fuse DODGE RAM 2001 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 607 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE RUNNING

ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system.

2. Poor lighting circuit Z33-ground. 2. Test for voltage drop across Z33-ground

locations.

3. High resistance in fog lamp circuit. 3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit Z33-ground. 1. Test for voltage drop across Z33-ground

locations.

2. High resistance in fog lamp circuit. 2. Test amperage draw of fog lamp circuit.

3. Faulty fog lamp switch. 3. Replace fog lamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices.

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1.Trace short and replace fuse.

2. No Z33-ground at fog lamps. 2. Repair circuit ground.

3. Faulty fog lamp switch. 3. Replace fog lamp switch.

4. Broken connector terminal or wire

splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Defective or burned out bulb. 5. Replace bulb.

FOG LAMPS ARE

INOPERATIVE AND FOG

LAMP INDICATOR LIGHT

ALWAYS STAYS ON.1. Fog lamp/DRL* feed shorted to

ground.1. Check wiring circuit from fog lamp/DRL*

fuse to fog lamp. Trace short circuit in

wiring and repair.

FOG LAMPS ARE

INOPERATIVE AND FOG

LAMP INDICATOR LIGHT

IS ILLUMINATED.1. Fog lamp/DRL* fuse defective. 1. Trace short circuit and replace fuse.

2. Open circuit from fog lamp fuse to

fog lamp.2. Check wiring circuit from fog lamp/DRL*

fuse to fog lamp. Trace open circuit in

wiring and repair.

PARK LAMPS ARE

INOPERATIVE. FOG LAMP

INDICATOR IS ON WHEN

ALL SWITCHES ARE OFF

AND FUNCTIONS

OPPOSITE TO FOG

LAMPS.1. Park lamp feed is shorted. 1. Check wiring circuit from park lamp fuse

to headlamp switch. Trace short circuit in

wiring and repair.

PARK LAMPS ARE

INOPERATIVE. FOG LAMP

INDICATOR FUNCTIONS

OPPOSITE TO FOG

LAMPS.1. Park lamp fuse is defective. 1. Trace short circuit and replace fuse.

2. Open circuit from park lamp fuse

to headlamp switch.2. Check wiring circuit from park lamp fuse

to headlamp switch. Trace open circuit in

wiring and repair.

*Canada vehicles use Daytime Running Lamps (DRL).

8L - 10 LAMPS/LIGHTING - EXTERIORBR/BE

FOG LAMP (Continued)

Page 608 of 2889

Additional fog lamp diagnostic procedures listed are for vehicles equipped with quad headlamps and the DRL

option.

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE INOPERATIVE

AND FOG LAMP INDICATOR

S TAY S A LWAY S O N .1 Fog lamp/DRL* feed shorted to

ground.1. Check wiring circuit from fog

lamp/DRL* fuse to fog lamp.Trace

short circuit in wiring and repair.

FOG LAMP INDICATOR COMES

ON WITH OUT ILLUMINATING THE

FOG LAMPS1. Fog lamp/DRL* fuse defective. 1. Trace short circuit and replace

fuse.

FOG LAMPS INOPERATIVE WITH

INGNITION OFF.Open circuit from fog lamp fuse to

fog lamp.1. Check wiring circuit from fog

lamp/DRL* fuse to fog lamp. Trace

open circuit in wiring and repair.

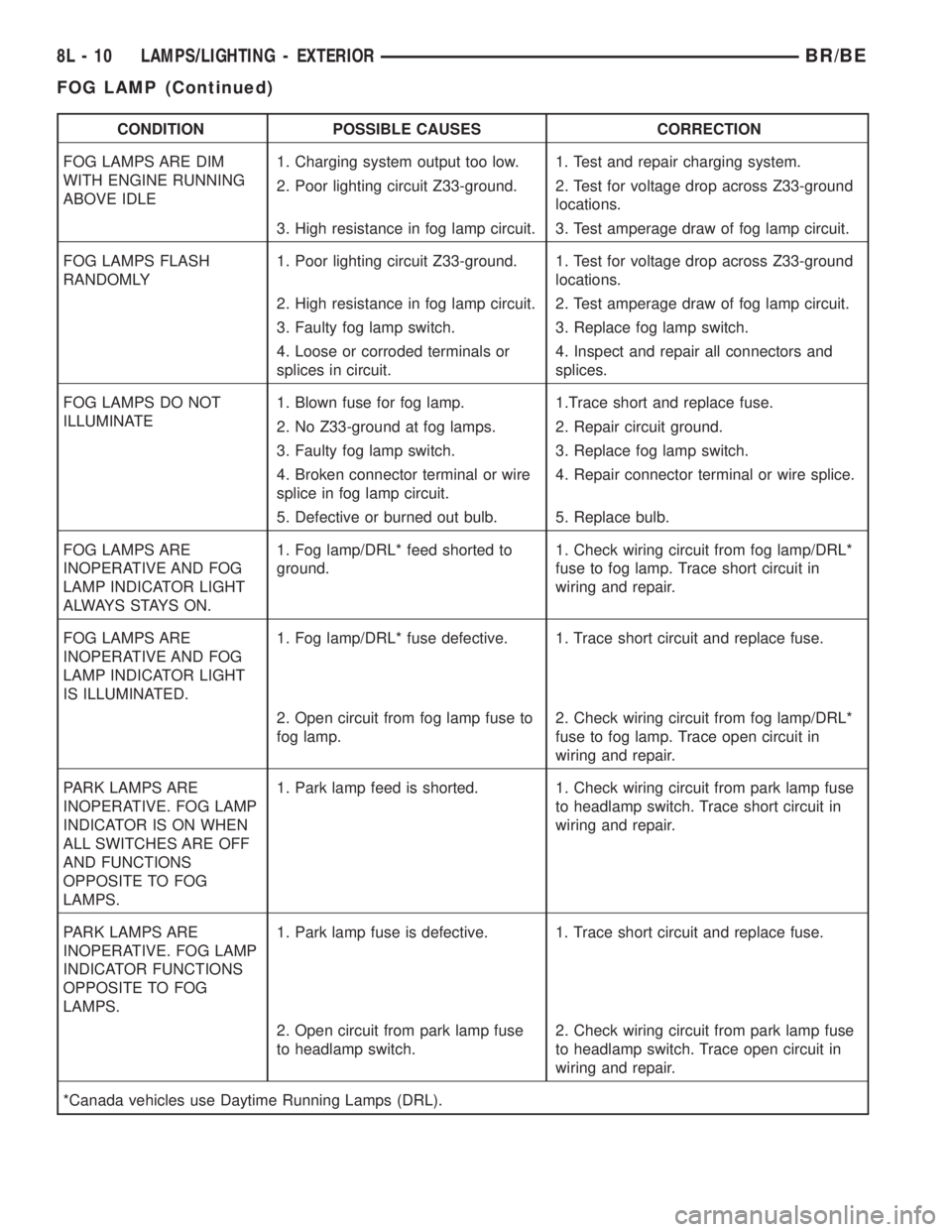

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disengage fog lamp harness connector.

(3) Rotate bulb assembly counterclockwise and

pull from lamp to separate (Fig. 9).

INSTALLATION

CAUTION: Do not touch the bulb glass with fingers

or other oily surfaces. Reduced bulb life will result.

(1) Position bulb assembly in lamp and rotate

clockwise.

(2) Connect fog lamp harness connector.

(3) Connect the battery negative cable.

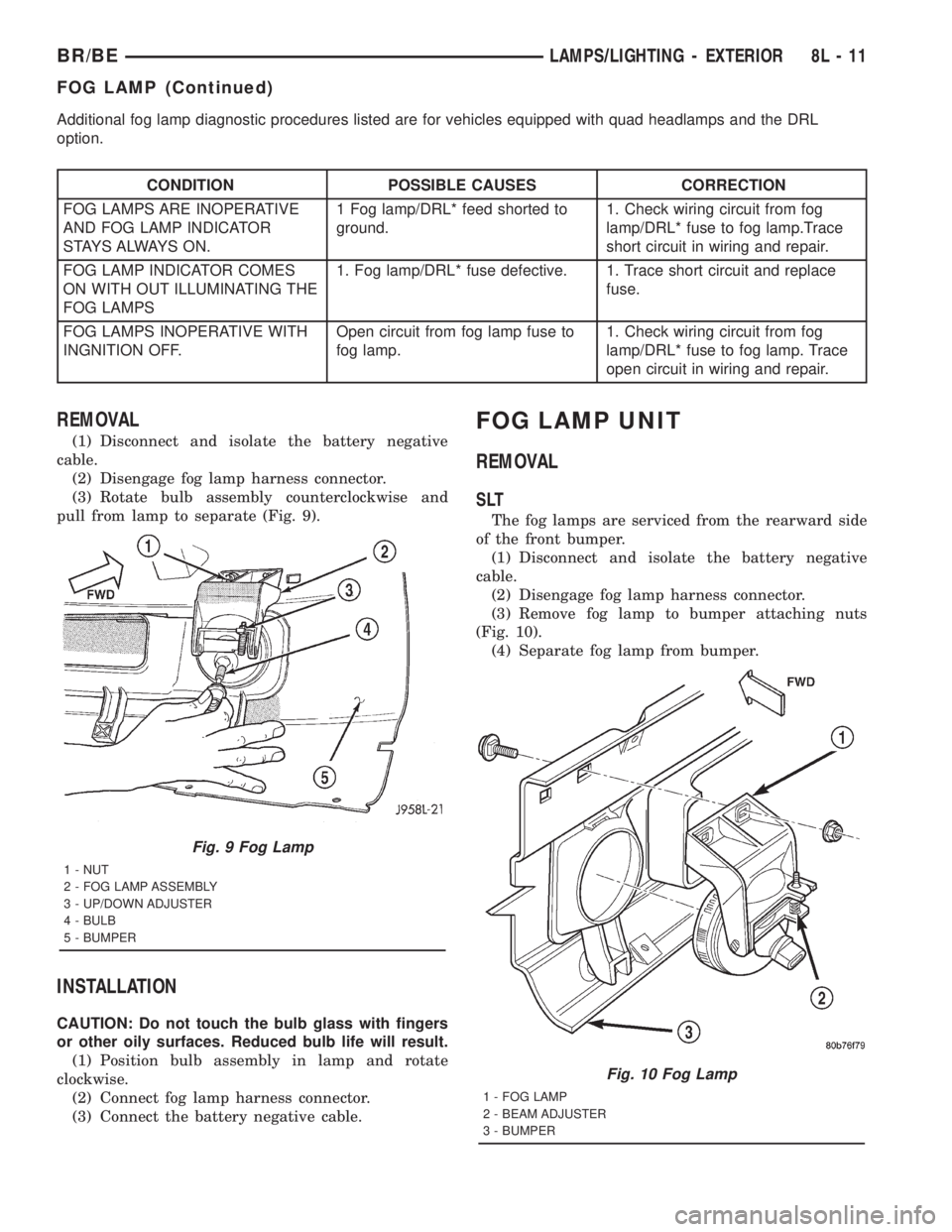

FOG LAMP UNIT

REMOVAL

SLT

The fog lamps are serviced from the rearward side

of the front bumper.

(1) Disconnect and isolate the battery negative

cable.

(2) Disengage fog lamp harness connector.

(3) Remove fog lamp to bumper attaching nuts

(Fig. 10).

(4) Separate fog lamp from bumper.

Fig. 9 Fog Lamp

1 - NUT

2 - FOG LAMP ASSEMBLY

3 - UP/DOWN ADJUSTER

4 - BULB

5 - BUMPER

Fig. 10 Fog Lamp

1 - FOG LAMP

2 - BEAM ADJUSTER

3 - BUMPER

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 11

FOG LAMP (Continued)

Page 610 of 2889

HEADLAMP

DESCRIPTION

Headlamps on the Ram Pick-Up are modular in

design. The turn/park lamp module is incorporated

into the headlamp module. The module contains two

bulbs; a dual filament headlamp bulb, and a dual fil-

ament turn/park bulb. The Sport headlamp module

has two separate bulbs for the headlamp illumina-

tion.

OPERATION

Headlamps and parking lamps are controlled by

the headlamp switch. The multifunction switch

mounted on the steering column controls the high

beam function, and the turn signal function.

DIAGNOSIS AND TESTING - HEADLAMP

A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. For com-

plete circuit diagrams, refer to the appropriate wir-

ing information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

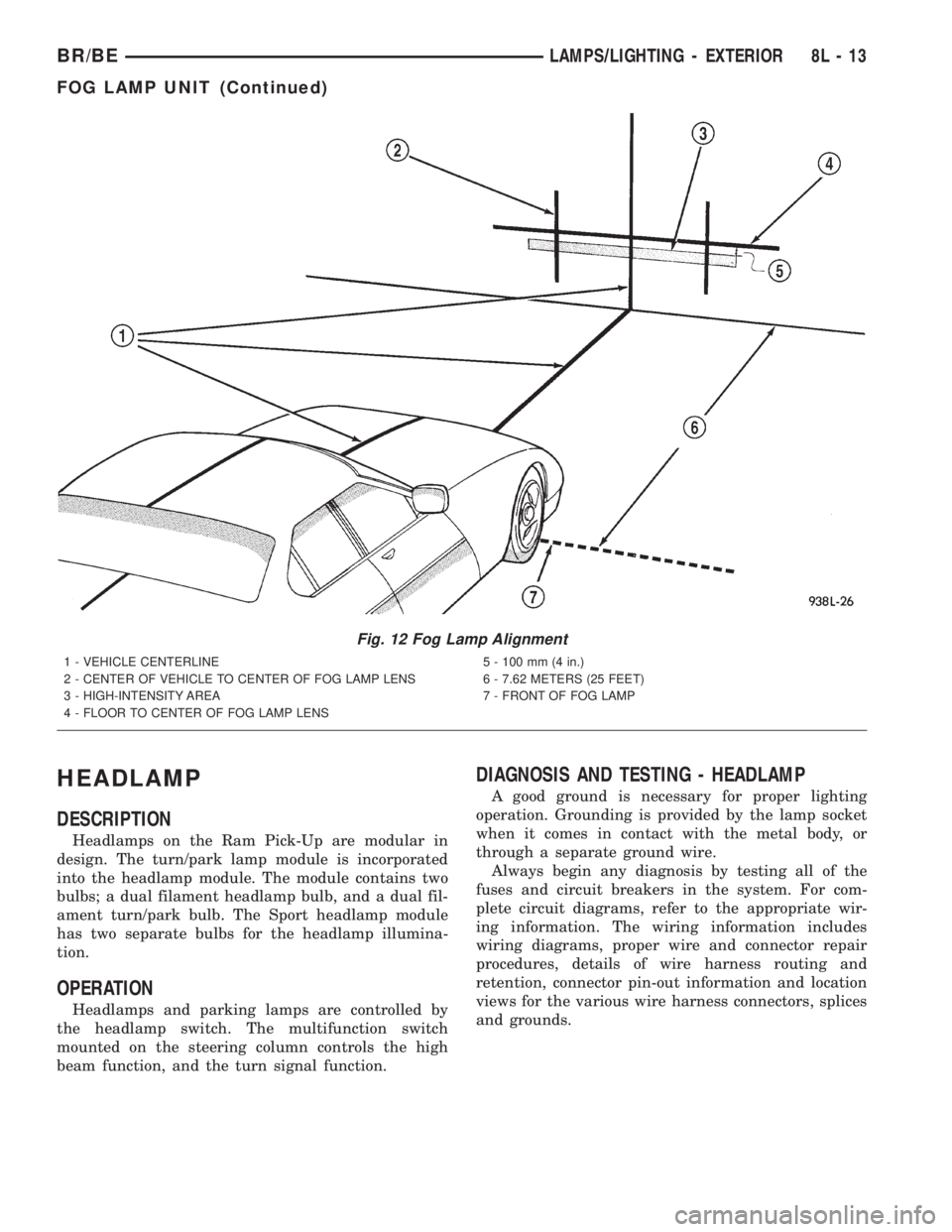

Fig. 12 Fog Lamp Alignment

1 - VEHICLE CENTERLINE

2 - CENTER OF VEHICLE TO CENTER OF FOG LAMP LENS

3 - HIGH-INTENSITY AREA

4 - FLOOR TO CENTER OF FOG LAMP LENS5 - 100 mm (4 in.)

6 - 7.62 METERS (25 FEET)

7 - FRONT OF FOG LAMP

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 13

FOG LAMP UNIT (Continued)

Page 611 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

OR IGNITION TURNED

OFF2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system.

4. Battery has insufficient charge. 4. Test battery state-of -charge.

5. Battery is sulfated or shorted. 5. Load test battery.

6. Poor lighting circuit Z3-ground. 6. Test for voltage drop across Z3-ground

locations.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS BURN

OUT1. Charging system output too high. 1. Test and repair charging system.

FREQUENTLY 2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING1. Charging system output too low. 1. Test and repair charging system.

ABOVE IDLE* 2. Poor lighting circuit Z3-ground. 2. Test for voltage drop across Z3-ground

locations.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z3-ground. 1. Test for voltage drop across Z3-ground

locations.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp circuit.

Should not exceed 30 amps.

3. Faulty headlamps switch circuit

breaker.3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices.

HEADLAMPS (HIGH &

LOW) DO NOT

ILLUMINATE1. No voltage at either headlamp. 1. Voltage should always be present. Trace

short circuit and replace BOTH headlamp

fuses. Check wiring circuit from Right

headlamp fuse to headlamp. (Repeat for

Left side)

2. No ground for high and low beam

circuit.2. Ground should always be present

according to switch position. Check ground

at headlamp switch. Check wiring circuit

from headlamp switch to Multifunction

switch. Check headlamp switch and

Multifunction switch continuity. Repair circuit

ground.

3. Headlamp bulb(s) defective. 3. Replace bulb(s).

4. Faulty headlamp switch. 4. Replace headlamp switch.

5. Faulty headlamp dimmer

(Multifunction) switch.5. Replace Multifunction switch.

8L - 14 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP (Continued)

Page 612 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

6. Broken connector terminal or wire

splice in headlamp circuit.6. Repair connector terminal or wire splice.

HEADLAMPS (LOW

BEAM) DO NOT

ILLUMINATE.1. No ground for low beam circuit. 1. Ground should be present according to

Multifunction switch position. Check wiring

circuit from Multifunction switch to

headlamp . Trace open circuit in wiring and

repair.

Check Multifunction Switch for continuity.

HEADLAMPS (HIGH

BEAM) DO NOT

ILLUMINATE.1. No ground for high beam circuit. 1. Ground should be present according to

Multifunction switch position. Check wiring

circuit from Multifunction switch to

headlamp . Trace open circuit in wiring and

repair.

Check Multifunction Switch for continuity.

HEADLAMPS (LOW

BEAM) ALWAYS

ILLUMINATE AND CAN

NOT BE SHUT OFF.1. Low beam circuit from bulb to

Multifunction switch is shorted to

ground.1. Ground should be present according to

Multifunction switch position. Check wiring

circuit from Multifunction switch to

headlamp . Trace short circuit in wiring and

repair.

HEADLAMPS (HIGH

BEAM) ALWAYS

ILLUMINATE AND CAN

NOT BE SHUT OFF.1. High beam circuit from bulb to

Multifunction switch is shorted to

ground.1. Ground should be present according to

Multifunction switch position. Check wiring

circuit from Multifunction switch to

headlamp . Trace short circuit in wiring and

repair.

QUAD LAMPS DO NOT

ILLUMINATE AND HIGH

BEAMS ILLUMINATE.1. No voltage at either headlamp. 1. Voltage should always be present. Check

Quad lamp fuse. Check wiring circuit from

Quad lamp fuse to Quad lamp. Repeat for

left side

2. No ground for Quad beam circuit. 2. Ground should be present according to

Multifunction switch position. Check ground

at quad lamp relay. Check for battery

voltage at quad lamp relay. Check quad

lamp relay. Check relay control circuit (relay

coil to high beam).

3. If voltage and ground are present,

bulb(s) is defective.3.

Replace bulb(s).

HEADLAMP SWITCH OFF

HEADLAMPS AND

HIGHBEAM INDICATOR

REMAIN ON AND ARE

DIM.1. Headlamp switch feed circuit

shorted to ground.1. Check wiring circuit from right headlamp

fuse to headlamp. Repeat for left side.

Trace short circuit in wiring and repair.

HEADLAMP SWITCH ON

(LOW BEAMS ON), ONE

LOW BEAM ON AND

BOTH HIGH BEAMS DIM.1. Headlamp feed circuit shorted to

ground.1. Check wiring circuit from right headlamp

fuse to headlamp. Repeat for left side.

Trace short circuit in wiring and repair.

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 15

HEADLAMP (Continued)

Page 613 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMP SWITCH ON

(HIGH BEAMS ON), ONE

HIGH BEAM ON AND

BOTH LOW BEAMS DIM.1. Headlamp feed circuit shorted to

ground.1. Check wiring circuit from right headlamp

fuse to headlamp. Repeat for left side.

Trace short circuit in wiring and repair.

HEADLAMP SWITCH ON,

ONE HEADLAMP

FILAMENT WILL BE AT

FULL INTENSITY AND ALL

OTHER FILAMENTS ARE

ON AND DIM.1. Blown headlamp fuse. 1. Trace short circuit and replace fuse.

2. Open circuit from headlamp fuse

to headlamp.2. Repair open headlamp circuit.

1. HEADLAMPS STAY ON

WITH KEY OUT (DRLM

EQUIPPED VEHICLES).1. Failed DRLM 1. Replace DRLM.

*Canada vehicles must have lamps ON.

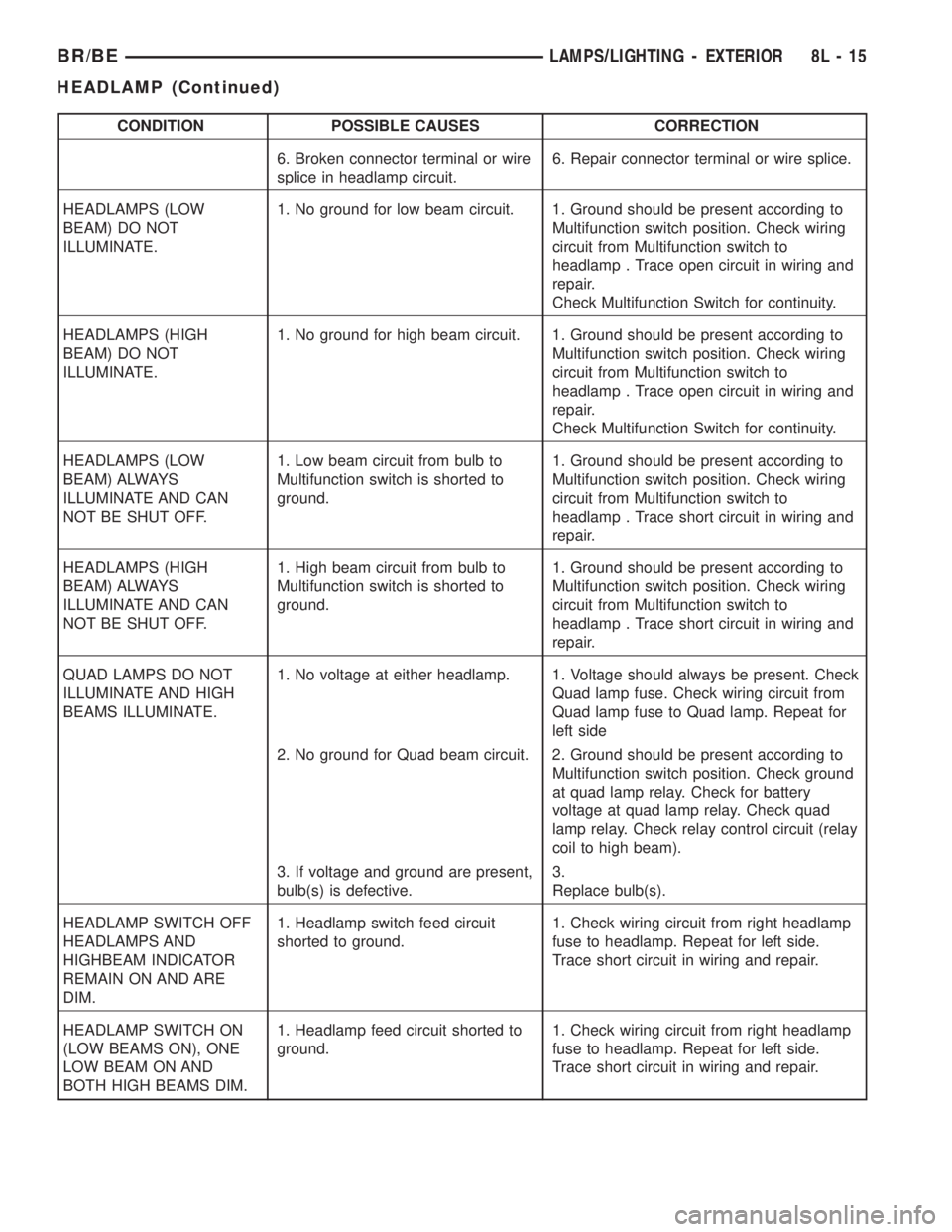

REMOVAL

On the driver side, the battery and battery tray

must be removed to service the headlamp bulb.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(3) Disengage wire connector from headlamp

bulb(s).

(4) Remove retaining ring holding bulb(s) to head-

lamp (Fig. 13).

(5) Pull bulb(s) from headlamp.

INSTALLATION

CAUTION: Do not touch the bulb glass with fingers

or other oily surfaces. Reduced bulb life will result.

(1) Position bulb(s) in headlamp.

(2) Install retaining ring holding bulb(s) to head-

lamp.

(3) Connect wire connector to headlamp bulb(s).

(4) Install battery tray, if removed (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/TRAY - INSTAL-

LATION).

(5) Connect battery negative cable.

HEADLAMP RELAY

DESCRIPTION

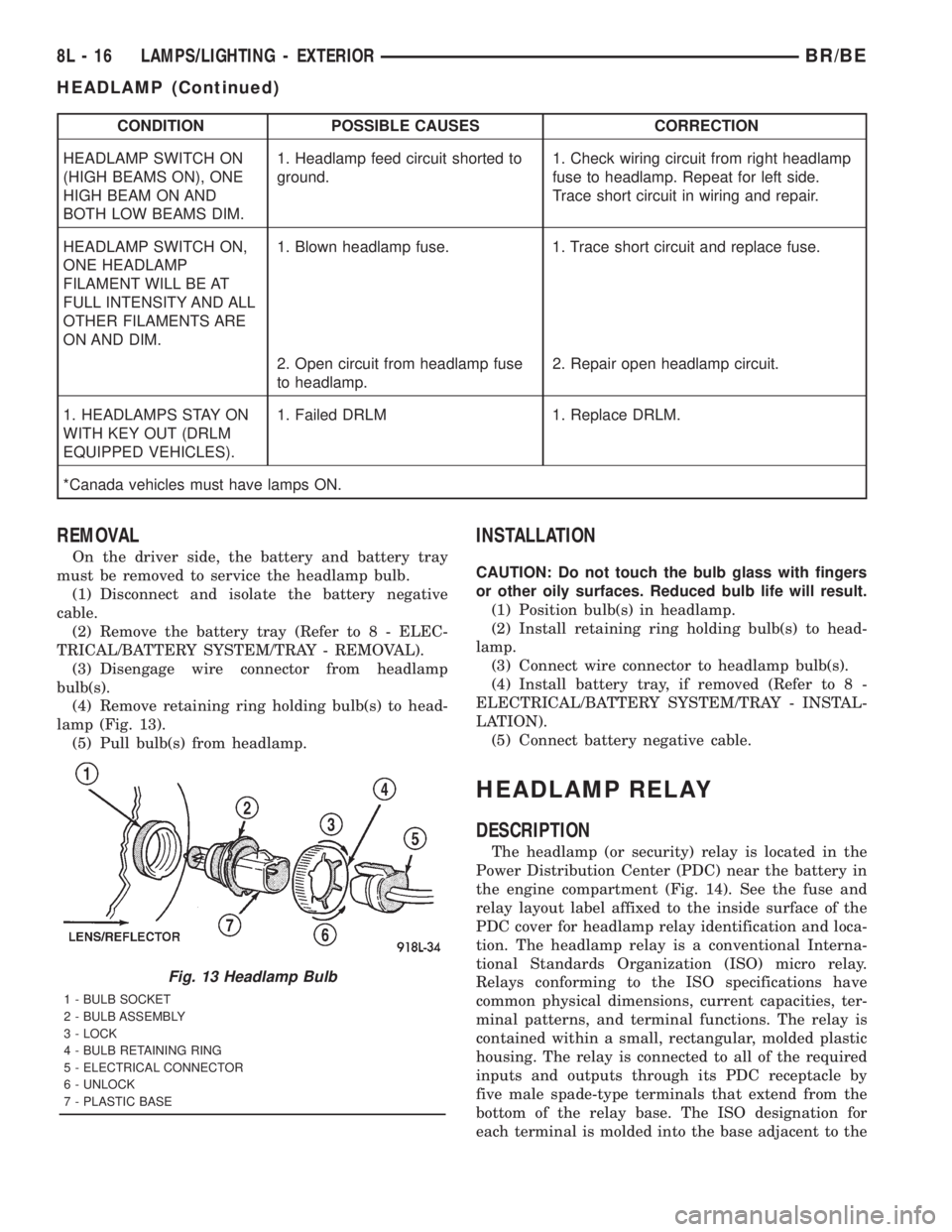

The headlamp (or security) relay is located in the

Power Distribution Center (PDC) near the battery in

the engine compartment (Fig. 14). See the fuse and

relay layout label affixed to the inside surface of the

PDC cover for headlamp relay identification and loca-

tion. The headlamp relay is a conventional Interna-

tional Standards Organization (ISO) micro relay.

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The relay is

contained within a small, rectangular, molded plastic

housing. The relay is connected to all of the required

inputs and outputs through its PDC receptacle by

five male spade-type terminals that extend from the

bottom of the relay base. The ISO designation for

each terminal is molded into the base adjacent to the

Fig. 13 Headlamp Bulb

1 - BULB SOCKET

2 - BULB ASSEMBLY

3 - LOCK

4 - BULB RETAINING RING

5 - ELECTRICAL CONNECTOR

6 - UNLOCK

7 - PLASTIC BASE

8L - 16 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP (Continued)

Page 614 of 2889

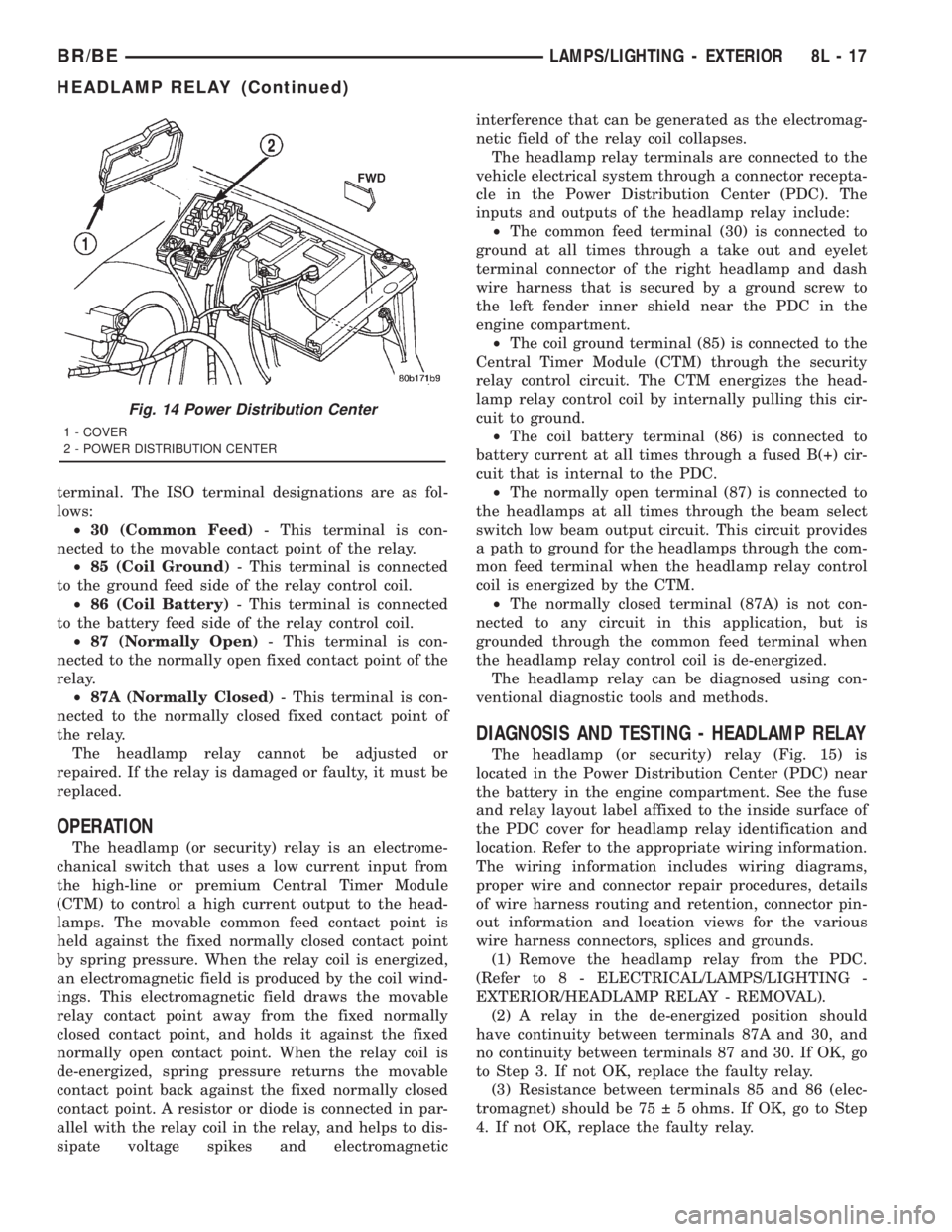

terminal. The ISO terminal designations are as fol-

lows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The headlamp relay cannot be adjusted or

repaired. If the relay is damaged or faulty, it must be

replaced.

OPERATION

The headlamp (or security) relay is an electrome-

chanical switch that uses a low current input from

the high-line or premium Central Timer Module

(CTM) to control a high current output to the head-

lamps. The movable common feed contact point is

held against the fixed normally closed contact point

by spring pressure. When the relay coil is energized,

an electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. A resistor or diode is connected in par-

allel with the relay coil in the relay, and helps to dis-

sipate voltage spikes and electromagneticinterference that can be generated as the electromag-

netic field of the relay coil collapses.

The headlamp relay terminals are connected to the

vehicle electrical system through a connector recepta-

cle in the Power Distribution Center (PDC). The

inputs and outputs of the headlamp relay include:

²The common feed terminal (30) is connected to

ground at all times through a take out and eyelet

terminal connector of the right headlamp and dash

wire harness that is secured by a ground screw to

the left fender inner shield near the PDC in the

engine compartment.

²The coil ground terminal (85) is connected to the

Central Timer Module (CTM) through the security

relay control circuit. The CTM energizes the head-

lamp relay control coil by internally pulling this cir-

cuit to ground.

²The coil battery terminal (86) is connected to

battery current at all times through a fused B(+) cir-

cuit that is internal to the PDC.

²The normally open terminal (87) is connected to

the headlamps at all times through the beam select

switch low beam output circuit. This circuit provides

a path to ground for the headlamps through the com-

mon feed terminal when the headlamp relay control

coil is energized by the CTM.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but is

grounded through the common feed terminal when

the headlamp relay control coil is de-energized.

The headlamp relay can be diagnosed using con-

ventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - HEADLAMP RELAY

The headlamp (or security) relay (Fig. 15) is

located in the Power Distribution Center (PDC) near

the battery in the engine compartment. See the fuse

and relay layout label affixed to the inside surface of

the PDC cover for headlamp relay identification and

location. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

(1) Remove the headlamp relay from the PDC.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/HEADLAMP RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

Fig. 14 Power Distribution Center

1 - COVER

2 - POWER DISTRIBUTION CENTER

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 17

HEADLAMP RELAY (Continued)

Page 615 of 2889

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, test the relay input and output cir-

cuits. If not OK, replace the faulty relay.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Power

Distribution Center (PDC) (Fig. 16).

(3) See the fuse and relay layout label affixed to

the underside of the PDC cover for headlamp (or

security) relay identification and location.(4) Remove the headlamp relay by grasping it

firmly and pulling it straight out from the receptacle

in the PDC.

INSTALLATION

(1) See the fuse and relay layout label affixed to

the underside of the PDC cover for the proper head-

lamp (or security) relay location.

(2) Position the headlamp relay in the proper

receptacle in the PDC.

(3) Align the headlamp relay terminals with the

terminal cavities in the PDC receptacle.

(4) Push firmly and evenly on the top of the head-

lamp relay until the terminals are fully seated in the

terminal cavities in the PDC receptacle.

(5) Reinstall and latch the cover onto the PDC.

(6) Connect the battery negative cable.

HEADLAMP SWITCH

DESCRIPTION

The headlamp switch module is located on the

instrument panel. The headlamp switch controls the

parking lamps, and the headlamps. A separate switch

in the module controls the interior lamps and instru-

ment cluster illumination. This switch also contains

a rheostat for controlling the illumination level of the

cluster lamps.

OPERATION

The headlamp switch has an off position, a parking

lamp position, and a headlamp on position. High

beams are controlled by the multifunction switch on

the steering column. The headlamp switch cannot be

repaired. It must be replaced.

DIAGNOSIS AND TESTING - HEADLAMP

SWITCH

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Fig. 15 Headlamp Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 16 Power Distribution Center

1 - COVER

2 - POWER DISTRIBUTION CENTER

8L - 18 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP RELAY (Continued)

Page 621 of 2889

includes momentary switching of the headlamp high

beam circuits to provide an optical horn feature

(sometimes referred to as flash-to-pass), which allows

the vehicle operator to momentarily flash the head-

lamp high beams as an optical signalling device.

²Intermittent Wipe Mode- The control knob of

the multi-function switch provides an intermittent

wipe mode with multiple delay interval positions.

²Turn Signal Control- The internal circuitry

and hardware of the multi-function switch provide

both momentary non-detent switching and detent

switching with automatic cancellation for both the

left and right turn signals.

²Washer Mode- A button on the end of the con-

trol stalk of the multi-function switch provides

washer system operation when the button is

depressed towards the steering column.

The multi-function switch cannot be adjusted or

repaired. If any function of the switch is faulty, or if

the switch is damaged, the entire switch unit must

be replaced.

OPERATION

The multi-function switch uses conventionally

switched outputs and a variable resistor to control

the many functions and features it provides using

hard wired circuitry. The switch is grounded at all

times through a single wire take out with an eyelet

terminal connector of the instrument panel wire har-

ness that is secured by a nut to a ground stud

located on the instrument panel armature, just above

and to the left of the glove box opening. When the

ignition switch is in the Accessory or On positions,

battery current from a fuse in the Junction Block

(JB) is provided through a fused ignition switch out-

put (run-acc) circuit. Following are descriptions of

the how the multi-function switch operates to control

the many functions and features it provides:

²Continuous Wipe Modes- When the control

knob of the multi-function switch is rotated to the

High or Low positions, the circuitry within the

switch provides a battery current output directly to

the high or low speed brush of the wiper motor.

When the control knob is in the Off position, the cir-

cuitry within the switch connects the output of the

wiper motor park switch to the low speed brush of

the wiper motor.

²Hazard Warning Control- The hazard warn-

ing push button is pushed down to unlatch the

switch and activate the hazard warning system, and

pushed down again to latch the switch and turn the

system off. When the hazard warning switch is

latched (hazard warning off), the push button will be

in a lowered position on the top of the steering col-

umn shroud; and, when the hazard warning switch is

unlatched (hazard warning on), the push button willbe in a raised position. The multi-function switch

hazard warning circuitry simultaneously provides a

signal to the hazard warning sense of the combina-

tion flasher to activate or deactivate the flasher out-

put, and directs the output of the flasher to the

hazard warning lamps.

²Headlamp Beam Selection- The multi-func-

tion switch control stalk is pulled towards the steer-

ing wheel past a detent, then released to actuate the

headlamp beam selection switch. Each time the con-

trol stalk is actuated in this manner, the opposite

headlamp mode from what is currently selected will

be activated. The internal circuitry of the headlamp

beam selection switch directs the output of the head-

lamp switch through hard wired circuitry to activate

the selected headlamp beam.

²Headlamp Optical Horn- The left multi-func-

tion switch control stalk is pulled towards the steer-

ing wheel to just before a detent, to momentarily

activate the headlamp high beams. The high beams

will remain illuminated until the control stalk is

released. The internal circuitry of the headlamp

beam selection switch provides a momentary ground

path to the headlamp high beams.

²Intermittent Wipe Mode- When the multi-

function switch control knob is rotated to the Delay

position, the circuitry within the switch connects the

output of the wiper motor relay to the low speed

brush of the wiper motor and provides a battery cur-

rent signal to the Central Timer Module (CTM). If

the Delay mode is selected, the control knob can then

be rotated to multiple minor detent positions, which

actuates a variable resistor within the switch and

provides a hard wired output to the CTM that sig-

nals the desired delay interval for the intermittent

wiper feature.

²Turn Signal Control- The multi-function

switch control stalk actuates the turn signal switch.

When the control stalk is moved in the upward direc-

tion, the right turn signal circuitry is activated; and,

when the control stalk is moved in the downward

direction, the left turn signal circuitry is activated.

The multi-function switch turn signal circuitry simul-

taneously provides a signal to the turn signal sense

of the combination flasher to activate or deactivate

the flasher output, and directs the output of the

flasher to the proper turn signal lamps. The turn sig-

nal switch has a detent position in each direction

that provides turn signals with automatic cancella-

tion, and an intermediate, momentary position in

each direction that provides turn signals only until

the left multi-function switch control stalk is

released. When the control stalk is moved to a turn

signal switch detent position, the cancel actuator

extends toward the center of the steering column. A

turn signal cancel cam that is integral to the clock-

8L - 24 LAMPS/LIGHTING - EXTERIORBR/BE

MULTI-FUNCTION SWITCH (Continued)

Page 645 of 2889

DIAGNOSIS & TESTING - COMPASS MINI-TRIP

COMPUTER

If the problem with the compass mini-trip com-

puter module is an inoperative security indicator

lamp, refer toSecurity Indicator Lampin Vehicle

Theft/Security Systems. If the problem with the com-

pass mini-trip computer module is an ªOCº or ªSCº in

the compass/thermometer display, refer toAmbient

Temperature Sensorin the Diagnosis and Testing

section of this group. If the problem with the com-

pass mini-trip computer module is an inaccurate or

scrambled display, refer toSelf-Diagnostic Testin

the Diagnosis and Testing section of this group. If the

problem with the compass mini-trip computer module

is incorrect Vacuum Fluorescent Display (VFD) dim-

ming levels, use a DRBtscan tool and the proper

Diagnostic Procedures manual to test for the correct

dimming message inputs being received from the

instrument cluster over the Chrysler Collision Detec-

tion (CCD) data bus. If the problem is a no-display

condition, use the following procedures. For complete

circuit diagrams, refer toOverhead Consolein the

Contents of Wiring Diagrams.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the battery as

required.

(3) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 4.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 5. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the overhead console. Check for continuity

between the ground circuit cavities of the roof wire

harness connector for the overhead console and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

roof wire harness connector for the overhead console.

If OK, go to Step 7. If not OK, repair the open fused

B(+) circuit to the junction block fuse as required.(7) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the roof wire har-

ness connector for the overhead console. If OK, refer

toSelf-Diagnostic Testin the Diagnosis and Test-

ing section of this group for further diagnosis of the

compass mini-trip computer module and the CCD

data bus. If not OK, repair the open fused ignition

switch output (run/start) circuit to the junction block

fuse as required.

SELF-DIAGNOSTIC TEST

A self-diagnostic test is used to determine that the

compass mini-trip computer module is operating

properly electrically. Initiate the self-diagnostic test

as follows:

(1) With the ignition switch in the Off position,

simultaneously depress and hold the Step button and

the U.S./Metric button.

(2) Turn the ignition switch to the On position.

(3) Continue to hold both buttons depressed until

the compass mini-trip computer module enters the

display segment test. In this test, all of the Vacuum

Fluorescent Display (VFD) segments are lighted

while the compass mini-trip computer module per-

forms the following checks:

²Microprocessor RAM read/write test

²Non-volatile memory read/write test

²Microprocessor ROM verification test

²CCD communications test.

(4) Following completion of these tests, the com-

pass mini-trip computer will display one of three

messages: ªPASS,º ªFAIL,º or ªCCd.º Respond to the

respective test results as follows:

²If the ªPASSº message is displayed, but compass

mini-trip computer operation is still improper, the

use of a DRB scan tool and the proper Diagnostic

Procedures manual are required for further diagno-

sis.

²If the ªFAILº message is displayed, the compass

mini-trip computer module is faulty and must be

replaced.

²If the ªCCdº message is displayed, the use of a

DRBtscan tool and the proper Diagnostic Proce-

dures manual are required for further diagnosis.

²If any VFD segment should fail to light during

the display segment test, the compass mini-trip com-

puter module is faulty and must be replaced.

(5) If all tests are passed, or if the ignition switch

is turned to the Off position, the compass mini-trip

computer module will automatically return to normal

operation.

8M - 10 MESSAGE SYSTEMSBR/BE

COMPASS/MINI-TRIP COMPUTER (Continued)