compression ratio DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1115 of 2255

lower rails. Insert oil rail spacer first, then side

rails.

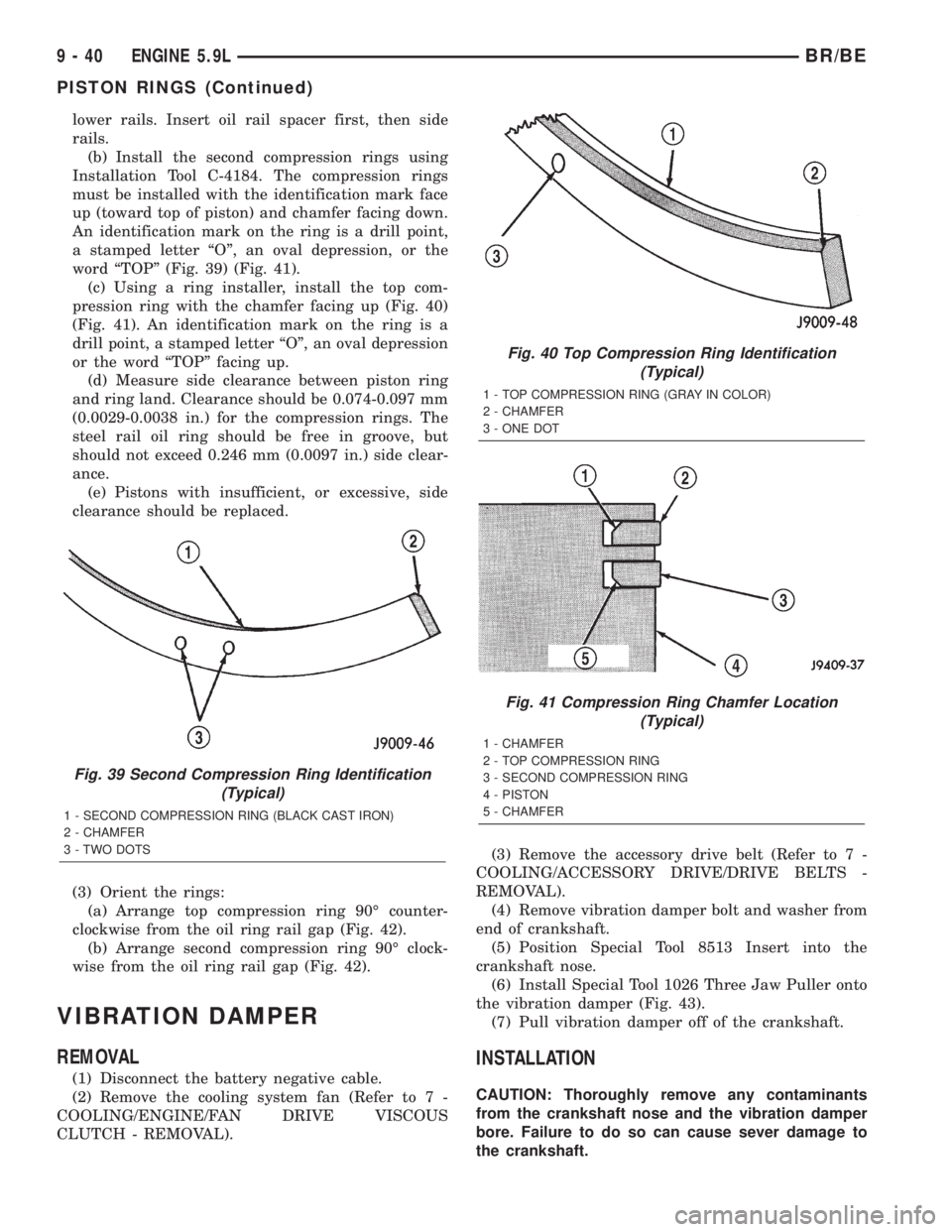

(b) Install the second compression rings using

Installation Tool C-4184. The compression rings

must be installed with the identification mark face

up (toward top of piston) and chamfer facing down.

An identification mark on the ring is a drill point,

a stamped letter ªOº, an oval depression, or the

word ªTOPº (Fig. 39) (Fig. 41).

(c) Using a ring installer, install the top com-

pression ring with the chamfer facing up (Fig. 40)

(Fig. 41). An identification mark on the ring is a

drill point, a stamped letter ªOº, an oval depression

or the word ªTOPº facing up.

(d) Measure side clearance between piston ring

and ring land. Clearance should be 0.074-0.097 mm

(0.0029-0.0038 in.) for the compression rings. The

steel rail oil ring should be free in groove, but

should not exceed 0.246 mm (0.0097 in.) side clear-

ance.

(e) Pistons with insufficient, or excessive, side

clearance should be replaced.

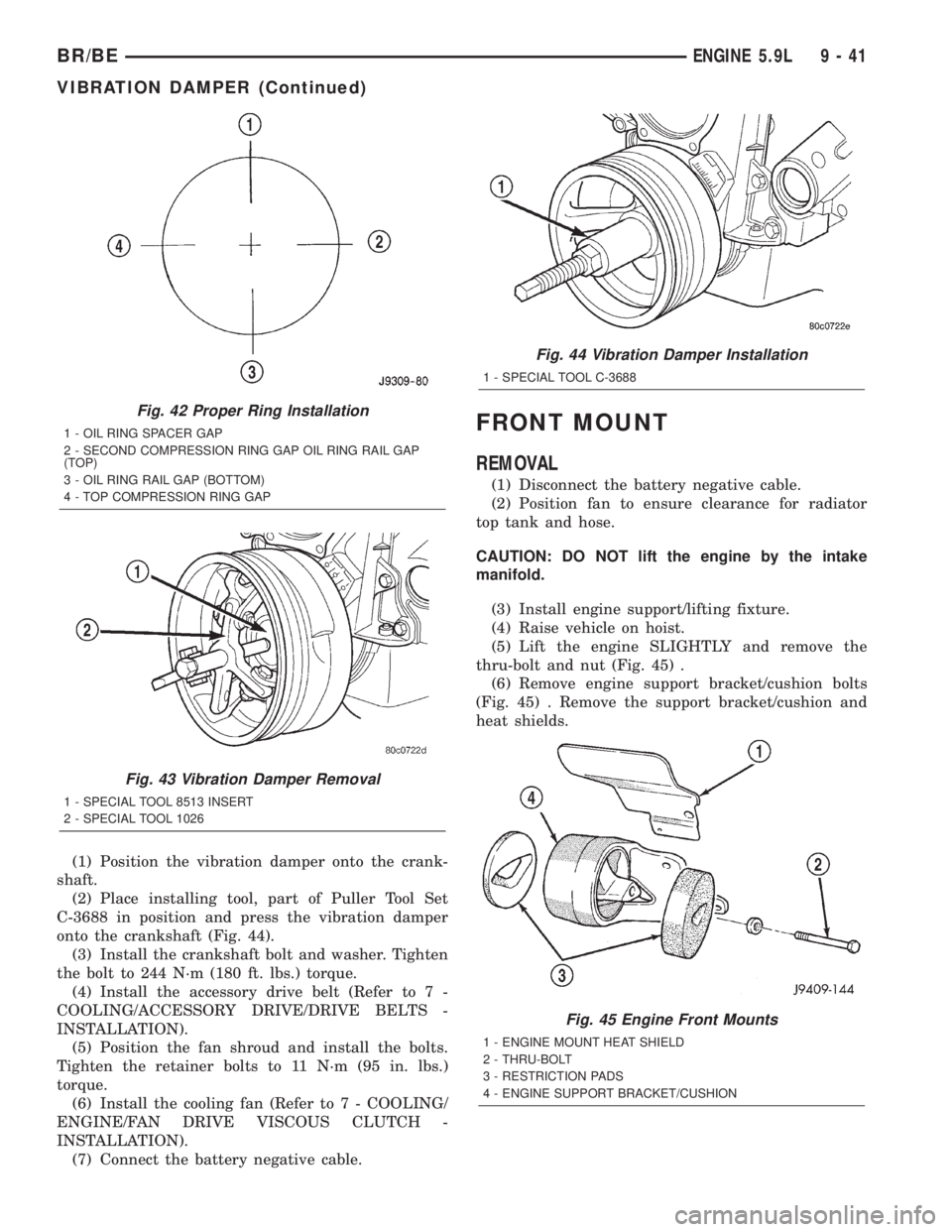

(3) Orient the rings:

(a) Arrange top compression ring 90É counter-

clockwise from the oil ring rail gap (Fig. 42).

(b) Arrange second compression ring 90É clock-

wise from the oil ring rail gap (Fig. 42).

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the cooling system fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

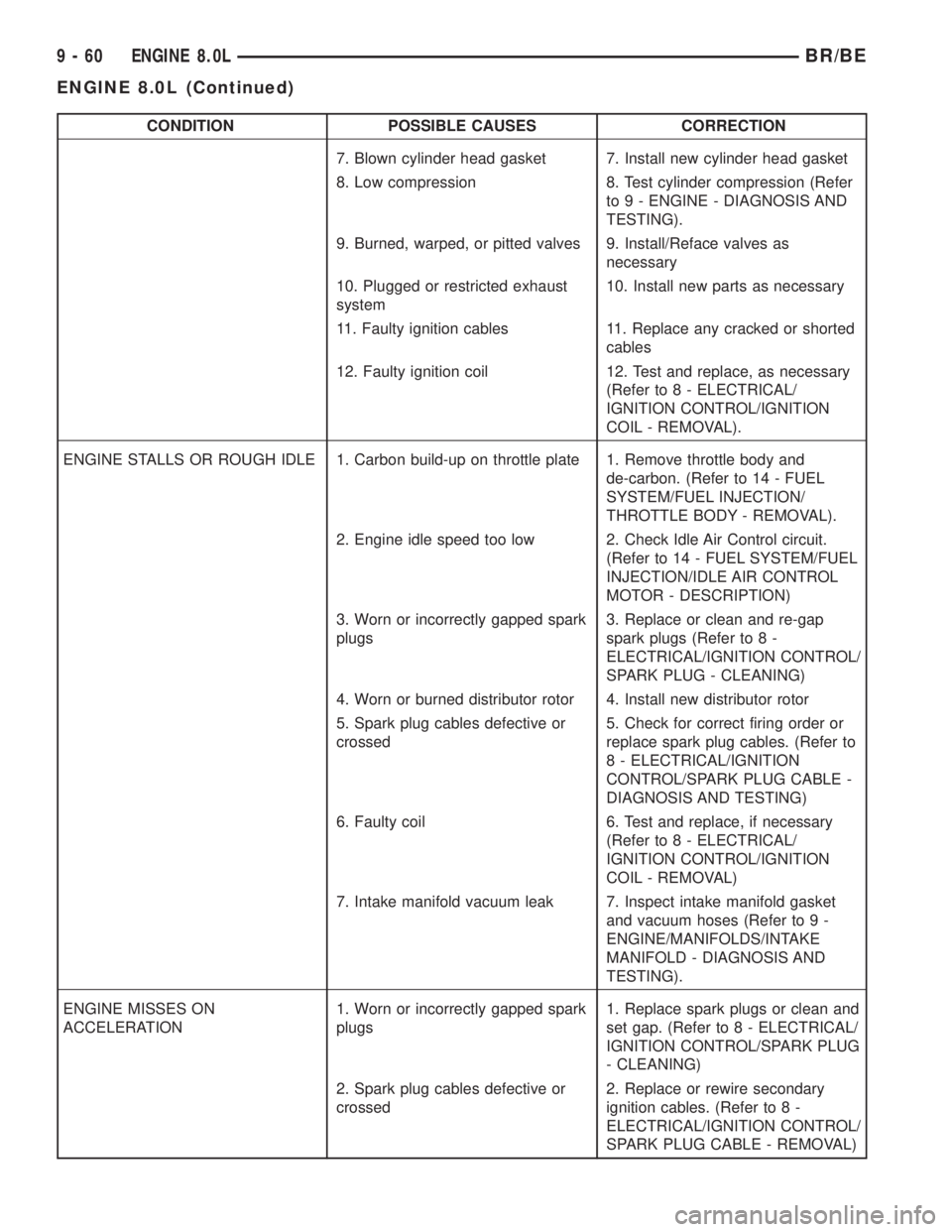

(4) Remove vibration damper bolt and washer from

end of crankshaft.

(5) Position Special Tool 8513 Insert into the

crankshaft nose.

(6) Install Special Tool 1026 Three Jaw Puller onto

the vibration damper (Fig. 43).

(7) Pull vibration damper off of the crankshaft.

INSTALLATION

CAUTION: Thoroughly remove any contaminants

from the crankshaft nose and the vibration damper

bore. Failure to do so can cause sever damage to

the crankshaft.

Fig. 39 Second Compression Ring Identification

(Typical)

1 - SECOND COMPRESSION RING (BLACK CAST IRON)

2 - CHAMFER

3 - TWO DOTS

Fig. 40 Top Compression Ring Identification

(Typical)

1 - TOP COMPRESSION RING (GRAY IN COLOR)

2 - CHAMFER

3 - ONE DOT

Fig. 41 Compression Ring Chamfer Location

(Typical)

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

9 - 40 ENGINE 5.9LBR/BE

PISTON RINGS (Continued)

Page 1116 of 2255

(1) Position the vibration damper onto the crank-

shaft.

(2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 44).

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 244 N´m (180 ft. lbs.) torque.

(4) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(5) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N´m (95 in. lbs.)

torque.

(6) Install the cooling fan (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH -

INSTALLATION).

(7) Connect the battery negative cable.

FRONT MOUNT

REMOVAL

(1) Disconnect the battery negative cable.

(2) Position fan to ensure clearance for radiator

top tank and hose.

CAUTION: DO NOT lift the engine by the intake

manifold.

(3) Install engine support/lifting fixture.

(4) Raise vehicle on hoist.

(5) Lift the engine SLIGHTLY and remove the

thru-bolt and nut (Fig. 45) .

(6) Remove engine support bracket/cushion bolts

(Fig. 45) . Remove the support bracket/cushion and

heat shields.

Fig. 42 Proper Ring Installation

1 - OIL RING SPACER GAP

2 - SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 - OIL RING RAIL GAP (BOTTOM)

4 - TOP COMPRESSION RING GAP

Fig. 43 Vibration Damper Removal

1 - SPECIAL TOOL 8513 INSERT

2 - SPECIAL TOOL 1026

Fig. 44 Vibration Damper Installation

1 - SPECIAL TOOL C-3688

Fig. 45 Engine Front Mounts

1 - ENGINE MOUNT HEAT SHIELD

2 - THRU-BOLT

3 - RESTRICTION PADS

4 - ENGINE SUPPORT BRACKET/CUSHION

BR/BEENGINE 5.9L 9 - 41

VIBRATION DAMPER (Continued)

Page 1135 of 2255

CONDITION POSSIBLE CAUSES CORRECTION

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression (Refer

to 9 - ENGINE - DIAGNOSIS AND

TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as

necessary

10. Plugged or restricted exhaust

system10. Install new parts as necessary

11. Faulty ignition cables 11. Replace any cracked or shorted

cables

12. Faulty ignition coil 12. Test and replace, as necessary

(Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

ENGINE STALLS OR ROUGH IDLE 1. Carbon build-up on throttle plate 1. Remove throttle body and

de-carbon. (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/

THROTTLE BODY - REMOVAL).

2. Engine idle speed too low 2. Check Idle Air Control circuit.

(Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/IDLE AIR CONTROL

MOTOR - DESCRIPTION)

3. Worn or incorrectly gapped spark

plugs3. Replace or clean and re-gap

spark plugs (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG - CLEANING)

4. Worn or burned distributor rotor 4. Install new distributor rotor

5. Spark plug cables defective or

crossed5. Check for correct firing order or

replace spark plug cables. (Refer to

8 - ELECTRICAL/IGNITION

CONTROL/SPARK PLUG CABLE -

DIAGNOSIS AND TESTING)

6. Faulty coil 6. Test and replace, if necessary

(Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL)

7. Intake manifold vacuum leak 7. Inspect intake manifold gasket

and vacuum hoses (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE

MANIFOLD - DIAGNOSIS AND

TESTING).

ENGINE MISSES ON

ACCELERATION1. Worn or incorrectly gapped spark

plugs1. Replace spark plugs or clean and

set gap. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING)

2. Spark plug cables defective or

crossed2. Replace or rewire secondary

ignition cables. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG CABLE - REMOVAL)

9 - 60 ENGINE 8.0LBR/BE

ENGINE 8.0L (Continued)

Page 1146 of 2255

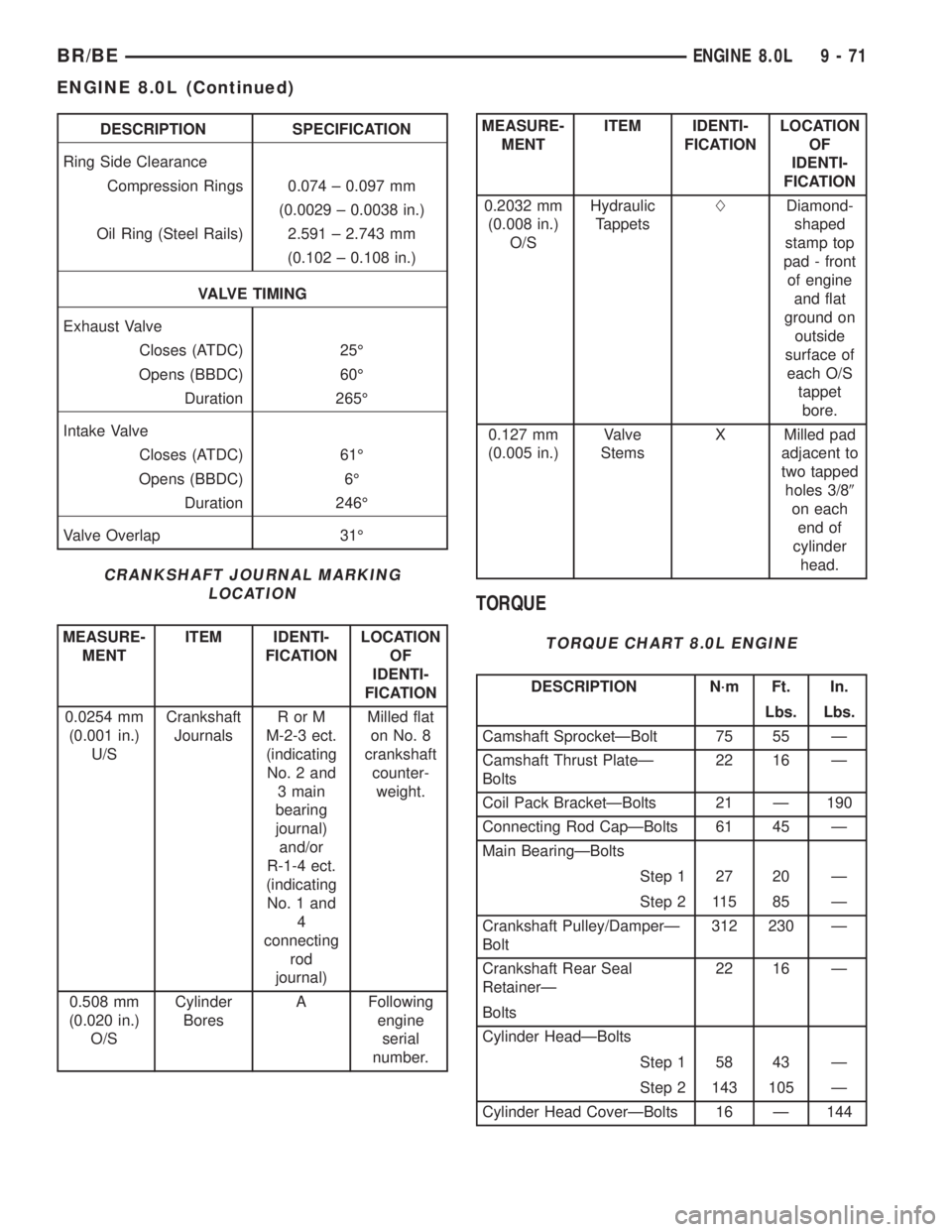

DESCRIPTION SPECIFICATION

Ring Side Clearance

Compression Rings 0.074 ± 0.097 mm

(0.0029 ± 0.0038 in.)

Oil Ring (Steel Rails) 2.591 ± 2.743 mm

(0.102 ± 0.108 in.)

VALVE TIMING

Exhaust Valve

Closes (ATDC) 25É

Opens (BBDC) 60É

Duration 265É

Intake Valve

Closes (ATDC) 61É

Opens (BBDC) 6É

Duration 246É

Valve Overlap 31É

CRANKSHAFT JOURNAL MARKING

LOCATION

MEASURE-

MENTITEM IDENTI-

FICATIONLOCATION

OF

IDENTI-

FICATION

0.0254 mm

(0.001 in.)

U/SCrankshaft

JournalsRorM

M-2-3 ect.

(indicating

No. 2 and

3 main

bearing

journal)

and/or

R-1-4 ect.

(indicating

No. 1 and

4

connecting

rod

journal)Milled flat

on No. 8

crankshaft

counter-

weight.

0.508 mm

(0.020 in.)

O/SCylinder

BoresA Following

engine

serial

number.

MEASURE-

MENTITEM IDENTI-

FICATIONLOCATION

OF

IDENTI-

FICATION

0.2032 mm

(0.008 in.)

O/SHydraulic

TappetsLDiamond-

shaped

stamp top

pad - front

of engine

and flat

ground on

outside

surface of

each O/S

tappet

bore.

0.127 mm

(0.005 in.)Valve

StemsX Milled pad

adjacent to

two tapped

holes 3/89

on each

end of

cylinder

head.

TORQUE

TORQUE CHART 8.0L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Camshaft SprocketÐBolt 75 55 Ð

Camshaft Thrust PlateÐ

Bolts22 16 Ð

Coil Pack BracketÐBolts 21 Ð 190

Connecting Rod CapÐBolts 61 45 Ð

Main BearingÐBolts

Step 1 27 20 Ð

Step 2 115 85 Ð

Crankshaft Pulley/DamperÐ

Bolt312 230 Ð

Crankshaft Rear Seal

RetainerÐ22 16 Ð

Bolts

Cylinder HeadÐBolts

Step 1 58 43 Ð

Step 2 143 105 Ð

Cylinder Head CoverÐBolts 16 Ð 144

BR/BEENGINE 8.0L 9 - 71

ENGINE 8.0L (Continued)

Page 1151 of 2255

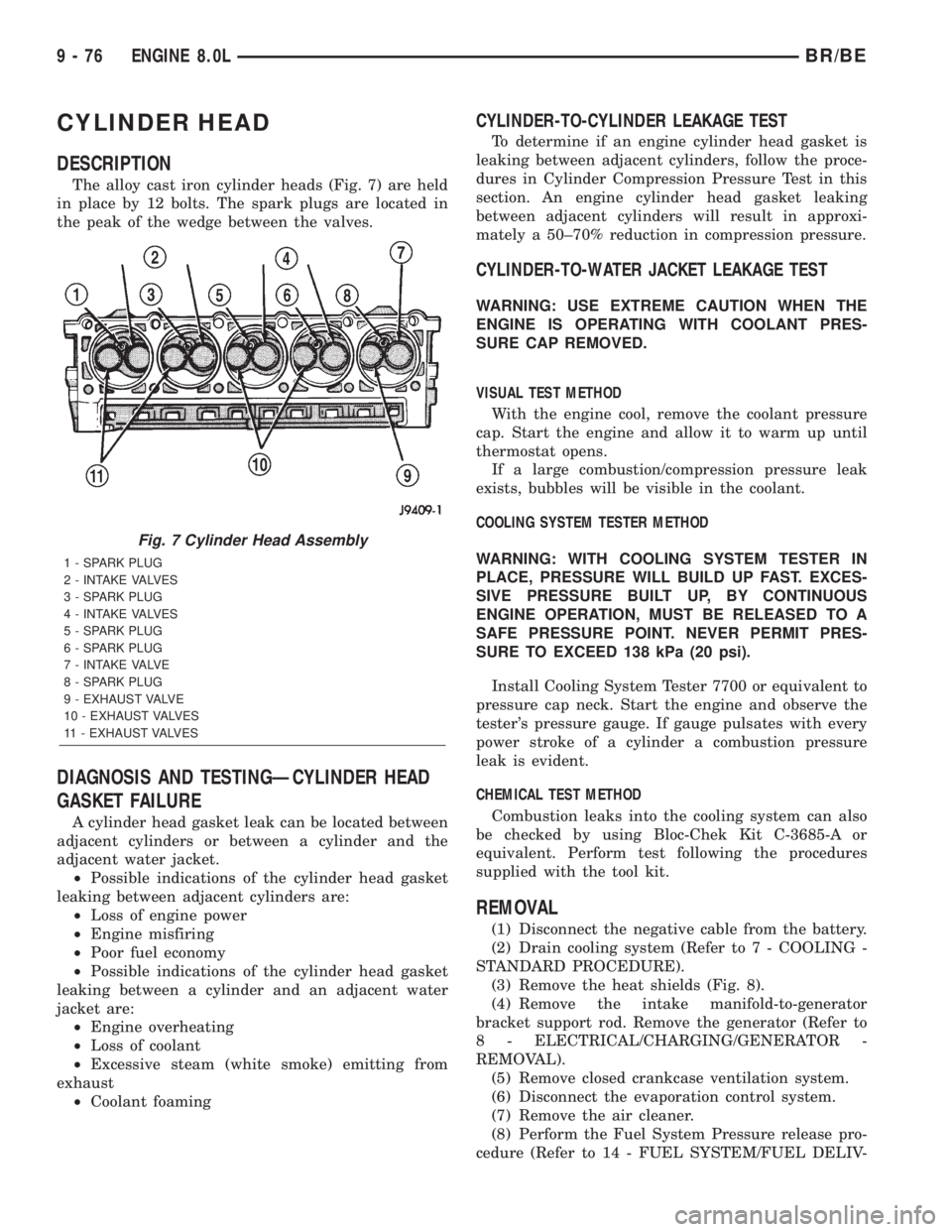

CYLINDER HEAD

DESCRIPTION

The alloy cast iron cylinder heads (Fig. 7) are held

in place by 12 bolts. The spark plugs are located in

the peak of the wedge between the valves.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the heat shields (Fig. 8).

(4) Remove the intake manifold-to-generator

bracket support rod. Remove the generator (Refer to

8 - ELECTRICAL/CHARGING/GENERATOR -

REMOVAL).

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Remove the air cleaner.

(8) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

Fig. 7 Cylinder Head Assembly

1 - SPARK PLUG

2 - INTAKE VALVES

3 - SPARK PLUG

4 - INTAKE VALVES

5 - SPARK PLUG

6 - SPARK PLUG

7 - INTAKE VALVE

8 - SPARK PLUG

9 - EXHAUST VALVE

10 - EXHAUST VALVES

11 - EXHAUST VALVES

9 - 76 ENGINE 8.0LBR/BE

Page 1169 of 2255

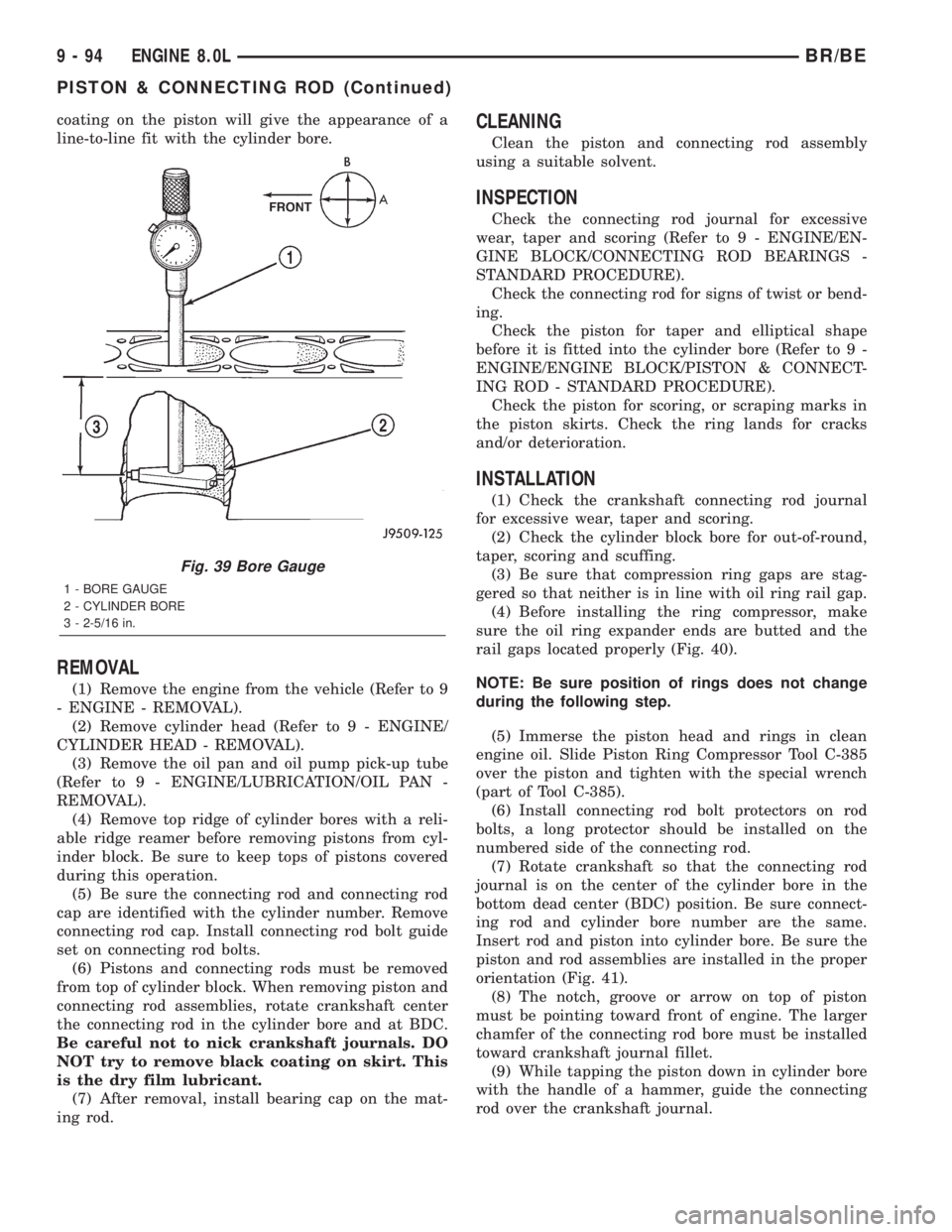

coating on the piston will give the appearance of a

line-to-line fit with the cylinder bore.

REMOVAL

(1) Remove the engine from the vehicle (Refer to 9

- ENGINE - REMOVAL).

(2) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan and oil pump pick-up tube

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block. Be sure to keep tops of pistons covered

during this operation.

(5) Be sure the connecting rod and connecting rod

cap are identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing piston and

connecting rod assemblies, rotate crankshaft center

the connecting rod in the cylinder bore and at BDC.

Be careful not to nick crankshaft journals. DO

NOT try to remove black coating on skirt. This

is the dry film lubricant.

(7) After removal, install bearing cap on the mat-

ing rod.

CLEANING

Clean the piston and connecting rod assembly

using a suitable solvent.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Check the crankshaft connecting rod journal

for excessive wear, taper and scoring.

(2) Check the cylinder block bore for out-of-round,

taper, scoring and scuffing.

(3) Be sure that compression ring gaps are stag-

gered so that neither is in line with oil ring rail gap.

(4) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located properly (Fig. 40).

NOTE: Be sure position of rings does not change

during the following step.

(5) Immerse the piston head and rings in clean

engine oil. Slide Piston Ring Compressor Tool C-385

over the piston and tighten with the special wrench

(part of Tool C-385).

(6) Install connecting rod bolt protectors on rod

bolts, a long protector should be installed on the

numbered side of the connecting rod.

(7) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore in the

bottom dead center (BDC) position. Be sure connect-

ing rod and cylinder bore number are the same.

Insert rod and piston into cylinder bore. Be sure the

piston and rod assemblies are installed in the proper

orientation (Fig. 41).

(8) The notch, groove or arrow on top of piston

must be pointing toward front of engine. The larger

chamfer of the connecting rod bore must be installed

toward crankshaft journal fillet.

(9) While tapping the piston down in cylinder bore

with the handle of a hammer, guide the connecting

rod over the crankshaft journal.

Fig. 39 Bore Gauge

1 - BORE GAUGE

2 - CYLINDER BORE

3 - 2-5/16 in.

9 - 94 ENGINE 8.0LBR/BE

PISTON & CONNECTING ROD (Continued)

Page 1171 of 2255

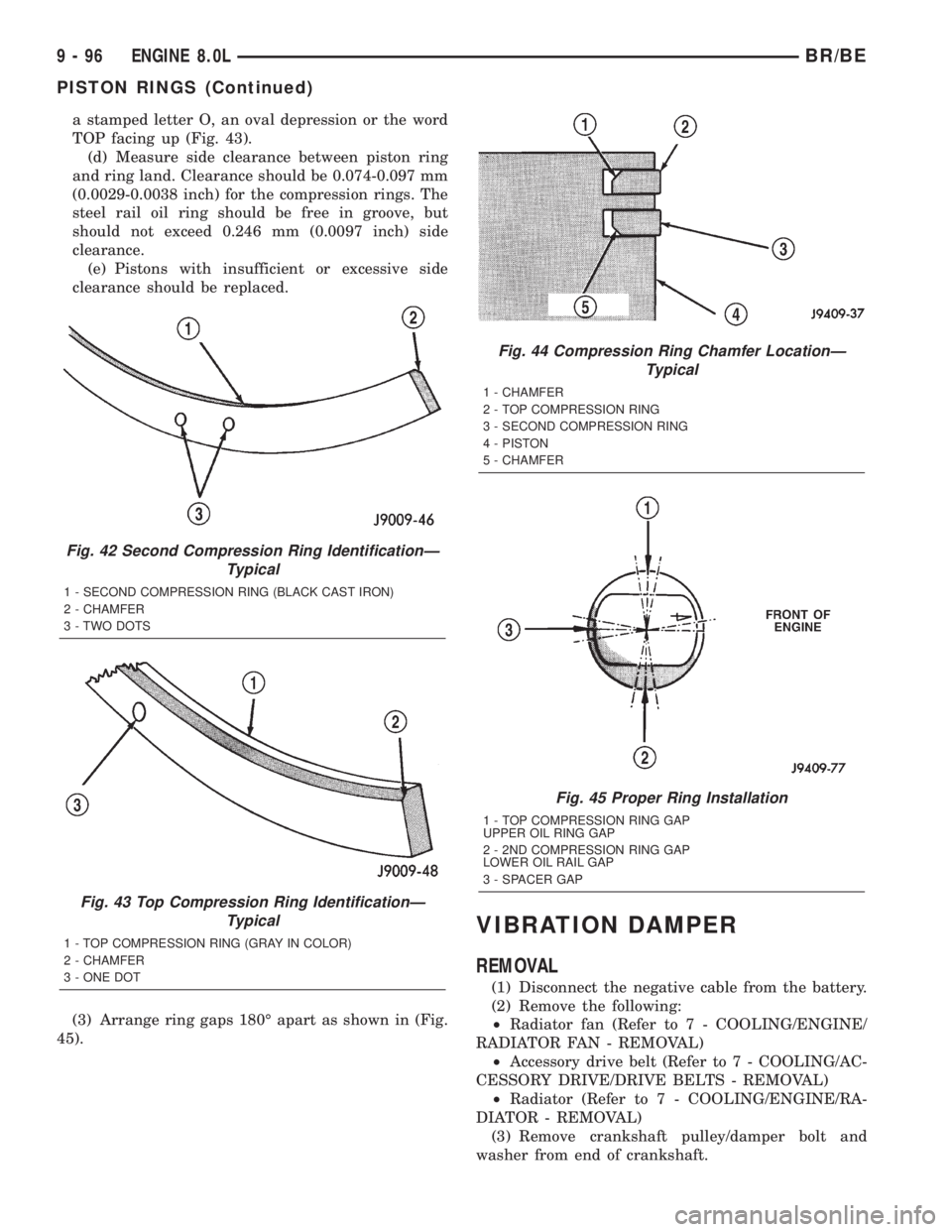

a stamped letter O, an oval depression or the word

TOP facing up (Fig. 43).

(d) Measure side clearance between piston ring

and ring land. Clearance should be 0.074-0.097 mm

(0.0029-0.0038 inch) for the compression rings. The

steel rail oil ring should be free in groove, but

should not exceed 0.246 mm (0.0097 inch) side

clearance.

(e) Pistons with insufficient or excessive side

clearance should be replaced.

(3) Arrange ring gaps 180É apart as shown in (Fig.

45).

VIBRATION DAMPER

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the following:

²Radiator fan (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - REMOVAL)

²Accessory drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - REMOVAL)

²Radiator (Refer to 7 - COOLING/ENGINE/RA-

DIATOR - REMOVAL)

(3) Remove crankshaft pulley/damper bolt and

washer from end of crankshaft.

Fig. 42 Second Compression Ring IdentificationÐ

Typical

1 - SECOND COMPRESSION RING (BLACK CAST IRON)

2 - CHAMFER

3 - TWO DOTS

Fig. 43 Top Compression Ring IdentificationÐ

Typical

1 - TOP COMPRESSION RING (GRAY IN COLOR)

2 - CHAMFER

3 - ONE DOT

Fig. 44 Compression Ring Chamfer LocationÐ

Typical

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

Fig. 45 Proper Ring Installation

1 - TOP COMPRESSION RING GAP

UPPER OIL RING GAP

2 - 2ND COMPRESSION RING GAP

LOWER OIL RAIL GAP

3 - SPACER GAP

9 - 96 ENGINE 8.0LBR/BE

PISTON RINGS (Continued)

Page 1192 of 2255

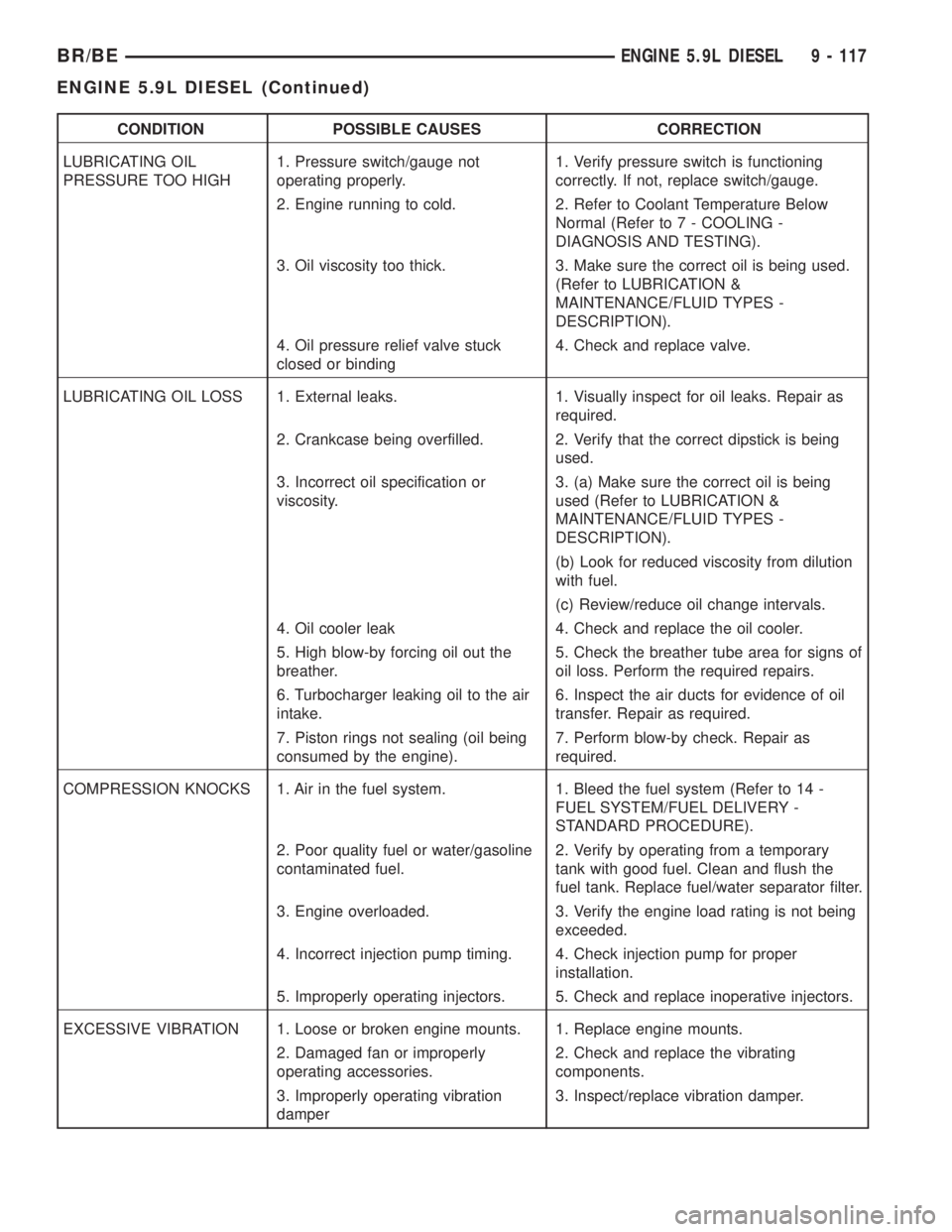

CONDITION POSSIBLE CAUSES CORRECTION

LUBRICATING OIL

PRESSURE TOO HIGH1. Pressure switch/gauge not

operating properly.1. Verify pressure switch is functioning

correctly. If not, replace switch/gauge.

2. Engine running to cold. 2. Refer to Coolant Temperature Below

Normal (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

3. Oil viscosity too thick. 3. Make sure the correct oil is being used.

(Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

DESCRIPTION).

4. Oil pressure relief valve stuck

closed or binding4. Check and replace valve.

LUBRICATING OIL LOSS 1. External leaks. 1. Visually inspect for oil leaks. Repair as

required.

2. Crankcase being overfilled. 2. Verify that the correct dipstick is being

used.

3. Incorrect oil specification or

viscosity.3. (a) Make sure the correct oil is being

used (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(b) Look for reduced viscosity from dilution

with fuel.

(c) Review/reduce oil change intervals.

4. Oil cooler leak 4. Check and replace the oil cooler.

5. High blow-by forcing oil out the

breather.5. Check the breather tube area for signs of

oil loss. Perform the required repairs.

6. Turbocharger leaking oil to the air

intake.6. Inspect the air ducts for evidence of oil

transfer. Repair as required.

7. Piston rings not sealing (oil being

consumed by the engine).7. Perform blow-by check. Repair as

required.

COMPRESSION KNOCKS 1. Air in the fuel system. 1. Bleed the fuel system (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

2. Poor quality fuel or water/gasoline

contaminated fuel.2. Verify by operating from a temporary

tank with good fuel. Clean and flush the

fuel tank. Replace fuel/water separator filter.

3. Engine overloaded. 3. Verify the engine load rating is not being

exceeded.

4. Incorrect injection pump timing. 4. Check injection pump for proper

installation.

5. Improperly operating injectors. 5. Check and replace inoperative injectors.

EXCESSIVE VIBRATION 1. Loose or broken engine mounts. 1. Replace engine mounts.

2. Damaged fan or improperly

operating accessories.2. Check and replace the vibrating

components.

3. Improperly operating vibration

damper3. Inspect/replace vibration damper.

BR/BEENGINE 5.9L DIESEL 9 - 117

ENGINE 5.9L DIESEL (Continued)

Page 1202 of 2255

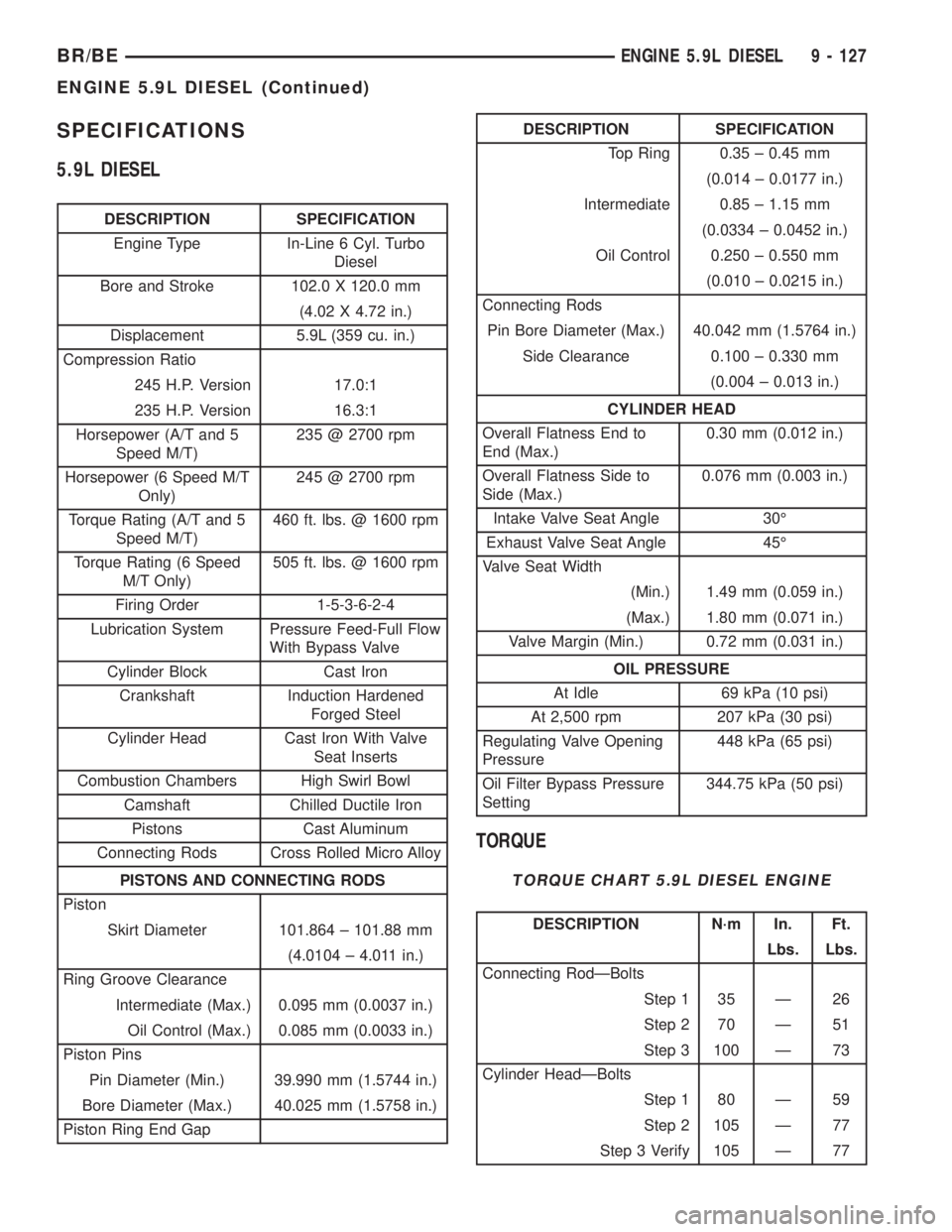

SPECIFICATIONS

5.9L DIESEL

DESCRIPTION SPECIFICATION

Engine Type In-Line 6 Cyl. Turbo

Diesel

Bore and Stroke 102.0 X 120.0 mm

(4.02 X 4.72 in.)

Displacement 5.9L (359 cu. in.)

Compression Ratio

245 H.P. Version 17.0:1

235 H.P. Version 16.3:1

Horsepower (A/T and 5

Speed M/T)235 @ 2700 rpm

Horsepower (6 Speed M/T

Only)245 @ 2700 rpm

Torque Rating (A/T and 5

Speed M/T)460 ft. lbs. @ 1600 rpm

Torque Rating (6 Speed

M/T Only)505 ft. lbs. @ 1600 rpm

Firing Order 1-5-3-6-2-4

Lubrication System Pressure Feed-Full Flow

With Bypass Valve

Cylinder Block Cast Iron

Crankshaft Induction Hardened

Forged Steel

Cylinder Head Cast Iron With Valve

Seat Inserts

Combustion Chambers High Swirl Bowl

Camshaft Chilled Ductile Iron

Pistons Cast Aluminum

Connecting Rods Cross Rolled Micro Alloy

PISTONS AND CONNECTING RODS

Piston

Skirt Diameter 101.864 ± 101.88 mm

(4.0104 ± 4.011 in.)

Ring Groove Clearance

Intermediate (Max.) 0.095 mm (0.0037 in.)

Oil Control (Max.) 0.085 mm (0.0033 in.)

Piston Pins

Pin Diameter (Min.) 39.990 mm (1.5744 in.)

Bore Diameter (Max.) 40.025 mm (1.5758 in.)

Piston Ring End Gap

DESCRIPTION SPECIFICATION

Top Ring 0.35 ± 0.45 mm

(0.014 ± 0.0177 in.)

Intermediate 0.85 ± 1.15 mm

(0.0334 ± 0.0452 in.)

Oil Control 0.250 ± 0.550 mm

(0.010 ± 0.0215 in.)

Connecting Rods

Pin Bore Diameter (Max.) 40.042 mm (1.5764 in.)

Side Clearance 0.100 ± 0.330 mm

(0.004 ± 0.013 in.)

CYLINDER HEAD

Overall Flatness End to

End (Max.)0.30 mm (0.012 in.)

Overall Flatness Side to

Side (Max.)0.076 mm (0.003 in.)

Intake Valve Seat Angle 30É

Exhaust Valve Seat Angle 45É

Valve Seat Width

(Min.) 1.49 mm (0.059 in.)

(Max.) 1.80 mm (0.071 in.)

Valve Margin (Min.) 0.72 mm (0.031 in.)

OIL PRESSURE

At Idle 69 kPa (10 psi)

At 2,500 rpm 207 kPa (30 psi)

Regulating Valve Opening

Pressure448 kPa (65 psi)

Oil Filter Bypass Pressure

Setting344.75 kPa (50 psi)

TORQUE

TORQUE CHART 5.9L DIESEL ENGINE

DESCRIPTION N´m In. Ft.

Lbs. Lbs.

Connecting RodÐBolts

Step 1 35 Ð 26

Step 2 70 Ð 51

Step 3 100 Ð 73

Cylinder HeadÐBolts

Step 1 80 Ð 59

Step 2 105 Ð 77

Step 3 Verify 105 Ð 77

BR/BEENGINE 5.9L DIESEL 9 - 127

ENGINE 5.9L DIESEL (Continued)

Page 1281 of 2255

(4) Connect the DRBIIItto the pressure trans-

ducer following the instructions supplied with the

DRB IIIt.

(5) Enter DRBIIItinto pressure reading mode and

test drive vehicle.

(6) The turbocharger boost pressure must be

between 110 - 138 kpa (16 - 20 psi.). If pressure read-

ings are lower than 110 kpa (16 psi.) inspect for the

following:

²Restricted air inlet system

²Leak in the charge air cooler system (Refer to 11

- EXHAUST SYSTEM/TURBOCHARGER SYSTEM/

CHARGE AIR COOLER AND PLUMBING - DIAG-

NOSIS AND TESTING)

²Turbocharger wastegate broken or misadjusted

²Turbocharger damaged (Refer to 11 - EXHAUST

SYSTEM/TURBOCHARGER SYSTEM/TURBO-

CHARGER - INSPECTION)

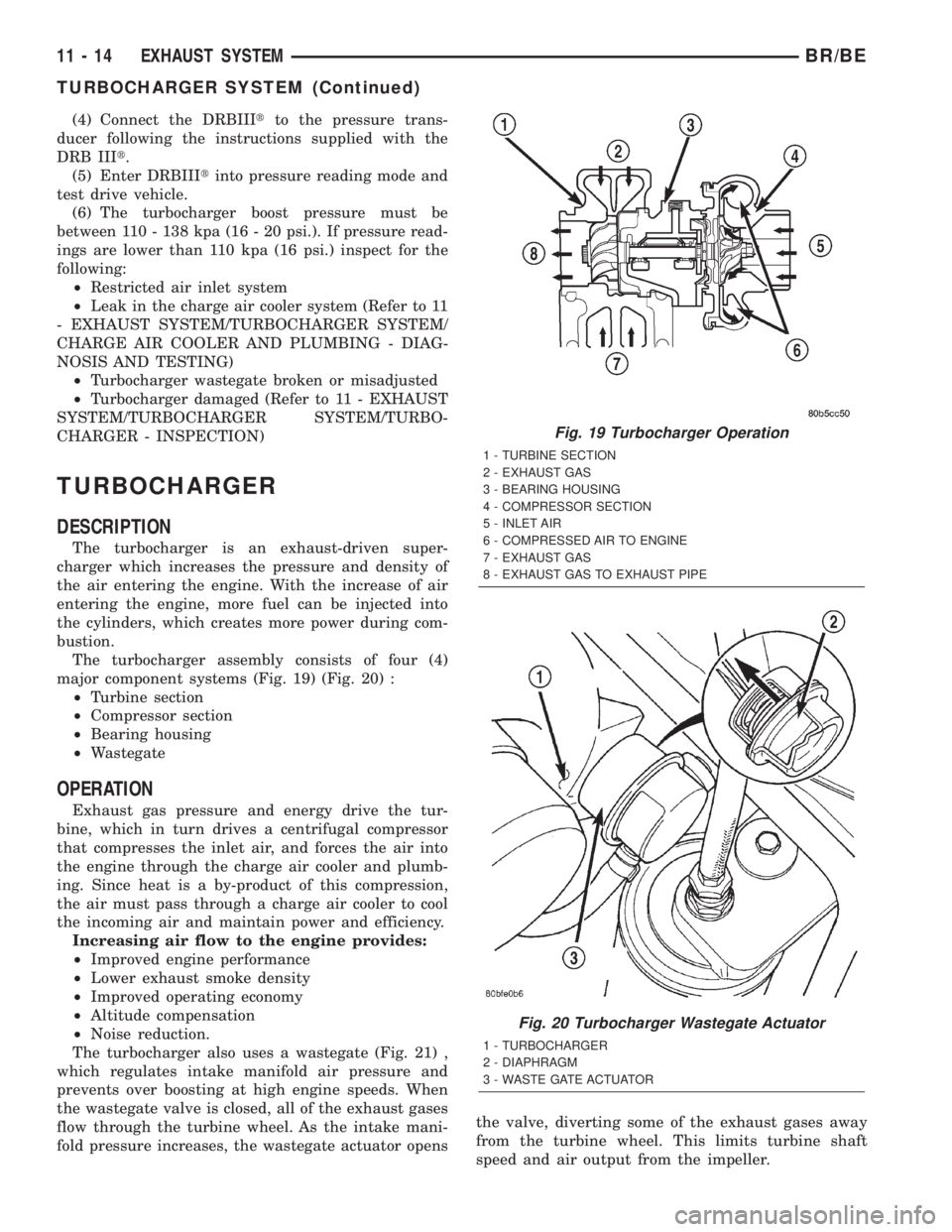

TURBOCHARGER

DESCRIPTION

The turbocharger is an exhaust-driven super-

charger which increases the pressure and density of

the air entering the engine. With the increase of air

entering the engine, more fuel can be injected into

the cylinders, which creates more power during com-

bustion.

The turbocharger assembly consists of four (4)

major component systems (Fig. 19) (Fig. 20) :

²Turbine section

²Compressor section

²Bearing housing

²Wastegate

OPERATION

Exhaust gas pressure and energy drive the tur-

bine, which in turn drives a centrifugal compressor

that compresses the inlet air, and forces the air into

the engine through the charge air cooler and plumb-

ing. Since heat is a by-product of this compression,

the air must pass through a charge air cooler to cool

the incoming air and maintain power and efficiency.

Increasing air flow to the engine provides:

²Improved engine performance

²Lower exhaust smoke density

²Improved operating economy

²Altitude compensation

²Noise reduction.

The turbocharger also uses a wastegate (Fig. 21) ,

which regulates intake manifold air pressure and

prevents over boosting at high engine speeds. When

the wastegate valve is closed, all of the exhaust gases

flow through the turbine wheel. As the intake mani-

fold pressure increases, the wastegate actuator opensthe valve, diverting some of the exhaust gases away

from the turbine wheel. This limits turbine shaft

speed and air output from the impeller.

Fig. 19 Turbocharger Operation

1 - TURBINE SECTION

2 - EXHAUST GAS

3 - BEARING HOUSING

4 - COMPRESSOR SECTION

5 - INLET AIR

6 - COMPRESSED AIR TO ENGINE

7 - EXHAUST GAS

8 - EXHAUST GAS TO EXHAUST PIPE

Fig. 20 Turbocharger Wastegate Actuator

1 - TURBOCHARGER

2 - DIAPHRAGM

3 - WASTE GATE ACTUATOR

11 - 14 EXHAUST SYSTEMBR/BE

TURBOCHARGER SYSTEM (Continued)