belt DODGE RAM 2001 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 678 of 2889

Deployment of the airbags depends upon the angle

and severity of the impact. The airbag system is

designed to deploy upon a frontal impact within a

thirty degree angle from either side of the vehicle

center line. Deployment is not based upon vehicle

speed; rather, deployment is based upon the rate of

deceleration as measured by the forces of gravity (G

force) upon the airbag system impact sensor, which is

integral to the ACM. When a frontal impact is severe

enough, the microprocessor in the ACM signals the

inflator units of both airbag modules to deploy the

airbags. During a frontal vehicle impact, the knee

blockers work in concert with properly fastened and

adjusted seat belts to restrain both the driver and

the front seat passenger in the proper position for an

airbag deployment. The knee blockers also absorb

and distribute the crash energy from the driver and

the front seat passenger to the structure of the

instrument panel.

Typically, the driver and front seat passenger recall

more about the events preceding and following a col-

lision than they have of the airbag deployment itself.

This is because the airbag deployment and deflation

occur so rapidly. In a typical 48 kilometer-per-hour

(30 mile-per-hour) barrier impact, from the moment

of impact until both airbags are fully inflated takes

about 40 milliseconds. Within one to two seconds

from the moment of impact, both airbags are almost

entirely deflated. The times cited for these events are

approximations, which apply only to a barrier impact

at the given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

airbag system circuits or components, it stores a

fault code or Diagnostic Trouble Code (DTC) in its

memory circuit and sends an electronic message to

the EMIC to turn on the airbag indicator. Proper

testing of the airbag system components, the

Chrysler Collision Detection (CCD) data bus, the

data bus message inputs to and outputs from the

EMIC or the ACM, as well as the retrieval or erasure

of a DTC from the ACM requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passenger restraints,

including the airbag system.

WARNING

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTROMECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY AIR-

BAG SYSTEM OR RELATED STEERING WHEEL,STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENTS YOU MUST FIRST DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE (GROUND)

CABLE. THEN WAIT TWO MINUTES FOR THE SYS-

TEM CAPACITOR TO DISCHARGE BEFORE FUR-

THER SYSTEM SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO DO THIS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE DRIVER AIRBAG INFLATOR UNIT

CONTAINS SODIUM AZIDE AND POTASSIUM

NITRATE. THESE MATERIALS ARE POISONOUS

AND EXTREMELY FLAMMABLE. CONTACT WITH

ACID, WATER, OR HEAVY METALS MAY PRODUCE

HARMFUL AND IRRITATING GASES (SODIUM

HYDROXIDE IS FORMED IN THE PRESENCE OF

MOISTURE) OR COMBUSTIBLE COMPOUNDS. THE

PASSENGER AIRBAG UNIT CONTAINS ARGON GAS

PRESSURIZED TO OVER 2500 PSI. DO NOT

ATTEMPT TO DISMANTLE AN AIRBAG UNIT OR

TAMPER WITH ITS INFLATOR. DO NOT PUNCTURE,

INCINERATE, OR BRING INTO CONTACT WITH

ELECTRICITY. DO NOT STORE AT TEMPERATURES

EXCEEDING 93É C (200É F).

WARNING: REPLACE AIRBAG SYSTEM COMPO-

NENTS ONLY WITH PARTS SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

SUBSTITUTE PARTS MAY APPEAR INTERCHANGE-

ABLE, BUT INTERNAL DIFFERENCES MAY RESULT

IN INFERIOR OCCUPANT PROTECTION.

WARNING: THE FASTENERS, SCREWS, AND

BOLTS ORIGINALLY USED FOR THE AIRBAG SYS-

TEM COMPONENTS HAVE SPECIAL COATINGS

AND ARE SPECIFICALLY DESIGNED FOR THE AIR-

BAG SYSTEM. THEY MUST NEVER BE REPLACED

WITH ANY SUBSTITUTES. ANY TIME A NEW FAS-

TENER IS NEEDED, REPLACE IT WITH THE COR-

RECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR SPECIFIED IN THE DAIMLER-

CHRYSLER MOPAR PARTS CATALOG.

WARNING: WHEN A STEERING COLUMN HAS AN

AIRBAG UNIT ATTACHED, NEVER PLACE THE COL-

UMN ON THE FLOOR OR ANY OTHER SURFACE

WITH THE STEERING WHEEL OR AIRBAG UNIT

FACE DOWN.

BR/BERESTRAINTS 8O - 3

RESTRAINTS (Continued)

Page 684 of 2889

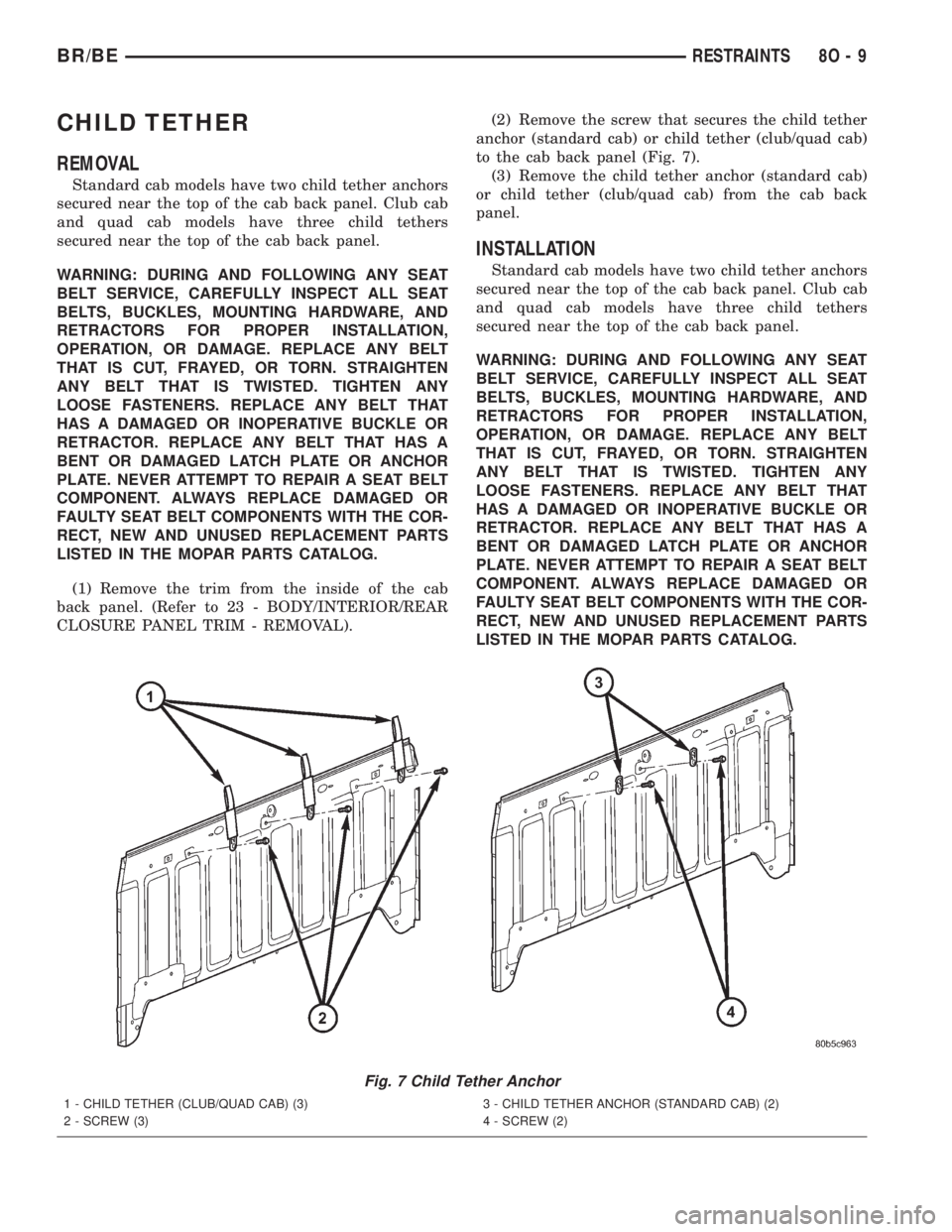

CHILD TETHER

REMOVAL

Standard cab models have two child tether anchors

secured near the top of the cab back panel. Club cab

and quad cab models have three child tethers

secured near the top of the cab back panel.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the trim from the inside of the cab

back panel. (Refer to 23 - BODY/INTERIOR/REAR

CLOSURE PANEL TRIM - REMOVAL).(2) Remove the screw that secures the child tether

anchor (standard cab) or child tether (club/quad cab)

to the cab back panel (Fig. 7).

(3) Remove the child tether anchor (standard cab)

or child tether (club/quad cab) from the cab back

panel.

INSTALLATION

Standard cab models have two child tether anchors

secured near the top of the cab back panel. Club cab

and quad cab models have three child tethers

secured near the top of the cab back panel.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

Fig. 7 Child Tether Anchor

1 - CHILD TETHER (CLUB/QUAD CAB) (3)

2 - SCREW (3)3 - CHILD TETHER ANCHOR (STANDARD CAB) (2)

4 - SCREW (2)

BR/BERESTRAINTS 8O - 9

Page 693 of 2889

INSTALLATION

The following procedure is for replacement of a

faulty or damaged driver airbag. If the driver airbag

has been deployed, the clockspring and the steering

column assembly must also be replaced. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

REMOVAL) and (Refer to 19 - STEERING/COLUMN

- REMOVAL).

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

WARNING: USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.

WARNING: THE DRIVER AIRBAG TRIM COVER

MUST NEVER BE PAINTED. REPLACEMENT TRIM

COVERS ARE SERVICED IN THE ORIGINAL COL-

ORS. PAINT MAY CHANGE THE WAY IN WHICH THE

MATERIAL OF THE TRIM COVER RESPONDS TO AN

AIRBAG DEPLOYMENT. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN OCCUPANT

INJURIES UPON AIRBAG DEPLOYMENT.

(1) Assemble the driver airbag trim cover onto the

airbag housing. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - ASSEMBLY).

(2) When installing the driver airbag, reconnect

the clockspring driver airbag pigtail wire harness

connector to the airbag inflator connector receptacle

by pressing straight in on the connector (Fig. 10). You

can be certain that the connector is fully engaged by

listening carefully for a distinct, audible click as the

connector snaps into place.

(3) Reconnect the clockspring horn switch pigtail

wire harness connector to the horn switch feed pig-

tail wire connector, which is located on the back of

the driver airbag.(4) Carefully position the driver airbag in the

steering wheel. Be certain that the clockspring pig-

tail wires in the steering wheel hub area are not

pinched between the driver airbag and the steering

wheel.

(5) From the underside of the steering wheel,

install and tighten the two screws that secure the

driver airbag to the steering wheel armature.

Tighten the screws to 10.2 N´m (90 in. lbs.).

(6) Do not reconnect the battery negative cable at

this time. The airbag system verification test proce-

dure should be performed following service of any

airbag system component. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

VERIFICATION TEST).

FRONT SEAT BELT &

RETRACTOR

REMOVAL - STANDARD CAB

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

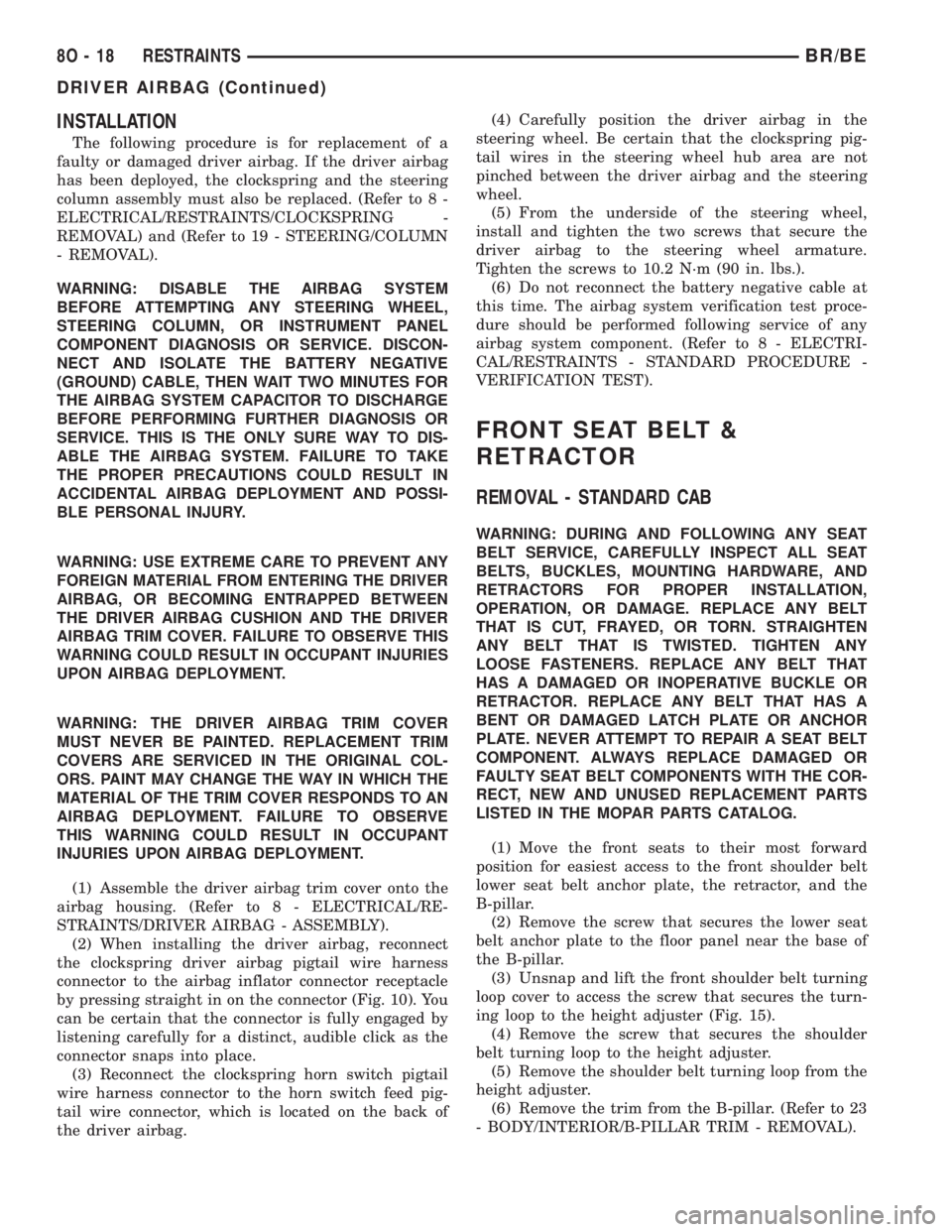

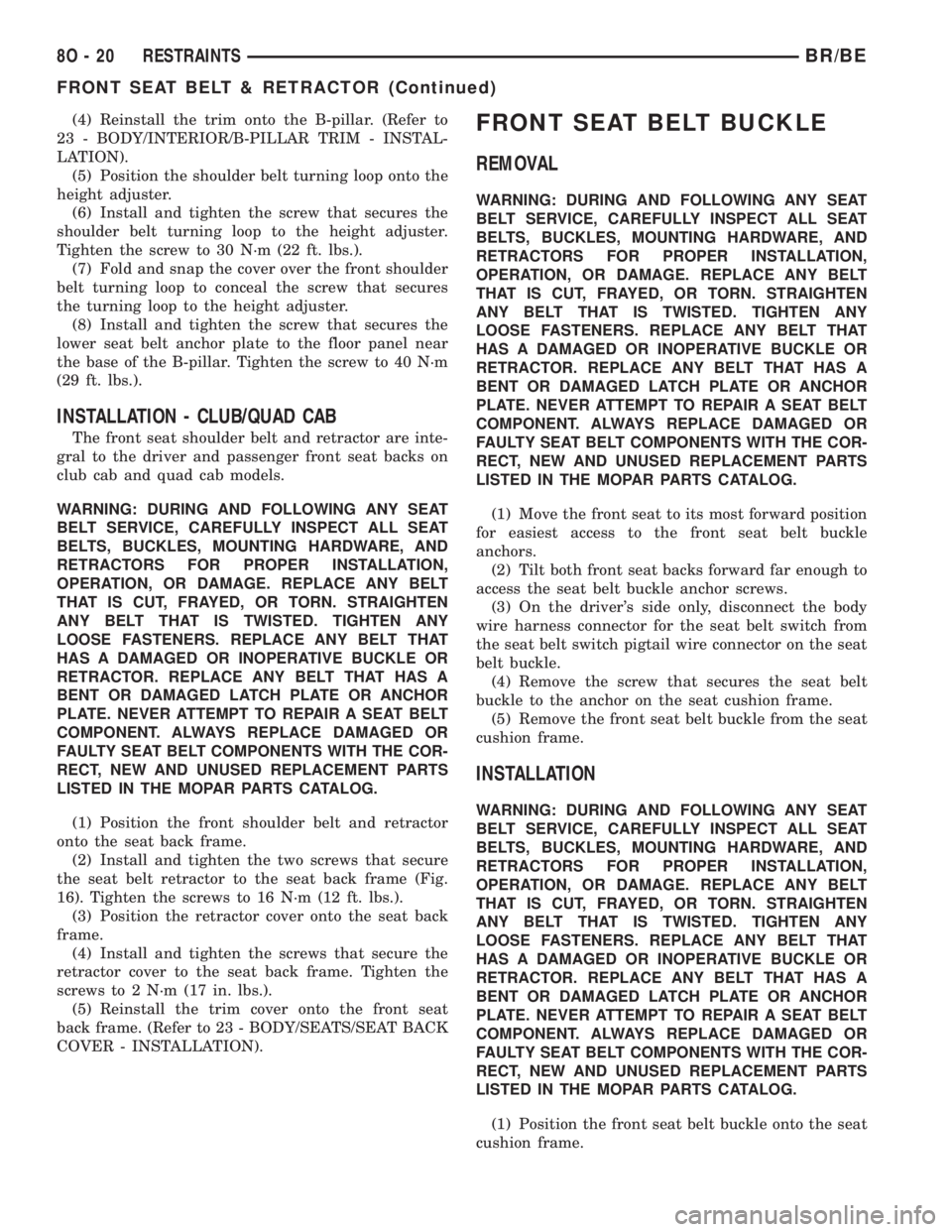

(1) Move the front seats to their most forward

position for easiest access to the front shoulder belt

lower seat belt anchor plate, the retractor, and the

B-pillar.

(2) Remove the screw that secures the lower seat

belt anchor plate to the floor panel near the base of

the B-pillar.

(3) Unsnap and lift the front shoulder belt turning

loop cover to access the screw that secures the turn-

ing loop to the height adjuster (Fig. 15).

(4) Remove the screw that secures the shoulder

belt turning loop to the height adjuster.

(5) Remove the shoulder belt turning loop from the

height adjuster.

(6) Remove the trim from the B-pillar. (Refer to 23

- BODY/INTERIOR/B-PILLAR TRIM - REMOVAL).

8O - 18 RESTRAINTSBR/BE

DRIVER AIRBAG (Continued)

Page 694 of 2889

(7) Disengage the front seat shoulder belt turning

loop and lower seat belt anchor plate from the B-pil-

lar trim.

(8) Remove the screw that secures the retractor to

the B-pillar.

(9) Remove the front shoulder belt and retractor

from the B-pillar.

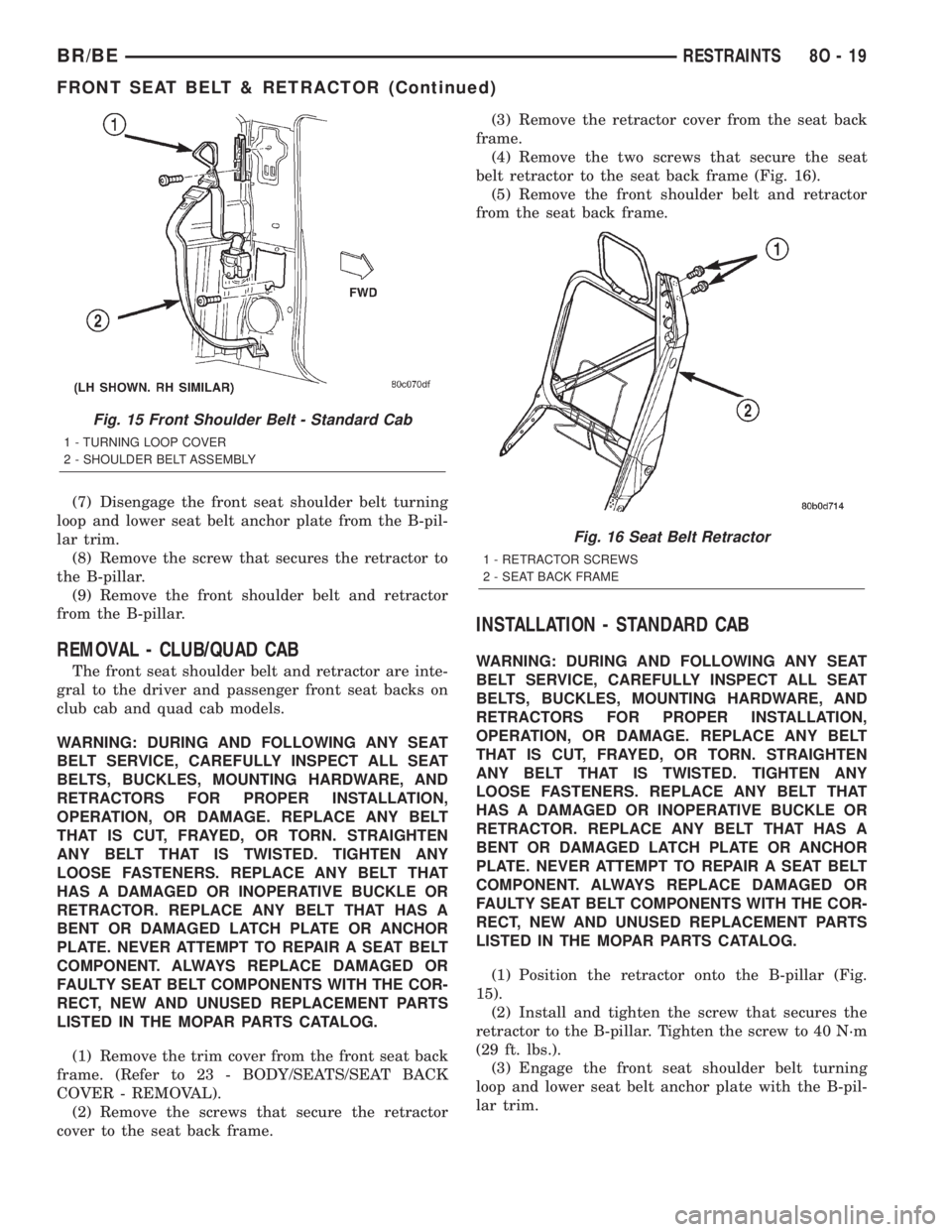

REMOVAL - CLUB/QUAD CAB

The front seat shoulder belt and retractor are inte-

gral to the driver and passenger front seat backs on

club cab and quad cab models.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the trim cover from the front seat back

frame. (Refer to 23 - BODY/SEATS/SEAT BACK

COVER - REMOVAL).

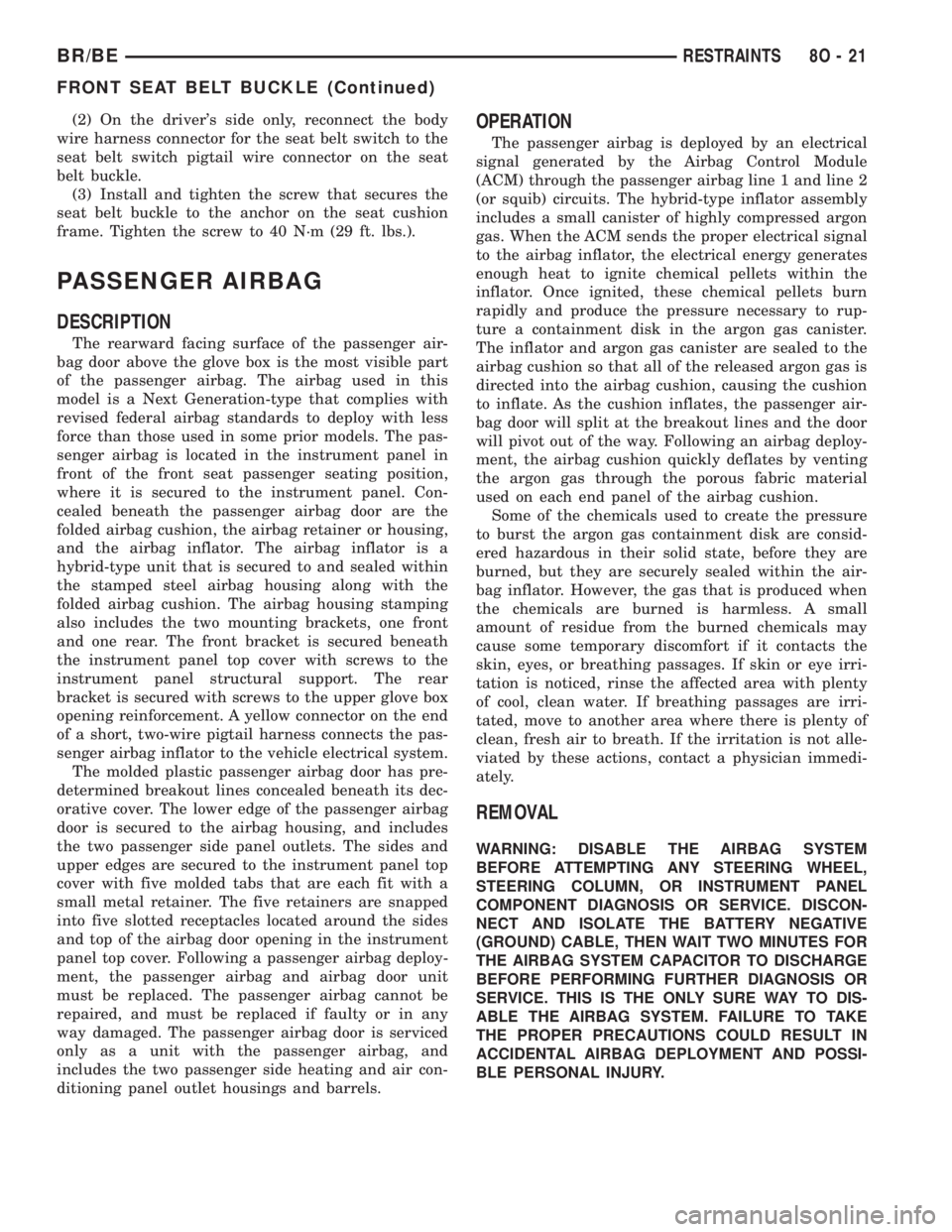

(2) Remove the screws that secure the retractor

cover to the seat back frame.(3) Remove the retractor cover from the seat back

frame.

(4) Remove the two screws that secure the seat

belt retractor to the seat back frame (Fig. 16).

(5) Remove the front shoulder belt and retractor

from the seat back frame.

INSTALLATION - STANDARD CAB

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the retractor onto the B-pillar (Fig.

15).

(2) Install and tighten the screw that secures the

retractor to the B-pillar. Tighten the screw to 40 N´m

(29 ft. lbs.).

(3) Engage the front seat shoulder belt turning

loop and lower seat belt anchor plate with the B-pil-

lar trim.

Fig. 15 Front Shoulder Belt - Standard Cab

1 - TURNING LOOP COVER

2 - SHOULDER BELT ASSEMBLY

Fig. 16 Seat Belt Retractor

1 - RETRACTOR SCREWS

2 - SEAT BACK FRAME

BR/BERESTRAINTS 8O - 19

FRONT SEAT BELT & RETRACTOR (Continued)

Page 695 of 2889

(4) Reinstall the trim onto the B-pillar. (Refer to

23 - BODY/INTERIOR/B-PILLAR TRIM - INSTAL-

LATION).

(5) Position the shoulder belt turning loop onto the

height adjuster.

(6) Install and tighten the screw that secures the

shoulder belt turning loop to the height adjuster.

Tighten the screw to 30 N´m (22 ft. lbs.).

(7) Fold and snap the cover over the front shoulder

belt turning loop to conceal the screw that secures

the turning loop to the height adjuster.

(8) Install and tighten the screw that secures the

lower seat belt anchor plate to the floor panel near

the base of the B-pillar. Tighten the screw to 40 N´m

(29 ft. lbs.).

INSTALLATION - CLUB/QUAD CAB

The front seat shoulder belt and retractor are inte-

gral to the driver and passenger front seat backs on

club cab and quad cab models.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the front shoulder belt and retractor

onto the seat back frame.

(2) Install and tighten the two screws that secure

the seat belt retractor to the seat back frame (Fig.

16). Tighten the screws to 16 N´m (12 ft. lbs.).

(3) Position the retractor cover onto the seat back

frame.

(4) Install and tighten the screws that secure the

retractor cover to the seat back frame. Tighten the

screws to 2 N´m (17 in. lbs.).

(5) Reinstall the trim cover onto the front seat

back frame. (Refer to 23 - BODY/SEATS/SEAT BACK

COVER - INSTALLATION).

FRONT SEAT BELT BUCKLE

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Move the front seat to its most forward position

for easiest access to the front seat belt buckle

anchors.

(2) Tilt both front seat backs forward far enough to

access the seat belt buckle anchor screws.

(3) On the driver's side only, disconnect the body

wire harness connector for the seat belt switch from

the seat belt switch pigtail wire connector on the seat

belt buckle.

(4) Remove the screw that secures the seat belt

buckle to the anchor on the seat cushion frame.

(5) Remove the front seat belt buckle from the seat

cushion frame.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the front seat belt buckle onto the seat

cushion frame.

8O - 20 RESTRAINTSBR/BE

FRONT SEAT BELT & RETRACTOR (Continued)

Page 696 of 2889

(2) On the driver's side only, reconnect the body

wire harness connector for the seat belt switch to the

seat belt switch pigtail wire connector on the seat

belt buckle.

(3) Install and tighten the screw that secures the

seat belt buckle to the anchor on the seat cushion

frame. Tighten the screw to 40 N´m (29 ft. lbs.).

PASSENGER AIRBAG

DESCRIPTION

The rearward facing surface of the passenger air-

bag door above the glove box is the most visible part

of the passenger airbag. The airbag used in this

model is a Next Generation-type that complies with

revised federal airbag standards to deploy with less

force than those used in some prior models. The pas-

senger airbag is located in the instrument panel in

front of the front seat passenger seating position,

where it is secured to the instrument panel. Con-

cealed beneath the passenger airbag door are the

folded airbag cushion, the airbag retainer or housing,

and the airbag inflator. The airbag inflator is a

hybrid-type unit that is secured to and sealed within

the stamped steel airbag housing along with the

folded airbag cushion. The airbag housing stamping

also includes the two mounting brackets, one front

and one rear. The front bracket is secured beneath

the instrument panel top cover with screws to the

instrument panel structural support. The rear

bracket is secured with screws to the upper glove box

opening reinforcement. A yellow connector on the end

of a short, two-wire pigtail harness connects the pas-

senger airbag inflator to the vehicle electrical system.

The molded plastic passenger airbag door has pre-

determined breakout lines concealed beneath its dec-

orative cover. The lower edge of the passenger airbag

door is secured to the airbag housing, and includes

the two passenger side panel outlets. The sides and

upper edges are secured to the instrument panel top

cover with five molded tabs that are each fit with a

small metal retainer. The five retainers are snapped

into five slotted receptacles located around the sides

and top of the airbag door opening in the instrument

panel top cover. Following a passenger airbag deploy-

ment, the passenger airbag and airbag door unit

must be replaced. The passenger airbag cannot be

repaired, and must be replaced if faulty or in any

way damaged. The passenger airbag door is serviced

only as a unit with the passenger airbag, and

includes the two passenger side heating and air con-

ditioning panel outlet housings and barrels.

OPERATION

The passenger airbag is deployed by an electrical

signal generated by the Airbag Control Module

(ACM) through the passenger airbag line 1 and line 2

(or squib) circuits. The hybrid-type inflator assembly

includes a small canister of highly compressed argon

gas. When the ACM sends the proper electrical signal

to the airbag inflator, the electrical energy generates

enough heat to ignite chemical pellets within the

inflator. Once ignited, these chemical pellets burn

rapidly and produce the pressure necessary to rup-

ture a containment disk in the argon gas canister.

The inflator and argon gas canister are sealed to the

airbag cushion so that all of the released argon gas is

directed into the airbag cushion, causing the cushion

to inflate. As the cushion inflates, the passenger air-

bag door will split at the breakout lines and the door

will pivot out of the way. Following an airbag deploy-

ment, the airbag cushion quickly deflates by venting

the argon gas through the porous fabric material

used on each end panel of the airbag cushion.

Some of the chemicals used to create the pressure

to burst the argon gas containment disk are consid-

ered hazardous in their solid state, before they are

burned, but they are securely sealed within the air-

bag inflator. However, the gas that is produced when

the chemicals are burned is harmless. A small

amount of residue from the burned chemicals may

cause some temporary discomfort if it contacts the

skin, eyes, or breathing passages. If skin or eye irri-

tation is noticed, rinse the affected area with plenty

of cool, clean water. If breathing passages are irri-

tated, move to another area where there is plenty of

clean, fresh air to breath. If the irritation is not alle-

viated by these actions, contact a physician immedi-

ately.

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

BR/BERESTRAINTS 8O - 21

FRONT SEAT BELT BUCKLE (Continued)

Page 701 of 2889

(5) Position the passenger airbag on/off switch and

face plate unit to the opening in the instrument

panel (Fig. 21).

(6) Install and tighten the three screws that secure

the passenger airbag on/off switch face plate to the

instrument panel. Tighten the screws to 2.2 N´m (20

in. lbs.).

(7) Reinstall the glove box onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - INSTALLATION).

(8) Reinstall the cluster bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(9) Do not reconnect the battery negative cable at

this time. The airbag system verification test proce-

dure should be performed following service of any

airbag system component. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

VERIFICATION TEST).

REAR SEAT BELT &

RETRACTOR

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the rear seat from the passenger com-

partment. (Refer to 23 - BODY/SEATS/REAR SEAT -

REMOVAL).

(2) Remove the trim cover from the door sill.

(Refer to 23 - BODY/INTERIOR/DOOR SILL TRIM -

REMOVAL).

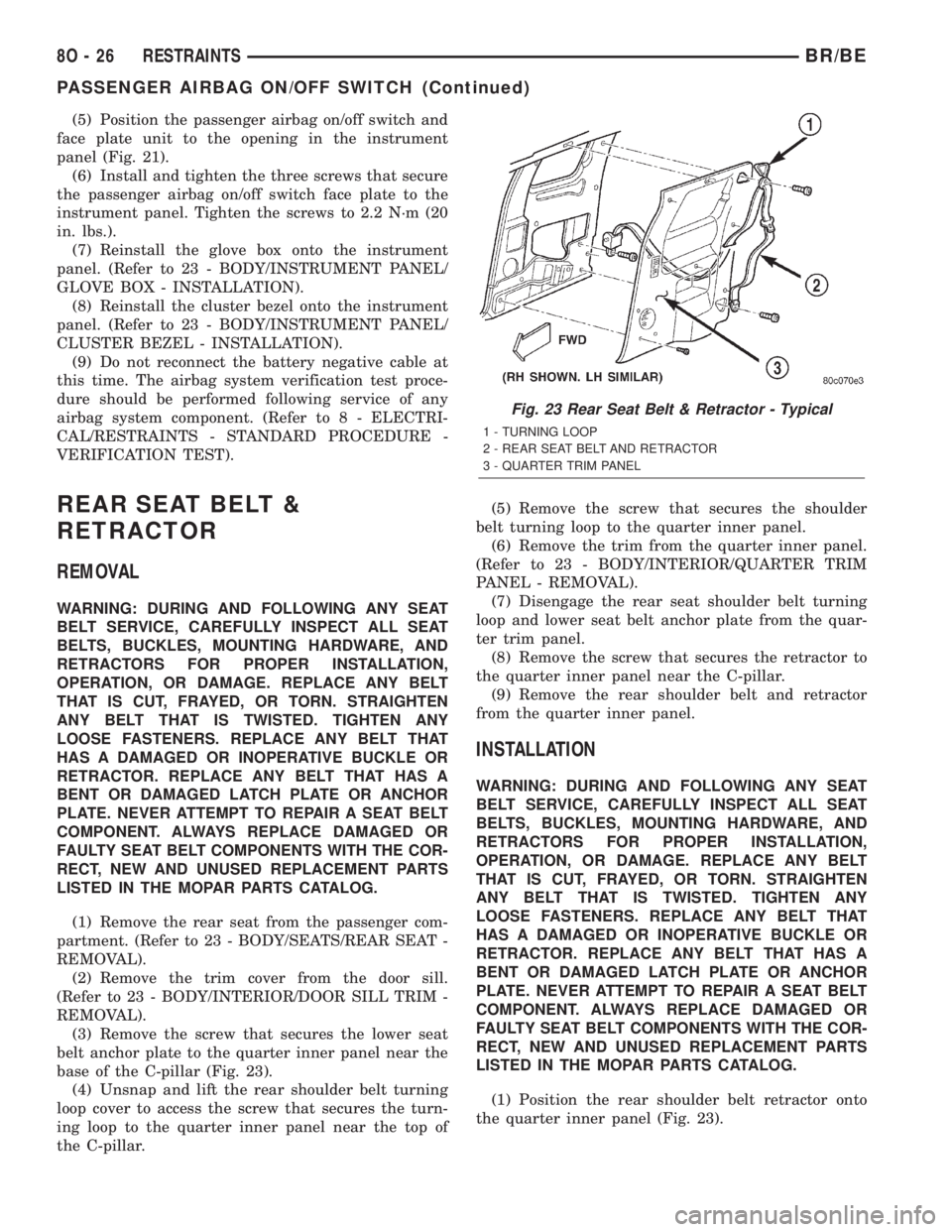

(3) Remove the screw that secures the lower seat

belt anchor plate to the quarter inner panel near the

base of the C-pillar (Fig. 23).

(4) Unsnap and lift the rear shoulder belt turning

loop cover to access the screw that secures the turn-

ing loop to the quarter inner panel near the top of

the C-pillar.(5) Remove the screw that secures the shoulder

belt turning loop to the quarter inner panel.

(6) Remove the trim from the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(7) Disengage the rear seat shoulder belt turning

loop and lower seat belt anchor plate from the quar-

ter trim panel.

(8) Remove the screw that secures the retractor to

the quarter inner panel near the C-pillar.

(9) Remove the rear shoulder belt and retractor

from the quarter inner panel.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the rear shoulder belt retractor onto

the quarter inner panel (Fig. 23).

Fig. 23 Rear Seat Belt & Retractor - Typical

1 - TURNING LOOP

2 - REAR SEAT BELT AND RETRACTOR

3 - QUARTER TRIM PANEL

8O - 26 RESTRAINTSBR/BE

PASSENGER AIRBAG ON/OFF SWITCH (Continued)

Page 702 of 2889

(2) Install and tighten the screw that secures the

retractor to the quarter inner panel. Tighten the

screw to 40 N´m (29 ft. lbs.).

(3) Engage the rear seat shoulder belt turning loop

and lower seat belt anchor plate with the quarter

trim panel.

(4) Reinstall the trim onto the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - INSTALLATION).

(5) Position the shoulder belt turning loop onto the

quarter inner panel near the top of the C-pillar.

(6) Install and tighten the screw that secures the

shoulder belt turning loop to the quarter inner panel.

Tighten the screw to 40 N´m (29 ft. lbs.).

(7) Fold and snap the cover over the rear shoulder

belt turning loop to conceal the screw that secures

the turning loop to the quarter inner panel.

(8) Position the lower seat belt anchor plate onto

the quarter inner panel near the base of the C-pillar.

(9) Install and tighten the screw that secures the

lower seat belt anchor plate to the quarter inner

panel near the base of the C-pillar. Tighten the screw

to 40 N´m (29 ft. lbs.).

(10) Reinstall the trim cover onto the door sill.

(Refer to 23 - BODY/INTERIOR/DOOR SILL TRIM -

INSTALLATION).

(11) Reinstall the rear seat into the passenger

compartment. (Refer to 23 - BODY/SEATS/REAR

SEAT - INSTALLATION).

REAR SEAT BELT BUCKLE

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

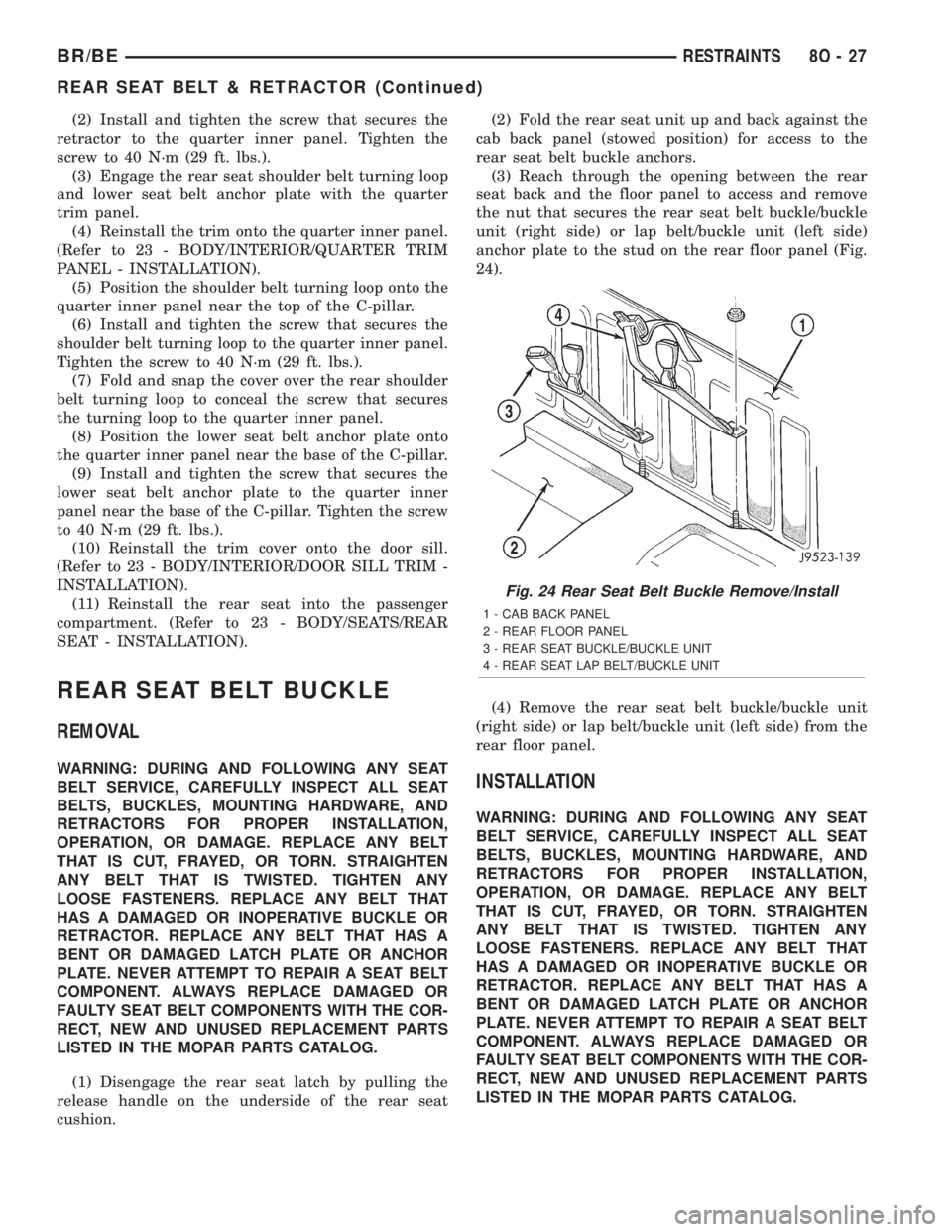

(1) Disengage the rear seat latch by pulling the

release handle on the underside of the rear seat

cushion.(2) Fold the rear seat unit up and back against the

cab back panel (stowed position) for access to the

rear seat belt buckle anchors.

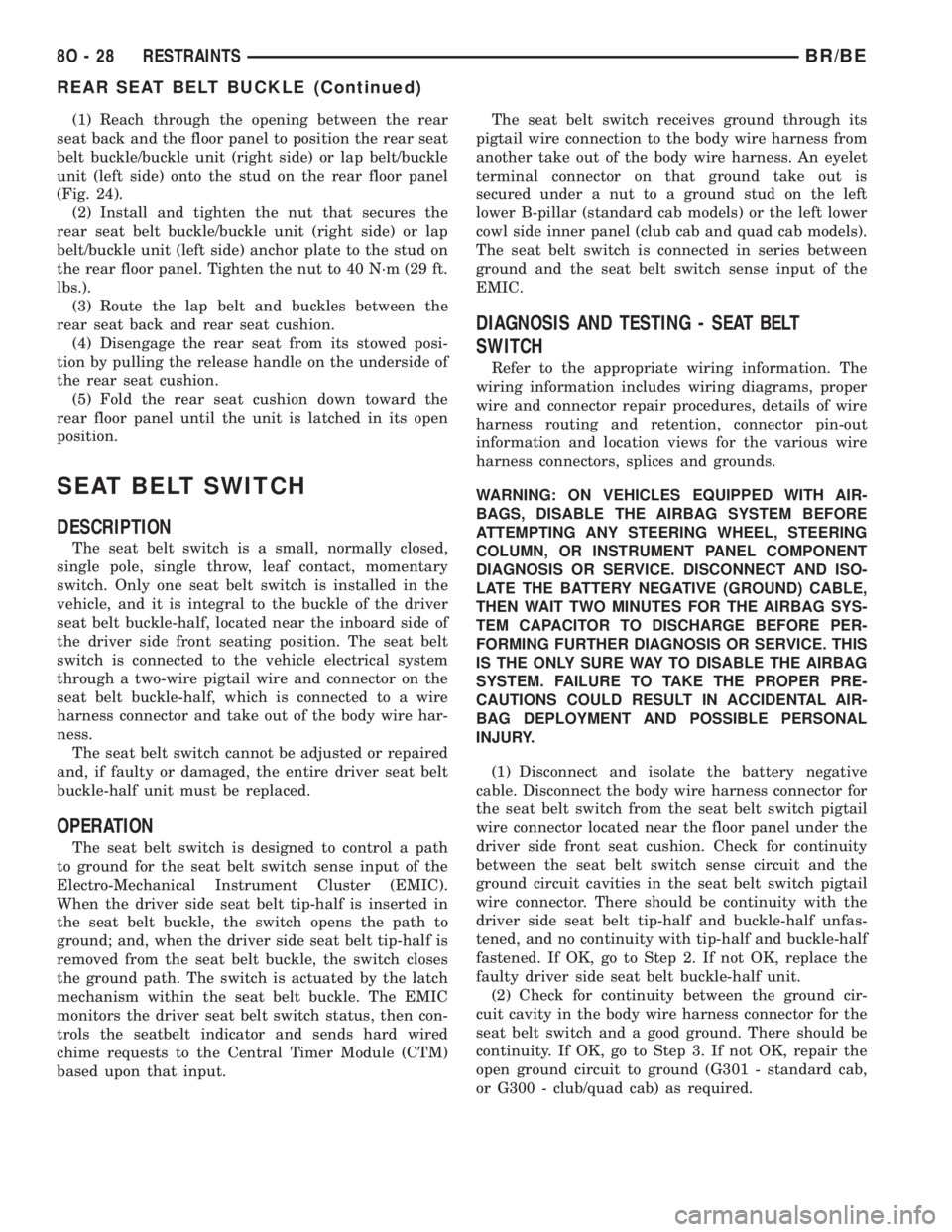

(3) Reach through the opening between the rear

seat back and the floor panel to access and remove

the nut that secures the rear seat belt buckle/buckle

unit (right side) or lap belt/buckle unit (left side)

anchor plate to the stud on the rear floor panel (Fig.

24).

(4) Remove the rear seat belt buckle/buckle unit

(right side) or lap belt/buckle unit (left side) from the

rear floor panel.INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

Fig. 24 Rear Seat Belt Buckle Remove/Install

1 - CAB BACK PANEL

2 - REAR FLOOR PANEL

3 - REAR SEAT BUCKLE/BUCKLE UNIT

4 - REAR SEAT LAP BELT/BUCKLE UNIT

BR/BERESTRAINTS 8O - 27

REAR SEAT BELT & RETRACTOR (Continued)

Page 703 of 2889

(1) Reach through the opening between the rear

seat back and the floor panel to position the rear seat

belt buckle/buckle unit (right side) or lap belt/buckle

unit (left side) onto the stud on the rear floor panel

(Fig. 24).

(2) Install and tighten the nut that secures the

rear seat belt buckle/buckle unit (right side) or lap

belt/buckle unit (left side) anchor plate to the stud on

the rear floor panel. Tighten the nut to 40 N´m (29 ft.

lbs.).

(3) Route the lap belt and buckles between the

rear seat back and rear seat cushion.

(4) Disengage the rear seat from its stowed posi-

tion by pulling the release handle on the underside of

the rear seat cushion.

(5) Fold the rear seat cushion down toward the

rear floor panel until the unit is latched in its open

position.

SEAT BELT SWITCH

DESCRIPTION

The seat belt switch is a small, normally closed,

single pole, single throw, leaf contact, momentary

switch. Only one seat belt switch is installed in the

vehicle, and it is integral to the buckle of the driver

seat belt buckle-half, located near the inboard side of

the driver side front seating position. The seat belt

switch is connected to the vehicle electrical system

through a two-wire pigtail wire and connector on the

seat belt buckle-half, which is connected to a wire

harness connector and take out of the body wire har-

ness.

The seat belt switch cannot be adjusted or repaired

and, if faulty or damaged, the entire driver seat belt

buckle-half unit must be replaced.

OPERATION

The seat belt switch is designed to control a path

to ground for the seat belt switch sense input of the

Electro-Mechanical Instrument Cluster (EMIC).

When the driver side seat belt tip-half is inserted in

the seat belt buckle, the switch opens the path to

ground; and, when the driver side seat belt tip-half is

removed from the seat belt buckle, the switch closes

the ground path. The switch is actuated by the latch

mechanism within the seat belt buckle. The EMIC

monitors the driver seat belt switch status, then con-

trols the seatbelt indicator and sends hard wired

chime requests to the Central Timer Module (CTM)

based upon that input.The seat belt switch receives ground through its

pigtail wire connection to the body wire harness from

another take out of the body wire harness. An eyelet

terminal connector on that ground take out is

secured under a nut to a ground stud on the left

lower B-pillar (standard cab models) or the left lower

cowl side inner panel (club cab and quad cab models).

The seat belt switch is connected in series between

ground and the seat belt switch sense input of the

EMIC.

DIAGNOSIS AND TESTING - SEAT BELT

SWITCH

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Disconnect the body wire harness connector for

the seat belt switch from the seat belt switch pigtail

wire connector located near the floor panel under the

driver side front seat cushion. Check for continuity

between the seat belt switch sense circuit and the

ground circuit cavities in the seat belt switch pigtail

wire connector. There should be continuity with the

driver side seat belt tip-half and buckle-half unfas-

tened, and no continuity with tip-half and buckle-half

fastened. If OK, go to Step 2. If not OK, replace the

faulty driver side seat belt buckle-half unit.

(2) Check for continuity between the ground cir-

cuit cavity in the body wire harness connector for the

seat belt switch and a good ground. There should be

continuity. If OK, go to Step 3. If not OK, repair the

open ground circuit to ground (G301 - standard cab,

or G300 - club/quad cab) as required.

8O - 28 RESTRAINTSBR/BE

REAR SEAT BELT BUCKLE (Continued)

Page 704 of 2889

(3) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the seat

belt switch sense circuit cavity in the instrument

panel wire harness connector (Connector C2) for the

instrument cluster and a good ground. There should

be no continuity. If OK, go to Step 4. If not OK,

repair the shorted seat belt switch sense circuit

between the seat belt switch and the instrument

cluster as required.

(4) Check for continuity between the seat belt

switch sense circuit cavities in the body wire harness

connector for the seat belt switch and the instrument

panel wire harness connector (Connector C2) for the

instrument cluster. There should be continuity. If

OK, proceed to the diagnosis for the instrument clus-

ter. (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). If not OK,

repair the open seat belt switch sense circuit between

the seat belt switch and the instrument cluster as

required.

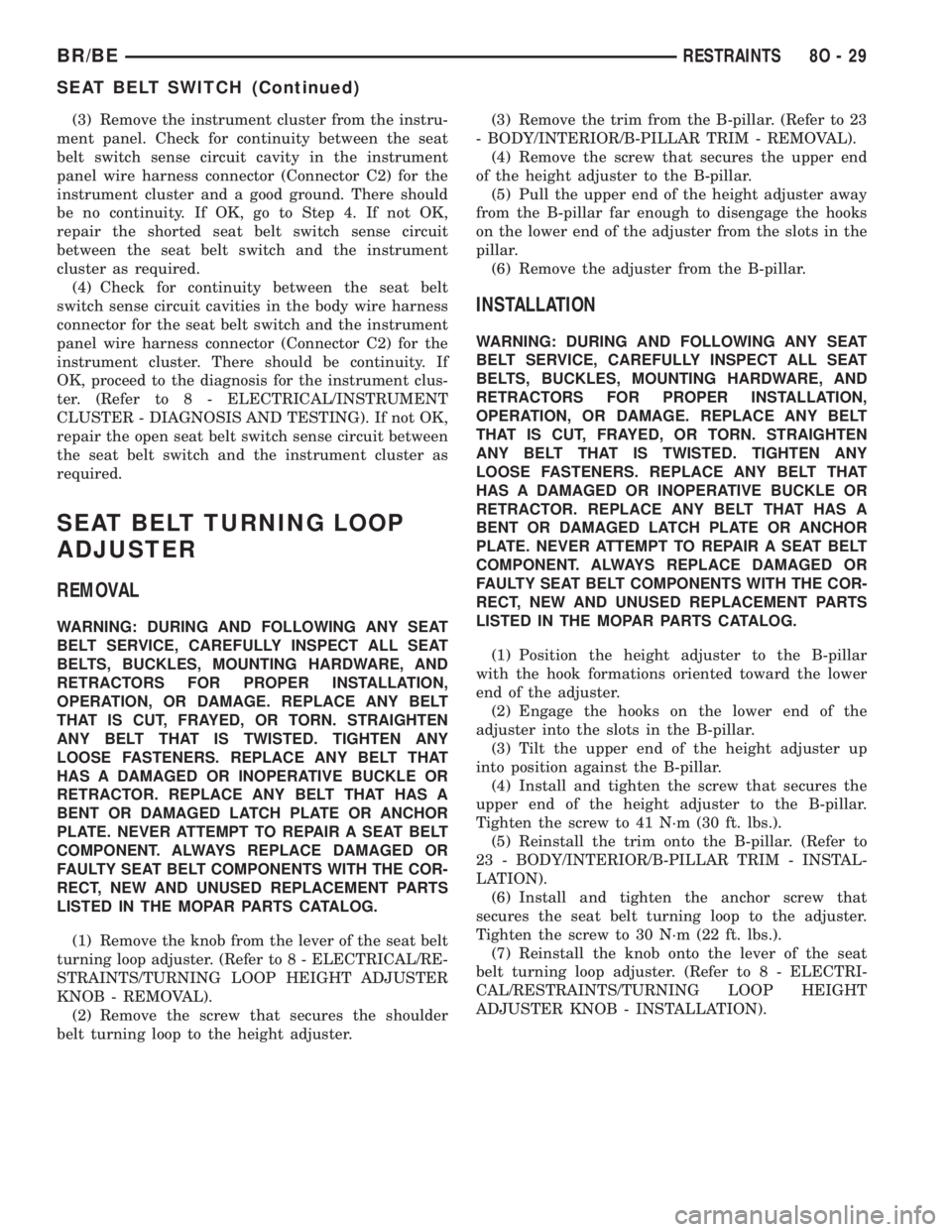

SEAT BELT TURNING LOOP

ADJUSTER

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the knob from the lever of the seat belt

turning loop adjuster. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/TURNING LOOP HEIGHT ADJUSTER

KNOB - REMOVAL).

(2) Remove the screw that secures the shoulder

belt turning loop to the height adjuster.(3) Remove the trim from the B-pillar. (Refer to 23

- BODY/INTERIOR/B-PILLAR TRIM - REMOVAL).

(4) Remove the screw that secures the upper end

of the height adjuster to the B-pillar.

(5) Pull the upper end of the height adjuster away

from the B-pillar far enough to disengage the hooks

on the lower end of the adjuster from the slots in the

pillar.

(6) Remove the adjuster from the B-pillar.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the height adjuster to the B-pillar

with the hook formations oriented toward the lower

end of the adjuster.

(2) Engage the hooks on the lower end of the

adjuster into the slots in the B-pillar.

(3) Tilt the upper end of the height adjuster up

into position against the B-pillar.

(4) Install and tighten the screw that secures the

upper end of the height adjuster to the B-pillar.

Tighten the screw to 41 N´m (30 ft. lbs.).

(5) Reinstall the trim onto the B-pillar. (Refer to

23 - BODY/INTERIOR/B-PILLAR TRIM - INSTAL-

LATION).

(6) Install and tighten the anchor screw that

secures the seat belt turning loop to the adjuster.

Tighten the screw to 30 N´m (22 ft. lbs.).

(7) Reinstall the knob onto the lever of the seat

belt turning loop adjuster. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/TURNING LOOP HEIGHT

ADJUSTER KNOB - INSTALLATION).

BR/BERESTRAINTS 8O - 29

SEAT BELT SWITCH (Continued)