torque DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2473 of 2889

(8) Clean gasket sealer residue from retainer and

inspect retainer for cracks or other damage.

(9) Applya3mm(1/8 in.) bead of MopartGasket

Maker, or equivalent silicone adhesive, to sealing

surface of retainer.

(10) Align cavity in seal retainer with fluid return

hole in front of case.

CAUTION: Do not block fluid return cavity on seal-

ing surface of retainer when applying MoparTGas-

ket Maker, or equivalent silicone adhesive sealer.

Seal failure and fluid leak can result.

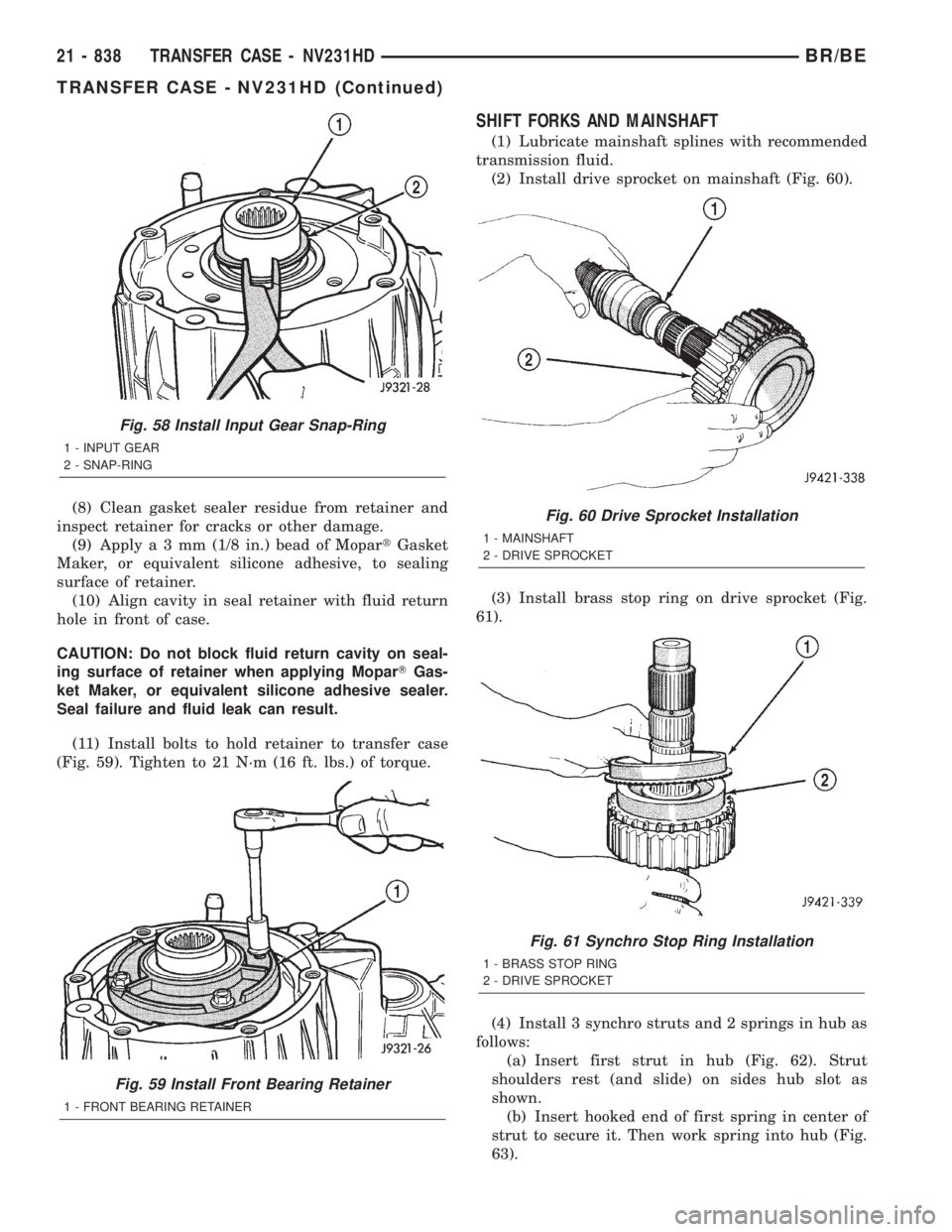

(11) Install bolts to hold retainer to transfer case

(Fig. 59). Tighten to 21 N´m (16 ft. lbs.) of torque.

SHIFT FORKS AND MAINSHAFT

(1) Lubricate mainshaft splines with recommended

transmission fluid.

(2) Install drive sprocket on mainshaft (Fig. 60).

(3) Install brass stop ring on drive sprocket (Fig.

61).

(4) Install 3 synchro struts and 2 springs in hub as

follows:

(a) Insert first strut in hub (Fig. 62). Strut

shoulders rest (and slide) on sides hub slot as

shown.

(b) Insert hooked end of first spring in center of

strut to secure it. Then work spring into hub (Fig.

63).

Fig. 58 Install Input Gear Snap-Ring

1 - INPUT GEAR

2 - SNAP-RING

Fig. 59 Install Front Bearing Retainer

1 - FRONT BEARING RETAINER

Fig. 60 Drive Sprocket Installation

1 - MAINSHAFT

2 - DRIVE SPROCKET

Fig. 61 Synchro Stop Ring Installation

1 - BRASS STOP RING

2 - DRIVE SPROCKET

21 - 838 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2477 of 2889

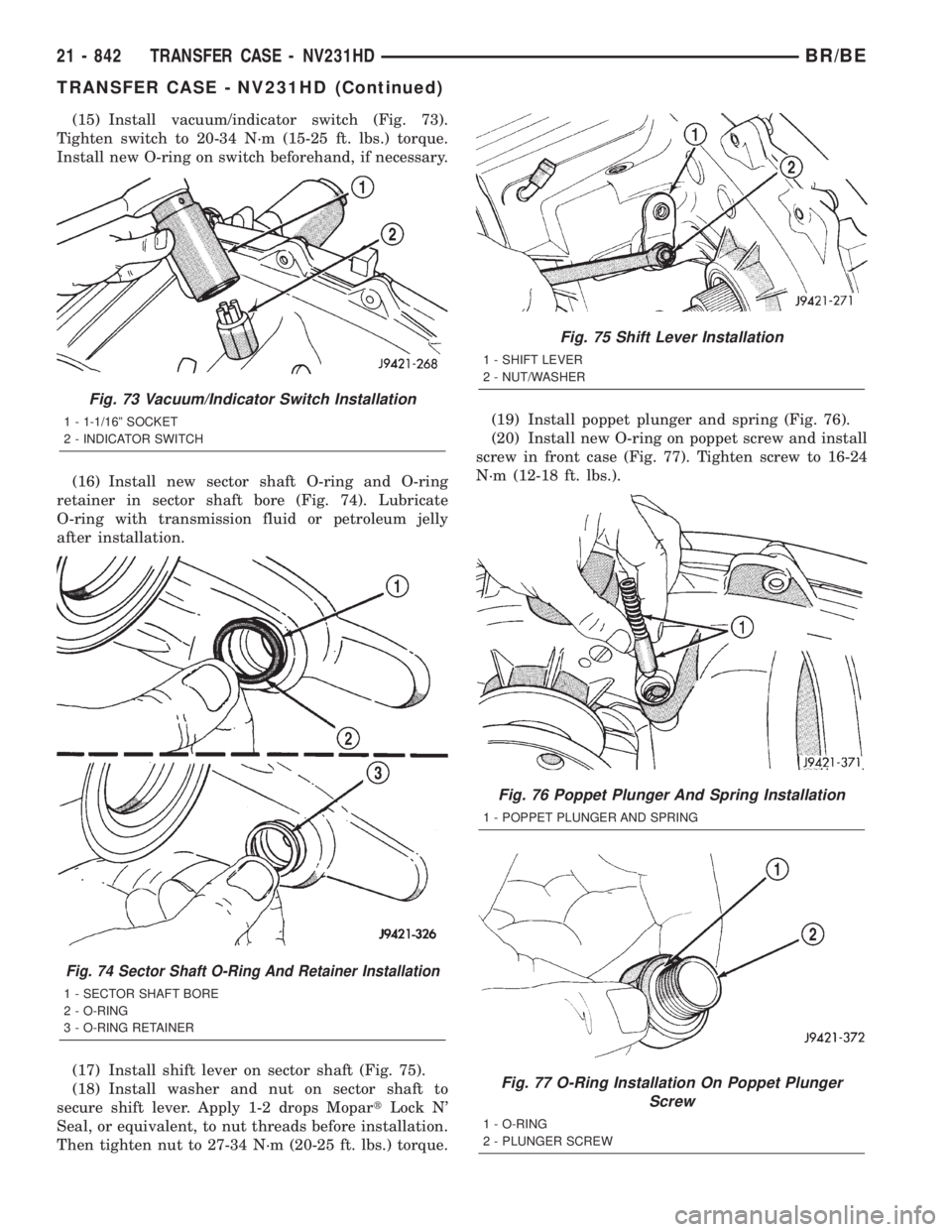

(15) Install vacuum/indicator switch (Fig. 73).

Tighten switch to 20-34 N´m (15-25 ft. lbs.) torque.

Install new O-ring on switch beforehand, if necessary.

(16) Install new sector shaft O-ring and O-ring

retainer in sector shaft bore (Fig. 74). Lubricate

O-ring with transmission fluid or petroleum jelly

after installation.

(17) Install shift lever on sector shaft (Fig. 75).

(18) Install washer and nut on sector shaft to

secure shift lever. Apply 1-2 drops MopartLock N'

Seal, or equivalent, to nut threads before installation.

Then tighten nut to 27-34 N´m (20-25 ft. lbs.) torque.(19) Install poppet plunger and spring (Fig. 76).

(20) Install new O-ring on poppet screw and install

screw in front case (Fig. 77). Tighten screw to 16-24

N´m (12-18 ft. lbs.).

Fig. 73 Vacuum/Indicator Switch Installation

1 - 1-1/16º SOCKET

2 - INDICATOR SWITCH

Fig. 74 Sector Shaft O-Ring And Retainer Installation

1 - SECTOR SHAFT BORE

2 - O-RING

3 - O-RING RETAINER

Fig. 75 Shift Lever Installation

1 - SHIFT LEVER

2 - NUT/WASHER

Fig. 76 Poppet Plunger And Spring Installation

1 - POPPET PLUNGER AND SPRING

Fig. 77 O-Ring Installation On Poppet Plunger

Screw

1 - O-RING

2 - PLUNGER SCREW

21 - 842 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2480 of 2889

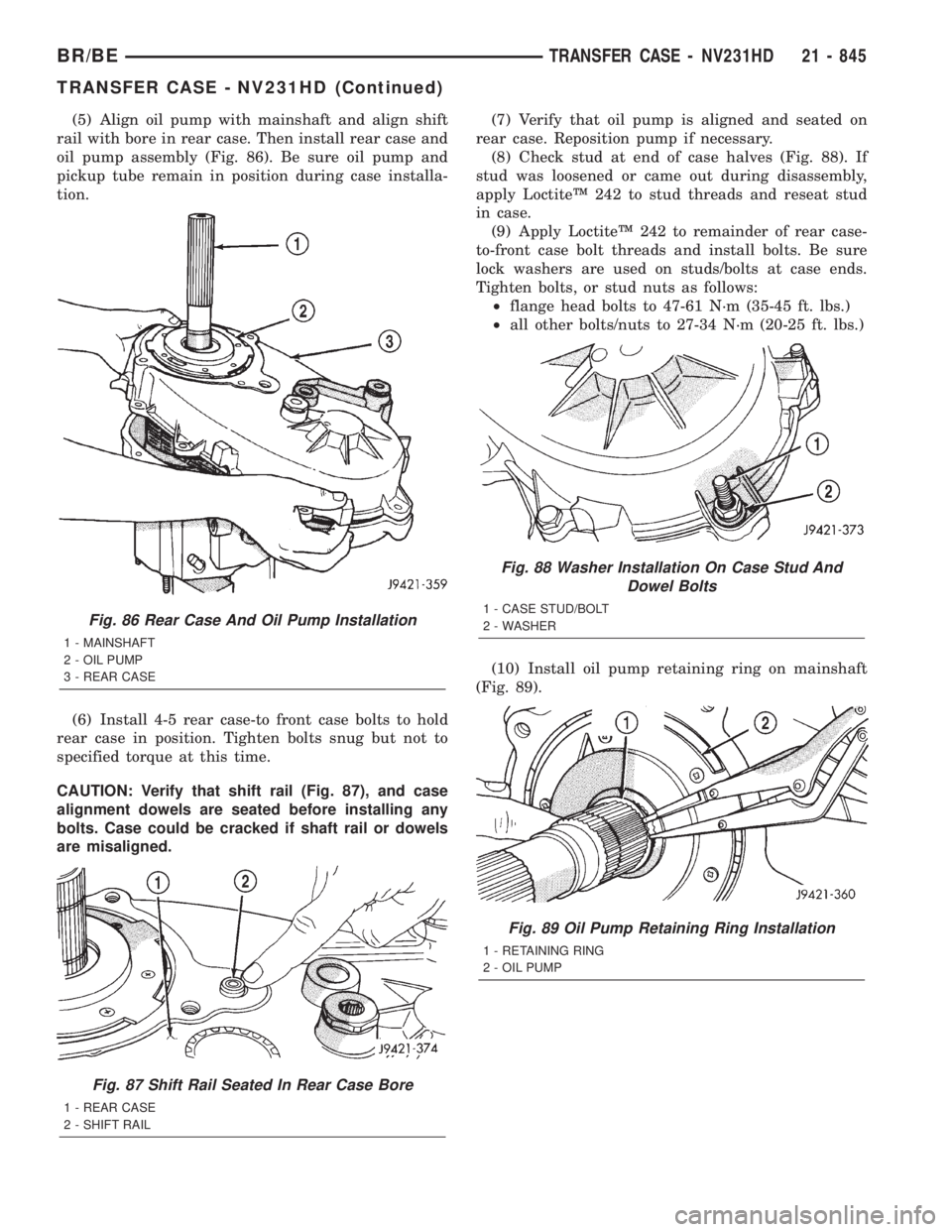

(5) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 86). Be sure oil pump and

pickup tube remain in position during case installa-

tion.

(6) Install 4-5 rear case-to front case bolts to hold

rear case in position. Tighten bolts snug but not to

specified torque at this time.

CAUTION: Verify that shift rail (Fig. 87), and case

alignment dowels are seated before installing any

bolts. Case could be cracked if shaft rail or dowels

are misaligned.(7) Verify that oil pump is aligned and seated on

rear case. Reposition pump if necessary.

(8) Check stud at end of case halves (Fig. 88). If

stud was loosened or came out during disassembly,

apply LoctiteŸ 242 to stud threads and reseat stud

in case.

(9) Apply LoctiteŸ 242 to remainder of rear case-

to-front case bolt threads and install bolts. Be sure

lock washers are used on studs/bolts at case ends.

Tighten bolts, or stud nuts as follows:

²flange head bolts to 47-61 N´m (35-45 ft. lbs.)

²all other bolts/nuts to 27-34 N´m (20-25 ft. lbs.)

(10) Install oil pump retaining ring on mainshaft

(Fig. 89).

Fig. 86 Rear Case And Oil Pump Installation

1 - MAINSHAFT

2 - OIL PUMP

3 - REAR CASE

Fig. 87 Shift Rail Seated In Rear Case Bore

1 - REAR CASE

2 - SHIFT RAIL

Fig. 88 Washer Installation On Case Stud And

Dowel Bolts

1 - CASE STUD/BOLT

2 - WASHER

Fig. 89 Oil Pump Retaining Ring Installation

1 - RETAINING RING

2 - OIL PUMP

BR/BETRANSFER CASE - NV231HD 21 - 845

TRANSFER CASE - NV231HD (Continued)

Page 2481 of 2889

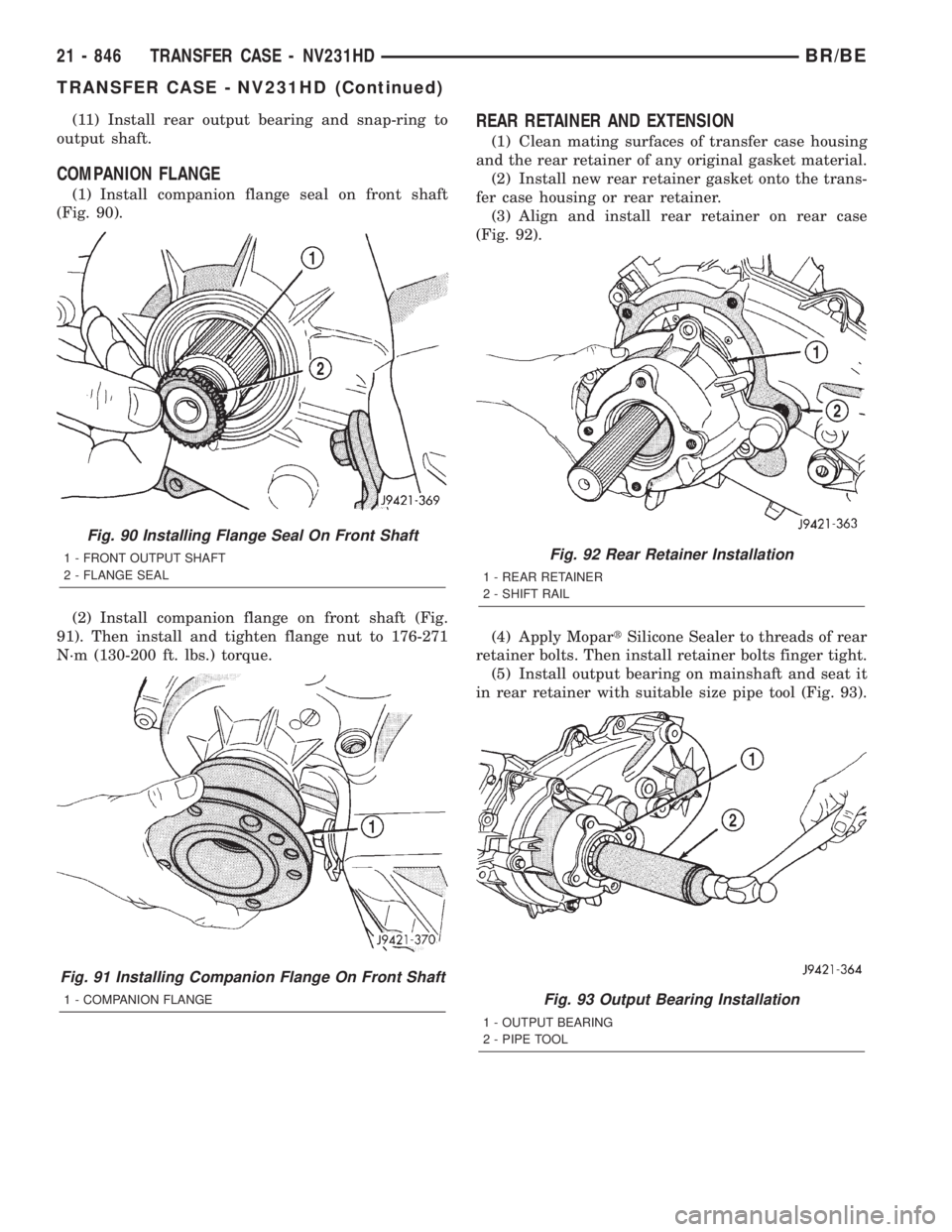

(11) Install rear output bearing and snap-ring to

output shaft.

COMPANION FLANGE

(1) Install companion flange seal on front shaft

(Fig. 90).

(2) Install companion flange on front shaft (Fig.

91). Then install and tighten flange nut to 176-271

N´m (130-200 ft. lbs.) torque.

REAR RETAINER AND EXTENSION

(1) Clean mating surfaces of transfer case housing

and the rear retainer of any original gasket material.

(2) Install new rear retainer gasket onto the trans-

fer case housing or rear retainer.

(3) Align and install rear retainer on rear case

(Fig. 92).

(4) Apply MopartSilicone Sealer to threads of rear

retainer bolts. Then install retainer bolts finger tight.

(5) Install output bearing on mainshaft and seat it

in rear retainer with suitable size pipe tool (Fig. 93).

Fig. 90 Installing Flange Seal On Front Shaft

1 - FRONT OUTPUT SHAFT

2 - FLANGE SEAL

Fig. 91 Installing Companion Flange On Front Shaft

1 - COMPANION FLANGE

Fig. 92 Rear Retainer Installation

1 - REAR RETAINER

2 - SHIFT RAIL

Fig. 93 Output Bearing Installation

1 - OUTPUT BEARING

2 - PIPE TOOL

21 - 846 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2482 of 2889

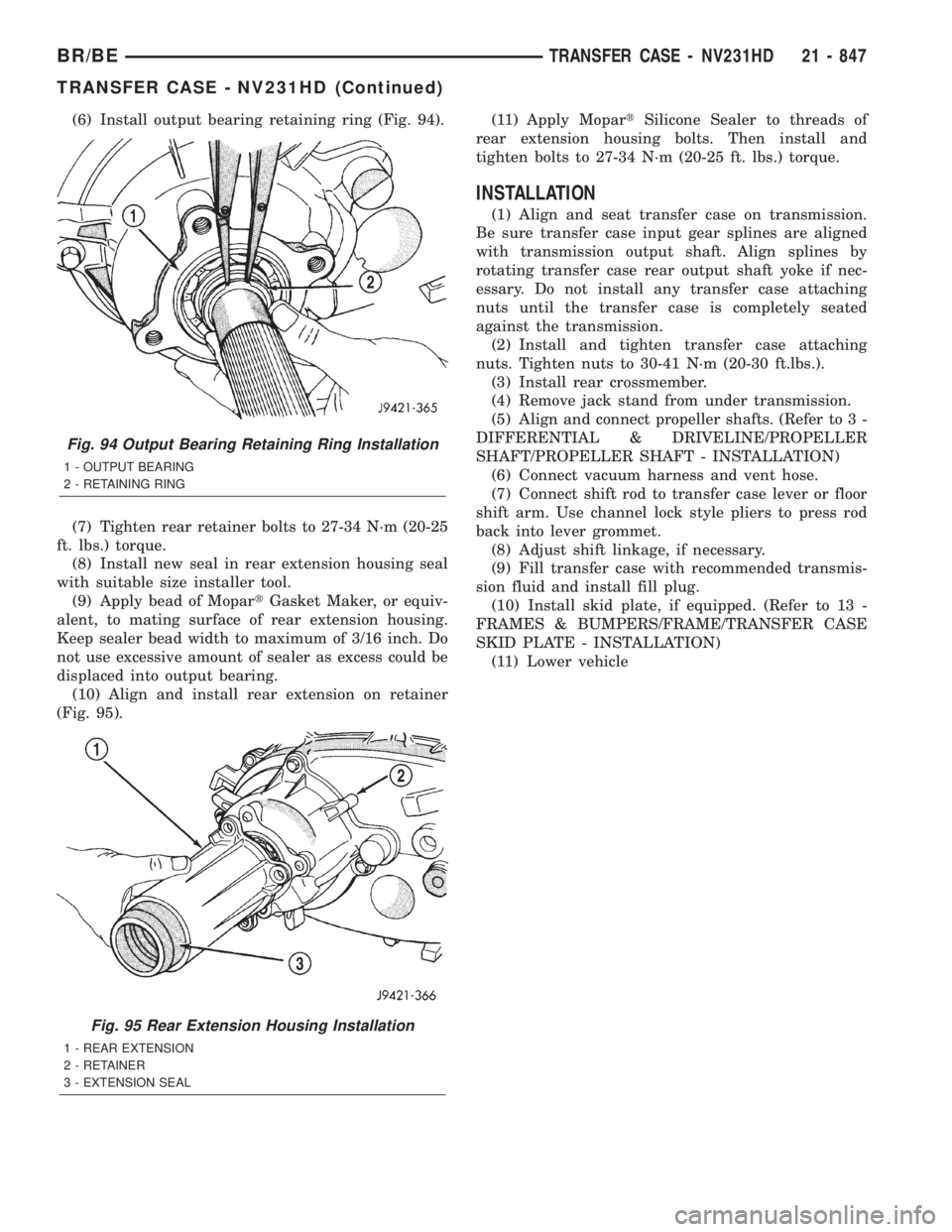

(6) Install output bearing retaining ring (Fig. 94).

(7) Tighten rear retainer bolts to 27-34 N´m (20-25

ft. lbs.) torque.

(8) Install new seal in rear extension housing seal

with suitable size installer tool.

(9) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of rear extension housing.

Keep sealer bead width to maximum of 3/16 inch. Do

not use excessive amount of sealer as excess could be

displaced into output bearing.

(10) Align and install rear extension on retainer

(Fig. 95).(11) Apply MopartSilicone Sealer to threads of

rear extension housing bolts. Then install and

tighten bolts to 27-34 N´m (20-25 ft. lbs.) torque.

INSTALLATION

(1) Align and seat transfer case on transmission.

Be sure transfer case input gear splines are aligned

with transmission output shaft. Align splines by

rotating transfer case rear output shaft yoke if nec-

essary. Do not install any transfer case attaching

nuts until the transfer case is completely seated

against the transmission.

(2) Install and tighten transfer case attaching

nuts. Tighten nuts to 30-41 N´m (20-30 ft.lbs.).

(3) Install rear crossmember.

(4) Remove jack stand from under transmission.

(5) Align and connect propeller shafts. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(6) Connect vacuum harness and vent hose.

(7) Connect shift rod to transfer case lever or floor

shift arm. Use channel lock style pliers to press rod

back into lever grommet.

(8) Adjust shift linkage, if necessary.

(9) Fill transfer case with recommended transmis-

sion fluid and install fill plug.

(10) Install skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

(11) Lower vehicle

Fig. 94 Output Bearing Retaining Ring Installation

1 - OUTPUT BEARING

2 - RETAINING RING

Fig. 95 Rear Extension Housing Installation

1 - REAR EXTENSION

2 - RETAINER

3 - EXTENSION SEAL

BR/BETRANSFER CASE - NV231HD 21 - 847

TRANSFER CASE - NV231HD (Continued)

Page 2483 of 2889

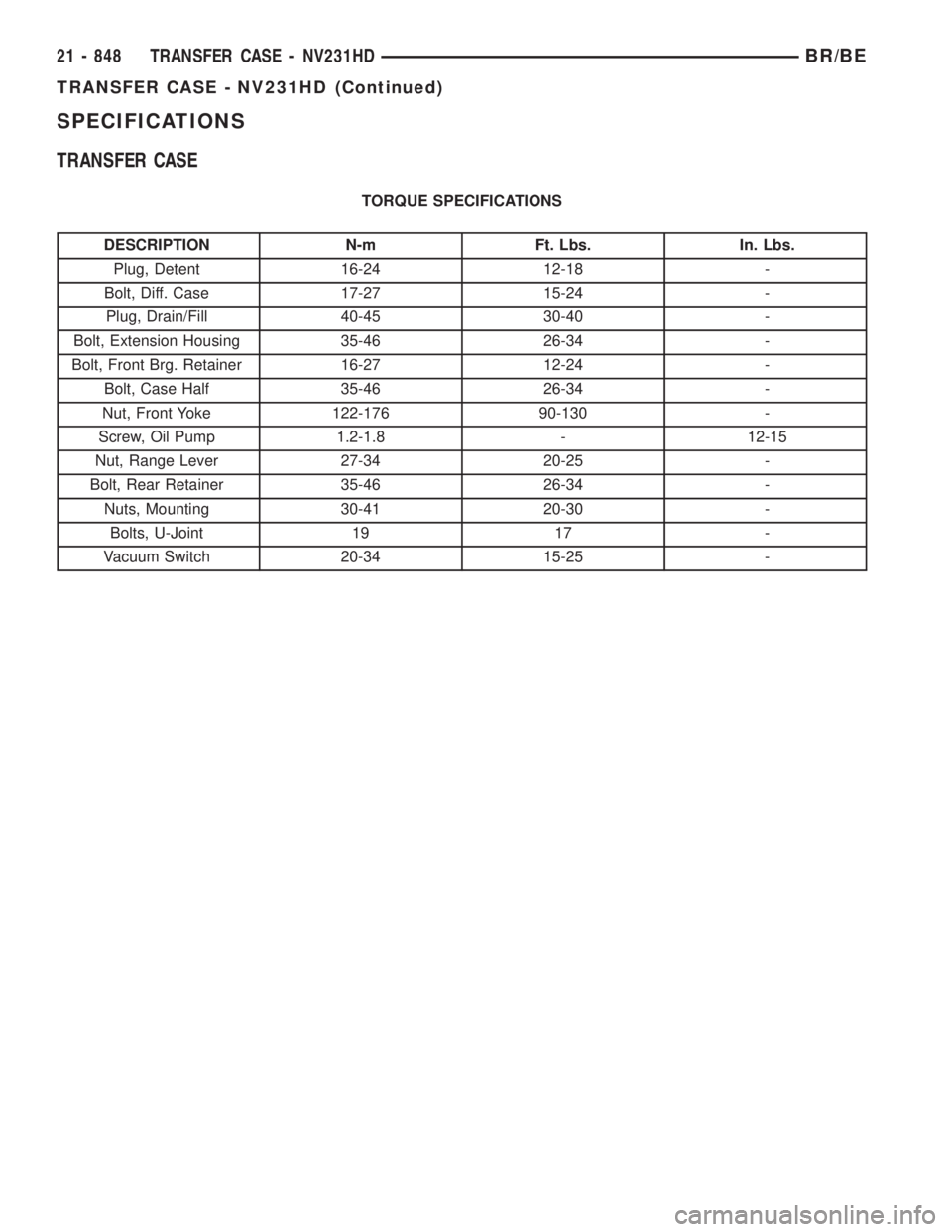

SPECIFICATIONS

TRANSFER CASE

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Bolt, Diff. Case 17-27 15-24 -

Plug, Drain/Fill 40-45 30-40 -

Bolt, Extension Housing 35-46 26-34 -

Bolt, Front Brg. Retainer 16-27 12-24 -

Bolt, Case Half 35-46 26-34 -

Nut, Front Yoke 122-176 90-130 -

Screw, Oil Pump 1.2-1.8 - 12-15

Nut, Range Lever 27-34 20-25 -

Bolt, Rear Retainer 35-46 26-34 -

Nuts, Mounting 30-41 20-30 -

Bolts, U-Joint 19 17 -

Vacuum Switch 20-34 15-25 -

21 - 848 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2487 of 2889

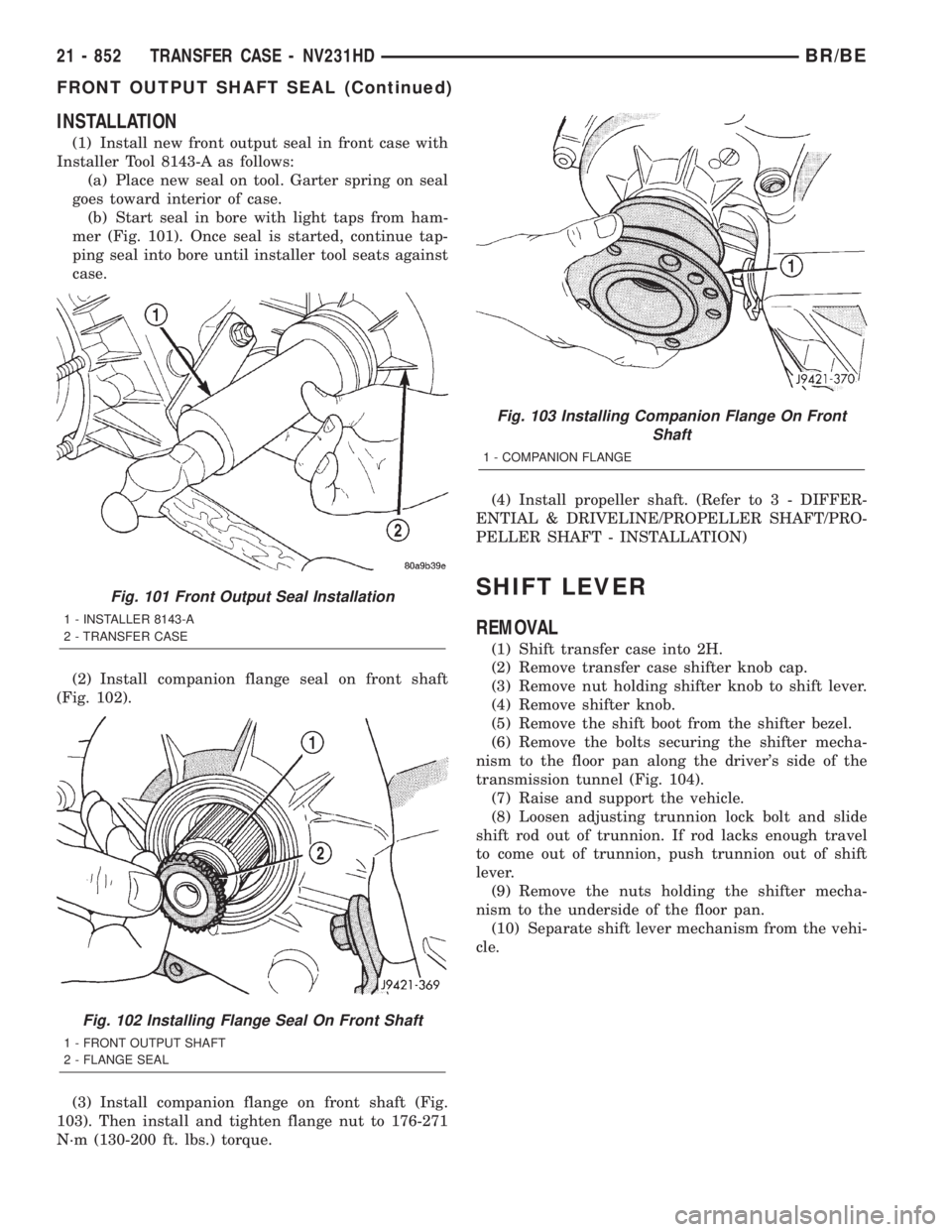

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 8143-A as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 101). Once seal is started, continue tap-

ping seal into bore until installer tool seats against

case.

(2) Install companion flange seal on front shaft

(Fig. 102).

(3) Install companion flange on front shaft (Fig.

103). Then install and tighten flange nut to 176-271

N´m (130-200 ft. lbs.) torque.(4) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

SHIFT LEVER

REMOVAL

(1) Shift transfer case into 2H.

(2) Remove transfer case shifter knob cap.

(3) Remove nut holding shifter knob to shift lever.

(4) Remove shifter knob.

(5) Remove the shift boot from the shifter bezel.

(6) Remove the bolts securing the shifter mecha-

nism to the floor pan along the driver's side of the

transmission tunnel (Fig. 104).

(7) Raise and support the vehicle.

(8) Loosen adjusting trunnion lock bolt and slide

shift rod out of trunnion. If rod lacks enough travel

to come out of trunnion, push trunnion out of shift

lever.

(9) Remove the nuts holding the shifter mecha-

nism to the underside of the floor pan.

(10) Separate shift lever mechanism from the vehi-

cle.

Fig. 101 Front Output Seal Installation

1 - INSTALLER 8143-A

2 - TRANSFER CASE

Fig. 102 Installing Flange Seal On Front Shaft

1 - FRONT OUTPUT SHAFT

2 - FLANGE SEAL

Fig. 103 Installing Companion Flange On Front

Shaft

1 - COMPANION FLANGE

21 - 852 TRANSFER CASE - NV231HDBR/BE

FRONT OUTPUT SHAFT SEAL (Continued)

Page 2489 of 2889

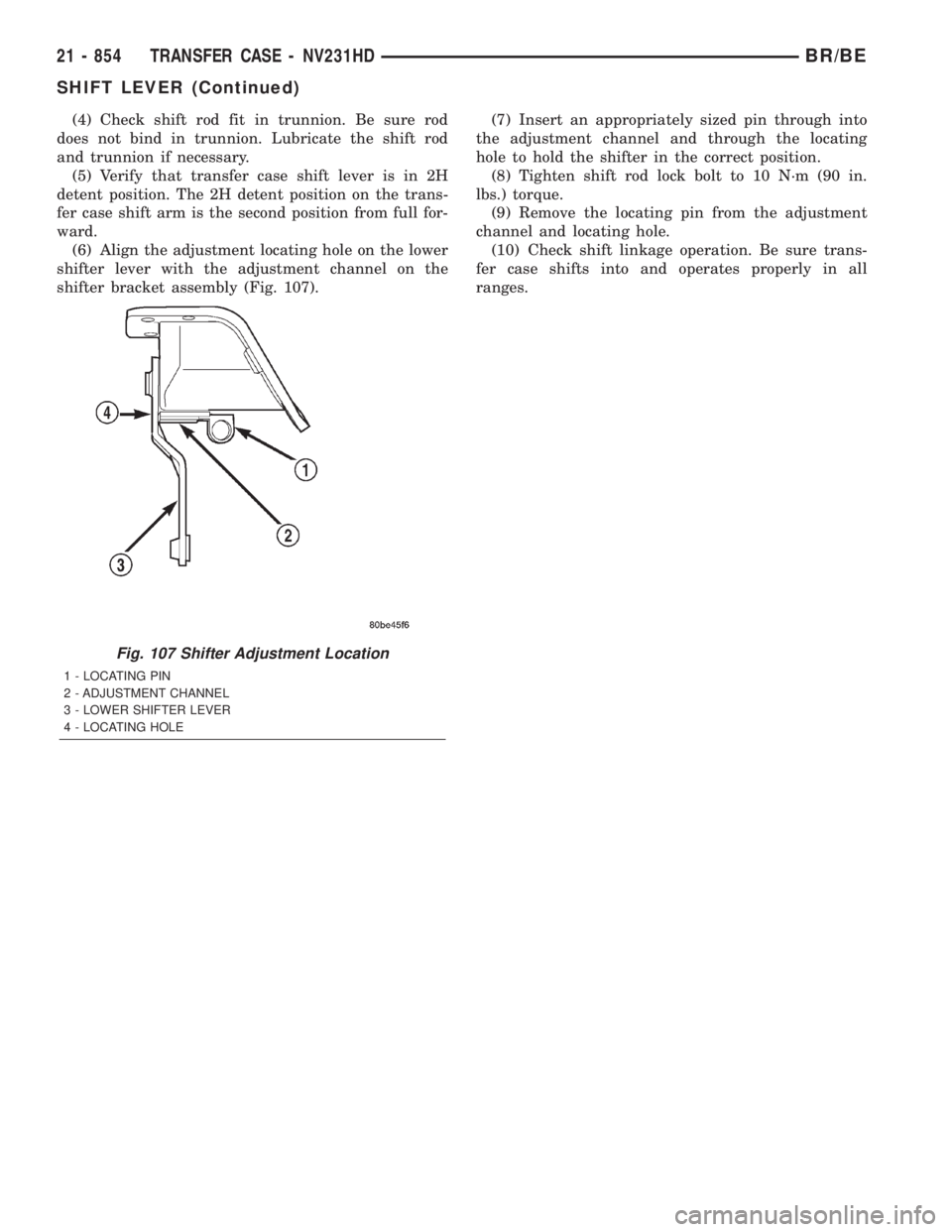

(4) Check shift rod fit in trunnion. Be sure rod

does not bind in trunnion. Lubricate the shift rod

and trunnion if necessary.

(5) Verify that transfer case shift lever is in 2H

detent position. The 2H detent position on the trans-

fer case shift arm is the second position from full for-

ward.

(6) Align the adjustment locating hole on the lower

shifter lever with the adjustment channel on the

shifter bracket assembly (Fig. 107).(7) Insert an appropriately sized pin through into

the adjustment channel and through the locating

hole to hold the shifter in the correct position.

(8) Tighten shift rod lock bolt to 10 N´m (90 in.

lbs.) torque.

(9) Remove the locating pin from the adjustment

channel and locating hole.

(10) Check shift linkage operation. Be sure trans-

fer case shifts into and operates properly in all

ranges.

Fig. 107 Shifter Adjustment Location

1 - LOCATING PIN

2 - ADJUSTMENT CHANNEL

3 - LOWER SHIFTER LEVER

4 - LOCATING HOLE

21 - 854 TRANSFER CASE - NV231HDBR/BE

SHIFT LEVER (Continued)

Page 2490 of 2889

TRANSFER CASE - NV241LD

TABLE OF CONTENTS

page page

TRANSFER CASE - NV241LD

DESCRIPTION..........................855

OPERATION............................855

DIAGNOSIS AND TESTING................856

TRANSFER CASE.....................856

REMOVAL.............................858

DISASSEMBLY..........................858

CLEANING.............................866

INSPECTION...........................867

ASSEMBLY............................869

INSTALLATION..........................882

SPECIFICATIONS........................883

SPECIAL TOOLS........................884EXTENSION HOUSING BUSHING AND SEAL

REMOVAL.............................885

INSTALLATION..........................885

FLUID

STANDARD PROCEDURE.................885

FLUID DRAIN AND REFILL...............885

FRONT OUTPUT SHAFT SEAL

REMOVAL.............................886

INSTALLATION..........................886

SHIFT LEVER

REMOVAL.............................887

INSTALLATION..........................888

ADJUSTMENTS.........................888

TRANSFER CASE - NV241LD

DESCRIPTION

The NV241LD transfer case is a part-time transfer

case with a low-range gear system. It provides three

operating ranges plus a NEUTRAL position. The low

range position provides a gear reduction ratio of

2.72:1 for increased low speed torque capability.

The synchronizer mechanism consists of a brass

stop ring, synchro hub, and the sliding clutch. The

synchronizer components allow the transfer case to

be shifted between the 2H and 4H operating ranges

while the vehicle is in motion.

The gear cases, retainer and extension are all of

aluminum. Drive sprockets and an interconnecting

drive chain are used to transmit engine torque to the

front/rear propeller shafts. The mainshaft, input gear

and front output shaft are supported by ball and nee-

dle bearings.

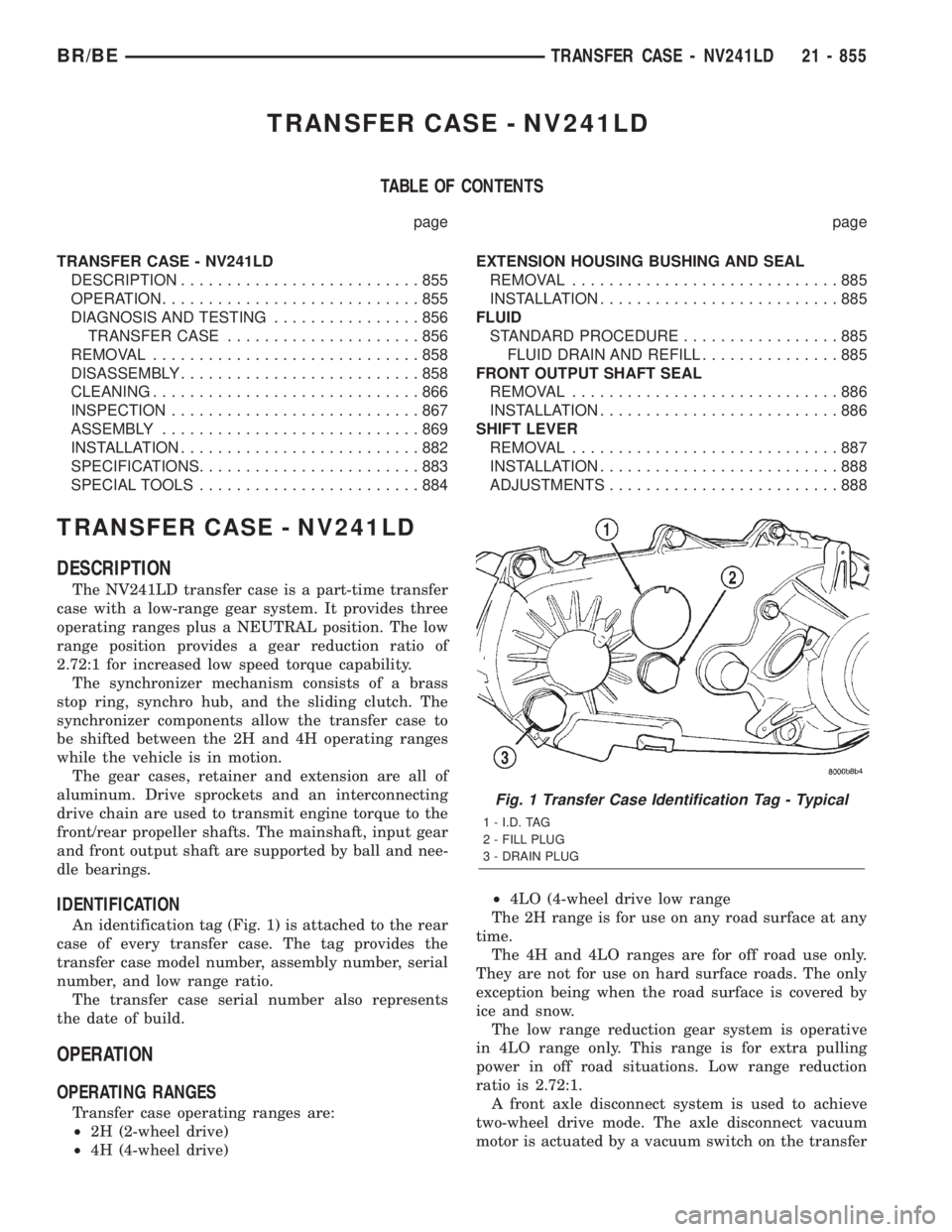

IDENTIFICATION

An identification tag (Fig. 1) is attached to the rear

case of every transfer case. The tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

OPERATING RANGES

Transfer case operating ranges are:

²2H (2-wheel drive)

²4H (4-wheel drive)²4LO (4-wheel drive low range

The 2H range is for use on any road surface at any

time.

The 4H and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The only

exception being when the road surface is covered by

ice and snow.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

A front axle disconnect system is used to achieve

two-wheel drive mode. The axle disconnect vacuum

motor is actuated by a vacuum switch on the transfer

Fig. 1 Transfer Case Identification Tag - Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

BR/BETRANSFER CASE - NV241LD 21 - 855

Page 2492 of 2889

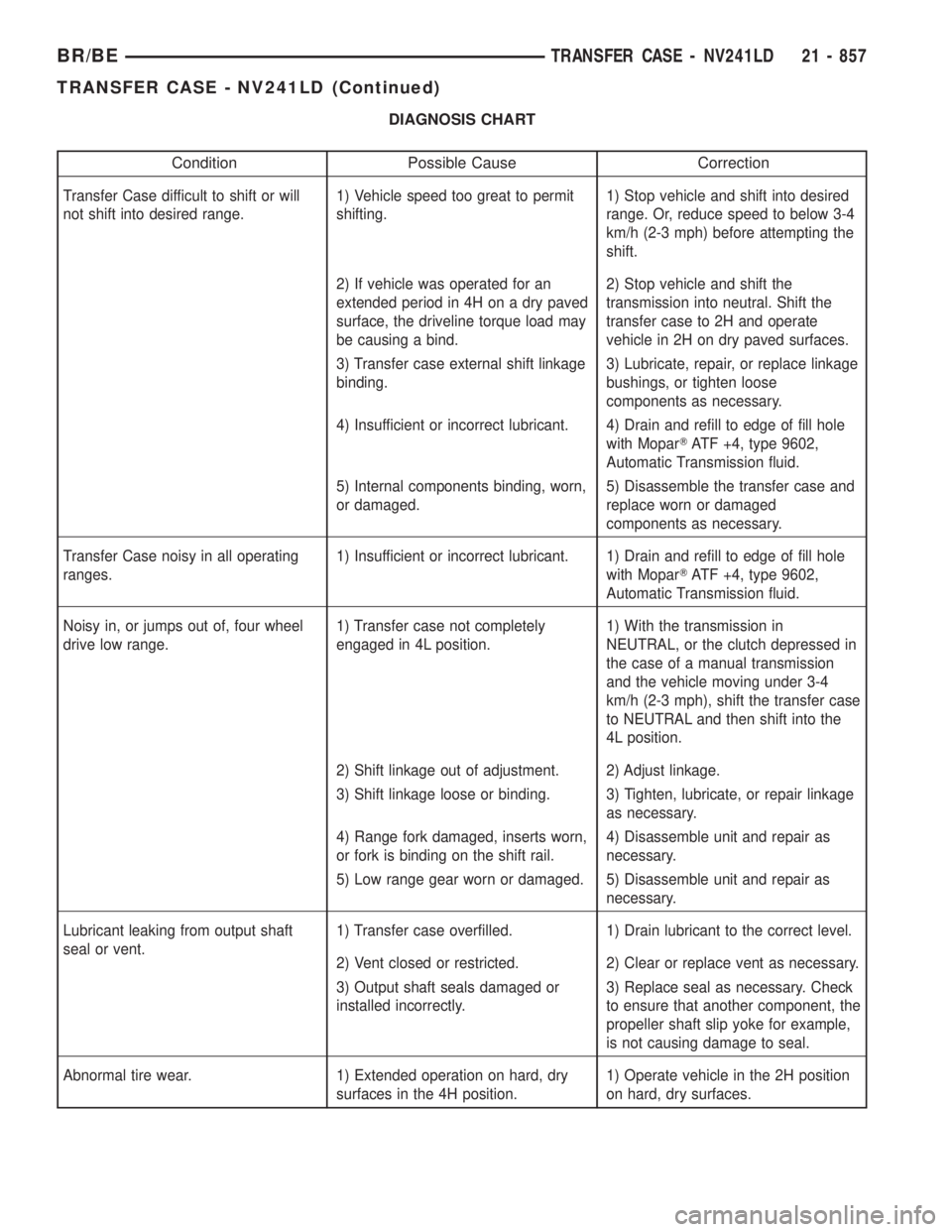

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer Case difficult to shift or will

not shift into desired range.1) Vehicle speed too great to permit

shifting.1) Stop vehicle and shift into desired

range. Or, reduce speed to below 3-4

km/h (2-3 mph) before attempting the

shift.

2) If vehicle was operated for an

extended period in 4H on a dry paved

surface, the driveline torque load may

be causing a bind.2) Stop vehicle and shift the

transmission into neutral. Shift the

transfer case to 2H and operate

vehicle in 2H on dry paved surfaces.

3) Transfer case external shift linkage

binding.3) Lubricate, repair, or replace linkage

bushings, or tighten loose

components as necessary.

4) Insufficient or incorrect lubricant. 4) Drain and refill to edge of fill hole

with MoparTATF +4, type 9602,

Automatic Transmission fluid.

5) Internal components binding, worn,

or damaged.5) Disassemble the transfer case and

replace worn or damaged

components as necessary.

Transfer Case noisy in all operating

ranges.1) Insufficient or incorrect lubricant. 1) Drain and refill to edge of fill hole

with MoparTATF +4, type 9602,

Automatic Transmission fluid.

Noisy in, or jumps out of, four wheel

drive low range.1) Transfer case not completely

engaged in 4L position.1) With the transmission in

NEUTRAL, or the clutch depressed in

the case of a manual transmission

and the vehicle moving under 3-4

km/h (2-3 mph), shift the transfer case

to NEUTRAL and then shift into the

4L position.

2) Shift linkage out of adjustment. 2) Adjust linkage.

3) Shift linkage loose or binding. 3) Tighten, lubricate, or repair linkage

as necessary.

4) Range fork damaged, inserts worn,

or fork is binding on the shift rail.4) Disassemble unit and repair as

necessary.

5) Low range gear worn or damaged. 5) Disassemble unit and repair as

necessary.

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct level.

2) Vent closed or restricted. 2) Clear or replace vent as necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary. Check

to ensure that another component, the

propeller shaft slip yoke for example,

is not causing damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H position

on hard, dry surfaces.

BR/BETRANSFER CASE - NV241LD 21 - 857

TRANSFER CASE - NV241LD (Continued)