torque DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2572 of 2889

²Tighten lug nuts in same numbered sequence a

second time to the specified torque. This will ensure

that the wheels are thoroughly mated.²Check lug nut specified torque after 100 miles

(160 kilometers). Also after 500 miles (800 kilome-

ters) of vehicle operation.

NOTE: Wheel lug nuts should be tightened to spec-

ified torque at every maintenance interval thereafter.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lug Nut

BR1500 (5 Stud Wheel)130 95 Ð

Lug Nut

BR2500 (8 Stud Wheel)180 135 Ð

Lug Nut

BR3500 (8 Stud Dual

Wheel)195 145 Ð

Fig. 20 Oil Location

1 - PLACE TWO DROPS OF OIL HERE

BR/BETIRES/WHEELS 22 - 11

WHEELS (Continued)

Page 2634 of 2889

TORQUE SPECIFICATIONS

BODY COMPONENTS

Description N´m Ft.

lbs.In. lbs.

Bench seat front anchor

bolt54 40 Ð

Bench seat rear inboard

anchor nut40 30 Ð

Bench seat rear outboard

anchor nut54 40 Ð

Bench seat, rear seat

track to frame bolt25 18 Ð

Bench seat, front seat

track to frame bolt25 18 Ð

Bench seat, inboard

belt/buckle anchor bolt40 30 Ð

Bench seat back to

cushion pivot bolt25 18 Ð

Bench seat slider bolts 10 7 Ð

Cab mounting bolt 81 60 Ð

Front shoulder belt upper

anchor bolt39 28 Ð

Front belt buckle inboard

anchor nut45 33 Ð

Front belt retractor

anchor bolt39 28 Ð

Front shoulder belt lower

anchor bolt39 28 Ð

Front shoulder belt lower

anchor bolt45 33 Ð

Door hinge to A-pillar bolt 28 21 Ð

Door latch screw 11 8 Ð

Door latch striker screw 28 21 Ð

Door glass to lift plate

screw97Ð

Sliding backlite

latch/keeper screws1.5 Ð 15

Split bench seat front

anchor bolt54 40 Ð

Split bench seat rear

inboard anchor nut40 30 Ð

Split bench seat rear

outboard anchor nut54 40 Ð

Split bench seat track to

frame bolt25 18 Ð

Split bench seat back to

cushion pivot bolt25 18 Ð

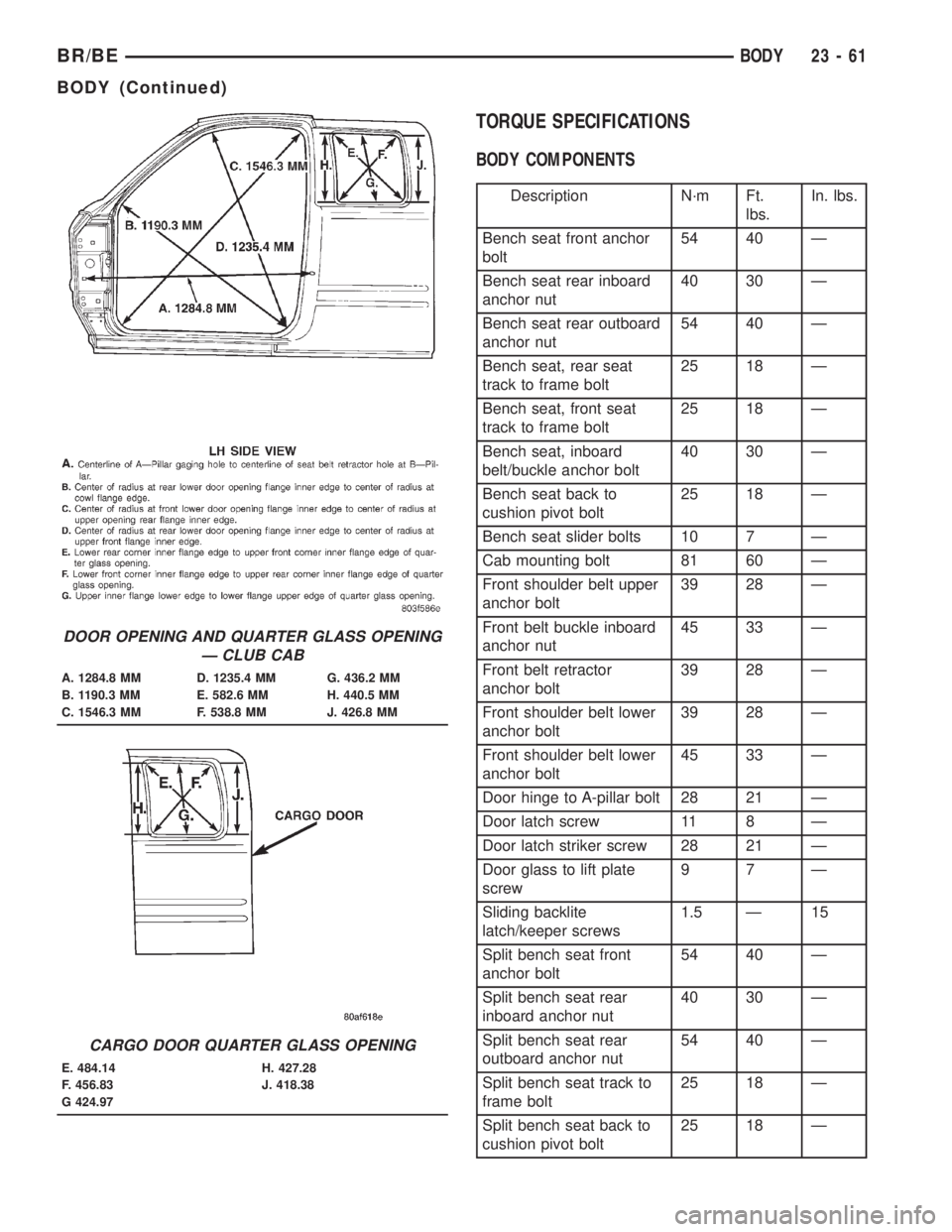

DOOR OPENING AND QUARTER GLASS OPENING

Ð CLUB CAB

A. 1284.8 MM D. 1235.4 MM G. 436.2 MM

B. 1190.3 MM E. 582.6 MM H. 440.5 MM

C. 1546.3 MM F. 538.8 MM J. 426.8 MM

CARGO DOOR QUARTER GLASS OPENING

E. 484.14 H. 427.28

F. 456.83 J. 418.38

G 424.97

BR/BEBODY 23 - 61

BODY (Continued)

Page 2641 of 2889

(15) Install outer belt weatherstrip (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR OUTER BELT

WEATHERSTRIP - INSTALLATION).

(16) Install glass run weatherstrip (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR GLASS RUN

WEATHERSTRIP - INSTALLATION).

DOOR

REMOVAL

(1) Remove cowl trim panel (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - REMOVAL).

(2) Disengage door wire harness connector of

instrument panel harness and push door harness

through access hole in pillar.

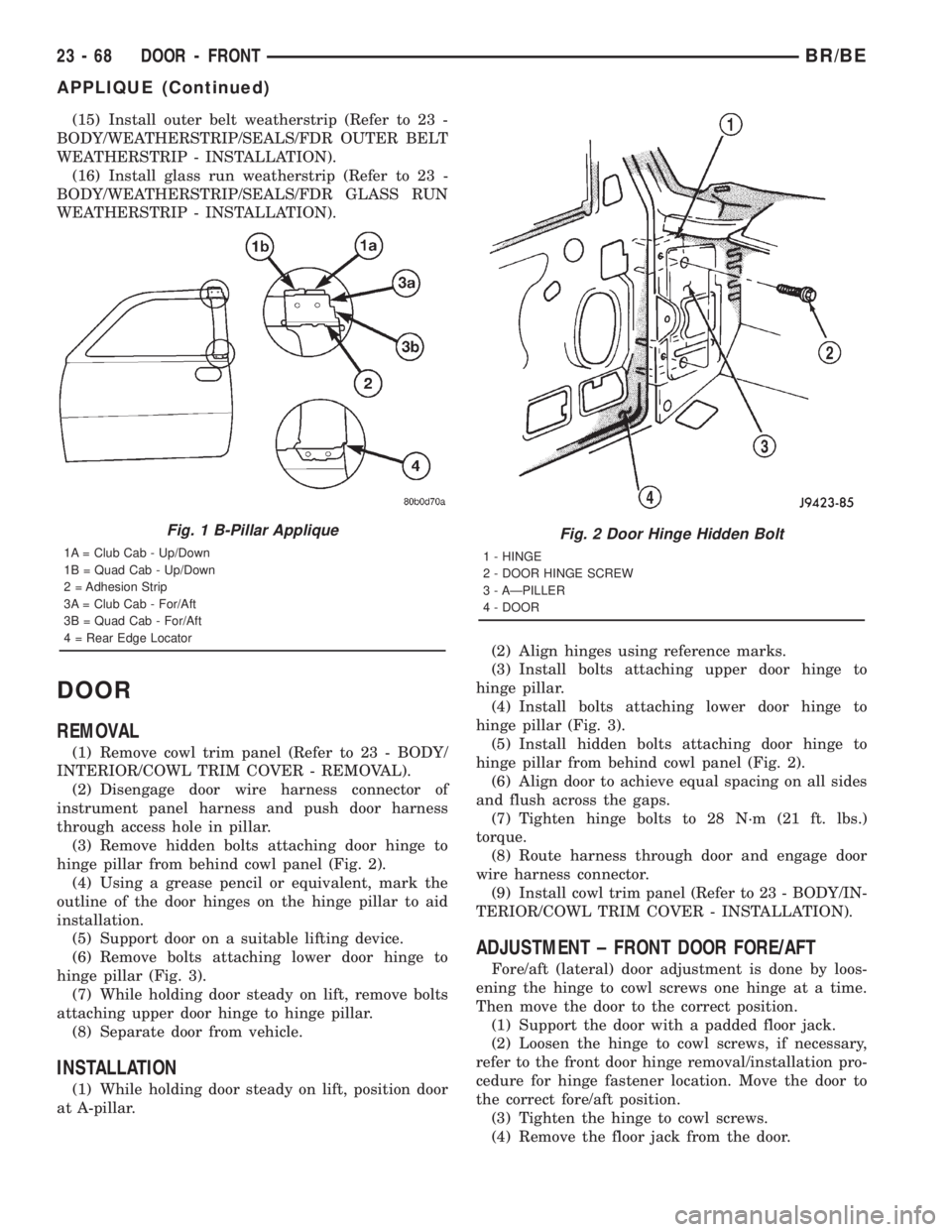

(3) Remove hidden bolts attaching door hinge to

hinge pillar from behind cowl panel (Fig. 2).

(4) Using a grease pencil or equivalent, mark the

outline of the door hinges on the hinge pillar to aid

installation.

(5) Support door on a suitable lifting device.

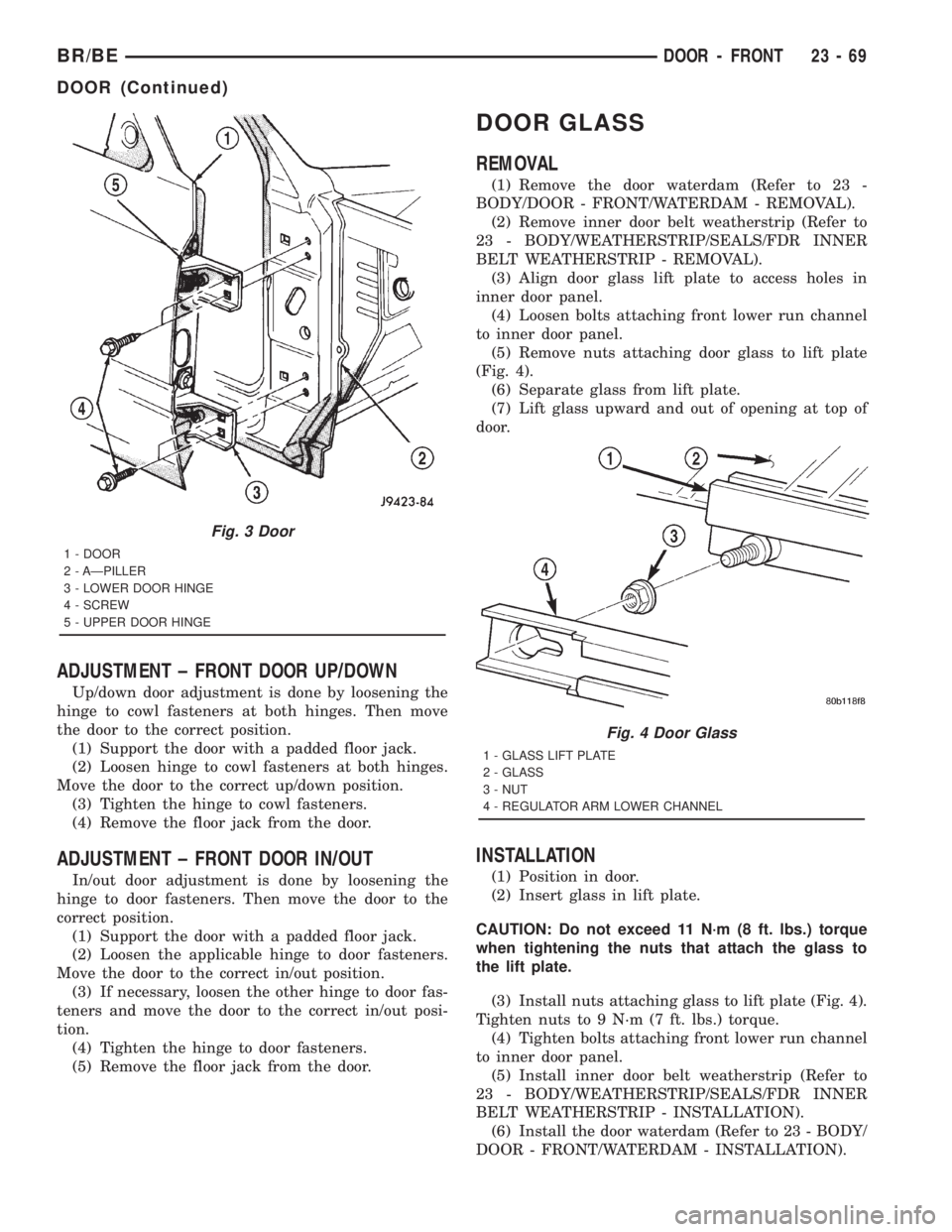

(6) Remove bolts attaching lower door hinge to

hinge pillar (Fig. 3).

(7) While holding door steady on lift, remove bolts

attaching upper door hinge to hinge pillar.

(8) Separate door from vehicle.

INSTALLATION

(1) While holding door steady on lift, position door

at A-pillar.(2) Align hinges using reference marks.

(3) Install bolts attaching upper door hinge to

hinge pillar.

(4) Install bolts attaching lower door hinge to

hinge pillar (Fig. 3).

(5) Install hidden bolts attaching door hinge to

hinge pillar from behind cowl panel (Fig. 2).

(6) Align door to achieve equal spacing on all sides

and flush across the gaps.

(7) Tighten hinge bolts to 28 N´m (21 ft. lbs.)

torque.

(8) Route harness through door and engage door

wire harness connector.

(9) Install cowl trim panel (Refer to 23 - BODY/IN-

TERIOR/COWL TRIM COVER - INSTALLATION).

ADJUSTMENT ± FRONT DOOR FORE/AFT

Fore/aft (lateral) door adjustment is done by loos-

ening the hinge to cowl screws one hinge at a time.

Then move the door to the correct position.

(1) Support the door with a padded floor jack.

(2) Loosen the hinge to cowl screws, if necessary,

refer to the front door hinge removal/installation pro-

cedure for hinge fastener location. Move the door to

the correct fore/aft position.

(3) Tighten the hinge to cowl screws.

(4) Remove the floor jack from the door.

Fig. 1 B-Pillar Applique

1A = Club Cab - Up/Down

1B = Quad Cab - Up/Down

2 = Adhesion Strip

3A = Club Cab - For/Aft

3B = Quad Cab - For/Aft

4 = Rear Edge Locator

Fig. 2 Door Hinge Hidden Bolt

1 - HINGE

2 - DOOR HINGE SCREW

3 - AÐPILLER

4 - DOOR

23 - 68 DOOR - FRONTBR/BE

APPLIQUE (Continued)

Page 2642 of 2889

ADJUSTMENT ± FRONT DOOR UP/DOWN

Up/down door adjustment is done by loosening the

hinge to cowl fasteners at both hinges. Then move

the door to the correct position.

(1) Support the door with a padded floor jack.

(2) Loosen hinge to cowl fasteners at both hinges.

Move the door to the correct up/down position.

(3) Tighten the hinge to cowl fasteners.

(4) Remove the floor jack from the door.

ADJUSTMENT ± FRONT DOOR IN/OUT

In/out door adjustment is done by loosening the

hinge to door fasteners. Then move the door to the

correct position.

(1) Support the door with a padded floor jack.

(2) Loosen the applicable hinge to door fasteners.

Move the door to the correct in/out position.

(3) If necessary, loosen the other hinge to door fas-

teners and move the door to the correct in/out posi-

tion.

(4) Tighten the hinge to door fasteners.

(5) Remove the floor jack from the door.

DOOR GLASS

REMOVAL

(1) Remove the door waterdam (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Remove inner door belt weatherstrip (Refer to

23 - BODY/WEATHERSTRIP/SEALS/FDR INNER

BELT WEATHERSTRIP - REMOVAL).

(3) Align door glass lift plate to access holes in

inner door panel.

(4) Loosen bolts attaching front lower run channel

to inner door panel.

(5) Remove nuts attaching door glass to lift plate

(Fig. 4).

(6) Separate glass from lift plate.

(7) Lift glass upward and out of opening at top of

door.

INSTALLATION

(1) Position in door.

(2) Insert glass in lift plate.

CAUTION: Do not exceed 11 N´m (8 ft. lbs.) torque

when tightening the nuts that attach the glass to

the lift plate.

(3) Install nuts attaching glass to lift plate (Fig. 4).

Tighten nuts to 9 N´m (7 ft. lbs.) torque.

(4) Tighten bolts attaching front lower run channel

to inner door panel.

(5) Install inner door belt weatherstrip (Refer to

23 - BODY/WEATHERSTRIP/SEALS/FDR INNER

BELT WEATHERSTRIP - INSTALLATION).

(6) Install the door waterdam (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION).

Fig. 3 Door

1 - DOOR

2 - AÐPILLER

3 - LOWER DOOR HINGE

4 - SCREW

5 - UPPER DOOR HINGE

Fig. 4 Door Glass

1 - GLASS LIFT PLATE

2 - GLASS

3 - NUT

4 - REGULATOR ARM LOWER CHANNEL

BR/BEDOOR - FRONT 23 - 69

DOOR (Continued)

Page 2644 of 2889

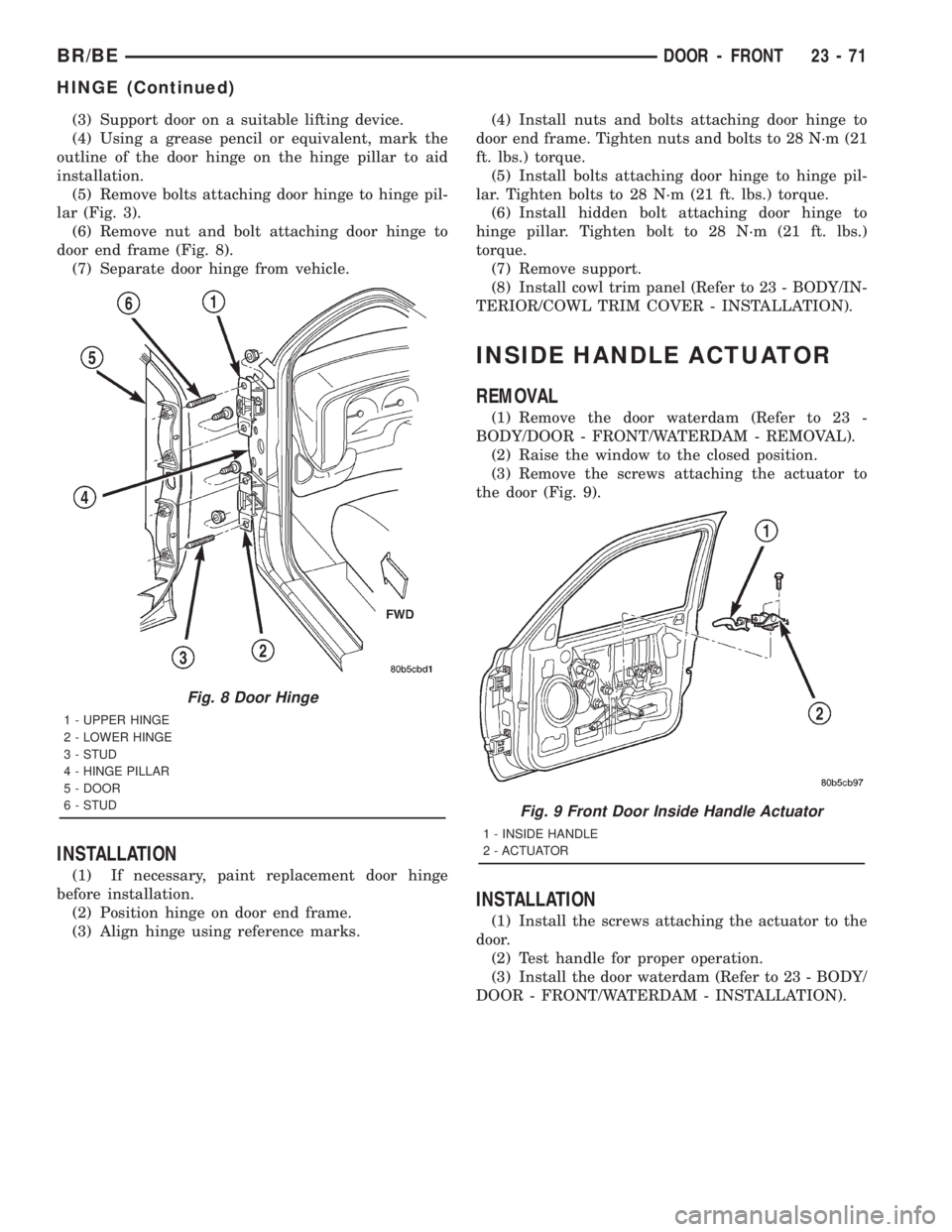

(3) Support door on a suitable lifting device.

(4) Using a grease pencil or equivalent, mark the

outline of the door hinge on the hinge pillar to aid

installation.

(5) Remove bolts attaching door hinge to hinge pil-

lar (Fig. 3).

(6) Remove nut and bolt attaching door hinge to

door end frame (Fig. 8).

(7) Separate door hinge from vehicle.

INSTALLATION

(1) If necessary, paint replacement door hinge

before installation.

(2) Position hinge on door end frame.

(3) Align hinge using reference marks.(4) Install nuts and bolts attaching door hinge to

door end frame. Tighten nuts and bolts to 28 N´m (21

ft. lbs.) torque.

(5) Install bolts attaching door hinge to hinge pil-

lar. Tighten bolts to 28 N´m (21 ft. lbs.) torque.

(6) Install hidden bolt attaching door hinge to

hinge pillar. Tighten bolt to 28 N´m (21 ft. lbs.)

torque.

(7) Remove support.

(8) Install cowl trim panel (Refer to 23 - BODY/IN-

TERIOR/COWL TRIM COVER - INSTALLATION).

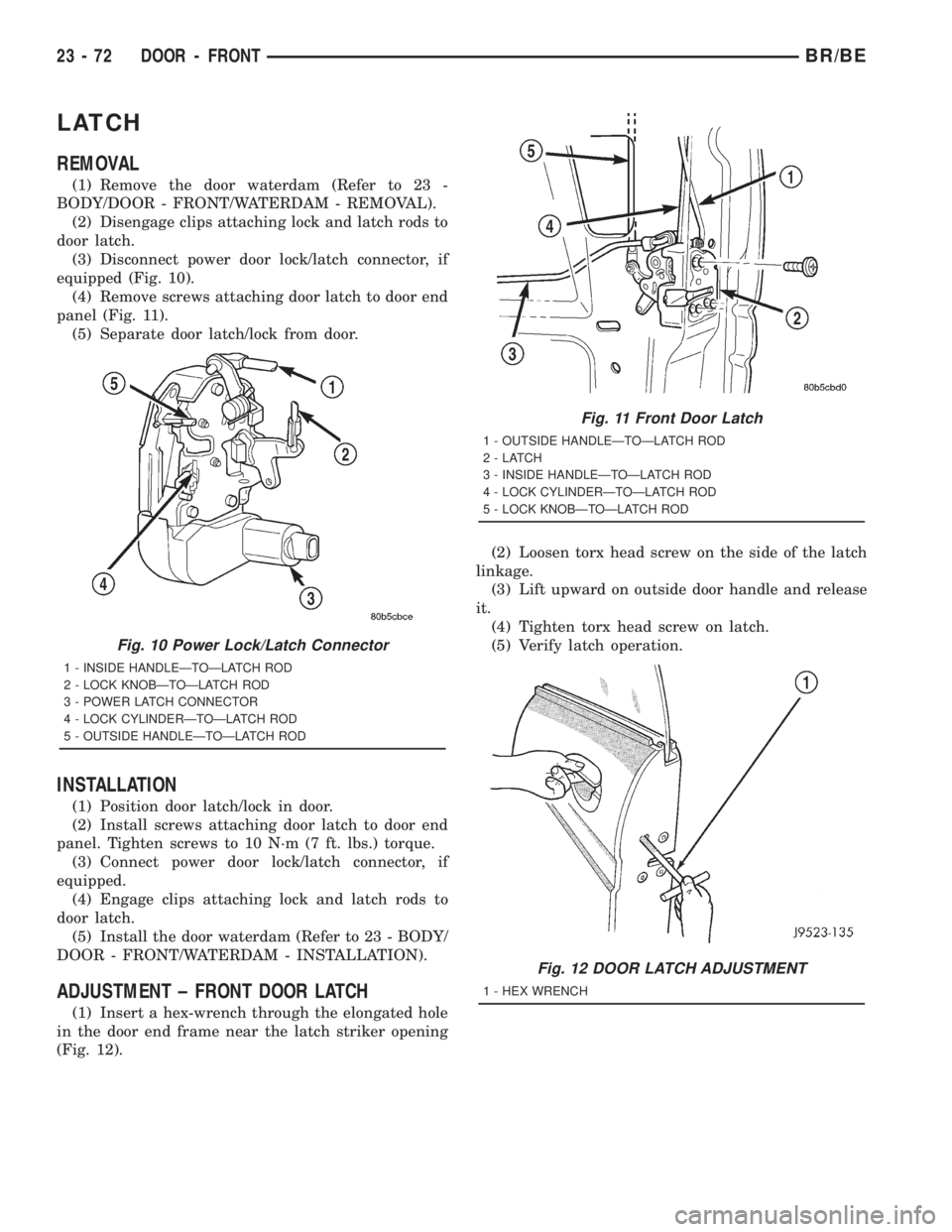

INSIDE HANDLE ACTUATOR

REMOVAL

(1) Remove the door waterdam (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Raise the window to the closed position.

(3) Remove the screws attaching the actuator to

the door (Fig. 9).

INSTALLATION

(1) Install the screws attaching the actuator to the

door.

(2) Test handle for proper operation.

(3) Install the door waterdam (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION).

Fig. 8 Door Hinge

1 - UPPER HINGE

2 - LOWER HINGE

3 - STUD

4 - HINGE PILLAR

5 - DOOR

6 - STUD

Fig. 9 Front Door Inside Handle Actuator

1 - INSIDE HANDLE

2 - ACTUATOR

BR/BEDOOR - FRONT 23 - 71

HINGE (Continued)

Page 2645 of 2889

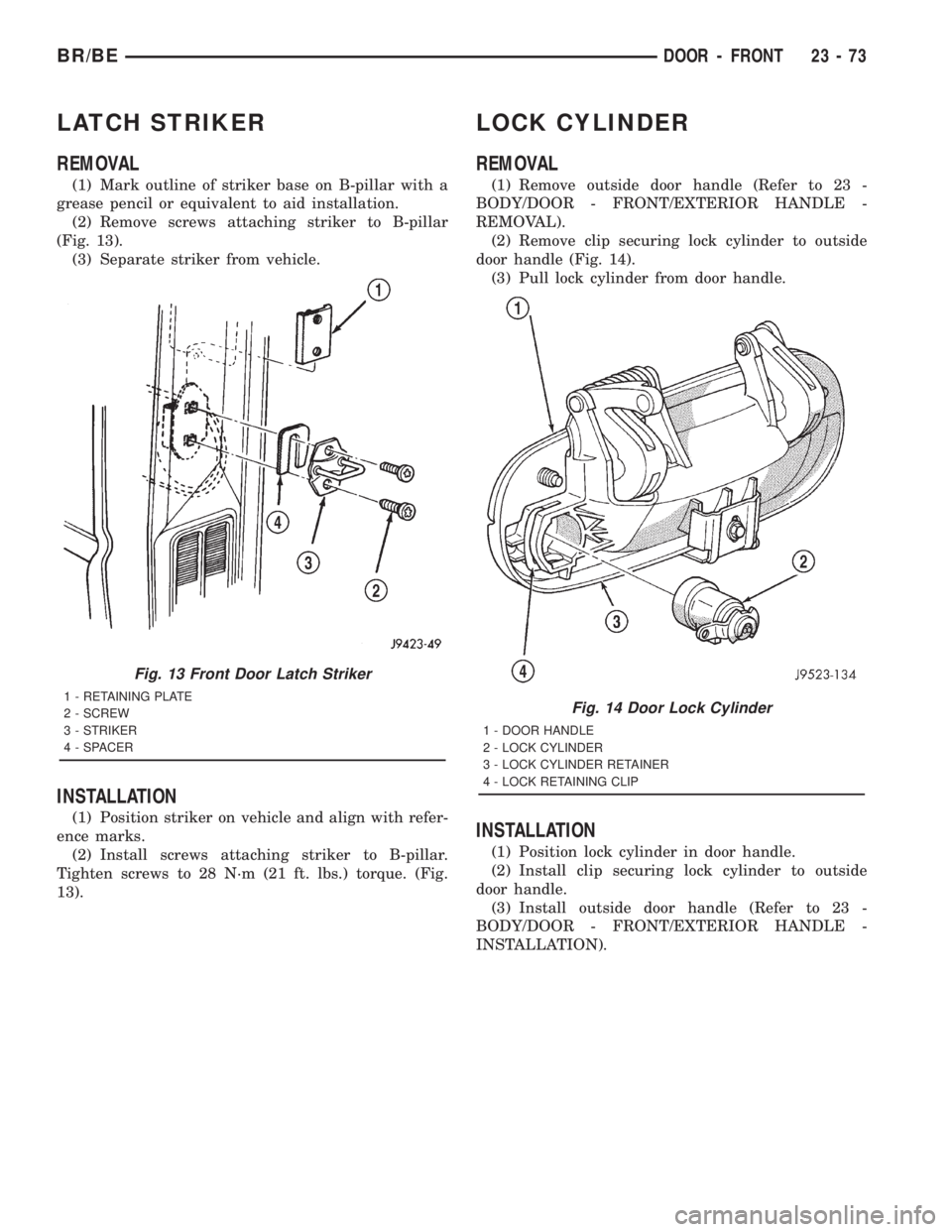

LATCH

REMOVAL

(1) Remove the door waterdam (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Disengage clips attaching lock and latch rods to

door latch.

(3) Disconnect power door lock/latch connector, if

equipped (Fig. 10).

(4) Remove screws attaching door latch to door end

panel (Fig. 11).

(5) Separate door latch/lock from door.

INSTALLATION

(1) Position door latch/lock in door.

(2) Install screws attaching door latch to door end

panel. Tighten screws to 10 N´m (7 ft. lbs.) torque.

(3) Connect power door lock/latch connector, if

equipped.

(4) Engage clips attaching lock and latch rods to

door latch.

(5) Install the door waterdam (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION).

ADJUSTMENT ± FRONT DOOR LATCH

(1) Insert a hex-wrench through the elongated hole

in the door end frame near the latch striker opening

(Fig. 12).(2) Loosen torx head screw on the side of the latch

linkage.

(3) Lift upward on outside door handle and release

it.

(4) Tighten torx head screw on latch.

(5) Verify latch operation.

Fig. 10 Power Lock/Latch Connector

1 - INSIDE HANDLEÐTOÐLATCH ROD

2 - LOCK KNOBÐTOÐLATCH ROD

3 - POWER LATCH CONNECTOR

4 - LOCK CYLINDERÐTOÐLATCH ROD

5 - OUTSIDE HANDLEÐTOÐLATCH ROD

Fig. 11 Front Door Latch

1 - OUTSIDE HANDLEÐTOÐLATCH ROD

2-LATCH

3 - INSIDE HANDLEÐTOÐLATCH ROD

4 - LOCK CYLINDERÐTOÐLATCH ROD

5 - LOCK KNOBÐTOÐLATCH ROD

Fig. 12 DOOR LATCH ADJUSTMENT

1 - HEX WRENCH

23 - 72 DOOR - FRONTBR/BE

Page 2646 of 2889

LATCH STRIKER

REMOVAL

(1) Mark outline of striker base on B-pillar with a

grease pencil or equivalent to aid installation.

(2) Remove screws attaching striker to B-pillar

(Fig. 13).

(3) Separate striker from vehicle.

INSTALLATION

(1) Position striker on vehicle and align with refer-

ence marks.

(2) Install screws attaching striker to B-pillar.

Tighten screws to 28 N´m (21 ft. lbs.) torque. (Fig.

13).

LOCK CYLINDER

REMOVAL

(1) Remove outside door handle (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

REMOVAL).

(2) Remove clip securing lock cylinder to outside

door handle (Fig. 14).

(3) Pull lock cylinder from door handle.

INSTALLATION

(1) Position lock cylinder in door handle.

(2) Install clip securing lock cylinder to outside

door handle.

(3) Install outside door handle (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

INSTALLATION).

Fig. 13 Front Door Latch Striker

1 - RETAINING PLATE

2 - SCREW

3 - STRIKER

4 - SPACERFig. 14 Door Lock Cylinder

1 - DOOR HANDLE

2 - LOCK CYLINDER

3 - LOCK CYLINDER RETAINER

4 - LOCK RETAINING CLIP

BR/BEDOOR - FRONT 23 - 73

Page 2651 of 2889

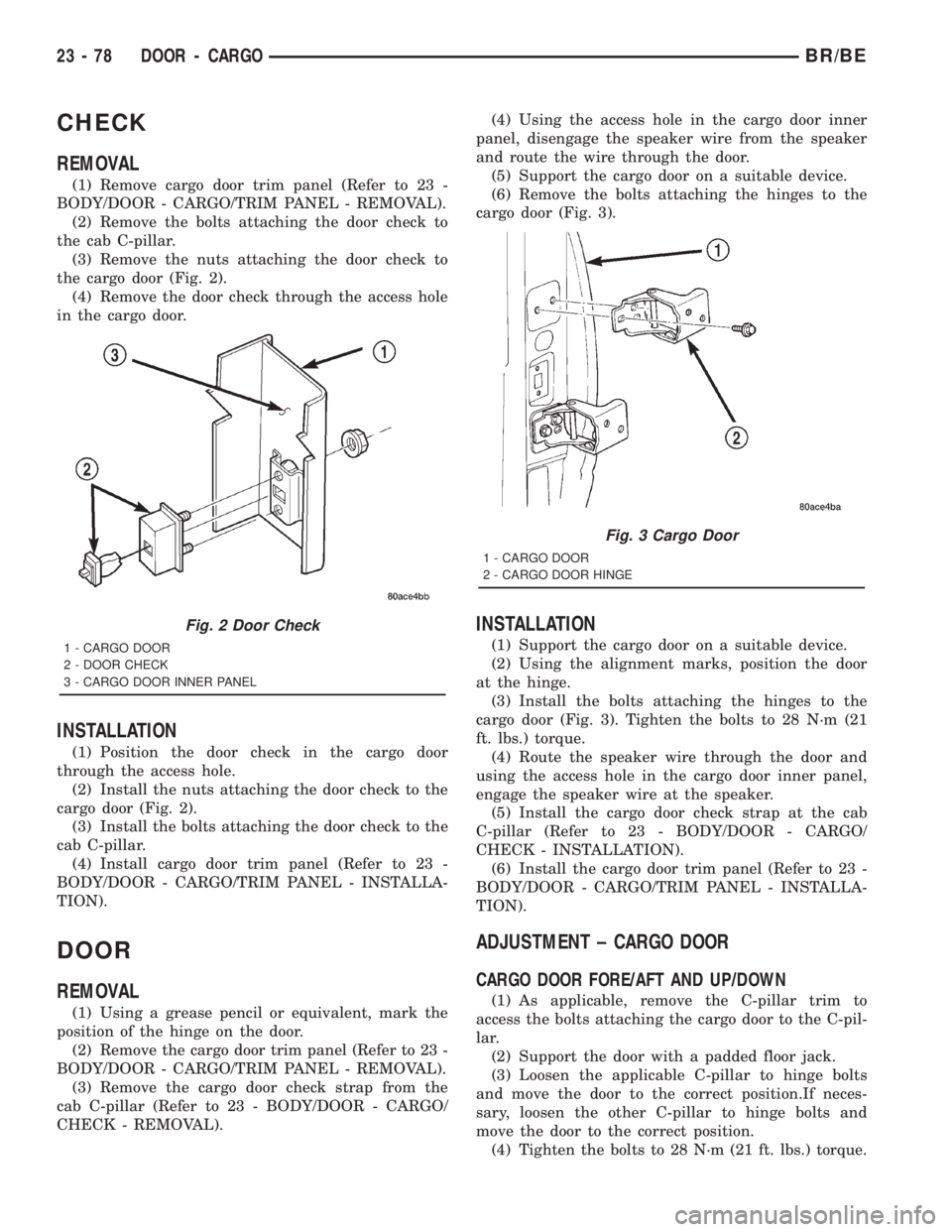

CHECK

REMOVAL

(1) Remove cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - REMOVAL).

(2) Remove the bolts attaching the door check to

the cab C-pillar.

(3) Remove the nuts attaching the door check to

the cargo door (Fig. 2).

(4) Remove the door check through the access hole

in the cargo door.

INSTALLATION

(1) Position the door check in the cargo door

through the access hole.

(2) Install the nuts attaching the door check to the

cargo door (Fig. 2).

(3) Install the bolts attaching the door check to the

cab C-pillar.

(4) Install cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - INSTALLA-

TION).

DOOR

REMOVAL

(1) Using a grease pencil or equivalent, mark the

position of the hinge on the door.

(2) Remove the cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - REMOVAL).

(3) Remove the cargo door check strap from the

cab C-pillar (Refer to 23 - BODY/DOOR - CARGO/

CHECK - REMOVAL).(4) Using the access hole in the cargo door inner

panel, disengage the speaker wire from the speaker

and route the wire through the door.

(5) Support the cargo door on a suitable device.

(6) Remove the bolts attaching the hinges to the

cargo door (Fig. 3).

INSTALLATION

(1) Support the cargo door on a suitable device.

(2) Using the alignment marks, position the door

at the hinge.

(3) Install the bolts attaching the hinges to the

cargo door (Fig. 3). Tighten the bolts to 28 N´m (21

ft. lbs.) torque.

(4) Route the speaker wire through the door and

using the access hole in the cargo door inner panel,

engage the speaker wire at the speaker.

(5) Install the cargo door check strap at the cab

C-pillar (Refer to 23 - BODY/DOOR - CARGO/

CHECK - INSTALLATION).

(6) Install the cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - INSTALLA-

TION).

ADJUSTMENT ± CARGO DOOR

CARGO DOOR FORE/AFT AND UP/DOWN

(1) As applicable, remove the C-pillar trim to

access the bolts attaching the cargo door to the C-pil-

lar.

(2) Support the door with a padded floor jack.

(3) Loosen the applicable C-pillar to hinge bolts

and move the door to the correct position.If neces-

sary, loosen the other C-pillar to hinge bolts and

move the door to the correct position.

(4) Tighten the bolts to 28 N´m (21 ft. lbs.) torque.

Fig. 2 Door Check

1 - CARGO DOOR

2 - DOOR CHECK

3 - CARGO DOOR INNER PANEL

Fig. 3 Cargo Door

1 - CARGO DOOR

2 - CARGO DOOR HINGE

23 - 78 DOOR - CARGOBR/BE

Page 2652 of 2889

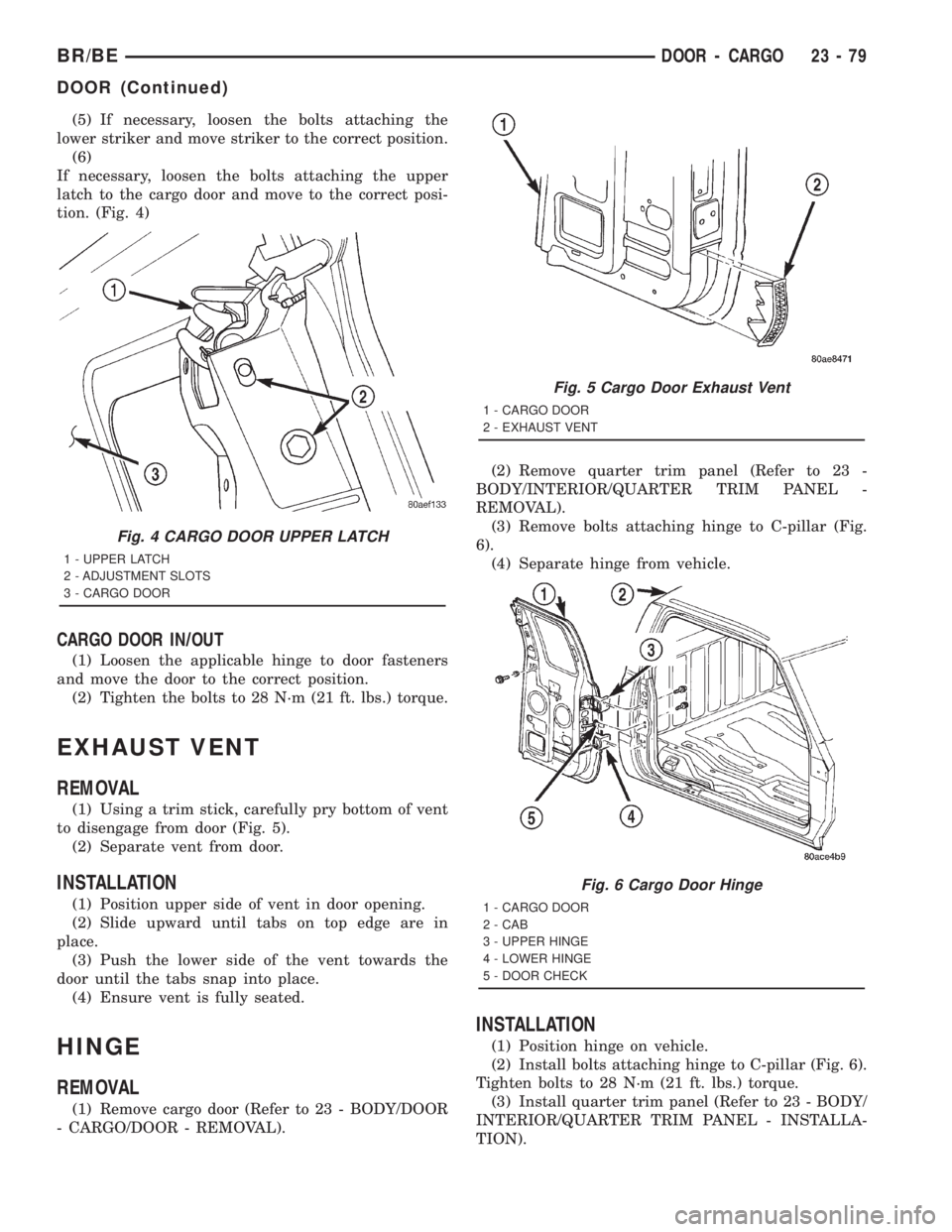

(5) If necessary, loosen the bolts attaching the

lower striker and move striker to the correct position.

(6)

If necessary, loosen the bolts attaching the upper

latch to the cargo door and move to the correct posi-

tion. (Fig. 4)

CARGO DOOR IN/OUT

(1) Loosen the applicable hinge to door fasteners

and move the door to the correct position.

(2) Tighten the bolts to 28 N´m (21 ft. lbs.) torque.

EXHAUST VENT

REMOVAL

(1) Using a trim stick, carefully pry bottom of vent

to disengage from door (Fig. 5).

(2) Separate vent from door.

INSTALLATION

(1) Position upper side of vent in door opening.

(2) Slide upward until tabs on top edge are in

place.

(3) Push the lower side of the vent towards the

door until the tabs snap into place.

(4) Ensure vent is fully seated.

HINGE

REMOVAL

(1) Remove cargo door (Refer to 23 - BODY/DOOR

- CARGO/DOOR - REMOVAL).(2) Remove quarter trim panel (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL).

(3) Remove bolts attaching hinge to C-pillar (Fig.

6).

(4) Separate hinge from vehicle.

INSTALLATION

(1) Position hinge on vehicle.

(2) Install bolts attaching hinge to C-pillar (Fig. 6).

Tighten bolts to 28 N´m (21 ft. lbs.) torque.

(3) Install quarter trim panel (Refer to 23 - BODY/

INTERIOR/QUARTER TRIM PANEL - INSTALLA-

TION).

Fig. 4 CARGO DOOR UPPER LATCH

1 - UPPER LATCH

2 - ADJUSTMENT SLOTS

3 - CARGO DOOR

Fig. 5 Cargo Door Exhaust Vent

1 - CARGO DOOR

2 - EXHAUST VENT

Fig. 6 Cargo Door Hinge

1 - CARGO DOOR

2 - CAB

3 - UPPER HINGE

4 - LOWER HINGE

5 - DOOR CHECK

BR/BEDOOR - CARGO 23 - 79

DOOR (Continued)

Page 2653 of 2889

(4) Install cargo door (Refer to 23 - BODY/DOOR -

CARGO/DOOR - INSTALLATION).

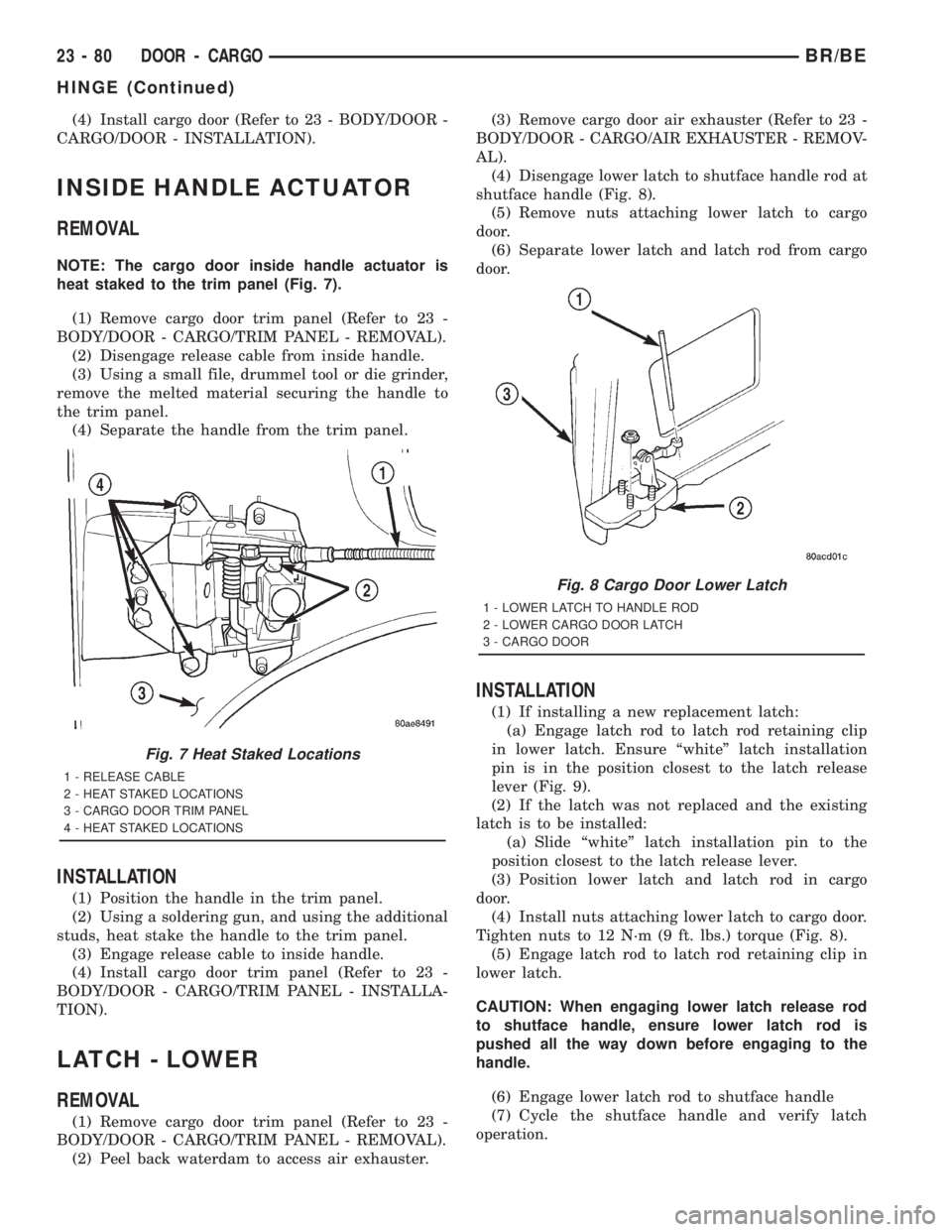

INSIDE HANDLE ACTUATOR

REMOVAL

NOTE: The cargo door inside handle actuator is

heat staked to the trim panel (Fig. 7).

(1) Remove cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - REMOVAL).

(2) Disengage release cable from inside handle.

(3) Using a small file, drummel tool or die grinder,

remove the melted material securing the handle to

the trim panel.

(4) Separate the handle from the trim panel.

INSTALLATION

(1) Position the handle in the trim panel.

(2) Using a soldering gun, and using the additional

studs, heat stake the handle to the trim panel.

(3) Engage release cable to inside handle.

(4) Install cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - INSTALLA-

TION).

LATCH - LOWER

REMOVAL

(1) Remove cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - REMOVAL).

(2) Peel back waterdam to access air exhauster.(3) Remove cargo door air exhauster (Refer to 23 -

BODY/DOOR - CARGO/AIR EXHAUSTER - REMOV-

AL).

(4) Disengage lower latch to shutface handle rod at

shutface handle (Fig. 8).

(5) Remove nuts attaching lower latch to cargo

door.

(6) Separate lower latch and latch rod from cargo

door.

INSTALLATION

(1) If installing a new replacement latch:

(a) Engage latch rod to latch rod retaining clip

in lower latch. Ensure ªwhiteº latch installation

pin is in the position closest to the latch release

lever (Fig. 9).

(2) If the latch was not replaced and the existing

latch is to be installed:

(a) Slide ªwhiteº latch installation pin to the

position closest to the latch release lever.

(3) Position lower latch and latch rod in cargo

door.

(4) Install nuts attaching lower latch to cargo door.

Tighten nuts to 12 N´m (9 ft. lbs.) torque (Fig. 8).

(5) Engage latch rod to latch rod retaining clip in

lower latch.

CAUTION: When engaging lower latch release rod

to shutface handle, ensure lower latch rod is

pushed all the way down before engaging to the

handle.

(6) Engage lower latch rod to shutface handle

(7) Cycle the shutface handle and verify latch

operation.

Fig. 7 Heat Staked Locations

1 - RELEASE CABLE

2 - HEAT STAKED LOCATIONS

3 - CARGO DOOR TRIM PANEL

4 - HEAT STAKED LOCATIONS

Fig. 8 Cargo Door Lower Latch

1 - LOWER LATCH TO HANDLE ROD

2 - LOWER CARGO DOOR LATCH

3 - CARGO DOOR

23 - 80 DOOR - CARGOBR/BE

HINGE (Continued)