power DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1842 of 2255

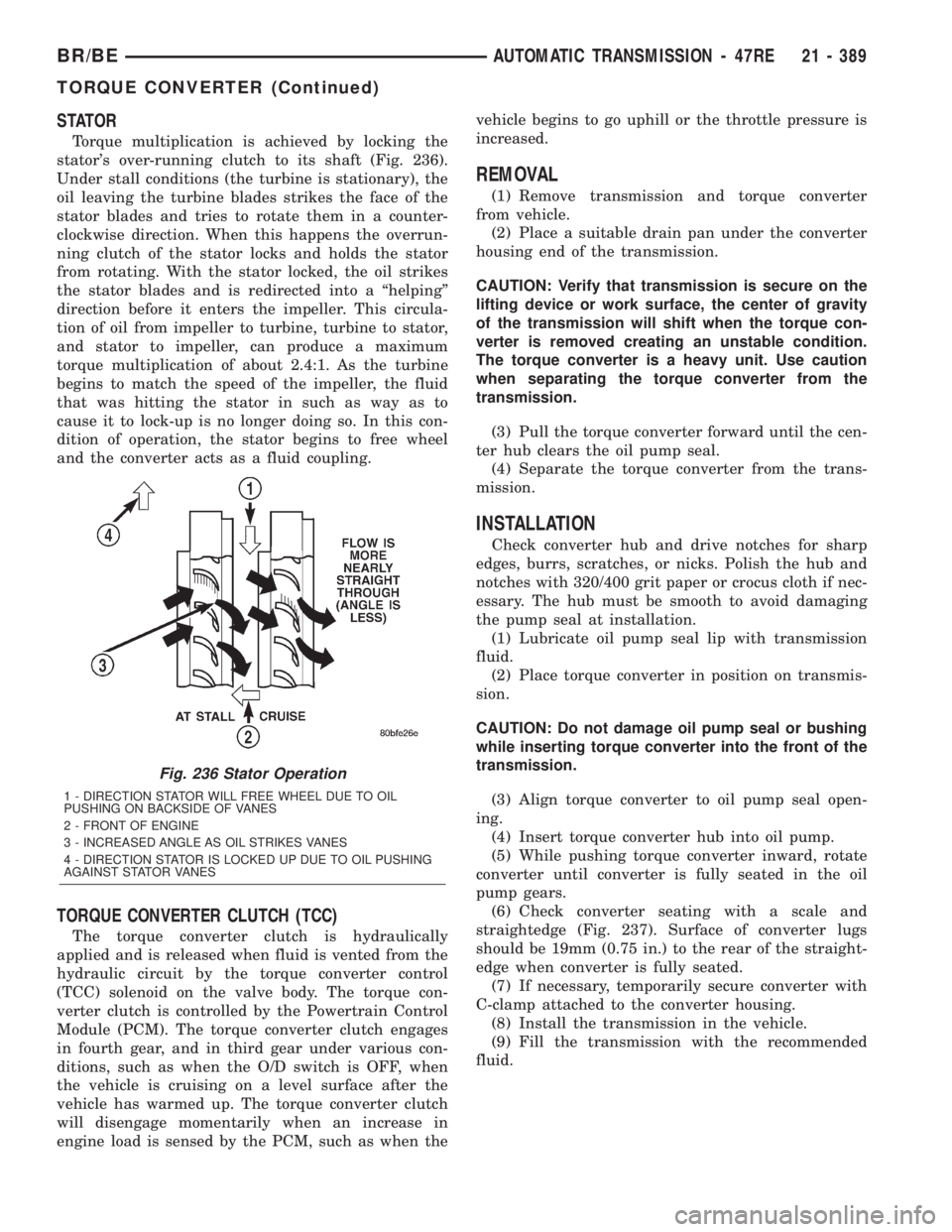

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 236).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the overrun-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically

applied and is released when fluid is vented from the

hydraulic circuit by the torque converter control

(TCC) solenoid on the valve body. The torque con-

verter clutch is controlled by the Powertrain Control

Module (PCM). The torque converter clutch engages

in fourth gear, and in third gear under various con-

ditions, such as when the O/D switch is OFF, when

the vehicle is cruising on a level surface after the

vehicle has warmed up. The torque converter clutch

will disengage momentarily when an increase in

engine load is sensed by the PCM, such as when thevehicle begins to go uphill or the throttle pressure is

increased.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 237). Surface of converter lugs

should be 19mm (0.75 in.) to the rear of the straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

(9) Fill the transmission with the recommended

fluid.

Fig. 236 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 389

TORQUE CONVERTER (Continued)

Page 1884 of 2255

exception being when the road surface is covered by

ice and snow.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

A front axle disconnect system is used to achieve

two-wheel drive mode. The axle disconnect vacuum

motor is actuated by a vacuum switch on the transfer

case. The switch is operated by the transfer case

range rod.

SHIFT MECHANISM

The transfer case is operated by an adjustable floor

mounted shift linkage. The transfer case shift lever

is directly attached to the shift sector. The sector

operates the range and mode forks within the trans-

fer case.

A straight line shift pattern is used with a NEU-

TRAL detent. Lever range positions are imprinted in

the shift knob.

SHIFTING

The synchronizer components allow the transfer

case to be shifted between the 2H and 4H operating

ranges while the vehicle is in motion. The vehicle

must have the transmission placed in NEUTRAL, or

the clutch depressed in the case of a manual trans-

mission, and be moving less than 2-3 MPH when

shifting into the 4L operating range.

DIAGNOSIS AND TESTING - TRANSFER CASE

Before beginning repair on a suspected transfer

case malfunction, check all other driveline compo-

nents beforehand.

The actual cause of a problem may be related to

such items as: front hubs, axles, propeller shafts,

wheels and tires, transmission, or clutch instead. If

all other driveline components are in good condition

and operating properly, refer to the Diagnosis Chart

for further information.

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer Case difficult to shift or will

not shift into desired range.1) Vehicle speed too great to permit

shifting.1) Stop vehicle and shift into

desired range. Or, reduce speed to

below 3-4 km/h (2-3 mph) before

attempting the shift.

2) If vehicle was operated for an

extended period in 4H on a dry

paved surface, the driveline torque

load may be causing a bind.2) Stop vehicle and shift the

transmission into neutral. Shift the

transfer case to 2H and operate

vehicle in 2H on dry paved

surfaces.

3) Transfer case external shift

linkage binding.3) Lubricate, repair, or replace

linkage bushings, or tighten loose

components as necessary.

4) Insufficient or incorrect lubricant. 4) Drain and refill to edge of fill hole

with MoparTATF +4, type 9602,

Automatic Transmission fluid.

5) Internal components binding,

worn, or damaged.5) Disassemble the transfer case

and replace worn or damaged

components as necessary.

Transfer Case noisy in all operating

ranges.1) Insufficient or incorrect lubricant. 1) Drain and refill to edge of fill hole

with MoparTATF +4, type 9602,

Automatic Transmission fluid.

BR/BETRANSFER CASE - NV241LD 21 - 431

TRANSFER CASE - NV241LD (Continued)

Page 1918 of 2255

TRANSFER CASE - NV241HD

TABLE OF CONTENTS

page page

TRANSFER CASE - NV241HD

DESCRIPTION........................465

OPERATION..........................467

DIAGNOSIS AND TESTING - TRANSFER

CASE..............................467

REMOVAL............................469

DISASSEMBLY........................469

CLEANING...........................476

INSPECTION.........................476

ASSEMBLY...........................480

INSTALLATION........................494

SPECIFICATIONS

TRANSFER CASE....................495

SPECIAL TOOLS

TRANSFER CASE - NV241HD...........495EXTENSION HOUSING BUSHING AND SEAL

REMOVAL............................497

INSTALLATION........................497

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL............................497

FRONT OUTPUT SHAFT SEAL

REMOVAL............................498

INSTALLATION........................498

SHIFT LEVER

REMOVAL............................499

INSTALLATION........................500

ADJUSTMENTS

ADJUSTMENT - SHIFT LEVER..........500

TRANSFER CASE - NV241HD

DESCRIPTION

The NV241HD is a part-time transfer case with a

low-range gear system. The transfer case provides

three operating ranges plus a NEUTRAL position.

The low range position provides a gear reduction

ratio of 2.72:1 for increased low speed torque capabil-

ity. Operating ranges are: 2H, 4H, and 4LO.

The synchronizer mechanism consists of a brass

stop ring, synchronizer hub, and the sliding clutch

(Fig. 1). The synchronizer components allow the

transfer case to be shifted between the 2H and 4H

operating ranges while the vehicle is in motion.The gear cases, retainer and extension are all of

aluminum. Drive sprockets and an interconnecting

drive chain are used to transmit engine torque to the

front/rear propeller shafts. The mainshaft, input gear

and front output shaft are supported by ball and nee-

dle bearings.

PTO CAPABILITY

The NV241HD transfer case has power take-off

capability. A PTO gear permanently attached to the

planetary carrier, and a removable PTO cover are

provided for this purpose.

BR/BETRANSFER CASE - NV241HD 21 - 465

Page 1920 of 2255

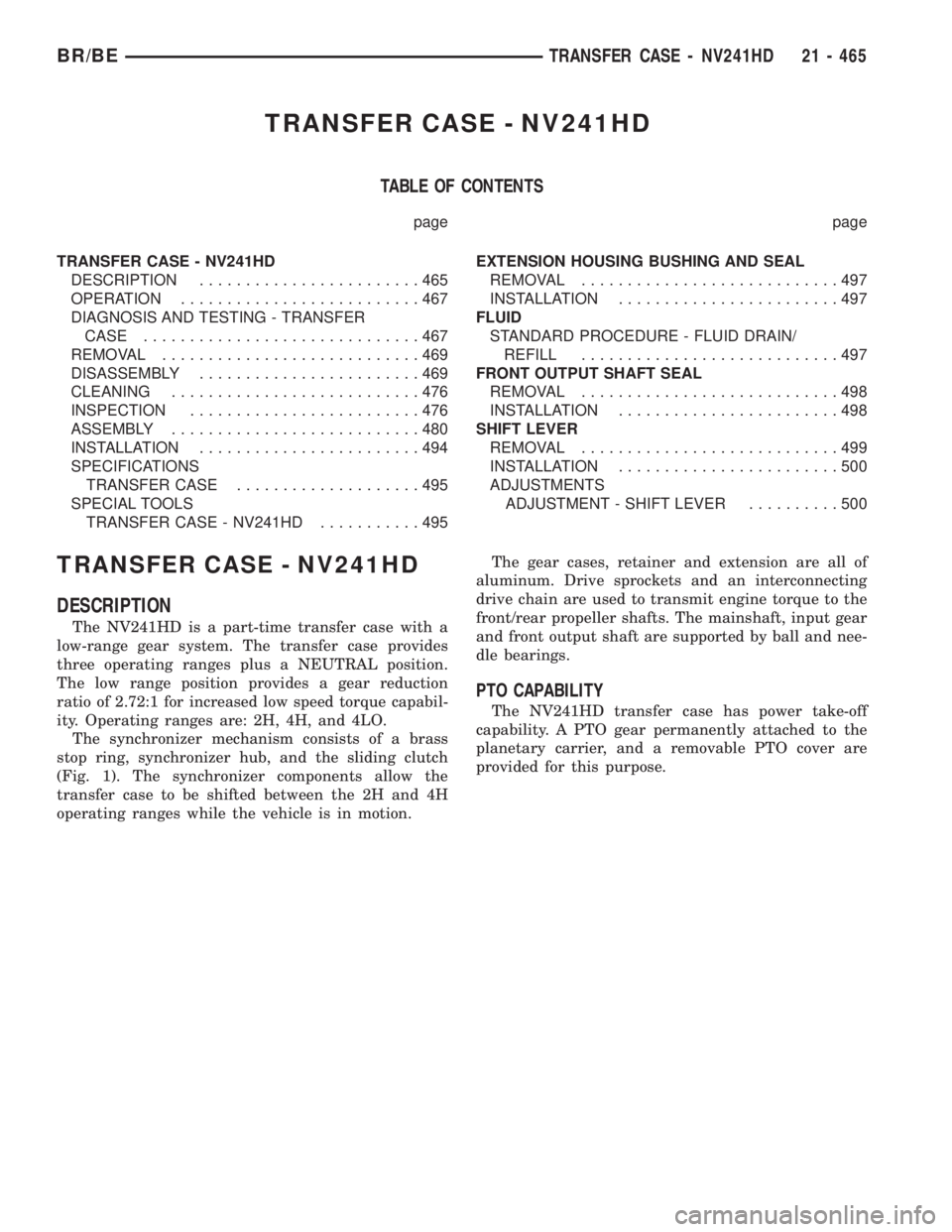

IDENTIFICATION

An identification tag (Fig. 2) is attached to the rear

case of every transfer case. The tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

OPERATING RANGES

Transfer case operating ranges are:

²2H (2-wheel drive)

²4H (4-wheel drive)

²4LO (4-wheel drive low range)

The 2H range is for use on any road surface at any

time.

The 4H and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The onlyexception being when the road surface is covered by

ice and snow or other loose, slippery material.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

A front axle disconnect system is used to achieve

two-wheel drive mode. The axle disconnect vacuum

motor is actuated by a vacuum switch on the transfer

case. The switch is operated by the transfer case

range rod.

SHIFT MECHANISM

The transfer case is operated by an adjustable floor

mounted shift linkage. The transfer case shift lever

is directly attached to the shift sector. The sector

operates the range and mode forks within the trans-

fer case.

A straight line shift pattern is used with a NEU-

TRAL detent. Lever range positions are imprinted in

the shift knob.

SHIFTING

The synchronizer components allow the transfer

case to be shifted between the 2H and 4H operating

ranges while the vehicle is in motion. The vehicle

must have the transmission placed in NEUTRAL, or

the clutch depressed in the case of a manual trans-

mission, and be moving less than 2-3 MPH when

shifting into the 4L operating range.

DIAGNOSIS AND TESTING - TRANSFER CASE

Before beginning repair on a suspected transfer

case malfunction, check all other driveline compo-

nents beforehand.

The actual cause of a problem may be related to

such items as: front hubs, axles, propeller shafts,

wheels and tires, transmission, or clutch instead. If

all other driveline components are in good condition

and operating properly, refer to the Diagnosis Chart

for further information.

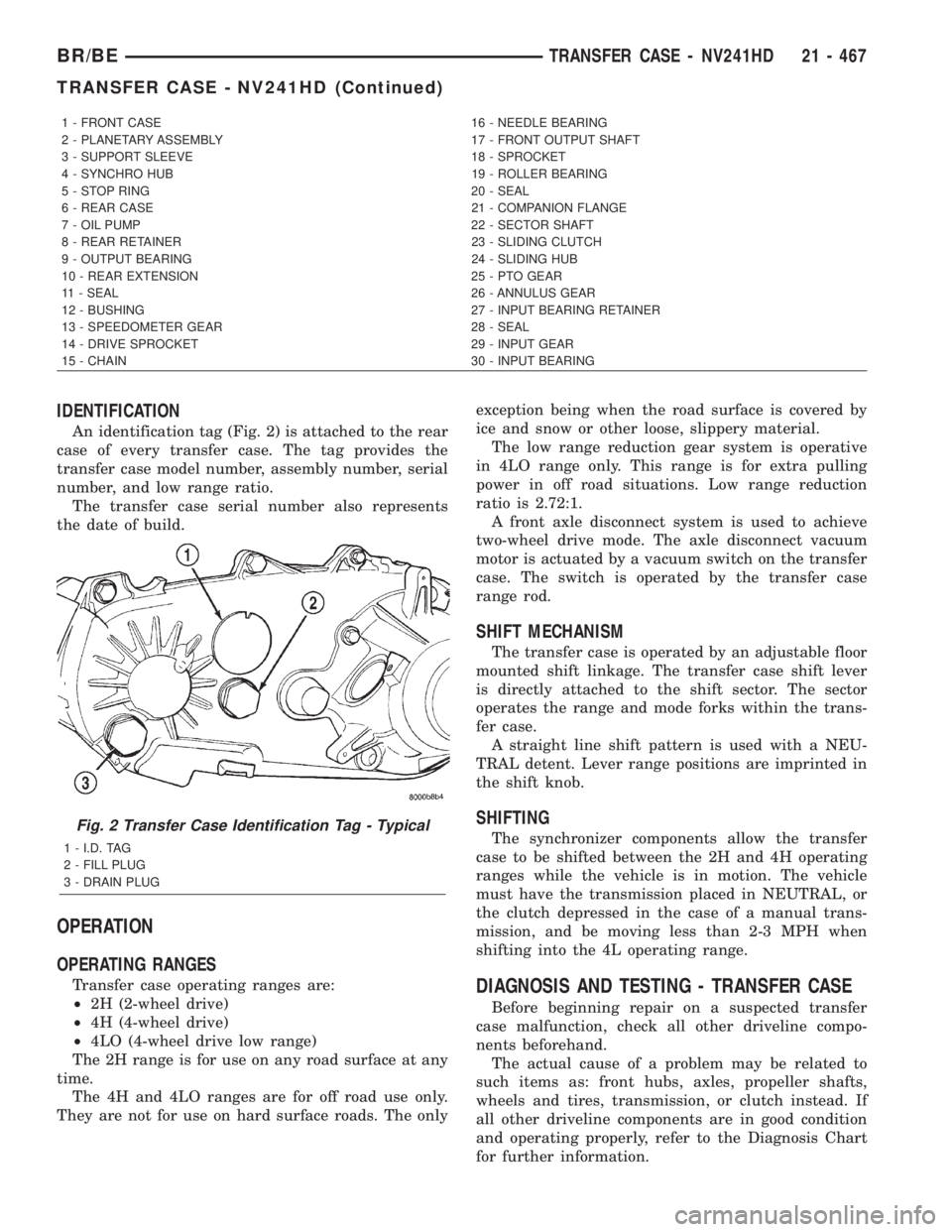

1 - FRONT CASE 16 - NEEDLE BEARING

2 - PLANETARY ASSEMBLY 17 - FRONT OUTPUT SHAFT

3 - SUPPORT SLEEVE 18 - SPROCKET

4 - SYNCHRO HUB 19 - ROLLER BEARING

5 - STOP RING 20 - SEAL

6 - REAR CASE 21 - COMPANION FLANGE

7 - OIL PUMP 22 - SECTOR SHAFT

8 - REAR RETAINER 23 - SLIDING CLUTCH

9 - OUTPUT BEARING 24 - SLIDING HUB

10 - REAR EXTENSION 25 - PTO GEAR

11 - SEAL 26 - ANNULUS GEAR

12 - BUSHING 27 - INPUT BEARING RETAINER

13 - SPEEDOMETER GEAR 28 - SEAL

14 - DRIVE SPROCKET 29 - INPUT GEAR

15 - CHAIN 30 - INPUT BEARING

Fig. 2 Transfer Case Identification Tag - Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

BR/BETRANSFER CASE - NV241HD 21 - 467

TRANSFER CASE - NV241HD (Continued)

Page 2029 of 2255

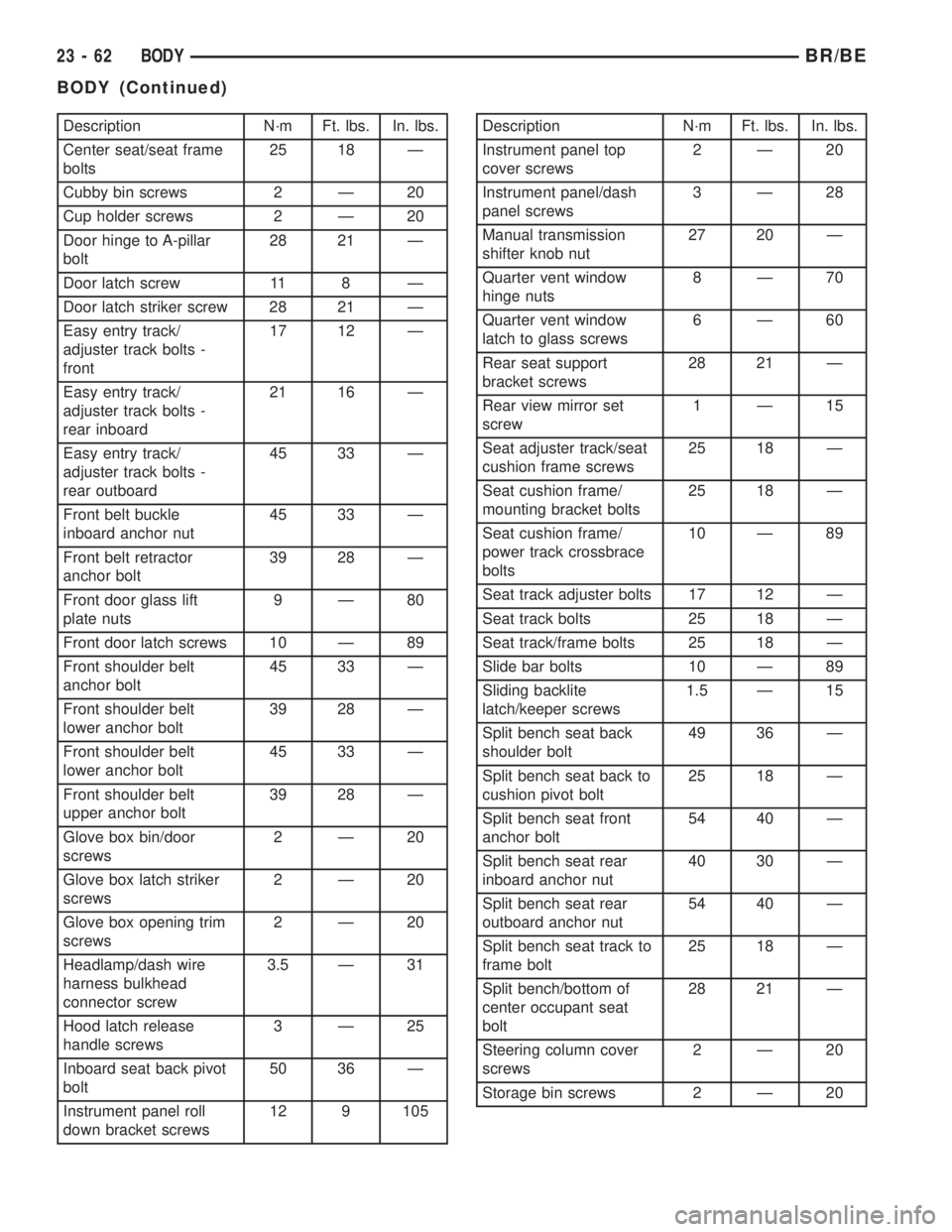

Description N´m Ft. lbs. In. lbs.

Center seat/seat frame

bolts25 18 Ð

Cubby bin screws 2 Ð 20

Cup holder screws 2 Ð 20

Door hinge to A-pillar

bolt28 21 Ð

Door latch screw 11 8 Ð

Door latch striker screw 28 21 Ð

Easy entry track/

adjuster track bolts -

front17 12 Ð

Easy entry track/

adjuster track bolts -

rear inboard21 16 Ð

Easy entry track/

adjuster track bolts -

rear outboard45 33 Ð

Front belt buckle

inboard anchor nut45 33 Ð

Front belt retractor

anchor bolt39 28 Ð

Front door glass lift

plate nuts9Ð80

Front door latch screws 10 Ð 89

Front shoulder belt

anchor bolt45 33 Ð

Front shoulder belt

lower anchor bolt39 28 Ð

Front shoulder belt

lower anchor bolt45 33 Ð

Front shoulder belt

upper anchor bolt39 28 Ð

Glove box bin/door

screws2Ð20

Glove box latch striker

screws2Ð20

Glove box opening trim

screws2Ð20

Headlamp/dash wire

harness bulkhead

connector screw3.5 Ð 31

Hood latch release

handle screws3Ð25

Inboard seat back pivot

bolt50 36 Ð

Instrument panel roll

down bracket screws12 9 105Description N´m Ft. lbs. In. lbs.

Instrument panel top

cover screws2Ð20

Instrument panel/dash

panel screws3Ð28

Manual transmission

shifter knob nut27 20 Ð

Quarter vent window

hinge nuts8Ð70

Quarter vent window

latch to glass screws6Ð60

Rear seat support

bracket screws28 21 Ð

Rear view mirror set

screw1Ð15

Seat adjuster track/seat

cushion frame screws25 18 Ð

Seat cushion frame/

mounting bracket bolts25 18 Ð

Seat cushion frame/

power track crossbrace

bolts10 Ð 89

Seat track adjuster bolts 17 12 Ð

Seat track bolts 25 18 Ð

Seat track/frame bolts 25 18 Ð

Slide bar bolts 10 Ð 89

Sliding backlite

latch/keeper screws1.5 Ð 15

Split bench seat back

shoulder bolt49 36 Ð

Split bench seat back to

cushion pivot bolt25 18 Ð

Split bench seat front

anchor bolt54 40 Ð

Split bench seat rear

inboard anchor nut40 30 Ð

Split bench seat rear

outboard anchor nut54 40 Ð

Split bench seat track to

frame bolt25 18 Ð

Split bench/bottom of

center occupant seat

bolt28 21 Ð

Steering column cover

screws2Ð20

Storage bin screws 2 Ð 20

23 - 62 BODYBR/BE

BODY (Continued)

Page 2039 of 2255

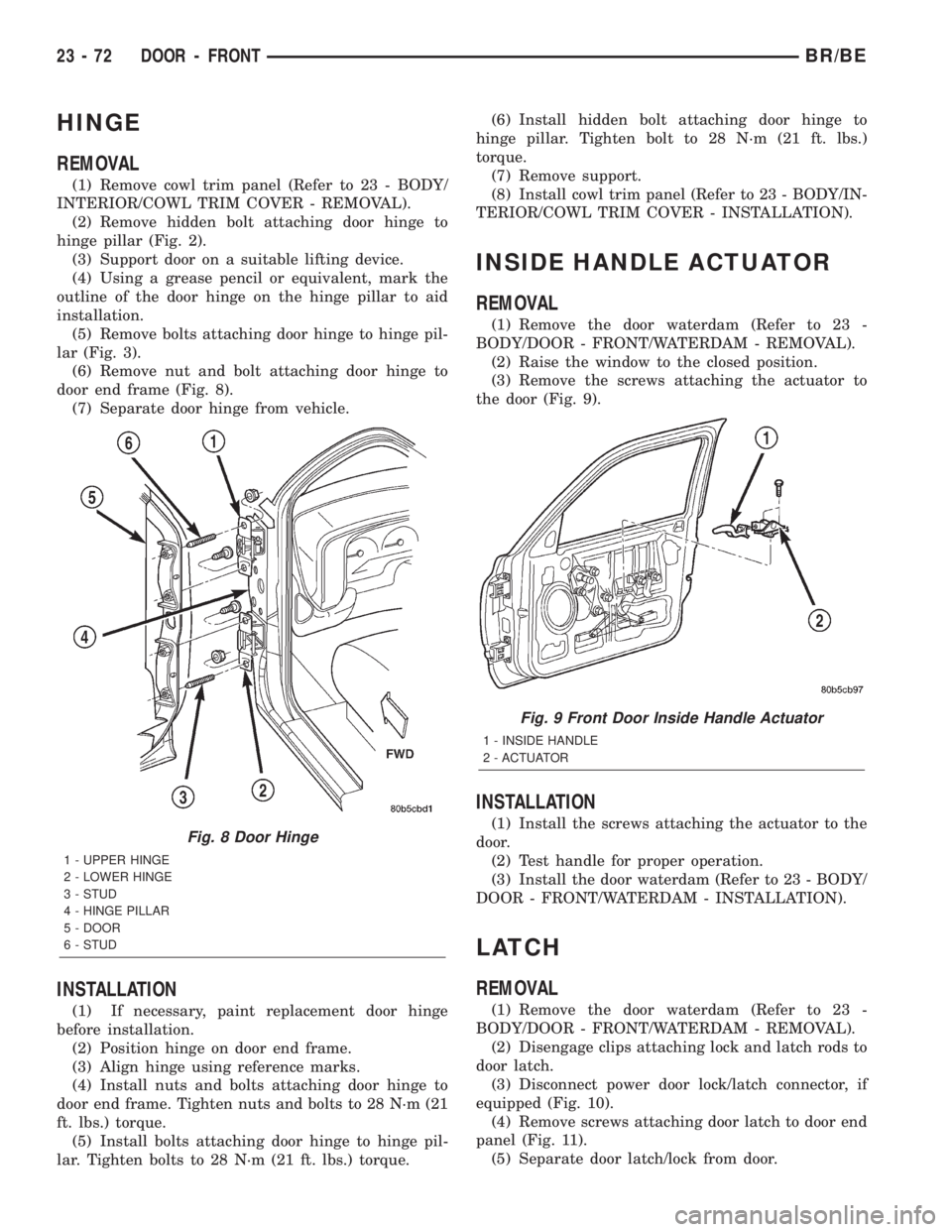

HINGE

REMOVAL

(1) Remove cowl trim panel (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - REMOVAL).

(2) Remove hidden bolt attaching door hinge to

hinge pillar (Fig. 2).

(3) Support door on a suitable lifting device.

(4) Using a grease pencil or equivalent, mark the

outline of the door hinge on the hinge pillar to aid

installation.

(5) Remove bolts attaching door hinge to hinge pil-

lar (Fig. 3).

(6) Remove nut and bolt attaching door hinge to

door end frame (Fig. 8).

(7) Separate door hinge from vehicle.

INSTALLATION

(1) If necessary, paint replacement door hinge

before installation.

(2) Position hinge on door end frame.

(3) Align hinge using reference marks.

(4) Install nuts and bolts attaching door hinge to

door end frame. Tighten nuts and bolts to 28 N´m (21

ft. lbs.) torque.

(5) Install bolts attaching door hinge to hinge pil-

lar. Tighten bolts to 28 N´m (21 ft. lbs.) torque.(6) Install hidden bolt attaching door hinge to

hinge pillar. Tighten bolt to 28 N´m (21 ft. lbs.)

torque.

(7) Remove support.

(8) Install cowl trim panel (Refer to 23 - BODY/IN-

TERIOR/COWL TRIM COVER - INSTALLATION).

INSIDE HANDLE ACTUATOR

REMOVAL

(1) Remove the door waterdam (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Raise the window to the closed position.

(3) Remove the screws attaching the actuator to

the door (Fig. 9).

INSTALLATION

(1) Install the screws attaching the actuator to the

door.

(2) Test handle for proper operation.

(3) Install the door waterdam (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION).

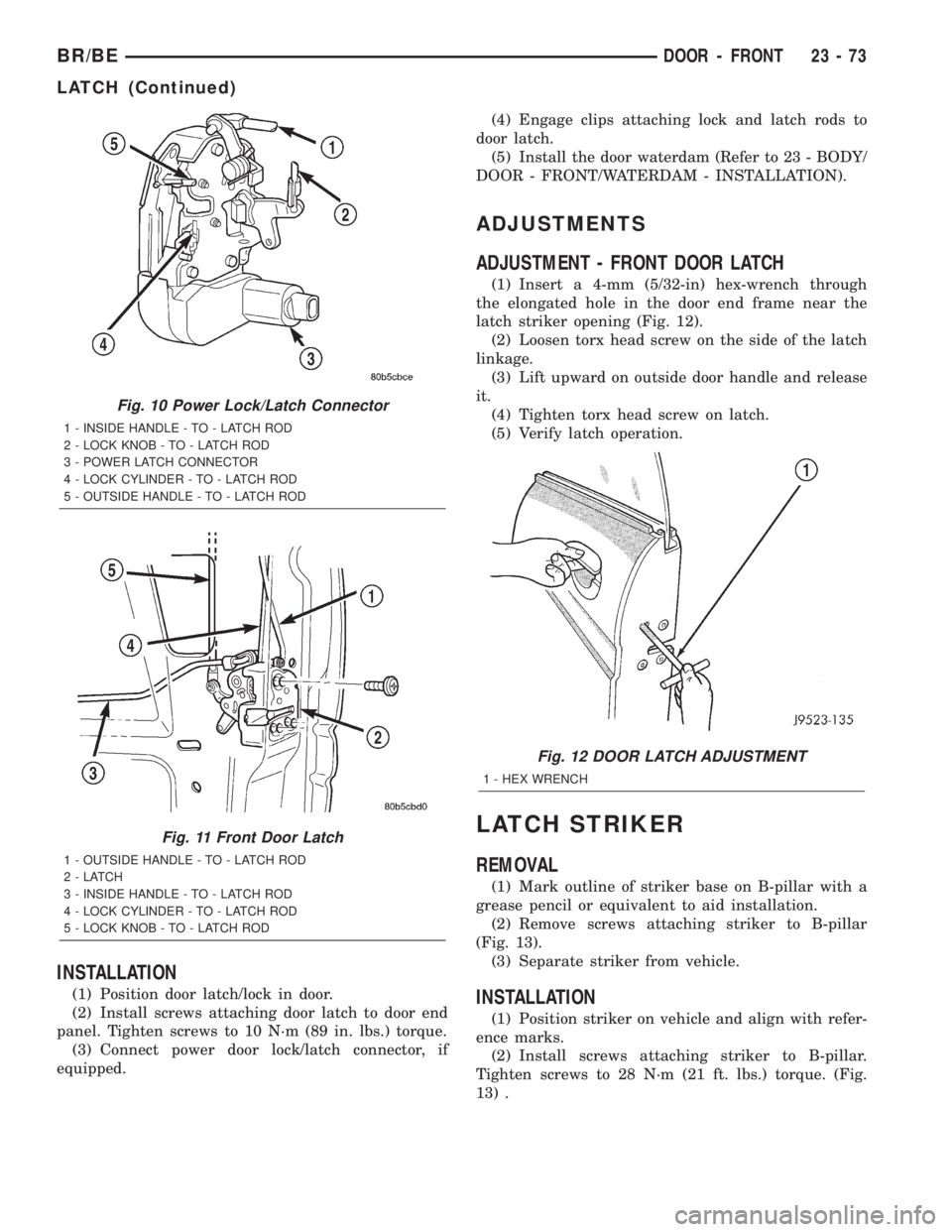

LATCH

REMOVAL

(1) Remove the door waterdam (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Disengage clips attaching lock and latch rods to

door latch.

(3) Disconnect power door lock/latch connector, if

equipped (Fig. 10).

(4) Remove screws attaching door latch to door end

panel (Fig. 11).

(5) Separate door latch/lock from door.

Fig. 8 Door Hinge

1 - UPPER HINGE

2 - LOWER HINGE

3 - STUD

4 - HINGE PILLAR

5 - DOOR

6 - STUD

Fig. 9 Front Door Inside Handle Actuator

1 - INSIDE HANDLE

2 - ACTUATOR

23 - 72 DOOR - FRONTBR/BE

Page 2040 of 2255

INSTALLATION

(1) Position door latch/lock in door.

(2) Install screws attaching door latch to door end

panel. Tighten screws to 10 N´m (89 in. lbs.) torque.

(3) Connect power door lock/latch connector, if

equipped.(4) Engage clips attaching lock and latch rods to

door latch.

(5) Install the door waterdam (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION).

ADJUSTMENTS

ADJUSTMENT - FRONT DOOR LATCH

(1) Insert a 4-mm (5/32-in) hex-wrench through

the elongated hole in the door end frame near the

latch striker opening (Fig. 12).

(2) Loosen torx head screw on the side of the latch

linkage.

(3) Lift upward on outside door handle and release

it.

(4) Tighten torx head screw on latch.

(5) Verify latch operation.

LATCH STRIKER

REMOVAL

(1) Mark outline of striker base on B-pillar with a

grease pencil or equivalent to aid installation.

(2) Remove screws attaching striker to B-pillar

(Fig. 13).

(3) Separate striker from vehicle.

INSTALLATION

(1) Position striker on vehicle and align with refer-

ence marks.

(2) Install screws attaching striker to B-pillar.

Tighten screws to 28 N´m (21 ft. lbs.) torque. (Fig.

13) .

Fig. 10 Power Lock/Latch Connector

1 - INSIDE HANDLE - TO - LATCH ROD

2 - LOCK KNOB - TO - LATCH ROD

3 - POWER LATCH CONNECTOR

4 - LOCK CYLINDER - TO - LATCH ROD

5 - OUTSIDE HANDLE - TO - LATCH ROD

Fig. 11 Front Door Latch

1 - OUTSIDE HANDLE - TO - LATCH ROD

2-LATCH

3 - INSIDE HANDLE - TO - LATCH ROD

4 - LOCK CYLINDER - TO - LATCH ROD

5 - LOCK KNOB - TO - LATCH ROD

Fig. 12 DOOR LATCH ADJUSTMENT

1 - HEX WRENCH

BR/BEDOOR - FRONT 23 - 73

LATCH (Continued)

Page 2042 of 2255

INSTALLATION

(1) Position flag cover on door.

(2) Install nuts attaching mirror flag cover to door

frame.

(3) Install flag door seal.

(4) Install door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

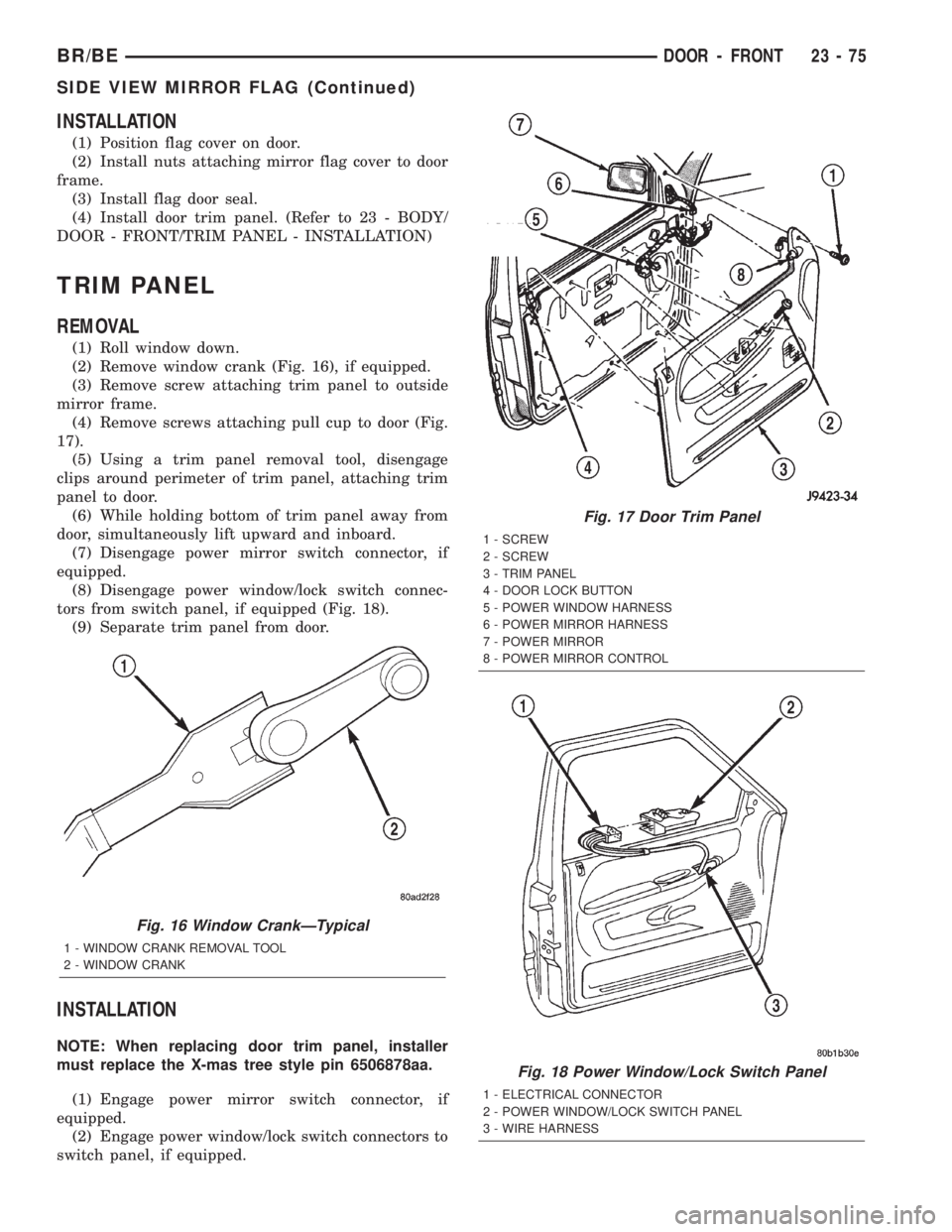

TRIM PANEL

REMOVAL

(1) Roll window down.

(2) Remove window crank (Fig. 16), if equipped.

(3) Remove screw attaching trim panel to outside

mirror frame.

(4) Remove screws attaching pull cup to door (Fig.

17).

(5) Using a trim panel removal tool, disengage

clips around perimeter of trim panel, attaching trim

panel to door.

(6) While holding bottom of trim panel away from

door, simultaneously lift upward and inboard.

(7) Disengage power mirror switch connector, if

equipped.

(8) Disengage power window/lock switch connec-

tors from switch panel, if equipped (Fig. 18).

(9) Separate trim panel from door.

INSTALLATION

NOTE: When replacing door trim panel, installer

must replace the X-mas tree style pin 6506878aa.

(1) Engage power mirror switch connector, if

equipped.

(2) Engage power window/lock switch connectors to

switch panel, if equipped.

Fig. 16 Window CrankÐTypical

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

Fig. 17 Door Trim Panel

1 - SCREW

2 - SCREW

3 - TRIM PANEL

4 - DOOR LOCK BUTTON

5 - POWER WINDOW HARNESS

6 - POWER MIRROR HARNESS

7 - POWER MIRROR

8 - POWER MIRROR CONTROL

Fig. 18 Power Window/Lock Switch Panel

1 - ELECTRICAL CONNECTOR

2 - POWER WINDOW/LOCK SWITCH PANEL

3 - WIRE HARNESS

BR/BEDOOR - FRONT 23 - 75

SIDE VIEW MIRROR FLAG (Continued)

Page 2043 of 2255

(3) Position trim panel on door.

(4) Engage clips around perimeter of trim panel,

attaching trim panel to door.

(5) Install screws attaching pull cup to door.

(6) Install screw attaching trim panel to outside

mirror frame.

(7) Install window crank, if equipped.

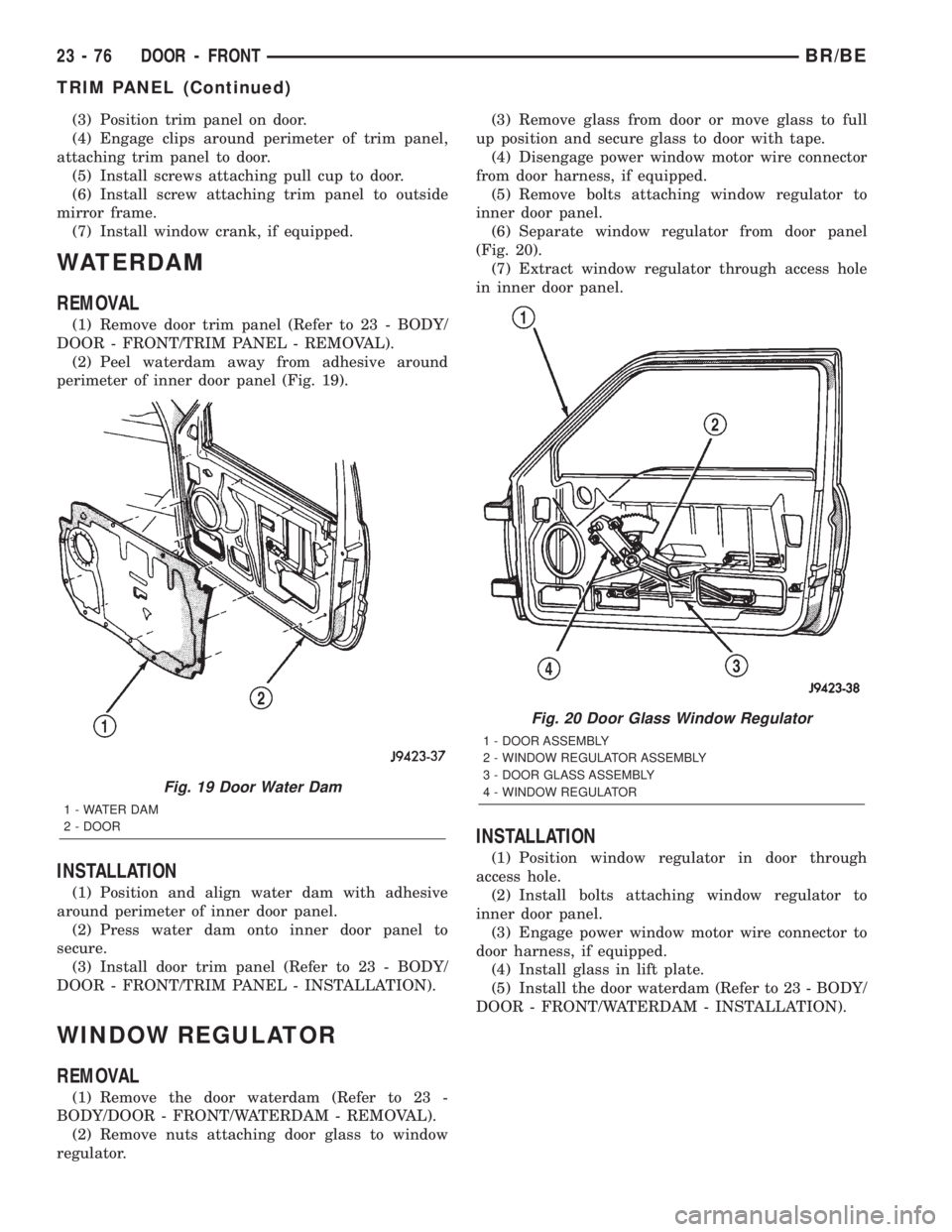

WATERDAM

REMOVAL

(1) Remove door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Peel waterdam away from adhesive around

perimeter of inner door panel (Fig. 19).

INSTALLATION

(1) Position and align water dam with adhesive

around perimeter of inner door panel.

(2) Press water dam onto inner door panel to

secure.

(3) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

WINDOW REGULATOR

REMOVAL

(1) Remove the door waterdam (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Remove nuts attaching door glass to window

regulator.(3) Remove glass from door or move glass to full

up position and secure glass to door with tape.

(4) Disengage power window motor wire connector

from door harness, if equipped.

(5) Remove bolts attaching window regulator to

inner door panel.

(6) Separate window regulator from door panel

(Fig. 20).

(7) Extract window regulator through access hole

in inner door panel.

INSTALLATION

(1) Position window regulator in door through

access hole.

(2) Install bolts attaching window regulator to

inner door panel.

(3) Engage power window motor wire connector to

door harness, if equipped.

(4) Install glass in lift plate.

(5) Install the door waterdam (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION).

Fig. 19 Door Water Dam

1 - WATER DAM

2 - DOOR

Fig. 20 Door Glass Window Regulator

1 - DOOR ASSEMBLY

2 - WINDOW REGULATOR ASSEMBLY

3 - DOOR GLASS ASSEMBLY

4 - WINDOW REGULATOR

23 - 76 DOOR - FRONTBR/BE

TRIM PANEL (Continued)

Page 2060 of 2255

LEFT FRONT FENDER

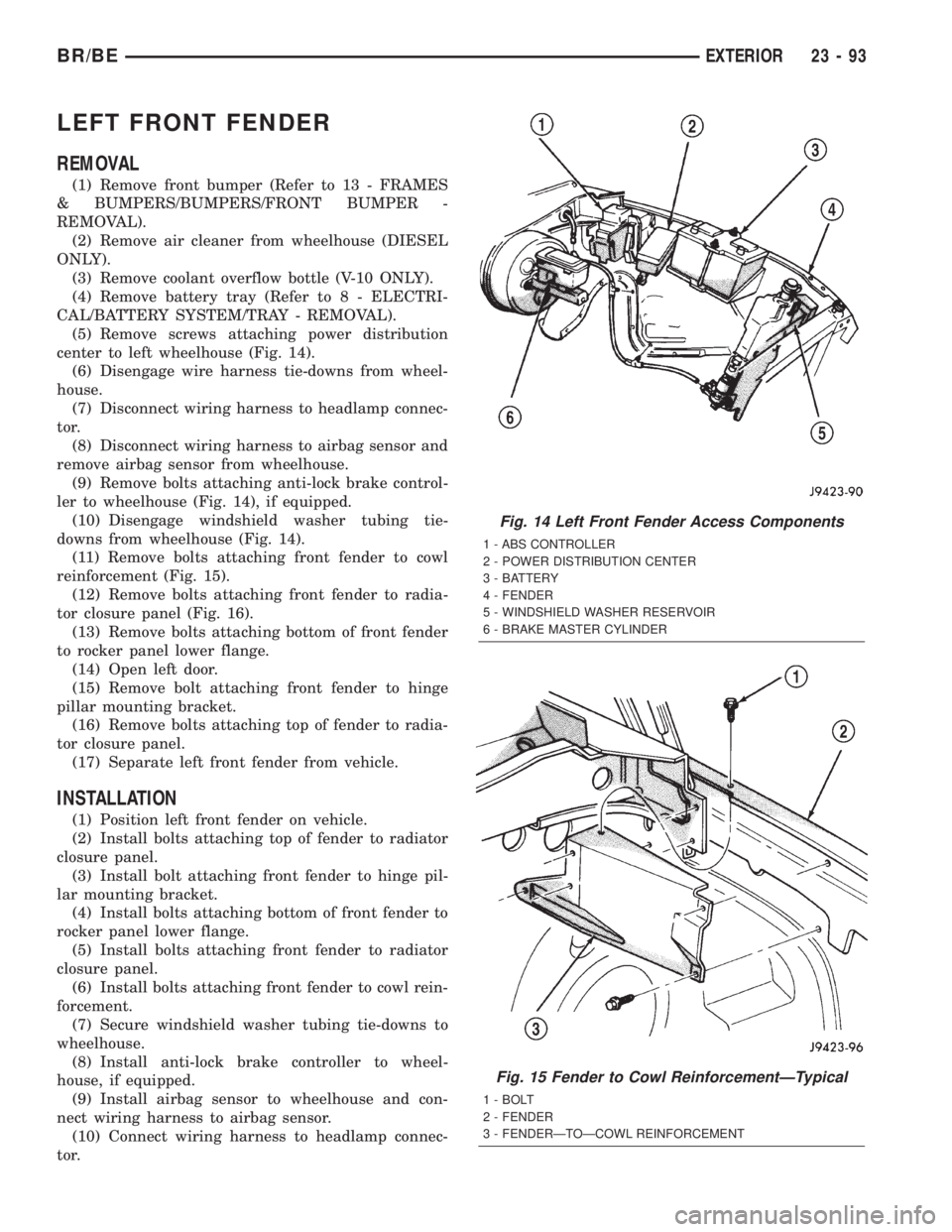

REMOVAL

(1) Remove front bumper (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT BUMPER -

REMOVAL).

(2) Remove air cleaner from wheelhouse (DIESEL

ONLY).

(3) Remove coolant overflow bottle (V-10 ONLY).

(4) Remove battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - REMOVAL).

(5) Remove screws attaching power distribution

center to left wheelhouse (Fig. 14).

(6) Disengage wire harness tie-downs from wheel-

house.

(7) Disconnect wiring harness to headlamp connec-

tor.

(8) Disconnect wiring harness to airbag sensor and

remove airbag sensor from wheelhouse.

(9) Remove bolts attaching anti-lock brake control-

ler to wheelhouse (Fig. 14), if equipped.

(10) Disengage windshield washer tubing tie-

downs from wheelhouse (Fig. 14).

(11) Remove bolts attaching front fender to cowl

reinforcement (Fig. 15).

(12) Remove bolts attaching front fender to radia-

tor closure panel (Fig. 16).

(13) Remove bolts attaching bottom of front fender

to rocker panel lower flange.

(14) Open left door.

(15) Remove bolt attaching front fender to hinge

pillar mounting bracket.

(16) Remove bolts attaching top of fender to radia-

tor closure panel.

(17) Separate left front fender from vehicle.

INSTALLATION

(1) Position left front fender on vehicle.

(2) Install bolts attaching top of fender to radiator

closure panel.

(3) Install bolt attaching front fender to hinge pil-

lar mounting bracket.

(4) Install bolts attaching bottom of front fender to

rocker panel lower flange.

(5) Install bolts attaching front fender to radiator

closure panel.

(6) Install bolts attaching front fender to cowl rein-

forcement.

(7) Secure windshield washer tubing tie-downs to

wheelhouse.

(8) Install anti-lock brake controller to wheel-

house, if equipped.

(9) Install airbag sensor to wheelhouse and con-

nect wiring harness to airbag sensor.

(10) Connect wiring harness to headlamp connec-

tor.

Fig. 14 Left Front Fender Access Components

1 - ABS CONTROLLER

2 - POWER DISTRIBUTION CENTER

3 - BATTERY

4 - FENDER

5 - WINDSHIELD WASHER RESERVOIR

6 - BRAKE MASTER CYLINDER

Fig. 15 Fender to Cowl ReinforcementÐTypical

1 - BOLT

2 - FENDER

3 - FENDERÐTOÐCOWL REINFORCEMENT

BR/BEEXTERIOR 23 - 93