DODGE RAM 2002 Service Repair Manual

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 311 of 2255

(2) Install rubber insulators to alignment dowels

at lower part of radiator.

(3) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(4) Install two upper radiator mounting bolts.

Tighten bolts to 11 N´m (95 in. lbs.) torque.

(5) Connect both radiator hoses and install hose

clamps.

(6) Install windshield washer reservoir tank.

(7) Position fan shroud to flanges on sides of radi-

ator. Install fan shroud mounting bolts (Fig. 37).

Tighten bolts to 6 N´m (50 in. lbs.) torque.

(8) Install coolant reserve/overflow tank hose to

radiator filler neck nipple.

(9) Connect the overflow hose to the radiator.

(10) Install battery negative cables.

(11) Position heater controls tofull heatposition.

(12) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(13) Operate engine until it reaches normal tem-

perature. Check cooling system fluid levels.

RADIATOR - 5.9L DIESEL

DESCRIPTION

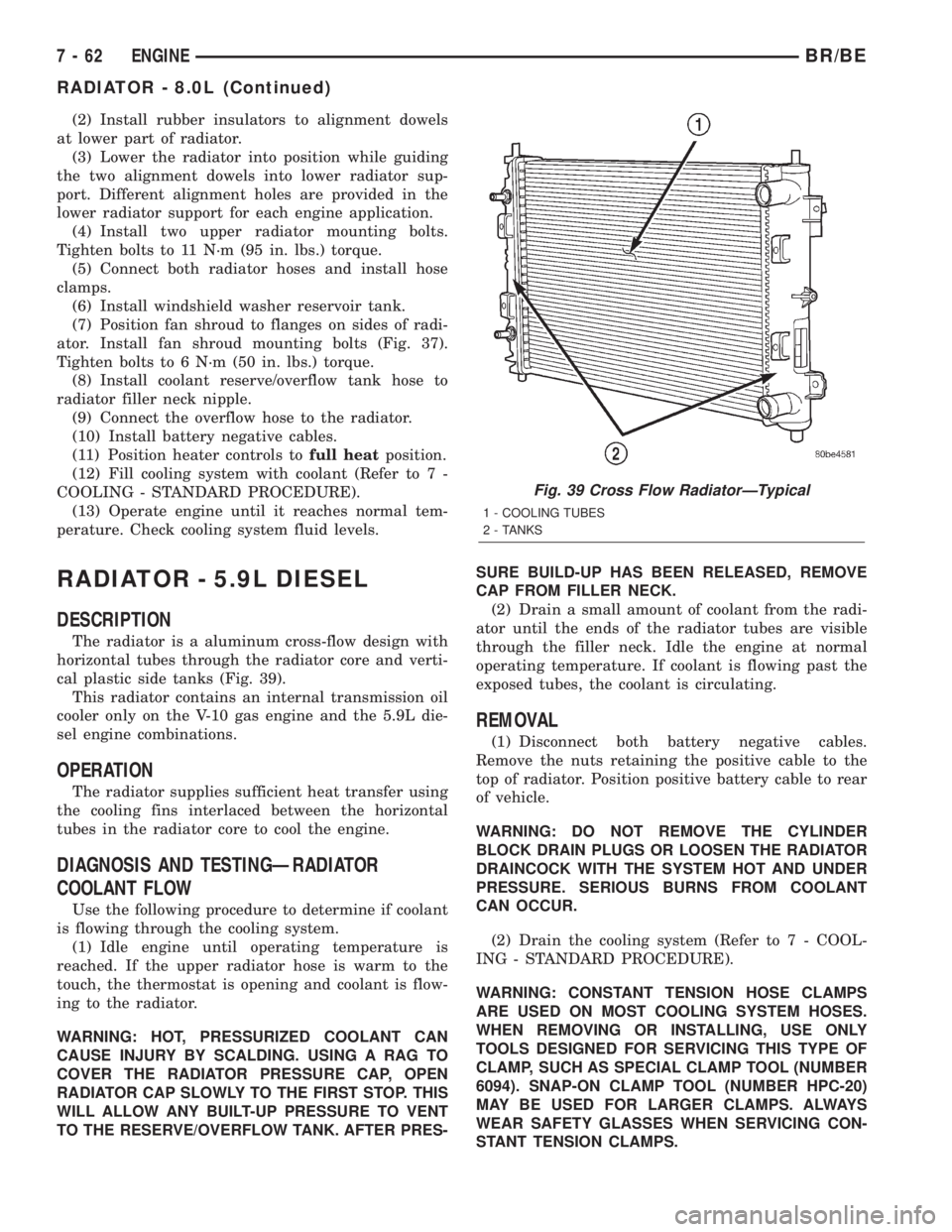

The radiator is a aluminum cross-flow design with

horizontal tubes through the radiator core and verti-

cal plastic side tanks (Fig. 39).

This radiator contains an internal transmission oil

cooler only on the V-10 gas engine and the 5.9L die-

sel engine combinations.

OPERATION

The radiator supplies sufficient heat transfer using

the cooling fins interlaced between the horizontal

tubes in the radiator core to cool the engine.

DIAGNOSIS AND TESTINGÐRADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

REMOVAL

(1) Disconnect both battery negative cables.

Remove the nuts retaining the positive cable to the

top of radiator. Position positive battery cable to rear

of vehicle.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

Fig. 39 Cross Flow RadiatorÐTypical

1 - COOLING TUBES

2 - TANKS

7 - 62 ENGINEBR/BE

RADIATOR - 8.0L (Continued)

Page 312 of 2255

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(3) Remove hose clamps and hoses from radiator.

(4) Remove coolant reserve/overflow tank hose

from radiator filler neck nipple.

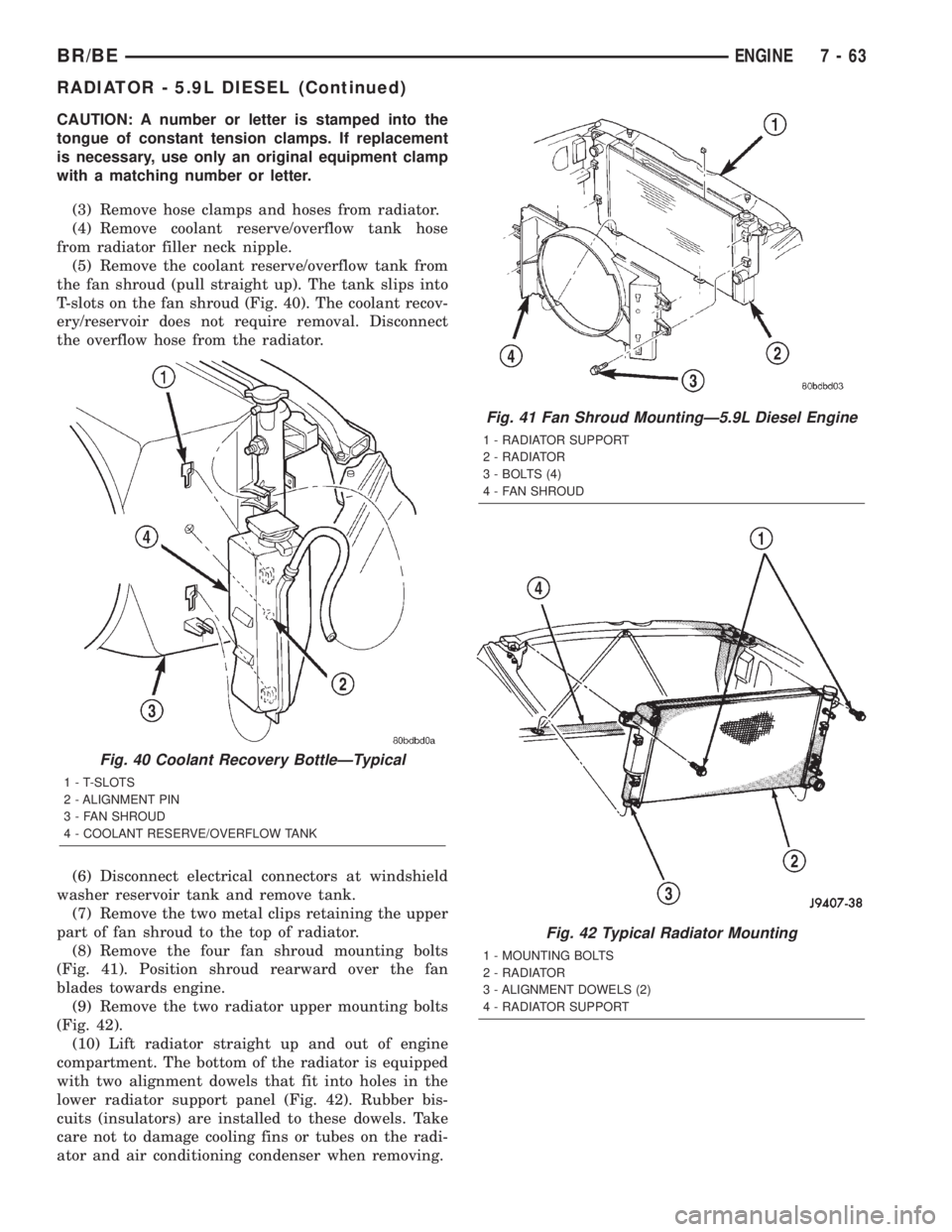

(5) Remove the coolant reserve/overflow tank from

the fan shroud (pull straight up). The tank slips into

T-slots on the fan shroud (Fig. 40). The coolant recov-

ery/reservoir does not require removal. Disconnect

the overflow hose from the radiator.

(6) Disconnect electrical connectors at windshield

washer reservoir tank and remove tank.

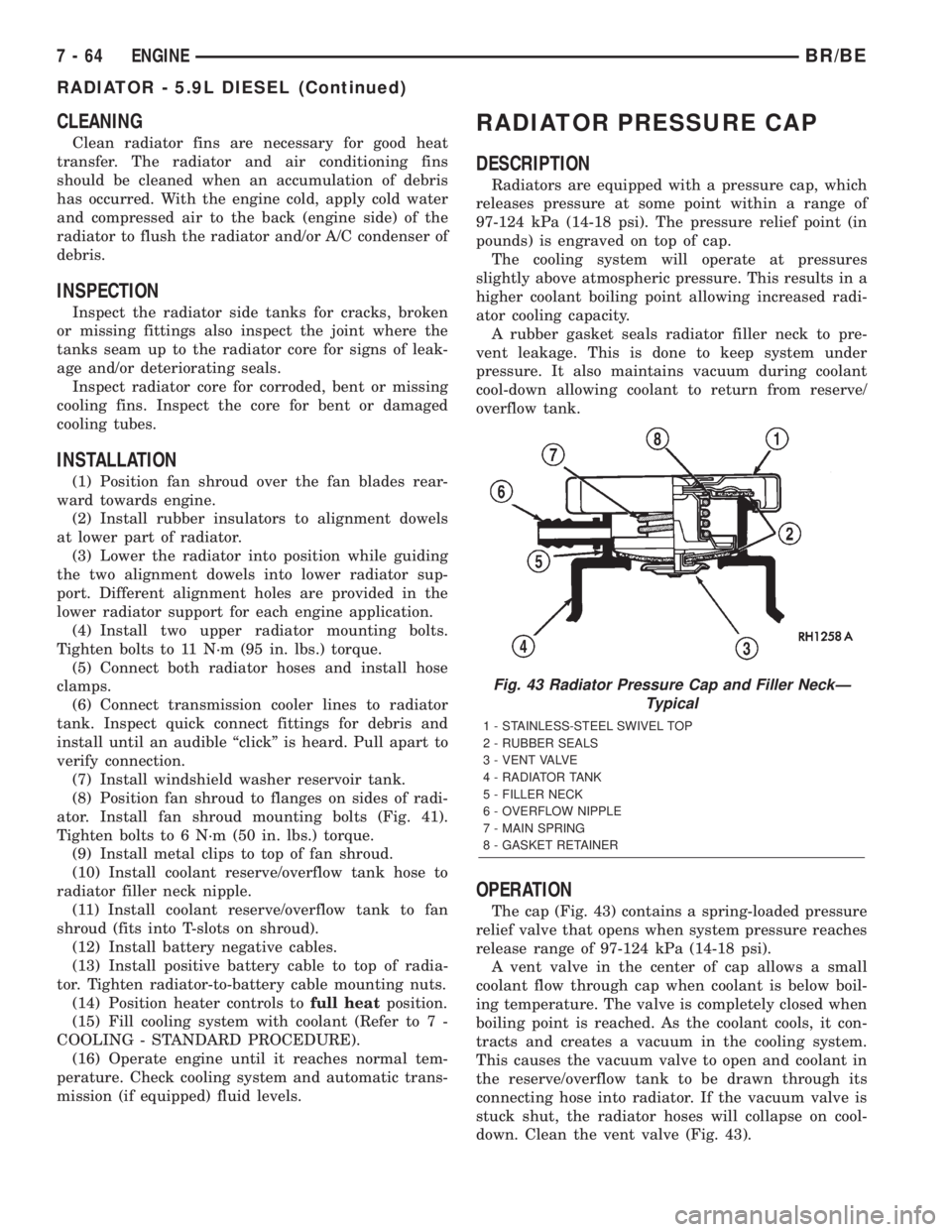

(7) Remove the two metal clips retaining the upper

part of fan shroud to the top of radiator.

(8) Remove the four fan shroud mounting bolts

(Fig. 41). Position shroud rearward over the fan

blades towards engine.

(9) Remove the two radiator upper mounting bolts

(Fig. 42).

(10) Lift radiator straight up and out of engine

compartment. The bottom of the radiator is equipped

with two alignment dowels that fit into holes in the

lower radiator support panel (Fig. 42). Rubber bis-

cuits (insulators) are installed to these dowels. Take

care not to damage cooling fins or tubes on the radi-

ator and air conditioning condenser when removing.

Fig. 40 Coolant Recovery BottleÐTypical

1 - T-SLOTS

2 - ALIGNMENT PIN

3 - FAN SHROUD

4 - COOLANT RESERVE/OVERFLOW TANK

Fig. 41 Fan Shroud MountingÐ5.9L Diesel Engine

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 42 Typical Radiator Mounting

1 - MOUNTING BOLTS

2 - RADIATOR

3 - ALIGNMENT DOWELS (2)

4 - RADIATOR SUPPORT

BR/BEENGINE 7 - 63

RADIATOR - 5.9L DIESEL (Continued)

Page 313 of 2255

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and air conditioning fins

should be cleaned when an accumulation of debris

has occurred. With the engine cold, apply cold water

and compressed air to the back (engine side) of the

radiator to flush the radiator and/or A/C condenser of

debris.

INSPECTION

Inspect the radiator side tanks for cracks, broken

or missing fittings also inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Position fan shroud over the fan blades rear-

ward towards engine.

(2) Install rubber insulators to alignment dowels

at lower part of radiator.

(3) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(4) Install two upper radiator mounting bolts.

Tighten bolts to 11 N´m (95 in. lbs.) torque.

(5) Connect both radiator hoses and install hose

clamps.

(6) Connect transmission cooler lines to radiator

tank. Inspect quick connect fittings for debris and

install until an audible ªclickº is heard. Pull apart to

verify connection.

(7) Install windshield washer reservoir tank.

(8) Position fan shroud to flanges on sides of radi-

ator. Install fan shroud mounting bolts (Fig. 41).

Tighten bolts to 6 N´m (50 in. lbs.) torque.

(9) Install metal clips to top of fan shroud.

(10) Install coolant reserve/overflow tank hose to

radiator filler neck nipple.

(11) Install coolant reserve/overflow tank to fan

shroud (fits into T-slots on shroud).

(12) Install battery negative cables.

(13) Install positive battery cable to top of radia-

tor. Tighten radiator-to-battery cable mounting nuts.

(14) Position heater controls tofull heatposition.

(15) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Operate engine until it reaches normal tem-

perature. Check cooling system and automatic trans-

mission (if equipped) fluid levels.

RADIATOR PRESSURE CAP

DESCRIPTION

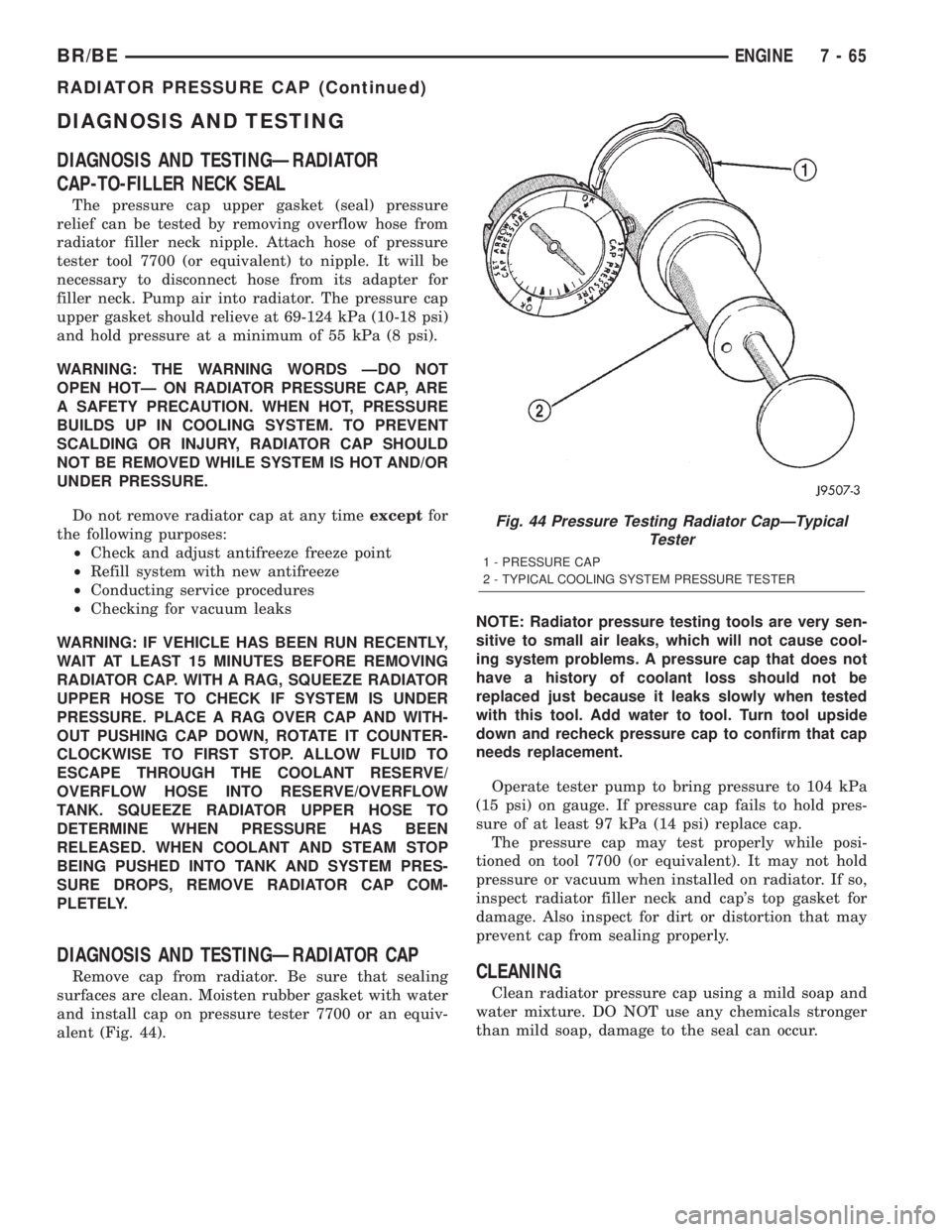

Radiators are equipped with a pressure cap, which

releases pressure at some point within a range of

97-124 kPa (14-18 psi). The pressure relief point (in

pounds) is engraved on top of cap.

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity.

A rubber gasket seals radiator filler neck to pre-

vent leakage. This is done to keep system under

pressure. It also maintains vacuum during coolant

cool-down allowing coolant to return from reserve/

overflow tank.

OPERATION

The cap (Fig. 43) contains a spring-loaded pressure

relief valve that opens when system pressure reaches

release range of 97-124 kPa (14-18 psi).

A vent valve in the center of cap allows a small

coolant flow through cap when coolant is below boil-

ing temperature. The valve is completely closed when

boiling point is reached. As the coolant cools, it con-

tracts and creates a vacuum in the cooling system.

This causes the vacuum valve to open and coolant in

the reserve/overflow tank to be drawn through its

connecting hose into radiator. If the vacuum valve is

stuck shut, the radiator hoses will collapse on cool-

down. Clean the vent valve (Fig. 43).

Fig. 43 Radiator Pressure Cap and Filler NeckÐ

Typical

1 - STAINLESS-STEEL SWIVEL TOP

2 - RUBBER SEALS

3 - VENT VALVE

4 - RADIATOR TANK

5 - FILLER NECK

6 - OVERFLOW NIPPLE

7 - MAIN SPRING

8 - GASKET RETAINER

7 - 64 ENGINEBR/BE

RADIATOR - 5.9L DIESEL (Continued)

Page 314 of 2255

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐRADIATOR

CAP-TO-FILLER NECK SEAL

The pressure cap upper gasket (seal) pressure

relief can be tested by removing overflow hose from

radiator filler neck nipple. Attach hose of pressure

tester tool 7700 (or equivalent) to nipple. It will be

necessary to disconnect hose from its adapter for

filler neck. Pump air into radiator. The pressure cap

upper gasket should relieve at 69-124 kPa (10-18 psi)

and hold pressure at a minimum of 55 kPa (8 psi).

WARNING: THE WARNING WORDS ÐDO NOT

OPEN HOTÐ ON RADIATOR PRESSURE CAP, ARE

A SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, RADIATOR CAP SHOULD

NOT BE REMOVED WHILE SYSTEM IS HOT AND/OR

UNDER PRESSURE.

Do not remove radiator cap at any timeexceptfor

the following purposes:

²Check and adjust antifreeze freeze point

²Refill system with new antifreeze

²Conducting service procedures

²Checking for vacuum leaks

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT AT LEAST 15 MINUTES BEFORE REMOVING

RADIATOR CAP. WITH A RAG, SQUEEZE RADIATOR

UPPER HOSE TO CHECK IF SYSTEM IS UNDER

PRESSURE. PLACE A RAG OVER CAP AND WITH-

OUT PUSHING CAP DOWN, ROTATE IT COUNTER-

CLOCKWISE TO FIRST STOP. ALLOW FLUID TO

ESCAPE THROUGH THE COOLANT RESERVE/

OVERFLOW HOSE INTO RESERVE/OVERFLOW

TANK. SQUEEZE RADIATOR UPPER HOSE TO

DETERMINE WHEN PRESSURE HAS BEEN

RELEASED. WHEN COOLANT AND STEAM STOP

BEING PUSHED INTO TANK AND SYSTEM PRES-

SURE DROPS, REMOVE RADIATOR CAP COM-

PLETELY.

DIAGNOSIS AND TESTINGÐRADIATOR CAP

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install cap on pressure tester 7700 or an equiv-

alent (Fig. 44).NOTE: Radiator pressure testing tools are very sen-

sitive to small air leaks, which will not cause cool-

ing system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.

Operate tester pump to bring pressure to 104 kPa

(15 psi) on gauge. If pressure cap fails to hold pres-

sure of at least 97 kPa (14 psi) replace cap.

The pressure cap may test properly while posi-

tioned on tool 7700 (or equivalent). It may not hold

pressure or vacuum when installed on radiator. If so,

inspect radiator filler neck and cap's top gasket for

damage. Also inspect for dirt or distortion that may

prevent cap from sealing properly.CLEANING

Clean radiator pressure cap using a mild soap and

water mixture. DO NOT use any chemicals stronger

than mild soap, damage to the seal can occur.

Fig. 44 Pressure Testing Radiator CapÐTypical

Tester

1 - PRESSURE CAP

2 - TYPICAL COOLING SYSTEM PRESSURE TESTER

BR/BEENGINE 7 - 65

RADIATOR PRESSURE CAP (Continued)

Page 315 of 2255

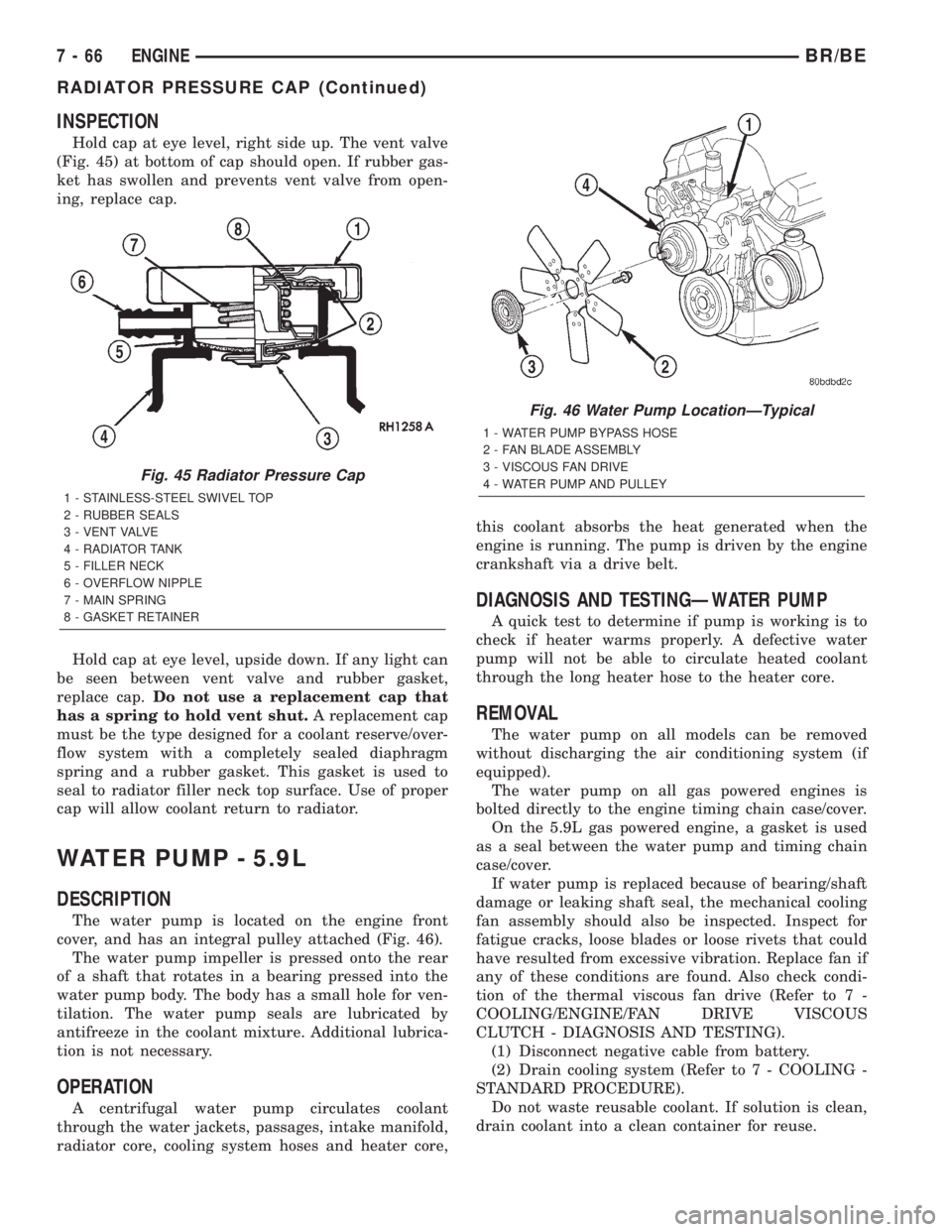

INSPECTION

Hold cap at eye level, right side up. The vent valve

(Fig. 45) at bottom of cap should open. If rubber gas-

ket has swollen and prevents vent valve from open-

ing, replace cap.

Hold cap at eye level, upside down. If any light can

be seen between vent valve and rubber gasket,

replace cap.Do not use a replacement cap that

has a spring to hold vent shut.A replacement cap

must be the type designed for a coolant reserve/over-

flow system with a completely sealed diaphragm

spring and a rubber gasket. This gasket is used to

seal to radiator filler neck top surface. Use of proper

cap will allow coolant return to radiator.

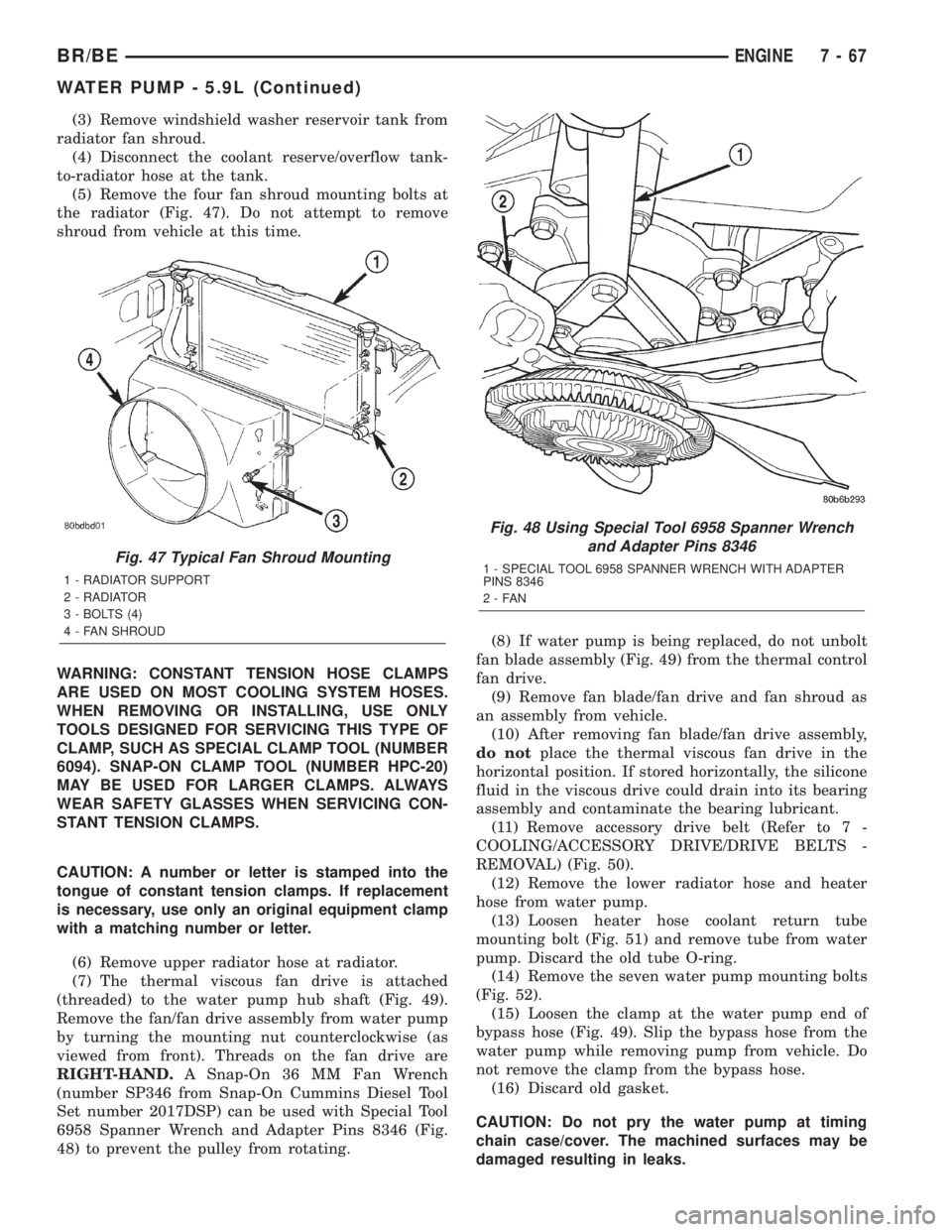

WATER PUMP - 5.9L

DESCRIPTION

The water pump is located on the engine front

cover, and has an integral pulley attached (Fig. 46).

The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven-

tilation. The water pump seals are lubricated by

antifreeze in the coolant mixture. Additional lubrica-

tion is not necessary.

OPERATION

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core,this coolant absorbs the heat generated when the

engine is running. The pump is driven by the engine

crankshaft via a drive belt.

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

The water pump on all models can be removed

without discharging the air conditioning system (if

equipped).

The water pump on all gas powered engines is

bolted directly to the engine timing chain case/cover.

On the 5.9L gas powered engine, a gasket is used

as a seal between the water pump and timing chain

case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for

fatigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if

any of these conditions are found. Also check condi-

tion of the thermal viscous fan drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - DIAGNOSIS AND TESTING).

(1) Disconnect negative cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

Fig. 45 Radiator Pressure Cap

1 - STAINLESS-STEEL SWIVEL TOP

2 - RUBBER SEALS

3 - VENT VALVE

4 - RADIATOR TANK

5 - FILLER NECK

6 - OVERFLOW NIPPLE

7 - MAIN SPRING

8 - GASKET RETAINER

Fig. 46 Water Pump LocationÐTypical

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

7 - 66 ENGINEBR/BE

RADIATOR PRESSURE CAP (Continued)

Page 316 of 2255

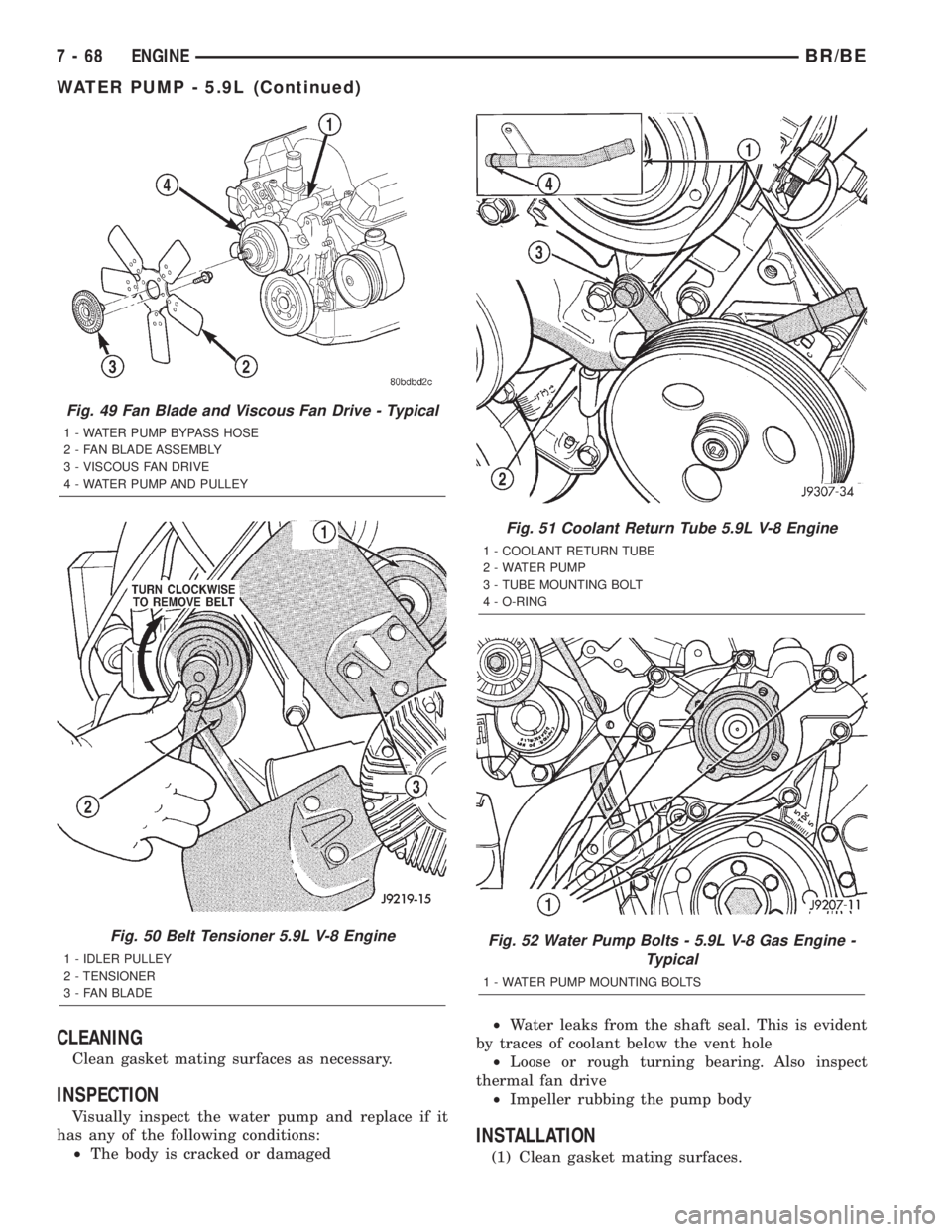

(3) Remove windshield washer reservoir tank from

radiator fan shroud.

(4) Disconnect the coolant reserve/overflow tank-

to-radiator hose at the tank.

(5) Remove the four fan shroud mounting bolts at

the radiator (Fig. 47). Do not attempt to remove

shroud from vehicle at this time.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(6) Remove upper radiator hose at radiator.

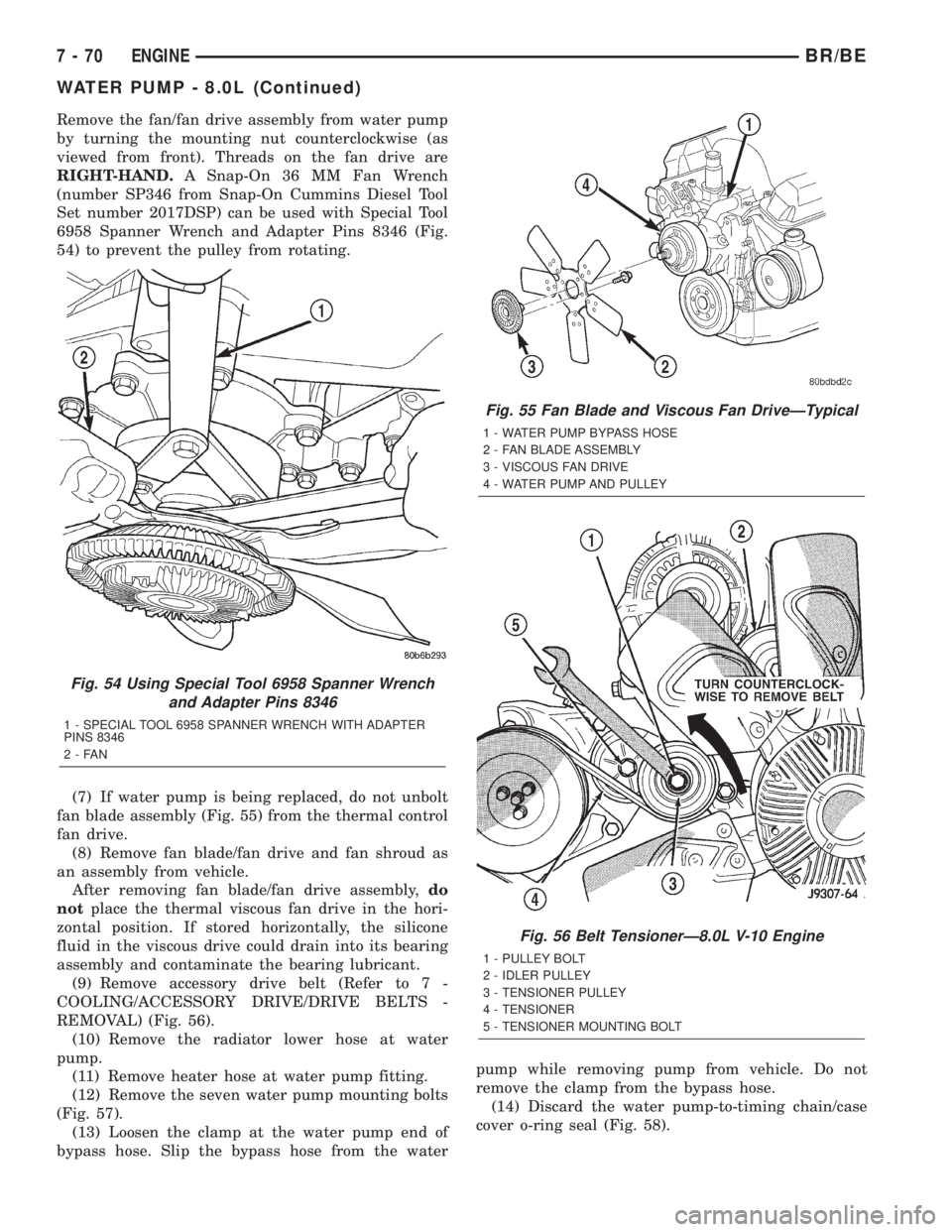

(7) The thermal viscous fan drive is attached

(threaded) to the water pump hub shaft (Fig. 49).

Remove the fan/fan drive assembly from water pump

by turning the mounting nut counterclockwise (as

viewed from front). Threads on the fan drive are

RIGHT-HAND.A Snap-On 36 MM Fan Wrench

(number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used with Special Tool

6958 Spanner Wrench and Adapter Pins 8346 (Fig.

48) to prevent the pulley from rotating.(8) If water pump is being replaced, do not unbolt

fan blade assembly (Fig. 49) from the thermal control

fan drive.

(9) Remove fan blade/fan drive and fan shroud as

an assembly from vehicle.

(10) After removing fan blade/fan drive assembly,

do notplace the thermal viscous fan drive in the

horizontal position. If stored horizontally, the silicone

fluid in the viscous drive could drain into its bearing

assembly and contaminate the bearing lubricant.

(11) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL) (Fig. 50).

(12) Remove the lower radiator hose and heater

hose from water pump.

(13) Loosen heater hose coolant return tube

mounting bolt (Fig. 51) and remove tube from water

pump. Discard the old tube O-ring.

(14) Remove the seven water pump mounting bolts

(Fig. 52).

(15) Loosen the clamp at the water pump end of

bypass hose (Fig. 49). Slip the bypass hose from the

water pump while removing pump from vehicle. Do

not remove the clamp from the bypass hose.

(16) Discard old gasket.

CAUTION: Do not pry the water pump at timing

chain case/cover. The machined surfaces may be

damaged resulting in leaks.

Fig. 47 Typical Fan Shroud Mounting

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 48 Using Special Tool 6958 Spanner Wrench

and Adapter Pins 8346

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

BR/BEENGINE 7 - 67

WATER PUMP - 5.9L (Continued)

Page 317 of 2255

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing. Also inspect

thermal fan drive

²Impeller rubbing the pump body

INSTALLATION

(1) Clean gasket mating surfaces.

Fig. 49 Fan Blade and Viscous Fan Drive - Typical

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

Fig. 50 Belt Tensioner 5.9L V-8 Engine

1 - IDLER PULLEY

2 - TENSIONER

3 - FAN BLADE

Fig. 51 Coolant Return Tube 5.9L V-8 Engine

1 - COOLANT RETURN TUBE

2 - WATER PUMP

3 - TUBE MOUNTING BOLT

4 - O-RING

Fig. 52 Water Pump Bolts - 5.9L V-8 Gas Engine -

Typical

1 - WATER PUMP MOUNTING BOLTS

7 - 68 ENGINEBR/BE

WATER PUMP - 5.9L (Continued)

Page 318 of 2255

(2) Using a new gasket, install water pump to

engine as follows: Guide water pump nipple into

bypass hose as pump is being installed. Install water

pump bolts (Fig. 52). Tighten water pump mounting

bolts to 40 N´m (30 ft. lbs.) torque.

(3) Position bypass hose clamp to bypass hose.

(4) Spin water pump to be sure that pump impel-

ler does not rub against timing chain case/cover.

(5) Install a new o-ring to the heater hose coolant

return tube (Fig. 51). Coat the new o-ring with anti-

freeze before installation.

(6) Install coolant return tube and its mounting

bolt to engine (Fig. 51). Be sure the slot in tube

bracket is bottomed to mounting bolt. This will prop-

erly position return tube.

(7) Connect radiator lower hose to water pump.

(8) Connect heater hose and hose clamp to coolant

return tube.

(9) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLATION)

(Fig. 50).

(10) Position fan shroud and fan blade/viscous fan

drive assembly to vehicle as a complete unit.

(11) Install fan shroud.

(12) Install fan blade/viscous fan drive assembly to

water pump shaft.

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect negative battery cable.

(15) Start and warm the engine. Check for leaks.

WATER PUMP - 8.0L

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

NOTE:

The water pump on all models can be removed

without discharging the air conditioning system (if

equipped).

The water pump on all gas powered engines is

bolted directly to the engine timing chain case/

cover.

On the 8.0L V-10 engine, a rubber o-ring (instead of

a gasket) is used as a seal between the water pump

and timing chain case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for

fatigue cracks, loose blades or loose rivets that couldhave resulted from excessive vibration. Replace fan if

any of these conditions are found. Also check condi-

tion of the thermal viscous fan drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - DIAGNOSIS AND TESTING).

(1) Disconnect negative battery cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3) Remove windshield washer reservoir tank from

radiator fan shroud.

(4) Remove the four fan shroud mounting bolts at

the radiator (Fig. 53). Do not attempt to remove

shroud from vehicle at this time.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(5) Remove radiator upper hose at radiator.

(6) The thermal viscous fan drive is attached

(threaded) to the water pump hub shaft (Fig. 55).

Fig. 53 Typical Fan Shroud Mounting

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

BR/BEENGINE 7 - 69

WATER PUMP - 5.9L (Continued)

Page 319 of 2255

Remove the fan/fan drive assembly from water pump

by turning the mounting nut counterclockwise (as

viewed from front). Threads on the fan drive are

RIGHT-HAND.A Snap-On 36 MM Fan Wrench

(number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used with Special Tool

6958 Spanner Wrench and Adapter Pins 8346 (Fig.

54) to prevent the pulley from rotating.

(7) If water pump is being replaced, do not unbolt

fan blade assembly (Fig. 55) from the thermal control

fan drive.

(8) Remove fan blade/fan drive and fan shroud as

an assembly from vehicle.

After removing fan blade/fan drive assembly,do

notplace the thermal viscous fan drive in the hori-

zontal position. If stored horizontally, the silicone

fluid in the viscous drive could drain into its bearing

assembly and contaminate the bearing lubricant.

(9) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL) (Fig. 56).

(10) Remove the radiator lower hose at water

pump.

(11) Remove heater hose at water pump fitting.

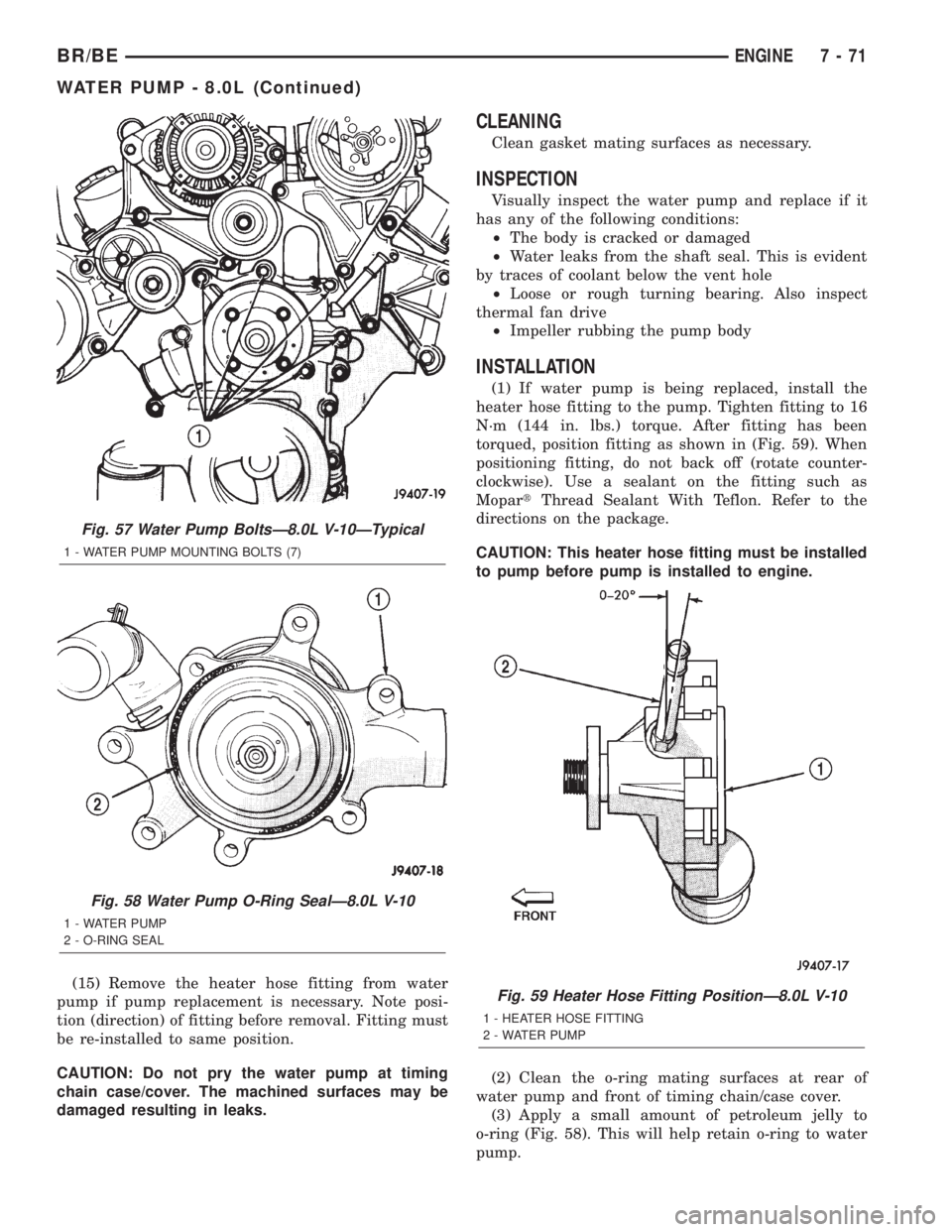

(12) Remove the seven water pump mounting bolts

(Fig. 57).

(13) Loosen the clamp at the water pump end of

bypass hose. Slip the bypass hose from the waterpump while removing pump from vehicle. Do not

remove the clamp from the bypass hose.

(14) Discard the water pump-to-timing chain/case

cover o-ring seal (Fig. 58).

Fig. 54 Using Special Tool 6958 Spanner Wrench

and Adapter Pins 8346

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

Fig. 55 Fan Blade and Viscous Fan DriveÐTypical

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

Fig. 56 Belt TensionerÐ8.0L V-10 Engine

1 - PULLEY BOLT

2 - IDLER PULLEY

3 - TENSIONER PULLEY

4 - TENSIONER

5 - TENSIONER MOUNTING BOLT

7 - 70 ENGINEBR/BE

WATER PUMP - 8.0L (Continued)

Page 320 of 2255

(15) Remove the heater hose fitting from water

pump if pump replacement is necessary. Note posi-

tion (direction) of fitting before removal. Fitting must

be re-installed to same position.

CAUTION: Do not pry the water pump at timing

chain case/cover. The machined surfaces may be

damaged resulting in leaks.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing. Also inspect

thermal fan drive

²Impeller rubbing the pump body

INSTALLATION

(1) If water pump is being replaced, install the

heater hose fitting to the pump. Tighten fitting to 16

N´m (144 in. lbs.) torque. After fitting has been

torqued, position fitting as shown in (Fig. 59). When

positioning fitting, do not back off (rotate counter-

clockwise). Use a sealant on the fitting such as

MopartThread Sealant With Teflon. Refer to the

directions on the package.

CAUTION: This heater hose fitting must be installed

to pump before pump is installed to engine.

(2) Clean the o-ring mating surfaces at rear of

water pump and front of timing chain/case cover.

(3) Apply a small amount of petroleum jelly to

o-ring (Fig. 58). This will help retain o-ring to water

pump.

Fig. 57 Water Pump BoltsÐ8.0L V-10ÐTypical

1 - WATER PUMP MOUNTING BOLTS (7)

Fig. 58 Water Pump O-Ring SealÐ8.0L V-10

1 - WATER PUMP

2 - O-RING SEAL

Fig. 59 Heater Hose Fitting PositionÐ8.0L V-10

1 - HEATER HOSE FITTING

2 - WATER PUMP

BR/BEENGINE 7 - 71

WATER PUMP - 8.0L (Continued)