rear view mirror DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 516 of 2889

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED MIRRORS......................... 1 HEATED SEATSYSTEM..................... 5

HEATED MIRRORS

TABLE OF CONTENTS

page page

HEATED MIRRORS

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................2

HEATED MIRROR SYSTEM................2

MIRROR SWITCH

DESCRIPTION............................3

OPERATION.............................3DIAGNOSIS AND TESTING..................3

HEATED MIRROR SWITCH................3

HEATED MIRROR GRID

DESCRIPTION............................4

OPERATION.............................4

DIAGNOSIS AND TESTING..................0

HEATED MIRROR GRID...................4

HEATED MIRRORS

DESCRIPTION - HEATED MIRROR SYSTEM

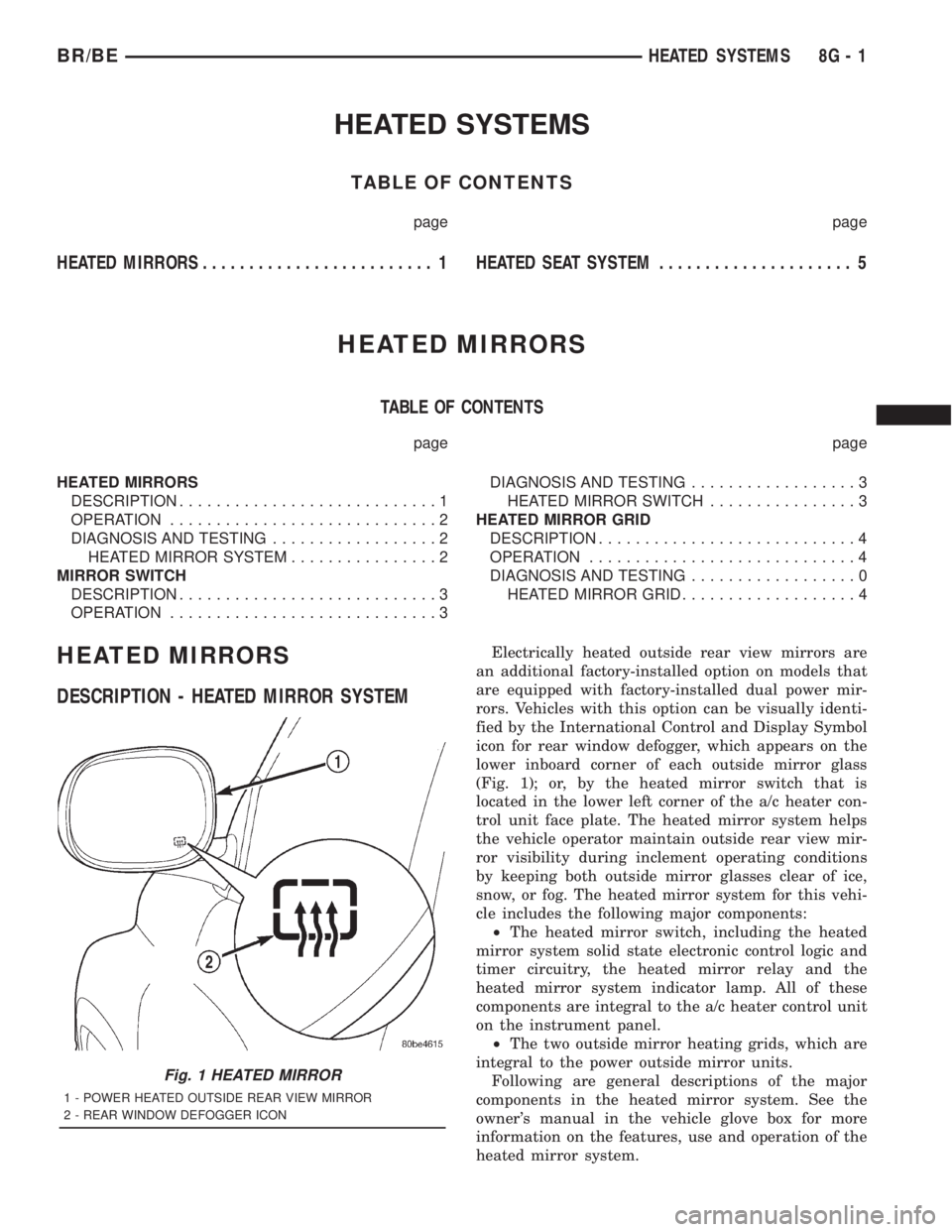

Electrically heated outside rear view mirrors are

an additional factory-installed option on models that

are equipped with factory-installed dual power mir-

rors. Vehicles with this option can be visually identi-

fied by the International Control and Display Symbol

icon for rear window defogger, which appears on the

lower inboard corner of each outside mirror glass

(Fig. 1); or, by the heated mirror switch that is

located in the lower left corner of the a/c heater con-

trol unit face plate. The heated mirror system helps

the vehicle operator maintain outside rear view mir-

ror visibility during inclement operating conditions

by keeping both outside mirror glasses clear of ice,

snow, or fog. The heated mirror system for this vehi-

cle includes the following major components:

²The heated mirror switch, including the heated

mirror system solid state electronic control logic and

timer circuitry, the heated mirror relay and the

heated mirror system indicator lamp. All of these

components are integral to the a/c heater control unit

on the instrument panel.

²The two outside mirror heating grids, which are

integral to the power outside mirror units.

Following are general descriptions of the major

components in the heated mirror system. See the

owner's manual in the vehicle glove box for more

information on the features, use and operation of the

heated mirror system.

Fig. 1 HEATED MIRROR

1 - POWER HEATED OUTSIDE REAR VIEW MIRROR

2 - REAR WINDOW DEFOGGER ICON

BR/BEHEATED SYSTEMS 8G - 1

Page 517 of 2889

OPERATION - HEATED MIRROR SYSTEM

The solid state electronic control logic and timer

circuitry for the heated mirror system receives bat-

tery current from a fuse in the Junction Block (JB)

only when the ignition switch is in the On or Start

positions. After the heated mirror system is turned

On, the electronic control logic and timer circuitry

will automatically turn the system off after a pro-

grammed time interval of about fifteen minutes.

After the initial time interval has expired, if the

heated mirror switch is depressed and released a sec-

ond time during the same ignition cycle, the elec-

tronic control logic and timer circuitry will

automatically turn the heated mirror system off after

a programmed time interval of about five minutes.

The heated mirror system will be shut off automati-

cally if the ignition switch is turned to the Off or

Accessory positions. After the heated mirror system

is turned On, it can also be turned off manually by

depressing and releasing the heated mirror switch a

second time.

When the heated mirror system is turned On, the

heated mirror system control logic and timer cir-

cuitry energizes the heated mirror system indicator

lamp and the heated mirror relay. When energized,

the heated mirror relay supplies fused ignition

switch output (run/start) current from a fuse in the

JB to the outside mirror heating grids located behind

the mirror glass of each of the outside rear view mir-

rors. When energized, each of the outside mirror

heating grids produces enough heat to warm the

glass of the outside rear view mirrors.

DIAGNOSIS AND TESTING - HEATED MIRROR

SYSTEM

If only one of the outside mirror heating grids is

inoperative, perform continuity checks on the circuits

and heater grid for that mirror only. If both outside

mirror heating grids are inoperative, proceed with

the heated mirror system diagnosis as follows. (Refer

to Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.The operation of the heated mirror system can be

confirmed in one of the following manners:

²Turn the ignition switch to the On position.

While monitoring the instrument panel voltmeter,

momentarily depress and release the heated mirror

switch. When the heated mirror system is turned On,

a distinct voltmeter needle deflection should be

noted.

²Turn the ignition switch to the On position.

Momentarily depress and release the heated mirror

switch to turn the heated mirror system On. The

heated mirror operation can be checked by feeling

the outside rear view mirror glass. A distinct differ-

ence in temperature between the unheated and

heated mirror glass can be detected within three to

four minutes of system operation.

The above checks will confirm system operation.

Illumination of the heated mirror system indicator

lamp means that there is electrical current available

at the heated mirror relay, but does not confirm that

the electrical current is reaching the outside mirror

heating grids.

If the heated mirror system does not operate, the

problem should be isolated in the following manner:

(1) Confirm that the ignition switch is in the On

position.

(2) Check the fuses in the Power Distribution Cen-

ter (PDC) and in the Junction Block (JB). The fuses

must be tight in their receptacles and all electrical

connections must be secure.

When the above steps have been completed and

both outside mirror heating grids are still inopera-

tive, one or more of the following is faulty:

²Heated mirror switch, electronic control logic

and timer circuitry, and heated mirror relay.

²Heated mirror wire harness circuits or connec-

tors.

²Outside mirror heating grid (both mirror grids

would have to be faulty).

If turning On the heated mirror system produces a

severe voltmeter deflection or fuse failures, check for

a shorted circuit between the output of the heated

mirror relay and the outside mirror heating grids.

8G - 2 HEATED MIRRORSBR/BE

HEATED MIRRORS (Continued)

Page 519 of 2889

(3) Disconnect and isolate the battery negative

cable. Disconnect the 3-way instrument panel wire

harness connector for the heated mirror switch from

the heated mirror switch connector receptacle on the

back of the a/c heater control. Check for continuity

between the ground circuit cavity of the wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run/start)

circuit cavity of the 3-way instrument panel wire

harness connector for the heated mirror switch. If

OK, go to Step 5. If not OK, repair the open fused

ignition switch output (run/start) circuit to the fuse

in the JB as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Reconnect the 3-way instrument panel wire harness

connector for the heated mirror switch to the heated

mirror switch connector receptacle on the back of the

a/c heater control. Reconnect the battery negative

cable. Turn the ignition switch to the On position.

Depress and release the heated mirror switch. The

amber heated mirror system indicator lamp next to

the heated mirror switch button should light. If OK,

go to Step 6. If not OK, replace the faulty a/c heater

control.

(6) Back probe the fused heated mirror relay out-

put circuit cavity of the 3-way instrument panel wire

harness connector for the heated mirror switch on

the back of the a/c heater control and check for volt-

age (battery voltage less the resistance in both out-

side mirror heating grids). If OK, (Refer to 8 -

ELECTRICAL/HEATED MIRRORS/HEATED MIR-

ROR GRID - DIAGNOSIS AND TESTING).

HEATED MIRROR GRID

DESCRIPTION

Vehicles equipped with the optional heated mirror

system have an electrically operated heating grid

located behind the mirror glass of each power oper-

ated outside rear view mirror. The outside mirror

heating grid consists of two thin laminations of plas-

tic that approximate the outer dimensions and shape

of the mirror glass. A single length of resistor wire

weaves in a back and forth pattern between, and is

held in place by the two thin laminations of plastic.

The two ends of the resistor wire terminate near the

inboard edge of the grid, where they are soldered to

the ground feed and battery current feed wires con-

tained in the power mirror wire harness. The heating

grid is then sandwiched between the back of themolded plastic mirror glass case and the mirror

glass, where it remains in direct contact with the

back of the mirror glass at all times.

The outside mirror heating grids cannot be

repaired and, if faulty or damaged, the entire outside

power mirror unit must be replaced. Refer to Power

Mirrors for the service procedures.

OPERATION

One end of the outside mirror heating grid resistor

wire is connected to a ground feed at all times

through a body ground screw located inside the left

rear corner of the truck cab. Battery current is

directed to the other end of the outside mirror heat-

ing grid resistor wire by the energized heated mirror

relay when the heated mirror switch is in the On

position. As electrical current passes through the

heating grid, the resistance of the wire in the heating

grid converts some of that electrical current into

heat. The heat produced by the heating grid is then

conducted through the back of the mirror glass to

help keep the glass clear of ice, snow or fog.

DIAGNOSIS AND TESTING - HEATED MIRROR

GRID

For circuit descriptions and diagrams (Refer to

Appropriate Wiring Information).

(1) Disconnect and isolate the battery negative

cable. Disconnect the door wire harness connector

from the power mirror wire harness connector at the

power mirror with the inoperative heating grid.

Check for continuity between the ground circuit cav-

ity in the door wire harness connector for the power

mirror and a good ground. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground as

required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Turn on the

heated mirror system. Check for voltage (battery

voltage less the resistance in the outside mirror heat-

ing grid that is still connected) at the fused heated

mirror relay output circuit cavity in the door wire

harness connector for the power mirror. If OK, go to

Step 3. If not OK, repair the open fused heated mir-

ror relay output circuit to the heater and air condi-

tioner control unit as required.

(3) Check the outside mirror heating grid by test-

ing for continuity between the ground circuit and the

fused heated mirror relay output circuit cavities in

the power mirror wire harness connector. There

should be continuity. If not OK, replace the faulty

power mirror. If OK, check the resistance through

the outside mirror heating grid. The correct resis-

tance should be from 10 to 16 ohms when measured

at an ambient temperature of 21É C (70É F). If not

OK, replace the faulty power mirror.

8G - 4 HEATED MIRRORSBR/BE

MIRROR SWITCH (Continued)

Page 659 of 2889

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION...........................10

OPERATION.............................10

AUTOMATIC DAY / NIGHT MIRROR

DESCRIPTION...........................10

OPERATION.............................11

DIAGNOSIS AND TESTING.................11

AUTOMATIC DAY/NIGHT MIRROR..........11

REMOVAL..............................12

INSTALLATION...........................12

POWER MIRROR SWITCH

DESCRIPTION...........................12OPERATION.............................12

REMOVAL..............................12

INSTALLATION...........................13

SIDEVIEW MIRROR

DESCRIPTION...........................13

OPERATION.............................13

DIAGNOSIS AND TESTING.................13

SIDEVIEW MIRROR.....................13

REMOVAL..............................14

POWER MIRRORS

DESCRIPTION

AUTOMATIC DAY / NIGHT MIRROR

The automatic day/night mirror system is able to

automatically change the reflectance of the inside

rear view mirror in order to reduce the glare of head-

lamps approaching the vehicle from the rear. The

automatic day/night rear view mirror receives bat-

tery current through a fuse in the junction block only

when the ignition switch is in the On position.

OUTSIDE REAR VIEW MIRROR

The heated mirror option includes an electric heat-

ing grid behind the mirror glass in each outside mir-

ror, which can clear the mirror glass of ice, snow, or

fog. The heating grid receives fused battery current

through the heated mirror relay in the heater and air

conditioner control only when the ignition switch is

in the On position, and the heated mirror system is

turned on. (Refer to 8 - ELECTRICAL/HEATED

MIRRORS - DESCRIPTION) for more information.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the power mirror system.

OPERATION

AUTOMATIC DAY / NIGHT MIRROR

A switch located on the bottom of the automatic

day/night mirror housing allows the vehicle operator

to select whether the automatic dimming feature is

operational. When the automatic day/night mirror isturned on, the mirror switch is lighted by an integral

Light-Emitting Diode (LED). The mirror will auto-

matically disable its self-dimming feature whenever

the vehicle is being driven in reverse.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the automatic day/night mirror system.

OUTSIDE REAR VIEW MIRROR

The heated mirror option includes an electric heat-

ing grid behind the mirror glass in each outside mir-

ror, which can clear the mirror glass of ice, snow, or

fog. The heating grid receives fused battery current

through the heated mirror relay in the heater and air

conditioner control only when the ignition switch is

in the On position, and the heated mirror system is

turned on. (Refer to 8 - ELECTRICAL/HEATED

MIRRORS - OPERATION) for more information.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the power mirror system.

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

The automatic day/night mirror uses a thin layer

of electrochromic material between two pieces of con-

ductive glass to make up the face of the mirror.

When the mirror switch is in the On position, two

photocell sensors are used by the mirror circuitry to

monitor external light levels and adjust the reflec-

tance of the mirror.

8N - 10 POWER MIRRORSBR/BE

Page 660 of 2889

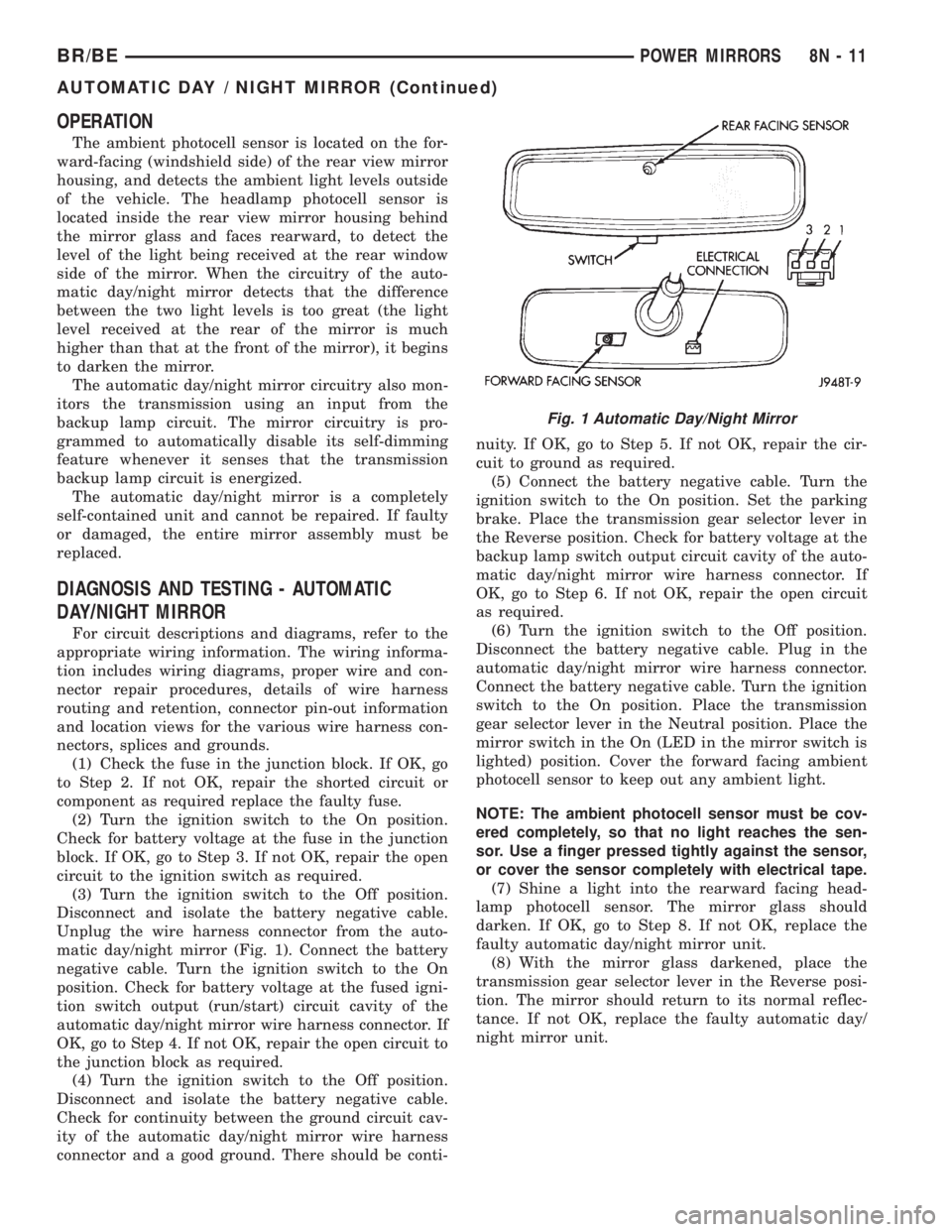

OPERATION

The ambient photocell sensor is located on the for-

ward-facing (windshield side) of the rear view mirror

housing, and detects the ambient light levels outside

of the vehicle. The headlamp photocell sensor is

located inside the rear view mirror housing behind

the mirror glass and faces rearward, to detect the

level of the light being received at the rear window

side of the mirror. When the circuitry of the auto-

matic day/night mirror detects that the difference

between the two light levels is too great (the light

level received at the rear of the mirror is much

higher than that at the front of the mirror), it begins

to darken the mirror.

The automatic day/night mirror circuitry also mon-

itors the transmission using an input from the

backup lamp circuit. The mirror circuitry is pro-

grammed to automatically disable its self-dimming

feature whenever it senses that the transmission

backup lamp circuit is energized.

The automatic day/night mirror is a completely

self-contained unit and cannot be repaired. If faulty

or damaged, the entire mirror assembly must be

replaced.

DIAGNOSIS AND TESTING - AUTOMATIC

DAY/NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the junction block. If OK, go

to Step 2. If not OK, repair the shorted circuit or

component as required replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 3. If not OK, repair the open

circuit to the ignition switch as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Unplug the wire harness connector from the auto-

matic day/night mirror (Fig. 1). Connect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run/start) circuit cavity of the

automatic day/night mirror wire harness connector. If

OK, go to Step 4. If not OK, repair the open circuit to

the junction block as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the On position. Set the parking

brake. Place the transmission gear selector lever in

the Reverse position. Check for battery voltage at the

backup lamp switch output circuit cavity of the auto-

matic day/night mirror wire harness connector. If

OK, go to Step 6. If not OK, repair the open circuit

as required.

(6) Turn the ignition switch to the Off position.

Disconnect the battery negative cable. Plug in the

automatic day/night mirror wire harness connector.

Connect the battery negative cable. Turn the ignition

switch to the On position. Place the transmission

gear selector lever in the Neutral position. Place the

mirror switch in the On (LED in the mirror switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The mirror glass should

darken. If OK, go to Step 8. If not OK, replace the

faulty automatic day/night mirror unit.

(8) With the mirror glass darkened, place the

transmission gear selector lever in the Reverse posi-

tion. The mirror should return to its normal reflec-

tance. If not OK, replace the faulty automatic day/

night mirror unit.

Fig. 1 Automatic Day/Night Mirror

BR/BEPOWER MIRRORS 8N - 11

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 2640 of 2889

DOOR - FRONT

TABLE OF CONTENTS

page page

APPLIQUE

REMOVAL..............................67

INSTALLATION...........................67

DOOR

REMOVAL..............................68

INSTALLATION...........................68

ADJUSTMENTS..........................68

DOOR GLASS

REMOVAL..............................69

INSTALLATION...........................69

EXTERIOR HANDLE

REMOVAL..............................70

INSTALLATION...........................70

GLASS RUN CHANNEL

REMOVAL..............................70

INSTALLATION...........................70

HINGE

REMOVAL..............................70

INSTALLATION...........................71

INSIDE HANDLE ACTUATOR

REMOVAL..............................71

INSTALLATION...........................71LATCH

REMOVAL..............................72

INSTALLATION...........................72

ADJUSTMENTS..........................72

LATCH STRIKER

REMOVAL..............................73

INSTALLATION...........................73

LOCK CYLINDER

REMOVAL..............................73

INSTALLATION...........................73

SIDE VIEW MIRROR FLAG

REMOVAL..............................74

INSTALLATION...........................74

TRIM PANEL

REMOVAL..............................74

INSTALLATION...........................74

WATERDAM

REMOVAL..............................75

INSTALLATION...........................75

WINDOW REGULATOR

REMOVAL..............................75

INSTALLATION...........................76

APPLIQUE

REMOVAL

(1) Using a heat lamp, warm B-pillar to 38É C

(100É F).

(2) Remove glass run weatherstrip (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR GLASS RUN

WEATHERSTRIP - REMOVAL).

(3) Remove outer belt weatherstrip (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR OUTER BELT

WEATHERSTRIP - REMOVAL).

(4) Using an even pressure pull, peel B-pillar

applique away from the B-pillar.

INSTALLATION

Installation equipment needed:

²Lint free applicator cloth

²six inch applicator squeegee

²Piercing pin

(1) Clean B-pillar using Mopar Super Kleen or

equivalent.

(2) Wipe surface with a lint free cloth.

(3) Using a heat gun, warm surface to 22É C (70É

F).(4) Fold down, up/down locator tab (1a or 1b) (Fig.

1)along crease.

(5) Remove carrier from adhesion strip (2).

(6) Using up/down locator tab (1a or 1b) and fore/

aft locator tab (3a or 3b), position the applique on the

upper portion of the B-pillar.

(7) Using the lower edge locator (4), position the

applique on the lower portion of the B-pillar.

(8) Verify the applique is positioned correctly and

press the adhesion strip (2) to the door to tempo-

rarily secure it in place.

(9) Remove the carrier for the applique.

(10) Holding the applique from the surface, apply

firm downward pressure with a six inch applicator

squeegee. Ensure the lower rear edge (4) is aligned

correctly.

(11) Wrap edges around door to at least a 90É

angle.

(12) Remove premask by pulling in a firm contin-

uous manner from top down at 180É.

(13) Complete wrapping applique around the door

edges.

(14) Inspect for air bubbles. Small bubbles can be

pierced with a sharp pin and smoothed out.

BR/BEDOOR - FRONT 23 - 67

Page 2659 of 2889

EXTERIOR

TABLE OF CONTENTS

page page

EXTERIOR

DESCRIPTION...........................86

OPERATION.............................86

BODY SIDE MOLDINGS

REMOVAL..............................87

INSTALLATION...........................87

BODY STRIPES AND DECALS

REMOVAL..............................87

INSTALLATION...........................87

TAPE STRIPE

REMOVAL..............................88

INSTALLATION...........................88

EXTERIOR NAME PLATES

REMOVAL..............................89

INSTALLATION...........................89

COWL GRILLE

REMOVAL..............................90

INSTALLATION...........................90

ROOF JOINT MOLDING

REMOVAL..............................91

INSTALLATION...........................91

GRILLE

REMOVAL..............................91

INSTALLATION...........................91

GRILLE FRAME

REMOVAL..............................91

INSTALLATION...........................92

FRONT END SPLASH SHIELDS

REMOVAL..............................92

INSTALLATION...........................92LEFT FRONT FENDER

REMOVAL..............................92

INSTALLATION...........................93

RIGHT FRONT FENDER

REMOVAL..............................94

INSTALLATION...........................94

FUEL FILL DOOR

REMOVAL..............................95

INSTALLATION...........................95

REAR FENDER

REMOVAL..............................95

INSTALLATION...........................95

REAR SPLASH SHIELD

REMOVAL..............................96

INSTALLATION...........................96

REAR WHEELHOUSE LINER

REMOVAL..............................96

INSTALLATION...........................96

CARGO BOX

REMOVAL..............................96

INSTALLATION...........................97

SIDE VIEW MIRROR

REMOVAL..............................97

INSTALLATION...........................97

SIDE VIEW MIRROR - LOW MOUNTED

REMOVAL..............................98

INSTALLATION...........................98

SIDE VIEW MIRROR GLASS

REMOVAL..............................98

INSTALLATION...........................98

EXTERIOR

DESCRIPTION

Exterior sheet metal components make up the

exterior of the vehicle. Some exterior metal systems

are welded assemblies, such as doors and hoods.

Some exterior trim items are made of composite.

OPERATION

The exterior is finished in various metal stampings

and composite moldings. These assemblies give the

vehicle a finished appearance and protect the occu-

pants from the elements. Some components are partof the energy absorbing system used to protect the

occupants in collisions. The exterior sheet metal is

repairable and adjustable for fit and finish. Welded

and bonded component systems are adjustable as a

system. Trim components made of composite are

stamped with the type of material used. Daimler-

Chrysler uses various fasteners to retain trim items.

At times, it is not possible to remove trim items

without damaging the fastener. If it is not possible to

remove an item without damaging a component, cut

or break the fasteners and use new ones when

installing the component.

23 - 86 EXTERIORBR/BE

Page 2670 of 2889

(6) Using a suitable lifting device, separate cargo

box from vehicle.

INSTALLATION

(1) Using a suitable lifting device, position cargo

box on vehicle.

(2) Installnewbolts attaching cargo box to frame

rails. Tighten bolts to 54 N´m (40 ft. lbs.) torque.

(3) Engage tail lamp wire connector to main body

harness at left rear frame rail.

(4) Install fuel fill neck.

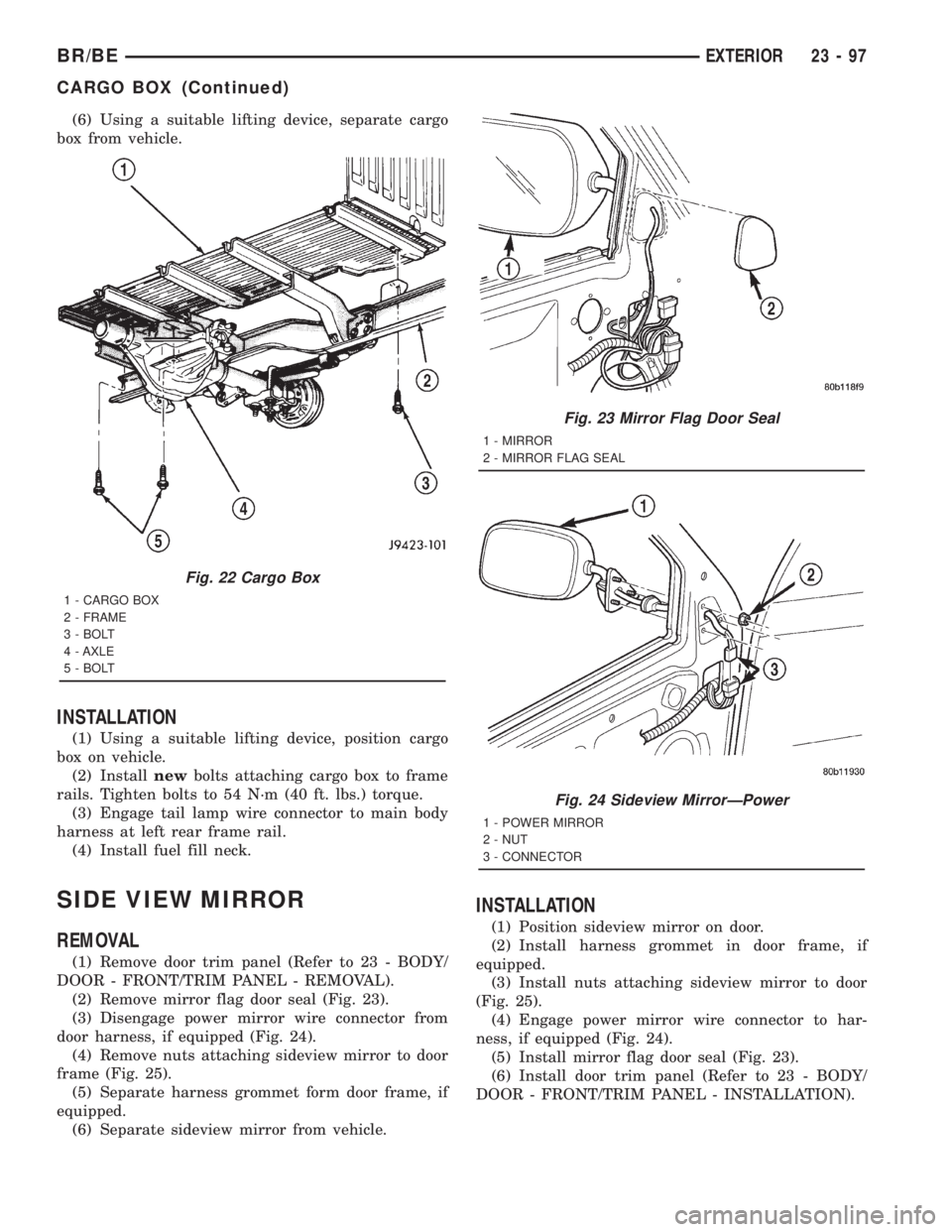

SIDE VIEW MIRROR

REMOVAL

(1) Remove door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Remove mirror flag door seal (Fig. 23).

(3) Disengage power mirror wire connector from

door harness, if equipped (Fig. 24).

(4) Remove nuts attaching sideview mirror to door

frame (Fig. 25).

(5) Separate harness grommet form door frame, if

equipped.

(6) Separate sideview mirror from vehicle.

INSTALLATION

(1) Position sideview mirror on door.

(2) Install harness grommet in door frame, if

equipped.

(3) Install nuts attaching sideview mirror to door

(Fig. 25).

(4) Engage power mirror wire connector to har-

ness, if equipped (Fig. 24).

(5) Install mirror flag door seal (Fig. 23).

(6) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

Fig. 22 Cargo Box

1 - CARGO BOX

2 - FRAME

3 - BOLT

4 - AXLE

5 - BOLT

Fig. 23 Mirror Flag Door Seal

1 - MIRROR

2 - MIRROR FLAG SEAL

Fig. 24 Sideview MirrorÐPower

1 - POWER MIRROR

2 - NUT

3 - CONNECTOR

BR/BEEXTERIOR 23 - 97

CARGO BOX (Continued)

Page 2691 of 2889

INTERIOR

TABLE OF CONTENTS

page page

INTERIOR

CAUTION..............................118

A-PILLAR GRAB HANDLE

REMOVAL.............................119

INSTALLATION..........................119

A-PILLAR TRIM

REMOVAL.............................119

INSTALLATION..........................119

COWL TRIM COVER

REMOVAL.............................119

INSTALLATION..........................120

B-PILLAR TRIM

REMOVAL.............................120

INSTALLATION..........................120

REAR CLOSURE PANEL TRIM

REMOVAL.............................120

INSTALLATION..........................121

REAR FLOOR STOWAGE TRAY

REMOVAL.............................121

INSTALLATION..........................121

DOOR SILL TRIM

REMOVAL.............................121

INSTALLATION..........................121

SHIFT BOOT - MANUAL TRANSMISSION

REMOVAL.............................122

INSTALLATION..........................122

4WD FLOOR SHIFT BOOT

REMOVAL.............................122

INSTALLATION..........................122

CENTER CONSOLE

REMOVAL.............................122INSTALLATION..........................122

CARPETS AND FLOOR MATS

REMOVAL.............................123

INSTALLATION..........................123

ASSIST HANDLE

REMOVAL.............................124

INSTALLATION..........................124

COAT HOOK

REMOVAL.............................124

INSTALLATION..........................125

HEADLINER

REMOVAL.............................125

INSTALLATION..........................125

BODY VENT

REMOVAL.............................126

INSTALLATION..........................126

REAR VIEW MIRROR

REMOVAL.............................126

INSTALLATION..........................126

SUN VISOR

REMOVAL.............................127

INSTALLATION..........................127

QUARTER TRIM PANEL

REMOVAL.............................127

INSTALLATION..........................128

C-PILLAR TRIM

REMOVAL.............................128

INSTALLATION..........................128

INTERIOR

CAUTION

CAUTION: Do not attempt to remove interior trim

panels/moldings without first removing the neces-sary adjacent panels. To avoid damaging the pan-

els, ensure that all the screws and clips are

removed before attempting to remove an interior

trim panel/molding. Trim panels are somewhat flex-

ible but can be damaged if handled improperly.

23 - 118 INTERIORBR/BE

Page 2699 of 2889

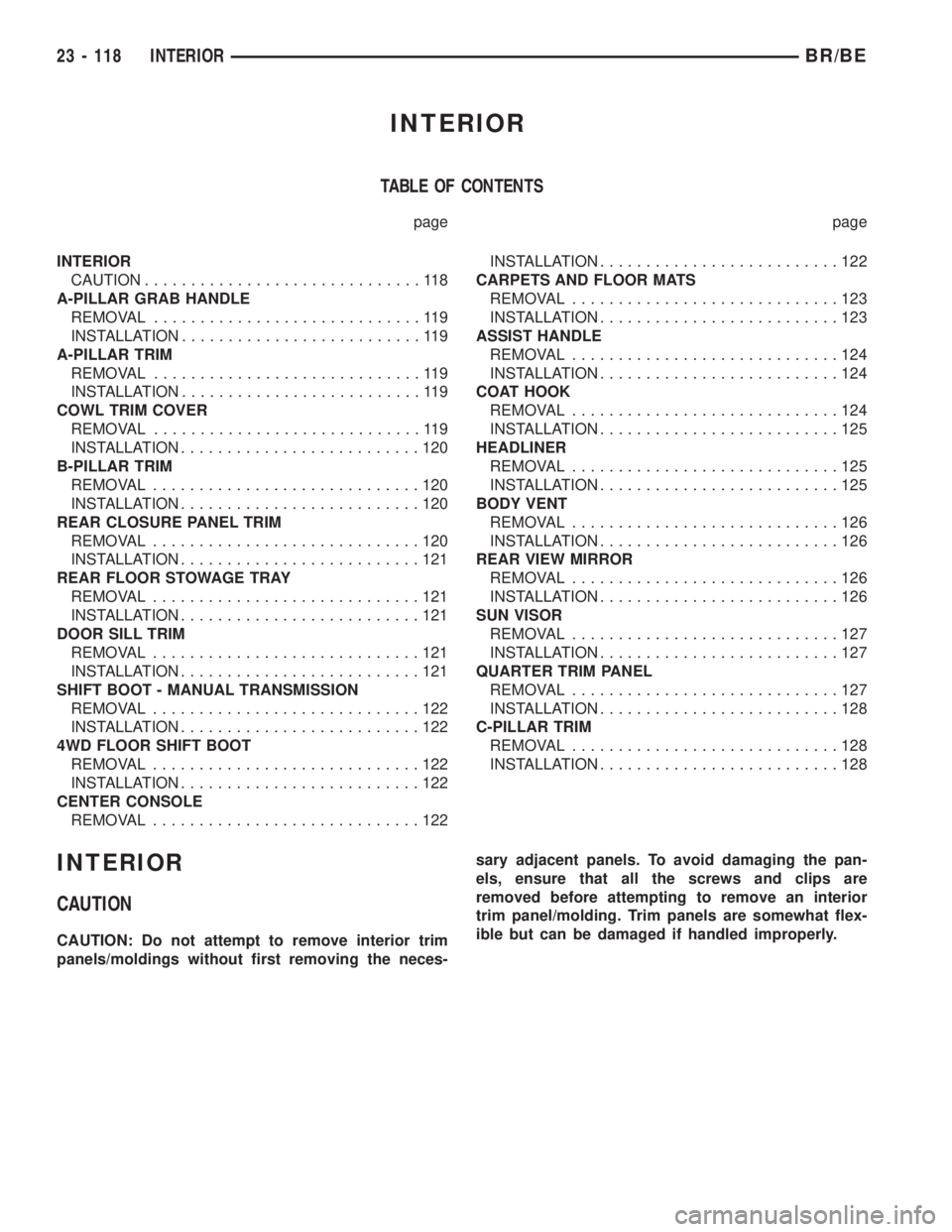

BODY VENT

REMOVAL

(1) Open door.

(2) Pull outward at top of vent to disengage clips

attaching vent to door jamb (Fig. 16).

(3) Separate vent from door jamb.

INSTALLATION

(1) Position vent from in jamb.

(2) Press vent inward to engage clips.

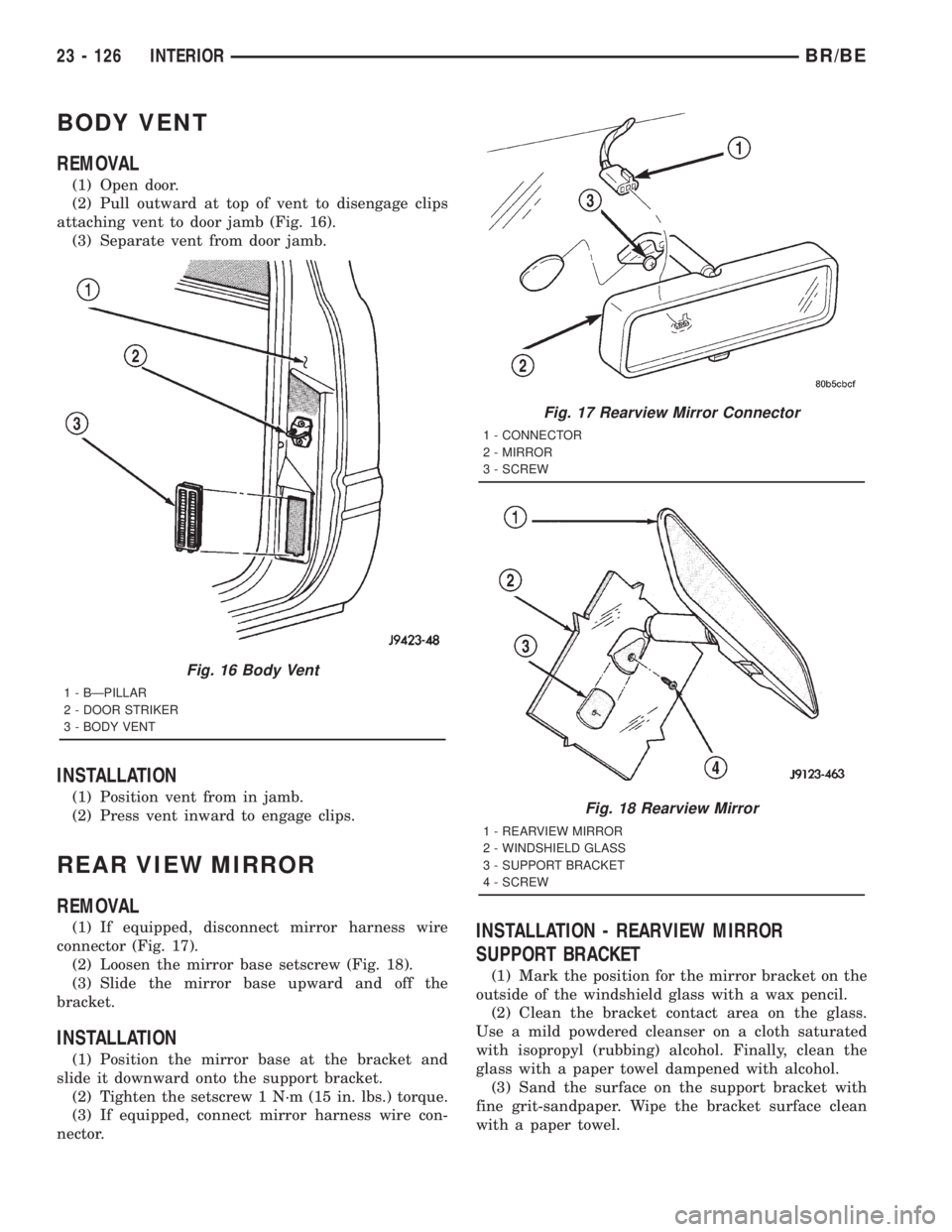

REAR VIEW MIRROR

REMOVAL

(1) If equipped, disconnect mirror harness wire

connector (Fig. 17).

(2) Loosen the mirror base setscrew (Fig. 18).

(3) Slide the mirror base upward and off the

bracket.

INSTALLATION

(1) Position the mirror base at the bracket and

slide it downward onto the support bracket.

(2) Tighten the setscrew 1 N´m (15 in. lbs.) torque.

(3) If equipped, connect mirror harness wire con-

nector.

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET

(1) Mark the position for the mirror bracket on the

outside of the windshield glass with a wax pencil.

(2) Clean the bracket contact area on the glass.

Use a mild powdered cleanser on a cloth saturated

with isopropyl (rubbing) alcohol. Finally, clean the

glass with a paper towel dampened with alcohol.

(3) Sand the surface on the support bracket with

fine grit-sandpaper. Wipe the bracket surface clean

with a paper towel.

Fig. 16 Body Vent

1 - BÐPILLAR

2 - DOOR STRIKER

3 - BODY VENT

Fig. 17 Rearview Mirror Connector

1 - CONNECTOR

2 - MIRROR

3 - SCREW

Fig. 18 Rearview Mirror

1 - REARVIEW MIRROR

2 - WINDSHIELD GLASS

3 - SUPPORT BRACKET

4 - SCREW

23 - 126 INTERIORBR/BE