front brakes DODGE RAM 2001 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2567 of 2889

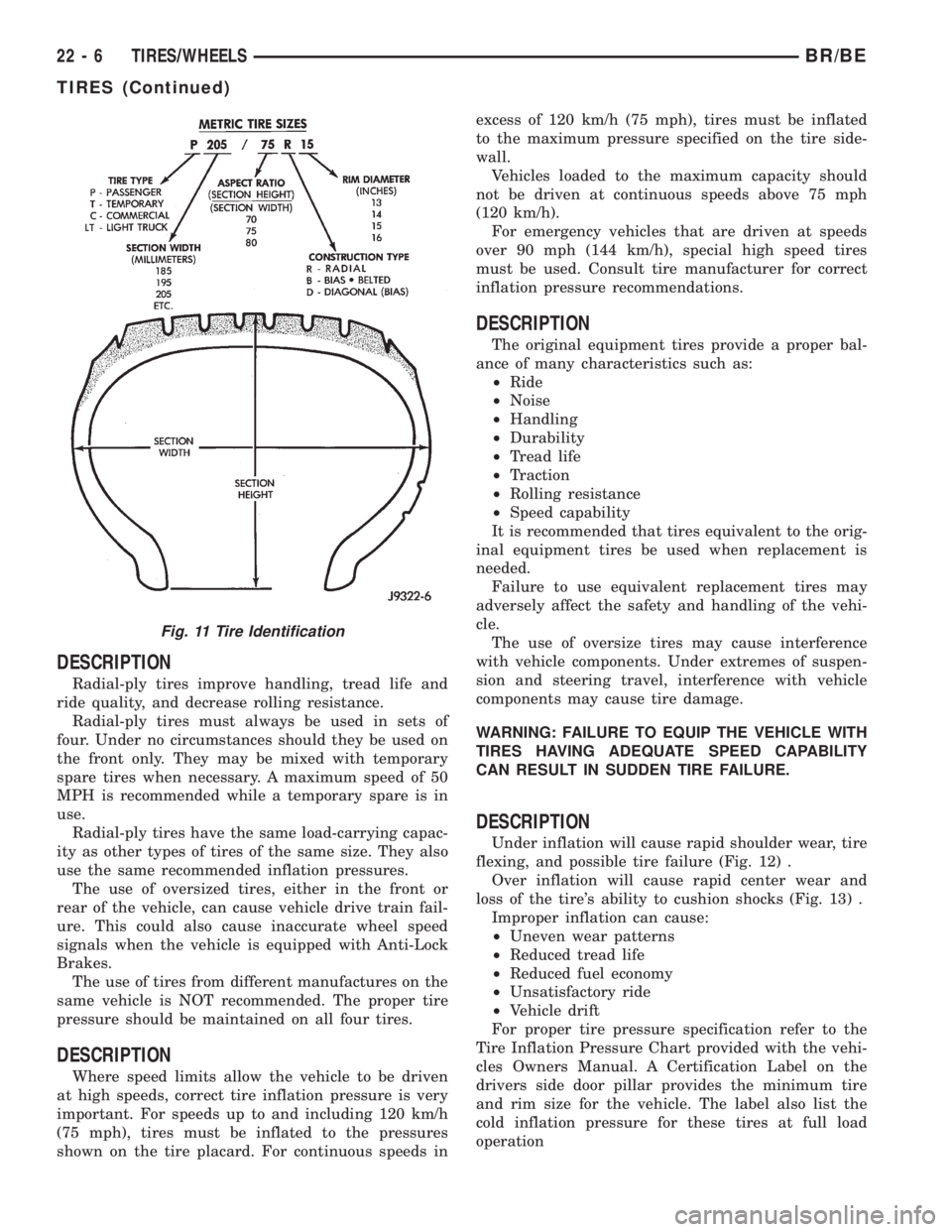

DESCRIPTION

Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

DESCRIPTION

Where speed limits allow the vehicle to be driven

at high speeds, correct tire inflation pressure is very

important. For speeds up to and including 120 km/h

(75 mph), tires must be inflated to the pressures

shown on the tire placard. For continuous speeds inexcess of 120 km/h (75 mph), tires must be inflated

to the maximum pressure specified on the tire side-

wall.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

For emergency vehicles that are driven at speeds

over 90 mph (144 km/h), special high speed tires

must be used. Consult tire manufacturer for correct

inflation pressure recommendations.

DESCRIPTION

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

It is recommended that tires equivalent to the orig-

inal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The use of oversize tires may cause interference

with vehicle components. Under extremes of suspen-

sion and steering travel, interference with vehicle

components may cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

DESCRIPTION

Under inflation will cause rapid shoulder wear, tire

flexing, and possible tire failure (Fig. 12) .

Over inflation will cause rapid center wear and

loss of the tire's ability to cushion shocks (Fig. 13) .

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²Vehicle drift

For proper tire pressure specification refer to the

Tire Inflation Pressure Chart provided with the vehi-

cles Owners Manual. A Certification Label on the

drivers side door pillar provides the minimum tire

and rim size for the vehicle. The label also list the

cold inflation pressure for these tires at full load

operation

Fig. 11 Tire Identification

22 - 6 TIRES/WHEELSBR/BE

TIRES (Continued)

Page 2573 of 2889

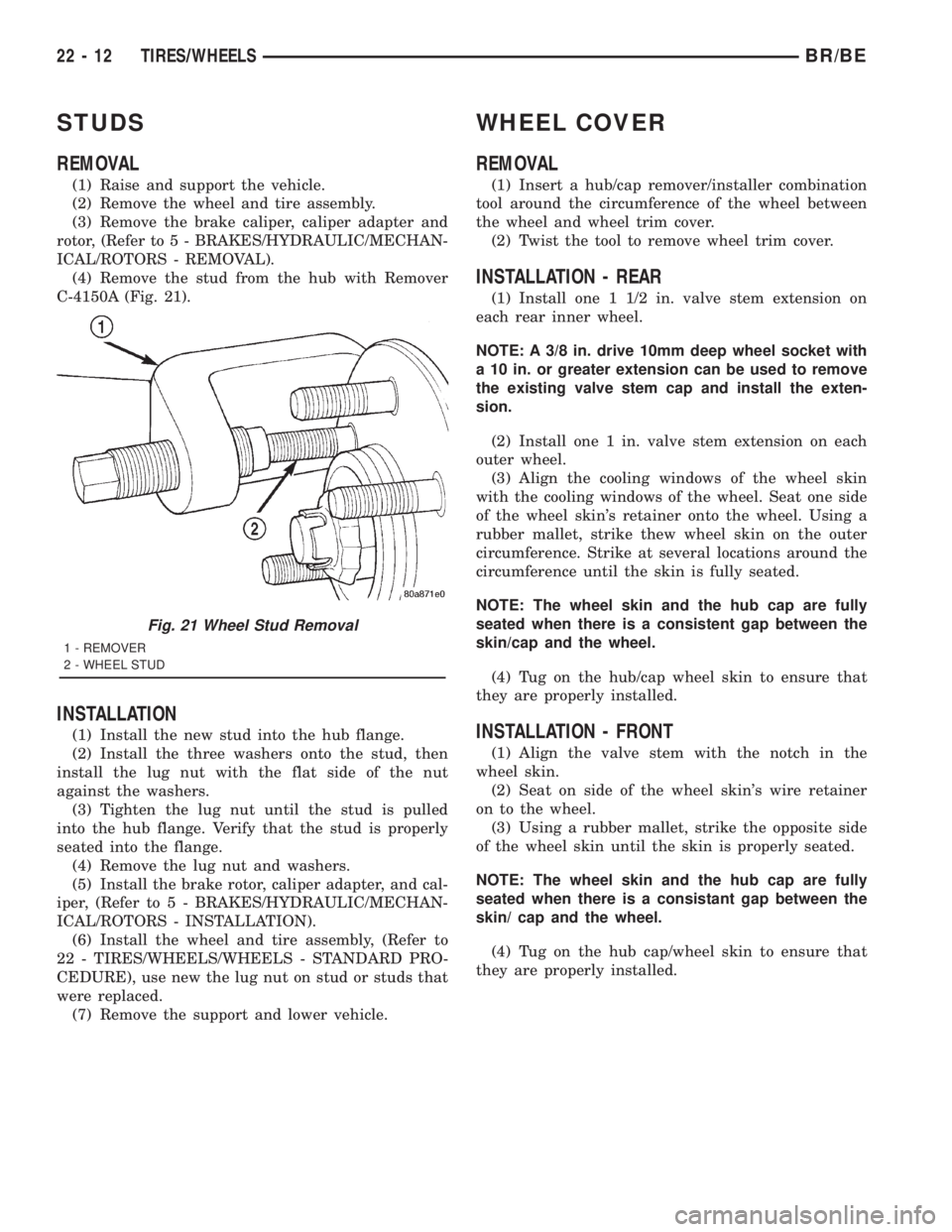

STUDS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake caliper, caliper adapter and

rotor, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove the stud from the hub with Remover

C-4150A (Fig. 21).

INSTALLATION

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and cal-

iper, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - INSTALLATION).

(6) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE), use new the lug nut on stud or studs that

were replaced.

(7) Remove the support and lower vehicle.

WHEEL COVER

REMOVAL

(1) Insert a hub/cap remover/installer combination

tool around the circumference of the wheel between

the wheel and wheel trim cover.

(2) Twist the tool to remove wheel trim cover.

INSTALLATION - REAR

(1) Install one 1 1/2 in. valve stem extension on

each rear inner wheel.

NOTE: A 3/8 in. drive 10mm deep wheel socket with

a 10 in. or greater extension can be used to remove

the existing valve stem cap and install the exten-

sion.

(2) Install one 1 in. valve stem extension on each

outer wheel.

(3) Align the cooling windows of the wheel skin

with the cooling windows of the wheel. Seat one side

of the wheel skin's retainer onto the wheel. Using a

rubber mallet, strike thew wheel skin on the outer

circumference. Strike at several locations around the

circumference until the skin is fully seated.

NOTE: The wheel skin and the hub cap are fully

seated when there is a consistent gap between the

skin/cap and the wheel.

(4) Tug on the hub/cap wheel skin to ensure that

they are properly installed.

INSTALLATION - FRONT

(1) Align the valve stem with the notch in the

wheel skin.

(2) Seat on side of the wheel skin's wire retainer

on to the wheel.

(3) Using a rubber mallet, strike the opposite side

of the wheel skin until the skin is properly seated.

NOTE: The wheel skin and the hub cap are fully

seated when there is a consistant gap between the

skin/ cap and the wheel.

(4) Tug on the hub cap/wheel skin to ensure that

they are properly installed.

Fig. 21 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

22 - 12 TIRES/WHEELSBR/BE

Page 2679 of 2889

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Airbag Control Module (ACM) and

bracket from the floor panel transmission tunnel.

(Refer to 8 - ELECTRICAL/RESTRAINTS/AIRBAG

CONTROL MODULE - REMOVAL).

(3) Remove the trim from the left and right cowl

side inner panels. (Refer to 23 - BODY/INTERIOR/

COWL TRIM COVER - REMOVAL).

(4) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(5) Remove the two screws that secure the inside

hood latch release handle to the instrument panel

lower reinforcement and lower the release handle to

the floor.

(6) Disconnect the clockspring pigtail wire connec-

tor from the instrument panel wire harness connec-

tor located on the instrument panel lower

reinforcement.

(7) If the vehicle is so equipped, disconnect the

overdrive lockout switch pigtail wire connector from

the instrument panel wire harness connector near

the instrument panel lower reinforcement.

(8) Remove the steering column from the vehicle,

but do not remove the driver airbag, the steering

wheel, or the switches from the column. Be certain

that the steering wheel is locked and secured from

rotation to prevent the loss of clockspring centering.

(Refer to 19 - STEERING/COLUMN - REMOVAL).

(9) From under the driver side of the instrument

panel, perform the following:

(a) Disengage the park brake release handle

linkage rod from the park brake mechanism on theleft cowl side inner panel. (Refer to 5 - BRAKES/

PARKING BRAKE/RELEASE - REMOVAL).

(b) Disconnect the instrument panel wire har-

ness connector from the park brake switch on the

park brake mechanism.

(c) Disconnect the three connectors (one from the

body wire harness, and two from the headlamp and

dash wire harness) from the three connector recep-

tacles located closest to the dash panel on the back

of the Junction Block (JB).

(d) Remove the screw from the center of the

headlamp and dash wire harness to instrument

panel wire harness bulkhead connector and discon-

nect the connector.

(e) Disconnect the instrument panel wire har-

ness to door wire harness connector located directly

below the instrument panel wire harness to head-

lamp and dash wire harness bulkhead connector.

(f) If the vehicle is equipped with the Infinity

sound system option, disconnect the Infinity wire

harness connector from the instrument panel wire

harness connector that is secured to the outboard

side of the instrument panel wire harness to head-

lamp and dash wire harness bulkhead connector.

(g) Disconnect the instrument panel wire har-

ness connector from the stop lamp switch.

(h) Disconnect the heater-A/C housing vacuum

harness connector from the heater-A/C control vac-

uum harness connector located near the left end of

the heater-A/C housing.

(10) From under the passenger side of the instru-

ment panel, disconnect the two halves of the radio

antenna coaxial cable connector.

(11) Loosen the right and left instrument panel

cowl side roll-down bracket screws about 13 mm

(0.50 inch) (Fig. 1).

(12) Remove the five screws that secure the top of

the instrument panel to the top of the dash panel,

removing the center screw last.

(13) Roll down the instrument panel and install a

temporary hook in the center hole on top of the

instrument panel. Secure the other end of the hook

to the center hole in the top of the dash panel. The

hook should support the instrument panel in its

rolled down position about 46 cm (18 inches) from

the dash panel.

(14) With the instrument panel supported in the

roll-down position, disconnect the instrument panel

wire harness connectors from the heater-A/C housing

wire harness connectors.

(15) With the aid of an assistant, remove the tem-

porary hook and lift the instrument panel assembly

off of the roll-down bracket screws and remove it

from the vehicle.

23 - 106 INSTRUMENT PANEL SYSTEMBR/BE

INSTRUMENT PANEL SYSTEM (Continued)

Page 2840 of 2889

ROAD TEST

DESCRIPTION - ROAD TEST INSPECTION

The following items must be inspected during the

road test portion of the new vehicle inspection.

²Check neutral safety switch operation

²Check operation of shift/clutch interlock system

²Check operation of gauges and warning lights

²Check horn operation

²Check operation of turn signals and emergency

flashers

²Check all mirror adjustments, including day/

night function

²Check windshield wipers for proper wipe pattern

and intermittent mode (if equipped)

²Check washer spray pattern

²Check heater, defroster and air conditioning for

proper operation

²Check that the fan operates quietly

²Check the rear window defroster (if equipped)

²Leave air selection lever in the fresh air position

²Check the rear heater and air conditioning for

proper operation

²Check the rear air register locations

²Check that the indicator lamps operate properly

²Check the operation of the radio, cassette and/or

compact disc player, and that sound quality is good

²Ensure that the clock displays the correct time

²Check that the trip computer/maintenance

reminder operates in all modes

²Check all speed control functions

²Check the service brakes to ensure that they

stop the vehicle in a straight line, without noise,

shudder or vibration

²Check the brake warning light

²Check the parking brake operation

²Check the engine's performance

²Check the transmission's performance for

smooth, quiet operation. If the vehicle is a 4x4, check

that the transfer case shifts easily among all ranges

²Check Autostick function (if equipped)

²Check the vehicle's steering and handling

²The steering wheel should be centered when

traveling in a straight line

²The vehicle should not pull or vibrate

²Check for squeaks, rattles and wind noise

²Check any other vehicle aspects you believe are

important, but that may not be included on the New

Vehicle Preparation Form

²Fill fuel tank with specified grade of fuel

INSPECTION - FUEL

Fill fuel tank with specified grade of gasoline (reg-

ular, midgrade or premium).

INSPECTION - OTHER

As part of DaimlerChrysler's Customer One philos-

ophy, the ªOtherº blank is provided on the New Vehi-

cle Preparation Form. This is designed to encourage

you to check any aspects of vehicle operation that

you believe are important to your customers, but that

do not appear elsewhere on the form.

INSPECTION - SQUEAKS, RATTLES AND WIND

NOISE

(1) Make sure that the instrument panel, glove

box, seats, steering wheel and column are free from

squeaks and rattles. Tighten any obvious loose fas-

teners.

(2) Check that the windows and doors are free

from squeaks, rattles and wind noise.

(3) Check that the vehicle exterior is free from

squeaks, rattles and noise, front and rear.

(4) Make sure that all interior panels are free from

squeaks and rattles.

INSPECTION - STEERING AND HANDLING

(1) Check that the power assist works properly (if

equipped). Steering should not require excessive

effort.

(2) Make sure the steering wheel does not vibrate

at idle or road speed.

(3) Ensure that the steering wheel is centered

when traveling straight ahead.

(4) Check that the vehicle does not drift to one

side.

(5) Make sure that the vehicle does not vibrate/

shake.

INSPECTION - TRANSMISSION/TRANSFER

CASE

AUTOMATIC TRANSMISSION

(1) Make sure that the park lock holds the vehicle

With the vehicle on a grade, put automatic trans-

mission in PARK and slowly release the service

brake to see if park lock holds. If it does not hold, the

transmission requires further service.

(2) Make sure shift lever operates easily/ smoothly

(Fig. 36).

Check for smooth shifting. Check for proper

upshifting and downshifting.

MANUAL TRANSMISSION

(1) Check that the shifter operates easily (Fig. 38).

(2) Make sure that the clutch operates smoothly

(Fig. 37).

(3) Look for proper synchronization.

The gears should not grind.

BR/BENEW VEHICLE PREPARATION 30 - 15

Page 2850 of 2889

AUTOMATIC TRANSMISSION - 44RE -

REMOVAL.........................21-330

AUTOMATIC TRANSMISSION - 46RE -

ASSEMBLY.........................21-510

AUTOMATIC TRANSMISSION - 46RE -

CLEANING.........................21-509

AUTOMATIC TRANSMISSION - 46RE -

DESCRIPTION......................21-478

AUTOMATIC TRANSMISSION - 46RE -

DISASSEMBLY......................21-503

AUTOMATIC TRANSMISSION - 46RE -

INSPECTION.......................21-510

AUTOMATIC TRANSMISSION - 46RE -

INSTALLATION......................21-518

AUTOMATIC TRANSMISSION - 46RE -

OPERATION........................21-480

AUTOMATIC TRANSMISSION - 46RE -

REMOVAL.........................21-502

AUTOMATIC TRANSMISSION - 47RE -

ASSEMBLY.........................21-681

AUTOMATIC TRANSMISSION - 47RE -

CLEANING.........................21-680

AUTOMATIC TRANSMISSION - 47RE -

DESCRIPTION......................21-649

AUTOMATIC TRANSMISSION - 47RE -

DISASSEMBLY......................21-674

AUTOMATIC TRANSMISSION - 47RE -

INSPECTION.......................21-681

AUTOMATIC TRANSMISSION - 47RE -

INSTALLATION......................21-688

AUTOMATIC TRANSMISSION - 47RE -

OPERATION........................21-651

AUTOMATIC TRANSMISSION - 47RE -

REMOVAL...........................21-673

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING......21-143,21-314,

21-486,21-657

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-5

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-5

AXLE - 216FBI - ADJUSTMENTS, FRONT . . . 3-17

AXLE - 216FBI - DESCRIPTION, FRONT....3-12

AXLE - 216FBI - INSTALLATION, FRONT....3-17

AXLE - 216FBI - OPERATION, FRONT......3-12

AXLE - 216FBI - REMOVAL, FRONT.......3-16

AXLE - 248FBI - ADJUSTMENTS, FRONT . . . 3-50

AXLE - 248FBI - DESCRIPTION, FRONT....3-45

AXLE - 248FBI - INSTALLATION, FRONT....3-50

AXLE - 248FBI - OPERATION, FRONT......3-45

AXLE - 248FBI - REMOVAL, FRONT.......3-50

AXLE - 248RBI - ADJUSTMENTS, REAR . . . 3-114

AXLE - 248RBI - DESCRIPTION, REAR....3-109

AXLE - 248RBI - INSTALLATION, REAR . . . 3-114

AXLE - 248RBI - OPERATION, REAR......3-109

AXLE - 248RBI - REMOVAL, REAR.......3-113

AXLE - 267RBI - ADJUSTMENTS, REAR . . . 3-145

AXLE - 267RBI - DESCRIPTION, REAR....3-140

AXLE - 267RBI - INSTALLATION, REAR . . . 3-145

AXLE - 267RBI - OPERATION, REAR......3-140

AXLE - 267RBI - REMOVAL, REAR.......3-144

AXLE - 286RBI - ADJUSTMENTS, REAR . . . 3-174

AXLE - 286RBI - DESCRIPTION, REAR....3-169

AXLE - 286RBI - INSTALLATION, REAR . . . 3-174

AXLE - 286RBI - OPERATION, REAR......3-169

AXLE - 286RBI - REMOVAL, REAR.......3-173

AXLE - 9 1/4 - ADJUSTMENTS, REAR.....3-84

AXLE - 9 1/4 - DESCRIPTION, REAR......3-77

AXLE - 9 1/4 - INSTALLATION, REAR......3-84

AXLE - 9 1/4 - OPERATION, REAR........3-77

AXLE - 9 1/4 - REMOVAL, REAR..........3-83

AXLE - DIAGNOSIS AND TESTING . . . 3-111,3-13,

3-142,3-171,3-46,3-80

AXLE - INSTALLATION, INTERMEDIATE....3-61

AXLE - REMOVAL, INTERMEDIATE........3-60

AXLE, 216FBI - FRONT.................3-25

AXLE, 248FBI - FRONT.................3-58

AXLE, 248RBI - REAR.................3-122

AXLE, 267RBI - REAR.................3-153

AXLE, 286 RBI - REAR................3-182

AXLE, 286RBI - REAR

.................3-182

AXLE, 9 1/4 - REAR

...................3-90

AXLE BEARINGS - INSTALLATION

. . 3-125,3-156,

3-185,3-95

AXLE BEARINGS - REMOVAL

. 3-125,3-156,3-185,

3-94

AXLE SHAFT SEALS - INSTALLATION

. 3-29,3-61,

3-94AXLE SHAFT SEALS - REMOVAL . 3-29,3-61,3-94

AXLE SHAFTS - INSTALLATION....3-125,3-156,

3-185,3-28,3-60,3-93

AXLE SHAFTS - INTERMEDIATE -

INSTALLATION........................3-28

AXLE SHAFTS - INTERMEDIATE -

REMOVAL...........................3-28

AXLE SHAFTS - REMOVAL . . . 3-125,3-156,3-185,

3-28,3-60,3-93

AXLE, SPECIAL TOOLS - FRONT..........3-58

AXLE VACUUM MOTOR - ASSEMBLY . . 3-33,3-65

AXLE VACUUM MOTOR - DESCRIPTION . . . 3-29,

3-62

AXLE VACUUM MOTOR - DISASSEMBLY . . . 3-33,

3-65

AXLE VACUUM MOTOR - INSTALLATION . . . 3-33,

3-65

AXLE VACUUM MOTOR - OPERATION . 3-30,3-62

AXLE VACUUM MOTOR - REMOVAL . . . 3-33,3-65

AXLES, SPECIAL TOOLS - FRONT.........3-25

BACK - BENCH SEAT - INSTALLATION,

SEAT .............................23-135

BACK - BENCH SEAT - REMOVAL, SEAT . . 23-135

BACK - SPLIT BENCH - INSTALLATION,

SEAT .............................23-136

BACK - SPLIT BENCH - REMOVAL, SEAT . 23-135

BACK COVER - INSTALLATION, SEAT....23-137

BACK COVER - REMOVAL, SEAT........23-137

BACK COVER - SPLIT BENCH -

INSTALLATION, SEAT.................23-138

BACK COVER - SPLIT BENCH -

REMOVAL, SEAT....................23-137

BACK RECLINER - INSTALLATION, SEAT . 23-138

BACK RECLINER - REMOVAL, SEAT.....23-138

BACKLITE - INSTALLATION............23-145

BACKLITE - REMOVAL................23-145

BACKLITE LATCH AND KEEPER -

INSTALLATION......................23-146

BACKLITE LATCH AND KEEPER -

REMOVAL.........................23-146

BACKLITE VENT GLASS - INSTALLATION . 23-147

BACKLITE VENT GLASS - REMOVAL.....23-147

BAFFLE - INSTALLATION, HVAC

HOUSING INLET.....................24-37

BAFFLE - REMOVAL, HVAC HOUSING

INLET..............................24-36

BALANCE - STANDARD PROCEDURES,

TIRE AND WHEEL.....................22-4

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.............................2-10

BALL JOINT - DIAGNOSIS AND TESTING,

UPPER..............................2-12

BALL JOINT - INSTALLATION, LOWER.....2-25

BALL JOINT - INSTALLATION, UPPER.....2-25

BAND OPERATION - DIAGNOSIS AND

TESTING, AIR CHECKING

TRANSMISSION CLUTCH.......21-147,21-318

BAND OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING

TRANSMISSION CLUTCH.......21-490,21-661

BANDS - ADJUSTMENT . . 21-193,21-364,21-539,

21-709

BANDS - DESCRIPTION . . 21-192,21-363,21-538,

21-709

BANDS - OPERATION....21-192,21-364,21-539,

21-709

BAR - DESCRIPTION, STABILIZER....2-12,2-22,

2-30

BAR - DESCRIPTION, TRACK............2-23

BAR - DIAGNOSIS AND TESTING, TRACK . . . 2-23

BAR - INSTALLATION, STABILIZER . . . 2-12,2-23,

2-30

BAR - INSTALLATION, TRACK............2-23

BAR - OPERATION, STABILIZER . . 2-12,2-22,2-30

BAR - OPERATION, TRACK..............2-23

BAR - REMOVAL, STABILIZER . . . 2-12,2-22,2-30

BAR - REMOVAL, TRACK...............2-23

BARRELS - INSTALLATION, PANEL

OUTLET............................24-32

BARRELS - REMOVAL, PANEL OUTLET . . . 24-32

BASE BRAKE, SPECIFICATIONS

............5-2

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING

.............................5-5

BASE BRAKES, SPECIAL TOOLS

...........5-4

BASE COAT/CLEAR COAT FINISH -

DESCRIPTION

......................23-129

BASE COAT/CLEAR COAT FINISH -

OPERATION

........................23-129BATTERIES - STANDARD PROCEDURE,

RKE TRANSMITTER...................8N-8

BATTERY - DESCRIPTION...............8F-6

BATTERY - DIAGNOSIS AND TESTING.....8F-7

BATTERY - INSPECTION................30-7

BATTERY - INSTALLATION..............8F-17

BATTERY - OPERATION.................8F-7

BATTERY - REMOVAL.................8F-17

BATTERY CABLE - DESCRIPTION........8F-19

BATTERY CABLE - OPERATION..........8F-20

BATTERY CABLES - DIAGNOSIS &

TESTING...........................8F-20

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-9

BATTERY ELECTROLYTE LEVEL -

STANDARD PROCEDURE, CHECKING......8F-8

BATTERY HOLDDOWN - DESCRIPTION....8F-18

BATTERY HOLDDOWN - INSTALLATION . . . 8F-18

BATTERY HOLDDOWN - OPERATION.....8F-18

BATTERY HOLDDOWN - REMOVAL.......8F-18

BATTERY, SPECIFICATIONS..............8F-6

BATTERY SYSTEM - CLEANING...........8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-5

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-29

BATTERY TEMPERATURE SENSOR -

INSTALLATION.......................8F-29

BATTERY TEMPERATURE SENSOR -

OPERATION.........................8F-29

BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-29

BATTERY TRAY - DESCRIPTION.........8F-24

BATTERY TRAY - INSTALLATION.........8F-25

BATTERY TRAY - OPERATION...........8F-25

BATTERY TRAY - REMOVAL............8F-25

BEAM INDICATOR - DESCRIPTION, HIGH . . 8J-21

BEAM INDICATOR - DIAGNOSIS AND

TESTING, HIGH......................8J-22

BEAM INDICATOR - OPERATION, HIGH....8J-22

BEARING - CENTER BEARING

ADJUSTMENT, CENTER.................3-10

BEARING - DESCRIPTION, CENTER.......3-10

BEARING - DESCRIPTION, CLUTCH

RELEASE............................6-14

BEARING - DESCRIPTION, PILOT.........6-17

BEARING - INSTALLATION, CENTER.......3-10

BEARING - INSTALLATION, CLUTCH

RELEASE............................6-15

BEARING - INSTALLATION, HUB

...........2-9

BEARING - INSTALLATION, OUTPUT

SHAFT FRONT

....21-213,21-384,21-560,21-730

BEARING - INSTALLATION, OUTPUT

SHAFT REAR

.....21-213,21-384,21-560,21-731

BEARING - INSTALLATION, PILOT

........6-18

BEARING - INSTALLATION, PITMAN

......19-21

BEARING - OPERATION, CENTER

.........3-10

BEARING - OPERATION, CLUTCH

RELEASE

............................6-14

BEARING - OPERATION, PILOT

...........6-18

BEARING - REMOVAL, CENTER

...........3-10

BEARING - REMOVAL, CLUTCH RELEASE

. . . 6-15

BEARING - REMOVAL, HUB

..............2-9

BEARING - REMOVAL, OUTPUT SHAFT

FRONT

..........21-213,21-384,21-559,21-730

BEARING - REMOVAL, OUTPUT SHAFT

REAR

...........21-213,21-384,21-560,21-731

BEARING - REMOVAL, PILOT

............6-18

BEARING - REMOVAL, PITMAN

..........19-20

BEARING ADJUSTMENT, CENTER

BEARING - CENTER

....................3-10

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

........9-274

BEARING CLEARANCE - STANDARD

PROCEDURE, MAIN

...................9-275

BEARING FITTING - STANDARD

PROCEDURE, CONNECTING ROD

. . . 9-144,9-202,

9-88

BEARING FITTING - STANDARD

PROCEDURE, CRANKSHAFT MAIN

. . . 9-146,9-90

BEARING FITTING - STANDARD

PROCEDURE, MAIN

...............9-203,9-33

BR/BEINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 2852 of 2889

BODY CONTROL/CENTRAL TIMER

MODULE - INSTALLATION...............8E-6

BODY CONTROL/CENTRAL TIMER

MODULE - OPERATION.................8E-3

BODY CONTROL/CENTRAL TIMER

MODULE - REMOVAL..................8E-5

BODY GAP AND FLUSH

MEASUREMENTS, SPECIFICATIONS......23-56

BODY OPENING DIMENSIONS,

SPECIFICATIONS.....................23-60

BODY SEALER LOCATIONS,

SPECIFICATIONS.....................23-47

BODY SEALING - INSPECTION..........30-10

BODY SIDE MOLDINGS - INSTALLATION . . 23-87

BODY SIDE MOLDINGS - REMOVAL......23-87

BODY STRIPES AND DECALS -

INSTALLATION.......................23-87

BODY STRIPES AND DECALS -

REMOVAL..........................23-87

BODY VENT - INSTALLATION..........23-126

BODY VENT - REMOVAL..............23-126

BOOST PRESSURE - DIAGNOSIS AND

TESTING...........................14-89

BOOSTER - DIAGNOSIS AND TESTING,

HYDRAULIC..........................5-17

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-29

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-20

BOOSTER - REMOVAL, POWER BRAKE....5-19

BOOT - INSTALLATION, 4WD FLOOR

SHIFT..............................23-122

BOOT - MANUAL TRANSMISSION -

INSTALLATION, SHIFT................23-122

BOOT - MANUAL TRANSMISSION -

REMOVAL, SHIFT....................23-122

BOOT - REMOVAL, 4WD FLOOR SHIFT . . . 23-122

BORE, DE-GLAZE - STANDARD

PROCEDURE-CYLINDER...............9-264

BORE HONING - STANDARD

PROCEDURE, CYLINDER . . 9-10,9-126,9-180,9-69

BORE REPAIR - STANDARD

PROCEDURE, CAM...................9-267

BORE REPAIR - STANDARD

PROCEDURE, CYLINDER...............9-265

BOX - ASSEMBLY, GLOVE.............23-112

BOX - DISASSEMBLY, GLOVE..........23-112

BOX - INSTALLATION, CARGO..........23-97

BOX - INSTALLATION, GLOVE..........23-113

BOX - REMOVAL, CARGO..............23-96

BOX - REMOVAL, GLOVE.............23-112

BOX LAMP AND SWITCH -

INSTALLATION, GLOVE................8L-35

BOX LAMP AND SWITCH - REMOVAL,

GLOVE.............................8L-35

BOX LATCH STRIKER - INSTALLATION,

GLOVE............................23-113

BOX LATCH STRIKER - REMOVAL,

GLOVE............................23-113

BOX OPENING UPPER TRIM -

INSTALLATION, GLOVE...............23-114

BOX OPENING UPPER TRIM - REMOVAL,

GLOVE............................23-114

B-PILLAR DOOR SEAL - INSTALLATION . . 23-152

B-PILLAR DOOR SEAL - REMOVAL......23-152

B-PILLAR TRIM - INSTALLATION

.......23-120

B-PILLAR TRIM - REMOVAL

...........23-120

BR PAINT COLOR CODES,

SPECIFICATIONS - 2001

..............23-129

BRACKET - INSTALLATION, CAB

CHASSIS ADAPTER

....................13-9

BRACKET - INSTALLATION, REARVIEW

MIRROR SUPPORT

..................23-126

BRACKET - REMOVAL, CAB CHASSIS

ADAPTER

............................13-9

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK

..........................8E-11

BRAKE - INSPECTION, PARKING

.........30-17

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK

..........................8E-12

BRAKE - OPERATION, CONTROLLER

ANTILOCK

..........................8E-11

BRAKE - REMOVAL, CONTROLLER

ANTILOCK

..........................8E-12

BRAKE BOOSTER - INSTALLATION,

POWER

.............................5-20

BRAKE BOOSTER - REMOVAL, POWER

....5-19BRAKE CABLE - 2500/3500 WITH REAR

DISC BRAKES - INSTALLATION, REAR

PARK...............................5-38

BRAKE CABLE - 2500/3500 WITH REAR

DISC BRAKES - REMOVAL, REAR

PARK...............................5-37

BRAKE CABLE - INSTALLATION, FRONT

PARKING............................5-39

BRAKE CABLE - REMOVAL, FRONT

PARKING............................5-37

BRAKE CABLE 2500/3500 SERIES WITH

DRUM BRAKES - INSTALLATION, REAR

PARK...............................5-39

BRAKE CABLES - 1500 SERIES -

INSTALLATION, REAR PARK.............5-39

BRAKE CABLES - 1500 SERIES -

REMOVAL, REAR PARK.................5-37

BRAKE CABLES 2500/3500 SERIES WITH

DRUM BRAKES - REMOVAL, REAR

PARK...............................5-38

BRAKE CALIPERS - ASSEMBLY, DISC......5-12

BRAKE CALIPERS - CLEANING, DISC......5-12

BRAKE CALIPERS - DISASSEMBLY, DISC . . . 5-11

BRAKE CALIPERS - INSPECTION, DISC....5-12

BRAKE DRUM - ADJUSTMENT, REAR......5-34

BRAKE DRUM - DIAGNOSIS AND

TESTING............................5-33

BRAKE DRUM MACHINING - STANDARD

PROCEDURE.........................5-33

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-14

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-14

BRAKE FLUID, SPECIFICATIONS..........5-15

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-16

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-16

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-16

BRAKE LAMP SWITCH - DESCRIPTION....8L-4

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING........................8L-5

BRAKE LAMP SWITCH - INSTALLATION....8L-5

BRAKE LAMP SWITCH - OPERATION......8L-4

BRAKE LAMP SWITCH - REMOVAL.......8L-5

BRAKE ROTOR - DIAGNOSIS AND

TESTING, DISC.......................5-20

BRAKE SHOES - 2500/3500 -

INSTALLATION, REAR DRUM IN HAT

PARK...............................5-42

BRAKE SHOES - 2500/3500 - REMOVAL,

REAR DRUM IN HAT PARK..............5-41

BRAKE SHOES-11 INCH - INSTALLATION,

REAR...............................5-27

BRAKE SHOES-11 INCH - REMOVAL,

REAR...............................5-25

BRAKE, SPECIFICATIONS - BASE..........5-2

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-5

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION

.......................8J-16

BRAKE/PARK BRAKE INDICATOR -

OPERATION

.........................8J-16

BRAKES - DESCRIPTION, 2500/3500

WITH REAR DISC

.....................5-35

BRAKES - INSPECTION, SERVICE

........30-17

BRAKES - INSTALLATION, REAR PARK

BRAKE CABLE - 2500/3500 WITH

REAR DISC

..........................5-38

BRAKES - INSTALLATION, REAR PARK

BRAKE CABLE 2500/3500 SERIES

WITH DRUM

.........................5-39

BRAKES - OPERATION, 2500/3500 WITH

REAR DISC

..........................5-36

BRAKES - REMOVAL, REAR PARK

BRAKE CABLE - 2500/3500 WITH

REAR DISC

..........................5-37

BRAKES - REMOVAL, REAR PARK

BRAKE CABLES 2500/3500 SERIES

WITH DRUM

.........................5-38

BRAKES, SPECIAL TOOLS - BASE

.........5-4

BREAKER - DESCRIPTION, CIRCUIT

....8W-97-4

BREAKER - DIAGNOSIS & TESTING,

CIRCUIT

.........................8W-97-4

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH

............24-13BREATHER VAPOR CANISTER -

INSTALLATION, CRANKCASE............9-242

BREATHER VAPOR CANISTER -

REMOVAL, CRANKCASE...............9-241

BUCKLE - INSTALLATION, FRONT SEAT

BELT ..............................8O-20

BUCKLE - INSTALLATION, REAR SEAT

BELT ..............................8O-27

BUCKLE - REMOVAL, FRONT SEAT BELT . . 8O-20

BUCKLE - REMOVAL, REAR SEAT BELT . . . 8O-27

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE........................8F-11

BUMPER - DESCRIPTION, JOUNCE....2-28,2-9

BUMPER - INSTALLATION, FRONT........13-4

BUMPER - INSTALLATION, REAR.........13-5

BUMPER - INSTALLATION, SLAM........23-66

BUMPER - OPERATION, JOUNCE......2-28,2-9

BUMPER - REMOVAL, FRONT............13-3

BUMPER - REMOVAL, REAR.............13-5

BUMPER - REMOVAL, SLAM...........23-66

BUMPERS - DESCRIPTION..............13-1

BUMPER-SPORT - INSTALLATION,

FRONT..............................13-4

BUMPER-SPORT - REMOVAL, FRONT......13-4

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF . . . 21-199,21-370,21-545,

21-715

BUS - DESCRIPTION, CCD DATA..........8E-6

BUS - DIAGNOSIS AND TESTING, CCD

D ATA................................8E-11

BUS - OPERATION, CCD DATA...........8E-7

BUSHING - INSTALLATION,

DISTRIBUTOR...............9-150,9-37,9-94

BUSHING - INSTALLATION, EXTENSION

HOUSING........21-198,21-369,21-544,21-714

BUSHING - REMOVAL, DISTRIBUTOR....9-150,

9-37,9-94

BUSHING - REMOVAL, EXTENSION

HOUSING........21-198,21-369,21-544,21-714

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING....21-850,21-885,21-921

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING....21-850,21-885,21-921

BUSHINGS - INSTALLATION.............2-28

BUSHINGS - REMOVAL.................2-28

BYPASS HOSE WITH AIR CONDITIONING

- INSTALLATION, WATER PUMP..........7-77

BYPASS HOSE WITH AIR CONDITIONING

- REMOVAL, WATER PUMP..............7-74

BYPASS HOSE WITHOUT AIR

CONDITIONING - INSTALLATION,

WATER PUMP........................7-78

BYPASS HOSE WITHOUT AIR

CONDITIONING - REMOVAL, WATER

PUMP..............................7-77

CAB - INSTALLATION, CLUB/QUAD.......8O-20

CAB - INSTALLATION, STANDARD.......8O-19

CAB - REMOVAL, CLUB/QUAD..........8O-19

CAB - REMOVAL, STANDARD...........8O-18

CAB CHASSIS ADAPTER BRACKET -

INSTALLATION........................13-9

CAB CHASSIS ADAPTER BRACKET -

REMOVAL...........................13-9

CAB SIDE PANEL SPEAKER -

INSTALLATION, REAR.................8A-21

CAB SIDE PANEL SPEAKER - REMOVAL,

REAR..............................8A-20

CABLE - 2500/3500 WITH REAR DISC

BRAKES - INSTALLATION, REAR PARK

BRAKE..............................5-38

CABLE - 2500/3500 WITH REAR DISC

BRAKES - REMOVAL, REAR PARK

BRAKE..............................5-37

CABLE - ADJUSTMENTS,

TRANSMISSION THROTTLE VALVE.....21-254,

21-425,21-598,21-771

CABLE - DESCRIPTION.................8P-4

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, BATTERY........8F-19

CABLE - DESCRIPTION, SPARK PLUG.....8I-19

CABLE - DESCRIPTION, THROTTLE

VALVE

..........21-253,21-424,21-597,21-770

CABLE - INSTALLATION, CHECK

.........23-63

CABLE - INSTALLATION, FRONT

PARKING BRAKE

......................5-39

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA

.....................8A-10

CABLE - INSTALLATION, LATCH RELEASE

. 23-101

BR/BEINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2853 of 2889

CABLE - INSTALLATION, RELEASE.......23-83

CABLE - INSTALLATION, SPARK PLUG....8I-20

CABLE - INSTALLATION, THROTTLE

CONTROL....................14-105,14-50

CABLE - OPERATION...................8P-4

CABLE - OPERATION, ANTENNA BODY.....8A-4

CABLE - OPERATION, BATTERY..........8F-20

CABLE - OPERATION, SPARK PLUG.......8I-19

CABLE - REMOVAL, CHECK.............23-62

CABLE - REMOVAL, FRONT PARKING

BRAKE..............................5-37

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA...........................8A-9

CABLE - REMOVAL, LATCH RELEASE....23-101

CABLE - REMOVAL, RELEASE...........23-82

CABLE - REMOVAL, SPARK PLUG........8I-20

CABLE - REMOVAL, THROTTLE

CONTROL....................14-104,14-50

CABLE 2500/3500 SERIES WITH DRUM

BRAKES - INSTALLATION, REAR PARK

BRAKE..............................5-39

CABLE INSTALLATION, GASOLINE -

NEGATIVE..........................8F-24

CABLE INSTALLATION, GASOLINE -

POSITIVE...........................8F-23

CABLE ORDER, 8.0L V-10 ENGINE -

SPARK PLUG.........................8I-2

CABLE REMOVAL, GASOLINE -

NEGATIVE..........................8F-23

CABLE REMOVAL, GASOLINE - POSITIVE . . 8F-23

CABLE RESISTANCE, SPECIFICATIONS -

SPARK PLUG.........................8I-3

CABLE TENSIONER - ADJUSTMENT.......5-40

CABLES - 1500 SERIES - INSTALLATION,

REAR PARK BRAKE....................5-39

CABLES - 1500 SERIES - REMOVAL,

REAR PARK BRAKE....................5-37

CABLES - DIAGNOSIS & TESTING,

BATTERY...........................8F-20

CABLES - DIAGNOSIS AND TESTING,

SPARK PLUG........................8I-19

CABLES 2500/3500 SERIES WITH DRUM

BRAKES - REMOVAL, REAR PARK

BRAKE..............................5-38

CAB-TO- BED GROUND STRAP -

INSTALLATION.......................8A-14

CAB-TO- BED GROUND STRAP -

REMOVAL..........................8A-14

CALIBRATION - STANDARD PROCEDURE,

COMPASS...........................8M-4

CALIPERS - ASSEMBLY, DISC BRAKE......5-12

CALIPERS - CLEANING, DISC BRAKE......5-12

CALIPERS - DISASSEMBLY, DISC BRAKE . . . 5-11

CALIPERS - INSPECTION, DISC BRAKE....5-12

CAM - DESCRIPTION, TURN SIGNAL

CANCEL............................8L-30

CAM - OPERATION, TURN SIGNAL

CANCEL............................8L-31

CAM BORE REPAIR - STANDARD

PROCEDURE........................9-267

CAM/OVERDRIVE PISTON RETAINER -

ASSEMBLY, OVERRUNNING

CLUTCH.........21-236,21-406,21-581,21-752

CAM/OVERDRIVE PISTON RETAINER -

CLEANING, OVERRUNNING

CLUTCH.........21-236,21-406,21-580,21-752

CAM/OVERDRIVE PISTON RETAINER -

DESCRIPTION, OVERRUNNING

CLUTCH.........21-235,21-405,21-580,21-751

CAM/OVERDRIVE PISTON RETAINER -

DISASSEMBLY, OVERRUNNING

CLUTCH.........21-235,21-405,21-580,21-751

CAM/OVERDRIVE PISTON RETAINER -

INSPECTION, OVERRUNNING

CLUTCH.........21-236,21-406,21-580,21-752

CAM/OVERDRIVE PISTON RETAINER -

OPERATION, OVERRUNNING

CLUTCH.........21-235,21-405,21-580,21-751

CAMSHAFT & BEARINGS (IN BLOCK) -

INSPECTION

........................9-272

CAMSHAFT - INSTALLATION

. 9-144,9-201,9-273,

9-29,9-87

CAMSHAFT - REMOVAL

. 9-143,9-201,9-268,9-29,

9-86

CAMSHAFT BEARINGS - INSTALLATION

. . 9-144,

9-201,9-273,9-29,9-87

CAMSHAFT BEARINGS - REMOVAL

. 9-143,9-200,

9-268,9-29,9-86CANCEL CAM - DESCRIPTION, TURN

SIGNAL............................8L-30

CANCEL CAM - OPERATION, TURN

SIGNAL............................8L-31

CANISTER - DESCRIPTION, VAPOR......25-37

CANISTER - INSTALLATION, CRANKCASE

BREATHER VAPOR...................9-242

CANISTER - INSTALLATION, VAPOR......25-38

CANISTER - OPERATION, VAPOR........25-37

CANISTER - REMOVAL, CRANKCASE

BREATHER VAPOR...................9-241

CANISTER - REMOVAL, VAPOR..........25-37

CAP - CLEANING, RADIATOR PRESSURE . . . 7-66

CAP - DESCRIPTION, FUEL FILLER.......25-33

CAP - DESCRIPTION, RADIATOR

PRESSURE..........................7-65

CAP - DIAGNOSIS AND TESTING,

DISTRIBUTOR.......................8I-12

CAP - DIAGNOSIS AND TESTING,

RADIATOR...........................7-66

CAP - INSPECTION, RADIATOR

PRESSURE..........................7-66

CAP - OPERATION, FUEL FILLER........25-33

CAP - OPERATION, RADIATOR

PRESSURE..........................7-65

CAP - REMOVAL/INSTALLATION, FUEL

FILLER.............................25-33

CAPACITIES, SPECIFICATIONS - FLUID......0-6

CAPACITY TEST - DIAGNOSIS AND

TESTING, FUEL PUMP..................14-9

CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING, RADIATOR.....7-66

CARDAN UNIVERSAL JOINTS -

DISASSEMBLY, SINGLE.................3-11

CARDAN UNIVERSAL JOINTS -

INSTALLATION, SINGLE............3-34,3-66

CARDAN UNIVERSAL JOINTS -

REMOVAL, SINGLE................3-33,3-65

CAREFUL NEW VEHICLE PREPARATION -

DESCRIPTION, THE IMPORTANCE OF......30-1

CARGO BOX - INSTALLATION...........23-97

CARGO BOX - REMOVAL...............23-96

CARGO DOOR - ADJUSTMENT..........23-78

CARPETS AND FLOOR MATS -

INSTALLATION......................23-123

CARPETS AND FLOOR MATS - REMOVAL . 23-123

CARTRIDGE FUSE - DESCRIPTION,

GENERATOR......................8W-97-4

CARTRIDGE FUSE - INSTALLATION,

GENERATOR......................8W-97-4

CARTRIDGE FUSE - OPERATION,

GENERATOR......................8W-97-4

CARTRIDGE FUSE - REMOVAL,

GENERATOR......................8W-97-4

CASE - DIAGNOSIS AND TESTING,

TRANSFER.............21-821,21-856,21-892

CASE - INSPECTION, TRANSMISSION/

TRANSFER..........................30-15

CASE - NV231HD - ASSEMBLY,

TRANSFER.........................21-834

CASE - NV231HD - CLEANING,

TRANSFER.........................21-831

CASE - NV231HD - DESCRIPTION,

TRANSFER.........................21-820

CASE - NV231HD - DISASSEMBLY,

TRANSFER.........................21-822

CASE - NV231HD - INSPECTION,

TRANSFER.........................21-832

CASE - NV231HD - INSTALLATION,

TRANSFER.........................21-847

CASE - NV231HD - OPERATION,

TRANSFER.........................21-820

CASE - NV231HD - REMOVAL,

TRANSFER.........................21-822

CASE - NV241HD - ASSEMBLY,

TRANSFER.........................21-904

CASE - NV241HD - CLEANING,

TRANSFER.........................21-902

CASE - NV241HD - DESCRIPTION,

TRANSFER

.........................21-890

CASE - NV241HD - DISASSEMBLY,

TRANSFER

.........................21-894

CASE - NV241HD - INSPECTION,

TRANSFER

.........................21-902

CASE - NV241HD - INSTALLATION,

TRANSFER

.........................21-919

CASE - NV241HD - OPERATION,

TRANSFER

.........................21-892CASE - NV241HD - REMOVAL,

TRANSFER.........................21-894

CASE - NV241LD - ASSEMBLY,

TRANSFER.........................21-869

CASE - NV241LD - CLEANING,

TRANSFER.........................21-866

CASE - NV241LD - DESCRIPTION,

TRANSFER.........................21-855

CASE - NV241LD - DISASSEMBLY,

TRANSFER.........................21-858

CASE - NV241LD - INSPECTION,

TRANSFER.........................21-867

CASE - NV241LD - INSTALLATION,

TRANSFER.........................21-882

CASE - NV241LD - OPERATION,

TRANSFER.........................21-855

CASE - NV241LD - REMOVAL,

TRANSFER.........................21-858

CASE BEARINGS - INSTALLATION,

DIFFERENTIAL . . . 3-103,3-134,3-164,3-192,3-39,

3-71

CASE BEARINGS - REMOVAL,

DIFFERENTIAL . . . 3-103,3-134,3-164,3-192,3-39,

3-71

CASE FLUID - DESCRIPTION, TRANSFER....0-5

CASE, NV231HD - TRANSFER..........21-849

CASE, NV241HD - TRANSFER..........21-920

CASE, NV241LD - TRANSFER..........21-884

CASE SKID PLATE - INSTALLATION,

TRANSFER..........................13-11

CASE SKID PLATE - REMOVAL,

TRANSFER..........................13-11

CASE, SPECIFICATIONS - TRANSFER.....21-848,

21-883,21-919

CASTER CORRECTION MEASUREMENT -

STANDARD PROCEDURES...............2-3

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- DESCRIPTION.......................11-5

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- INSPECTION........................11-5

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- INSTALLATION......................11-5

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- OPERATION.........................11-5

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- REMOVAL..........................11-5

CATALYTIC CONVERTER - 5.9L HEAVY

DUTY/8.0L - DESCRIPTION..............11-6

CATALYTIC CONVERTER - 5.9L HEAVY

DUTY/8.0L - INSPECTION...............11-7

CATALYTIC CONVERTER - 5.9L HEAVY

DUTY/8.0L - INSTALLATION.............11-7

CATALYTIC CONVERTER - 5.9L HEAVY

DUTY/8.0L - OPERATION................11-6

CATALYTIC CONVERTER - 5.9L HEAVY

DUTY/8.0L - REMOVAL.................11-6

CATCH - INSPECTION, HOOD LATCH/

SAFETY.............................30-4

CAUSES OF BURNT FLUID - DIAGNOSIS

AND TESTING....21-199,21-370,21-545,21-715

CAUTION, INTERIOR.................23-118

CAUTION, REFRIGERANT HOSES/LINES/

TUBES PRECAUTIONS.................24-42

CCD DATA BUS - DESCRIPTION..........8E-6

CCD DATA BUS - DIAGNOSIS AND

TESTING...........................8E-11

CCD DATA BUS - OPERATION............8E-7

CENTER - DESCRIPTION, POWER

DISTRIBUTION....................8W-97-7

CENTER - INSTALLATION, POWER

DISTRIBUTION

....................8W-97-8

CENTER - OPERATION, POWER

DISTRIBUTION

....................8W-97-8

CENTER - REMOVAL, POWER

DISTRIBUTION

....................8W-97-8

CENTER BEARING - CENTER BEARING

ADJUSTMENT

........................3-10

CENTER BEARING - DESCRIPTION

........3-10

CENTER BEARING - INSTALLATION

.......3-10

CENTER BEARING - OPERATION

..........3-10

CENTER BEARING - REMOVAL

...........3-10

CENTER BEARING ADJUSTMENT,

CENTER BEARING

.....................3-10

CENTER CONSOLE - INSTALLATION

.....23-122

CENTER CONSOLE - REMOVAL

.........23-122

CENTER CONSOLE LID - INSTALLATION

. . 23-132

CENTER CONSOLE LID - REMOVAL

.....23-131

6 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2859 of 2889

DOOR CYLINDER LOCK SWITCH -

OPERATION..........................8N-5

DOOR CYLINDER LOCK SWITCH -

REMOVAL...........................8N-6

DOOR FORE/AFT - ADJUSTMENT, FRONT . . 23-68

DOOR GLASS - INSTALLATION..........23-69

DOOR GLASS - REMOVAL.............23-69

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT...............23-154

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT...................23-153

DOOR INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT...............23-154

DOOR INNER BELT WEATHERSTRIP -

REMOVAL, FRONT...................23-154

DOOR IN/OUT - ADJUSTMENT, FRONT....23-69

DOOR LATCH - ADJUSTMENT, FRONT....23-72

DOOR LOCKS - INSPECTION, DOORS.....30-11

DOOR OPENING SEAL - INSTALLATION . . 23-153

DOOR OPENING SEAL - REMOVAL......23-153

DOOR OUTER BELT WEATHERSTRIP -

INSTALLATION, FRONT...............23-154

DOOR OUTER BELT WEATHERSTRIP -

REMOVAL, FRONT...................23-154

DOOR SEAL - INSTALLATION, B-PILLAR . 23-152

DOOR SEAL - REMOVAL, B-PILLAR.....23-152

DOOR SECOND WEATHERSTRIP -

INSTALLATION, FRONT...............23-155

DOOR SECOND WEATHERSTRIP -

REMOVAL, FRONT...................23-154

DOOR SILL TRIM - INSTALLATION......23-121

DOOR SILL TRIM - REMOVAL.........23-121

DOOR SPEAKER - INSTALLATION, FRONT . 8A-20

DOOR SPEAKER - INSTALLATION, REAR . . 8A-21

DOOR SPEAKER - REMOVAL, FRONT.....8A-20

DOOR SPEAKER - REMOVAL, REAR......8A-21

DOOR UP/DOWN - ADJUSTMENT, FRONT . 23-69

DOOR UPPER CORNER SEAL -

INSTALLATION, FRONT...............23-154

DOOR UPPER CORNER SEAL -

REMOVAL, FRONT...................23-154

DOORS AND DOOR LOCKS -

INSPECTION........................30-11

DOORS AND LOCKS - INSPECTION,

WINDOWS..........................30-14

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE.................5-8

DRAIN AND REFILL - STANDARD

PROCEDURE, FLUID.....21-851,21-885,21-922

DRAIN MANIFOLD - DESCRIPTION, FUEL . . 14-86

DRAIN MANIFOLD - INSTALLATION,

FUEL..............................14-86

DRAIN MANIFOLD - OPERATION, FUEL . . . 14-86

DRAIN MANIFOLD - REMOVAL, FUEL.....14-86

DRAINBACK VALVE - DESCRIPTION,

TORQUE CONVERTER....21-262,21-432,21-605,

21-778

DRAINBACK VALVE - OPERATION,

TORQUE CONVERTER....21-262,21-432,21-605,

21-778

DRAINBACK VALVE - STANDARD

PROCEDURE, TORQUE

CONVERTER.....21-262,21-432,21-606,21-778

DRAINING AT FUEL FILTER - STANDARD

PROCEDURES, WATER................14-56

DRAINING COOLING SYSTEM

3.9L/5.2L/5.9L/8.0L ENGINES -

STANDARD PROCEDURE................7-15

DRAINING COOLING SYSTEM 5.9L

DIESEL ENGINE - STANDARD

PROCEDURE.........................7-15

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-15

DRIVE - DIAGNOSIS AND TESTING,

VISCOUS FAN....................7-56,7-58

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY.................7-24,7-27,7-31

DRIVE BELTS - 3.9L/5.2L/5.9L -

INSTALLATION........................7-27

DRIVE BELTS - 3.9L/5.2L/5.9L -

REMOVAL...........................7-26

DRIVE BELTS - 5.9L DIESEL -

INSTALLATION

........................7-34

DRIVE BELTS - 5.9L DIESEL - REMOVAL

. . . 7-33

DRIVE BELTS - 8.0L - INSTALLATION

......7-30

DRIVE BELTS - 8.0L - REMOVAL

.........7-30

DRIVE INDICATOR - DIAGNOSIS AND

TESTING, FOUR-WHEEL

...............8J-29DRIVE VISCOUS CLUTCH - 3.9L/5.2L/

5.9L/8.0L - DESCRIPTION, FAN...........7-56

DRIVE VISCOUS CLUTCH - 3.9L/5.2L/

5.9L/8.0L - OPERATION, FAN............7-56

DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION, FAN............7-57

DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION, FAN..............7-57

DRIVER AIRBAG - ASSEMBLY..........8O-17

DRIVER AIRBAG - DESCRIPTION........8O-14

DRIVER AIRBAG - DISASSEMBLY........8O-15

DRIVER AIRBAG - INSTALLATION.......8O-18

DRIVER AIRBAG - OPERATION..........8O-14

DRIVER AIRBAG - REMOVAL...........8O-14

DRIVER POWER SEAT SWITCH -

DESCRIPTION.......................8N-16

DRIVER POWER SEAT SWITCH -

DIAGNOSIS & TESTING...............8N-16

DRIVER POWER SEAT SWITCH -

INSTALLATION......................8N-17

DRIVER POWER SEAT SWITCH -

OPERATION.........................8N-16

DRIVER POWER SEAT SWITCH -

REMOVAL..........................8N-17

DRIVER SEAT HEATER SWITCH -

DESCRIPTION........................8G-7

DRIVER SEAT HEATER SWITCH -

INSTALLATION.......................8G-9

DRIVER SEAT HEATER SWITCH -

OPERATION..........................8G-7

DRIVER SEAT HEATER SWITCH -

REMOVAL.............................8G-9

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE............8W-01-7

DRUM - ADJUSTMENT, REAR BRAKE......5-34

DRUM - CLEANING....................5-33

DRUM - DESCRIPTION.................5-32

DRUM - DIAGNOSIS AND TESTING,

BRAKE..............................5-33

DRUM - INSPECTION..................5-33

DRUM - OPERATION...................5-32

DRUM BRAKES - INSTALLATION, REAR

PARK BRAKE CABLE 2500/3500

SERIES WITH........................5-39

DRUM BRAKES - REMOVAL, REAR PARK

BRAKE CABLES 2500/3500 SERIES

WITH...............................5-38

DRUM IN HAT PARK BRAKE SHOES -

2500/3500 - INSTALLATION, REAR........5-42

DRUM IN HAT PARK BRAKE SHOES -

2500/3500 - REMOVAL, REAR...........5-41

DRUM MACHINING - STANDARD

PROCEDURE, BRAKE...................5-33

DUAL REAR WHEEL INSTALLATION -

STARDARD PROCEDURE...............22-10

DUCT ADAPTER - INSTALLATION,

DEFROSTER AND DEMISTER

...........24-35

DUCT ADAPTER - REMOVAL,

DEFROSTER AND DEMISTER

...........24-35

DUCTS - INSTALLATION, DEFROSTER

AND DEMISTER

......................24-35

DUCTS - REMOVAL, DEFROSTER AND

DEMISTER

..........................24-34

DUCTS - REMOVAL, INSTRUMENT

PANEL

.............................24-37

DUCTS - REMOVAL, INSTRUMENT

PANEL DEMISTER

....................24-37

DUTY ENGINE (1500 AND 2500 MODELS

EXCEPT 8.0L) MAINTENANCE

SCHEDULES, MAINTENANCE

SCHEDULES - LIGHT

....................0-7

DUTY ENGINE (FEDERAL ONLY - 2500

8.0L HD AND 3500 5.9L& 8.0L

MODELS) MAINTENANCE SCHEDULES

- DESCRIPTION, HEAVY

................0-17

DUTY TRUCK MAINTENANCE SCHEDULE

(8.0L 2500 & 3500 MODELS -

CALIFORNIA ONLY) - DESCRIPTION,

MEDIUM

............................0-13

DUTY/8.0L - DESCRIPTION, CATALYTIC

CONVERTER - 5.9L HEAVY

..............11-6

DUTY/8.0L - INSPECTION, CATALYTIC

CONVERTER - 5.9L HEAVY

..............11-7

DUTY/8.0L - INSPECTION, EXHAUST

PIPE - 5.9L HEAVY

....................11-9

DUTY/8.0L - INSPECTION, TAILPIPE -

5.9L HEAVY

.........................11-12DUTY/8.0L - INSTALLATION, CATALYTIC

CONVERTER - 5.9L HEAVY..............11-7

DUTY/8.0L - INSTALLATION, EXHAUST

PIPE - 5.9L HEAVY....................11-9

DUTY/8.0L - INSTALLATION, TAILPIPE -

5.9L HEAVY.........................11-12

DUTY/8.0L - OPERATION, CATALYTIC

CONVERTER - 5.9L HEAVY..............11-6

DUTY/8.0L - REMOVAL, CATALYTIC

CONVERTER - 5.9L HEAVY..............11-6

DUTY/8.0L - REMOVAL, EXHAUST PIPE -

5.9L HEAVY..........................11-8

DUTY/8.0L - REMOVAL, TAILPIPE - 5.9L

HEAVY .............................11-12

EASY ENTRY SEAT TRACK -

INSTALLATION......................23-142

EASY ENTRY SEAT TRACK - REMOVAL . . 23-142

ECM - DESCRIPTION..................8E-13

ECM - OPERATION...................8E-13

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING......21-199,21-370,

21-545,21-715

ELECTRICAL CONTROLS - DIAGNOSIS

AND TESTING, OVERDRIVE.....21-215,21-386,

21-579,21-732

ELECTROLYTE LEVEL - STANDARD

PROCEDURE, CHECKING BATTERY........8F-8

ELECTRONIC FEATURES - DESCRIPTION,

PROGRAMMABLE....................30-20

ELECTRONIC FEATURES - OPERATION,

PROGRAMMABLE....................30-20

ELECTRONIC GOVERNOR -

DESCRIPTION....21-194,21-365,21-540,21-710

ELECTRONIC GOVERNOR -

INSTALLATION....21-197,21-367,21-543,21-713

ELECTRONIC GOVERNOR - OPERATION

. 21-194,

21-365,21-541,21-711

ELECTRONIC GOVERNOR - REMOVAL

. . . 21-196,

21-367,21-542,21-712

ELEMENT - DESCRIPTION, HEATED

SEAT

..............................8G-10

ELEMENT - INSTALLATION, AIR

CLEANER

...........................9-245

ELEMENT - OPERATION, HEATED SEAT

. . . 8G-10

ELEMENT - REMOVAL, AIR CLEANER

.....9-244

ELEMENT AND SENSOR - DIAGNOSIS &

TESTING, HEATED SEAT

...............8G-11

EMERGENCY SIGNALS - INSPECTION,

TURN

..............................30-19

END SPLASH SHIELDS - INSTALLATION,

FRONT

.............................23-92

END SPLASH SHIELDS - REMOVAL,

FRONT

.............................23-92

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW - 3.9L/5.2L/5.9L

...........7-1

ENGINE - DESCRIPTION, FUEL

REQUIREMENTS - DIESEL

...............0-2

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIESEL

..............7-12

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM GAS

.................7-7

ENGINE - DIAGNOSIS AND TESTING,

DIESEL

.............................11-4

ENGINE - DIAGNOSIS AND TESTING,

GAS

................................11-4

ENGINE - ENGINE FIRING ORDER, 3.9L

V-6

.................................8I-2

ENGINE - IGNITION COIL RESISTANCE,

8.0L V-10

............................8I-3

ENGINE - INSTALLATION

...............9-241

ENGINE - INSTALLATION, DIESEL

........19-35

ENGINE - INSTALLATION, GASOLINE

.....19-35

ENGINE - REMOVAL

..................9-238

ENGINE - REMOVAL, DIESEL

...........19-33

ENGINE - REMOVAL, GASOLINE

.........19-33

ENGINE - SPARK PLUG CABLE ORDER,

8.0L V-10

............................8I-2

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 5.9L

DIESEL

.............................7-15

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 5.9L

DIESEL

.............................7-15

ENGINE - TORQUE, DIESEL

.............14-90

ENGINE - VISUAL INSPECTION, 8.0L

.....14-32

12 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2866 of 2889

INJECTION PUMP TIMING - DIAGNOSIS

AND TESTING, FUEL..................14-66

INJECTION SYSTEM - DESCRIPTION, AIR . 25-25

INJECTION SYSTEM - DESCRIPTION,

DIESEL FUEL........................14-87

INJECTION SYSTEM - OPERATION, AIR . . . 25-27

INJECTION SYSTEM - TORQUE, AIR......25-28

INJECTOR - DESCRIPTION, FUEL . . . 14-53,14-93

INJECTOR - INSTALLATION, FUEL . . 14-53,14-98

INJECTOR - OPERATION, FUEL.....14-53,14-94

INJECTOR - REMOVAL, FUEL......14-53,14-96

INJECTOR FIRING ORDER, DIESEL -

FUEL..............................14-58

INJECTOR TEST - DIAGNOSIS AND

TESTING, FUEL.................14-53,14-95

INLET BAFFLE - INSTALLATION, HVAC

HOUSING...........................24-37

INLET BAFFLE - REMOVAL, HVAC

HOUSING...........................24-36

INLET FILTER - INSTALLATION..........14-22

INLET FILTER - REMOVAL..............14-22

INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-154

INNER BELT WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-154

IN/OUT - ADJUSTMENT, FRONT DOOR....23-69

INPUT - DESCRIPTION, VEHICLE SPEED . . . 8P-1

INPUT - OPERATION, ASD SENSE - PCM . . . 8I-3

INSIDE HANDLE ACTUATOR -

INSTALLATION...................23-71,23-80

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-71,

23-80

INSPECTION - DESCRIPTION, ROAD

TEST..............................30-15

INSPECTION - DIAGNOSIS AND

TESTING, WHEEL....................22-10

INSPECTION - INFORMATION LABELS -

STANDARD PROCEDURE...............30-22

INSPECTION, 3.9L/5.2L/5.9L ENGINES -

VISUAL............................14-28

INSPECTION, 8.0L ENGINE - VISUAL.....14-32

INSPECTION, A/C COMPRESSOR

CLUTCH............................24-16

INSPECTION, ACCUMULATOR . . . 21-192,21-363,

21-538,21-708

INSPECTION, AUTOMATIC

TRANSMISSION - 42RE...............21-165

INSPECTION, AUTOMATIC

TRANSMISSION - 44RE...............21-337

INSPECTION, AUTOMATIC

TRANSMISSION - 46RE...............21-510

INSPECTION, AUTOMATIC

TRANSMISSION - 47RE...............21-681

INSPECTION, BATTERY.................30-7

INSPECTION, BATTERY SYSTEM..........8F-5

INSPECTION, BODY SEALING...........30-10

INSPECTION, CAMSHAFT & BEARINGS

(IN BLOCK).........................9-272

INSPECTION, CATALYTIC CONVERTER -

3.9L/5.2L/5.9L........................11-5

INSPECTION, CATALYTIC CONVERTER -

5.9L HEAVY DUTY/8.0L.................11-7

INSPECTION, CHARGE AIR COOLER AND

PLUMBING.........................11-18

INSPECTION, COMPASS...............30-12

INSPECTION, CROSSHEADS............9-250

INSPECTION, CYLINDER HEAD....9-137,9-193,

9-23,9-250,9-80

INSPECTION, CYLINDER HEAD COVER(S) . 9-138,

9-194,9-24,9-253,9-81

INSPECTION, DISC BRAKE CALIPERS......5-12

INSPECTION, DOORS AND DOOR LOCKS . . 30-11

INSPECTION, DRUM...................5-33

INSPECTION, ENGINE BLOCK . 9-142,9-200,9-267,

9-28,9-86

INSPECTION, ENGINE PERFORMANCE....30-16

INSPECTION, EXHAUST MANIFOLD . 9-112,9-168,

9-225,9-304,9-55

INSPECTION, EXHAUST PIPE -

3.9L/5.2L/5.9L........................11-7

INSPECTION, EXHAUST PIPE - 5.9L

DIESEL

.............................11-9

INSPECTION, EXHAUST PIPE - 5.9L

HEAVY DUTY/8.0L

.....................11-9

INSPECTION, FIT AND FINISH

......30-10,30-12

INSPECTION, FLUID LEVELS

.............30-4

INSPECTION, FRONT CLUTCH

. . . 21-205,21-376,

21-550,21-721INSPECTION, FRONT SERVO....21-207,21-378,

21-553,21-723

INSPECTION, FUEL...................30-15

INSPECTION, GAUGES/WARNING LIGHTS . 30-19

INSPECTION, HEATER/AIR CONDITIONER . . 30-17

INSPECTION, HOOD LATCH/SAFETY

CATCH ..............................30-4

INSPECTION, HORN..................30-19

INSPECTION, INTAKE MANIFOLD . . . 9-110,9-166,

9-223,9-302,9-53

INSPECTION, INTAKE/EXHAUST VALVES

& SEATS ..............9-141,9-198,9-27,9-84

INSPECTION, KEYLESS ENTRY..........30-11

INSPECTION, LIGHTS AND SWITCHES....30-12

INSPECTION, LINES/HOSES.............30-6

INSPECTION, MANUAL - NV3500........21-15

INSPECTION, MEASURING TIMING

CHAIN STRETCH.......9-114,9-170,9-227,9-58

INSPECTION, MIRROR................30-19

INSPECTION, NEUTRAL SAFETY SWITCH . . 30-19

INSPECTION, OIL COOLER & LINES -

CLEANING..........................9-296

INSPECTION, OIL PAN . 9-106,9-162,9-219,9-297,

9-49

INSPECTION, OIL PRESSURE RELIEF

VALVE .............................9-297

INSPECTION, OIL PUMP....9-107,9-163,9-220,

9-299,9-50

INSPECTION, OIL PUMP . . 21-211,21-382,21-557,

21-728

INSPECTION, OTHER..................30-15

INSPECTION, OVERDRIVE UNIT . . 21-224,21-394,

21-569,21-741

INSPECTION, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON RETAINER....21-236,

21-406,21-580,21-752

INSPECTION, PARKING BRAKE..........30-17

INSPECTION, PISTON & CONNECTING

ROD ............9-154,9-209,9-285,9-41,9-98

INSPECTION, PLANETARY GEARTRAIN/

OUTPUT SHAFT . . . 21-241,21-411,21-587,21-760

INSPECTION, PUSHRODS..............9-250

INSPECTION, RADIATOR - 3.9L/5.2L/5.9L . . . 7-61

INSPECTION, RADIATOR - 5.9L DIESEL....7-65

INSPECTION, RADIATOR - 8.0L..........7-62

INSPECTION, RADIATOR FAN -

3.9L/5.2L/5.9L/8.0L....................7-43

INSPECTION, RADIATOR FAN - 5.9L

DIESEL.............................7-44

INSPECTION, RADIATOR PRESSURE CAP . . . 7-66

INSPECTION, RADIO..................30-17

INSPECTION, REAR CLUTCH....21-248,21-419,

21-593,21-765

INSPECTION, RECEIVING...............30-3

INSPECTION, ROCKER ARM / ADJUSTER

ASSY..............................9-262

INSPECTION, SEAT BELTS, SHOULDER

BELTS, RETRACTORS AND HEAD

RESTRAINTS........................30-12

INSPECTION, SEATS..................30-13

INSPECTION, SERVICE BRAKES.........30-17

INSPECTION, SHIFT/CLUTCH INTERLOCK

SYSTEM............................30-19

INSPECTION, SOLID LIFTERS/TAPPETS . . . 9-281

INSPECTION, SPEED CONTROL.........30-17

INSPECTION, SQUEAKS, RATTLES AND

WIND NOISE........................30-15

INSPECTION, STEERING AND HANDLING

. . 30-15

INSPECTION, TAILPIPE - 3.9L/5.2L/5.9L

. . . 11-11

INSPECTION, TAILPIPE - 5.9L DIESEL

....11-12

INSPECTION, TAILPIPE - 5.9L HEAVY

DUTY/8.0L

..........................11-12

INSPECTION, TIRE PRESSURES

..........30-8

INSPECTION, TRANSFER CASE -

NV231HD

..........................21-832

INSPECTION, TRANSFER CASE -

NV241HD

..........................21-902

INSPECTION, TRANSFER CASE -

NV241LD

..........................21-867

INSPECTION, TRANSMISSION

.....21-109,21-64

INSPECTION, TRANSMISSION/TRANSFER

CASE

..............................30-15

INSPECTION, TRIP COMPUTER/

MAINTENANCE REMINDER

.............30-17

INSPECTION, TURBOCHARGER

..........11-16

INSPECTION, TURN AND EMERGENCY

SIGNALS

...........................30-19INSPECTION, VALVE BODY......21-293,21-465,

21-637,21-809

INSPECTION, VIBRATION DAMPER.......9-289

INSPECTION, VISUAL..................30-8

INSPECTION, WATER PUMP -

3.9L/5.2L/5.9L........................7-69

INSPECTION, WATER PUMP - 5.9L

DIESEL.............................7-73

INSPECTION, WATER PUMP - 8.0L........7-72

INSPECTION, WHEEL CYLINDERS........5-31

INSPECTION, WINDOWS, DOORS AND

LOCKS.............................30-14

INSPECTION WINDSHIELD WIPERS/

WASHERS, ROAD TEST................30-18

INSPECTION, WIPER & WASHER

SYSTEM............................8R-6

INSPECTION, WIRING..................30-7

INSTALLED - INSTALLATION, FRONT OIL

SEAL - FRONT COVER.................9-205

INSTALLED - REMOVAL, FRONT OIL

SEAL - FRONT COVER.................9-204

INSTRUMENT CLUSTER - ASSEMBLY.....8J-13

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING........................8J-6

INSTRUMENT CLUSTER - DISASSEMBLY . . 8J-11

INSTRUMENT CLUSTER - INSTALLATION . . 8J-14

INSTRUMENT CLUSTER - OPERATION.....8J-3

INSTRUMENT CLUSTER - REMOVAL.....8J-10

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-10

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-9

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-37

INSTRUMENT PANEL DUCTS - REMOVAL . 24-37

INSTRUMENT PANEL SYSTEM -

DESCRIPTION......................23-104

INSTRUMENT PANEL SYSTEM -

INSTALLATION......................23-107

INSTRUMENT PANEL SYSTEM -

OPERATION........................23-105

INSTRUMENT PANEL SYSTEM -

REMOVAL.........................23-106

INSTRUMENT PANEL TOP COVER -

INSTALLATION......................23-115

INSTRUMENT PANEL TOP COVER -

REMOVAL.........................23-114

INTAKE AIR HEATER - DESCRIPTION....14-100

INTAKE AIR HEATER - INSTALLATION....14-101

INTAKE AIR HEATER - OPERATION......14-100

INTAKE AIR HEATER - REMOVAL.......14-100

INTAKE AIR HEATER RELAY -

DESCRIPTION......................14-101

INTAKE AIR HEATER RELAY -

INSTALLATION......................14-102

INTAKE AIR HEATER RELAY -

OPERATION........................14-102

INTAKE AIR HEATER RELAY - REMOVAL . 14-102

INTAKE MANIFOLD - CLEANING

....9-110,9-166,

9-223,9-302,9-53

INTAKE MANIFOLD - DESCRIPTION

. 9-109,9-165,

9-222,9-52

INTAKE MANIFOLD - INSPECTION

. . 9-110,9-166,

9-223,9-302,9-53

INTAKE MANIFOLD - INSTALLATION

.....9-111,

9-166,9-223,9-302,9-53

INTAKE MANIFOLD - OPERATION

. . 9-109,9-165,

9-52

INTAKE MANIFOLD - REMOVAL

....9-110,9-166,

9-222,9-301,9-53

INTAKE MANIFOLD LEAKAGE -

DIAGNOSIS AND TESTING

. . . 9-110,9-165,9-222,

9-53

INTAKE/EXHAUST VALVES & SEATS -

CLEANING

.............9-140,9-198,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION

.....9-138,9-195,9-25,9-253,9-81

INTAKE/EXHAUST VALVES & SEATS -

INSPECTION

...........9-141,9-198,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION

.........9-141,9-260,9-28,9-85

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL

.............9-140,9-258,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

STANDARD PROCEDURE-

VALVES,GUIDES AND SPRINGS

.........9-253

BR/BEINDEX 19

Description Group-Page Description Group-Page Description Group-Page

Page 2871 of 2889

OIL SEAL - REAR - REMOVAL,

CRANKSHAFT.....9-149,9-206,9-278,9-35,9-92

OIL SEAL RETAINER - INSTALLATION,

CRANKSHAFT REAR.............9-206,9-279

OIL SEAL RETAINER - REMOVAL,

CRANKSHAFT REAR.............9-206,9-278

OIL SERVICE, OIL - STANDARD

PROCEDURE-ENGINE.................9-295

ON-BOARD DIAGNOSTICS (OBD) -

DIAGNOSIS AND TESTING...............7-4

ONE WAY CHECK VALVE - DESCRIPTION . . 25-30

ONE WAY CHECK VALVE - INSTALLATION . 25-30

ONE WAY CHECK VALVE - OPERATION....25-30

ONE WAY CHECK VALVE - REMOVAL.....25-30

ONE-WAY CHECK VALVE - DIAGNOSIS

AND TESTING.......................25-30

ON/OFF SWITCH - DESCRIPTION,

PASSENGER AIRBAG.................8O-23

ON/OFF SWITCH - INSTALLATION,

PASSENGER AIRBAG.................8O-25

ON/OFF SWITCH - OPERATION,

PASSENGER AIRBAG.................8O-24

ON/OFF SWITCH - REMOVAL,

PASSENGER AIRBAG.................8O-24

OPEN-CIRCUIT VOLTAGE TEST -

STANDARD PROCEDURE...............8F-13

OPENING COVER - INSTALLATION,

STEERING COLUMN.................23-116

OPENING COVER - REMOVAL, STEERING

COLUMN..........................23-115

OPENING DIMENSIONS, SPECIFICATIONS

- BODY............................23-60

OPENING SEAL - INSTALLATION, DOOR . . 23-153

OPENING SEAL - REMOVAL, DOOR.....23-153

OPENING UPPER TRIM - INSTALLATION,

GLOVE BOX........................23-114

OPENING UPPER TRIM - REMOVAL,

GLOVE BOX........................23-114

OPERATION, WIPERS/WASHERS.........8R-2

ORDER, 3.9L V-6 ENGINE - ENGINE

FIRING..............................8I-2

ORDER, 5.2L/5.9L V-8 ENGINES -

ENGINE FIRING.......................8I-2

ORDER, 8.0L V-10 ENGINE - SPARK

PLUG CABLE.........................8I-2

ORDER, DIESEL - FUEL INJECTOR

FIRING.............................14-58

ORIFICE TUBE - DESCRIPTION, A/C......24-53

ORIFICE TUBE - DIAGNOSIS AND

TESTING, FIXED.....................24-54

ORIFICE TUBE - OPERATION, A/C........24-53

ORIFICE TUBE - REMOVAL, A/C.........24-54

OTHER - INSPECTION.................30-15

OUT - STANDARD PROCEDURE, OWNER

CHECK.............................30-22

OUTBOARD IDENTIFICATION LAMP -

INSTALLATION.......................8L-29

OUTBOARD IDENTIFICATION LAMP -

REMOVAL..........................8L-28

OUTER BELT WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-154

OUTER BELT WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-154

OUTLET - DESCRIPTION, CIGAR

LIGHTER.........................8W-97-2

OUTLET - DESCRIPTION, POWER......8W-97-9

OUTLET - DIAGNOSIS & TESTING,

POWER.........................8W-97-10

OUTLET - INSTALLATION, CIGAR

LIGHTER.........................8W-97-3

OUTLET - INSTALLATION, POWER

....8W-97-11

OUTLET - OPERATION, CIGAR LIGHTER

. 8W-97-2

OUTLET - OPERATION, POWER

......8W-97-10

OUTLET - REMOVAL, CIGAR LIGHTER

. . 8W-97-3

OUTLET - REMOVAL, POWER

........8W-97-10

OUTLET BARRELS - INSTALLATION,

PANEL

.............................24-32

OUTLET BARRELS - REMOVAL, PANEL

. . . 24-32

OUTPUT - DESCRIPTION, PCM

...........8I-3

OUTPUT - DIAGNOSIS AND TESTING,

VACUUM PUMP

.......................7-35

OUTPUT - OPERATION, PCM

............14-53

OUTPUT - OPERATION, PCM

.............8I-3

OUTPUT SHAFT FRONT BEARING -

INSTALLATION

....21-213,21-384,21-560,21-730

OUTPUT SHAFT FRONT BEARING -

REMOVAL

.......21-213,21-384,21-559,21-730OUTPUT SHAFT REAR BEARING -

INSTALLATION....21-213,21-384,21-560,21-731

OUTPUT SHAFT REAR BEARING -

REMOVAL.......21-213,21-384,21-560,21-731

OUTPUT SHAFT SEAL - INSTALLATION,

FRONT................21-852,21-886,21-922

OUTPUT SHAFT SEAL - REMOVAL,

FRONT................21-851,21-886,21-922

OVERDRIVE CLUTCH - DESCRIPTION . . . 21-214,

21-385,21-560,21-731

OVERDRIVE CLUTCH - OPERATION.....21-214,

21-385,21-560,21-731

OVERDRIVE ELECTRICAL CONTROLS -

DIAGNOSIS AND TESTING......21-215,21-386,

21-579,21-732

OVERDRIVE OFF INDICATOR -

DESCRIPTION.......................8J-27

OVERDRIVE OFF INDICATOR -

OPERATION.........................8J-27

OVERDRIVE OFF SWITCH -

DESCRIPTION......................21-215

OVERDRIVE OFF SWITCH -

INSTALLATION......................21-215

OVERDRIVE OFF SWITCH - OPERATION . . 21-215

OVERDRIVE OFF SWITCH - REMOVAL . . . 21-215

OVERDRIVE SWITCH - DESCRIPTION . . . 21-385,

21-578,21-732

OVERDRIVE SWITCH - INSTALLATION . . . 21-386,

21-579,21-733

OVERDRIVE SWITCH - OPERATION.....21-385,

21-579,21-732

OVERDRIVE SWITCH - REMOVAL......21-386,

21-579,21-733

OVERDRIVE UNIT - ASSEMBLY . . 21-225,21-395,

21-569,21-742

OVERDRIVE UNIT - CLEANING . . . 21-224,21-394,

21-568,21-741

OVERDRIVE UNIT - DISASSEMBLY.....21-217,

21-387,21-562,21-734

OVERDRIVE UNIT - INSPECTION . 21-224,21-394,

21-569,21-741

OVERDRIVE UNIT - INSTALLATION.....21-234,

21-404,21-577,21-750

OVERDRIVE UNIT - REMOVAL . . . 21-216,21-387,

21-560,21-733

OVERFLOW VALVE - DESCRIPTION......14-83

OVERFLOW VALVE - DIAGNOSIS AND

TESTING...........................14-84

OVERFLOW VALVE - INSTALLATION......14-85

OVERFLOW VALVE - OPERATION........14-83

OVERFLOW VALVE - REMOVAL..........14-84

OVERHEAD CONSOLE - DESCRIPTION....8M-1

OVERHEAD CONSOLE - INSTALLATION....8M-8

OVERHEAD CONSOLE - OVERHEAD

CONSOLE ASSEMBLY..................8M-7