DODGE RAM 2002 Service Repair Manual

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 271 of 2255

INSTALLATION

CAUTION: If the pulley is to be removed from the

tensioner, its mounting bolt has left-hand threads.

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 88 N´m (65 ft. lbs.) torque.

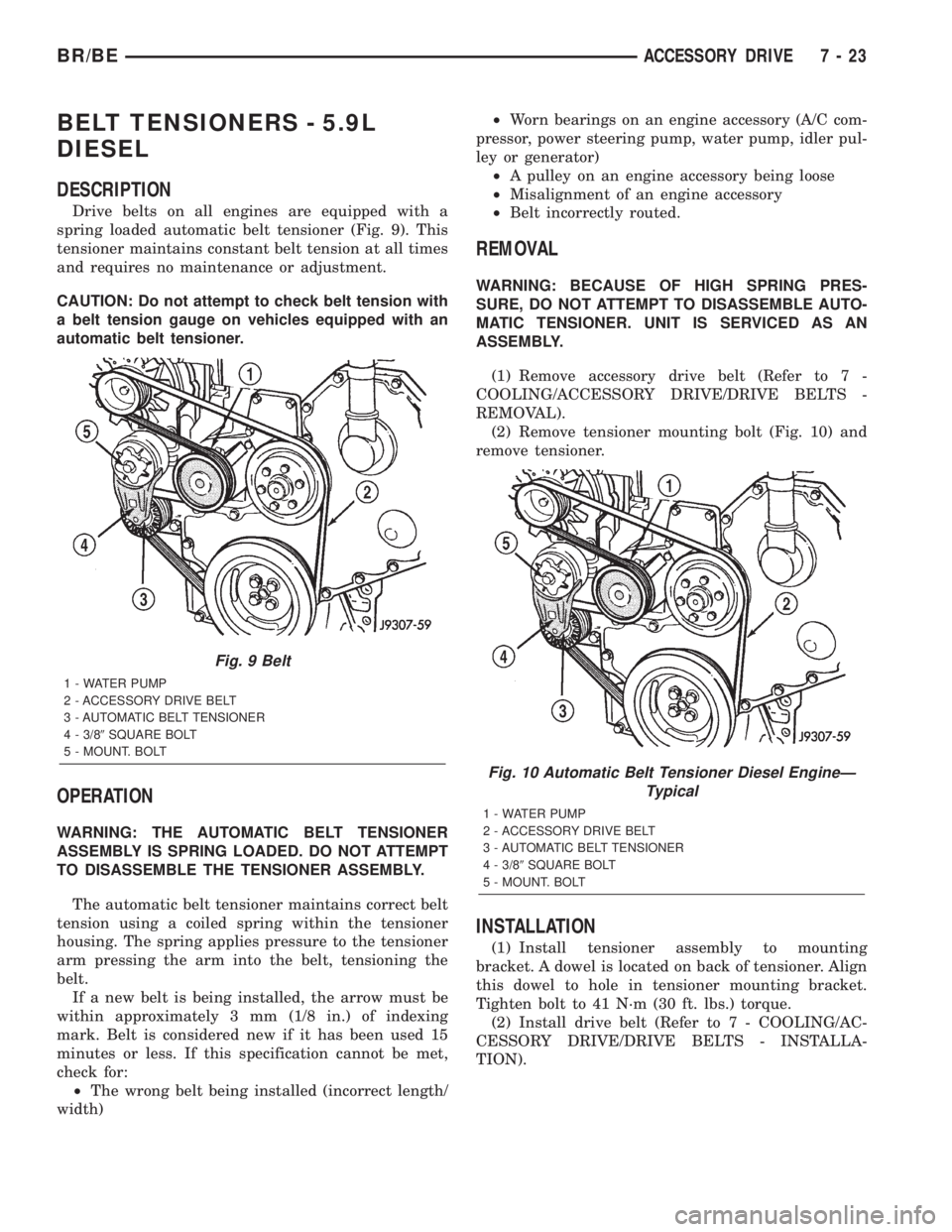

(2) Install tensioner assembly to mounting

bracket. A dowel pin is located on back of tensioner

(Fig. 7). Align this to dowel hole (Fig. 8) in tensioner

mounting bracket. Tighten bolt to 41 N´m (30 ft. lbs.)

torque.

(3) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

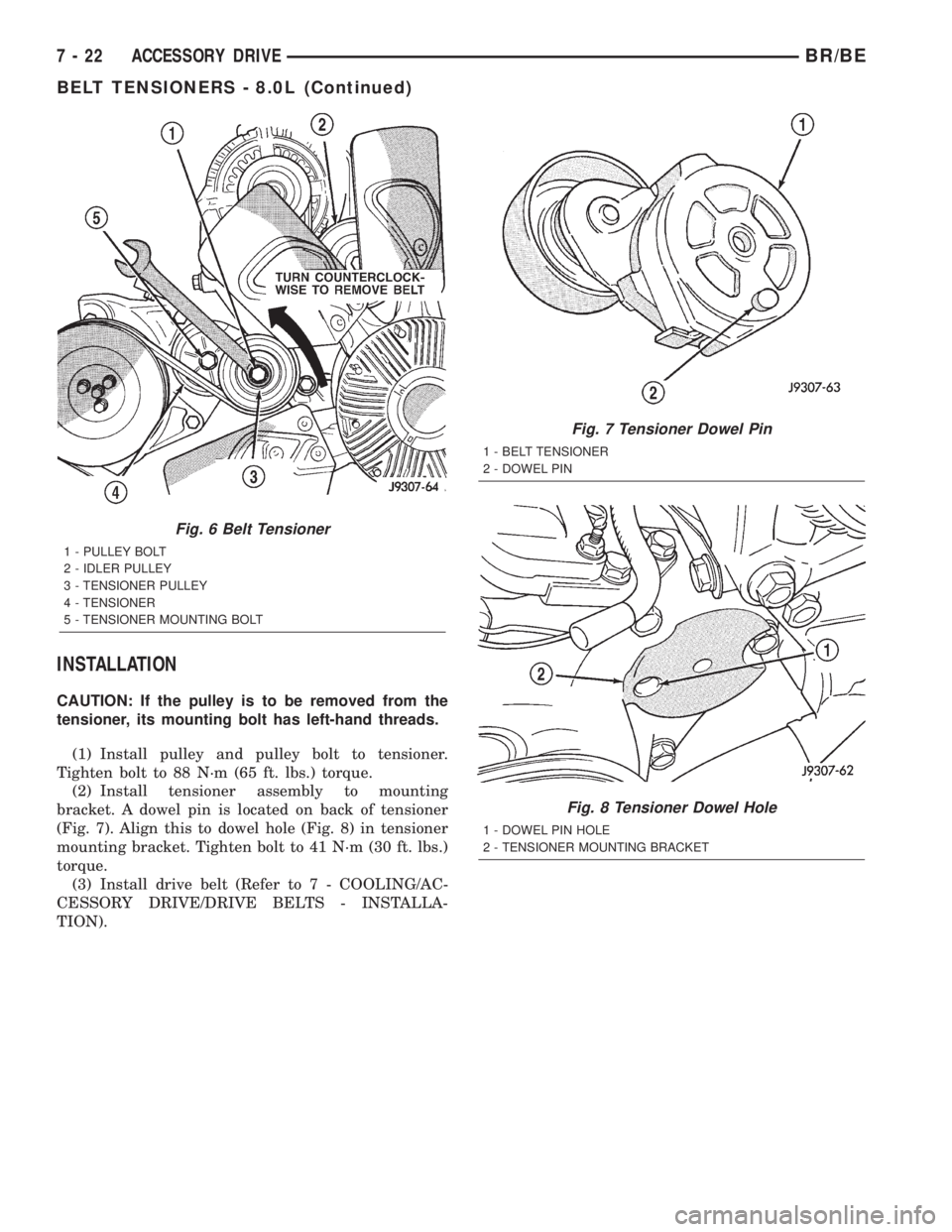

Fig. 6 Belt Tensioner

1 - PULLEY BOLT

2 - IDLER PULLEY

3 - TENSIONER PULLEY

4 - TENSIONER

5 - TENSIONER MOUNTING BOLT

Fig. 7 Tensioner Dowel Pin

1 - BELT TENSIONER

2 - DOWEL PIN

Fig. 8 Tensioner Dowel Hole

1 - DOWEL PIN HOLE

2 - TENSIONER MOUNTING BRACKET

7 - 22 ACCESSORY DRIVEBR/BE

BELT TENSIONERS - 8.0L (Continued)

Page 272 of 2255

BELT TENSIONERS - 5.9L

DIESEL

DESCRIPTION

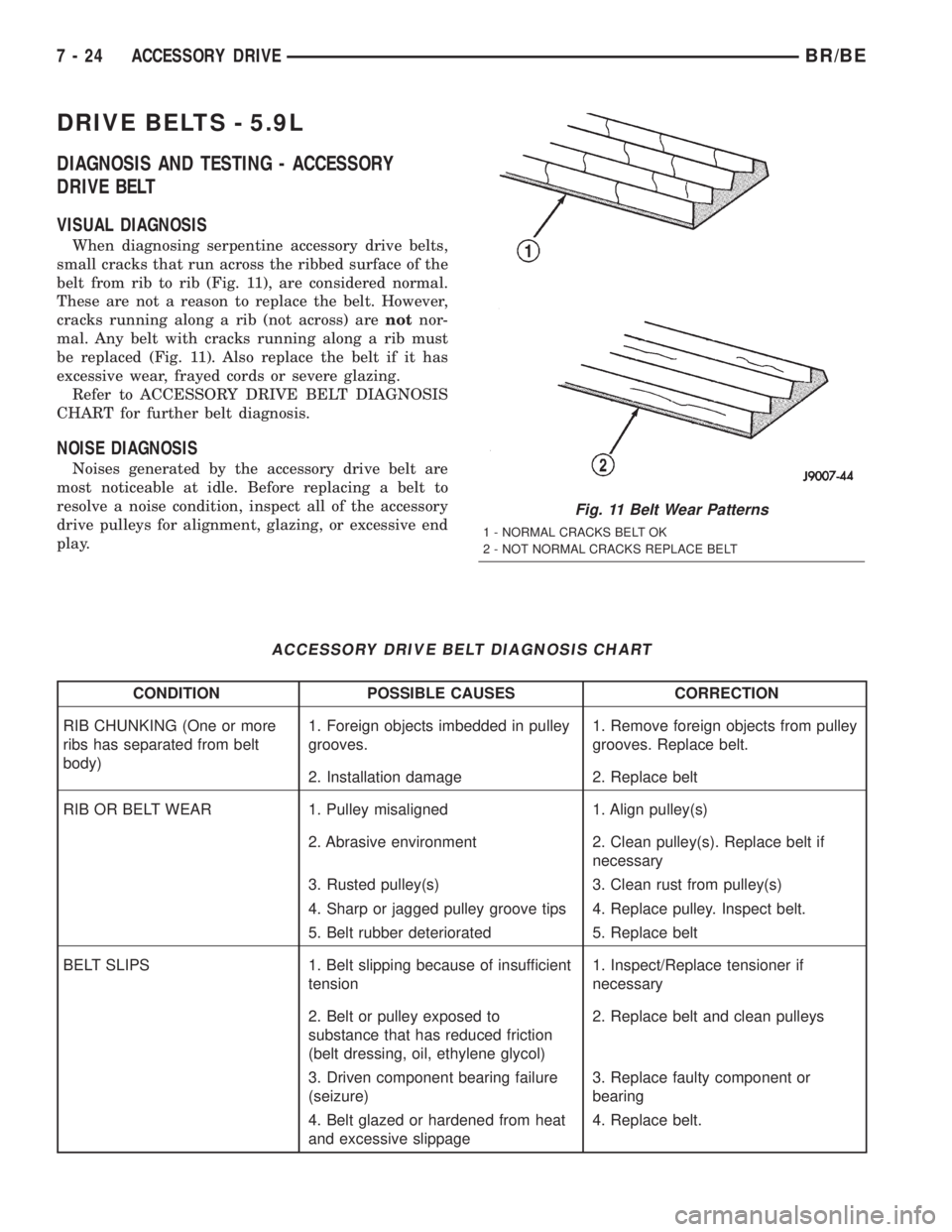

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Fig. 9). This

tensioner maintains constant belt tension at all times

and requires no maintenance or adjustment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

OPERATION

WARNING: THE AUTOMATIC BELT TENSIONER

ASSEMBLY IS SPRING LOADED. DO NOT ATTEMPT

TO DISASSEMBLE THE TENSIONER ASSEMBLY.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensioner

arm pressing the arm into the belt, tensioning the

belt.

If a new belt is being installed, the arrow must be

within approximately 3 mm (1/8 in.) of indexing

mark. Belt is considered new if it has been used 15

minutes or less. If this specification cannot be met,

check for:

²The wrong belt being installed (incorrect length/

width)²Worn bearings on an engine accessory (A/C com-

pressor, power steering pump, water pump, idler pul-

ley or generator)

²A pulley on an engine accessory being loose

²Misalignment of an engine accessory

²Belt incorrectly routed.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner mounting bolt (Fig. 10) and

remove tensioner.

INSTALLATION

(1) Install tensioner assembly to mounting

bracket. A dowel is located on back of tensioner. Align

this dowel to hole in tensioner mounting bracket.

Tighten bolt to 41 N´m (30 ft. lbs.) torque.

(2) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

Fig. 9 Belt

1 - WATER PUMP

2 - ACCESSORY DRIVE BELT

3 - AUTOMATIC BELT TENSIONER

4 - 3/89SQUARE BOLT

5 - MOUNT. BOLT

Fig. 10 Automatic Belt Tensioner Diesel EngineÐ

Typical

1 - WATER PUMP

2 - ACCESSORY DRIVE BELT

3 - AUTOMATIC BELT TENSIONER

4 - 3/89SQUARE BOLT

5 - MOUNT. BOLT

BR/BEACCESSORY DRIVE 7 - 23

Page 273 of 2255

DRIVE BELTS - 5.9L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

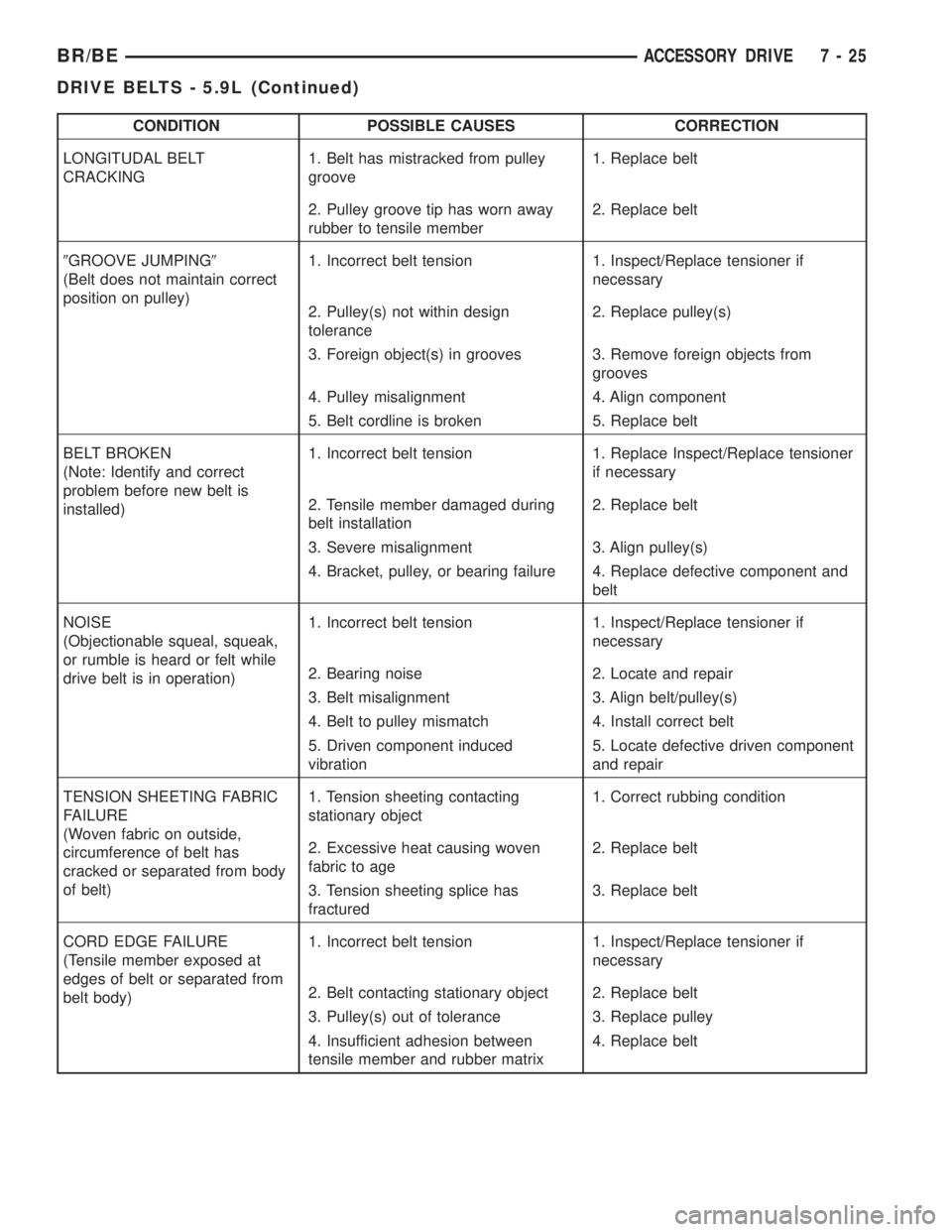

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 11), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 11). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

ACCESSORY DRIVE BELT DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

RIB CHUNKING (One or more

ribs has separated from belt

body)1. Foreign objects imbedded in pulley

grooves.1. Remove foreign objects from pulley

grooves. Replace belt.

2. Installation damage 2. Replace belt

RIB OR BELT WEAR 1. Pulley misaligned 1. Align pulley(s)

2. Abrasive environment 2. Clean pulley(s). Replace belt if

necessary

3. Rusted pulley(s) 3. Clean rust from pulley(s)

4. Sharp or jagged pulley groove tips 4. Replace pulley. Inspect belt.

5. Belt rubber deteriorated 5. Replace belt

BELT SLIPS 1. Belt slipping because of insufficient

tension1. Inspect/Replace tensioner if

necessary

2. Belt or pulley exposed to

substance that has reduced friction

(belt dressing, oil, ethylene glycol)2. Replace belt and clean pulleys

3. Driven component bearing failure

(seizure)3. Replace faulty component or

bearing

4. Belt glazed or hardened from heat

and excessive slippage4. Replace belt.

Fig. 11 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

7 - 24 ACCESSORY DRIVEBR/BE

Page 274 of 2255

CONDITION POSSIBLE CAUSES CORRECTION

LONGITUDAL BELT

CRACKING1. Belt has mistracked from pulley

groove1. Replace belt

2. Pulley groove tip has worn away

rubber to tensile member2. Replace belt

9GROOVE JUMPING9

(Belt does not maintain correct

position on pulley)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Pulley(s) not within design

tolerance2. Replace pulley(s)

3. Foreign object(s) in grooves 3. Remove foreign objects from

grooves

4. Pulley misalignment 4. Align component

5. Belt cordline is broken 5. Replace belt

BELT BROKEN

(Note: Identify and correct

problem before new belt is

installed)1. Incorrect belt tension 1. Replace Inspect/Replace tensioner

if necessary

2. Tensile member damaged during

belt installation2. Replace belt

3. Severe misalignment 3. Align pulley(s)

4. Bracket, pulley, or bearing failure 4. Replace defective component and

belt

NOISE

(Objectionable squeal, squeak,

or rumble is heard or felt while

drive belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration5. Locate defective driven component

and repair

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has

cracked or separated from body

of belt)1. Tension sheeting contacting

stationary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at

edges of belt or separated from

belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

BR/BEACCESSORY DRIVE 7 - 25

DRIVE BELTS - 5.9L (Continued)

Page 275 of 2255

REMOVAL

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label. This label is located

in the engine compartment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

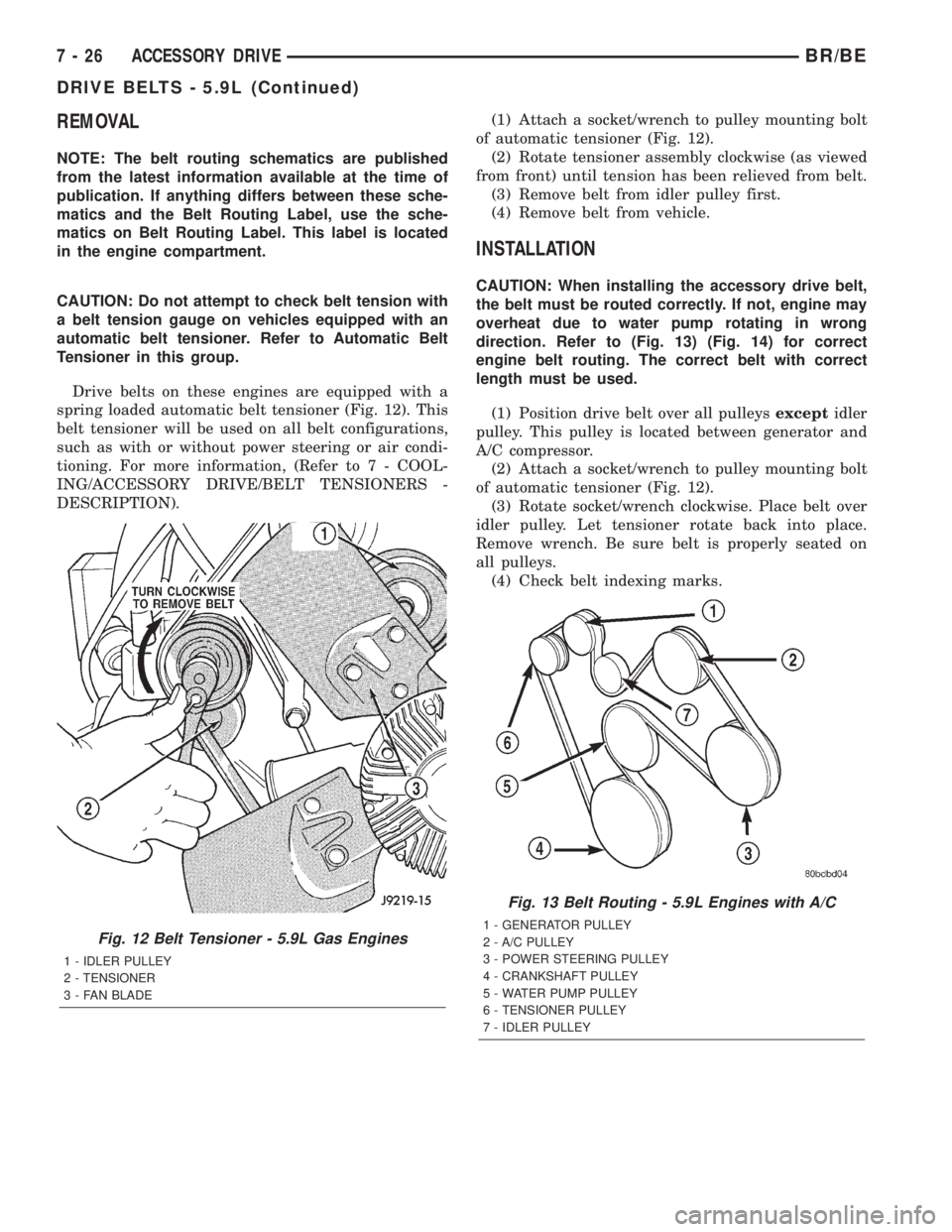

Drive belts on these engines are equipped with a

spring loaded automatic belt tensioner (Fig. 12). This

belt tensioner will be used on all belt configurations,

such as with or without power steering or air condi-

tioning. For more information, (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELT TENSIONERS -

DESCRIPTION).(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 12).

(2) Rotate tensioner assembly clockwise (as viewed

from front) until tension has been relieved from belt.

(3) Remove belt from idler pulley first.

(4) Remove belt from vehicle.

INSTALLATION

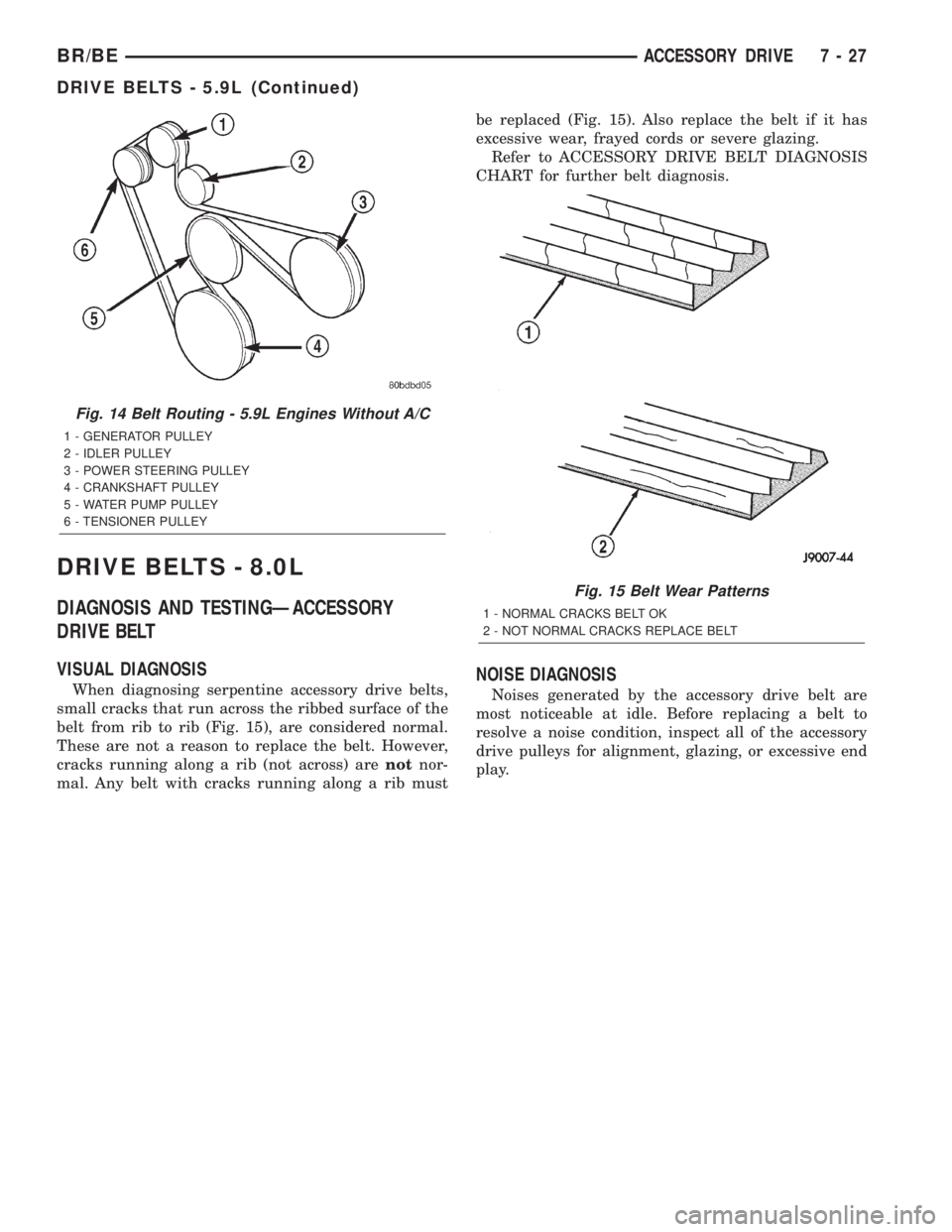

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 13) (Fig. 14) for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexceptidler

pulley. This pulley is located between generator and

A/C compressor.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 12).

(3) Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place.

Remove wrench. Be sure belt is properly seated on

all pulleys.

(4) Check belt indexing marks.

Fig. 12 Belt Tensioner - 5.9L Gas Engines

1 - IDLER PULLEY

2 - TENSIONER

3 - FAN BLADE

Fig. 13 Belt Routing - 5.9L Engines with A/C

1 - GENERATOR PULLEY

2 - A/C PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

7 - IDLER PULLEY

7 - 26 ACCESSORY DRIVEBR/BE

DRIVE BELTS - 5.9L (Continued)

Page 276 of 2255

DRIVE BELTS - 8.0L

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 15), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib mustbe replaced (Fig. 15). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

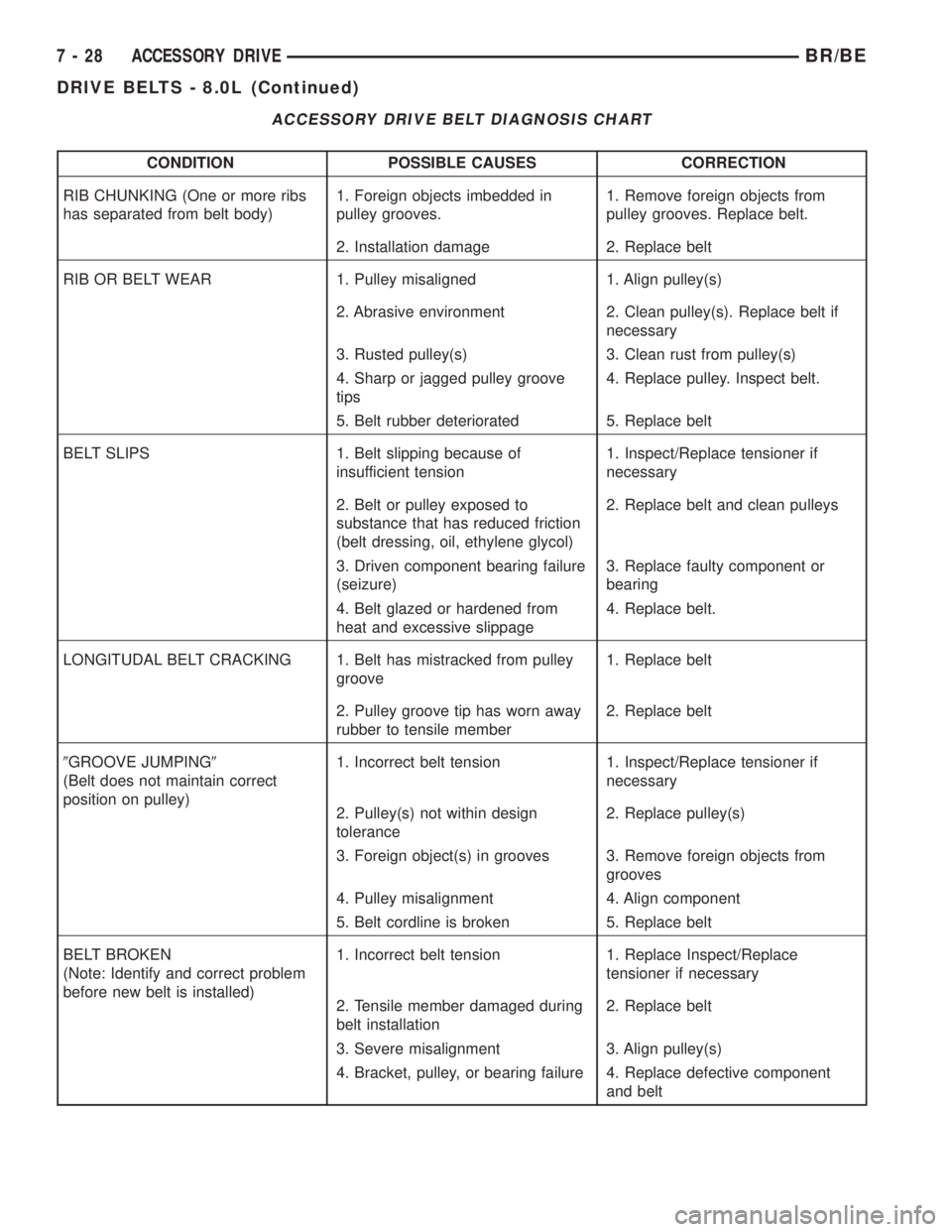

Fig. 14 Belt Routing - 5.9L Engines Without A/C

1 - GENERATOR PULLEY

2 - IDLER PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

Fig. 15 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

BR/BEACCESSORY DRIVE 7 - 27

DRIVE BELTS - 5.9L (Continued)

Page 277 of 2255

ACCESSORY DRIVE BELT DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

RIB CHUNKING (One or more ribs

has separated from belt body)1. Foreign objects imbedded in

pulley grooves.1. Remove foreign objects from

pulley grooves. Replace belt.

2. Installation damage 2. Replace belt

RIB OR BELT WEAR 1. Pulley misaligned 1. Align pulley(s)

2. Abrasive environment 2. Clean pulley(s). Replace belt if

necessary

3. Rusted pulley(s) 3. Clean rust from pulley(s)

4. Sharp or jagged pulley groove

tips4. Replace pulley. Inspect belt.

5. Belt rubber deteriorated 5. Replace belt

BELT SLIPS 1. Belt slipping because of

insufficient tension1. Inspect/Replace tensioner if

necessary

2. Belt or pulley exposed to

substance that has reduced friction

(belt dressing, oil, ethylene glycol)2. Replace belt and clean pulleys

3. Driven component bearing failure

(seizure)3. Replace faulty component or

bearing

4. Belt glazed or hardened from

heat and excessive slippage4. Replace belt.

LONGITUDAL BELT CRACKING 1. Belt has mistracked from pulley

groove1. Replace belt

2. Pulley groove tip has worn away

rubber to tensile member2. Replace belt

9GROOVE JUMPING9

(Belt does not maintain correct

position on pulley)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Pulley(s) not within design

tolerance2. Replace pulley(s)

3. Foreign object(s) in grooves 3. Remove foreign objects from

grooves

4. Pulley misalignment 4. Align component

5. Belt cordline is broken 5. Replace belt

BELT BROKEN

(Note: Identify and correct problem

before new belt is installed)1. Incorrect belt tension 1. Replace Inspect/Replace

tensioner if necessary

2. Tensile member damaged during

belt installation2. Replace belt

3. Severe misalignment 3. Align pulley(s)

4. Bracket, pulley, or bearing failure 4. Replace defective component

and belt

7 - 28 ACCESSORY DRIVEBR/BE

DRIVE BELTS - 8.0L (Continued)

Page 278 of 2255

CONDITION POSSIBLE CAUSES CORRECTION

NOISE (Objectional squeal, spueak,

or rumble is heard or felt while drive

belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration5. Locate defective driven

component and repair

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has cracked or

separated from body of belt)1. Tension sheeting contacting

stationary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

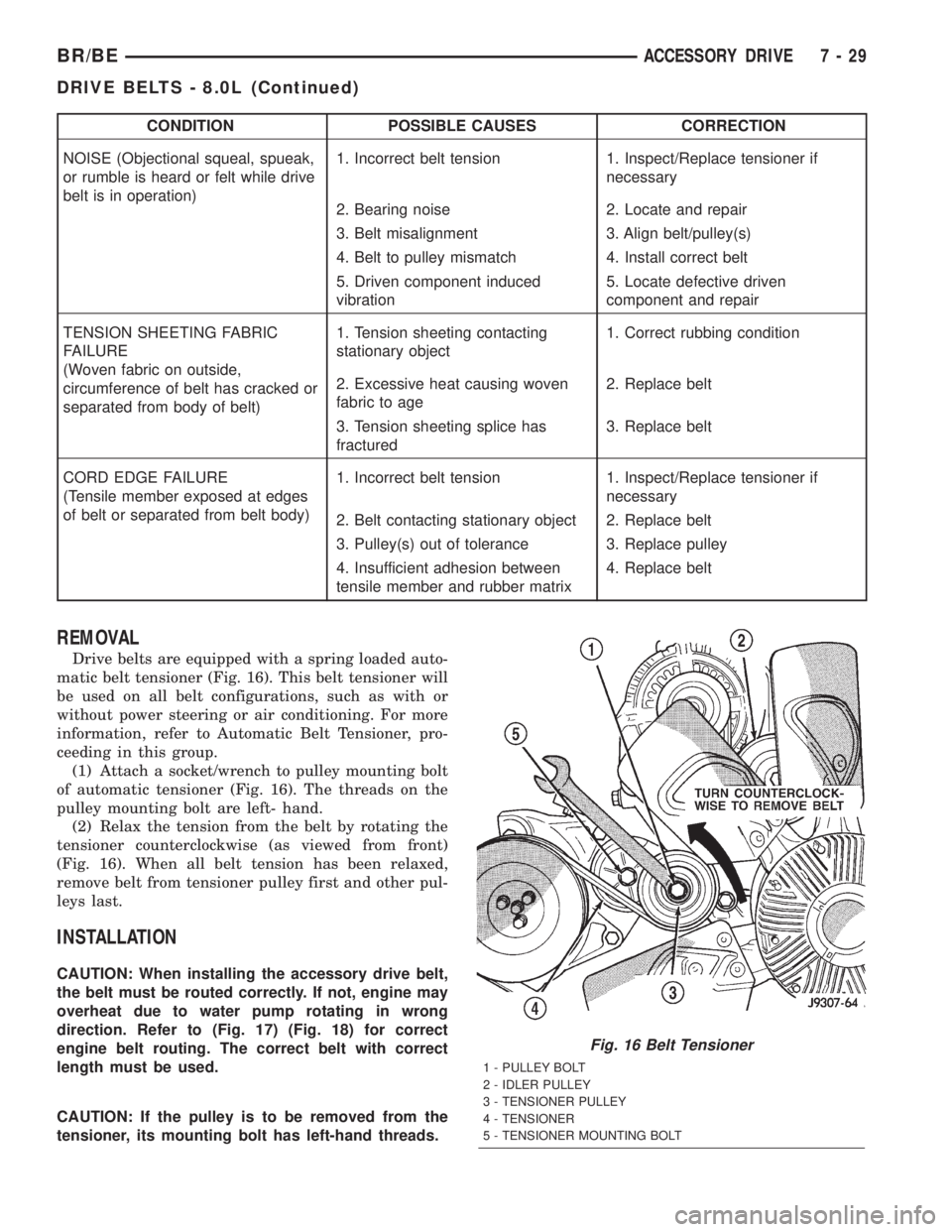

REMOVAL

Drive belts are equipped with a spring loaded auto-

matic belt tensioner (Fig. 16). This belt tensioner will

be used on all belt configurations, such as with or

without power steering or air conditioning. For more

information, refer to Automatic Belt Tensioner, pro-

ceeding in this group.

(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 16). The threads on the

pulley mounting bolt are left- hand.

(2) Relax the tension from the belt by rotating the

tensioner counterclockwise (as viewed from front)

(Fig. 16). When all belt tension has been relaxed,

remove belt from tensioner pulley first and other pul-

leys last.

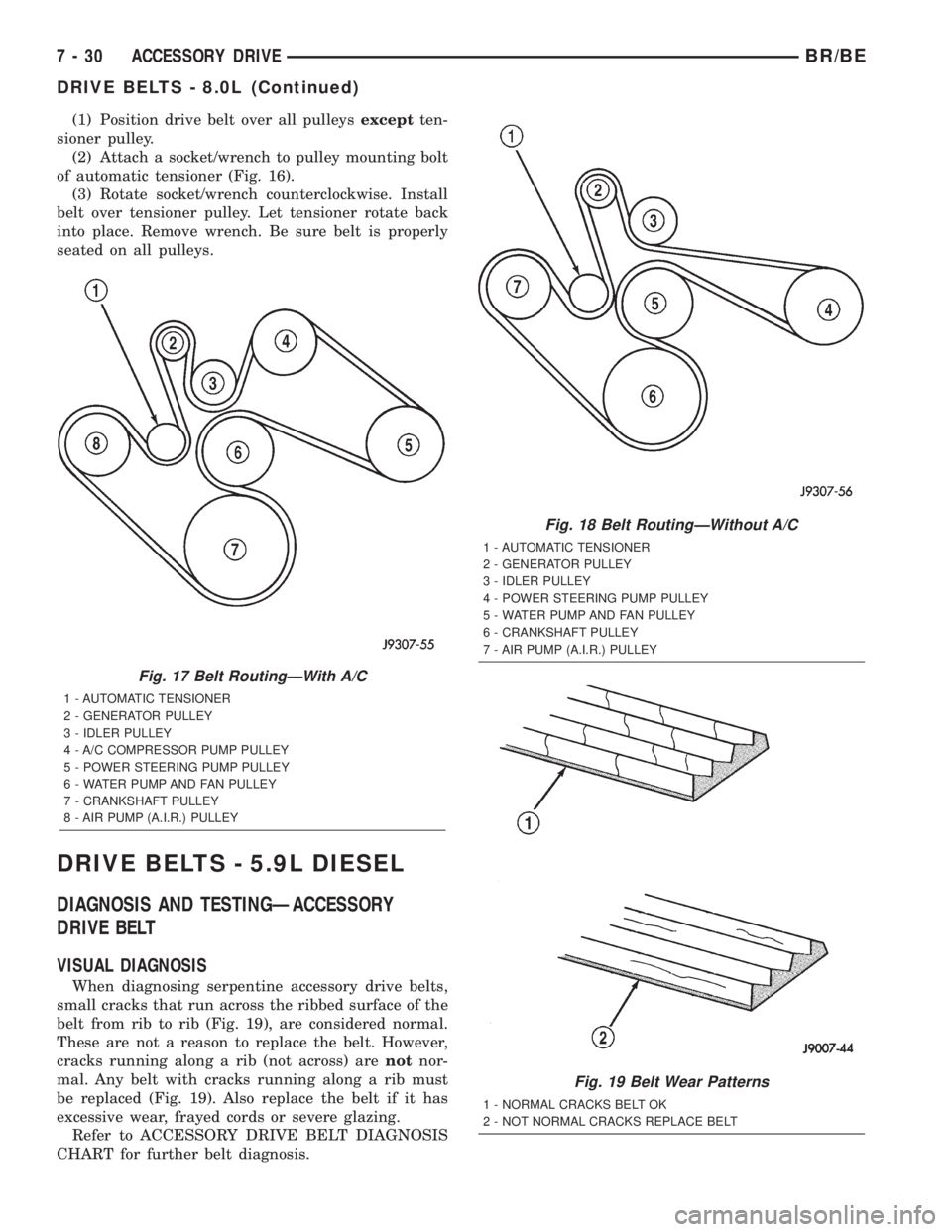

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 17) (Fig. 18) for correct

engine belt routing. The correct belt with correct

length must be used.

CAUTION: If the pulley is to be removed from the

tensioner, its mounting bolt has left-hand threads.

Fig. 16 Belt Tensioner

1 - PULLEY BOLT

2 - IDLER PULLEY

3 - TENSIONER PULLEY

4 - TENSIONER

5 - TENSIONER MOUNTING BOLT

BR/BEACCESSORY DRIVE 7 - 29

DRIVE BELTS - 8.0L (Continued)

Page 279 of 2255

(1) Position drive belt over all pulleysexceptten-

sioner pulley.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 16).

(3) Rotate socket/wrench counterclockwise. Install

belt over tensioner pulley. Let tensioner rotate back

into place. Remove wrench. Be sure belt is properly

seated on all pulleys.

DRIVE BELTS - 5.9L DIESEL

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

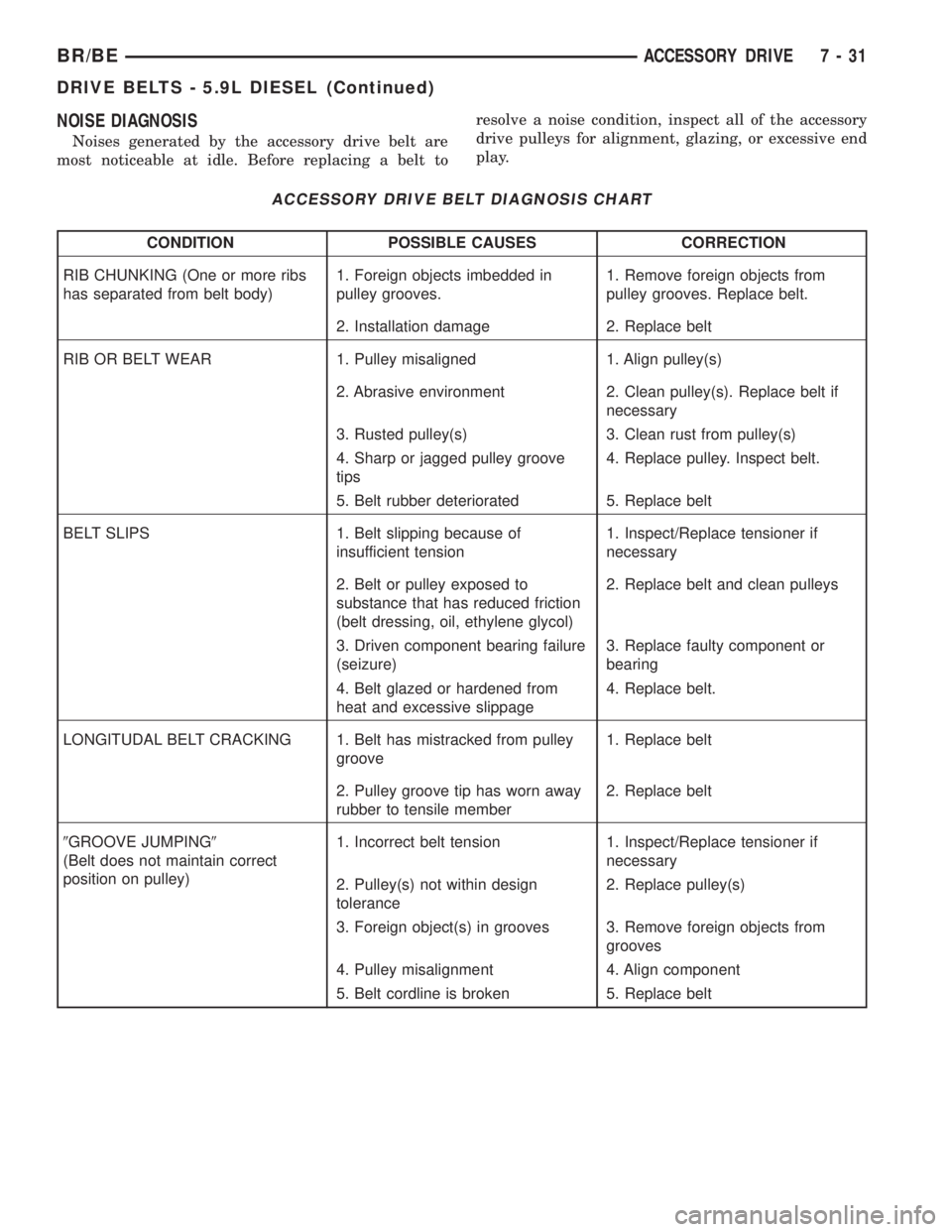

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 19), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 19). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

Fig. 17 Belt RoutingÐWith A/C

1 - AUTOMATIC TENSIONER

2 - GENERATOR PULLEY

3 - IDLER PULLEY

4 - A/C COMPRESSOR PUMP PULLEY

5 - POWER STEERING PUMP PULLEY

6 - WATER PUMP AND FAN PULLEY

7 - CRANKSHAFT PULLEY

8 - AIR PUMP (A.I.R.) PULLEY

Fig. 18 Belt RoutingÐWithout A/C

1 - AUTOMATIC TENSIONER

2 - GENERATOR PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - WATER PUMP AND FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AIR PUMP (A.I.R.) PULLEY

Fig. 19 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

7 - 30 ACCESSORY DRIVEBR/BE

DRIVE BELTS - 8.0L (Continued)

Page 280 of 2255

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt toresolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

ACCESSORY DRIVE BELT DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

RIB CHUNKING (One or more ribs

has separated from belt body)1. Foreign objects imbedded in

pulley grooves.1. Remove foreign objects from

pulley grooves. Replace belt.

2. Installation damage 2. Replace belt

RIB OR BELT WEAR 1. Pulley misaligned 1. Align pulley(s)

2. Abrasive environment 2. Clean pulley(s). Replace belt if

necessary

3. Rusted pulley(s) 3. Clean rust from pulley(s)

4. Sharp or jagged pulley groove

tips4. Replace pulley. Inspect belt.

5. Belt rubber deteriorated 5. Replace belt

BELT SLIPS 1. Belt slipping because of

insufficient tension1. Inspect/Replace tensioner if

necessary

2. Belt or pulley exposed to

substance that has reduced friction

(belt dressing, oil, ethylene glycol)2. Replace belt and clean pulleys

3. Driven component bearing failure

(seizure)3. Replace faulty component or

bearing

4. Belt glazed or hardened from

heat and excessive slippage4. Replace belt.

LONGITUDAL BELT CRACKING 1. Belt has mistracked from pulley

groove1. Replace belt

2. Pulley groove tip has worn away

rubber to tensile member2. Replace belt

9GROOVE JUMPING9

(Belt does not maintain correct

position on pulley)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Pulley(s) not within design

tolerance2. Replace pulley(s)

3. Foreign object(s) in grooves 3. Remove foreign objects from

grooves

4. Pulley misalignment 4. Align component

5. Belt cordline is broken 5. Replace belt

BR/BEACCESSORY DRIVE 7 - 31

DRIVE BELTS - 5.9L DIESEL (Continued)