manual transmission DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1 of 2255

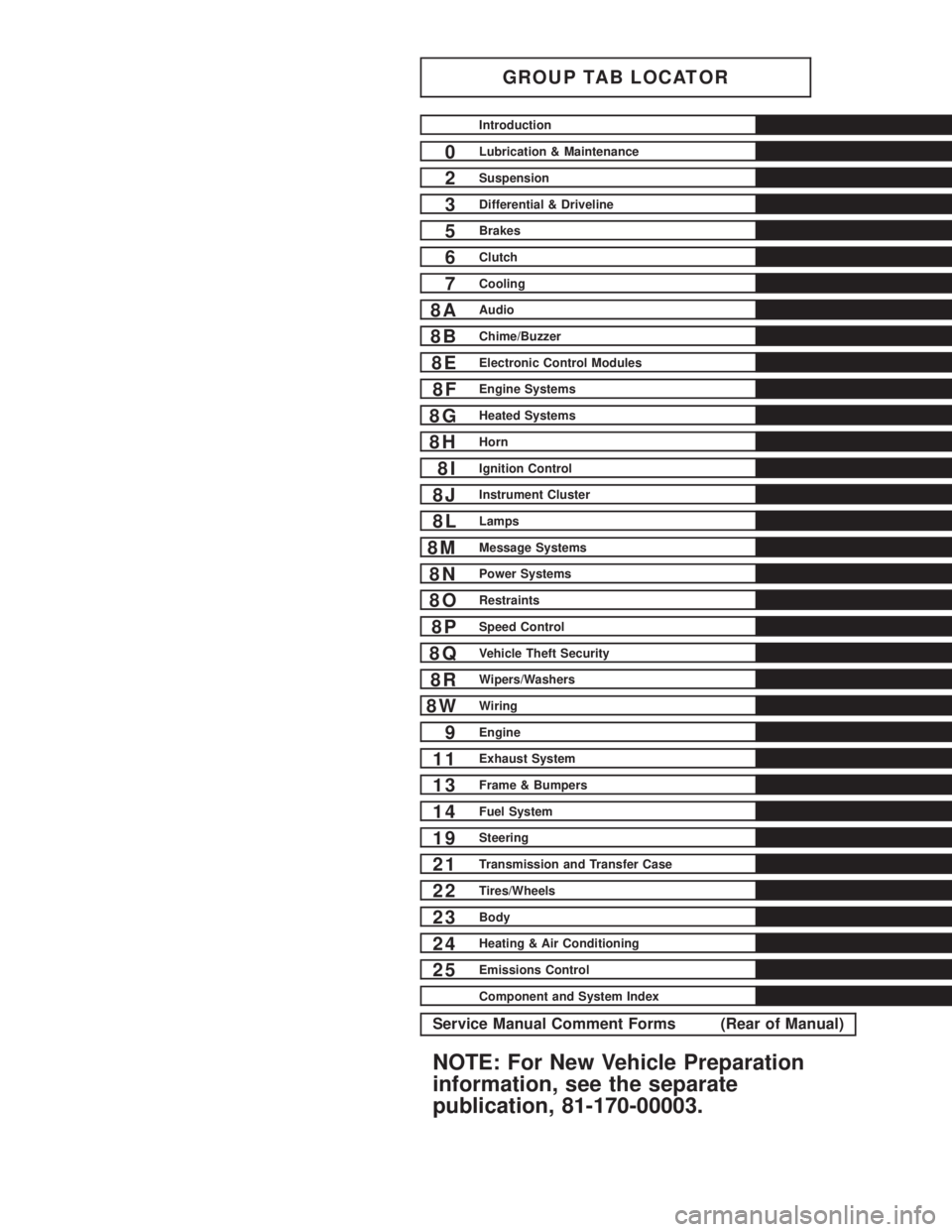

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

6Clutch

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission and Transfer Case

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

NOTE: For New Vehicle Preparation

information, see the separate

publication, 81-170-00003.

Page 5 of 2255

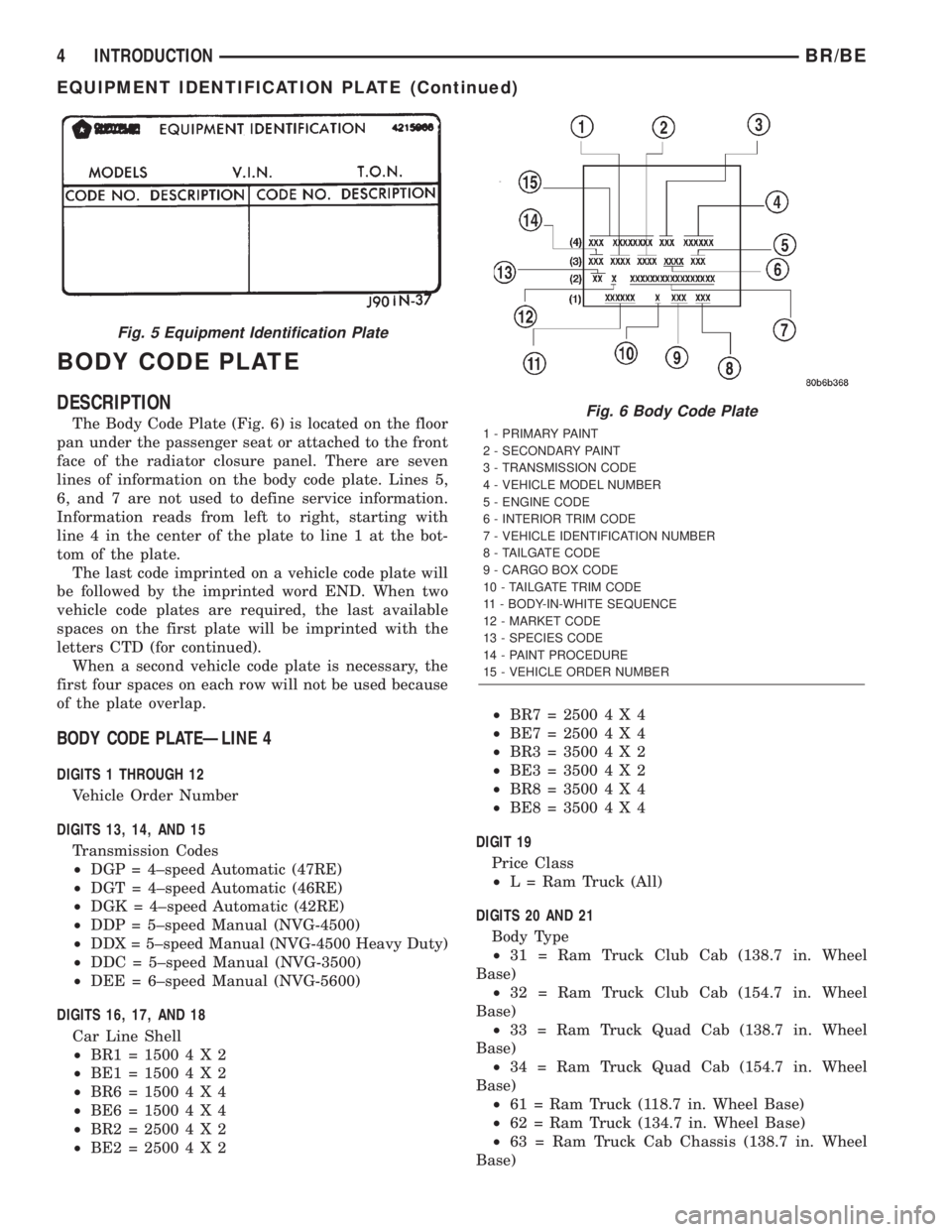

BODY CODE PLATE

DESCRIPTION

The Body Code Plate (Fig. 6) is located on the floor

pan under the passenger seat or attached to the front

face of the radiator closure panel. There are seven

lines of information on the body code plate. Lines 5,

6, and 7 are not used to define service information.

Information reads from left to right, starting with

line 4 in the center of the plate to line 1 at the bot-

tom of the plate.

The last code imprinted on a vehicle code plate will

be followed by the imprinted word END. When two

vehicle code plates are required, the last available

spaces on the first plate will be imprinted with the

letters CTD (for continued).

When a second vehicle code plate is necessary, the

first four spaces on each row will not be used because

of the plate overlap.

BODY CODE PLATEÐLINE 4

DIGITS 1 THROUGH 12

Vehicle Order Number

DIGITS 13, 14, AND 15

Transmission Codes

²DGP = 4±speed Automatic (47RE)

²DGT = 4±speed Automatic (46RE)

²DGK = 4±speed Automatic (42RE)

²DDP = 5±speed Manual (NVG-4500)

²DDX = 5±speed Manual (NVG-4500 Heavy Duty)

²DDC = 5±speed Manual (NVG-3500)

²DEE = 6±speed Manual (NVG-5600)

DIGITS 16, 17, AND 18

Car Line Shell

²BR1=15004X2

²BE1=15004X2

²BR6=15004X4

²BE6=15004X4

²BR2=25004X2

²BE2=25004X2²BR7=25004X4

²BE7=25004X4

²BR3=35004X2

²BE3=35004X2

²BR8=35004X4

²BE8=35004X4

DIGIT 19

Price Class

²L = Ram Truck (All)

DIGITS 20 AND 21

Body Type

²31 = Ram Truck Club Cab (138.7 in. Wheel

Base)

²32 = Ram Truck Club Cab (154.7 in. Wheel

Base)

²33 = Ram Truck Quad Cab (138.7 in. Wheel

Base)

²34 = Ram Truck Quad Cab (154.7 in. Wheel

Base)

²61 = Ram Truck (118.7 in. Wheel Base)

²62 = Ram Truck (134.7 in. Wheel Base)

²63 = Ram Truck Cab Chassis (138.7 in. Wheel

Base)

Fig. 5 Equipment Identification Plate

Fig. 6 Body Code Plate

1 - PRIMARY PAINT

2 - SECONDARY PAINT

3 - TRANSMISSION CODE

4 - VEHICLE MODEL NUMBER

5 - ENGINE CODE

6 - INTERIOR TRIM CODE

7 - VEHICLE IDENTIFICATION NUMBER

8 - TAILGATE CODE

9 - CARGO BOX CODE

10 - TAILGATE TRIM CODE

11 - BODY-IN-WHITE SEQUENCE

12 - MARKET CODE

13 - SPECIES CODE

14 - PAINT PROCEDURE

15 - VEHICLE ORDER NUMBER

4 INTRODUCTIONBR/BE

EQUIPMENT IDENTIFICATION PLATE (Continued)

Page 18 of 2255

DESCRIPTION - ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

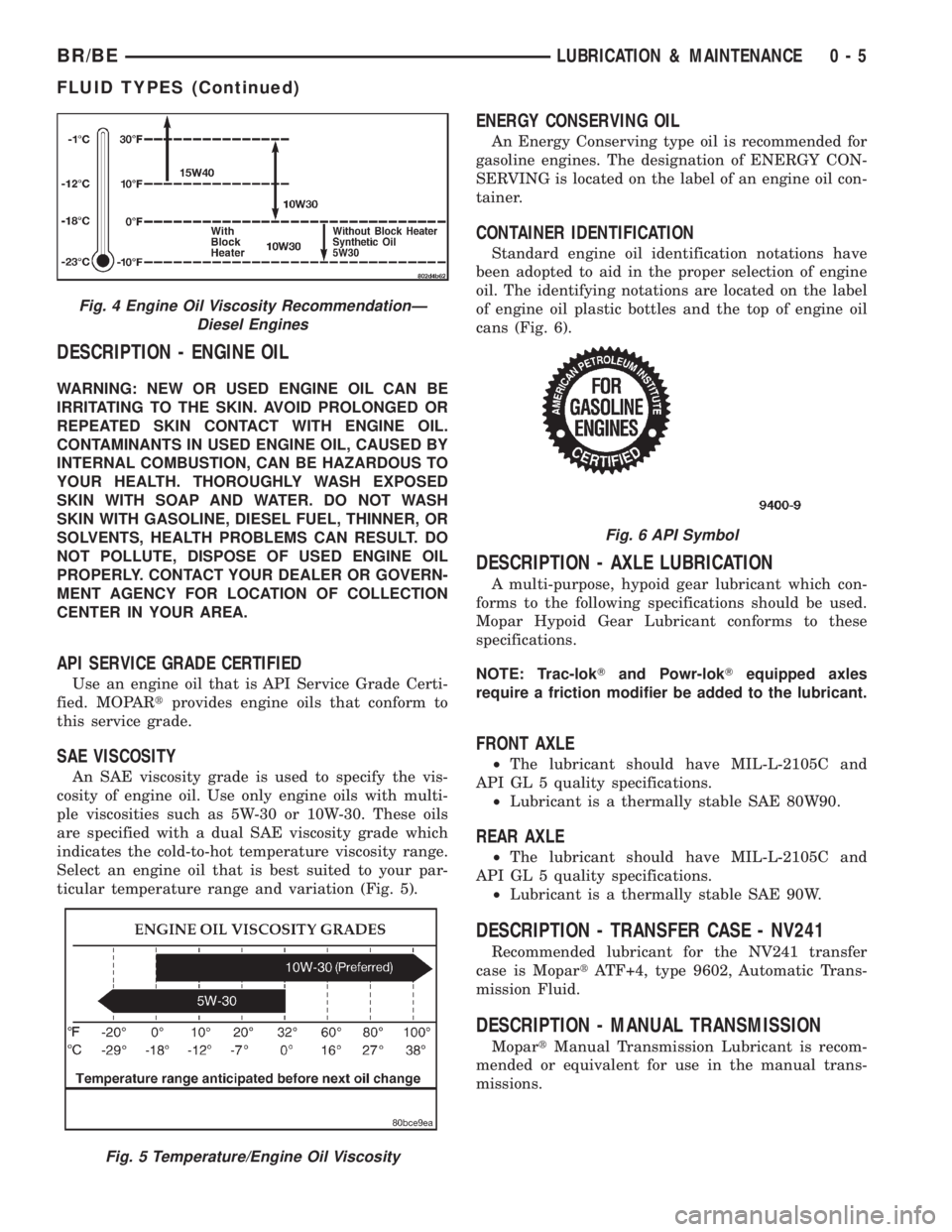

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These oils

are specified with a dual SAE viscosity grade which

indicates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 5).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 6).

DESCRIPTION - AXLE LUBRICATION

A multi-purpose, hypoid gear lubricant which con-

forms to the following specifications should be used.

Mopar Hypoid Gear Lubricant conforms to these

specifications.

NOTE: Trac-lokTand Powr-lokTequipped axles

require a friction modifier be added to the lubricant.

FRONT AXLE

²The lubricant should have MIL-L-2105C and

API GL 5 quality specifications.

²Lubricant is a thermally stable SAE 80W90.

REAR AXLE

²The lubricant should have MIL-L-2105C and

API GL 5 quality specifications.

²Lubricant is a thermally stable SAE 90W.

DESCRIPTION - TRANSFER CASE - NV241

Recommended lubricant for the NV241 transfer

case is MopartATF+4, type 9602, Automatic Trans-

mission Fluid.

DESCRIPTION - MANUAL TRANSMISSION

MopartManual Transmission Lubricant is recom-

mended or equivalent for use in the manual trans-

missions.

Fig. 4 Engine Oil Viscosity RecommendationÐ

Diesel Engines

Fig. 5 Temperature/Engine Oil Viscosity

Fig. 6 API Symbol

BR/BELUBRICATION & MAINTENANCE 0 - 5

FLUID TYPES (Continued)

Page 20 of 2255

DESCRIPTION SPECIFICATION

Dry fill capacity Depending on type and size of

internal cooler, length and inside diameter of cooler

lines, or use of an auxiliary cooler, these figures may

vary. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC/FLUID - STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV4500 3.8 L (8.0 pts.)

NV5600 4.5 L (9.5 pts.)

TRANSFER CASE

NV241 2.18 L (4.61 pts.)

NV241 HD 3.08 L (6.51 pts.)

FRONT AXLE .03 L (1 oz)

248-RBI (Model 60) 4.0 L (8.5 pts.)

REAR AXLE .03 L (1 oz)

248-RBI (Model 60) 2WD 2.9 L (6.1 pts.)

248-RBI (Model 60) 4WD 3.4 L (7.2 pts.)

267-RBI (Model 70)

2WD3.3 L (7.0 pts.)

267-RBI (Model 70)

4WD3.6 L (7.6 pts.)

286-RBI (Model 80)

2WD3.2 L (6.8 pts.)

286-RBI (Model 80)

4WD4.8 L (10.1 pts.)

REAR AXLE - LIMITED SLIP DIFFERENTIAL .03 L

(1 oz)

248-RBI (Model 60) 2WD 2.8 L (5.9 pts.)

248-RBI (Model 60) 4WD 3.2 L (6.8 pts.)

267-RBI (Model 70)

2WD3.1 L (6.5 pts.)

267-RBI (Model 70)

4WD3.4 L (7.2 pts.)

286-RBI (Model 80)

2WD3.0 L (6.3 pts.)

286-RBI (Model 80)

4WD4.5 L (9.5 pts.)

FRICTION MODIFIER .03 L (1 oz)

248-RBI (Model 60) 2WD 0.15 L (5 oz)

248-RBI (Model 60) 4WD 0.18 L (6 oz)

267-RBI (Model 70)

2WD0.21 L (7 oz)DESCRIPTION SPECIFICATION

267-RBI (Model 70)

4WD0.24 L (8 oz)

286-RBI (Model 80)

2WD0.21 L (7 oz)

286-RBI (Model 80)

4WD0.30 L (10 oz)

**** Includes 0.9L (1.0 qts.) for coolant reservoir.

*****Nominal refill capacities are shown. A variation

may be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

MAINTENANCE SCHEDULES

DESCRIPTION

9Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.9

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS.

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.

²DO NOT JUMP START WHEN MAINTENANCE

FREE BATTERY INDICATOR DOT IS YELLOW OR

BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

BR/BELUBRICATION & MAINTENANCE 0 - 7

FLUID CAPACITIES (Continued)

Page 21 of 2255

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

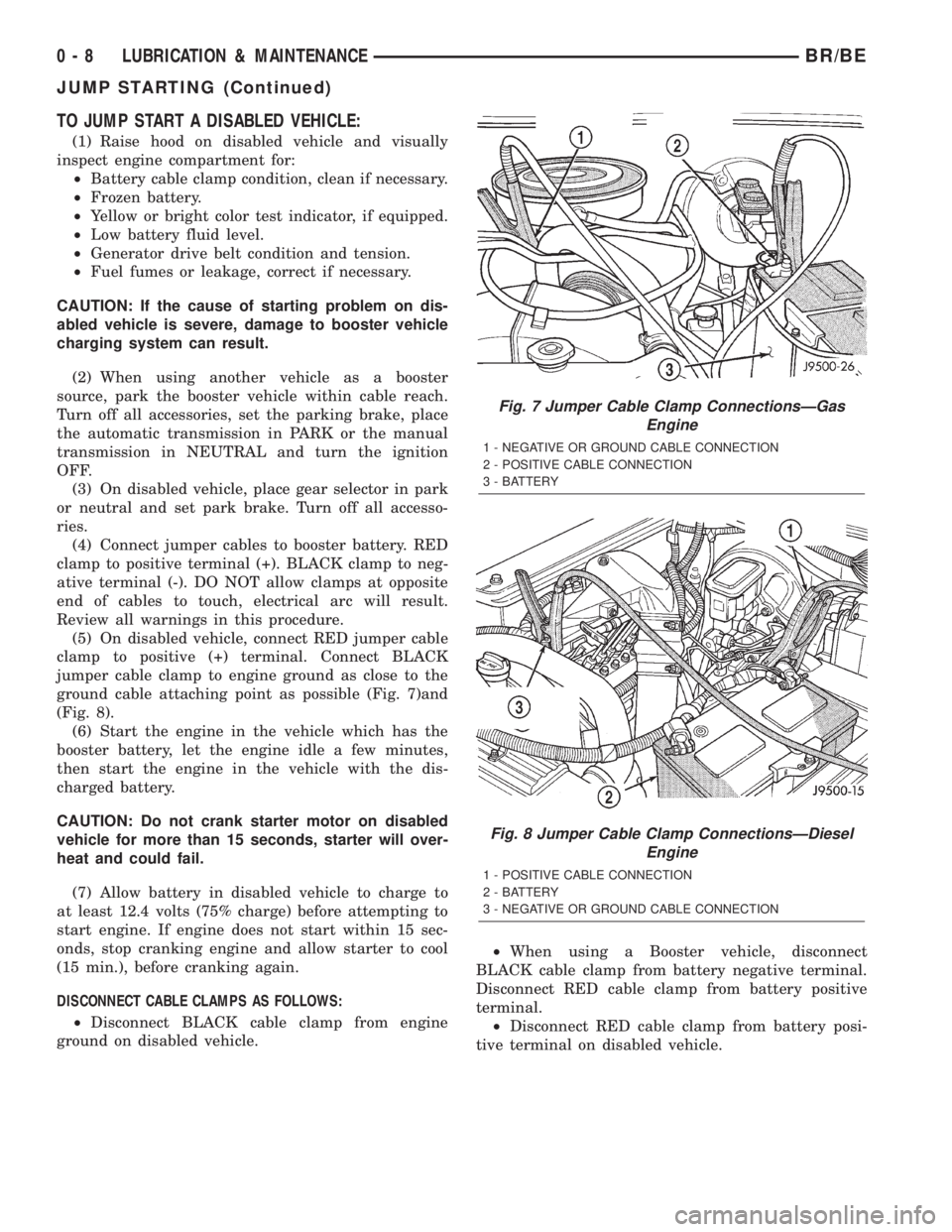

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 7)and

(Fig. 8).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

Fig. 7 Jumper Cable Clamp ConnectionsÐGas

Engine

1 - NEGATIVE OR GROUND CABLE CONNECTION

2 - POSITIVE CABLE CONNECTION

3 - BATTERY

Fig. 8 Jumper Cable Clamp ConnectionsÐDiesel

Engine

1 - POSITIVE CABLE CONNECTION

2 - BATTERY

3 - NEGATIVE OR GROUND CABLE CONNECTION

0 - 8 LUBRICATION & MAINTENANCEBR/BE

JUMP STARTING (Continued)

Page 22 of 2255

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to the Owner's Manual for emergency vehicle

lifting procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT (Fig. 9) OR SECURE VEHICLE TO HOIST-

ING DEVICE WHEN THESE CONDITIONS EXIST.

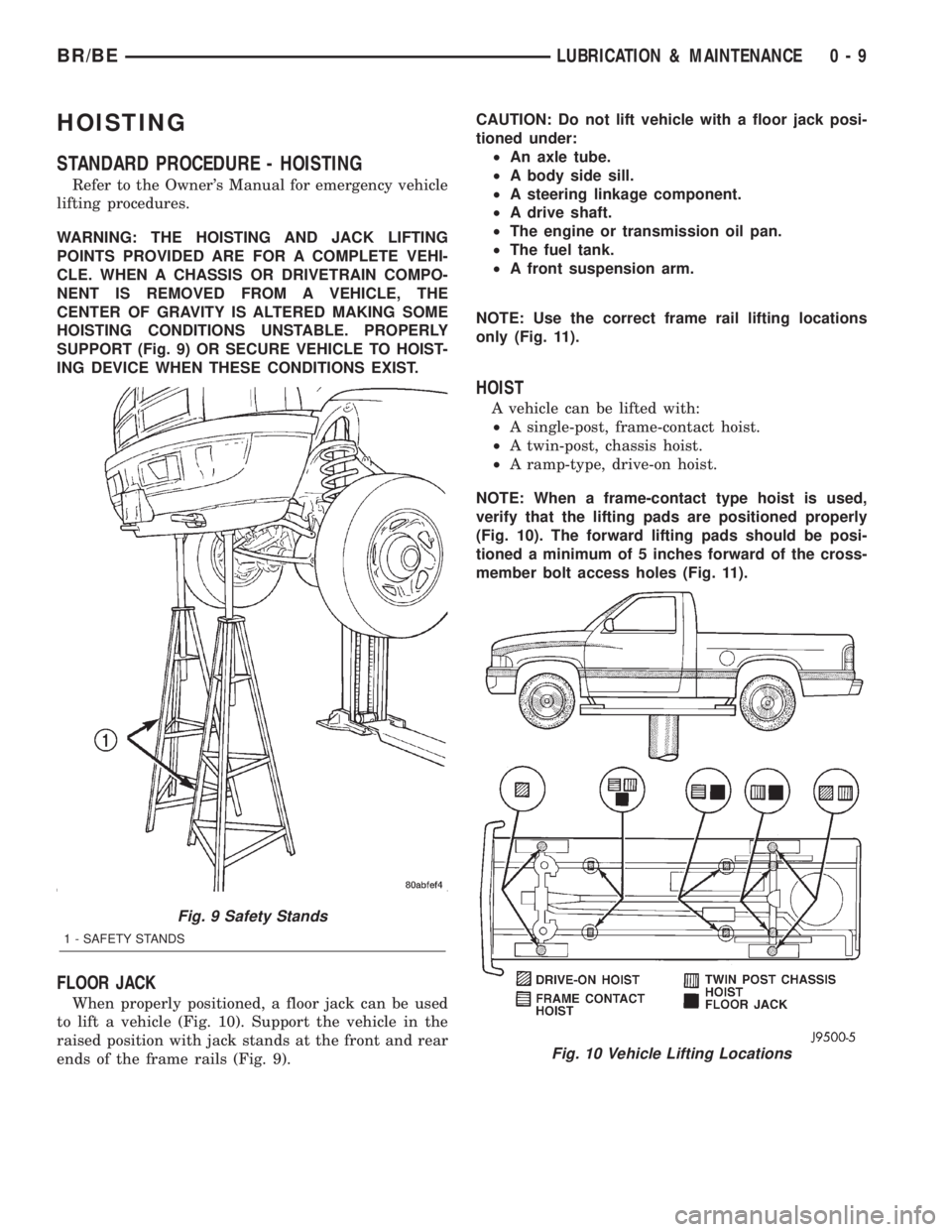

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a vehicle (Fig. 10). Support the vehicle in the

raised position with jack stands at the front and rear

ends of the frame rails (Fig. 9).CAUTION: Do not lift vehicle with a floor jack posi-

tioned under:

²An axle tube.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.

NOTE: Use the correct frame rail lifting locations

only (Fig. 11).

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 10). The forward lifting pads should be posi-

tioned a minimum of 5 inches forward of the cross-

member bolt access holes (Fig. 11).

Fig. 9 Safety Stands

1 - SAFETY STANDS

Fig. 10 Vehicle Lifting Locations

BR/BELUBRICATION & MAINTENANCE 0 - 9

Page 24 of 2255

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used on 4WD vehicles providedall the

wheels are lifted off the ground using tow dol-

lies.

FOUR-WHEEL-DRIVE VEHICLE TOWING

Chrysler Corporation recommends that a vehicle be

transported on a flat-bed device. A Wheel-lift or

Sling-type device can be used providedall the

wheels are lifted off the ground using tow dol-

lies.WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

BR/BELUBRICATION & MAINTENANCE 0 - 11

TOWING (Continued)

Page 235 of 2255

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems are caused

by wear or damage to one or more clutch compo-

nents. A visual inspection of the release components

will usually reveal the problem part.

Release problems can result in hard shifting and

noise. Items to look for are: leaks at the clutch cylin-

ders and interconnecting line; loose slave cylinder

bolts; worn/loose release fork and pivot stud; dam-

aged release bearing; and a worn clutch disc, or pres-

sure plate.

Normal condensation in vehicles that are stored or

out of service for long periods of time can generate

enough corrosion to make the disc stick to the fly-

wheel, or pressure plate. If this condition is experi-

enced, correction only requires that the disc be

loosened manually through the inspection plate open-

ing.

Engagement problems usually result in slip, chat-

ter/shudder, and noisy operation. The primary causes

are clutch disc contamination; clutch disc wear; mis-

alignment, or distortion; flywheel damage; or a com-

bination of the foregoing. A visual inspection is

required to determine the part actually causing the

problem.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial

(face) runout of anewdisc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain

another disc if runout is excessive.

Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab

and incomplete release or engagement. Be careful

when handling the cover and disc. Impact can distort

the cover, diaphragm spring, release fingers and the

hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign-

ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten-

ing.

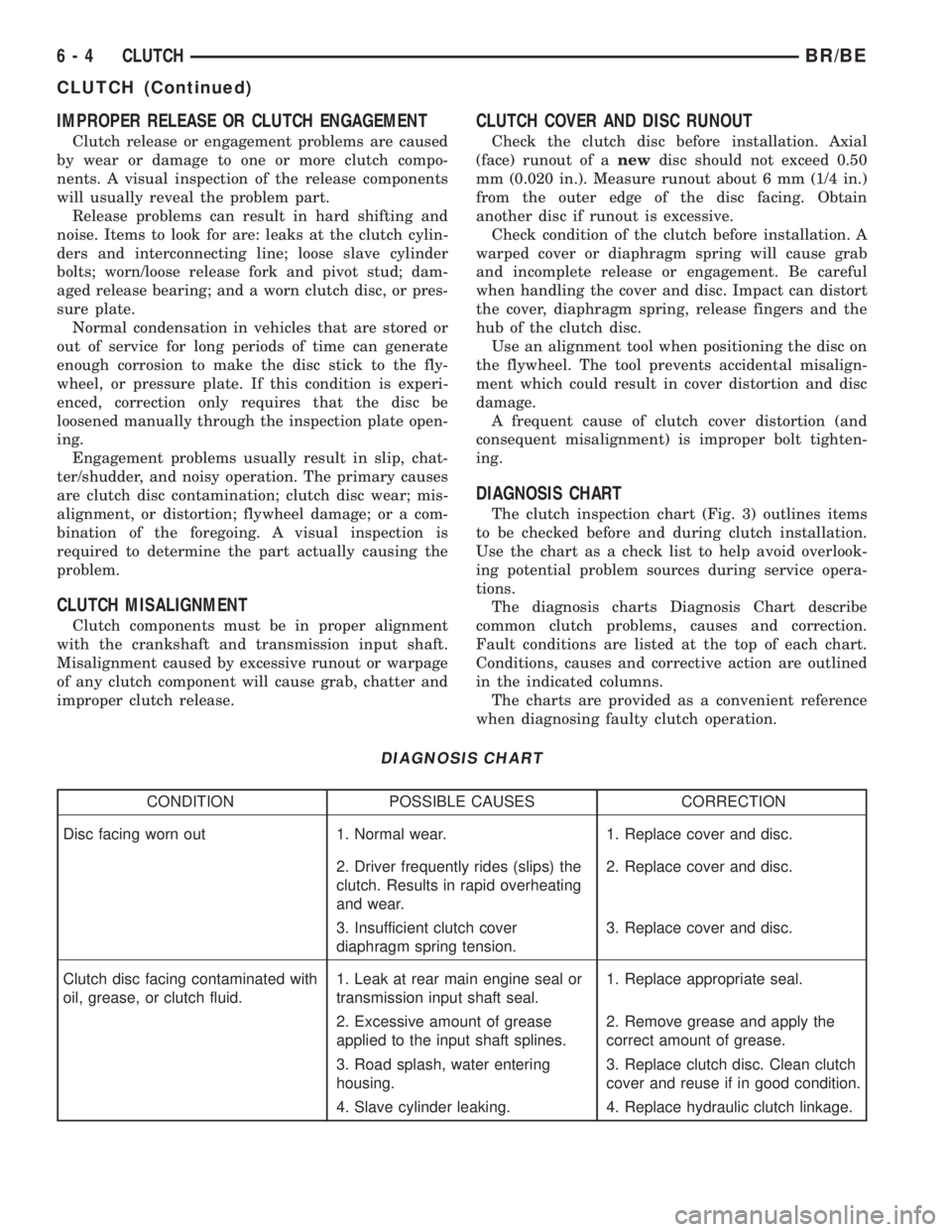

DIAGNOSIS CHART

The clutch inspection chart (Fig. 3) outlines items

to be checked before and during clutch installation.

Use the chart as a check list to help avoid overlook-

ing potential problem sources during service opera-

tions.

The diagnosis charts Diagnosis Chart describe

common clutch problems, causes and correction.

Fault conditions are listed at the top of each chart.

Conditions, causes and corrective action are outlined

in the indicated columns.

The charts are provided as a convenient reference

when diagnosing faulty clutch operation.

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Disc facing worn out 1. Normal wear. 1. Replace cover and disc.

2. Driver frequently rides (slips) the

clutch. Results in rapid overheating

and wear.2. Replace cover and disc.

3. Insufficient clutch cover

diaphragm spring tension.3. Replace cover and disc.

Clutch disc facing contaminated with

oil, grease, or clutch fluid.1. Leak at rear main engine seal or

transmission input shaft seal.1. Replace appropriate seal.

2. Excessive amount of grease

applied to the input shaft splines.2. Remove grease and apply the

correct amount of grease.

3. Road splash, water entering

housing.3. Replace clutch disc. Clean clutch

cover and reuse if in good condition.

4. Slave cylinder leaking. 4. Replace hydraulic clutch linkage.

6 - 4 CLUTCHBR/BE

CLUTCH (Continued)

Page 253 of 2255

DESCRIPTIONÐHOSE CLAMPS

The cooling system utilizes both worm drive and

spring type hose clamps. If a spring type clamp

replacement is necessary, replace with the original

Mopartequipment spring type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 4).

OPERATION

OPERATIONÐHOSE CLAMPS

The worm type hose clamp uses a specified torque

value to maintain proper tension on a hose connec-

tion.

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

OPERATIONÐCOOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED OR STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

²Increasing engine speed for more air flow is rec-

ommended.

TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

AIR CONDITIONING; ADD-ON OR AFTER MARKET:

A maximum cooling package should have been

ordered with vehicle if add-on or after market A/C is

installed. If not, maximum cooling system compo-

nents should be installed for model involved per

manufacturer's specifications.

RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, (Refer to 7 - COOLING - DIAGNOSIS AND

TESTING)

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

7 - 4 COOLINGBR/BE

COOLING (Continued)

Page 361 of 2255

²Head/Park Lights-On Warning- The CTM

chime tone generator will generate repetitive chime

tones at a fast rate to announce that hard wired

inputs from the driver door ajar switch, headlamp

switch, and ignition switch indicate that the exterior

lamps are turned On with the driver side front door

opened and the ignition switch in the Off position.

The chimes will continue to sound until the exterior

lamps are turned Off, the driver side front door is

closed, or the ignition switch is turned to the On

position, whichever occurs first.

²Key-In-Ignition Warning- The CTM chime

tone generator will generate repetitive chime tones at

a fast rate to announce that hard wired inputs from

the driver door ajar switch, headlamp switch, and

ignition switch indicate that the key is in the ignition

lock cylinder with the driver side front door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the key is

removed from the ignition lock cylinder, the driver

side front door is closed, or the ignition switch is

turned to the On position, whichever occurs first.

²Warning Chime Support- The CTM chime

tone generator will generate repetitive chime tones at

a slow rate to announce that a hard wired chime

request input has been received from the EMIC.

These chime tones provide an audible alert to the

vehicle operator that supplements certain visual indi-

cations displayed by the EMIC. Supplemented indica-

tions include the following:

²The ªAirbagº indicator is illuminated. The

chimes will continue to sound for a duration of about

four seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªCheck Gagesº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Fuelº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Washº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªTrans Tempº indicator is illuminated (auto-

matic transmission only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.²The vehicle is over a programmed speed value

(Middle East Gulf Coast Country (GCC) only). The

CTM chime tone generator will generate repetitive

chime tones at a slow rate to announce that the vehi-

cle speed exceeds a programmed value. The chimes

will continue to sound until the vehicle speed is

below the programmed value.

²The ªWater-In-Fuelº indicator is illuminated

(diesel engine only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.

The CTM provides chime service for all available

features in the chime warning system. The CTM

relies upon hard wired inputs from the driver door

ajar switch, the EMIC, the headlamp switch, and the

key-in ignition switch (ignition switch) to provide

chime service for all of the chime warning system

features. Upon receiving the proper inputs, the CTM

activates the integral chime tone generator to pro-

vide the audible chime tone to the vehicle operator.

The chime tone generator in the CTM is capable of

producing repeated chime tones at two different

rates, slow or fast. The slow chime rate is about fifty

chime tones per minute, while the fast chime rate is

about 180 chime tones per minute. The internal pro-

gramming of the CTM and the EMIC determines the

priority of each chime tone request input that is

received, as well as the rate and duration of each

chime tone that is to be generated.

The hard wired chime warning system inputs to

the CTM and the EMIC, as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

See the owner's manual in the vehicle glove box for

more information on the features provided by the

chime warning system.

DIAGNOSIS AND TESTING - CHIME WARNING

SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. The hard wired

chime warning system inputs to the Central Timer

Module (CTM) and the Electro-Mechanical Instru-

ment Cluster (EMIC), as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

8B - 2 CHIME/BUZZERBR/BE

CHIME WARNING SYSTEM (Continued)