bulb DODGE RAM 2002 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 527 of 2255

FOG LAMP UNIT

REMOVAL

SLT

The fog lamps are serviced from the rearward side

of the front bumper.

(1) Disconnect and isolate the battery negative

cable.

(2) Disengage fog lamp harness connector.

(3) Remove fog lamp to bumper attaching nuts

(Fig. 10).

(4) Separate fog lamp from bumper.

SPORT

The fog lamps are serviced from the rearward side

of the front fascia.

(1) Disconnect and isolate the battery negative

cable.

(2) Disengage fog lamp harness connector.

(3) Remove fog lamp to fascia attaching nuts (Fig.

11).

(4) Separate fog lamp from fascia.

INSTALLATION

SLT

(1) Position fog lamp in bumper.

(2) Install fog lamp to bumper attaching nuts.

(3) Connect fog lamp harness connector.

(4) Connect the battery negative cable.

(5) Check for proper operation and beam align-

ment.

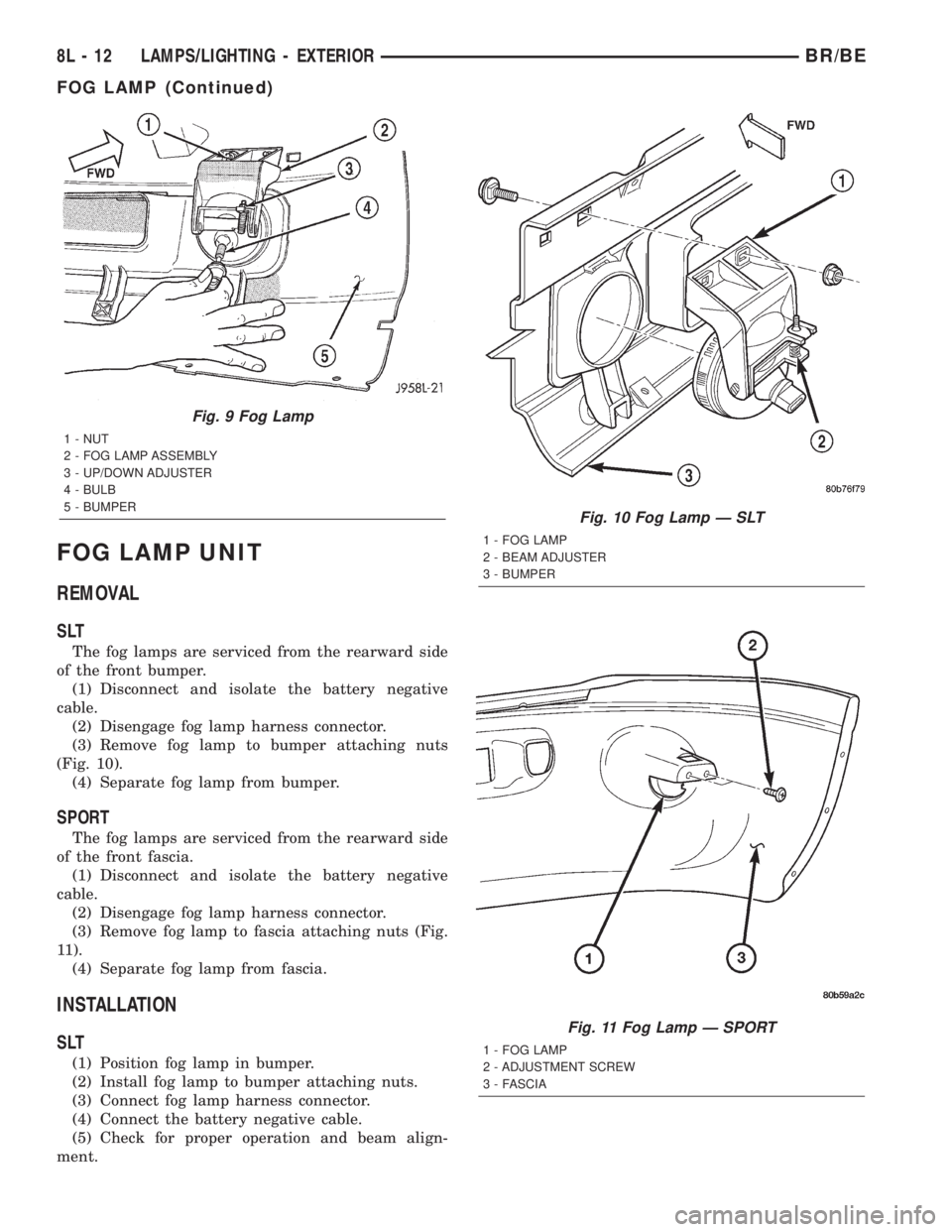

Fig. 9 Fog Lamp

1 - NUT

2 - FOG LAMP ASSEMBLY

3 - UP/DOWN ADJUSTER

4 - BULB

5 - BUMPER

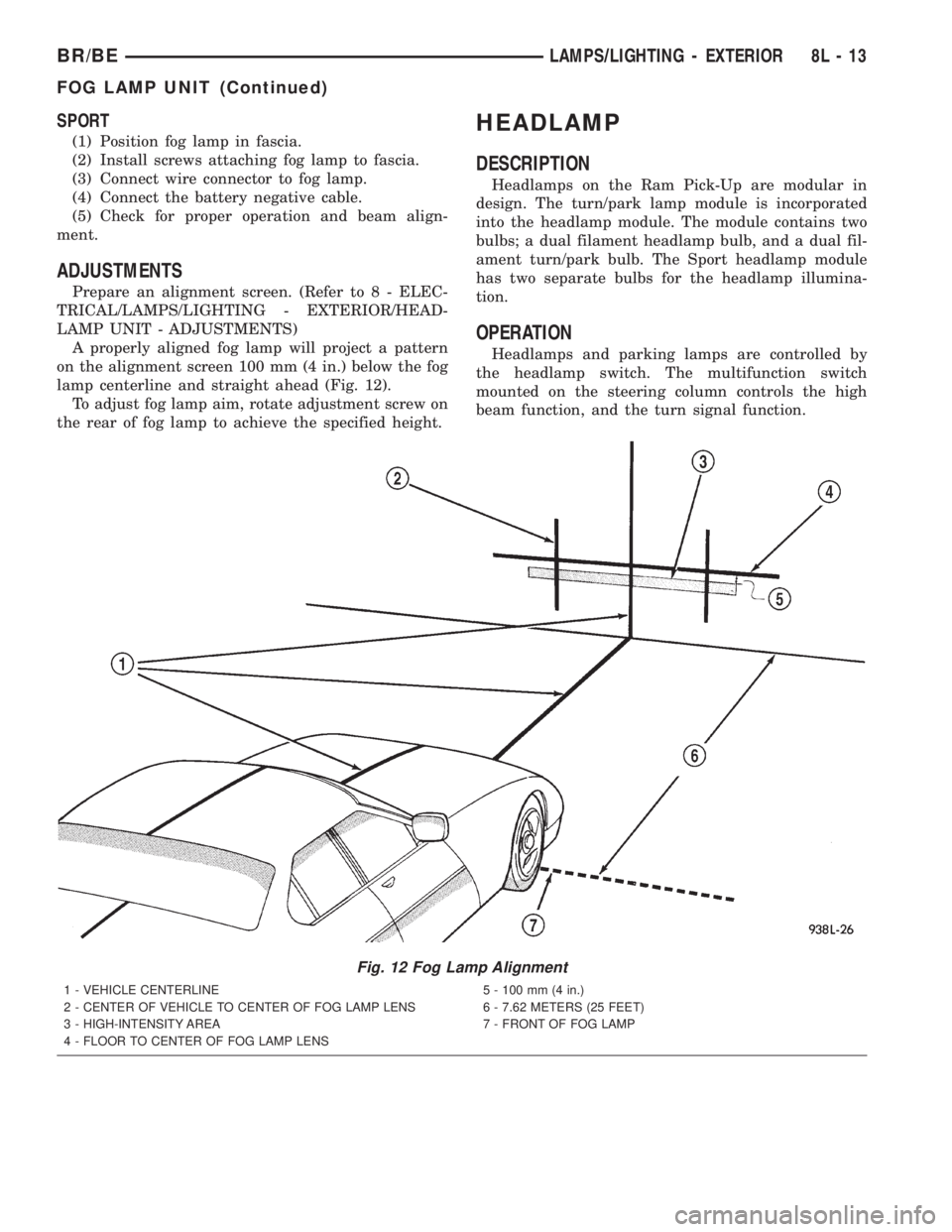

Fig. 10 Fog Lamp Ð SLT

1 - FOG LAMP

2 - BEAM ADJUSTER

3 - BUMPER

Fig. 11 Fog Lamp Ð SPORT

1 - FOG LAMP

2 - ADJUSTMENT SCREW

3 - FASCIA

8L - 12 LAMPS/LIGHTING - EXTERIORBR/BE

FOG LAMP (Continued)

Page 528 of 2255

SPORT

(1) Position fog lamp in fascia.

(2) Install screws attaching fog lamp to fascia.

(3) Connect wire connector to fog lamp.

(4) Connect the battery negative cable.

(5) Check for proper operation and beam align-

ment.

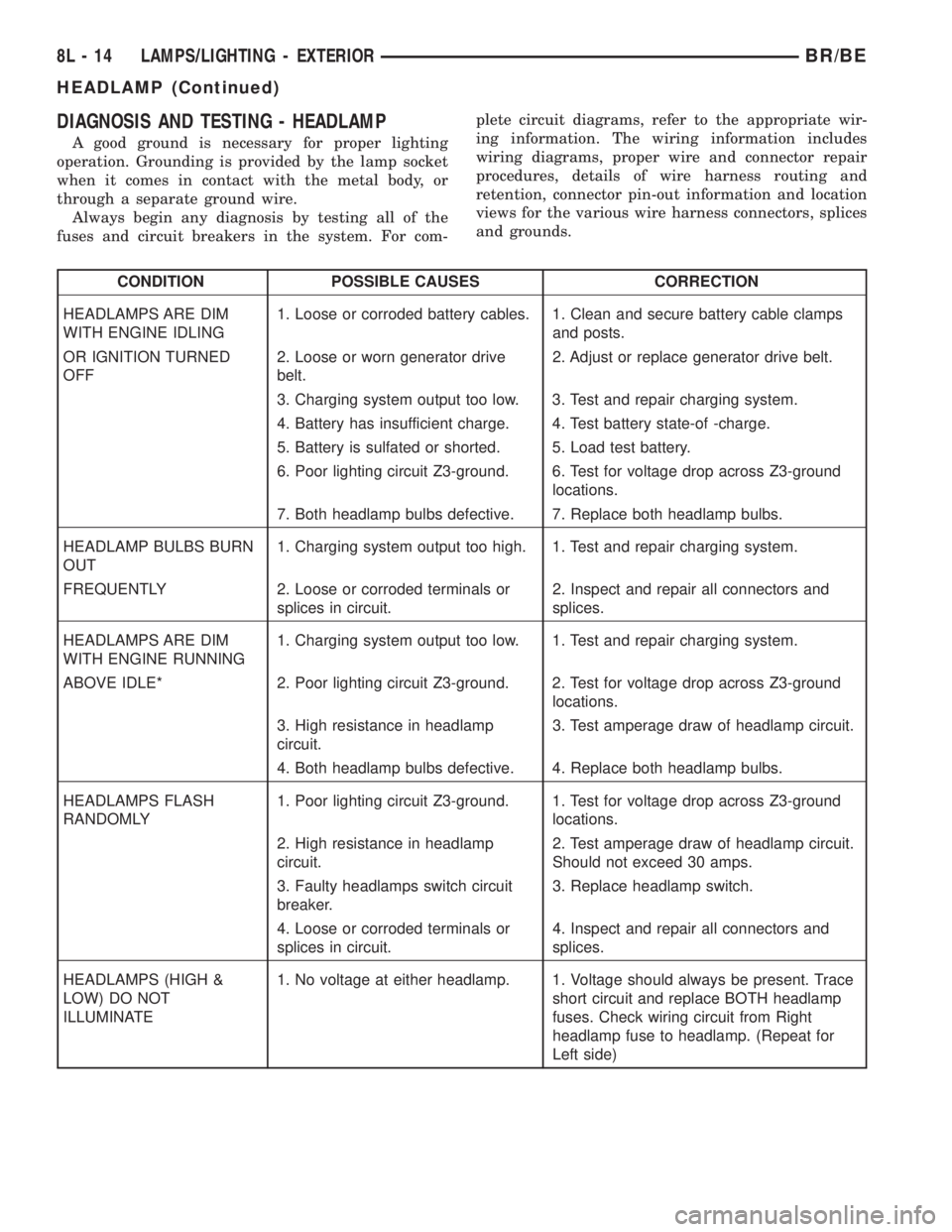

ADJUSTMENTS

Prepare an alignment screen. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - ADJUSTMENTS)

A properly aligned fog lamp will project a pattern

on the alignment screen 100 mm (4 in.) below the fog

lamp centerline and straight ahead (Fig. 12).

To adjust fog lamp aim, rotate adjustment screw on

the rear of fog lamp to achieve the specified height.

HEADLAMP

DESCRIPTION

Headlamps on the Ram Pick-Up are modular in

design. The turn/park lamp module is incorporated

into the headlamp module. The module contains two

bulbs; a dual filament headlamp bulb, and a dual fil-

ament turn/park bulb. The Sport headlamp module

has two separate bulbs for the headlamp illumina-

tion.

OPERATION

Headlamps and parking lamps are controlled by

the headlamp switch. The multifunction switch

mounted on the steering column controls the high

beam function, and the turn signal function.

Fig. 12 Fog Lamp Alignment

1 - VEHICLE CENTERLINE

2 - CENTER OF VEHICLE TO CENTER OF FOG LAMP LENS

3 - HIGH-INTENSITY AREA

4 - FLOOR TO CENTER OF FOG LAMP LENS5 - 100 mm (4 in.)

6 - 7.62 METERS (25 FEET)

7 - FRONT OF FOG LAMP

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 13

FOG LAMP UNIT (Continued)

Page 529 of 2255

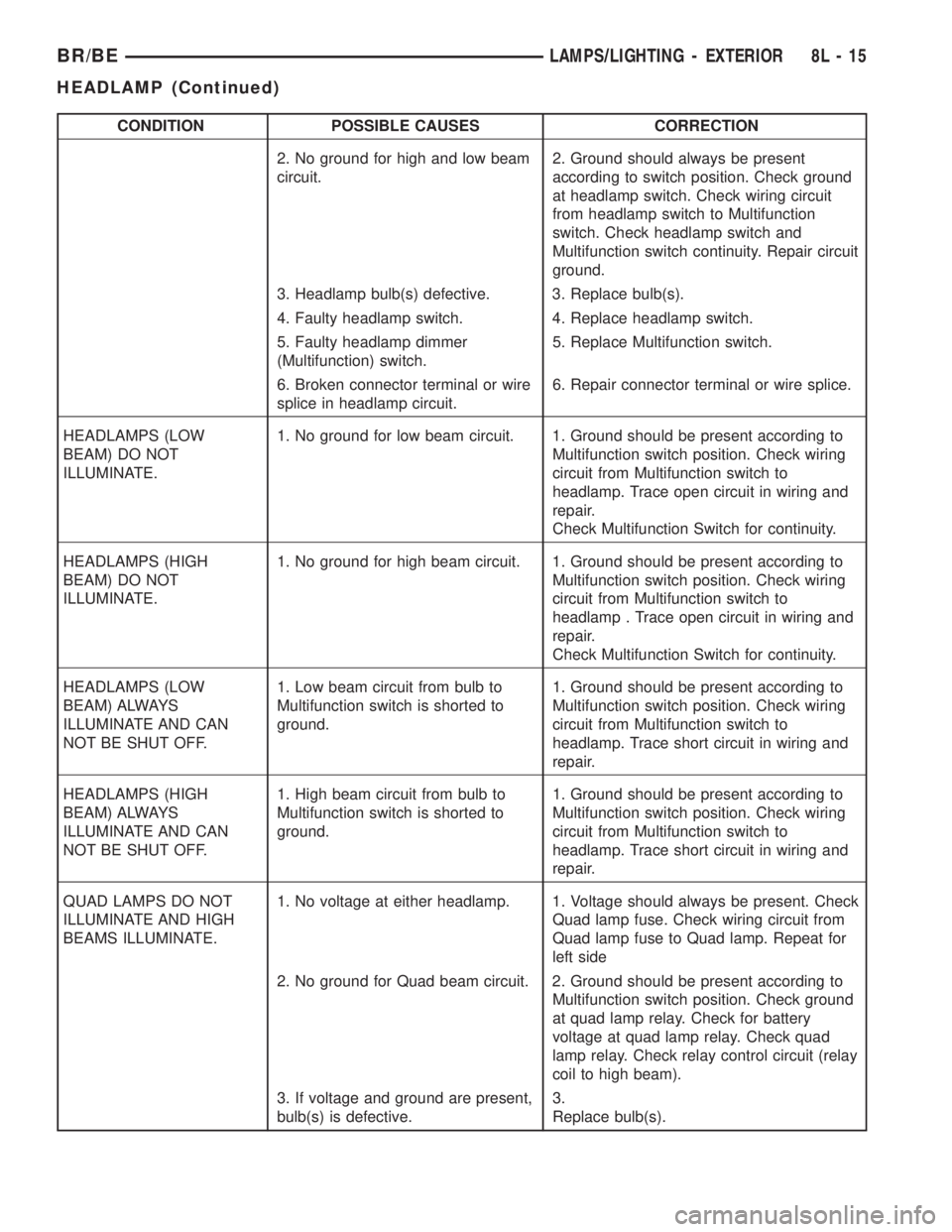

DIAGNOSIS AND TESTING - HEADLAMP

A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. For com-plete circuit diagrams, refer to the appropriate wir-

ing information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

OR IGNITION TURNED

OFF2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system.

4. Battery has insufficient charge. 4. Test battery state-of -charge.

5. Battery is sulfated or shorted. 5. Load test battery.

6. Poor lighting circuit Z3-ground. 6. Test for voltage drop across Z3-ground

locations.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS BURN

OUT1. Charging system output too high. 1. Test and repair charging system.

FREQUENTLY 2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING1. Charging system output too low. 1. Test and repair charging system.

ABOVE IDLE* 2. Poor lighting circuit Z3-ground. 2. Test for voltage drop across Z3-ground

locations.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z3-ground. 1. Test for voltage drop across Z3-ground

locations.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp circuit.

Should not exceed 30 amps.

3. Faulty headlamps switch circuit

breaker.3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices.

HEADLAMPS (HIGH &

LOW) DO NOT

ILLUMINATE1. No voltage at either headlamp. 1. Voltage should always be present. Trace

short circuit and replace BOTH headlamp

fuses. Check wiring circuit from Right

headlamp fuse to headlamp. (Repeat for

Left side)

8L - 14 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP (Continued)

Page 530 of 2255

CONDITION POSSIBLE CAUSES CORRECTION

2. No ground for high and low beam

circuit.2. Ground should always be present

according to switch position. Check ground

at headlamp switch. Check wiring circuit

from headlamp switch to Multifunction

switch. Check headlamp switch and

Multifunction switch continuity. Repair circuit

ground.

3. Headlamp bulb(s) defective. 3. Replace bulb(s).

4. Faulty headlamp switch. 4. Replace headlamp switch.

5. Faulty headlamp dimmer

(Multifunction) switch.5. Replace Multifunction switch.

6. Broken connector terminal or wire

splice in headlamp circuit.6. Repair connector terminal or wire splice.

HEADLAMPS (LOW

BEAM) DO NOT

ILLUMINATE.1. No ground for low beam circuit. 1. Ground should be present according to

Multifunction switch position. Check wiring

circuit from Multifunction switch to

headlamp. Trace open circuit in wiring and

repair.

Check Multifunction Switch for continuity.

HEADLAMPS (HIGH

BEAM) DO NOT

ILLUMINATE.1. No ground for high beam circuit. 1. Ground should be present according to

Multifunction switch position. Check wiring

circuit from Multifunction switch to

headlamp . Trace open circuit in wiring and

repair.

Check Multifunction Switch for continuity.

HEADLAMPS (LOW

BEAM) ALWAYS

ILLUMINATE AND CAN

NOT BE SHUT OFF.1. Low beam circuit from bulb to

Multifunction switch is shorted to

ground.1. Ground should be present according to

Multifunction switch position. Check wiring

circuit from Multifunction switch to

headlamp. Trace short circuit in wiring and

repair.

HEADLAMPS (HIGH

BEAM) ALWAYS

ILLUMINATE AND CAN

NOT BE SHUT OFF.1. High beam circuit from bulb to

Multifunction switch is shorted to

ground.1. Ground should be present according to

Multifunction switch position. Check wiring

circuit from Multifunction switch to

headlamp. Trace short circuit in wiring and

repair.

QUAD LAMPS DO NOT

ILLUMINATE AND HIGH

BEAMS ILLUMINATE.1. No voltage at either headlamp. 1. Voltage should always be present. Check

Quad lamp fuse. Check wiring circuit from

Quad lamp fuse to Quad lamp. Repeat for

left side

2. No ground for Quad beam circuit. 2. Ground should be present according to

Multifunction switch position. Check ground

at quad lamp relay. Check for battery

voltage at quad lamp relay. Check quad

lamp relay. Check relay control circuit (relay

coil to high beam).

3. If voltage and ground are present,

bulb(s) is defective.3.

Replace bulb(s).

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 15

HEADLAMP (Continued)

Page 531 of 2255

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMP SWITCH OFF

HEADLAMPS AND

HIGHBEAM INDICATOR

REMAIN ON AND ARE

DIM.1. Headlamp switch feed circuit

shorted to ground.1. Check wiring circuit from right headlamp

fuse to headlamp. Repeat for left side.

Trace short circuit in wiring and repair.

HEADLAMP SWITCH ON

(LOW BEAMS ON), ONE

LOW BEAM ON AND

BOTH HIGH BEAMS DIM.1. Headlamp feed circuit shorted to

ground.1. Check wiring circuit from right headlamp

fuse to headlamp. Repeat for left side.

Trace short circuit in wiring and repair.

HEADLAMP SWITCH ON

(HIGH BEAMS ON), ONE

HIGH BEAM ON AND

BOTH LOW BEAMS DIM.1. Headlamp feed circuit shorted to

ground.1. Check wiring circuit from right headlamp

fuse to headlamp. Repeat for left side.

Trace short circuit in wiring and repair.

HEADLAMP SWITCH ON,

ONE HEADLAMP

FILAMENT WILL BE AT

FULL INTENSITY AND ALL

OTHER FILAMENTS ARE

ON AND DIM.1. Blown headlamp fuse. 1. Trace short circuit and replace fuse.

2. Open circuit from headlamp fuse

to headlamp.2. Repair open headlamp circuit.

1. HEADLAMPS STAY ON

WITH KEY OUT (DRLM

EQUIPPED VEHICLES).1. Failed DRLM 1. Replace DRLM.

*Canada vehicles must have lamps ON.

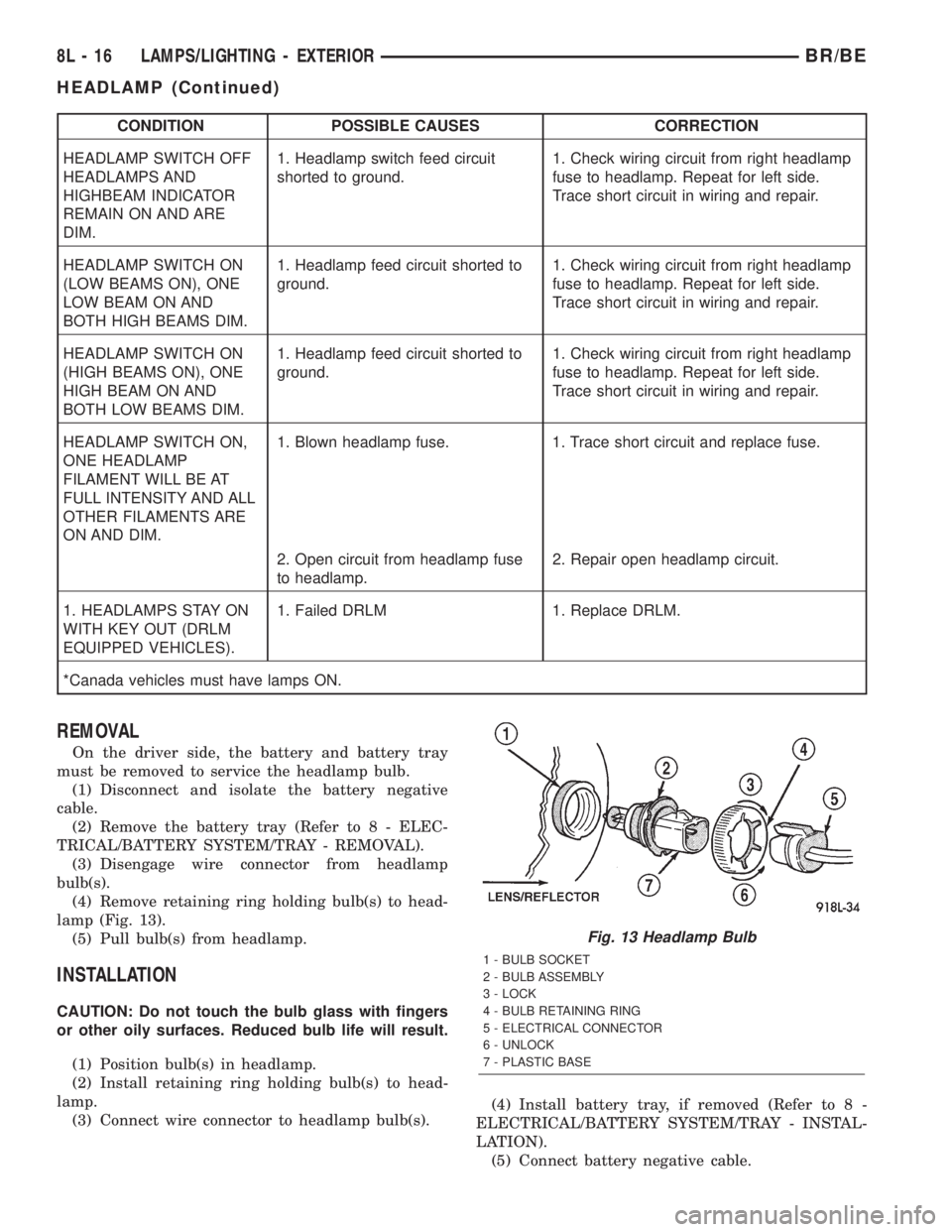

REMOVAL

On the driver side, the battery and battery tray

must be removed to service the headlamp bulb.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(3) Disengage wire connector from headlamp

bulb(s).

(4) Remove retaining ring holding bulb(s) to head-

lamp (Fig. 13).

(5) Pull bulb(s) from headlamp.

INSTALLATION

CAUTION: Do not touch the bulb glass with fingers

or other oily surfaces. Reduced bulb life will result.

(1) Position bulb(s) in headlamp.

(2) Install retaining ring holding bulb(s) to head-

lamp.

(3) Connect wire connector to headlamp bulb(s).(4) Install battery tray, if removed (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/TRAY - INSTAL-

LATION).

(5) Connect battery negative cable.

Fig. 13 Headlamp Bulb

1 - BULB SOCKET

2 - BULB ASSEMBLY

3 - LOCK

4 - BULB RETAINING RING

5 - ELECTRICAL CONNECTOR

6 - UNLOCK

7 - PLASTIC BASE

8L - 16 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP (Continued)

Page 535 of 2255

(4) Pull the headlamp switch away from the

instrument panel far enough to access the instru-

ment panel wire harness connectors.

(5) Disconnect the two instrument panel wire har-

ness connectors for the headlamp switch from the

connector receptacles on the back of the switch.

(6) Remove the headlamp switch from the instru-

ment panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the headlamp switch to the instru-

ment panel.

(2) Reconnect the two instrument panel wire har-

ness connectors for the headlamp switch to the con-

nector receptacles on the back of the switch.

(3) Position the headlamp switch into the instru-

ment panel.

(4) Install and tighten the three screws that secure

the headlamp switch to the instrument panel.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(5) Reinstall the cluster bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(6) Connect the battery negative cable.

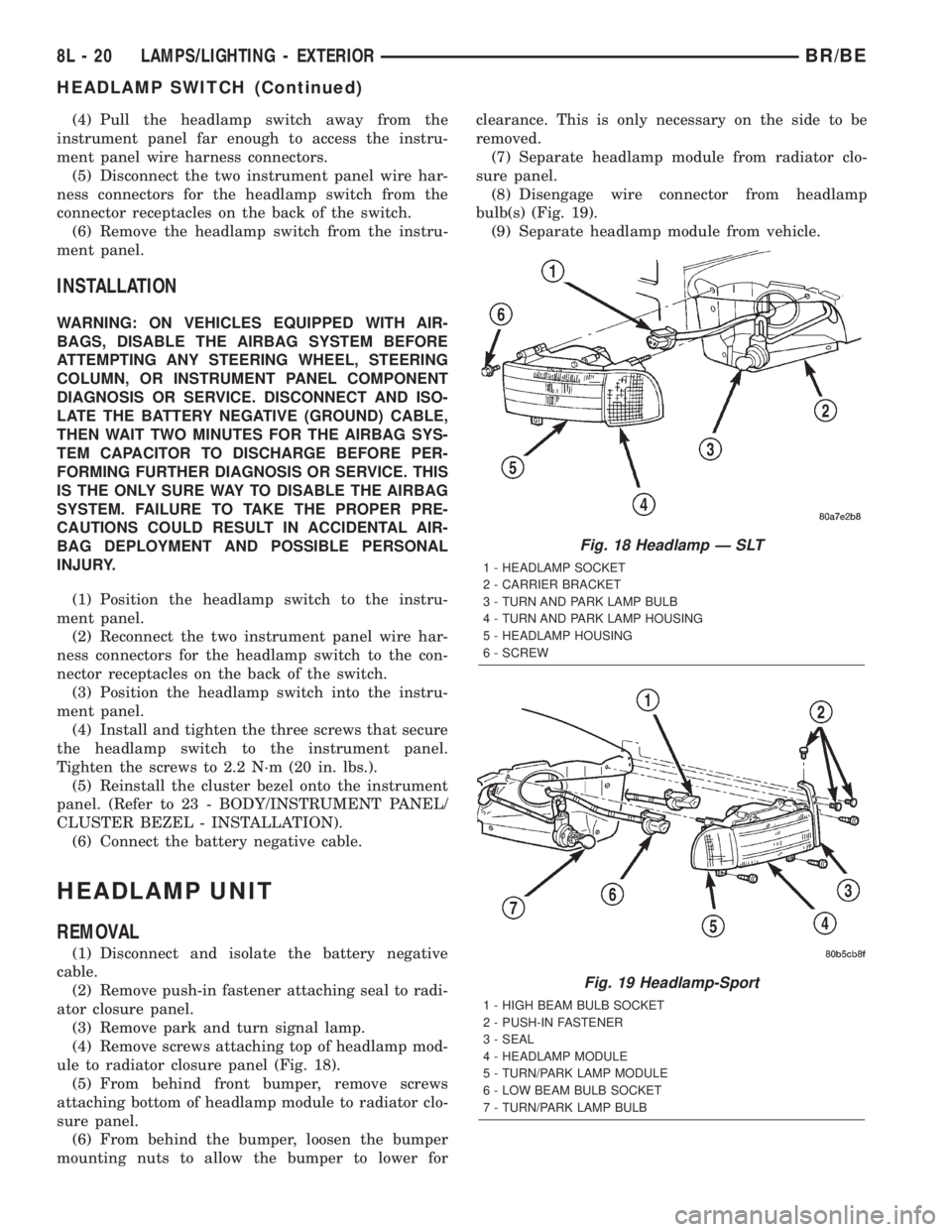

HEADLAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove push-in fastener attaching seal to radi-

ator closure panel.

(3) Remove park and turn signal lamp.

(4) Remove screws attaching top of headlamp mod-

ule to radiator closure panel (Fig. 18).

(5) From behind front bumper, remove screws

attaching bottom of headlamp module to radiator clo-

sure panel.

(6) From behind the bumper, loosen the bumper

mounting nuts to allow the bumper to lower forclearance. This is only necessary on the side to be

removed.

(7) Separate headlamp module from radiator clo-

sure panel.

(8) Disengage wire connector from headlamp

bulb(s) (Fig. 19).

(9) Separate headlamp module from vehicle.

Fig. 18 Headlamp Ð SLT

1 - HEADLAMP SOCKET

2 - CARRIER BRACKET

3 - TURN AND PARK LAMP BULB

4 - TURN AND PARK LAMP HOUSING

5 - HEADLAMP HOUSING

6 - SCREW

Fig. 19 Headlamp-Sport

1 - HIGH BEAM BULB SOCKET

2 - PUSH-IN FASTENER

3 - SEAL

4 - HEADLAMP MODULE

5 - TURN/PARK LAMP MODULE

6 - LOW BEAM BULB SOCKET

7 - TURN/PARK LAMP BULB

8L - 20 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP SWITCH (Continued)

Page 536 of 2255

INSTALLATION

(1) If removed, install headlamp bulb(s).

(2) Connect headlamp bulb wire connector(s).

(3) Position headlamp in radiator closure panel.

(4) From behind front bumper, install the screws

attaching bottom of headlamp module to radiator clo-

sure panel.

(5) From behind the bumper, tighten the bumper

mounting nuts.

(6) Install the screws attaching top of headlamp

module to radiator closure panel.

(7) Install park and turn signal lamp.

(8) Install push-in fastener attaching seal to radi-

ator closure panel.

(9) Connect the battery negative cable.

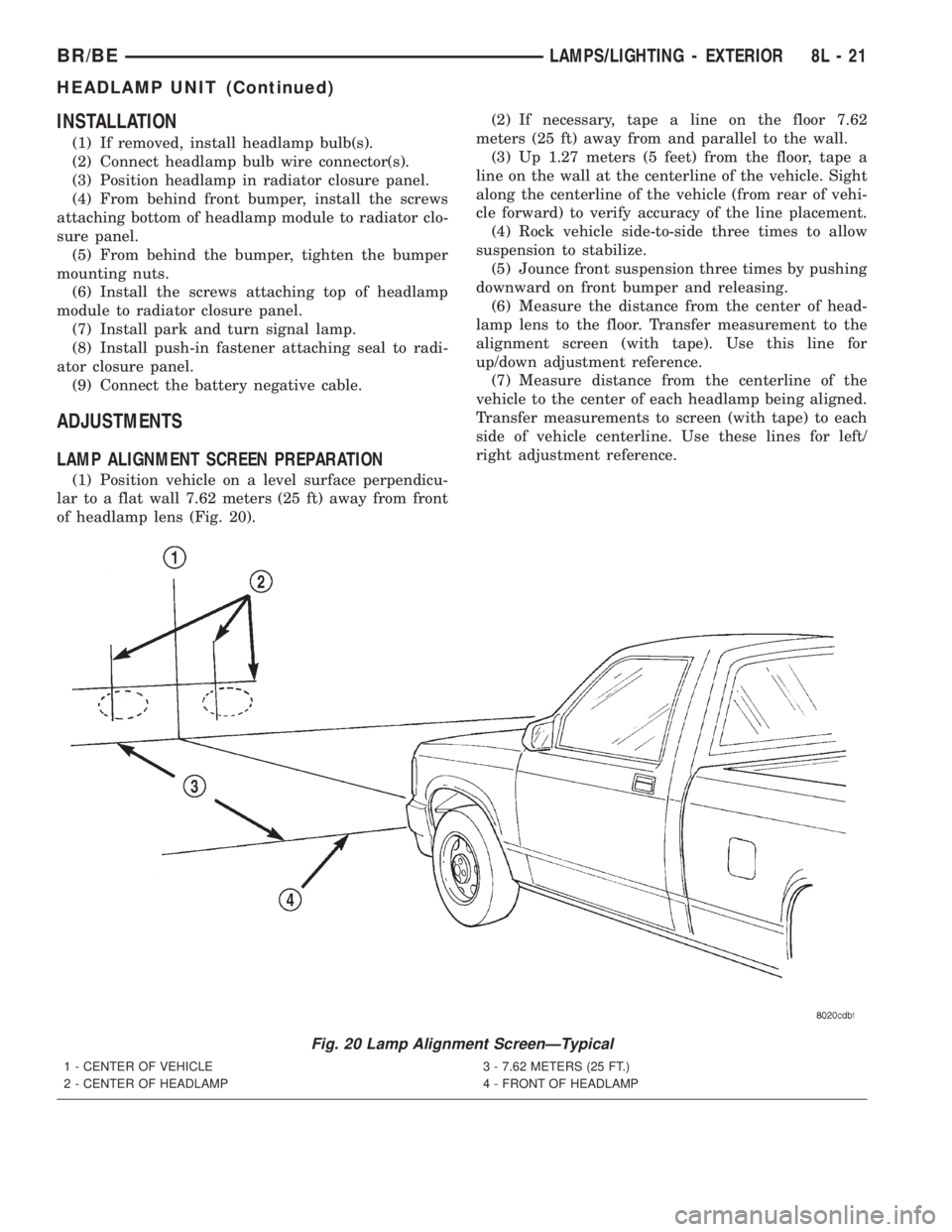

ADJUSTMENTS

LAMP ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft) away from front

of headlamp lens (Fig. 20).(2) If necessary, tape a line on the floor 7.62

meters (25 ft) away from and parallel to the wall.

(3) Up 1.27 meters (5 feet) from the floor, tape a

line on the wall at the centerline of the vehicle. Sight

along the centerline of the vehicle (from rear of vehi-

cle forward) to verify accuracy of the line placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize.

(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for

up/down adjustment reference.

(7) Measure distance from the centerline of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle centerline. Use these lines for left/

right adjustment reference.

Fig. 20 Lamp Alignment ScreenÐTypical

1 - CENTER OF VEHICLE

2 - CENTER OF HEADLAMP3 - 7.62 METERS (25 FT.)

4 - FRONT OF HEADLAMP

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 21

HEADLAMP UNIT (Continued)

Page 537 of 2255

VEHICLE PREPARATION FOR HEADLAMP

ALIGNMENT

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Verify headlamps are set for low beam opera-

tion.

(3) Correct defective components that could hinder

proper headlamp alignment.

(4) Verify proper tire inflation.

(5) Clean headlamp lenses.

(6) Verify that luggage area is not heavily loaded.

(7) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

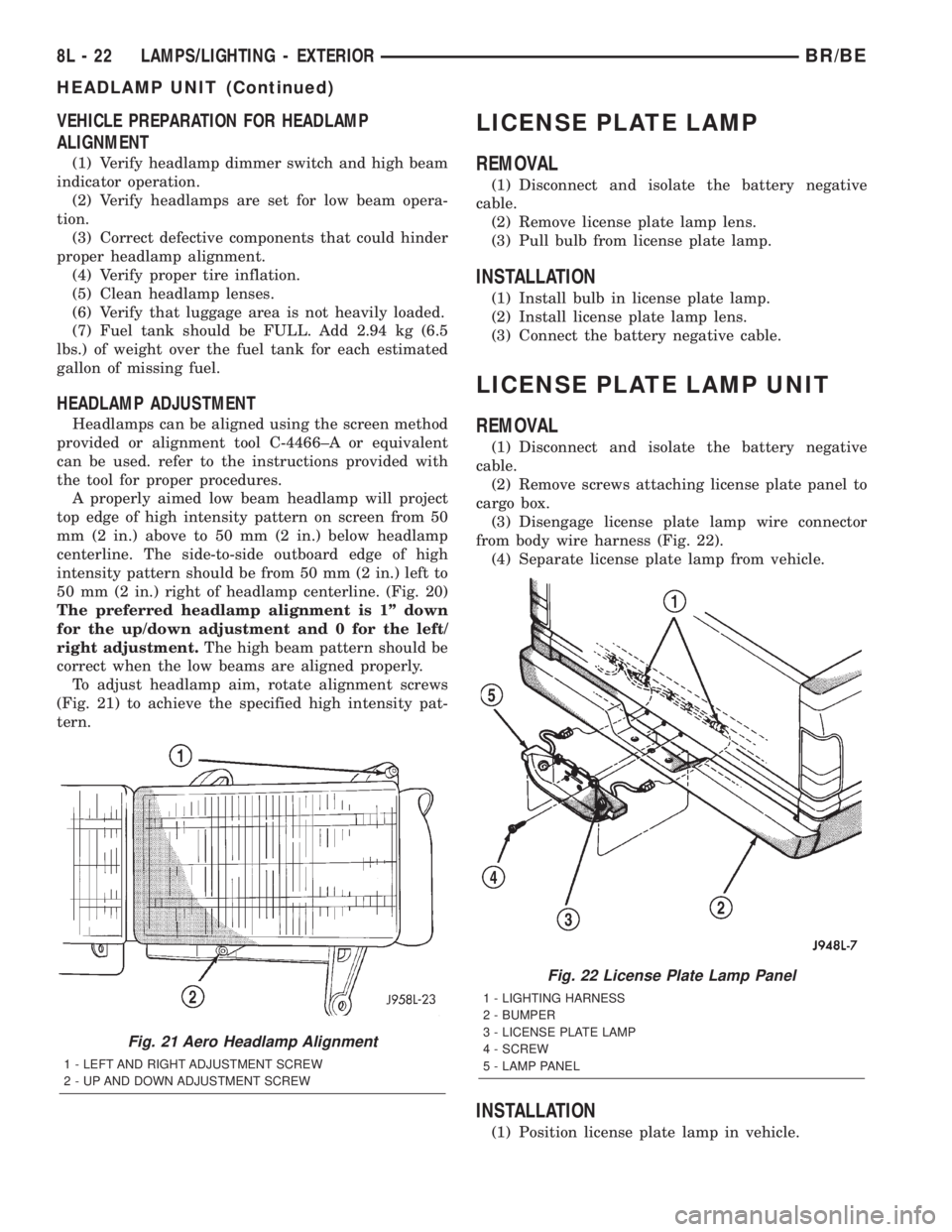

HEADLAMP ADJUSTMENT

Headlamps can be aligned using the screen method

provided or alignment tool C-4466±A or equivalent

can be used. refer to the instructions provided with

the tool for proper procedures.

A properly aimed low beam headlamp will project

top edge of high intensity pattern on screen from 50

mm (2 in.) above to 50 mm (2 in.) below headlamp

centerline. The side-to-side outboard edge of high

intensity pattern should be from 50 mm (2 in.) left to

50 mm (2 in.) right of headlamp centerline. (Fig. 20)

The preferred headlamp alignment is 1º down

for the up/down adjustment and 0 for the left/

right adjustment.The high beam pattern should be

correct when the low beams are aligned properly.

To adjust headlamp aim, rotate alignment screws

(Fig. 21) to achieve the specified high intensity pat-

tern.

LICENSE PLATE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove license plate lamp lens.

(3) Pull bulb from license plate lamp.

INSTALLATION

(1) Install bulb in license plate lamp.

(2) Install license plate lamp lens.

(3) Connect the battery negative cable.

LICENSE PLATE LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws attaching license plate panel to

cargo box.

(3) Disengage license plate lamp wire connector

from body wire harness (Fig. 22).

(4) Separate license plate lamp from vehicle.

INSTALLATION

(1) Position license plate lamp in vehicle.

Fig. 21 Aero Headlamp Alignment

1 - LEFT AND RIGHT ADJUSTMENT SCREW

2 - UP AND DOWN ADJUSTMENT SCREW

Fig. 22 License Plate Lamp Panel

1 - LIGHTING HARNESS

2 - BUMPER

3 - LICENSE PLATE LAMP

4 - SCREW

5 - LAMP PANEL

8L - 22 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP UNIT (Continued)

Page 543 of 2255

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

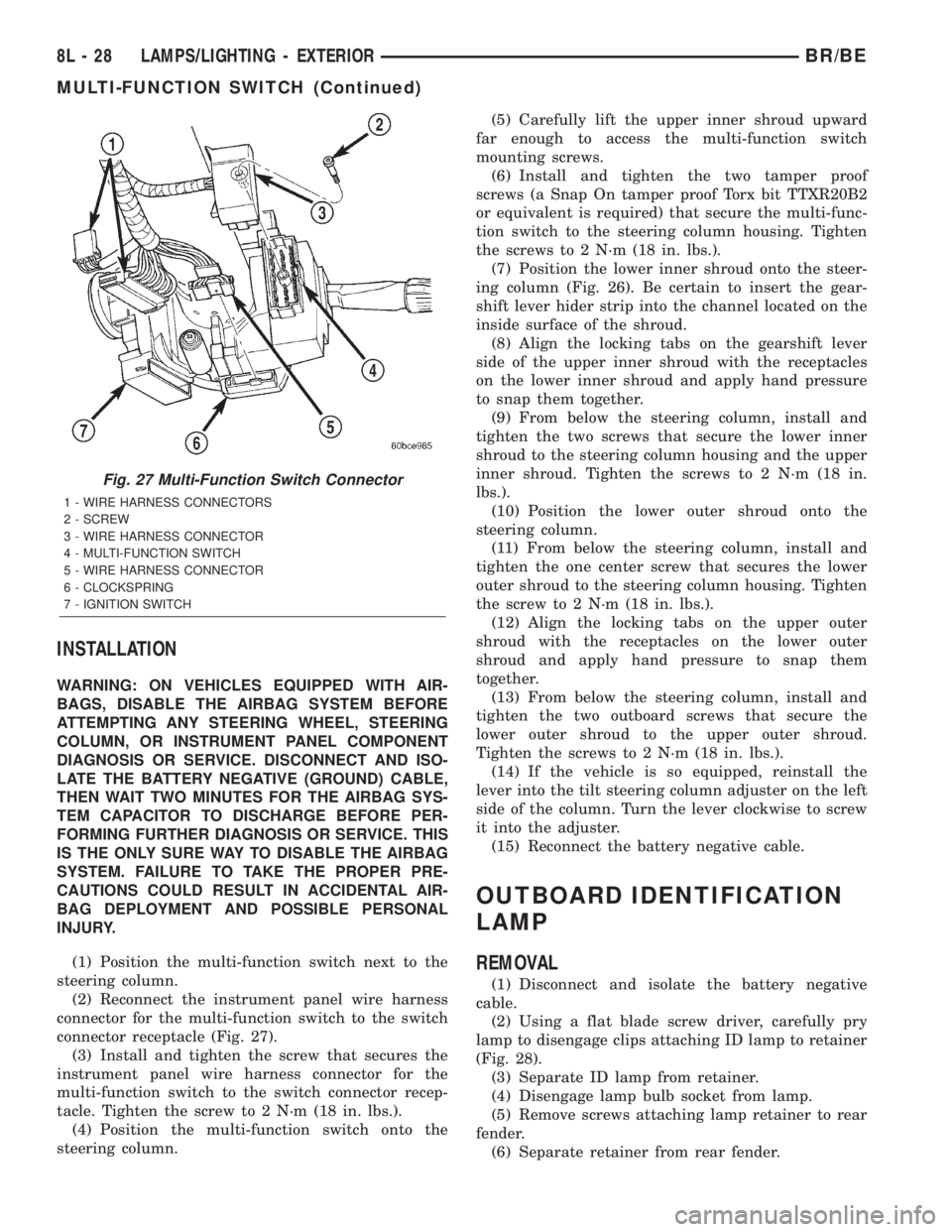

(1) Position the multi-function switch next to the

steering column.

(2) Reconnect the instrument panel wire harness

connector for the multi-function switch to the switch

connector receptacle (Fig. 27).

(3) Install and tighten the screw that secures the

instrument panel wire harness connector for the

multi-function switch to the switch connector recep-

tacle. Tighten the screw to 2 N´m (18 in. lbs.).

(4) Position the multi-function switch onto the

steering column.(5) Carefully lift the upper inner shroud upward

far enough to access the multi-function switch

mounting screws.

(6) Install and tighten the two tamper proof

screws (a Snap On tamper proof Torx bit TTXR20B2

or equivalent is required) that secure the multi-func-

tion switch to the steering column housing. Tighten

the screws to 2 N´m (18 in. lbs.).

(7) Position the lower inner shroud onto the steer-

ing column (Fig. 26). Be certain to insert the gear-

shift lever hider strip into the channel located on the

inside surface of the shroud.

(8) Align the locking tabs on the gearshift lever

side of the upper inner shroud with the receptacles

on the lower inner shroud and apply hand pressure

to snap them together.

(9) From below the steering column, install and

tighten the two screws that secure the lower inner

shroud to the steering column housing and the upper

inner shroud. Tighten the screws to 2 N´m (18 in.

lbs.).

(10) Position the lower outer shroud onto the

steering column.

(11) From below the steering column, install and

tighten the one center screw that secures the lower

outer shroud to the steering column housing. Tighten

the screw to 2 N´m (18 in. lbs.).

(12) Align the locking tabs on the upper outer

shroud with the receptacles on the lower outer

shroud and apply hand pressure to snap them

together.

(13) From below the steering column, install and

tighten the two outboard screws that secure the

lower outer shroud to the upper outer shroud.

Tighten the screws to 2 N´m (18 in. lbs.).

(14) If the vehicle is so equipped, reinstall the

lever into the tilt steering column adjuster on the left

side of the column. Turn the lever clockwise to screw

it into the adjuster.

(15) Reconnect the battery negative cable.

OUTBOARD IDENTIFICATION

LAMP

REMOVAL

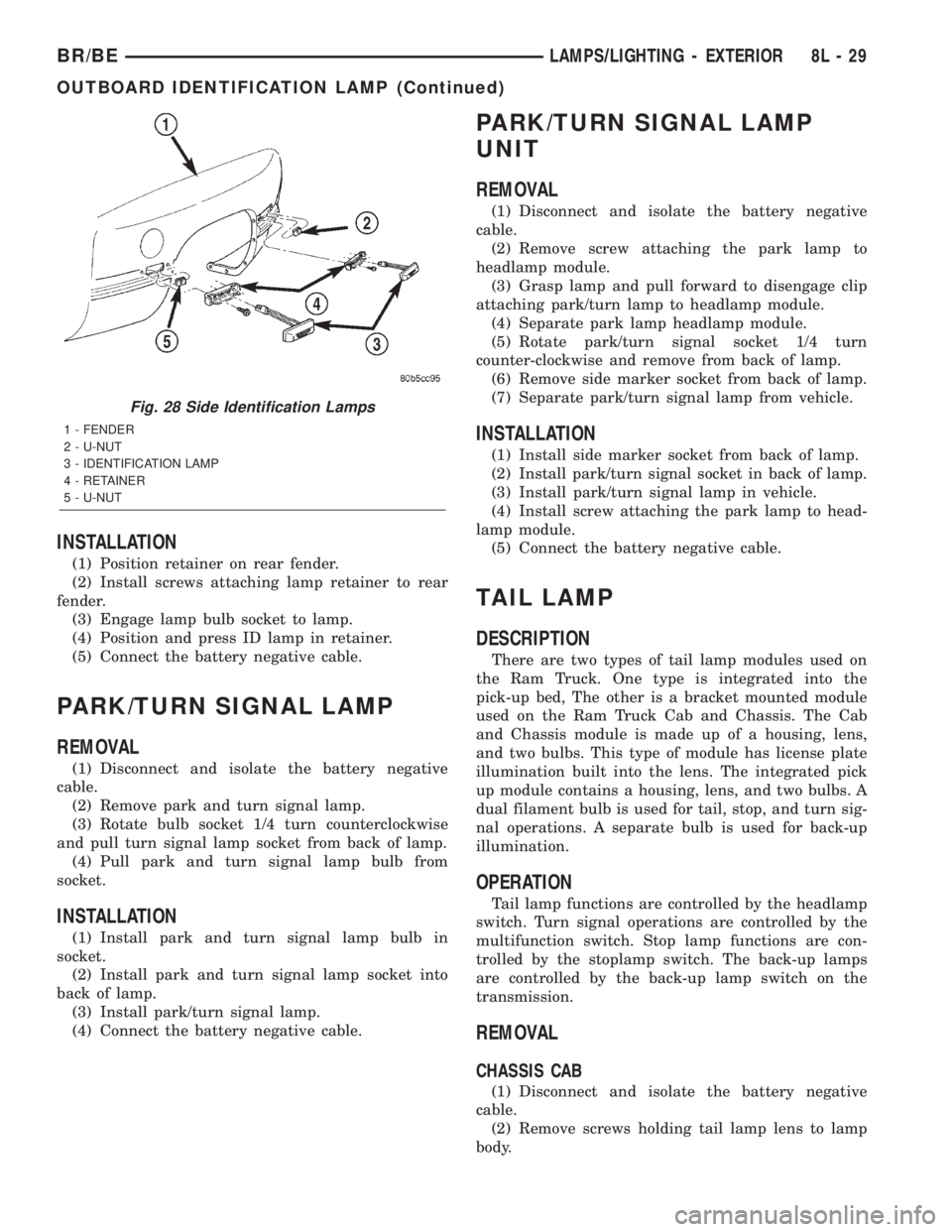

(1) Disconnect and isolate the battery negative

cable.

(2) Using a flat blade screw driver, carefully pry

lamp to disengage clips attaching ID lamp to retainer

(Fig. 28).

(3) Separate ID lamp from retainer.

(4) Disengage lamp bulb socket from lamp.

(5) Remove screws attaching lamp retainer to rear

fender.

(6) Separate retainer from rear fender.

Fig. 27 Multi-Function Switch Connector

1 - WIRE HARNESS CONNECTORS

2 - SCREW

3 - WIRE HARNESS CONNECTOR

4 - MULTI-FUNCTION SWITCH

5 - WIRE HARNESS CONNECTOR

6 - CLOCKSPRING

7 - IGNITION SWITCH

8L - 28 LAMPS/LIGHTING - EXTERIORBR/BE

MULTI-FUNCTION SWITCH (Continued)

Page 544 of 2255

INSTALLATION

(1) Position retainer on rear fender.

(2) Install screws attaching lamp retainer to rear

fender.

(3) Engage lamp bulb socket to lamp.

(4) Position and press ID lamp in retainer.

(5) Connect the battery negative cable.

PARK/TURN SIGNAL LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove park and turn signal lamp.

(3) Rotate bulb socket 1/4 turn counterclockwise

and pull turn signal lamp socket from back of lamp.

(4) Pull park and turn signal lamp bulb from

socket.

INSTALLATION

(1) Install park and turn signal lamp bulb in

socket.

(2) Install park and turn signal lamp socket into

back of lamp.

(3) Install park/turn signal lamp.

(4) Connect the battery negative cable.

PARK/TURN SIGNAL LAMP

UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screw attaching the park lamp to

headlamp module.

(3) Grasp lamp and pull forward to disengage clip

attaching park/turn lamp to headlamp module.

(4) Separate park lamp headlamp module.

(5) Rotate park/turn signal socket 1/4 turn

counter-clockwise and remove from back of lamp.

(6) Remove side marker socket from back of lamp.

(7) Separate park/turn signal lamp from vehicle.

INSTALLATION

(1) Install side marker socket from back of lamp.

(2) Install park/turn signal socket in back of lamp.

(3) Install park/turn signal lamp in vehicle.

(4) Install screw attaching the park lamp to head-

lamp module.

(5) Connect the battery negative cable.

TAIL LAMP

DESCRIPTION

There are two types of tail lamp modules used on

the Ram Truck. One type is integrated into the

pick-up bed, The other is a bracket mounted module

used on the Ram Truck Cab and Chassis. The Cab

and Chassis module is made up of a housing, lens,

and two bulbs. This type of module has license plate

illumination built into the lens. The integrated pick

up module contains a housing, lens, and two bulbs. A

dual filament bulb is used for tail, stop, and turn sig-

nal operations. A separate bulb is used for back-up

illumination.

OPERATION

Tail lamp functions are controlled by the headlamp

switch. Turn signal operations are controlled by the

multifunction switch. Stop lamp functions are con-

trolled by the stoplamp switch. The back-up lamps

are controlled by the back-up lamp switch on the

transmission.

REMOVAL

CHASSIS CAB

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws holding tail lamp lens to lamp

body.

Fig. 28 Side Identification Lamps

1 - FENDER

2 - U-NUT

3 - IDENTIFICATION LAMP

4 - RETAINER

5 - U-NUT

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 29

OUTBOARD IDENTIFICATION LAMP (Continued)