainer (Fig. 219). Be

sure spring is completely seated in retainer groove.

(11) Install bottom pressure plate (Fig. 216).

Ridged side of plate faces downward (toward piston)

and flat side toward clutch pack.

(12) Install first clutch disc in retainer on top of

bottom pressure plate. Then install a clutch plate fol-

lowed by a clutch disc until entire clutch pack is

installed (4 discs and 3 plates are required) (Fig.

216).

(13) Install top pressure plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

Fig. 215 Removing Input Shaft Snap-Ring

1 - REAR CLUTCH RETAINER

2 - INPUT SHAFT SNAP-RING

3 - SNAP-RING PLIERS

BR/BEAUTOMATIC TRANSMISSION - 44RE 21 - 419

REAR CLUTCH (Continued)

Page 2401 of 2889

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft if necessary.

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

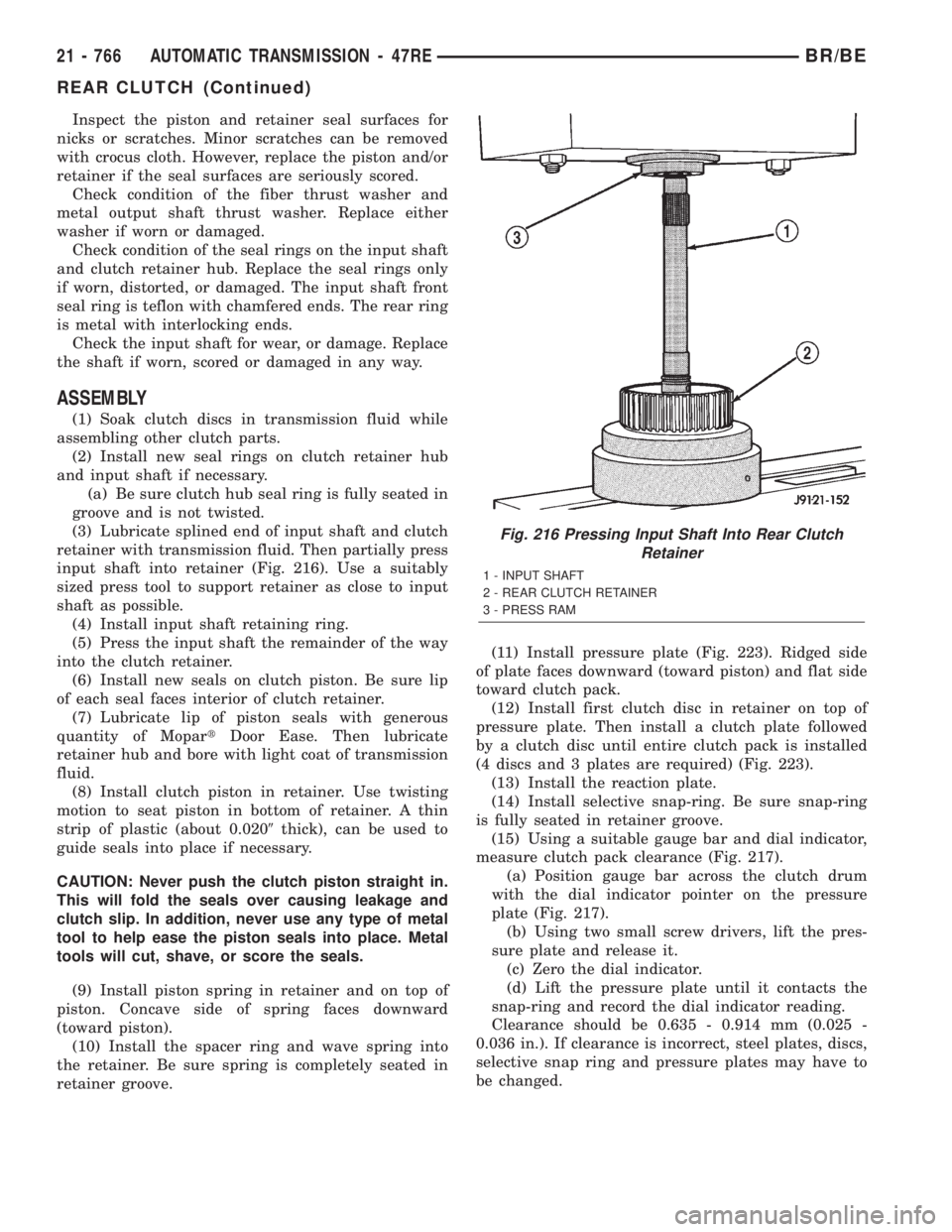

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then partially press

input shaft into retainer (Fig. 216). Use a suitably

sized press tool to support retainer as close to input

shaft as possible.

(4) Install input shaft retaining ring.

(5) Press the input shaft the remainder of the way

into the clutch retainer.

(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricate

retainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston. Concave side of spring faces downward

(toward piston).

(10) Install the spacer ring and wave spring into

the retainer. Be sure spring is completely seated in

retainer groove.(11) Install pressure plate (Fig. 223). Ridged side

of plate faces downward (toward piston) and flat side

toward clutch pack.

(12) Install first clutch disc in retainer on top of

pressure plate. Then install a clutch plate followed

by a clutch disc until entire clutch pack is installed

(4 discs and 3 plates are required) (Fig. 223).

(13) Install the reaction plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

(15) Using a suitable gauge bar and dial indicator,

measure clutch pack clearance (Fig. 217).

(a) Position gauge bar across the clutch drum

with the dial indicator pointer on the pressure

plate (Fig. 217).

(b) Using two small screw drivers, lift the pres-

sure plate and release it.

(c) Zero the dial indicator.

(d) Lift the pressure plate until it contacts the

snap-ring and record the dial indicator reading.

Clearance should be 0.635 - 0.914 mm (0.025 -

0.036 in.). If clearance is incorrect, steel plates, discs,

selective snap ring and pressure plates may have to

be changed.

Fig. 216 Pressing Input Shaft Into Rear Clutch

Retainer

1 - INPUT SHAFT

2 - REAR CLUTCH RETAINER

3 - PRESS RAM

21 - 766 AUTOMATIC TRANSMISSION - 47REBR/BE

REAR CLUTCH (Continued)

Page 2562 of 2889

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING..................1

TIRE AND WHEEL RUNOUT...............1

STANDARD PROCEDURE...................2

TIRE ROTATION.........................2

MATCH MOUNTING......................2

TIRE AND WHEEL BALANCE...............4

TIRES

DESCRIPTION............................5

DIAGNOSIS AND TESTING..................7

PRESSURE GAUGES....................7

TREAD WEAR INDICATORS...............7

TIRE WEAR PATTERNS...................7

TIRE NOISE OR VIBRATION...............8

STANDARD PROCEDURE...................8

REPAIRING LEAKS......................8

SPECIFICATIONS.........................9SPARE TIRE

DESCRIPTION............................9

WHEELS

DESCRIPTION............................9

OPERATION.............................10

DIAGNOSIS AND TESTING.................10

WHEEL INSPECTION....................10

STANDARD PROCEDURE..................10

DUAL WHEEL INSTALLATION.............10

SPECIFICATIONS.........................11

STUDS

REMOVAL..............................12

INSTALLATION...........................12

WHEEL COVER

REMOVAL..............................12

INSTALLATION...........................12

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

RUNOUT

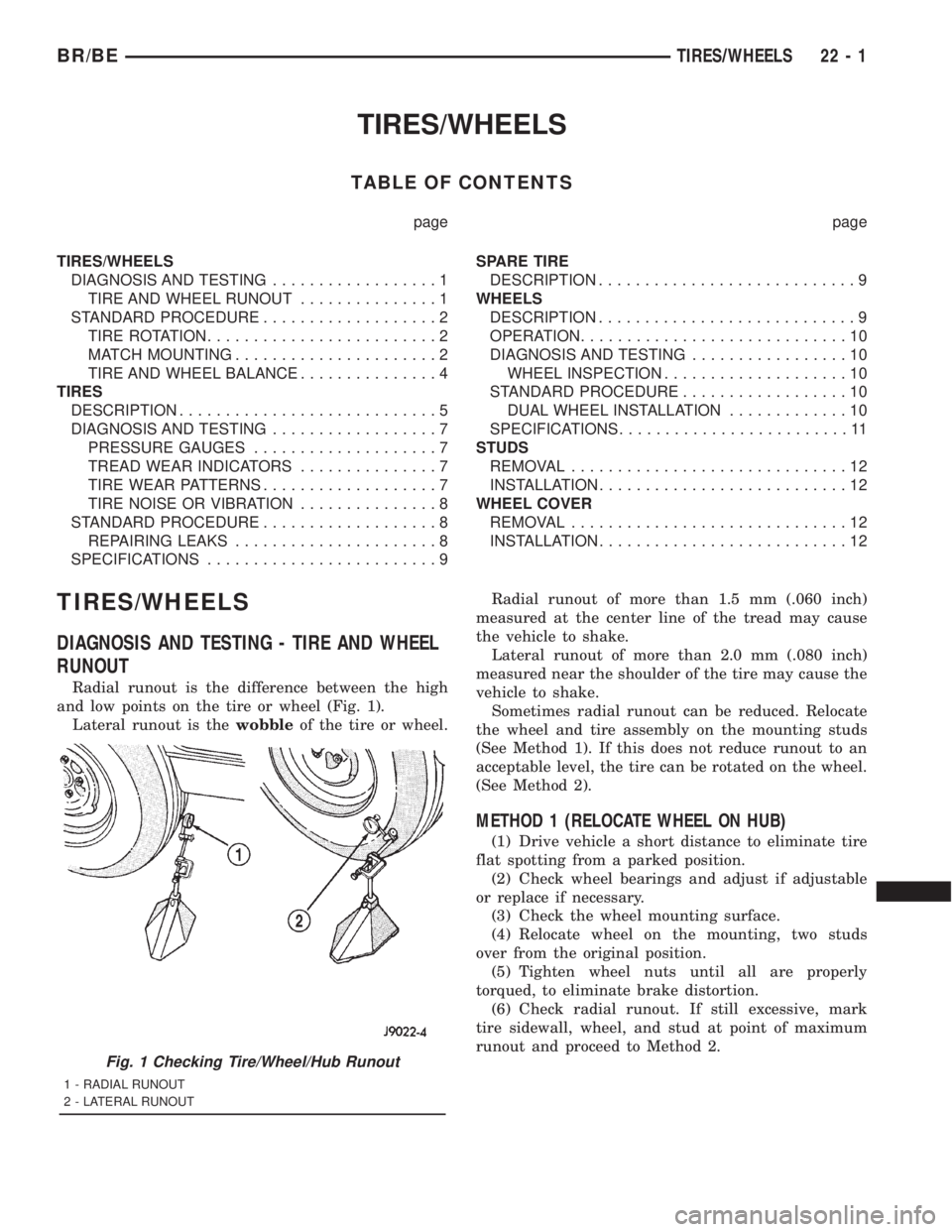

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is thewobbleof the tire or wheel.Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

BR/BETIRES/WHEELS 22 - 1

Page 2567 of 2889

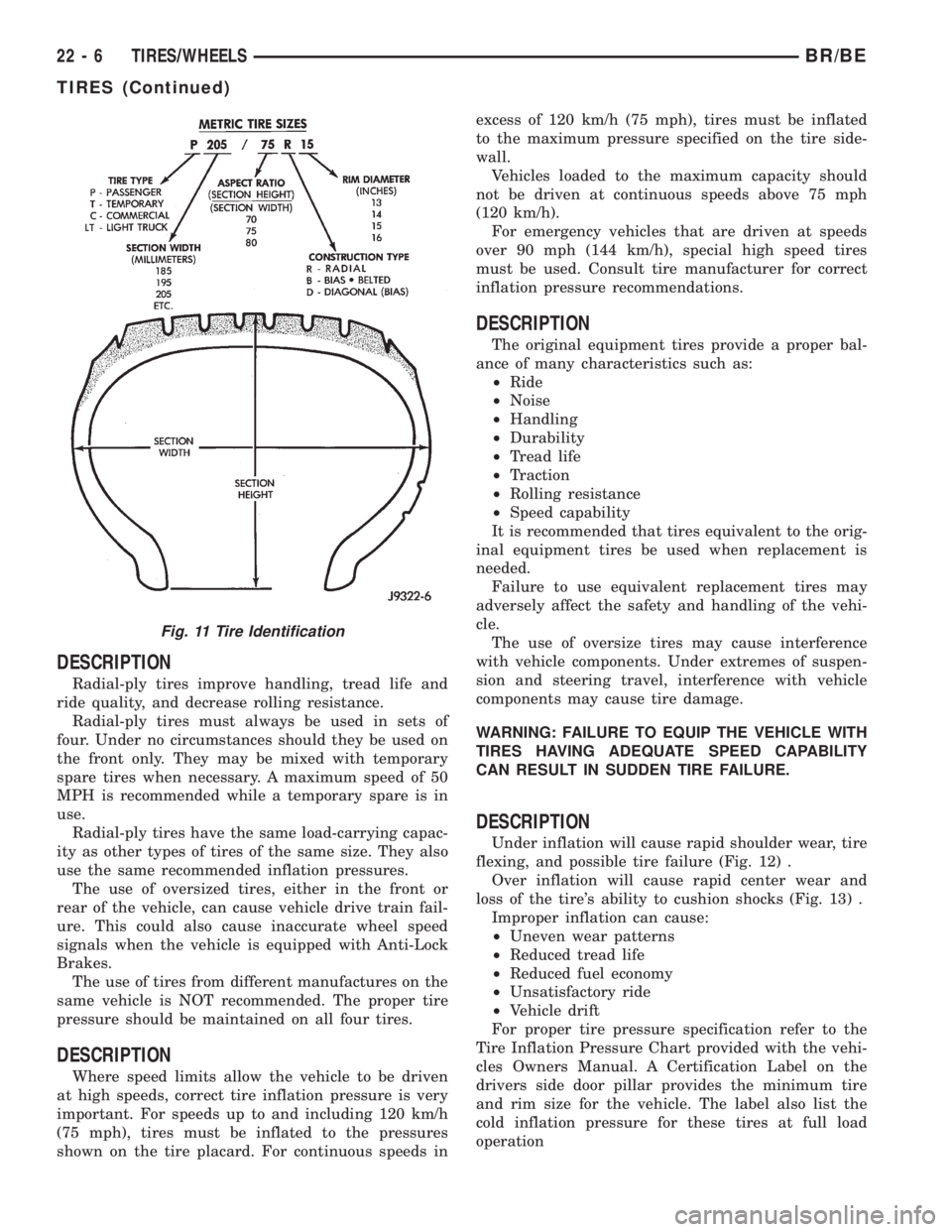

DESCRIPTION

Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

DESCRIPTION

Where speed limits allow the vehicle to be driven

at high speeds, correct tire inflation pressure is very

important. For speeds up to and including 120 km/h

(75 mph), tires must be inflated to the pressures

shown on the tire placard. For continuous speeds inexcess of 120 km/h (75 mph), tires must be inflated

to the maximum pressure specified on the tire side-

wall.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

For emergency vehicles that are driven at speeds

over 90 mph (144 km/h), special high speed tires

must be used. Consult tire manufacturer for correct

inflation pressure recommendations.

DESCRIPTION

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

It is recommended that tires equivalent to the orig-

inal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The use of oversize tires may cause interference

with vehicle components. Under extremes of suspen-

sion and steering travel, interference with vehicle

components may cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

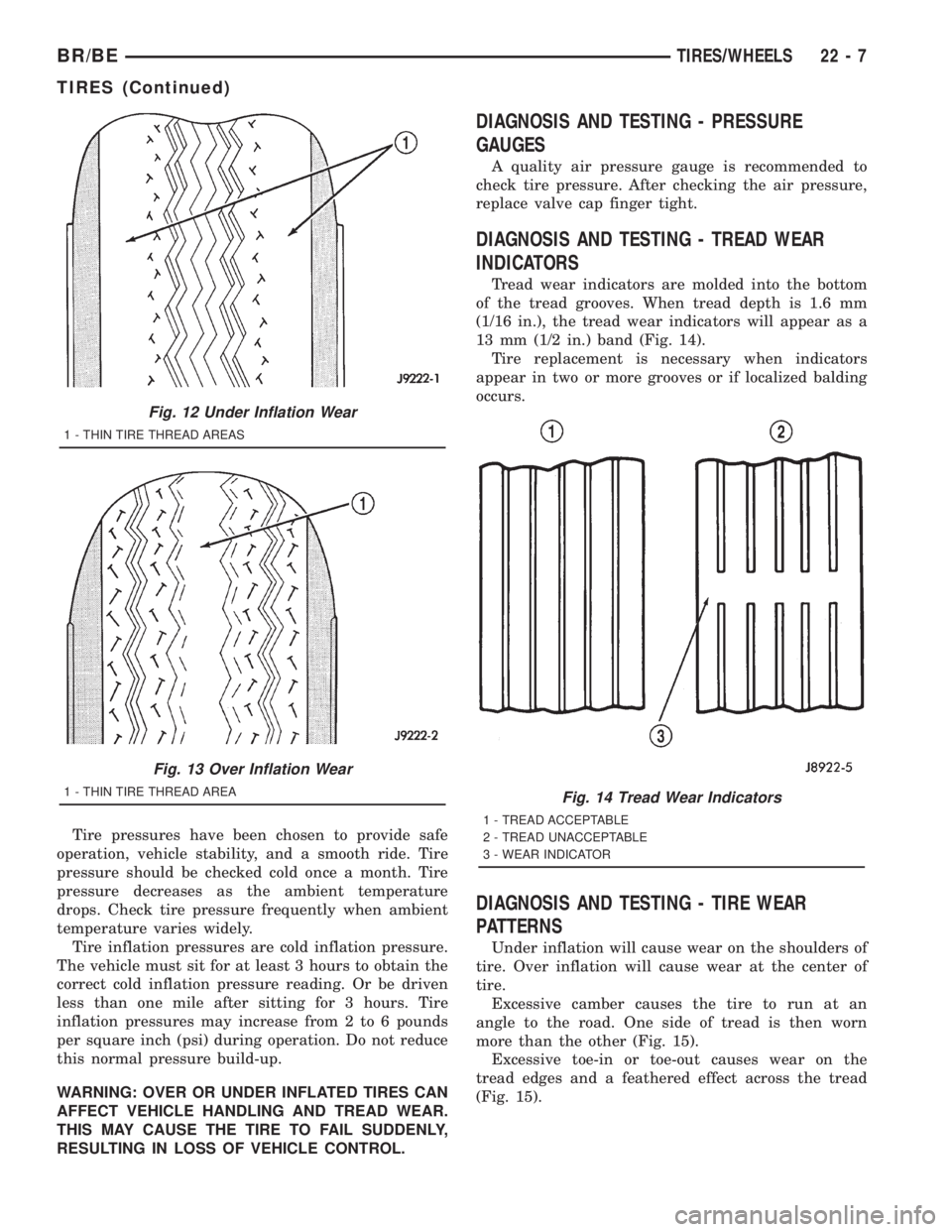

DESCRIPTION

Under inflation will cause rapid shoulder wear, tire

flexing, and possible tire failure (Fig. 12) .

Over inflation will cause rapid center wear and

loss of the tire's ability to cushion shocks (Fig. 13) .

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²Vehicle drift

For proper tire pressure specification refer to the

Tire Inflation Pressure Chart provided with the vehi-

cles Owners Manual. A Certification Label on the

drivers side door pillar provides the minimum tire

and rim size for the vehicle. The label also list the

cold inflation pressure for these tires at full load

operation

Fig. 11 Tire Identification

22 - 6 TIRES/WHEELSBR/BE

TIRES (Continued)

Page 2568 of 2889

Tire pressures have been chosen to provide safe

operation, vehicle stability, and a smooth ride. Tire

pressure should be checked cold once a month. Tire

pressure decreases as the ambient temperature

drops. Check tire pressure frequently when ambient

temperature varies widely.

Tire inflation pressures are cold inflation pressure.

The vehicle must sit for at least 3 hours to obtain the

correct cold inflation pressure reading. Or be driven

less than one mile after sitting for 3 hours. Tire

inflation pressures may increase from 2 to 6 pounds

per square inch (psi) during operation. Do not reduce

this normal pressure build-up.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING AND TREAD WEAR.

THIS MAY CAUSE THE TIRE TO FAIL SUDDENLY,

RESULTING IN LOSS OF VEHICLE CONTROL.

DIAGNOSIS AND TESTING - PRESSURE

GAUGES

A quality air pressure gauge is recommended to

check tire pressure. After checking the air pressure,

replace valve cap finger tight.

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 14).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 15).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 15).

Fig. 12 Under Inflation Wear

1 - THIN TIRE THREAD AREAS

Fig. 13 Over Inflation Wear

1 - THIN TIRE THREAD AREAFig. 14 Tread Wear Indicators

1 - TREAD ACCEPTABLE

2 - TREAD UNACCEPTABLE

3 - WEAR INDICATOR

BR/BETIRES/WHEELS 22 - 7

TIRES (Continued)