window switch DODGE RAM 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 2140 of 2255

(3) On vehicles with air conditioning, turn the

temperature control knob to the extreme counter

clockwise (Cool) position, and set the mode control

switch knob to the Bi-Level (A/C) position. The out-

side (recirculation) air door should be open to outside

air. If not OK, (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS - DIAGNOSIS AND TEST-

ING - VACUUM SYSTEM).

(4) Open the vehicle windows. Test the blower

motor operation in all speeds. If not OK, (Refer to 24

- HEATING & AIR CONDITIONING/DISTRIBU-

TION/BLOWER MOTOR - DIAGNOSIS AND TEST-

ING).

(5) On vehicles with air conditioning, the compres-

sor should be running and the air conditioning sys-

tem in operation unless the ambient air temperature

is below about -1É C (30É F). If not OK, (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE).

(6) Check the mode control switch operation. The

heater and air conditioner systems should respond as

described in the owner's manual in the vehicle glove

box to each mode selected. Reduce the engine speed

to normal idle. The vacuum will be high at low idle

and the vacuum actuators should respond quickly. If

not OK, (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - DIAGNOSIS AND TEST-

ING - VACUUM SYSTEM).

(7) If the vacuum tests, and the electrical compo-

nent and circuit tests reveal no problems, disassem-

ble the HVAC housing to inspect for mechanical

misalignment or binding of the mode doors (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION/HVAC HOUSING - DISASSEMBLY)

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

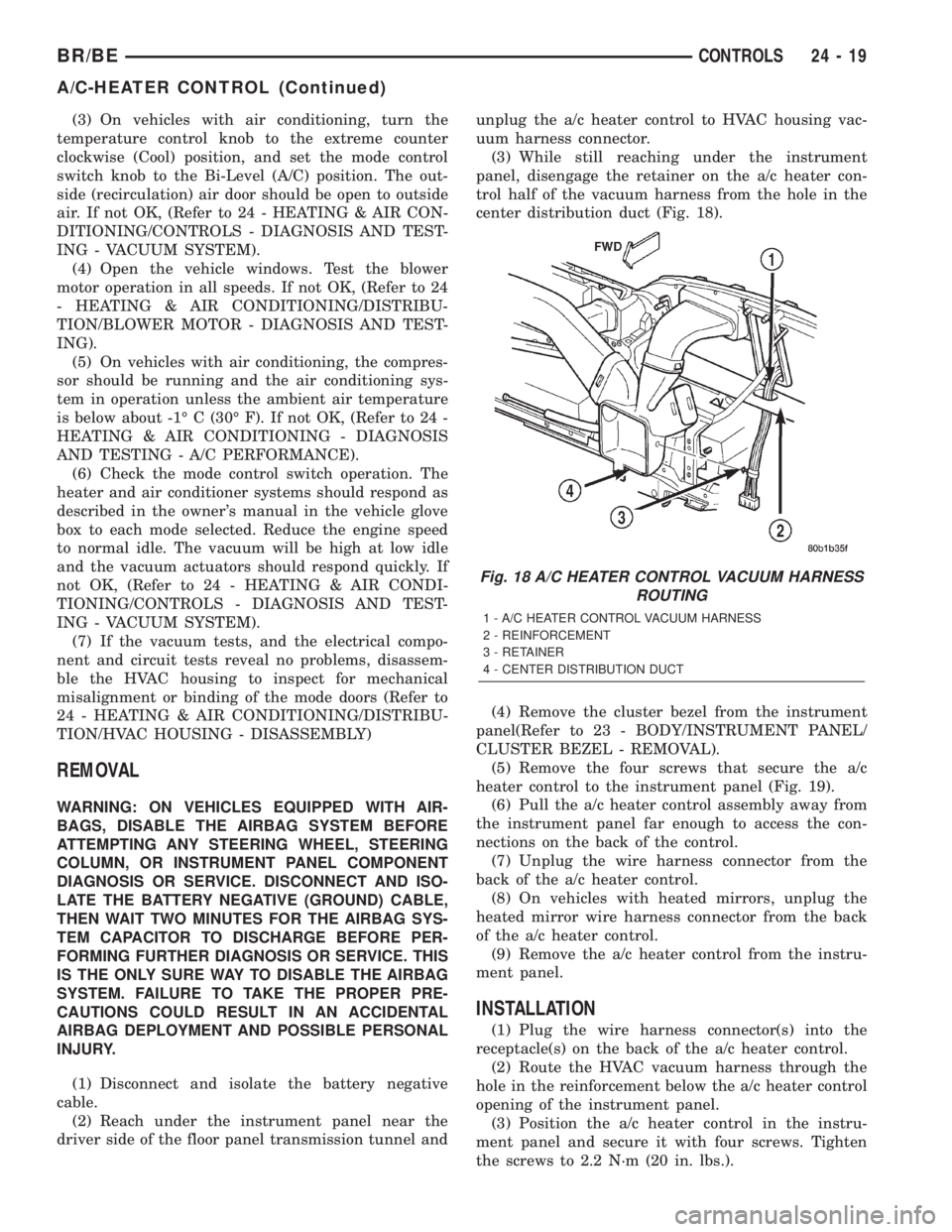

(2) Reach under the instrument panel near the

driver side of the floor panel transmission tunnel andunplug the a/c heater control to HVAC housing vac-

uum harness connector.

(3) While still reaching under the instrument

panel, disengage the retainer on the a/c heater con-

trol half of the vacuum harness from the hole in the

center distribution duct (Fig. 18).

(4) Remove the cluster bezel from the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(5) Remove the four screws that secure the a/c

heater control to the instrument panel (Fig. 19).

(6) Pull the a/c heater control assembly away from

the instrument panel far enough to access the con-

nections on the back of the control.

(7) Unplug the wire harness connector from the

back of the a/c heater control.

(8) On vehicles with heated mirrors, unplug the

heated mirror wire harness connector from the back

of the a/c heater control.

(9) Remove the a/c heater control from the instru-

ment panel.

INSTALLATION

(1) Plug the wire harness connector(s) into the

receptacle(s) on the back of the a/c heater control.

(2) Route the HVAC vacuum harness through the

hole in the reinforcement below the a/c heater control

opening of the instrument panel.

(3) Position the a/c heater control in the instru-

ment panel and secure it with four screws. Tighten

the screws to 2.2 N´m (20 in. lbs.).

Fig. 18 A/C HEATER CONTROL VACUUM HARNESS

ROUTING

1 - A/C HEATER CONTROL VACUUM HARNESS

2 - REINFORCEMENT

3 - RETAINER

4 - CENTER DISTRIBUTION DUCT

BR/BECONTROLS 24 - 19

A/C-HEATER CONTROL (Continued)

Page 2198 of 2255

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S's sensor strategy is based on the fact that

as a catalyst deteriorates, its oxygen storage capacity

and its efficiency are both reduced. By monitoring

the oxygen storage capacity of a catalyst, its effi-

ciency can be indirectly calculated. The upstream

O2S is used to detect the amount of oxygen in the

exhaust gas before the gas enters the catalytic con-

verter. The PCM calculates the A/F mixture from the

output of the O2S. A low voltage indicates high oxy-

gen content (lean mixture). A high voltage indicates a

low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL will be illu-

minated.

DESCRIPTION - TRIP DEFINITION

The term ªTripº has different meanings depending

on what the circumstances are. If the MIL (Malfunc-

tion Indicator Lamp) is OFF, a Trip is defined as

when the Oxygen Sensor Monitor and the Catalyst

Monitor have been completed in the same drive cycle.

When any Emission DTC is set, the MIL on the

dash is turned ON. When the MIL is ON, it takes 3

good trips to turn the MIL OFF. In this case, it

depends on what type of DTC is set to know what a

ªTripº is.For the Fuel Monitor or Mis-Fire Monitor (contin-

uous monitor), the vehicle must be operated in the

ªSimilar Condition Windowº for a specified amount of

time to be considered a Good Trip.

If a Non-Contiuous OBDII Monitor fails twice in a

row and turns ON the MIL, re-running that monitor

which previously failed, on the next start-up and

passing the monitor, is considered to be a Good Trip.

These will include the following:

²Oxygen Sensor

²Catalyst Monitor

²Purge Flow Monitor

²Leak Detection Pump Monitor (if equipped)

²EGR Monitor (if equipped)

²Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII

Monitor), a Good Trip is considered to be when the

Oxygen Sensor Monitor and Catalyst Monitor have

been completed; or 2 Minutes of engine run time if

the Oxygen Sensor Monitor or Catalyst Monitor have

been stopped from running.

It can take up to 2 Failures in a row to turn on the

MIL. After the MIL is ON, it takes 3 Good Trips to

turn the MIL OFF. After the MIL is OFF, the PCM

will self-erase the DTC after 40 Warm-up cycles. A

Warm-up cycle is counted when the ECT (Engine

Coolant Temperature Sensor) has crossed 160ÉF and

has risen by at least 40ÉF since the engine has been

started.

DESCRIPTION - COMPONENT MONITORS -

GAS ENGINES

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (MIL) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater,

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum if

the TPS indicates a small throttle opening.

All open/short circuit checks, or any component

that has an associated limp-in, will set a fault after 1

trip with the malfunction present. Components with-

out an associated limp-in will take two trips to illu-

minate the MIL.

BR/BEEMISSIONS CONTROL 25 - 19

EMISSIONS CONTROL (Continued)

Page 2201 of 2255

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-

sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.

²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

25 - 22 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2202 of 2255

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good Trip

Counter, the PCM automatically switches to a Warm-Up

Cycle Counter that can be viewed on the DRB III.

Warm-Up Cycles are used to erase DTCs and Freeze

Frames. Forty Warm-Up cycles must occur in order for

the PCM to self-erase a DTC and Freeze Frame. A

Warm-Up Cycle is defined as follows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for two

trip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²Upstream O2S VoltsÐ A live reading of the

Oxygen Sensor to indicate its performance. For

example, stuck lean, stuck rich, etc.

²SCW Time in Window (Similar Conditions

Window Time in Window)Ð A timer used by the

PCM that indicates that, after all Similar Conditions

have been met, if there has been enough good engine

running time in the SCW without failure detected.

This timer is used to increment a Good Trip.

²Fuel System Good Trip CounterÐATrip

Counter used to turn OFF the MIL for Fuel System

DTCs. To increment a Fuel System Good Trip, the

engine must be in the Similar Conditions Window,

Adaptive Memory Factor must be less than cali-

brated threshold and the Adaptive Memory Factor

must stay below that threshold for a calibrated

amount of time.

²Test Done This TripÐ Indicates that the

monitor has already been run and completed during

the current trip.

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

BR/BEEMISSIONS CONTROL 25 - 23

EMISSIONS CONTROL (Continued)

Page 2237 of 2255

MINI-TRIP COMPUTER - DIAGNOSIS

AND TESTING, COMPASS.............8M-10

MIRROR - DESCRIPTION, AUTOMATIC

DAY / NIGHT........................8N-11

MIRROR - DESCRIPTION, SIDEVIEW.....8N-14

MIRROR - DIAGNOSIS AND TESTING,

AUTOMATIC DAY/NIGHT...............8N-12

MIRROR - DIAGNOSIS AND TESTING,

SIDEVIEW..........................8N-14

MIRROR - INSTALLATION, AUTOMATIC

DAY / NIGHT........................8N-13

MIRROR - INSTALLATION, SIDE VIEW....23-98

MIRROR - LOW MOUNTED -

INSTALLATION, SIDE VIEW.............23-98

MIRROR - LOW MOUNTED - REMOVAL,

SIDE VIEW..........................23-98

MIRROR - OPERATION, AUTOMATIC DAY

/ NIGHT............................8N-12

MIRROR - OPERATION, SIDEVIEW.......8N-14

MIRROR - REMOVAL, AUTOMATIC DAY /

NIGHT.............................8N-13

MIRROR - REMOVAL, REAR VIEW......23-126

MIRROR - REMOVAL, SIDE VIEW........23-97

MIRROR - REMOVAL, SIDEVIEW........8N-15

MIRROR FLAG - INSTALLATION, SIDE

VIEW..............................23-75

MIRROR FLAG - REMOVAL, SIDE VIEW . . . 23-74

MIRROR GLASS - INSTALLATION, SIDE

VIEW..............................23-98

MIRROR GLASS - REMOVAL, SIDE VIEW . . 23-98

MIRROR GRID - DESCRIPTION, HEATED....8G-4

MIRROR GRID - DIAGNOSIS AND

TESTING, HEATED.....................8G-4

MIRROR GRID - OPERATION, HEATED.....8G-4

MIRROR SUPPORT BRACKET -

INSTALLATION, REARVIEW............23-126

MIRROR SWITCH - DESCRIPTION........8G-2

MIRROR SWITCH - DESCRIPTION,

POWER............................8N-13

MIRROR SWITCH - DIAGNOSIS AND

TESTING, HEATED.....................8G-3

MIRROR SWITCH - INSTALLATION,

POWER............................8N-14

MIRROR SWITCH - OPERATION..........8G-3

MIRROR SWITCH - OPERATION, POWER . . 8N-13

MIRROR SWITCH - REMOVAL, POWER . . . 8N-13

MIRROR SYSTEM - DESCRIPTION,

HEATED.............................8G-1

MIRROR SYSTEM - DIAGNOSIS AND

TESTING, HEATED.....................8G-2

MIRROR SYSTEM - OPERATION, HEATED . . 8G-2

MIRRORS - DESCRIPTION, POWER......8N-11

MIRRORS - OPERATION, POWER........8N-11

MODE - DESCRIPTION, CIRCUIT

ACTUATION TEST.....................25-2

MODE - DESCRIPTION, STATE DISPLAY

TEST...............................25-1

MODES OF OPERATION - DESCRIPTION . . . 8E-15

MODULE - DESCRIPTION, AIRBAG

CONTROL...........................8O-6

MODULE - DESCRIPTION, CENTRAL

TIMER..............................8E-1

MODULE - DESCRIPTION, DAYTIME

RUNNING LAMP......................8L-9

MODULE - DESCRIPTION, FUEL PUMP....14-12

MODULE - DESCRIPTION, FUEL TANK....14-82

MODULE - DESCRIPTION, HEATED SEAT . . 8E-20

MODULE - DESCRIPTION, WIPER

.......8R-13

MODULE - DIAGNOSIS AND TESTING,

CENTRAL TIMER

......................8E-4

MODULE - DIAGNOSIS AND TESTING,

HEATED SEAT

.......................8E-21

MODULE - INSTALLATION, AIRBAG

CONTROL

...........................8O-8

MODULE - INSTALLATION, CENTRAL

TIMER

..............................8E-6

MODULE - INSTALLATION, DAYTIME

RUNNING LAMP

......................8L-9

MODULE - INSTALLATION, ENGINE

CONTROL

..........................8E-14

MODULE - INSTALLATION, FUEL PUMP

. . . 14-13

MODULE - INSTALLATION, FUEL TANK

....14-83

MODULE - INSTALLATION, HEATED SEAT

. . 8E-23

MODULE - INSTALLATION, WIPER

.......8R-14

MODULE - OPERATION, AIRBAG

CONTROL

...........................8O-6

MODULE - OPERATION, CENTRAL TIMER

. . 8E-3MODULE - OPERATION, DAYTIME

RUNNING LAMP......................8L-9

MODULE - OPERATION, FUEL PUMP.....14-13

MODULE - OPERATION, FUEL TANK......14-82

MODULE - OPERATION, HEATED SEAT....8E-20

MODULE - OPERATION, WIPER.........8R-14

MODULE - REMOVAL, AIRBAG CONTROL . . 8O-7

MODULE - REMOVAL, CENTRAL TIMER....8E-5

MODULE - REMOVAL, DAYTIME

RUNNING LAMP......................8L-9

MODULE - REMOVAL, ENGINE CONTROL . . 8E-14

MODULE - REMOVAL, FUEL PUMP.......14-13

MODULE - REMOVAL, FUEL TANK.......14-83

MODULE - REMOVAL, HEATED SEAT.....8E-23

MODULE - REMOVAL, WIPER...........8R-14

MOLDING - INSTALLATION, ROOF JOINT . . 23-91

MOLDING - REMOVAL, ROOF JOINT......23-91

MOLDINGS - INSTALLATION, BODY SIDE . . 23-87

MOLDINGS - REMOVAL, BODY SIDE.....23-86

MONITORED SYSTEMS - DESCRIPTION . . . 25-17

MONITORS - DIESEL ENGINES -

DESCRIPTION, COMPONENT............25-20

MONITORS - GAS ENGINES -

DESCRIPTION, COMPONENT............25-19

MOTOR - ASSEMBLY, AXLE VACUUM......3-34

MOTOR - DESCRIPTION, AXLE VACUUM . . . 3-31

MOTOR - DESCRIPTION, BLOWER.......24-31

MOTOR - DESCRIPTION, IDLE AIR

CONTROL..........................14-40

MOTOR - DESCRIPTION, LUMBAR.......8N-19

MOTOR - DESCRIPTION, POWER LOCK....8N-7

MOTOR - DESCRIPTION, STARTER.......8F-37

MOTOR - DESCRIPTION, WINDOW......8N-26

MOTOR - DIAGNOSIS AND TESTING,

BLOWER...........................24-32

MOTOR - DIAGNOSIS AND TESTING,

LUMBAR...........................8N-19

MOTOR - DIAGNOSIS AND TESTING,

POWER LOCK........................8N-7

MOTOR - DIAGNOSIS AND TESTING,

STARTER ...........................8F-38

MOTOR - DIAGNOSIS AND TESTING,

VACUUM............................3-32

MOTOR - DIAGNOSIS AND TESTING,

WINDOW...........................8N-26

MOTOR - DISASSEMBLY, AXLE VACUUM . . . 3-34

MOTOR - INSTALLATION, AXLE VACUUM . . . 3-34

MOTOR - INSTALLATION, BLOWER......24-32

MOTOR - INSTALLATION, STARTER......8F-40

MOTOR - OPERATION, AXLE VACUUM.....3-31

MOTOR - OPERATION, BLOWER.........24-31

MOTOR - OPERATION, IDLE AIR

CONTROL..........................14-40

MOTOR - OPERATION, LUMBAR........8N-19

MOTOR - OPERATION, POWER LOCK.....8N-7

MOTOR - OPERATION, STARTER.........8F-37

MOTOR - REMOVAL, AXLE VACUUM......3-34

MOTOR - REMOVAL, BLOWER..........24-32

MOTOR - REMOVAL, STARTER..........8F-38

MOTOR - REMOVAL, WINDOW..........8N-26

MOTOR RELAY - DESCRIPTION,

BLOWER...........................24-22

MOTOR RELAY - DESCRIPTION,

STARTER ...........................8F-41

MOTOR RELAY - DIAGNOSIS AND

TESTING, BLOWER...................24-22

MOTOR RELAY - INSTALLATION,

BLOWER...........................24-23

MOTOR RELAY - INSTALLATION,

STARTER ...........................8F-42

MOTOR RELAY - OPERATION, BLOWER . . . 24-22

MOTOR RELAY - OPERATION, STARTER . . . 8F-41

MOTOR RELAY - REMOVAL, BLOWER....24-23

MOTOR RELAY - REMOVAL, STARTER....8F-42

MOTOR RESISTOR BLOCK -

DESCRIPTION, BLOWER...............24-23

MOTOR RESISTOR BLOCK - DIAGNOSIS

AND TESTING, BLOWER...............24-23

MOTOR RESISTOR BLOCK -

INSTALLATION, BLOWER

..............24-24

MOTOR RESISTOR BLOCK - OPERATION,

BLOWER

...........................24-23

MOTOR RESISTOR BLOCK - REMOVAL,

BLOWER

...........................24-24

MOTOR SWITCH - DESCRIPTION,

BLOWER

...........................24-24

MOTOR SWITCH - DIAGNOSIS AND

TESTING, BLOWER

...................24-25MOTOR SWITCH - OPERATION, BLOWER . . 24-24

MOTOR SWITCH - REMOVAL, BLOWER . . . 24-25

MOUNT - INSTALLATION, FRONT....9-174,9-42,

9-98

MOUNT - INSTALLATION, REAR . 9-174,9-42,9-98

MOUNT - REMOVAL, FRONT....9-173,9-41,9-97

MOUNT - REMOVAL, REAR.....9-174,9-42,9-98

MOUNTED - INSTALLATION, SIDE VIEW

MIRROR - LOW......................23-98

MOUNTED - REMOVAL, SIDE VIEW

MIRROR - LOW......................23-98

MOUNTED STOP LAMP - INSTALLATION,

CENTER HIGH........................8L-6

MOUNTED STOP LAMP - REMOVAL,

CENTER HIGH........................8L-6

MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER HIGH...........8L-6

MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER HIGH...............8L-6

MOUNTING - STANDARD PROCEDURE,

MATCH .............................22-3

MUFFLER - 3.9L/5.2L/5.9L/8.0L -

INSTALLATION.......................11-10

MUFFLER - 3.9L/5.2L/5.9L/8.0L -

REMOVAL..........................11-10

MUFFLER - 5.9L DIESEL - INSTALLATION . 11-11

MUFFLER - 5.9L DIESEL - REMOVAL.....11-11

MULTI-FUNCTION SWITCH -

DESCRIPTION.......................8L-23

MULTI-FUNCTION SWITCH - DIAGNOSIS

AND TESTING.......................8L-25

MULTI-FUNCTION SWITCH -

INSTALLATION.......................8L-28

MULTI-FUNCTION SWITCH - OPERATION . . 8L-24

MULTI-FUNCTION SWITCH - REMOVAL . . . 8L-27

NAME PLATES - INSTALLATION,

EXTERIOR..........................23-89

NAME PLATES - REMOVAL, EXTERIOR....23-89

NECK SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP-TO-FILLER..............7-65

NEGATIVE CABLE INSTALLATION,

GASOLINE ENGINE...................8F-22

NEGATIVE CABLE REMOVAL, GASOLINE

ENGINE............................8F-22

NIGHT MIRROR - DESCRIPTION,

AUTOMATIC DAY.....................8N-11

NIGHT MIRROR - INSTALLATION,

AUTOMATIC DAY.....................8N-13

NIGHT MIRROR - OPERATION,

AUTOMATIC DAY.....................8N-12

NIGHT MIRROR - REMOVAL,

AUTOMATIC DAY.....................8N-13

NOISE - DIAGNOSIS AND TESTING,

WIND...............................23-3

NOISE OR VIBRATION - DIAGNOSIS AND

TESTING, TIRE.......................22-9

NOISE SUPPRESSION COMPONENTS -

DESCRIPTION, RADIO.................8A-12

NOISE SUPPRESSION COMPONENTS -

DIAGNOSIS AND TESTING, RADIO.......8A-12

NON-DEPLOYED AIRBAGS - STANDARD

PROCEDURE, HANDLING...............8O-4

NON-MONITORED CIRCUITS - DIESEL -

OPERATION.........................25-24

NON-MONITORED CIRCUITS - GAS

ENGINES - OPERATION................25-24

NOZZLE - DESCRIPTION, WASHER.......8R-9

NOZZLE - INSTALLATION, WASHER.......8R-9

NOZZLE - OPERATION, WASHER.........8R-9

NOZZLE - REMOVAL, WASHER...........8R-9

NUMBER - DESCRIPTION, VEHICLE

IDENTIFICATION....................Intro.-1

NV241 - DESCRIPTION, TRANSFER CASE . . . 0-5

NV241HD - ASSEMBLY, TRANSFER CASE . 21-480

NV241HD - CLEANING, TRANSFER CASE . 21-476

NV241HD - DESCRIPTION, TRANSFER

CASE.............................21-465

NV241HD - DISASSEMBLY, TRANSFER

CASE.............................21-469

NV241HD - INSPECTION, TRANSFER

CASE.............................21-476

NV241HD - INSTALLATION, TRANSFER

CASE

.............................21-494

NV241HD - OPERATION, TRANSFER

CASE

.............................21-467

NV241HD - REMOVAL, TRANSFER CASE

. 21-469

NV241HD - TRANSFER CASE

..........21-495

NV241LD - ASSEMBLY, TRANSFER CASE

. 21-445

20 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2240 of 2255

PLATE - INSTALLATION, TRANSFER

CASE SKID.........................13-11

PLATE - REMOVAL, TRANSFER CASE

SKID..............................13-11

PLATE LAMP - INSTALLATION, LICENSE . . 8L-22

PLATE LAMP - REMOVAL, LICENSE......8L-22

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-22

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-22

PLATE, SPECIFICATIONS - FUEL

INJECTION PUMP DATA...............14-77

PLATES - INSTALLATION, EXTERIOR

NAME.............................23-89

PLATES - REMOVAL, EXTERIOR NAME....23-89

PLUG - CLEANING, SPARK.............8I-20

PLUG - DESCRIPTION, SPARK...........8I-16

PLUG - INSTALLATION, SPARK..........8I-20

PLUG - INSTALLATION, STEERING GEAR

HOUSING...........................19-30

PLUG - OPERATION, SPARK............8I-16

PLUG - REMOVAL, SPARK..............8I-19

PLUG - REMOVAL, STEERING GEAR

HOUSING...........................19-29

PLUG CABLE - DESCRIPTION, SPARK.....8I-20

PLUG CABLE - INSTALLATION, SPARK....8I-21

PLUG CABLE - OPERATION, SPARK.......8I-20

PLUG CABLE - REMOVAL, SPARK........8I-21

PLUG CABLE ORDER, 8.0L V-10 ENGINE

- SPARK .............................8I-3

PLUG CABLE RESISTANCE,

SPECIFICATIONS - SPARK...............8I-3

PLUG CABLES - DIAGNOSIS AND

TESTING, SPARK.....................8I-20

PLUG CONDITIONS - DIAGNOSIS AND

TESTING, SPARK.....................8I-17

PLUGS, SPECIFICATIONS - SPARK........8I-3

PLUMBING - CLEANING, CHARGE AIR

COOLER............................11-19

PLUMBING - DESCRIPTION, CHARGE

AIR COOLER........................11-18

PLUMBING - INSPECTION, CHARGE AIR

COOLER............................11-19

PLUMBING - INSTALLATION, CHARGE

AIR COOLER........................11-20

PLUMBING - OPERATION, CHARGE AIR

COOLER............................11-18

PLUMBING - REMOVAL, CHARGE AIR

COOLER............................11-18

PLUMBING - SERVICE CAUTIONS........24-42

PLUMBING - SERVICE WARNINGS.......24-42

POLISHING - DESCRIPTION, WET

SANDING/BUFFING..................23-130

PORT - DESCRIPTION, REFRIGERANT

SYSTEM SERVICE.....................24-1

PORT - OPERATION, REFRIGERANT

SYSTEM SERVICE.....................24-2

POSITION SENSOR - DESCRIPTION,

ACCELERATOR PEDAL.................14-95

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-50

POSITION SENSOR - INSTALLATION,

ACCELERATOR PEDAL.................14-97

POSITION SENSOR - OPERATION,

ACCELERATOR PEDAL.................14-95

POSITION SENSOR - OPERATION,

THROTTLE..........................14-50

POSITION SENSOR - REMOVAL,

ACCELERATOR PEDAL.................14-95

POSITION SWITCH - DESCRIPTION,

CLUTCH PEDAL.......................6-17

POSITION SWITCH - DIAGNOSIS AND

TESTING, PARK/NEUTRAL.......21-195,21-367

POSITION SWITCH - INSTALLATION,

PARK/NEUTRAL...............21-195,21-367

POSITION SWITCH - OPERATION,

CLUTCH PEDAL.......................6-17

POSITION SWITCH - REMOVAL,

PARK/NEUTRAL...............21-195,21-367

POSITIVE CABLE INSTALLATION,

GASOLINE ENGINE...................8F-22

POSITIVE CABLE REMOVAL, GASOLINE

ENGINE

............................8F-21

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE

..............8W-01-8

POWER BRAKE BOOSTER -

INSTALLATION

........................5-19

POWER BRAKE BOOSTER - REMOVAL

.....5-19

POWER DISTRIBUTION - DESCRIPTION

. 8W-97-1POWER DISTRIBUTION - OPERATION . . 8W-97-1

POWER DISTRIBUTION CENTER -

DESCRIPTION.....................8W-97-8

POWER DISTRIBUTION CENTER -

INSTALLATION...................8W-97-10

POWER DISTRIBUTION CENTER -

OPERATION.......................8W-97-8

POWER DISTRIBUTION CENTER -

REMOVAL........................8W-97-8

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS...................8W-97-2

POWER GROUNDS - DESCRIPTION......8E-17

POWER LOCK & REMOTE KEYLESS

ENTRY SYSTEM - DIAGNOSIS AND

TESTING............................8N-5

POWER LOCK MOTOR - DESCRIPTION....8N-7

POWER LOCK MOTOR - DIAGNOSIS AND

TESTING............................8N-7

POWER LOCK MOTOR - OPERATION......8N-7

POWER LOCK SWITCH - DESCRIPTION....8N-8

POWER LOCK SWITCH - DIAGNOSIS

AND TESTING........................8N-9

POWER LOCK SWITCH - OPERATION......8N-8

POWER LOCKS - DESCRIPTION..........8N-1

POWER LOCKS - DIAGNOSIS AND

TESTING............................8N-4

POWER LOCKS - OPERATION............8N-3

POWER MIRROR SWITCH -

DESCRIPTION.......................8N-13

POWER MIRROR SWITCH -

INSTALLATION......................8N-14

POWER MIRROR SWITCH - OPERATION . . 8N-13

POWER MIRROR SWITCH - REMOVAL . . . 8N-13

POWER MIRRORS - DESCRIPTION......8N-11

POWER MIRRORS - OPERATION........8N-11

POWER OUTLET - DESCRIPTION.....8W-97-10

POWER OUTLET - DIAGNOSIS AND

TESTING........................8W-97-10

POWER OUTLET - INSTALLATION....8W-97-11

POWER OUTLET - OPERATION.......8W-97-10

POWER OUTLET - REMOVAL........8W-97-11

POWER SEAT SWITCH - DESCRIPTION,

DRIVER............................8N-17

POWER SEAT SWITCH - DESCRIPTION,

PASSENGER........................8N-20

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, DRIVER................8N-17

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, PASSENGER............8N-20

POWER SEAT SWITCH - INSTALLATION,

DRIVER............................8N-18

POWER SEAT SWITCH - INSTALLATION,

PASSENGER........................8N-21

POWER SEAT SWITCH - OPERATION,

DRIVER............................8N-17

POWER SEAT SWITCH - OPERATION,

PASSENGER........................8N-20

POWER SEAT SWITCH - REMOVAL,

DRIVER............................8N-18

POWER SEAT SWITCH - REMOVAL,

PASSENGER........................8N-21

POWER SEAT SYSTEM - DESCRIPTION . . . 8N-16

POWER SEAT SYSTEM - DIAGNOSIS

AND TESTING.......................8N-16

POWER SEAT SYSTEM - OPERATION.....8N-16

POWER SEAT TRACK - DESCRIPTION....8N-21

POWER SEAT TRACK - DIAGNOSIS AND

TESTING...........................8N-22

POWER SEAT TRACK - INSTALLATION....8N-22

POWER SEAT TRACK - OPERATION......8N-22

POWER SEAT TRACK - REMOVAL.......8N-22

POWER STEERING FLOW AND

PRESSURE - DIAGNOSIS AND

TESTING............................19-4

POWER STEERING GEAR LEAKAGE -

DIAGNOSIS AND TESTING.............19-16

POWER STEERING GEAR, SPECIAL

TOOLS.............................19-22

POWER STEERING GEAR,

SPECIFICATIONS

.....................19-21

POWER STEERING PUMP - INITIAL

OPERATION - STANDARD PROCEDURE

. . . 19-33

POWER STEERING PUMP, SPECIAL

TOOLS

.............................19-38

POWER STEERING SYSTEM -

DIAGNOSIS AND TESTING

..............19-2

POWER STEERING SYSTEM -

STANDARD PROCEDURE, FLUSHING

.....19-34POWER WINDOW SWITCH -

DESCRIPTION.......................8N-24

POWER WINDOW SWITCH - DIAGNOSIS

AND TESTING.......................8N-24

POWER WINDOW SWITCH -

INSTALLATION......................8N-26

POWER WINDOW SWITCH - OPERATION . . 8N-24

POWER WINDOW SWITCH - REMOVAL . . . 8N-25

POWER WINDOWS - DESCRIPTION......8N-23

POWER WINDOWS - DIAGNOSIS AND

TESTING...........................8N-23

POWER WINDOWS - OPERATION........8N-23

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-9

POWR-LOK - ASSEMBLY, DIFFERENTIAL . . . 3-99

POWR-LOK - DISASSEMBLY,

DIFFERENTIAL........................3-99

POWR-LOK - DIAGNOSIS AND TESTING . . . 3-99

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING.........................7-4

PRESSURE - DESCRIPTION, HOSES......19-39

PRESSURE - DIAGNOSIS AND TESTING,

BOOST.............................14-93

PRESSURE - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION...........9-64,9-9

PRESSURE - DIAGNOSIS AND TESTING,

ENGINE OIL................9-101,9-178,9-45

PRESSURE - DIAGNOSIS AND TESTING,

FUEL TRANSFER PUMP...............14-84

PRESSURE - DIAGNOSIS AND TESTING,

POWER STEERING FLOW.................19-4

PRESSURE - DIAGNOSIS AND TESTING,

TURBOCHARGER BOOST...............11-13

PRESSURE - GAS ENGINES -

SPECIFICATIONS, FUEL SYSTEM.........14-3

PRESSURE - OPERATION, HOSES........19-39

PRESSURE BLEEDING - STANDARD

PROCEDURE..........................5-8

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-64

PRESSURE CAP - OPERATION,

RADIATOR...........................7-64

PRESSURE FOR HIGH SPEEDS -

DESCRIPTION, TIRE...................22-7

PRESSURE FUEL LINES - DESCRIPTION,

HIGH..............................14-78

PRESSURE FUEL LINES - OPERATION,

HIGH..............................14-78

PRESSURE GAUGE - DESCRIPTION, OIL . . 8J-25

PRESSURE GAUGE - OPERATION, OIL....8J-25

PRESSURE GAUGES - DIAGNOSIS AND

TESTING............................22-8

PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING, FUEL.........14-2

PRESSURE LEAKAGE - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION....9-64,9-9

PRESSURE RELEASE - STANDARD

PROCEDURE, FUEL SYSTEM.............14-3

PRESSURE RELIEF VALVE - CLEANING,

OIL................................9-180

PRESSURE RELIEF VALVE -

DESCRIPTION, HIGH

..................24-46

PRESSURE RELIEF VALVE - INSPECTION,

OIL

................................9-180

PRESSURE RELIEF VALVE -

INSTALLATION, OIL

...................9-180

PRESSURE RELIEF VALVE - OPERATION,

HIGH

..............................24-47

PRESSURE RELIEF VALVE - REMOVAL,

OIL

................................9-180

PRESSURE SENSOR/SWITCH -

INSTALLATION, OIL

...................9-181

PRESSURE SENSOR/SWITCH -

REMOVAL, OIL

......................9-181

PRESSURE SWITCH - DESCRIPTION, A/C

HIGH

..............................24-20

PRESSURE SWITCH - DESCRIPTION, A/C

LOW

..............................24-21

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C HIGH

...................24-20

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C LOW

...................24-21

PRESSURE SWITCH - INSTALLATION,

A/C HIGH

...........................24-20

PRESSURE SWITCH - INSTALLATION,

A/C LOW

...........................24-21

BR/BEINDEX 23

Description Group-Page Description Group-Page Description Group-Page

Page 2241 of 2255

PRESSURE SWITCH - OPERATION, A/C

HIGH..............................24-20

PRESSURE SWITCH - OPERATION, A/C

LOW ..............................24-21

PRESSURE SWITCH - REMOVAL, A/C

HIGH..............................24-20

PRESSURE SWITCH - REMOVAL, A/C

LOW ..............................24-21

PRESSURE TEST - DIAGNOSIS AND

TESTING, FUEL PUMP..................14-9

PRESSURE TEST - DIAGNOSIS AND

TESTING, HYDRAULIC...........21-270,21-98

PRESSURES - DESCRIPTION, TIRE

INFLATION...........................22-7

PRESSURES, DIESEL ENGINES - FUEL

SYSTEM............................14-62

PROGRAMMING - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-8

PROPELLER SHAFT - DIAGNOSIS AND

TESTING.............................3-1

PROPELLER SHAFT - FRONT -

INSTALLATION.........................3-7

PROPELLER SHAFT - FRONT - REMOVAL . . . 3-6

PROPELLER SHAFT - REAR -

INSTALLATION.........................3-7

PROPELLER SHAFT - REAR - REMOVAL....3-7

PROPELLER SHAFT - STANDARD

PROCEDURES.........................3-3

PROPELLER SHAFT, SPECIAL TOOLS.......3-6

PROPELLER SHAFT, SPECIFICATIONS.......3-6

PTO SWITCH - DESCRIPTION...........14-47

PTO SWITCH - OPERATION..............14-47

PULLEY - INSTALLATION..............19-39

PULLEY - REMOVAL..................19-38

PUMP - 5.9L - CLEANING, WATER........7-68

PUMP - 5.9L - DESCRIPTION, WATER.....7-66

PUMP - 5.9L - INSPECTION, WATER......7-68

PUMP - 5.9L - INSTALLATION, WATER.....7-68

PUMP - 5.9L - OPERATION, WATER.......7-66

PUMP - 5.9L - REMOVAL, WATER........7-66

PUMP - 5.9L DIESEL - CLEANING,

WATER .............................7-72

PUMP - 5.9L DIESEL - DESCRIPTION,

VACUUM............................7-33

PUMP - 5.9L DIESEL - DESCRIPTION,

WATER .............................7-72

PUMP - 5.9L DIESEL - INSPECTION,

WATER .............................7-72

PUMP - 5.9L DIESEL - INSTALLATION,

VACUUM............................7-36

PUMP - 5.9L DIESEL - INSTALLATION,

WATER .............................7-72

PUMP - 5.9L DIESEL - OPERATION,

VACUUM............................7-34

PUMP - 5.9L DIESEL - OPERATION,

WATER .............................7-72

PUMP - 5.9L DIESEL - REMOVAL,

VACUUM............................7-34

PUMP - 5.9L DIESEL - REMOVAL,

WATER .............................7-72

PUMP - 8.0L - CLEANING, WATER........7-71

PUMP - 8.0L - INSPECTION, WATER......7-71

PUMP - 8.0L - INSTALLATION, WATER.....7-71

PUMP - 8.0L - REMOVAL, WATER........7-69

PUMP - ASSEMBLY, OIL................9-49

PUMP - ASSEMBLY, OIL........21-169,21-340

PUMP - CLEANING, OIL..........9-104,9-181

PUMP - CLEANING, OIL........21-168,21-338

PUMP - DESCRIPTION................19-33

PUMP - DESCRIPTION, AIR INJECTION . . . 25-29

PUMP - DESCRIPTION, FUEL

............14-9

PUMP - DESCRIPTION, FUEL TRANSFER

. . 14-83

PUMP - DESCRIPTION, LEAK DETECTION

. 25-34

PUMP - DESCRIPTION, OIL

......21-166,21-336

PUMP - DIAGNOSIS AND TESTING, AIR

INJECTION

..........................25-29

PUMP - DIAGNOSIS AND TESTING,

WATER

.....................7-66,7-69,7-72

PUMP - DISASSEMBLY, OIL

.............9-47

PUMP - DISASSEMBLY, OIL

.....21-167,21-337

PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER

STEERING

..........................19-33

PUMP - INSPECTION, OIL

.....9-104,9-181,9-47

PUMP - INSPECTION, OIL

.......21-168,21-339

PUMP - INSTALLATION, AIR INJECTION

. . . 25-30

PUMP - INSTALLATION, FUEL TRANSFER

. 14-87PUMP - INSTALLATION, LEAK

DETECTION.........................25-34

PUMP - INSTALLATION, OIL . . . 9-106,9-182,9-50

PUMP - OPERATION..................19-33

PUMP - OPERATION, AIR INJECTION.....25-29

PUMP - OPERATION, FUEL..............14-9

PUMP - OPERATION, FUEL TRANSFER....14-83

PUMP - OPERATION, LEAK DETECTION . . . 25-34

PUMP - OPERATION, OIL.......21-166,21-336

PUMP - REMOVAL, AIR INJECTION......25-30

PUMP - REMOVAL, FUEL TRANSFER.....14-86

PUMP - REMOVAL, LEAK DETECTION....25-34

PUMP - REMOVAL, OIL.......9-104,9-181,9-47

PUMP 235 H.P. - DESCRIPTION, FUEL....14-69

PUMP 245 H.P. - DESCRIPTION, FUEL....14-69

PUMP AMPERAGE TEST - DIAGNOSIS

AND TESTING, FUEL..................14-10

PUMP BYPASS HOSE WITH AIR

CONDITIONING - INSTALLATION,

WATER .............................7-76

PUMP BYPASS HOSE WITH AIR

CONDITIONING - REMOVAL, WATER......7-73

PUMP BYPASS HOSE WITHOUT AIR

CONDITIONING - INSTALLATION,

WATER .............................7-77

PUMP BYPASS HOSE WITHOUT AIR

CONDITIONING - REMOVAL, WATER......7-76

PUMP CAPACITY TEST - DIAGNOSIS

AND TESTING, FUEL...................14-9

PUMP DATA PLATE, SPECIFICATIONS -

FUEL INJECTION.....................14-77

PUMP FILTER - INSTALLATION, AIR......25-30

PUMP FILTER - REMOVAL, AIR.........25-30

PUMP LEAKAGE - DIAGNOSIS AND

TESTING...........................19-33

PUMP MODULE - DESCRIPTION, FUEL....14-12

PUMP MODULE - INSTALLATION, FUEL . . . 14-13

PUMP MODULE - OPERATION, FUEL.....14-13

PUMP MODULE - REMOVAL, FUEL.......14-13

PUMP OUTPUT - DIAGNOSIS AND

TESTING, VACUUM....................7-34

PUMP PRESSURE - DIAGNOSIS AND

TESTING, FUEL TRANSFER.............14-84

PUMP PRESSURE TEST - DIAGNOSIS

AND TESTING, FUEL...................14-9

PUMP RELAY - DESCRIPTION, FUEL.....14-40

PUMP RELAY - DESCRIPTION, FUEL

INJECTION.........................14-103

PUMP RELAY - INSTALLATION, FUEL.....14-40

PUMP RELAY - OPERATION, FUEL.......14-40

PUMP RELAY - OPERATION, FUEL

INJECTION.........................14-103

PUMP RELAY - REMOVAL, FUEL........14-40

PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD AND FUEL...............8I-4

PUMP, SPECIAL TOOLS - POWER

STEERING..........................19-38

PUMP TIMING - DIAGNOSIS AND

TESTING, FUEL INJECTION.............14-70

PUMP VOLUME CHECK - STANDARD

PROCEDURE, OIL.............21-166,21-336

PUMP/MOTOR - DESCRIPTION, WASHER . . 8R-9

PUMP/MOTOR - INSTALLATION,

WASHER...........................8R-10

PUMP/MOTOR - OPERATION, WASHER....8R-9

PUMP/MOTOR - REMOVAL, WASHER....8R-10

PUSHRODS - CLEANING...............9-134

PUSHRODS - INSPECTION.............9-135

QUARTER TRIM PANEL - INSTALLATION . 23-128

QUARTER TRIM PANEL - REMOVAL.....23-128

QUARTER WINDOW - INSTALLATION....23-150

QUARTER WINDOW - REMOVAL

........23-150

QUICK CONNECT FITTING -

DESCRIPTION

.......................14-24

QUICK-CONNECT FITTINGS - STANDARD

PROCEDURE

........................14-24

RADIAL-PLY TIRES - DESCRIPTION

.......22-6

RADIATOR - 5.9L - CLEANING

...........7-59

RADIATOR - 5.9L - DESCRIPTION

........7-58

RADIATOR - 5.9L - INSPECTION

..........7-60

RADIATOR - 5.9L - INSTALLATION

........7-60

RADIATOR - 5.9L - OPERATION

..........7-58

RADIATOR - 5.9L - REMOVAL

............7-58

RADIATOR - 5.9L DIESEL - CLEANING

.....7-64

RADIATOR - 5.9L DIESEL -

DESCRIPTION

........................7-62

RADIATOR - 5.9L DIESEL - INSPECTION

. . . 7-64RADIATOR - 5.9L DIESEL -

INSTALLATION........................7-64

RADIATOR - 5.9L DIESEL - OPERATION....7-62

RADIATOR - 5.9L DIESEL - REMOVAL.....7-62

RADIATOR - 8.0L - CLEANING...........7-61

RADIATOR - 8.0L - DESCRIPTION........7-60

RADIATOR - 8.0L - INSPECTION..........7-61

RADIATOR - 8.0L - INSTALLATION........7-61

RADIATOR - 8.0L - OPERATION..........7-60

RADIATOR - 8.0L - REMOVAL............7-60

RADIATOR CAP - DIAGNOSIS AND

TESTING............................7-65

RADIATOR CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING..............7-65

RADIATOR COOLANT FLOW -

DIAGNOSIS AND TESTING......7-58,7-60,7-62

RADIATOR FAN - 5.9L DIESEL -

CLEANING...........................7-43

RADIATOR FAN - 5.9L DIESEL -

INSPECTION.........................7-43

RADIATOR FAN - 5.9L DIESEL -

INSTALLATION........................7-44

RADIATOR FAN - 5.9L DIESEL -

REMOVAL...........................7-43

RADIATOR FAN - 5.9L/8.0L - CLEANING....7-42

RADIATOR FAN - 5.9L/8.0L -

INSPECTION.........................7-42

RADIATOR FAN - 5.9L/8.0L -

INSTALLATION........................7-42

RADIATOR FAN - 5.9L/8.0L - REMOVAL....7-41

RADIATOR PRESSURE CAP -

DESCRIPTION........................7-64

RADIATOR PRESSURE CAP - OPERATION . . 7-64

RADIO - DESCRIPTION................8A-10

RADIO - DIAGNOSIS AND TESTING......8A-10

RADIO - INSTALLATION...............8A-11

RADIO - OPERATION..................8A-10

RADIO - REMOVAL...................8A-11

RADIO CHOKE RELAY - DESCRIPTION.....8A-7

RADIO CHOKE RELAY - DIAGNOSIS AND

TESTING............................8A-8

RADIO CHOKE RELAY - INSTALLATION....8A-9

RADIO CHOKE RELAY - OPERATION.......8A-8

RADIO CHOKE RELAY - REMOVAL........8A-8

RADIO NOISE SUPPRESSION

COMPONENTS - DESCRIPTION..........8A-12

RADIO NOISE SUPPRESSION

COMPONENTS - DIAGNOSIS AND

TESTING...........................8A-12

RATINGS, SPECIFICATIONS -

GENERATOR........................8F-26

RBI - REAR AXLE, 286................3-120

RE TRANSMISSION, SPECIAL TOOLS . . . 21-146,

21-316

READING LAMP - DESCRIPTION.........8L-36

READING LAMP - INSTALLATION........8L-37

READING LAMP - OPERATION..........8L-36

READING LAMP - REMOVAL............8L-36

REAR - DESCRIPTION..................2-25

REAR - DESCRIPTION, CRANKSHAFT OIL

SEAL...............................9-33

REAR - INSTALLATION.........5-14,5-22,5-25

REAR - INSTALLATION................22-12

REAR - INSTALLATION, CRANKSHAFT

OIL SEAL...................9-162,9-34,9-90

REAR - INSTALLATION, PROPELLER

SHAFT...............................3-7

REAR - OPERATION, CRANKSHAFT OIL

SEAL...............................9-33

REAR - REMOVAL.............5-10,5-21,5-23

REAR - REMOVAL, CRANKSHAFT OIL

SEAL......................9-161,9-33,9-90

REAR - REMOVAL, PROPELLER SHAFT.....3-7

REAR AXLE - 248RBI - ADJUSTMENTS....3-51

REAR AXLE - 248RBI - DESCRIPTION.....3-46

REAR AXLE - 248RBI - INSTALLATION.....3-51

REAR AXLE - 248RBI - OPERATION.......3-46

REAR AXLE - 248RBI - REMOVAL........3-51

REAR AXLE - 267RBI - ADJUSTMENTS....3-83

REAR AXLE - 267RBI - DESCRIPTION.....3-78

REAR AXLE - 267RBI - INSTALLATION.....3-82

REAR AXLE - 267RBI - OPERATION.......3-78

REAR AXLE - 267RBI - REMOVAL........3-82

REAR AXLE - 286RBI - ADJUSTMENTS

. . . 3-112

REAR AXLE - 286RBI - DESCRIPTION

....3-107

REAR AXLE - 286RBI - INSTALLATION

....3-112

REAR AXLE - 286RBI - OPERATION

......3-108

REAR AXLE - 286RBI - REMOVAL

.......3-112

24 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2247 of 2255

SUPPLY RESTRICTIONS - DIAGNOSIS

AND TESTING, FUEL..................14-60

SUPPLY TEST - DIAGNOSIS AND

TESTING, VACUUM....................8P-3

SUPPORT - INSTALLATION, LUMBAR....23-133

SUPPORT - REMOVAL, LUMBAR.......23-132

SUPPORT BRACKET - INSTALLATION,

REARVIEW MIRROR.................23-126

SUPPRESSION COMPONENTS -

DESCRIPTION, RADIO NOISE...........8A-12

SUPPRESSION COMPONENTS -

DIAGNOSIS AND TESTING, RADIO

NOISE.............................8A-12

SUSPENSION - STANDARD PROCEDURE,

ALIGNMENT LINK/COIL..................2-5

SUSPENSION, SPECIAL TOOLS -

INDEPENDENT FRONT...................2-9

SUSPENSION, SPECIAL TOOLS -

LINK/COIL...........................2-16

SUSPENSION-REAR, SPECIAL TOOLS.....2-27

SWITCH - DESCRIPTION...............8P-12

SWITCH - DESCRIPTION, A/C HIGH

PRESSURE.........................24-20

SWITCH - DESCRIPTION, A/C LOW

PRESSURE.........................24-21

SWITCH - DESCRIPTION, BLOWER

MOTOR............................24-24

SWITCH - DESCRIPTION, BRAKE LAMP....8L-4

SWITCH - DESCRIPTION, CLUTCH

PEDAL POSITION.....................6-17

SWITCH - DESCRIPTION, DOOR AJAR....8L-34

SWITCH - DESCRIPTION, DOOR

CYLINDER LOCK......................8N-5

SWITCH - DESCRIPTION, DRIVER

POWER SEAT.......................8N-17

SWITCH - DESCRIPTION, DRIVER SEAT

HEATER.............................8G-7

SWITCH - DESCRIPTION, HEADLAMP....8L-18

SWITCH - DESCRIPTION, HORN..........8H-4

SWITCH - DESCRIPTION, IGNITION......19-11

SWITCH - DESCRIPTION, KEY-IN

IGNITION............................19-9

SWITCH - DESCRIPTION, LUMBAR

CONTROL..........................8N-18

SWITCH - DESCRIPTION, MIRROR........8G-2

SWITCH - DESCRIPTION, MULTI-

FUNCTION..........................8L-23

SWITCH - DESCRIPTION, OVERDRIVE . . . 21-190,

21-344

SWITCH - DESCRIPTION, PASSENGER

AIRBAG ON/OFF.....................8O-23

SWITCH - DESCRIPTION, PASSENGER

POWER SEAT.......................8N-20

SWITCH - DESCRIPTION, PASSENGER

SEAT HEATER .......................8G-16

SWITCH - DESCRIPTION, POWER LOCK . . . 8N-8

SWITCH - DESCRIPTION, POWER

MIRROR...........................8N-13

SWITCH - DESCRIPTION, POWER

WINDOW...........................8N-24

SWITCH - DESCRIPTION, PTO..........14-47

SWITCH - DESCRIPTION, SEAT BELT.....8O-28

SWITCH - DESCRIPTION, WASHER

FLUID LEVEL.........................8R-7

SWITCH - DIAGNOSIS AND TESTING,

A/C HIGH PRESSURE.................24-20

SWITCH - DIAGNOSIS AND TESTING,

A/C LOW PRESSURE..................24-21

SWITCH - DIAGNOSIS AND TESTING,

BLOWER MOTOR....................24-25

SWITCH - DIAGNOSIS AND TESTING,

BRAKE LAMP........................8L-5

SWITCH - DIAGNOSIS AND TESTING,

DOOR AJAR.........................8L-34

SWITCH - DIAGNOSIS AND TESTING,

DOOR CYLINDER LOCK................8N-6

SWITCH - DIAGNOSIS AND TESTING,

DRIVER POWER SEAT................8N-17

SWITCH - DIAGNOSIS AND TESTING,

HEADLAMP

.........................8L-19

SWITCH - DIAGNOSIS AND TESTING,

HEATED MIRROR

.....................8G-3

SWITCH - DIAGNOSIS AND TESTING,

HEATED SEAT

...................8G-17,8G-8

SWITCH - DIAGNOSIS AND TESTING,

HORN

..............................8H-5

SWITCH - DIAGNOSIS AND TESTING,

IGNITION

...........................19-11SWITCH - DIAGNOSIS AND TESTING,

MULTI-FUNCTION....................8L-25

SWITCH - DIAGNOSIS AND TESTING,

PARK/NEUTRAL POSITION......21-195,21-367

SWITCH - DIAGNOSIS AND TESTING,

PASSENGER POWER SEAT.............8N-20

SWITCH - DIAGNOSIS AND TESTING,

POWER LOCK........................8N-9

SWITCH - DIAGNOSIS AND TESTING,

POWER WINDOW....................8N-24

SWITCH - DIAGNOSIS AND TESTING,

SEAT BELT .........................8O-28

SWITCH - INSTALLATION..............8P-14

SWITCH - INSTALLATION, A/C HIGH

PRESSURE.........................24-20

SWITCH - INSTALLATION, A/C LOW

PRESSURE.........................24-21

SWITCH - INSTALLATION, BRAKE LAMP . . . 8L-6

SWITCH - INSTALLATION, DOOR AJAR . . . 8L-35

SWITCH - INSTALLATION, DOOR

CYLINDER LOCK......................8N-6

SWITCH - INSTALLATION, DRIVER

POWER SEAT.......................8N-18

SWITCH - INSTALLATION, DRIVER SEAT

HEATER............................8G-10

SWITCH - INSTALLATION, GLOVE BOX

LAMP..............................8L-36

SWITCH - INSTALLATION, HEADLAMP....8L-20

SWITCH - INSTALLATION, IGNITION......19-12

SWITCH - INSTALLATION, MULTI-

FUNCTION..........................8L-28

SWITCH - INSTALLATION, OVERDRIVE....21-191,

21-345

SWITCH - INSTALLATION, PARK/

NEUTRAL POSITION...........21-195,21-367

SWITCH - INSTALLATION, PASSENGER

AIRBAG ON/OFF.....................8O-25

SWITCH - INSTALLATION, PASSENGER

POWER SEAT.......................8N-21

SWITCH - INSTALLATION, PASSENGER

SEAT HEATER .......................8G-19

SWITCH - INSTALLATION, POWER

MIRROR...........................8N-14

SWITCH - INSTALLATION, POWER

WINDOW...........................8N-26

SWITCH - INSTALLATION, WASHER

FLUID LEVEL.........................8R-8

SWITCH - OPERATION................8P-12

SWITCH - OPERATION, A/C HIGH

PRESSURE.........................24-20

SWITCH - OPERATION, A/C LOW

PRESSURE.........................24-21

SWITCH - OPERATION, BLOWER MOTOR . . 24-24

SWITCH - OPERATION, BRAKE LAMP......8L-4

SWITCH - OPERATION, CLUTCH PEDAL

POSITION...........................6-17

SWITCH - OPERATION, DOOR CYLINDER

LOCK...............................8N-5

SWITCH - OPERATION, DRIVER POWER

SEAT ..............................8N-17

SWITCH - OPERATION, DRIVER SEAT

HEATER.............................8G-8

SWITCH - OPERATION, HEADLAMP......8L-18

SWITCH - OPERATION, HORN...........8H-5

SWITCH - OPERATION, IGNITION........19-11

SWITCH - OPERATION, LUMBAR

CONTROL..........................8N-19

SWITCH - OPERATION, MIRROR.........8G-3

SWITCH - OPERATION, MULTI-FUNCTION

. 8L-24

SWITCH - OPERATION, OVERDRIVE

....21-190,

21-344

SWITCH - OPERATION, PASSENGER

AIRBAG ON/OFF

.....................8O-24

SWITCH - OPERATION, PASSENGER

POWER SEAT

.......................8N-20

SWITCH - OPERATION, PASSENGER

SEAT HEATER

.......................8G-17

SWITCH - OPERATION, POWER LOCK

.....8N-8

SWITCH - OPERATION, POWER MIRROR

. . 8N-13

SWITCH - OPERATION, POWER WINDOW

. 8N-24

SWITCH - OPERATION, PTO

............14-47

SWITCH - OPERATION, SEAT BELT

.......8O-28

SWITCH - OPERATION, WASHER FLUID

LEVEL

..............................8R-7

SWITCH - REMOVAL

..................8P-13

SWITCH - REMOVAL, A/C HIGH

PRESSURE

.........................24-20SWITCH - REMOVAL, A/C LOW

PRESSURE.........................24-21

SWITCH - REMOVAL, BLOWER MOTOR . . . 24-25

SWITCH - REMOVAL, BRAKE LAMP.......8L-5

SWITCH - REMOVAL, DOOR AJAR.......8L-35

SWITCH - REMOVAL, DOOR CYLINDER

LOCK...............................8N-6

SWITCH - REMOVAL, DRIVER POWER

SEAT ..............................8N-18

SWITCH - REMOVAL, DRIVER SEAT

HEATER.............................8G-9

SWITCH - REMOVAL, GLOVE BOX LAMP . . 8L-35

SWITCH - REMOVAL, HEADLAMP........8L-19

SWITCH - REMOVAL, HORN.............8H-5

SWITCH - REMOVAL, IGNITION.........19-12

SWITCH - REMOVAL, LUMBAR

CONTROL..........................8N-19

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-27

SWITCH - REMOVAL, OVERDRIVE......21-191,

21-344

SWITCH - REMOVAL, PARK/NEUTRAL

POSITION...................21-195,21-367

SWITCH - REMOVAL, PASSENGER

AIRBAG ON/OFF.....................8O-24

SWITCH - REMOVAL, PASSENGER

POWER SEAT.......................8N-21

SWITCH - REMOVAL, PASSENGER SEAT

HEATER............................8G-18

SWITCH - REMOVAL, POWER MIRROR . . . 8N-13

SWITCH - REMOVAL, POWER WINDOW . . 8N-25

SWITCH - REMOVAL, WASHER FLUID

LEVEL..............................8R-8

SWITCH AND KEY LOCK CYLINDER -

DIAGNOSIS AND TESTING, IGNITION......19-9

SWITCHES - DESCRIPTION, REMOTE.....8A-14

SWITCHES - DIAGNOSIS AND TESTING,

REMOTE...........................8A-15

SWITCHES - INSTALLATION, REMOTE....8A-16

SWITCHES - OPERATION, REMOTE......8A-15

SWITCHES - REMOVAL, REMOTE........8A-16

SYMBOLS - DESCRIPTION,

INTERNATIONAL....................Intro.-5

SYMBOLS - DESCRIPTION,

INTERNATIONAL.......................0-1

SYSTEM - CLEANING, BATTERY..........8F-5

SYSTEM - CLEANING, WIPER &

WASHER............................8R-6

SYSTEM - DESCRIPTION, AIR INJECTION . 25-26

SYSTEM - DESCRIPTION, BATTERY.......8F-1

SYSTEM - DESCRIPTION, CHIME

WARNING...........................8B-1

SYSTEM - DESCRIPTION, DIESEL FUEL

DELIVERY..........................14-55

SYSTEM - DESCRIPTION, DIESEL FUEL

INJECTION..........................14-91

SYSTEM - DESCRIPTION, EVAP.........25-32

SYSTEM - DESCRIPTION, FUEL

DELIVERY...........................14-2

SYSTEM - DESCRIPTION, HEATED

MIRROR............................8G-1

SYSTEM - DESCRIPTION, HEATED SEAT . . . 8G-5

SYSTEM - DESCRIPTION, INSTRUMENT

PANEL............................23-105

SYSTEM - DESCRIPTION, METRIC

......Intro.-9

SYSTEM - DESCRIPTION, POWER SEAT

. . 8N-16

SYSTEM - DESCRIPTION, REMOTE

KEYLESS ENTRY

......................8N-2

SYSTEM - DESCRIPTION, SPEED

CONTROL

...........................8P-1

SYSTEM - DESCRIPTION, TURN SIGNAL

& HAZARD WARNING

..................8L-2

SYSTEM - DIAGNOSIS AND TESTING,

AIR IN FUEL

........................14-60

SYSTEM - DIAGNOSIS AND TESTING,

AIRBAG

.............................8O-4

SYSTEM - DIAGNOSIS AND TESTING,

BASE BRAKE

..........................5-5

SYSTEM - DIAGNOSIS AND TESTING,

BATTERY

............................8F-2

SYSTEM - DIAGNOSIS AND TESTING,

CHARGING

..........................8F-25

SYSTEM - DIAGNOSIS AND TESTING,

CHIME WARNING

.....................8B-2

SYSTEM - DIAGNOSIS AND TESTING,

HEATED MIRROR

.....................8G-2

SYSTEM - DIAGNOSIS AND TESTING,

HEATED SEAT

........................8G-6

30 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2251 of 2255

VAPOR CANISTER - INSTALLATION......25-38

VAPOR CANISTER - INSTALLATION,

CRANKCASE BREATHER...............9-126

VAPOR CANISTER - OPERATION.........25-37

VAPOR CANISTER - REMOVAL..........25-38

VAPOR CANISTER - REMOVAL,

CRANKCASE BREATHER...............9-125

VARIATION ADJUSTMENT - STANDARD

PROCEDURE, COMPASS...............8M-4

VEHICLE EMISSION CONTROL

INFORMATION (VECI) - DESCRIPTION . . . Intro.-3

VEHICLE IDENTIFICATION NUMBER -

DESCRIPTION......................Intro.-1

VEHICLE SAFETY CERTIFICATION LABEL

- DESCRIPTION.....................Intro.-1

VEHICLE SPEED INPUT - DESCRIPTION....8P-2

VEHICLE THEFT SECURITY -

DESCRIPTION........................8Q-1

VEHICLE THEFT SECURITY - OPERATION . . 8Q-2

VEHICLE THEFT SECURITY SYSTEM -

DIAGNOSIS AND TESTING..............8Q-3

VENT - INSTALLATION, BODY..........23-126

VENT - INSTALLATION, EXHAUST........23-79

VENT - REMOVAL, BODY.............23-126

VENT - REMOVAL, EXHAUST...........23-79

VENT GLASS - INSTALLATION, BACKLITE . 23-146

VENT GLASS - REMOVAL, BACKLITE....23-146

VENT WINDOW - INSTALLATION........23-85

VENT WINDOW - REMOVAL............23-85

VIBRATION - DIAGNOSIS AND TESTING,

TIRE NOISE OR.......................22-9

VIBRATION DAMPER - INSPECTION......9-172

VIBRATION DAMPER - INSTALLATION....9-173,

9-40,9-97

VIBRATION DAMPER - REMOVAL . . . 9-172,9-40,

9-96

VIEW MIRROR - INSTALLATION, SIDE....23-98

VIEW MIRROR - LOW MOUNTED -

INSTALLATION, SIDE..................23-98

VIEW MIRROR - LOW MOUNTED -

REMOVAL, SIDE.....................23-98

VIEW MIRROR - REMOVAL, REAR......23-126

VIEW MIRROR - REMOVAL, SIDE........23-97

VIEW MIRROR FLAG - INSTALLATION,

SIDE..............................23-75

VIEW MIRROR FLAG - REMOVAL, SIDE . . . 23-74

VIEW MIRROR GLASS - INSTALLATION,

SIDE..............................23-98

VIEW MIRROR GLASS - REMOVAL, SIDE . . 23-98

VISCOUS CLUTCH - 5.9L DIESEL -

DESCRIPTION, FAN DRIVE..............7-56

VISCOUS CLUTCH - 5.9L DIESEL -

OPERATION, FAN DRIVE................7-56

VISCOUS CLUTCH - 5.9L/8.0L -

DESCRIPTION, FAN DRIVE..............7-55

VISCOUS CLUTCH - 5.9L/8.0L -

OPERATION, FAN DRIVE................7-55

VISCOUS FAN DRIVE - DIAGNOSIS AND

TESTING........................7-55,7-57

VISOR - INSTALLATION, SUN..........23-127

VISOR - REMOVAL, SUN..............23-127

VISUAL INSPECTION, 5.9L ENGINES.....14-29

VISUAL INSPECTION, 8.0L ENGINE......14-32

VOLT SUPPLIES - DESCRIPTION, 5......8E-17

VOLT SUPPLIES - OPERATION, 5........8E-19

VOLTAGE DROP - STANDARD

PROCEDURE, TESTING FOR A........8W-01-9

VOLTAGE GAUGE - DESCRIPTION........8J-33

VOLTAGE GAUGE - OPERATION..........8J-33

VOLTAGE POTENTIAL - STANDARD

PROCEDURE, TESTING OF...........8W-01-8

VOLTAGE REGULATOR - DESCRIPTION....8F-30

VOLTAGE REGULATOR - OPERATION.....8F-30

VOLTAGE TEST - STANDARD

PROCEDURE, OPEN-CIRCUIT...........8F-12

VOLUME CHECK - STANDARD

PROCEDURE, OIL PUMP........21-166,21-336

VTSS INDICATOR - DESCRIPTION........8Q-3

VTSS INDICATOR - DIAGNOSIS AND

TESTING............................8Q-4

VTSS INDICATOR - OPERATION

..........8Q-3

WAIT-TO-START INDICATOR -

DESCRIPTION

.......................8J-34

WAIT-TO-START INDICATOR -

OPERATION

.........................8J-34

WARNING - SAFETY PRECAUTIONS AND

WARNINGS

..........................23-1

WARNING, CLUTCH

.....................6-2WARNING, HYDRAULIC/MECHANICAL......5-4

WARNING, RESTRAINTS................8O-3

WARNING SYSTEM - DESCRIPTION,

CHIME..............................8B-1

WARNING SYSTEM - DESCRIPTION,

TURN SIGNAL & HAZARD...............8L-2

WARNING SYSTEM - DIAGNOSIS AND

TESTING, CHIME......................8B-2

WARNING SYSTEM - DIAGNOSIS AND

TESTING, TURN SIGNAL & HAZARD.......8L-3

WARNING SYSTEM - OPERATION,

CHIME..............................8B-1

WARNING SYSTEM - OPERATION, TURN

SIGNAL & HAZARD....................8L-2

WARNINGS, GENERAL..............8W-01-7

WARNINGS, PLUMBING - SERVICE......24-42

WARNINGS, WARNING - SAFETY

PRECAUTIONS........................23-1

WASHER FLUID INDICATOR -

DESCRIPTION.......................8J-35

WASHER FLUID INDICATOR -

DIAGNOSIS AND TESTING..............8J-35

WASHER FLUID INDICATOR -

OPERATION.........................8J-35

WASHER FLUID LEVEL SWITCH -

DESCRIPTION........................8R-7

WASHER FLUID LEVEL SWITCH -

INSTALLATION.......................8R-8

WASHER FLUID LEVEL SWITCH -

OPERATION..........................8R-7

WASHER FLUID LEVEL SWITCH -

REMOVAL...........................8R-8

WASHER HOSES/TUBES - DESCRIPTION . . . 8R-8

WASHER HOSES/TUBES - OPERATION.....8R-8

WASHER NOZZLE - DESCRIPTION........8R-9

WASHER NOZZLE - INSTALLATION.......8R-9

WASHER NOZZLE - OPERATION..........8R-9

WASHER NOZZLE - REMOVAL...........8R-9

WASHER PUMP/MOTOR - DESCRIPTION . . . 8R-9

WASHER PUMP/MOTOR - INSTALLATION . 8R-10

WASHER PUMP/MOTOR - OPERATION....8R-9

WASHER PUMP/MOTOR - REMOVAL.....8R-10

WASHER RESERVOIR - DESCRIPTION....8R-10

WASHER RESERVOIR - INSTALLATION . . . 8R-11

WASHER RESERVOIR - OPERATION......8R-10

WASHER RESERVOIR - REMOVAL.......8R-10

WASHER SYSTEM - CLEANING, WIPER....8R-6

WASHER SYSTEM - DIAGNOSIS AND

TESTING, WIPER.....................8R-3

WASHER SYSTEM - INSPECTION, WIPER . . 8R-6

WATER DRAINING AT FUEL FILTER -

STANDARD PROCEDURES..............14-61

WATER IN FUEL SENSOR -

DESCRIPTION.......................14-89

WATER IN FUEL SENSOR - OPERATION . . . 14-89

WATER IN FUEL SENSOR - REMOVAL....14-89

WATER LEAKS - DIAGNOSIS AND

TESTING............................23-2

WATER PUMP - 5.9L - CLEANING........7-68

WATER PUMP - 5.9L - DESCRIPTION......7-66

WATER PUMP - 5.9L - INSPECTION.......7-68

WATER PUMP - 5.9L - INSTALLATION.....7-68

WATER PUMP - 5.9L - OPERATION.......7-66

WATER PUMP - 5.9L - REMOVAL.........7-66

WATER PUMP - 5.9L DIESEL -

CLEANING...........................7-72

WATER PUMP - 5.9L DIESEL -

DESCRIPTION

........................7-72

WATER PUMP - 5.9L DIESEL -

INSPECTION

.........................7-72

WATER PUMP - 5.9L DIESEL -

INSTALLATION

........................7-72

WATER PUMP - 5.9L DIESEL -

OPERATION

..........................7-72

WATER PUMP - 5.9L DIESEL - REMOVAL

. . 7-72

WATER PUMP - 8.0L - CLEANING

........7-71

WATER PUMP - 8.0L - INSPECTION

.......7-71

WATER PUMP - 8.0L - INSTALLATION

.....7-71

WATER PUMP - 8.0L - REMOVAL

.........7-69

WATER PUMP - DIAGNOSIS AND

TESTING

....................7-66,7-69,7-72

WATER PUMP BYPASS HOSE WITH AIR

CONDITIONING - INSTALLATION

..........7-76

WATER PUMP BYPASS HOSE WITH AIR

CONDITIONING - REMOVAL

.............7-73

WATER PUMP BYPASS HOSE WITHOUT

AIR CONDITIONING - INSTALLATION

......7-77WATER PUMP BYPASS HOSE WITHOUT

AIR CONDITIONING - REMOVAL..........7-76

WATER SEPARATOR - DESCRIPTION,

FUEL FILTER........................14-63

WATER SEPARATOR - INSTALLATION,

FUEL FILTER........................14-65

WATER SEPARATOR - OPERATION, FUEL

FILTER.............................14-63

WATER SEPARATOR - REMOVAL, FUEL

FILTER.............................14-64

WATER TO OIL COOLER - REMOVAL......7-86

WATERDAM - INSTALLATION......23-76,23-85

WATERDAM - REMOVAL..........23-76,23-85

WATER-IN-FUEL INDICATOR -

DESCRIPTION.......................8J-36

WATER-IN-FUEL INDICATOR -

OPERATION.........................8J-36

WEAR INDICATORS - DIAGNOSIS AND

TESTING, TREAD......................22-8

WEAR PATTERNS - DIAGNOSIS AND

TESTING, TIRE.......................22-8

WEATHERSTRIP - INSTALLATION, COWL . 23-152

WEATHERSTRIP - INSTALLATION, FRONT

DOOR GLASS RUN..................23-153

WEATHERSTRIP - INSTALLATION, FRONT

DOOR INNER BELT..................23-153

WEATHERSTRIP - INSTALLATION, FRONT

DOOR OUTER BELT..................23-153

WEATHERSTRIP - INSTALLATION, FRONT

DOOR SECOND.....................23-154

WEATHERSTRIP - REMOVAL, COWL.....23-152

WEATHERSTRIP - REMOVAL, FRONT

DOOR GLASS RUN..................23-152

WEATHERSTRIP - REMOVAL, FRONT

DOOR INNER BELT..................23-153

WEATHERSTRIP - REMOVAL, FRONT

DOOR OUTER BELT..................23-153

WEATHERSTRIP - REMOVAL, FRONT

DOOR SECOND.....................23-154

WELD LOCATIONS, SPECIFICATIONS......23-4

WET SANDING/BUFFING & POLISHING -

DESCRIPTION......................23-130

WHEEL - INSTALLATION, STEERING......19-15

WHEEL - REMOVAL, STEERING.........19-15

WHEEL ALIGNMENT - DESCRIPTION.......2-1

WHEEL ALIGNMENT - OPERATION.........2-2

WHEEL BALANCE - STANDARD

PROCEDURE, TIRE....................22-4

WHEEL COVER - REMOVAL............22-12

WHEEL INSPECTION, DIAGNOSIS AND

TESTING...........................22-11

WHEEL INSTALLATION - STANDARD

PROCEDURE, DUAL REAR.............22-11

WHEEL RUNOUT - DIAGNOSIS AND

TESTING, TIRE.......................22-1

WHEEL SPEED SENSOR - DESCRIPTION,

FRONT..............................5-38

WHEEL SPEED SENSOR - DIAGNOSIS

AND TESTING, REAR...................5-40

WHEEL SPEED SENSOR -

INSTALLATION, REAR..................5-40

WHEEL SPEED SENSOR - OPERATION,

FRONT..............................5-38

WHEEL SPEED SENSOR - REMOVAL,

REAR...............................5-40

WHEELHOUSE LINER - INSTALLATION,

REAR..............................23-96

WHEELHOUSE LINER - REMOVAL, REAR . . 23-96

WHEELS - DESCRIPTION..............22-10

WHEELS - OPERATION................22-10

WIND NOISE - DIAGNOSIS AND TESTING . . 23-3

WINDOW - INSTALLATION, QUARTER . . . 23-150

WINDOW - INSTALLATION, VENT........23-85

WINDOW - REMOVAL, QUARTER.......23-150

WINDOW - REMOVAL, VENT............23-85

WINDOW MOTOR - DESCRIPTION.......8N-26

WINDOW MOTOR - DIAGNOSIS AND

TESTING...........................8N-26

WINDOW MOTOR - REMOVAL..........8N-26

WINDOW REGULATOR - INSTALLATION . . . 23-76

WINDOW REGULATOR - REMOVAL

......23-76

WINDOW SWITCH - DESCRIPTION,

POWER

............................8N-24

WINDOW SWITCH - DIAGNOSIS AND

TESTING, POWER

....................8N-24

WINDOW SWITCH - INSTALLATION,

POWER

............................8N-26

WINDOW SWITCH - OPERATION, POWER

. 8N-24

34 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2252 of 2255

WINDOW SWITCH - REMOVAL, POWER . . 8N-25

WINDOWS - DESCRIPTION, POWER.....8N-23

WINDOWS - DIAGNOSIS AND TESTING,

POWER............................8N-23

WINDOWS - OPERATION, POWER.......8N-23

WINDSHIELD - DESCRIPTION..........23-147

WINDSHIELD - INSTALLATION.........23-148

WINDSHIELD - REMOVAL.............23-147

WIPER & WASHER SYSTEM - CLEANING . . 8R-6

WIPER & WASHER SYSTEM -

DIAGNOSIS AND TESTING..............8R-3

WIPER & WASHER SYSTEM -

INSPECTION.........................8R-6

WIPER ARM - DESCRIPTION...........8R-11

WIPER ARM - INSTALLATION...........8R-12

WIPER ARM - OPERATION.............8R-11

WIPER ARM - REMOVAL..............8R-12

WIPER BLADE - DESCRIPTION..........8R-12

WIPER BLADE - INSTALLATION.........8R-13WIPER BLADE - OPERATION...........8R-13

WIPER BLADE - REMOVAL.............8R-13

WIPER MODULE - DESCRIPTION........8R-13