fuse DODGE RAM 2001 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 589 of 2889

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the instrument cluster from the instrument

panel. Check for continuity between the 4WD switch

sense circuit cavities of the instrument panel wire

harness connector (Connector C2) for the instrument

cluster and the engine wire harness connector for the

four-wheel drive switch. There should be continuity.

If OK, replace the faulty instrument cluster. If not

OK, repair the open 4WD switch sense circuit

between the instrument cluster and the four-wheel

drive switch as required.

INDICATOR STAYS ILLUMINATED WITH FOUR-WHEEL DRIVE

MODE NOT SELECTED

(1) Disconnect and isolate the battery negative

cable. Disconnect the engine wire harness connector

for the four-wheel drive switch from the switch con-

nector receptacle. Check for continuity between the

ground circuit terminal and the 4WD switch sense

circuit terminal in the four-wheel drive switch con-

nector receptacle. There should be no continuity. If

OK, repair the shorted 4WD switch sense circuit

between the four-wheel drive switch and the instru-

ment cluster as required. If not OK, replace the

faulty four-wheel drive switch.

SPEEDOMETER

DESCRIPTION

A speedometer is standard equipment on all instru-

ment clusters. The speedometer is located just to the

right of the tachometer near the center of the instru-

ment cluster. The speedometer consists of a movable

gauge needle or pointer controlled by the instrument

cluster circuitry and a fixed 210 degree primary scale

on the gauge dial face that reads left-to-right either

from 0 to 120 mph, or from 0 to 200 km/h, depending

upon the market for which the vehicle is manufac-

tured. Each version also has a secondary inner scale

on the gauge dial face that provides the equivalent

opposite units from the primary scale. Text appearing

on the cluster overlay just below the hub of the

speedometer needle abbreviates the unit of measure

for the primary scale in all upper case letters (i.e.:

MPH or KM/H), followed by the unit of measure for

the secondary scale in all lower case letters (i.e.: mph

or km/h). The speedometer graphics are white (pri-

mary scale) and red (secondary scale) against a black

field, making them clearly visible within the instru-

ment cluster in daylight. When illuminated from

behind by the panel lamps dimmer controlled cluster

illumination lighting with the exterior lamps turned

On, the white graphics appear blue-green, while the

red graphics still appear red. The orange gauge nee-

dle is internally illuminated. Gauge illumination isprovided by replaceable incandescent bulb and bulb

holder units located on the instrument cluster elec-

tronic circuit board. The speedometer is serviced as a

unit with the instrument cluster.

OPERATION

The speedometer gives an indication to the vehicle

operator of the vehicle road speed. This gauge is con-

trolled by the instrument cluster circuit board based

upon the cluster programming and electronic mes-

sages received by the cluster from the Powertrain

Control Module (PCM) over the Chrysler Collision

Detection (CCD) data bus. The speedometer is an air

core magnetic unit that receives battery current on

the instrument cluster electronic circuit board

through the fused ignition switch output (st-run) cir-

cuit whenever the ignition switch is in the On or

Start positions. The cluster is programmed to move

the gauge needle back to the low end of the scale

after the ignition switch is turned to the Off position.

The instrument cluster circuitry controls the gauge

needle position and provides the following features:

²Message Failure- If the cluster fails to receive

a speedometer message, it will hold the gauge needle

at the last indication for about four seconds, or until

the ignition switch is turned to the Off position,

whichever occurs first. If a new speedometer message

is not received after about four seconds, the gauge

needle will return to the far left (low) end of the

scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in a prescribed sequence in order to confirm the func-

tionality of the gauge and the cluster control cir-

cuitry.

The PCM continually monitors the vehicle speed

sensor to determine the vehicle road speed, then

sends the proper vehicle speed messages to the

instrument cluster. For further diagnosis of the

speedometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the vehicle speed

sensor, the PCM, the CCD data bus, or the message

inputs to the instrument cluster that control the

speedometer, a DRBIIItscan tool is required. Refer

to the appropriate diagnostic information.

TACHOMETER

DESCRIPTION

A tachometer is standard equipment on all instru-

ment clusters. The tachometer is located just to the

left of the speedometer near the center of the instru-

8J - 30 INSTRUMENT CLUSTERBR/BE

SHIFT INDICATOR (TRANSFER CASE) (Continued)

Page 590 of 2889

ment cluster. The tachometer consists of a movable

gauge needle or pointer controlled by the instrument

cluster circuitry and a fixed 210 degree scale on the

gauge dial face that reads left-to-right either from 0

to 6 for gasoline engines, or from 0 to 4 for diesel

engines. The text ªRPM X 1000º imprinted on the

cluster overlay directly below the hub of the tachom-

eter needle identifies that each number on the

tachometer scale is to be multiplied times 1000 rpm.

The gauge scale of the gasoline engine tachometer is

red lined at 5000 rpm, while the diesel engine

tachometer is red lined at 3375 rpm. The diesel

engine tachometer also includes text that specifies

ªDIESEL FUEL ONLYº located just above the hub of

the tachometer needle. The tachometer graphics are

white and red against a black field, making them

clearly visible within the instrument cluster in day-

light. When illuminated from behind by the panel

lamps dimmer controlled cluster illumination lighting

with the exterior lamps turned On, the white graph-

ics appear blue-green, while the red graphics still

appear red. The orange gauge needle is internally

illuminated. Gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. The tachometer is serviced as a unit with the

instrument cluster.

OPERATION

The tachometer gives an indication to the vehicle

operator of the engine speed. This gauge is controlled

by the instrument cluster circuit board based upon

the cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) over the Chrysler Collision Detection

(CCD) data bus. The tachometer is an air core mag-

netic unit that receives battery current on the instru-

ment cluster electronic circuit board through the

fused ignition switch output (st-run) circuit whenever

the ignition switch is in the On or Start positions.

The cluster is programmed to move the gauge needle

back to the low end of the scale after the ignition

switch is turned to the Off position. The instrument

cluster circuitry controls the gauge needle position

and provides the following features:

²Message Failure- If the cluster fails to receive

an engine speed message, it will hold the gauge nee-

dle at the last indication for about four seconds, or

until the ignition switch is turned to the Off position,

whichever occurs first. If a new engine speed mes-

sage is not received after about four seconds, the

gauge needle will return to the far left (low) end of

the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scalein a prescribed sequence in order to confirm the func-

tionality of the gauge and the cluster control cir-

cuitry.

The PCM continually monitors the crankshaft posi-

tion sensor to determine the engine speed, then

sends the proper engine speed messages to the

instrument cluster. For further diagnosis of the

tachometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the crankshaft position

sensor, the PCM, the CCD data bus, or the message

inputs to the instrument cluster that control the

tachometer, a DRBIIItscan tool is required. Refer to

the appropriate diagnostic information.

TRANSMISSION OVERTEMP

INDICATOR

DESCRIPTION

A transmission over-temperature indicator lamp is

standard equipment on all instrument clusters. How-

ever, on vehicles not equipped with the optional auto-

matic transmission, this indicator is electronically

disabled. The transmission over-temperature indica-

tor is located near the lower edge of the instrument

cluster overlay, to the left of center. The transmission

over-temperature indicator consists of a stencilled

cutout of the words ªTRANS TEMPº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A red

lens behind the cutout in the opaque layer of the

overlay causes the ªTRANS TEMPº text to appear in

red through the translucent outer layer of the over-

lay when the indicator is illuminated from behind by

a Light Emitting Diode (LED) soldered onto the

instrument cluster electronic circuit board. The

transmission over-temperature indicator is serviced

as a unit with the instrument cluster.

OPERATION

The transmission over-temperature indicator gives

an indication to the vehicle operator when the trans-

mission fluid temperature is excessive, which may

lead to accelerated transmission component wear or

failure. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon the

cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) over the Chrysler Collision Detection

(CCD) data bus. The transmission over-temperature

indicator Light Emitting Diode (LED) receives bat-

tery current on the instrument cluster electronic cir-

cuit board through the fused ignition switch output

BR/BEINSTRUMENT CLUSTER 8J - 31

TACHOMETER (Continued)

Page 592 of 2889

problems are found, the following procedure will help

locate a short or open in the left or right turn signal

indicator circuit. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.

(1) Disconnect and isolate the battery negative

cable. Remove the instrument cluster.

(2) Connect the battery negative cable. Activate

the hazard warning system by moving the hazard

warning switch button to the On position. Check for

battery voltage at the inoperative (right or left) turn

signal circuit cavity of the instrument panel wire

harness connector (Connector C2) for the instrument

cluster. There should be a switching (on and off) bat-

tery voltage signal. If OK, replace the faulty turn sig-

nal indicator bulb. If not OK, repair the open (right

or left) turn signal circuit to the left multi-function

switch as required.

UPSHIFT INDICATOR

DESCRIPTION

An upshift indicator is standard equipment on all

instrument clusters. However, on vehicles not

equipped with a manual transmission, this indicator

is disabled. The upshift indicator is located near the

fuel gauge in the instrument cluster overlay, to the

left of center. The upshift indicator consists of an

upward pointed arrow icon that is a stenciled cutout

in the opaque layer of the instrument cluster overlay.

The dark outer layer of the overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. An amber lens behind the cutout in the

opaque layer of the overlay causes the icon to appear

in amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by a replaceable incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. The upshift indicator is serviced

as a unit with the instrument cluster.

OPERATION

The upshift indicator gives an indication to the

vehicle operator when the transmission should be

shifted to the next highest gear in order to achieve

the best fuel economy. This indicator is controlled by

a transistor on the instrument cluster circuit board

based upon the cluster programming and electronic

messages received by the cluster from the Powertrain

Control Module (PCM) over the Chrysler Collision

Detection (CCD) data bus. The upshift indicator bulbreceives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (st-run) circuit whenever the ignition

switch is in the On or Start positions; therefore, the

lamp will always be off when the ignition switch is in

any position except On or Start. The bulb only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. On models not

equipped with a manual transmission, the incandes-

cent bulb and bulb holder unit are not installed at

the factory when the vehicle is built. The instrument

cluster will turn on the upshift indicator for the fol-

lowing reasons:

²Upshift Lamp-On Message- Each time the

cluster receives an upshift lamp-on message from the

PCM indicating the engine speed and load conditions

are right for a transmission upshift to occur, the

upshift indicator is illuminated. The indicator

remains illuminated until the cluster receives an

upshift lamp-off message from the PCM or until the

ignition switch is turned to the Off position, which-

ever occurs first. The PCM will normally send an

upshift lamp-off message three to five seconds after a

lamp-on message, if an upshift is not performed. The

indicator will then remain off until the vehicle stops

accelerating and is brought back into the range of

indicator operation, or until the transmission is

shifted into another gear.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the indicator and the

cluster control circuitry.

The PCM continually monitors the engine speed

and load conditions to determine the proper fuel and

ignition requirements. The PCM then sends the

proper messages to the instrument cluster. If the

upshift indicator fails to light during normal vehicle

operation, replace the bulb with a known good unit.

For further diagnosis of the upshift indicator or the

instrument cluster circuitry that controls the indica-

tor, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). For

proper diagnosis of the PCM, the CCD data bus, or

the message inputs to the instrument cluster that

control the upshift indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left quadrant of the instrument cluster,

BR/BEINSTRUMENT CLUSTER 8J - 33

TURN SIGNAL INDICATORS (Continued)

Page 593 of 2889

above the temperature gauge. The voltage gauge con-

sists of a movable gauge needle or pointer controlled

by the instrument cluster circuitry and a fixed 90

degree scale on the cluster overlay that reads left-to-

right from 8 volts to 18 volts. An International Con-

trol and Display Symbol icon for ªBattery Charging

Conditionº is located directly below the lowest grad-

uation of the gauge scale. The voltage gauge graphics

are white against a black field except for a single red

graduation at each end of the gauge scale, making

them clearly visible within the instrument cluster in

daylight. When illuminated from behind by the panel

lamps dimmer controlled cluster illumination lighting

with the exterior lamps turned On, the white graph-

ics appear blue-green and the red graphics appear

red. The orange gauge needle is internally illumi-

nated. Gauge illumination is provided by replaceable

incandescent bulb and bulb holder units located on

the instrument cluster electronic circuit board. The

voltage gauge is serviced as a unit with the instru-

ment cluster.

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon the cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Chrysler

Collision Detection (CCD) data bus. The voltage

gauge is an air core magnetic unit that receives bat-

tery current on the instrument cluster electronic cir-

cuit board through the fused ignition switch output

(st-run) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Charge Fail Message- Each time the cluster

receives a message from the PCM indicating a charge

fail condition (system voltage is 10.8 volts or lower),

the gauge needle is moved to the 8 volt graduation

on the gauge scale and the check gauges indicator is

illuminated. The gauge needle remains on the 8 volt

graduation and the check gauges indicator remains

illuminated until the cluster receives a message from

the PCM indicating there is no charge fail condition

(system voltage is 10.9 volts or higher, but lower

than 16.7 volts), or until the ignition switch is turned

to the Off position, whichever occurs first. On models

equipped with the optional diesel engine, the instru-

ment cluster is programmed to support the voltmeter

gauge needle above the low end of normal graduation

and suppress the check gauges indicator operationuntil ten seconds after the engine intake manifold air

heater has completed its cycle.

²Voltage High Message- Each time the cluster

receives a message from the PCM indicating a volt-

age high condition (system voltage is 16.7 volts or

higher), the gauge needle is moved to the 18 volt

graduation on the gauge scale and the check gauges

indicator is illuminated. The gauge needle remains

on the 18 volt graduation and the check gauges indi-

cator remains illuminated until the cluster receives a

message from the PCM indicating there is no voltage

high condition (system voltage is 16.6 volts or lower,

but higher than 10.9 volts), or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Message Failure- If the cluster fails to receive

a system voltage message, it will hold the gauge nee-

dle at the last indication until a new message is

received, or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in a prescribed sequence in order to confirm the func-

tionality of the gauge and the cluster control cir-

cuitry.

The PCM continually monitors the system voltage

to control the generator output. The PCM then sends

the proper system voltage messages to the instru-

ment cluster. For further diagnosis of the voltage

gauge or the instrument cluster circuitry that con-

trols the gauge, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING). If

the instrument cluster turns on the check gauges

indicator due to a charge fail or voltage high condi-

tion, it may indicate that the charging system

requires service. For proper diagnosis of the charging

system, the CCD data bus, or the message inputs to

the instrument cluster that control the voltage

gauge, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is standard equipment on

all instrument clusters, but is only functional in vehi-

cles equipped with an optional diesel engine. The

wait-to-start indicator is located near the lower edge

of the instrument cluster overlay, to the right of cen-

ter. The wait-to-start indicator consists of a stenciled

cutout of the text ªWAIT TO STARTº in the opaque

layer of the cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. A red lens located

8J - 34 INSTRUMENT CLUSTERBR/BE

VOLTAGE GAUGE (Continued)

Page 594 of 2889

behind the cutout causes the ªWAIT TO STARTº text

to appear in red through the translucent outer layer

of the overlay when the indicator is illuminated from

behind by a Light Emitting Diode (LED) that is sol-

dered onto the instrument cluster electronic circuit

board. The wait-to-start indicator is serviced as a

unit with the instrument cluster.

OPERATION

The wait-to-start indicator gives an indication to

the vehicle operator when the diesel engine intake

air heater is energized in its preheat operating mode.

This indicator is controlled by a hard wired input to

the instrument cluster from the Engine Control Mod-

ule (ECM). The wait-to-start indicator Light Emitting

Diode (LED) receives battery current on the instru-

ment cluster electronic circuit board through the

fused ignition switch output (st-run) circuit whenever

the ignition switch is in the On or Start positions;

therefore, the lamp will always be off when the igni-

tion switch is in any position except On or Start. The

indicator LED only illuminates when it is switched to

ground by the input from the ECM. The ECM will

turn on the wait-to-start indicator by pulling the

wait-to-start indicator driver circuit to ground each

time the ignition switch is turned to the On or Start

positions. The indicator then remains illuminated

until the ECM detects that the air within the intake

manifold is the proper temperature to ensure reliable

and efficient engine starting, until the ECM detects

that the engine is running, or until the ignition

switch is turned to the Off position, whichever occurs

first.

The ECM continually monitors the intake manifold

air temperature sensor, the Manifold Absolute Pres-

sure (MAP) sensor, and many other vehicle condi-

tions to determine when the wait-to-start indicator

should be illuminated. For proper diagnosis of the

wait-to-start indicator, the ECM, or the inputs the

ECM uses to control the wait-to-start indicator oper-

ation, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

WASHER FLUID INDICATOR

DESCRIPTION

A washer fluid indicator is standard equipment on

all instrument clusters. The washer fluid indicator is

located near the lower edge of the instrument cluster

overlay, to the right of center. The washer fluid indi-

cator consists of a stenciled cutout of the words

ªLOW WASHERº in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. An amber lens behindthe cutout in the opaque layer of the overlay causes

the ªLOW WASHERº text to appear in amber

through the translucent outer layer of the overlay

when it is illuminated from behind by a Light Emit-

ting Diode (LED) soldered onto the instrument clus-

ter electronic circuit board. The washer fluid

indicator is serviced as a unit with the instrument

cluster.

OPERATION

The washer fluid indicator gives an indication to

the vehicle operator when the fluid level in the

washer fluid reservoir is low. This indicator is con-

trolled by a transistor on the instrument cluster elec-

tronic circuit board based upon cluster programming

and a hard wired washer fluid level switch input to

the cluster. The washer fluid indicator Light Emit-

ting Diode (LED) receives battery current on the

instrument cluster electronic circuit board through

the fused ignition switch output (st-run) circuit

whenever the ignition switch is in the On or Start

positions; therefore, the indicator will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is pro-

vided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

washer fluid indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the indicator is illuminated

for about two seconds as a bulb test.

²Washer Fluid Level Switch Input- Immedi-

ately after the bulb test, if the cluster senses ground

on the washer fluid switch sense circuit for more

than about thirty seconds, it turns on the washer

fluid indicator. Any time after the bulb test, the clus-

ter must sense ground on the washer fluid switch

sense circuit for more than about sixty seconds before

it turns on the indicator. Once illuminated, the indi-

cator will remain illuminated until the ignition

switch is cycled and the cluster senses an open cir-

cuit on the low washer fluid sense input. This strat-

egy is intended to reduce the effect that fluid

sloshing within the washer reservoir can have on

reliable indicator operation.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The washer fluid level switch is connected in series

between ground and the washer fluid switch sense

input to the instrument cluster. For more informa-

tion on the washer fluid level switch,(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WASHER FLUID

LEVEL SWITCH - OPERATION). For further diag-

nosis of the washer fluid indicator or the instrument

BR/BEINSTRUMENT CLUSTER 8J - 35

WAIT-TO-START INDICATOR (Continued)

Page 596 of 2889

OPERATION

The water-in-fuel indicator gives an indication to

the vehicle operator when the water accumulated in

the diesel engine fuel filter/separator filter bowl

requires draining. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Engine Control

Module (ECM) over the Chrysler Collision Detection

(CCD) data bus. The water-in-fuel indicator Light

Emitting Diode (LED) receives battery current on the

instrument cluster electronic circuit board through

the fused ignition switch output (st-run) circuit

whenever the ignition switch is in the On or Start

positions; therefore, the indicator will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is

switched to ground by the instrument cluster transis-

tor. The instrument cluster will turn on the water-in-

fuel indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the indicator is illuminated

for about two seconds as a bulb test.

²Water-In-Fuel Lamp-On Message- Each time

the cluster receives a water-in-fuel lamp-on messagefrom the ECM, the indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a water-in-fuel lamp-off message from the

ECM or until the ignition switch is turned to the Off

position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The ECM continually monitors the water-in-fuel

sensor, then sends the proper messages to the instru-

ment cluster. For further diagnosis of the water-in-

fuel indicator or the instrument cluster circuitry that

controls the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the water-in-fuel

sensor, the ECM, the CCD data bus, or the message

inputs to the instrument cluster that control the

water-in-fuel indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic

information.

BR/BEINSTRUMENT CLUSTER 8J - 37

WATER-IN-FUEL INDICATOR (Continued)

Page 599 of 2889

MARKER LAMP

REMOVAL..............................22

INSTALLATION...........................23

MULTI-FUNCTION SWITCH

DESCRIPTION...........................23

OPERATION.............................24

DIAGNOSIS AND TESTING.................25

MULTI-FUNCTION SWITCH...............25

REMOVAL..............................27

INSTALLATION...........................28

OUTBOARD IDENTIFICATION LAMP

REMOVAL..............................28

INSTALLATION...........................29

PARK/TURN SIGNAL LAMP

REMOVAL..............................29

INSTALLATION...........................29

PARK/TURN SIGNAL LAMP UNIT

REMOVAL..............................29INSTALLATION...........................29

TAIL LAMP

DESCRIPTION...........................29

OPERATION.............................29

REMOVAL..............................29

INSTALLATION...........................30

TAIL LAMP UNIT

REMOVAL..............................30

INSTALLATION...........................30

TURN SIGNAL CANCEL CAM

DESCRIPTION...........................30

OPERATION.............................31

UNDERHOOD LAMP

REMOVAL..............................31

INSTALLATION...........................32

UNDERHOOD LAMP UNIT

REMOVAL..............................32

INSTALLATION...........................32

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION - TURN SIGNAL & HAZARD

WARNING SYSTEM

A turn signal and hazard warning system is stan-

dard factory-installed safety equipment on this

model. The turn signal and hazard warning system

includes the following major components, which are

described in further detail elsewhere in this service

information:

²Combination Flasher- The electronic combi-

nation flasher is installed in the Junction Block (JB),

which is located behind the fuse access panel on the

left outboard end of the instrument panel.

²Hazard Warning Switch- The hazard warning

switch is integral to the multi-function switch on the

left side of the steering column. The hazard warning

switch button protrudes from a dedicated opening in

the shroud on the top of the steering column, just

below the steering wheel.

²Turn Signal Cancel Cam- The turn signal

cancel cam is integral to the clockspring, which is

located beneath the steering column shrouds at the

top of the steering column, just below the steering

wheel.

²Turn Signal Indicators- The two turn signal

indicators, one right and one left, are integral to the

ElectroMechanical Instrument Cluster (EMIC)

located in the instrument panel.

²Turn Signal Lamps- The front turn signal

lamps are integral to the lower front outboard ends

of the headlamp modules, located just outboard of the

two sides of the radiator grille opening. The rear

turn signal lamps are integral to the taillamp mod-

ules located on either side of the vehicle. For pickup

models the taillamp modules are secured to the rear

of the quarter panels at each side of the tailgate

opening. For cab and chassis models the taillampmodules are secured by a stamped steel bracket on

the outboard side of each frame rail near the rear of

the vehicle.

²Turn Signal Switch- The turn signal switch is

integral to the multi-function switch on the left side

of the steering column. The multi-function switch

control stalk that actuates the turn signal switch

protrudes from a dedicated opening in the steering

column shrouds on the left side of the column, just

below the steering wheel.

Hard wired circuitry connects the turn signal and

hazard warning system components to each other

through the electrical system of the vehicle. These

hard wired circuits are integral to several wire har-

nesses, which are routed throughout the vehicle and

retained by many different methods. These circuits

may be connected to each other, to the vehicle elec-

trical system and to the turn signal and hazard

warning system components through the use of a

combination of soldered splices, splice block connec-

tors and many different types of wire harness termi-

nal connectors and insulators. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

OPERATION - TURN SIGNAL & HAZARD

WARNING SYSTEM

The turn signal system operates on battery current

received on a fused ignition switch output (run-acc)

circuit so that the turn signals will only operate with

the ignition switch in the On or Accessory positions.

The hazard warning system operates on non-

switched battery current received on a fused B(+) cir-

cuit so that the hazard warning remains operational

8L - 2 LAMPS/LIGHTING - EXTERIORBR/BE

Page 600 of 2889

regardless of the ignition switch position. When the

turn signal (multi-function) switch control stalk is

moved up (right turn) or down (left turn), the turn

signal system is activated. When the turn signal sys-

tem is activated, the circuitry of the turn signal

switch and the combination flasher will cause the

selected (right or left) turn signal indicator, front

park/turn signal lamp, and rear tail/stop/turn signal

lamp to flash on and off. With the hazard warning

(multi-function) switch in the On position, the hazard

warning system is activated. When the hazard warn-

ing system is activated, the circuitry of the hazard

warning switch and the combination flasher will

cause both the right side and the left side turn signal

indicators, front park/turn signal lamps, and rear

tail/stop/turn signal lamps to flash on and off.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the turn signal and hazard warning sys-

tem.

DIAGNOSIS AND TESTING - TURN SIGNAL &

HAZARD WARNING SYSTEM

When diagnosing the turn signal and hazard warn-

ing circuits, remember that high generator output

can burn out bulbs rapidly and repeatedly. If this is a

problem on the vehicle being diagnosed, be certain to

diagnose and repair the charging system as required.

If the problem being diagnosed is related to a failure

of the turn signals to automatically cancel following

completion of a turn, inspect the multi-function

switch for a faulty or damaged cancel actuator and

inspect the turn signal cancel cam on the clockspring

for damaged lobes or improper installation. Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Turn the ignition switch to the On position.

Actuate the turn signal switch or the hazard warning

switch. Observe the turn signal indicator lamp(s) in

the instrument cluster. If the flash rate is very high,

check for a turn signal bulb that is not lit or is very

dimly lit. Repair the circuits to that lamp or replace

the faulty bulb, as required. If the turn signal indi-

cator(s) fail to light, go to Step 2.

(2) Turn the ignition switch to the Off position.

Check the fused ignition switch output (run-acc) fuse

(Fuse 10 - 10 ampere) in the Junction Block (JB) and

the fused B(+) fuse (Fuse4-20ampere) in the

Power Distribution Center (PDC). If OK, go to Step

3. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse(s).

(3) Check for battery voltage at the fused B(+) fuse

(Fuse4-20ampere) in the PDC. If OK, go to Step 4.

If not OK, repair the open fused B(+) circuit between

the PDC and the battery as required.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run-acc) fuse (Fuse 10 - 10 ampere) in the

JB. If OK, go to Step 5. If not OK, repair the open

fused ignition switch output (run-acc) circuit between

the JB and the ignition switch as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the combination flasher from the JB and

replace it with a known good unit. Reconnect the bat-

tery negative cable. Test the operation of the turn

signal and hazard warning systems. If OK, discard

the faulty combination flasher. If not OK, remove the

test flasher and go to Step 6.

(6) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run-acc) circuit cavity in the JB receptacle

for the combination flasher. If OK, go to Step 7. If

not OK, repair the open fused ignition switch output

(run-acc) circuit between the combination flasher and

the fused ignition switch output (run-acc) fuse (Fuse

10 - 10 ampere) in the JB as required.

(7) Turn the ignition switch to the Off position.

Check for battery voltage at the fused B(+) circuit

cavity of the JB receptacle for the combination

flasher. If OK, go to Step 8. If not OK, repair the

open fused B(+) circuit between the combination

flasher and the fused B(+) fuse (Fuse4-20ampere)

in the PDC as required.

(8) Disconnect and isolate the battery negative

cable. Check for continuity between the ground cir-

cuit cavity of the JB receptacle for the combination

flasher and a good ground. There should be continu-

ity. If OK, go to Step 9. If not OK, repair the open

ground circuit to ground (G201) as required.

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 604 of 2889

COMBINATION FLASHER

DESCRIPTION

The combination flasher is located in the Junction

Block (JB) behind the fuse access panel on the left

outboard end of the instrument panel. The combina-

tion flasher is a smart relay that functions as both

the turn signal system and the hazard warning sys-

tem flasher. The combination flasher contains active

electronic Integrated Circuitry (IC) elements. This

flasher is designed to handle the current flow

requirements of the factory-installed lighting. If sup-

plemental lighting is added to the turn signal lamp

circuits, such as when towing a trailer with lights,

the combination flasher will automatically try to

compensate to keep the flash rate the same.

The combination flasher has five blade-type termi-

nals that connect it to the vehicle electrical system

through five matching cavities in the receptacle of

the JB. While the combination flasher has a Interna-

tional Standards Organization (ISO)-type relay ter-

minal configuration or footprint, the internal

circuitry is much different. The combination flasher

does not use standard ISO-relay inputs or provide

ISO-relay type outputs or functions. The combination

flasher should never be substituted for an ISO-relay

or replaced with an ISO-relay, or else component and

vehicle damage may occur.

The combination flasher cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

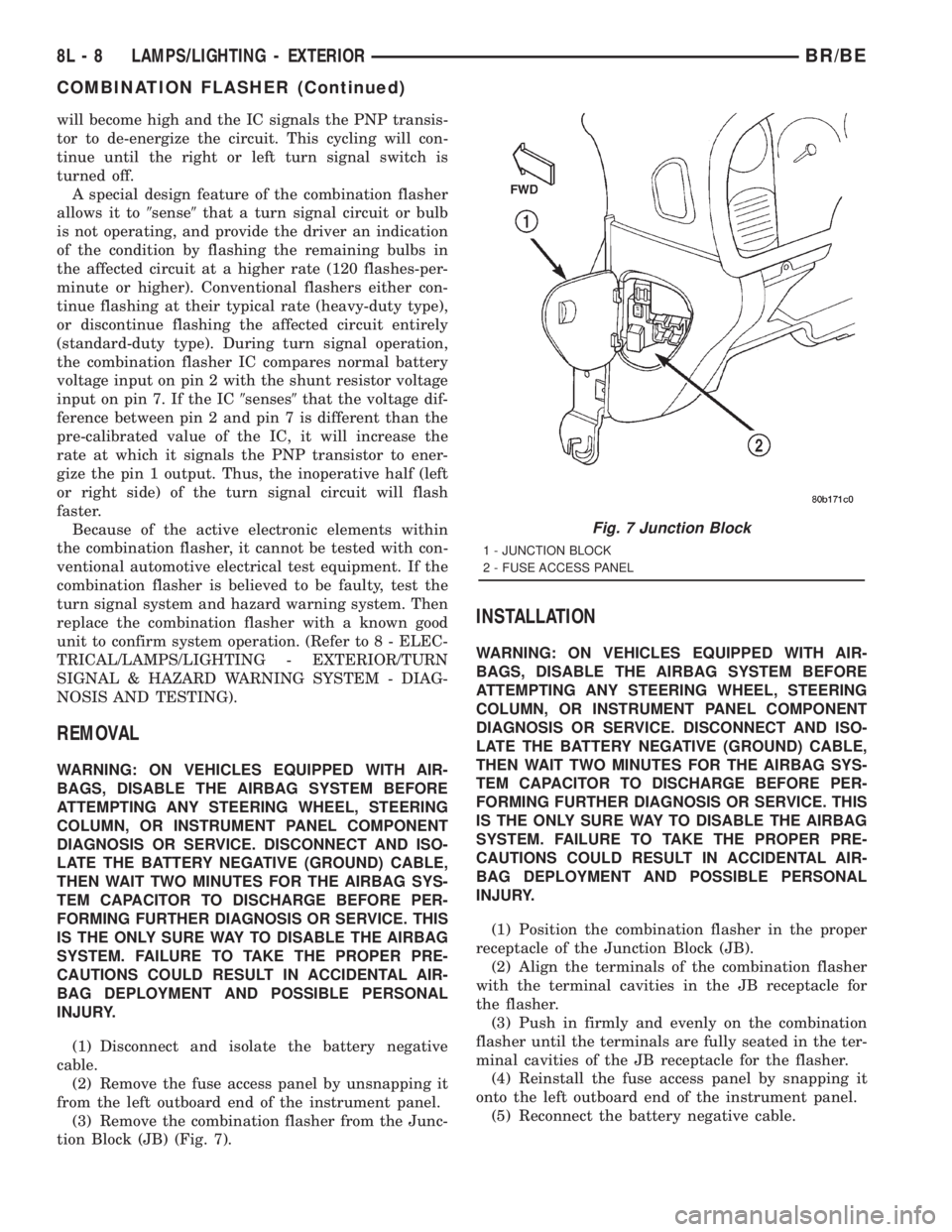

The combination flasher has five blade-type termi-

nals intended for the following inputs and outputs:

fused B(+), fused ignition switch output, ground, turn

signal circuit, and hazard warning circuit. Constant

battery voltage and ground are supplied to the

flasher so that it can perform the hazard warning

function, and ignition switched battery voltage is

supplied for the turn signal function.

The Integrated Circuitry (IC) within the combina-

tion flasher (Fig. 6) contains the logic that controls

the flasher operation and the flash rate. Pin 6 of the

IC receives a sense voltage from the hazard warning

circuit of the multi-function switch. When the hazard

warning switch is turned on, the9hazard on sense9

voltage will become low due to the circuit being

grounded through the turn signal bulbs. This low

voltage sense signals the IC to energize the flash con-

trol Positive-Negative-Positive (PNP) transistor at a

pre-calibrated flash rate or frequency. Each time the

PNP transistor energizes the hazard warning circuit,

the pin 69hazard on sense9voltage will become high

and the IC signals the PNP transistor to de-energize

the circuit. This cycling will continue until the haz-

ard warning switch is turned off.

Likewise, pin 8 of the IC receives a sense voltage

from the turn signal circuits of the multi-function

switch. When the left or right turn signal switch is

turned on, the9turn signal on sense9voltage will

become low due to the circuit being grounded

through the turn signal bulbs. This low voltage sense

signals the IC to energize the flash control PNP tran-

sistor at a pre-calibrated flash rate or frequency.

Each time the PNP transistor energizes the turn sig-

nal circuit, the pin 89turn signal on sense9voltage

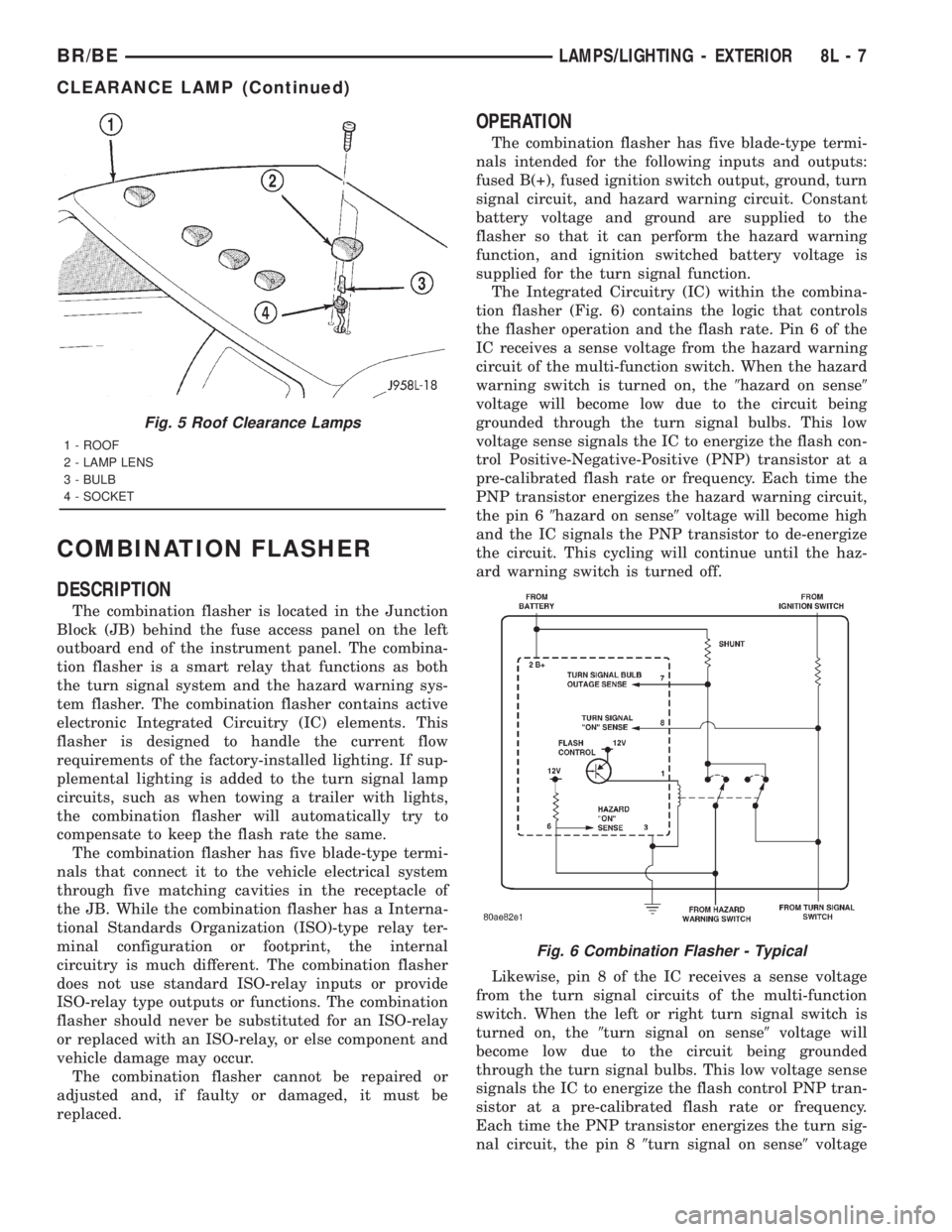

Fig. 5 Roof Clearance Lamps

1 - ROOF

2 - LAMP LENS

3 - BULB

4 - SOCKET

Fig. 6 Combination Flasher - Typical

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 7

CLEARANCE LAMP (Continued)

Page 605 of 2889

will become high and the IC signals the PNP transis-

tor to de-energize the circuit. This cycling will con-

tinue until the right or left turn signal switch is

turned off.

A special design feature of the combination flasher

allows it to9sense9that a turn signal circuit or bulb

is not operating, and provide the driver an indication

of the condition by flashing the remaining bulbs in

the affected circuit at a higher rate (120 flashes-per-

minute or higher). Conventional flashers either con-

tinue flashing at their typical rate (heavy-duty type),

or discontinue flashing the affected circuit entirely

(standard-duty type). During turn signal operation,

the combination flasher IC compares normal battery

voltage input on pin 2 with the shunt resistor voltage

input on pin 7. If the IC9senses9that the voltage dif-

ference between pin 2 and pin 7 is different than the

pre-calibrated value of the IC, it will increase the

rate at which it signals the PNP transistor to ener-

gize the pin 1 output. Thus, the inoperative half (left

or right side) of the turn signal circuit will flash

faster.

Because of the active electronic elements within

the combination flasher, it cannot be tested with con-

ventional automotive electrical test equipment. If the

combination flasher is believed to be faulty, test the

turn signal system and hazard warning system. Then

replace the combination flasher with a known good

unit to confirm system operation. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TURN

SIGNAL & HAZARD WARNING SYSTEM - DIAG-

NOSIS AND TESTING).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access panel by unsnapping it

from the left outboard end of the instrument panel.

(3) Remove the combination flasher from the Junc-

tion Block (JB) (Fig. 7).

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the combination flasher in the proper

receptacle of the Junction Block (JB).

(2) Align the terminals of the combination flasher

with the terminal cavities in the JB receptacle for

the flasher.

(3) Push in firmly and evenly on the combination

flasher until the terminals are fully seated in the ter-

minal cavities of the JB receptacle for the flasher.

(4) Reinstall the fuse access panel by snapping it

onto the left outboard end of the instrument panel.

(5) Reconnect the battery negative cable.

Fig. 7 Junction Block

1 - JUNCTION BLOCK

2 - FUSE ACCESS PANEL

8L - 8 LAMPS/LIGHTING - EXTERIORBR/BE

COMBINATION FLASHER (Continued)