sensor DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1862 of 2255

(8) Remove bolts attaching valve body to transmis-

sion case.

(9) Lower valve body enough to remove accumula-

tor piston and springs.

(10) Work manual lever shaft and electrical con-

nector out of transmission case.

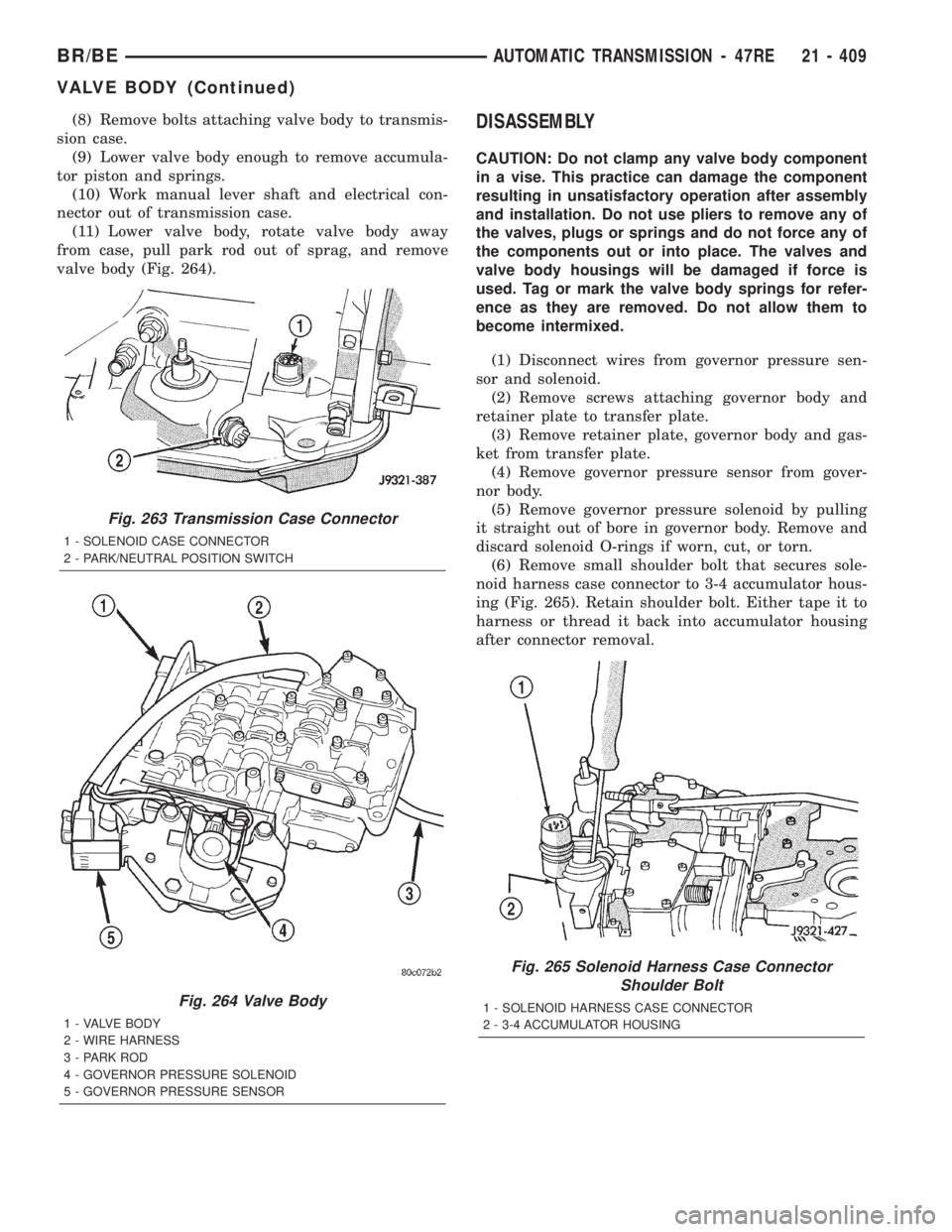

(11) Lower valve body, rotate valve body away

from case, pull park rod out of sprag, and remove

valve body (Fig. 264).DISASSEMBLY

CAUTION: Do not clamp any valve body component

in a vise. This practice can damage the component

resulting in unsatisfactory operation after assembly

and installation. Do not use pliers to remove any of

the valves, plugs or springs and do not force any of

the components out or into place. The valves and

valve body housings will be damaged if force is

used. Tag or mark the valve body springs for refer-

ence as they are removed. Do not allow them to

become intermixed.

(1) Disconnect wires from governor pressure sen-

sor and solenoid.

(2) Remove screws attaching governor body and

retainer plate to transfer plate.

(3) Remove retainer plate, governor body and gas-

ket from transfer plate.

(4) Remove governor pressure sensor from gover-

nor body.

(5) Remove governor pressure solenoid by pulling

it straight out of bore in governor body. Remove and

discard solenoid O-rings if worn, cut, or torn.

(6) Remove small shoulder bolt that secures sole-

noid harness case connector to 3-4 accumulator hous-

ing (Fig. 265). Retain shoulder bolt. Either tape it to

harness or thread it back into accumulator housing

after connector removal.

Fig. 263 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - PARK/NEUTRAL POSITION SWITCH

Fig. 264 Valve Body

1 - VALVE BODY

2 - WIRE HARNESS

3 - PARK ROD

4 - GOVERNOR PRESSURE SOLENOID

5 - GOVERNOR PRESSURE SENSOR

Fig. 265 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 409

VALVE BODY (Continued)

Page 1863 of 2255

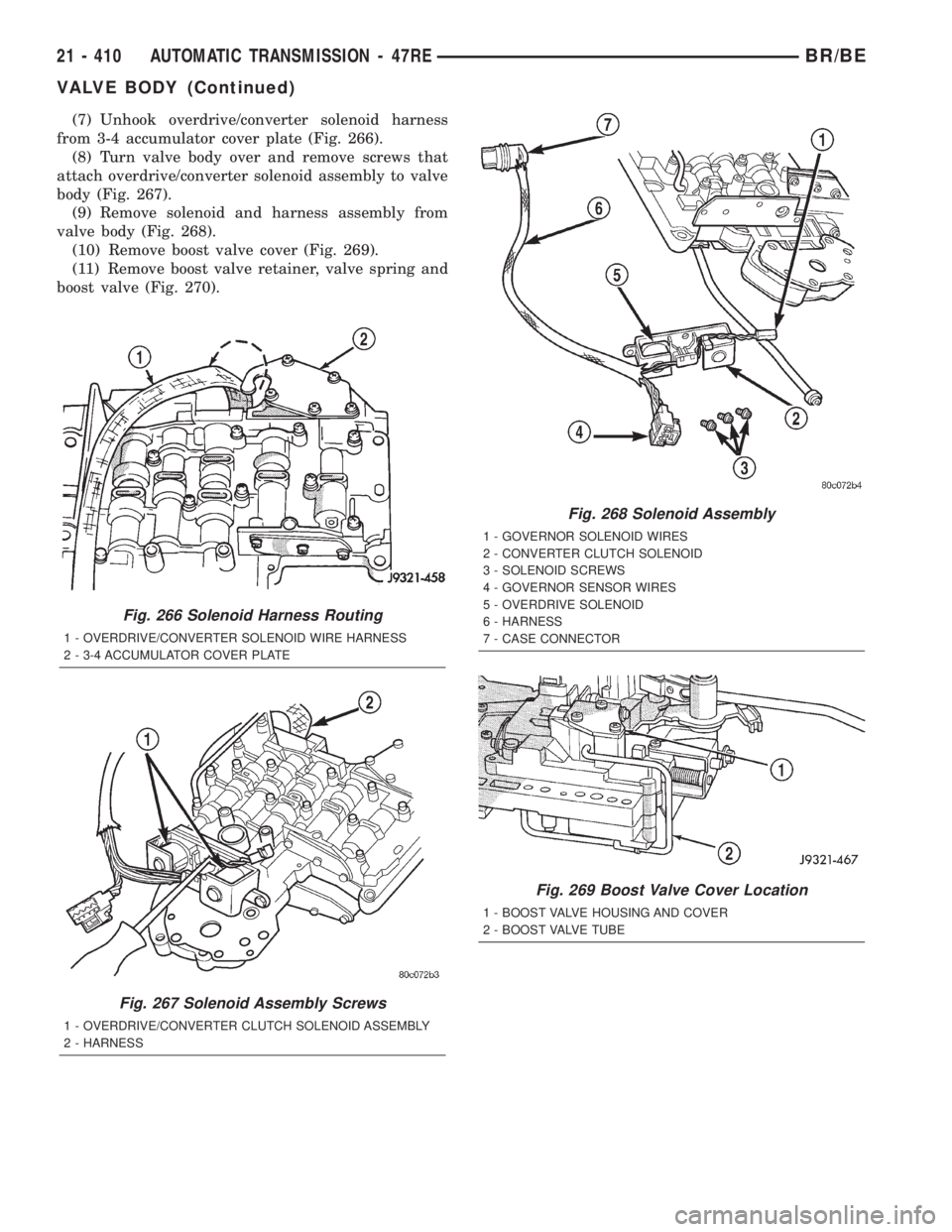

(7) Unhook overdrive/converter solenoid harness

from 3-4 accumulator cover plate (Fig. 266).

(8) Turn valve body over and remove screws that

attach overdrive/converter solenoid assembly to valve

body (Fig. 267).

(9) Remove solenoid and harness assembly from

valve body (Fig. 268).

(10) Remove boost valve cover (Fig. 269).

(11) Remove boost valve retainer, valve spring and

boost valve (Fig. 270).

Fig. 266 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

Fig. 267 Solenoid Assembly Screws

1 - OVERDRIVE/CONVERTER CLUTCH SOLENOID ASSEMBLY

2 - HARNESS

Fig. 268 Solenoid Assembly

1 - GOVERNOR SOLENOID WIRES

2 - CONVERTER CLUTCH SOLENOID

3 - SOLENOID SCREWS

4 - GOVERNOR SENSOR WIRES

5 - OVERDRIVE SOLENOID

6 - HARNESS

7 - CASE CONNECTOR

Fig. 269 Boost Valve Cover Location

1 - BOOST VALVE HOUSING AND COVER

2 - BOOST VALVE TUBE

21 - 410 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 1871 of 2255

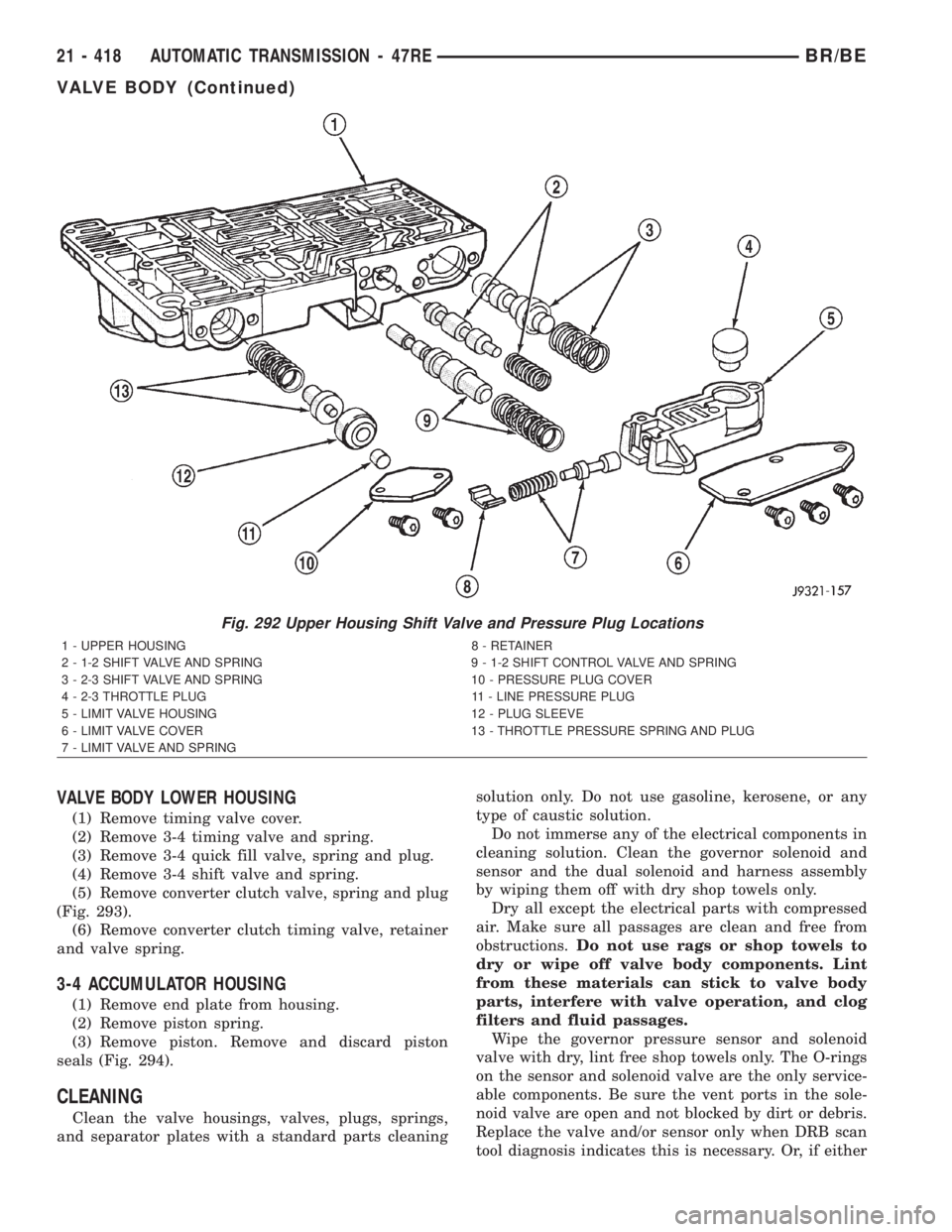

VALVE BODY LOWER HOUSING

(1) Remove timing valve cover.

(2) Remove 3-4 timing valve and spring.

(3) Remove 3-4 quick fill valve, spring and plug.

(4) Remove 3-4 shift valve and spring.

(5) Remove converter clutch valve, spring and plug

(Fig. 293).

(6) Remove converter clutch timing valve, retainer

and valve spring.

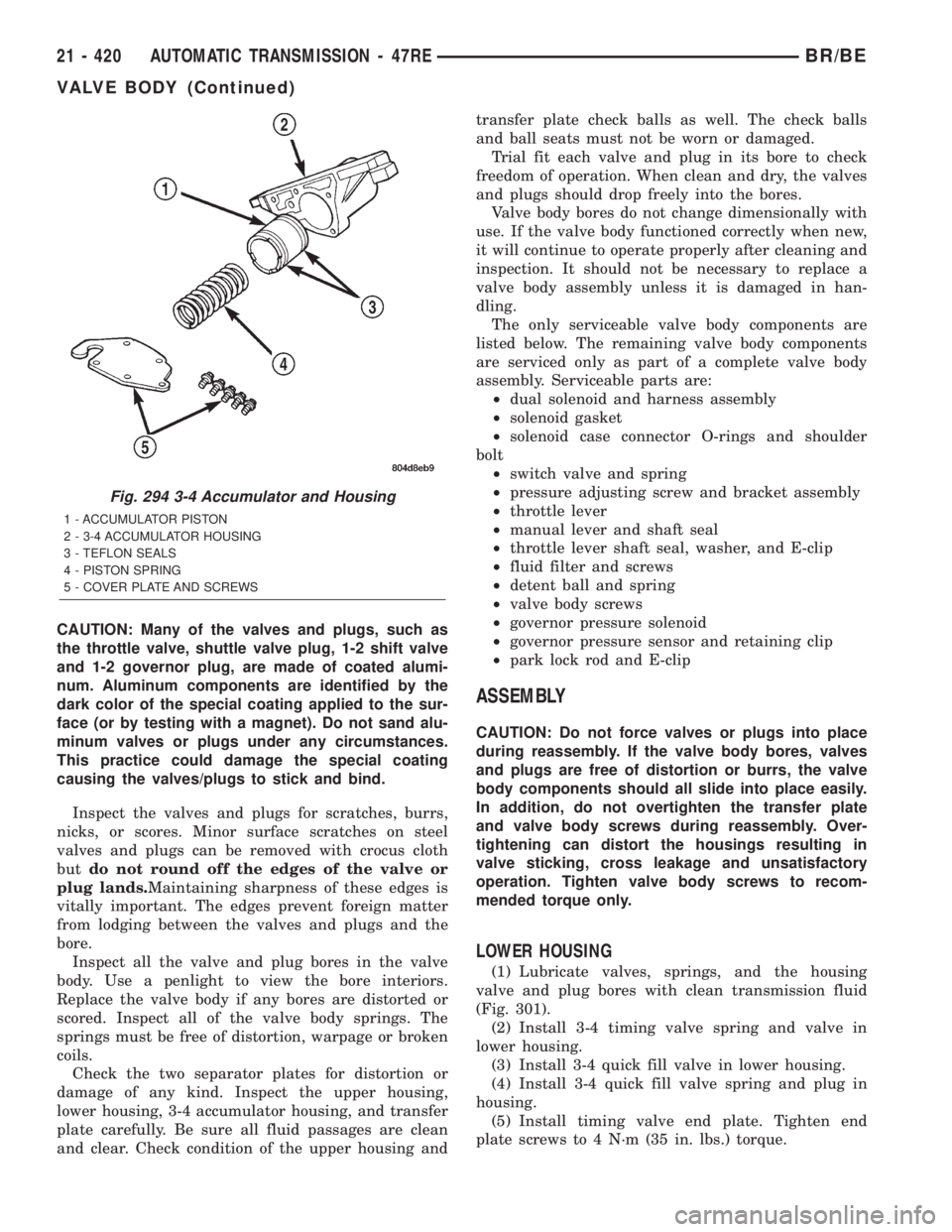

3-4 ACCUMULATOR HOUSING

(1) Remove end plate from housing.

(2) Remove piston spring.

(3) Remove piston. Remove and discard piston

seals (Fig. 294).

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaningsolution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if either

Fig. 292 Upper Housing Shift Valve and Pressure Plug Locations

1 - UPPER HOUSING 8 - RETAINER

2 - 1-2 SHIFT VALVE AND SPRING 9 - 1-2 SHIFT CONTROL VALVE AND SPRING

3 - 2-3 SHIFT VALVE AND SPRING 10 - PRESSURE PLUG COVER

4 - 2-3 THROTTLE PLUG 11 - LINE PRESSURE PLUG

5 - LIMIT VALVE HOUSING 12 - PLUG SLEEVE

6 - LIMIT VALVE COVER 13 - THROTTLE PRESSURE SPRING AND PLUG

7 - LIMIT VALVE AND SPRING

21 - 418 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 1873 of 2255

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing andtransfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

Valve body bores do not change dimensionally with

use. If the valve body functioned correctly when new,

it will continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

The only serviceable valve body components are

listed below. The remaining valve body components

are serviced only as part of a complete valve body

assembly. Serviceable parts are:

²dual solenoid and harness assembly

²solenoid gasket

²solenoid case connector O-rings and shoulder

bolt

²switch valve and spring

²pressure adjusting screw and bracket assembly

²throttle lever

²manual lever and shaft seal

²throttle lever shaft seal, washer, and E-clip

²fluid filter and screws

²detent ball and spring

²valve body screws

²governor pressure solenoid

²governor pressure sensor and retaining clip

²park lock rod and E-clip

ASSEMBLY

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the housings resulting in

valve sticking, cross leakage and unsatisfactory

operation. Tighten valve body screws to recom-

mended torque only.

LOWER HOUSING

(1) Lubricate valves, springs, and the housing

valve and plug bores with clean transmission fluid

(Fig. 301).

(2) Install 3-4 timing valve spring and valve in

lower housing.

(3) Install 3-4 quick fill valve in lower housing.

(4) Install 3-4 quick fill valve spring and plug in

housing.

(5) Install timing valve end plate. Tighten end

plate screws to 4 N´m (35 in. lbs.) torque.

Fig. 294 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 420 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 1880 of 2255

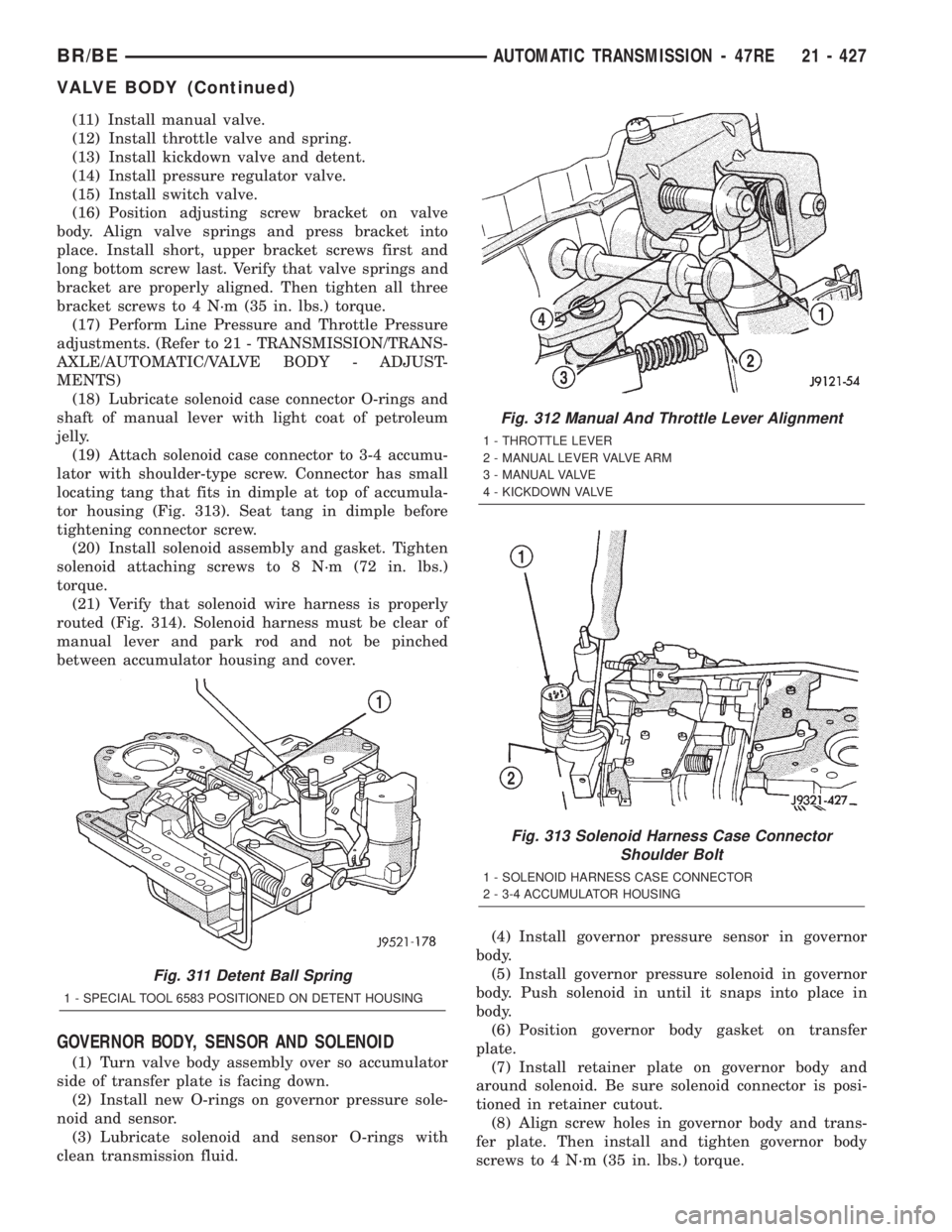

(11) Install manual valve.

(12) Install throttle valve and spring.

(13) Install kickdown valve and detent.

(14) Install pressure regulator valve.

(15) Install switch valve.

(16) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and

long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 N´m (35 in. lbs.) torque.

(17) Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC/VALVE BODY - ADJUST-

MENTS)

(18) Lubricate solenoid case connector O-rings and

shaft of manual lever with light coat of petroleum

jelly.

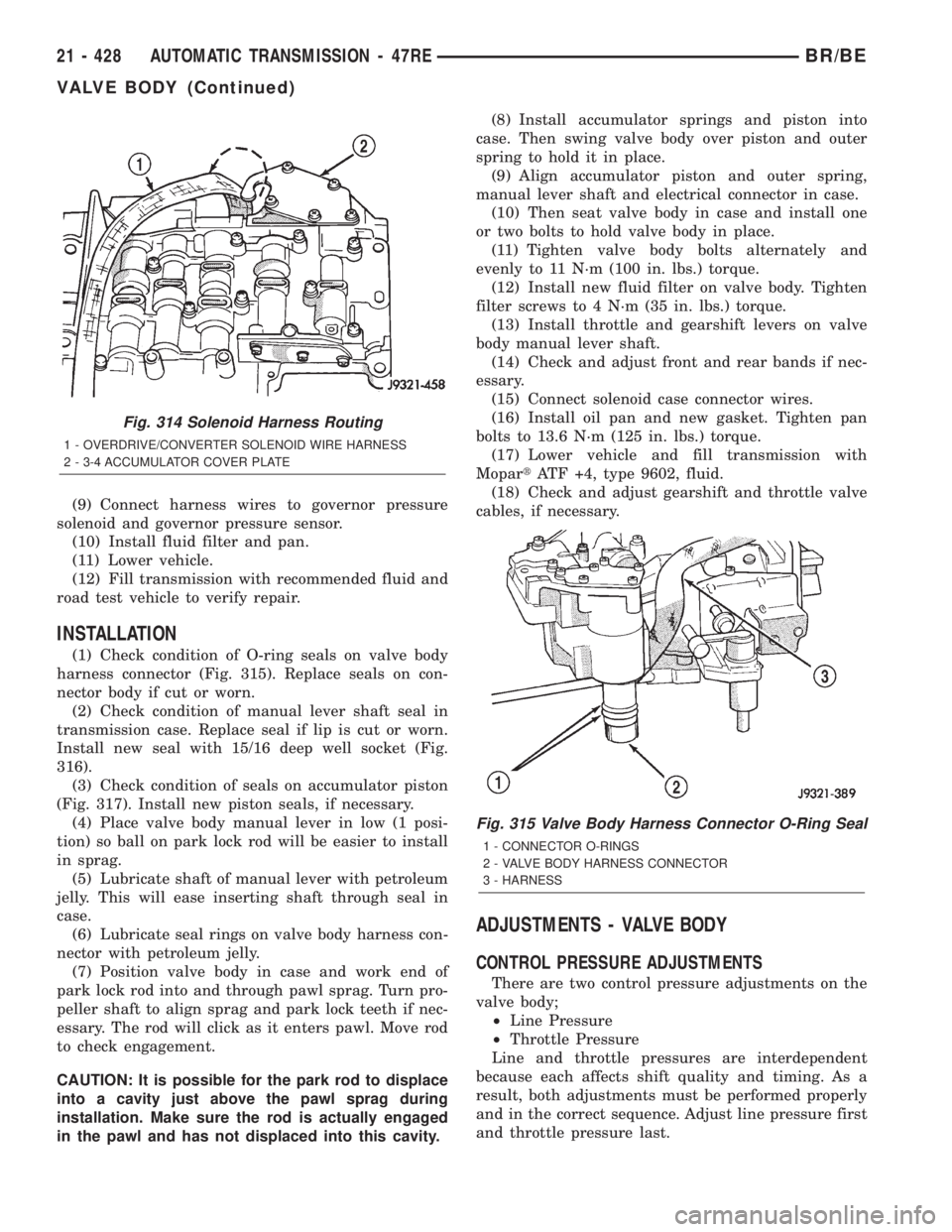

(19) Attach solenoid case connector to 3-4 accumu-

lator with shoulder-type screw. Connector has small

locating tang that fits in dimple at top of accumula-

tor housing (Fig. 313). Seat tang in dimple before

tightening connector screw.

(20) Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.)

torque.

(21) Verify that solenoid wire harness is properly

routed (Fig. 314). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.(4) Install governor pressure sensor in governor

body.

(5) Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in

body.

(6) Position governor body gasket on transfer

plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

Fig. 311 Detent Ball Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 312 Manual And Throttle Lever Alignment

1 - THROTTLE LEVER

2 - MANUAL LEVER VALVE ARM

3 - MANUAL VALVE

4 - KICKDOWN VALVE

Fig. 313 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 427

VALVE BODY (Continued)

Page 1881 of 2255

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.

(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 315). Replace seals on con-

nector body if cut or worn.

(2) Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig.

316).

(3) Check condition of seals on accumulator piston

(Fig. 317). Install new piston seals, if necessary.

(4) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(5) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(6) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(7) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.(8) Install accumulator springs and piston into

case. Then swing valve body over piston and outer

spring to hold it in place.

(9) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(10) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(11) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(12) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(13) Install throttle and gearshift levers on valve

body manual lever shaft.

(14) Check and adjust front and rear bands if nec-

essary.

(15) Connect solenoid case connector wires.

(16) Install oil pan and new gasket. Tighten pan

bolts to 13.6 N´m (125 in. lbs.) torque.

(17) Lower vehicle and fill transmission with

MopartATF +4, type 9602, fluid.

(18) Check and adjust gearshift and throttle valve

cables, if necessary.

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

Fig. 314 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

Fig. 315 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

21 - 428 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 2060 of 2255

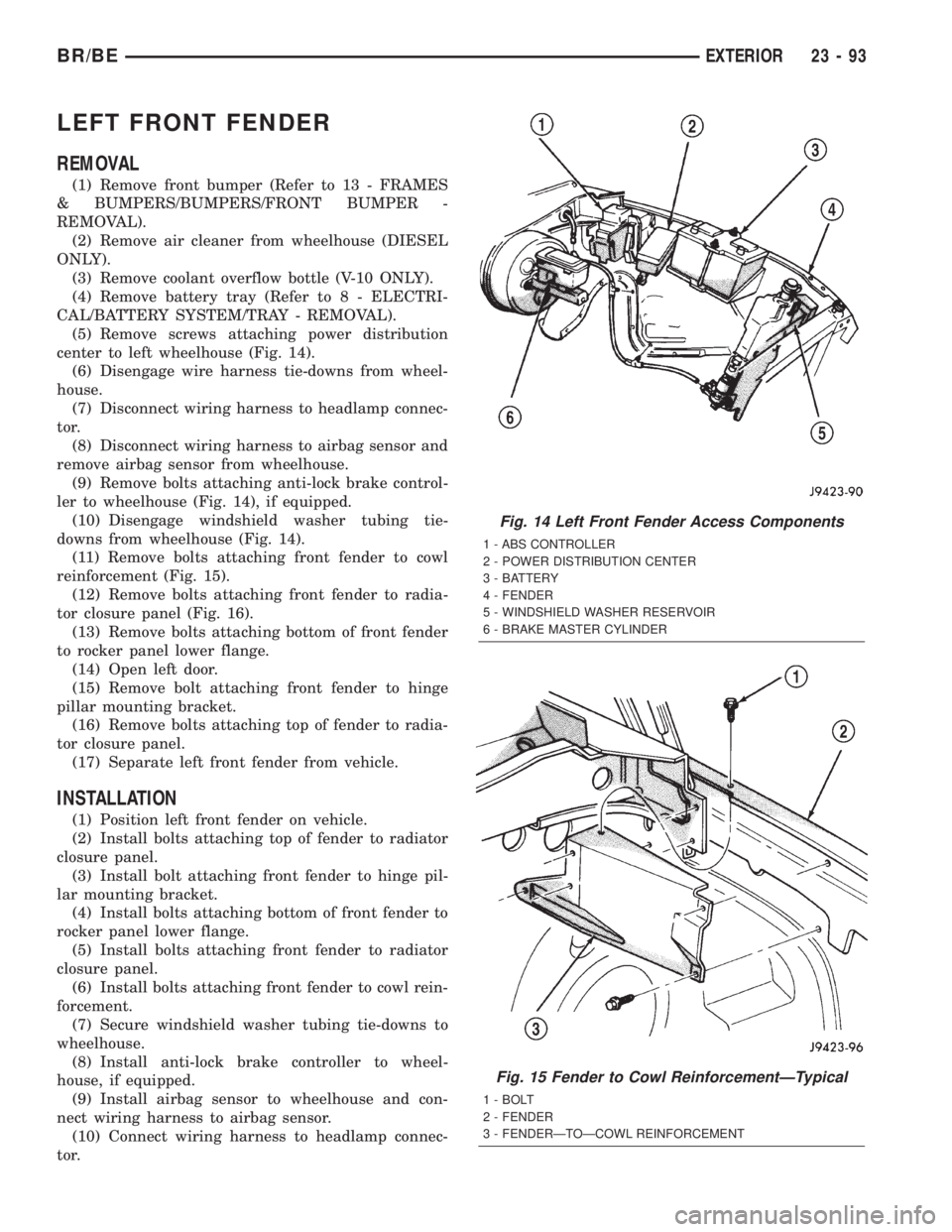

LEFT FRONT FENDER

REMOVAL

(1) Remove front bumper (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT BUMPER -

REMOVAL).

(2) Remove air cleaner from wheelhouse (DIESEL

ONLY).

(3) Remove coolant overflow bottle (V-10 ONLY).

(4) Remove battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - REMOVAL).

(5) Remove screws attaching power distribution

center to left wheelhouse (Fig. 14).

(6) Disengage wire harness tie-downs from wheel-

house.

(7) Disconnect wiring harness to headlamp connec-

tor.

(8) Disconnect wiring harness to airbag sensor and

remove airbag sensor from wheelhouse.

(9) Remove bolts attaching anti-lock brake control-

ler to wheelhouse (Fig. 14), if equipped.

(10) Disengage windshield washer tubing tie-

downs from wheelhouse (Fig. 14).

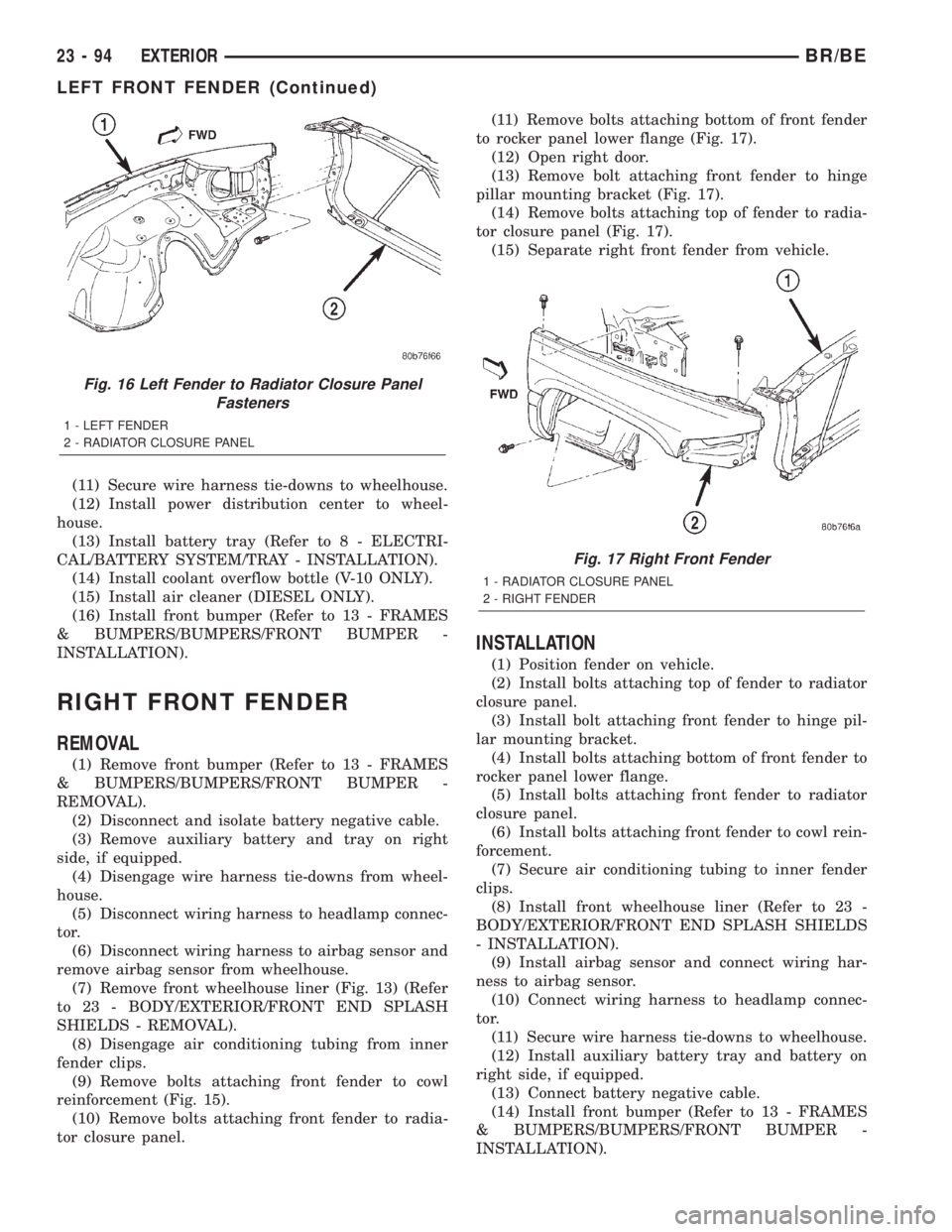

(11) Remove bolts attaching front fender to cowl

reinforcement (Fig. 15).

(12) Remove bolts attaching front fender to radia-

tor closure panel (Fig. 16).

(13) Remove bolts attaching bottom of front fender

to rocker panel lower flange.

(14) Open left door.

(15) Remove bolt attaching front fender to hinge

pillar mounting bracket.

(16) Remove bolts attaching top of fender to radia-

tor closure panel.

(17) Separate left front fender from vehicle.

INSTALLATION

(1) Position left front fender on vehicle.

(2) Install bolts attaching top of fender to radiator

closure panel.

(3) Install bolt attaching front fender to hinge pil-

lar mounting bracket.

(4) Install bolts attaching bottom of front fender to

rocker panel lower flange.

(5) Install bolts attaching front fender to radiator

closure panel.

(6) Install bolts attaching front fender to cowl rein-

forcement.

(7) Secure windshield washer tubing tie-downs to

wheelhouse.

(8) Install anti-lock brake controller to wheel-

house, if equipped.

(9) Install airbag sensor to wheelhouse and con-

nect wiring harness to airbag sensor.

(10) Connect wiring harness to headlamp connec-

tor.

Fig. 14 Left Front Fender Access Components

1 - ABS CONTROLLER

2 - POWER DISTRIBUTION CENTER

3 - BATTERY

4 - FENDER

5 - WINDSHIELD WASHER RESERVOIR

6 - BRAKE MASTER CYLINDER

Fig. 15 Fender to Cowl ReinforcementÐTypical

1 - BOLT

2 - FENDER

3 - FENDERÐTOÐCOWL REINFORCEMENT

BR/BEEXTERIOR 23 - 93

Page 2061 of 2255

(11) Secure wire harness tie-downs to wheelhouse.

(12) Install power distribution center to wheel-

house.

(13) Install battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION).

(14) Install coolant overflow bottle (V-10 ONLY).

(15) Install air cleaner (DIESEL ONLY).

(16) Install front bumper (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT BUMPER -

INSTALLATION).

RIGHT FRONT FENDER

REMOVAL

(1) Remove front bumper (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT BUMPER -

REMOVAL).

(2) Disconnect and isolate battery negative cable.

(3) Remove auxiliary battery and tray on right

side, if equipped.

(4) Disengage wire harness tie-downs from wheel-

house.

(5) Disconnect wiring harness to headlamp connec-

tor.

(6) Disconnect wiring harness to airbag sensor and

remove airbag sensor from wheelhouse.

(7) Remove front wheelhouse liner (Fig. 13) (Refer

to 23 - BODY/EXTERIOR/FRONT END SPLASH

SHIELDS - REMOVAL).

(8) Disengage air conditioning tubing from inner

fender clips.

(9) Remove bolts attaching front fender to cowl

reinforcement (Fig. 15).

(10) Remove bolts attaching front fender to radia-

tor closure panel.(11) Remove bolts attaching bottom of front fender

to rocker panel lower flange (Fig. 17).

(12) Open right door.

(13) Remove bolt attaching front fender to hinge

pillar mounting bracket (Fig. 17).

(14) Remove bolts attaching top of fender to radia-

tor closure panel (Fig. 17).

(15) Separate right front fender from vehicle.

INSTALLATION

(1) Position fender on vehicle.

(2) Install bolts attaching top of fender to radiator

closure panel.

(3) Install bolt attaching front fender to hinge pil-

lar mounting bracket.

(4) Install bolts attaching bottom of front fender to

rocker panel lower flange.

(5) Install bolts attaching front fender to radiator

closure panel.

(6) Install bolts attaching front fender to cowl rein-

forcement.

(7) Secure air conditioning tubing to inner fender

clips.

(8) Install front wheelhouse liner (Refer to 23 -

BODY/EXTERIOR/FRONT END SPLASH SHIELDS

- INSTALLATION).

(9) Install airbag sensor and connect wiring har-

ness to airbag sensor.

(10) Connect wiring harness to headlamp connec-

tor.

(11) Secure wire harness tie-downs to wheelhouse.

(12) Install auxiliary battery tray and battery on

right side, if equipped.

(13) Connect battery negative cable.

(14) Install front bumper (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT BUMPER -

INSTALLATION).

Fig. 16 Left Fender to Radiator Closure Panel

Fasteners

1 - LEFT FENDER

2 - RADIATOR CLOSURE PANEL

Fig. 17 Right Front Fender

1 - RADIATOR CLOSURE PANEL

2 - RIGHT FENDER

23 - 94 EXTERIORBR/BE

LEFT FRONT FENDER (Continued)

Page 2068 of 2255

HOOD

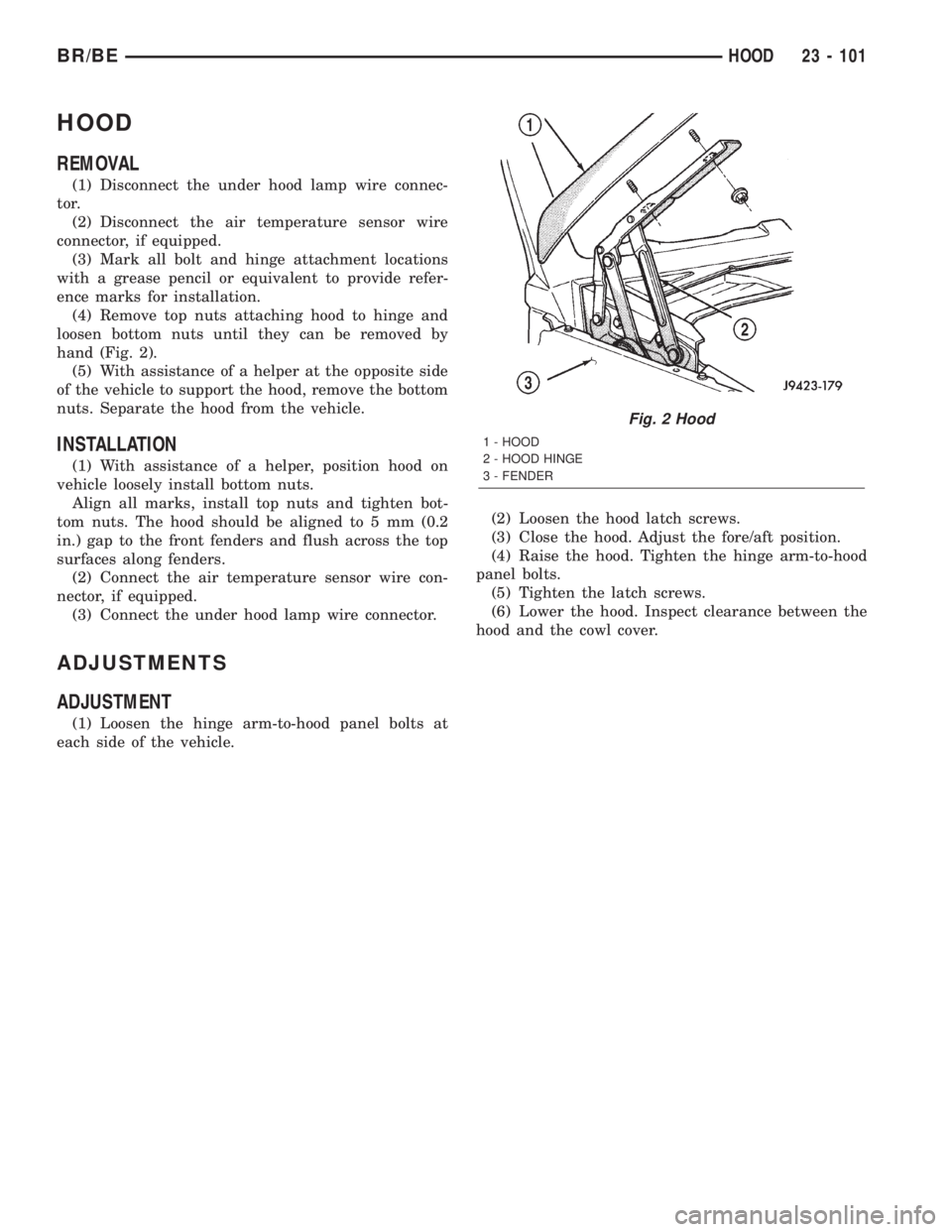

REMOVAL

(1) Disconnect the under hood lamp wire connec-

tor.

(2) Disconnect the air temperature sensor wire

connector, if equipped.

(3) Mark all bolt and hinge attachment locations

with a grease pencil or equivalent to provide refer-

ence marks for installation.

(4) Remove top nuts attaching hood to hinge and

loosen bottom nuts until they can be removed by

hand (Fig. 2).

(5) With assistance of a helper at the opposite side

of the vehicle to support the hood, remove the bottom

nuts. Separate the hood from the vehicle.

INSTALLATION

(1) With assistance of a helper, position hood on

vehicle loosely install bottom nuts.

Align all marks, install top nuts and tighten bot-

tom nuts. The hood should be aligned to 5 mm (0.2

in.) gap to the front fenders and flush across the top

surfaces along fenders.

(2) Connect the air temperature sensor wire con-

nector, if equipped.

(3) Connect the under hood lamp wire connector.

ADJUSTMENTS

ADJUSTMENT

(1) Loosen the hinge arm-to-hood panel bolts at

each side of the vehicle.(2) Loosen the hood latch screws.

(3) Close the hood. Adjust the fore/aft position.

(4) Raise the hood. Tighten the hinge arm-to-hood

panel bolts.

(5) Tighten the latch screws.

(6) Lower the hood. Inspect clearance between the

hood and the cowl cover.

Fig. 2 Hood

1 - HOOD

2 - HOOD HINGE

3 - FENDER

BR/BEHOOD 23 - 101

Page 2071 of 2255

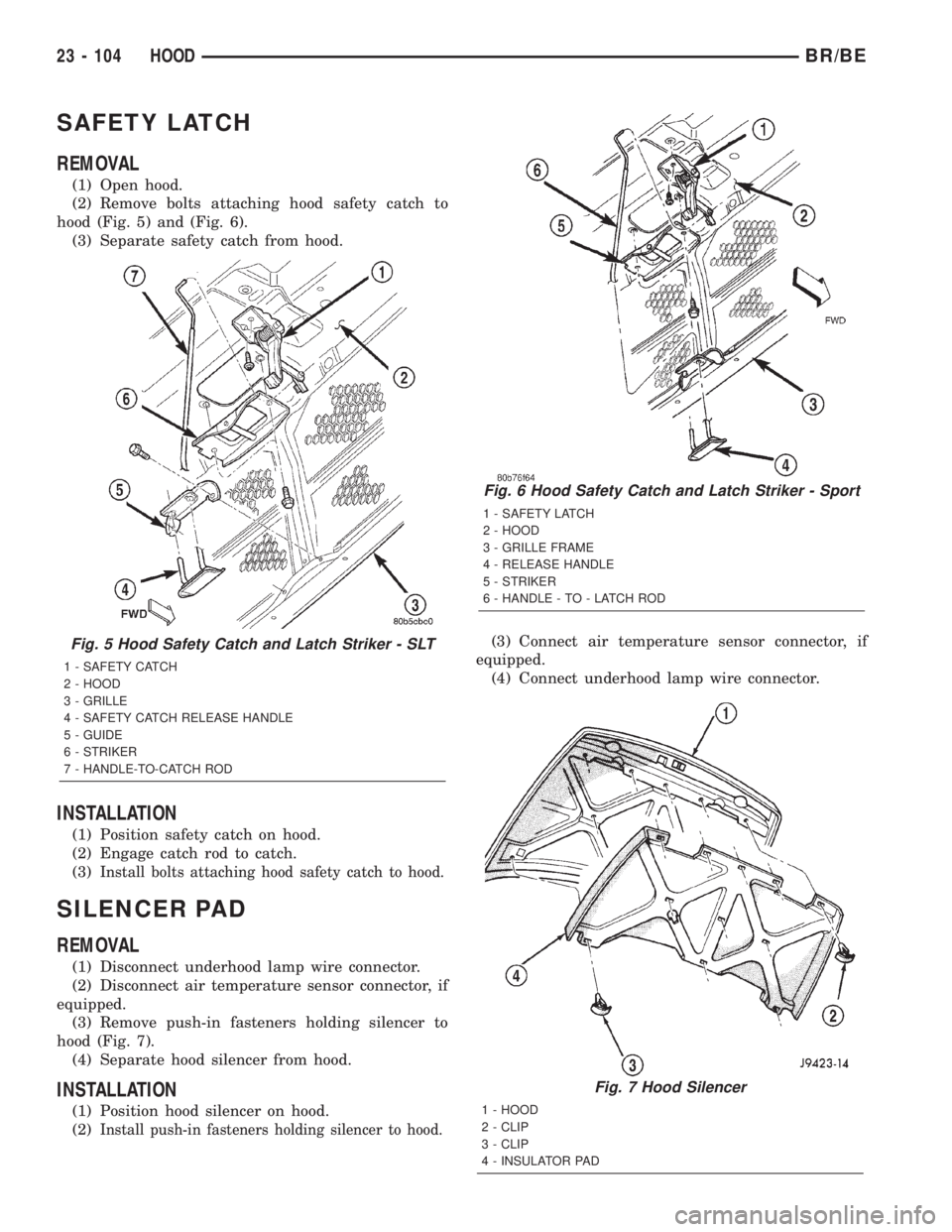

SAFETY LATCH

REMOVAL

(1) Open hood.

(2) Remove bolts attaching hood safety catch to

hood (Fig. 5) and (Fig. 6).

(3) Separate safety catch from hood.

INSTALLATION

(1) Position safety catch on hood.

(2) Engage catch rod to catch.

(3)

Install bolts attaching hood safety catch to hood.

SILENCER PAD

REMOVAL

(1) Disconnect underhood lamp wire connector.

(2) Disconnect air temperature sensor connector, if

equipped.

(3) Remove push-in fasteners holding silencer to

hood (Fig. 7).

(4) Separate hood silencer from hood.

INSTALLATION

(1) Position hood silencer on hood.

(2)

Install push-in fasteners holding silencer to hood.

(3) Connect air temperature sensor connector, if

equipped.

(4) Connect underhood lamp wire connector.

Fig. 6 Hood Safety Catch and Latch Striker - Sport

1 - SAFETY LATCH

2 - HOOD

3 - GRILLE FRAME

4 - RELEASE HANDLE

5 - STRIKER

6 - HANDLE - TO - LATCH ROD

Fig. 7 Hood Silencer

1 - HOOD

2 - CLIP

3 - CLIP

4 - INSULATOR PAD

Fig. 5 Hood Safety Catch and Latch Striker - SLT

1 - SAFETY CATCH

2 - HOOD

3 - GRILLE

4 - SAFETY CATCH RELEASE HANDLE

5 - GUIDE

6 - STRIKER

7 - HANDLE-TO-CATCH ROD

23 - 104 HOODBR/BE