charging DODGE RAM 2002 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1063 of 2255

(8) Remove the cigar lighter or power outlet mount

from the instrument panel.

INSTALLATION

(1) Reconnect the instrument panel wire harness

connector to the cigar lighter or power outlet recep-

tacle base connector receptacle.

(2) Install the cigar lighter or power outlet mount

into the instrument panel.

(3) Align the splines on the outside of the cigar

lighter or power outlet receptacle base connector

receptacle with the grooves on the inside of the

mount.

(4) Press firmly on the cigar lighter or power out-

let receptacle base until the retaining bosses of the

mount are fully engaged in their receptacles.

(5) Install the cigar lighter knob and element into

the cigar lighter receptacle base, or the protective cap

into the power outlet receptacle base.

(6) Reconnect the battery negative cable.

CIRCUIT BREAKER

DESCRIPTION

Automatic resetting circuit breakers are used to

protect a system circuit from a short circuit or over-

load. Some examples of his condition can be caused

by an obstructed or stuck seat adjuster or power win-

dow motor.

The circuit breaker cannot be repaired and, if

faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - CIRCUIT BREAKER

For circuit descriptions and diagrams, refer to Wir-

ing Diagrams.

(1) Locate the correct circuit breaker in the junc-

tion block. Pull out the circuit breaker slightly, but

be certain that the circuit breaker terminals still con-

tact the terminals in the junction block cavities.

(2) Connect the negative lead of a 12-volt DC volt-

meter to a good ground.

(3) With the voltmeter positive lead, check both

terminals of the circuit breaker for battery voltage.

If only one terminal has battery voltage, the circuit

breaker is faulty and must be replaced. If neither ter-

minal has battery voltage, repair the open circuit

from the Power Distribution Center (PDC) as

required.

GENERATOR CARTRIDGE

FUSE

DESCRIPTION

A 140 ampere generator cartridge fuse is used on

this model. The generator cartridge fuse is similar to

other cartridge fuses found in the Power Distribution

Center (PDC). This fuse has a color-coded plastic

housing and a clear plastic fuse conductor inspection

cover like other cartridge fuses, but has a higher cur-

rent rating and is connected and secured with screws

instead of being pushed onto male spade-type termi-

nals. The generator cartridge fuse cannot be repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The generator cartridge fuse is secured between

the two B(+) terminal stud connection bus bars

within the Power Distribution Center (PDC). This

fuse protects the vehicle electrical system from dam-

age that could be caused by excessive charging sys-

tem output and/or excessive electrical system current

levels resulting from a faulty generator or faulty

charging system control circuits. If the current rating

of the fuse is exceeded, the fuse conductor melts to

open the generator output circuit connection to the

PDC. If a generator cartridge fuse fails, be certain to

completely inspect and test the vehicle charging sys-

tem before replacing the fuse and returning the vehi-

cle to service. Refer toCharging Systemfor the

charging system diagnostic procedures. Refer toWir-

ing Diagramsfor the location of complete PDC cir-

cuit diagrams.

REMOVAL

If a generator cartridge fuse fails, be certain to

inspect and test the vehicle charging system before

replacing the cartridge fuse and returning the vehicle

to service. Refer toCharging Systemin the index of

this service manual for the charging system diagnos-

tic procedures.

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Power

Distribution Center (PDC).

(3) Remove the two screws that secure the genera-

tor cartridge fuse to the two B(+) terminal stud bus

bars within the PDC.

(4) Remove the generator cartridge fuse from the

PDC.

INSTALLATION

If a generator cartridge fuse fails, be certain to

inspect and test the vehicle charging system before

replacing the cartridge fuse and returning the vehicle

8W - 97 - 4 8W-97 POWER DISTRIBUTIONBR/BE

CIGAR LIGHTER OUTLET (Continued)

Page 1064 of 2255

to service. Refer toCharging Systemin the index of

this service manual for the charging system diagnos-

tic procedures.

(1) Position the generator cartridge fuse onto the

two B(+) terminal stud bus bars within the PDC.

(2) Install and tighten the two screws that secure

the generator cartridge fuse to the two B(+) terminal

stud bus bars within the PDC. Tighten the screws to

3.4 N´m (30 in. lbs.).Be certain that both screws

are tightened to the proper torque value.

(3) Install and latch the cover onto the PDC.

(4) Reconnect the battery negative cable.

IOD FUSE

DESCRIPTION

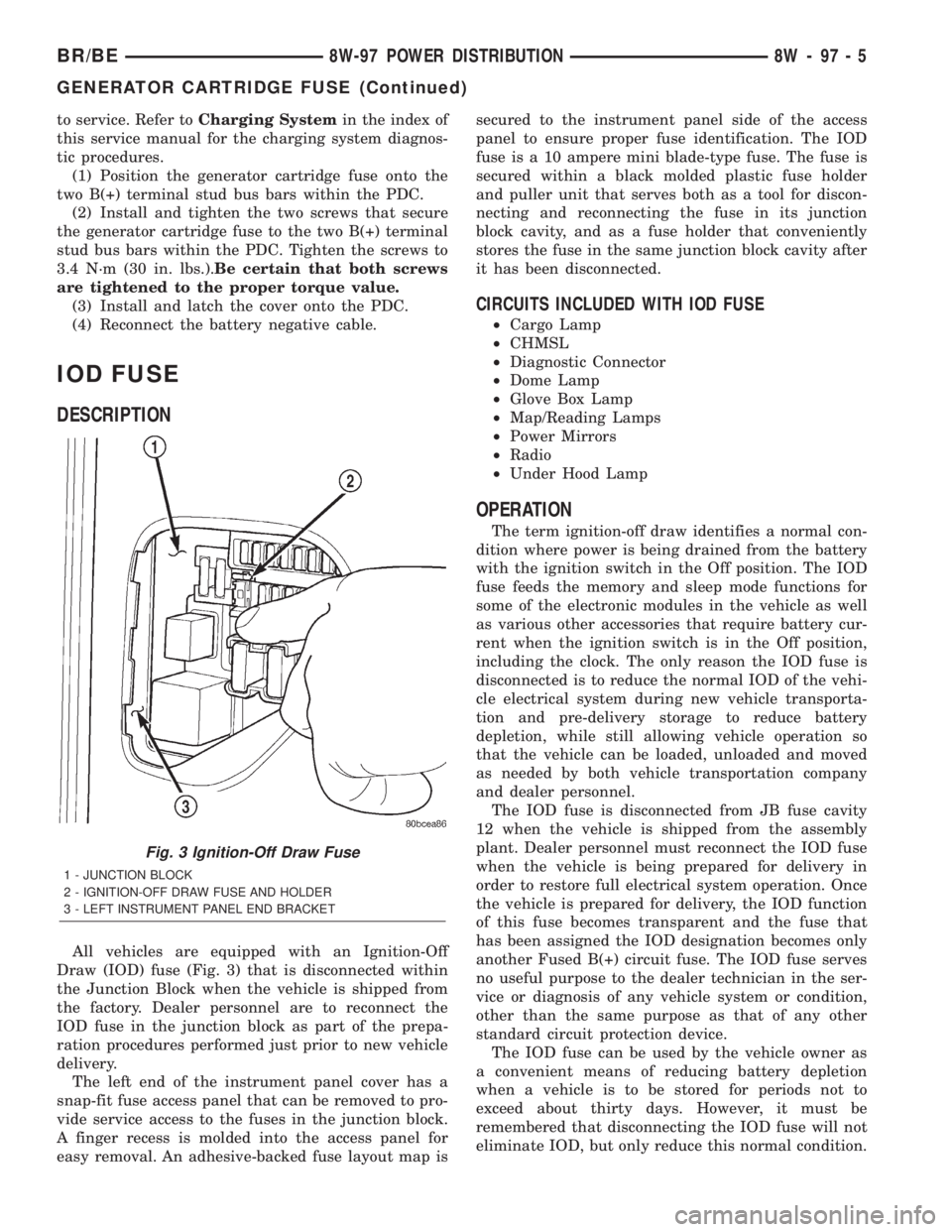

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse (Fig. 3) that is disconnected within

the Junction Block when the vehicle is shipped from

the factory. Dealer personnel are to reconnect the

IOD fuse in the junction block as part of the prepa-

ration procedures performed just prior to new vehicle

delivery.

The left end of the instrument panel cover has a

snap-fit fuse access panel that can be removed to pro-

vide service access to the fuses in the junction block.

A finger recess is molded into the access panel for

easy removal. An adhesive-backed fuse layout map issecured to the instrument panel side of the access

panel to ensure proper fuse identification. The IOD

fuse is a 10 ampere mini blade-type fuse. The fuse is

secured within a black molded plastic fuse holder

and puller unit that serves both as a tool for discon-

necting and reconnecting the fuse in its junction

block cavity, and as a fuse holder that conveniently

stores the fuse in the same junction block cavity after

it has been disconnected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cargo Lamp

²CHMSL

²Diagnostic Connector

²Dome Lamp

²Glove Box Lamp

²Map/Reading Lamps

²Power Mirrors

²Radio

²Under Hood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position,

including the clock. The only reason the IOD fuse is

disconnected is to reduce the normal IOD of the vehi-

cle electrical system during new vehicle transporta-

tion and pre-delivery storage to reduce battery

depletion, while still allowing vehicle operation so

that the vehicle can be loaded, unloaded and moved

as needed by both vehicle transportation company

and dealer personnel.

The IOD fuse is disconnected from JB fuse cavity

12 when the vehicle is shipped from the assembly

plant. Dealer personnel must reconnect the IOD fuse

when the vehicle is being prepared for delivery in

order to restore full electrical system operation. Once

the vehicle is prepared for delivery, the IOD function

of this fuse becomes transparent and the fuse that

has been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that disconnecting the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

Fig. 3 Ignition-Off Draw Fuse

1 - JUNCTION BLOCK

2 - IGNITION-OFF DRAW FUSE AND HOLDER

3 - LEFT INSTRUMENT PANEL END BRACKET

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 5

GENERATOR CARTRIDGE FUSE (Continued)

Page 1079 of 2255

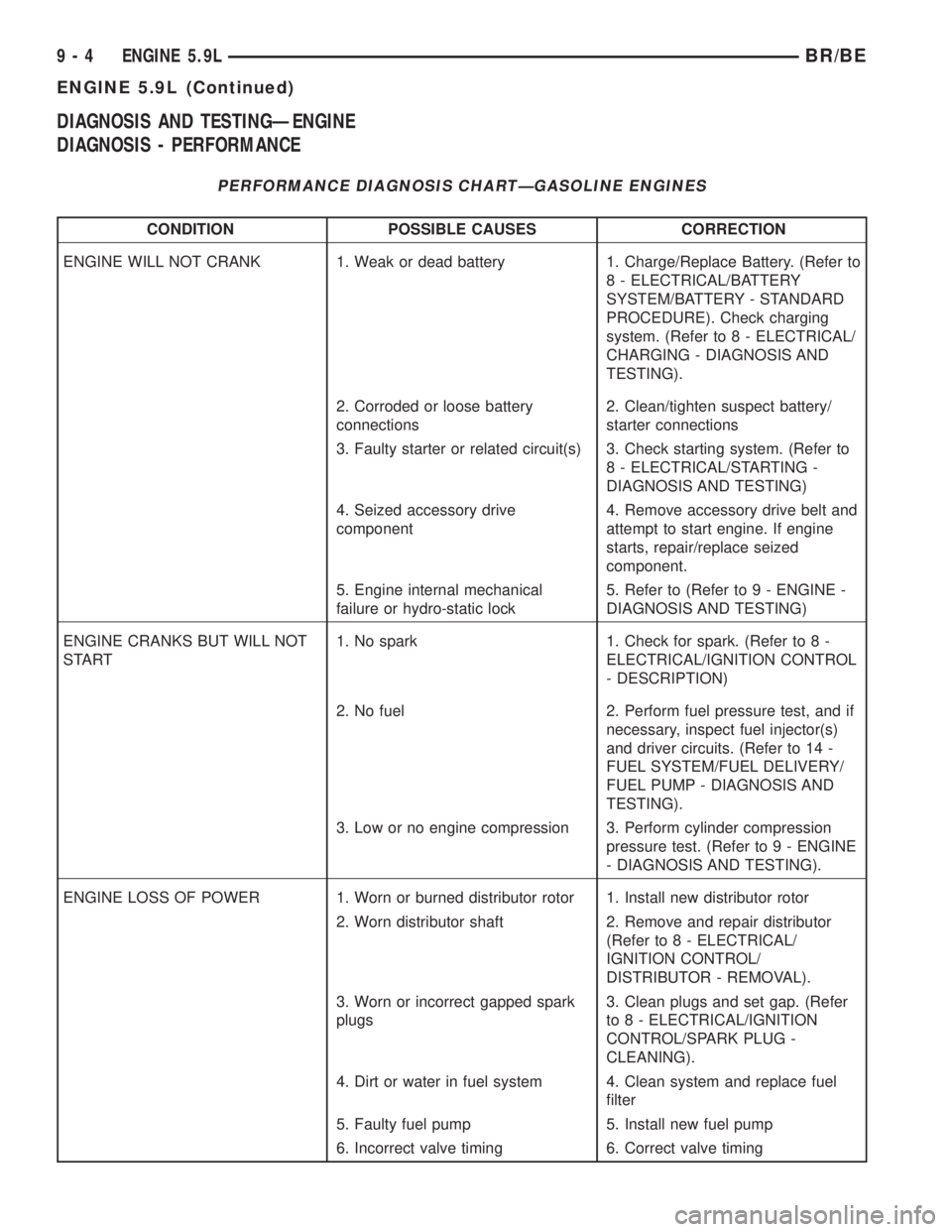

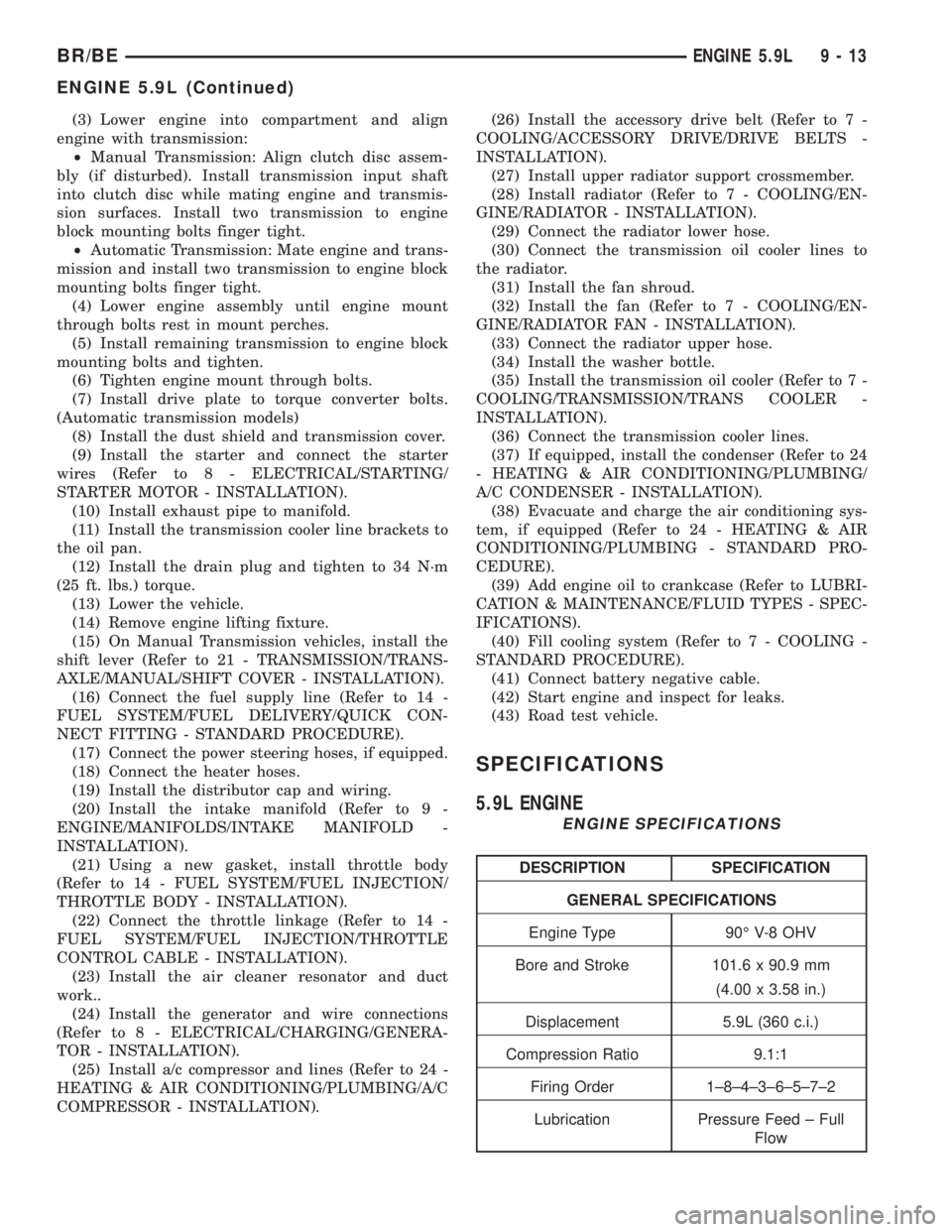

DIAGNOSIS AND TESTINGÐENGINE

DIAGNOSIS - PERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to

8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD

PROCEDURE). Check charging

system. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND

TESTING).

2. Corroded or loose battery

connections2. Clean/tighten suspect battery/

starter connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to

8 - ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Seized accessory drive

component4. Remove accessory drive belt and

attempt to start engine. If engine

starts, repair/replace seized

component.

5. Engine internal mechanical

failure or hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT WILL NOT

START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL

- DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s)

and driver circuits. (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/

FUEL PUMP - DIAGNOSIS AND

TESTING).

3. Low or no engine compression 3. Perform cylinder compression

pressure test. (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor

(Refer to 8 - ELECTRICAL/

IGNITION CONTROL/

DISTRIBUTOR - REMOVAL).

3. Worn or incorrect gapped spark

plugs3. Clean plugs and set gap. (Refer

to 8 - ELECTRICAL/IGNITION

CONTROL/SPARK PLUG -

CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel

filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

9 - 4 ENGINE 5.9LBR/BE

ENGINE 5.9L (Continued)

Page 1087 of 2255

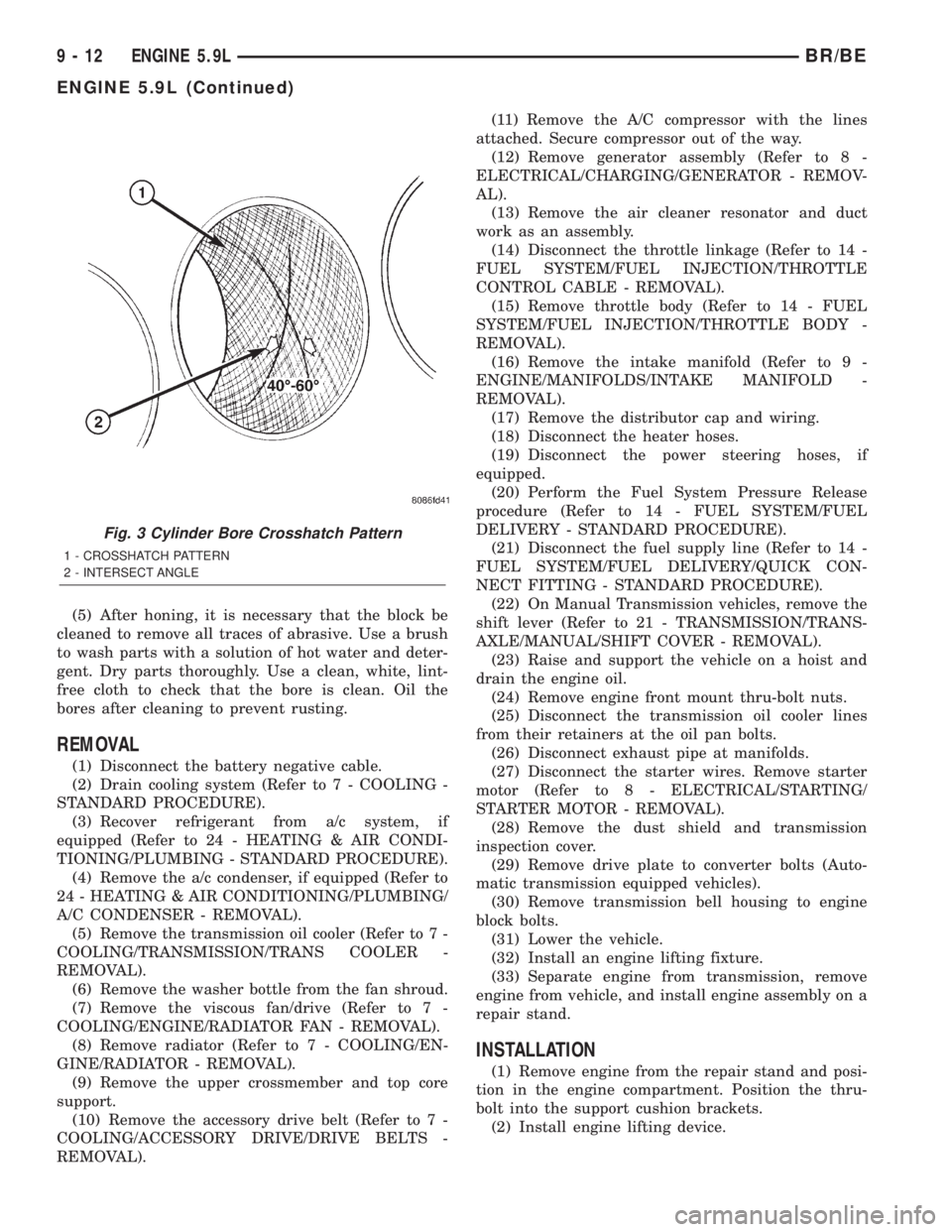

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Recover refrigerant from a/c system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(4) Remove the a/c condenser, if equipped (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(6) Remove the washer bottle from the fan shroud.

(7) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(8) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(9) Remove the upper crossmember and top core

support.

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).(11) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(12) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR - REMOV-

AL).

(13) Remove the air cleaner resonator and duct

work as an assembly.

(14) Disconnect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL).

(15) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(16) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(17) Remove the distributor cap and wiring.

(18) Disconnect the heater hoses.

(19) Disconnect the power steering hoses, if

equipped.

(20) Perform the Fuel System Pressure Release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(21) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(22) On Manual Transmission vehicles, remove the

shift lever (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/SHIFT COVER - REMOVAL).

(23) Raise and support the vehicle on a hoist and

drain the engine oil.

(24) Remove engine front mount thru-bolt nuts.

(25) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(26) Disconnect exhaust pipe at manifolds.

(27) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(28) Remove the dust shield and transmission

inspection cover.

(29) Remove drive plate to converter bolts (Auto-

matic transmission equipped vehicles).

(30) Remove transmission bell housing to engine

block bolts.

(31) Lower the vehicle.

(32) Install an engine lifting fixture.

(33) Separate engine from transmission, remove

engine from vehicle, and install engine assembly on a

repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install engine lifting device.

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

9 - 12 ENGINE 5.9LBR/BE

ENGINE 5.9L (Continued)

Page 1088 of 2255

(3) Lower engine into compartment and align

engine with transmission:

²Manual Transmission: Align clutch disc assem-

bly (if disturbed). Install transmission input shaft

into clutch disc while mating engine and transmis-

sion surfaces. Install two transmission to engine

block mounting bolts finger tight.

²Automatic Transmission: Mate engine and trans-

mission and install two transmission to engine block

mounting bolts finger tight.

(4) Lower engine assembly until engine mount

through bolts rest in mount perches.

(5) Install remaining transmission to engine block

mounting bolts and tighten.

(6) Tighten engine mount through bolts.

(7) Install drive plate to torque converter bolts.

(Automatic transmission models)

(8) Install the dust shield and transmission cover.

(9) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(10) Install exhaust pipe to manifold.

(11) Install the transmission cooler line brackets to

the oil pan.

(12) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(13) Lower the vehicle.

(14) Remove engine lifting fixture.

(15) On Manual Transmission vehicles, install the

shift lever (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/SHIFT COVER - INSTALLATION).

(16) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(17) Connect the power steering hoses, if equipped.

(18) Connect the heater hoses.

(19) Install the distributor cap and wiring.

(20) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(21) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(22) Connect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION).

(23) Install the air cleaner resonator and duct

work..

(24) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(25) Install a/c compressor and lines (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).(26) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(27) Install upper radiator support crossmember.

(28) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(29) Connect the radiator lower hose.

(30) Connect the transmission oil cooler lines to

the radiator.

(31) Install the fan shroud.

(32) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(33) Connect the radiator upper hose.

(34) Install the washer bottle.

(35) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(36) Connect the transmission cooler lines.

(37) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(38) Evacuate and charge the air conditioning sys-

tem, if equipped (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(39) Add engine oil to crankcase (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES - SPEC-

IFICATIONS).

(40) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(41) Connect battery negative cable.

(42) Start engine and inspect for leaks.

(43) Road test vehicle.

SPECIFICATIONS

5.9L ENGINE

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É V-8 OHV

Bore and Stroke 101.6 x 90.9 mm

(4.00 x 3.58 in.)

Displacement 5.9L (360 c.i.)

Compression Ratio 9.1:1

Firing Order 1±8±4±3±6±5±7±2

Lubrication Pressure Feed ± Full

Flow

BR/BEENGINE 5.9L 9 - 13

ENGINE 5.9L (Continued)

Page 1125 of 2255

(2) Position the oil pump cover onto the pump

body. Tighten cover bolts to 11 N´m (95 in. lbs.)

torque.

(3) Install the relief valve and spring. Insert the

cotter pin.

(4) Tap on a new retainer cap.

(5) Prime oil pump before installation by filling

rotor cavity with engine oil.

INSTALLATION

(1) Install oil pump. During installation slowly

rotate pump body to ensure driveshaft-to-pump rotor

shaft engagement.

(2) Hold the oil pump base flush against mating

surface on No.5 main bearing cap. Finger tighten

pump attaching bolts. Tighten attaching bolts to 41

N´m (30 ft. lbs.) torque.

(3) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

INTAKE MANIFOLD

DESCRIPTION

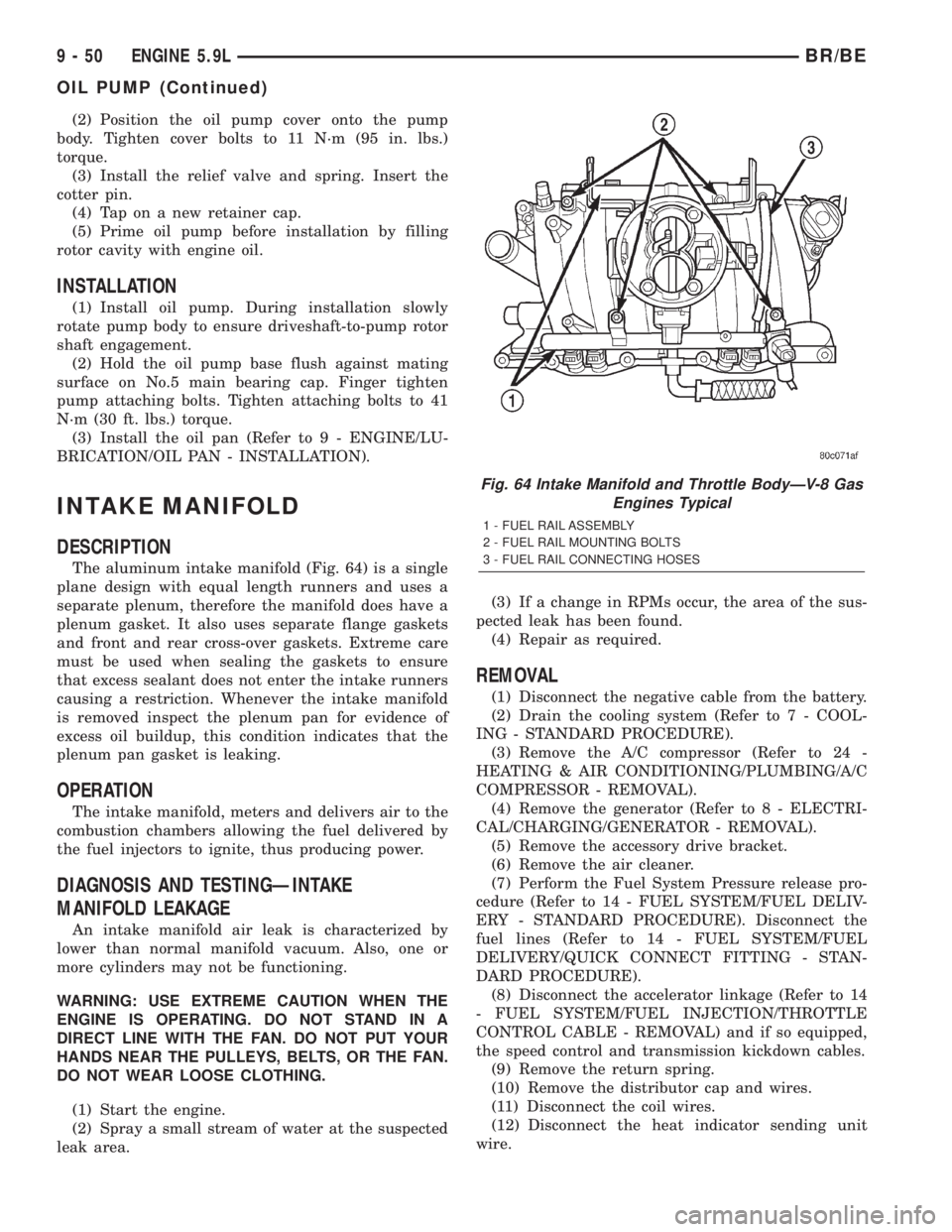

The aluminum intake manifold (Fig. 64) is a single

plane design with equal length runners and uses a

separate plenum, therefore the manifold does have a

plenum gasket. It also uses separate flange gaskets

and front and rear cross-over gaskets. Extreme care

must be used when sealing the gaskets to ensure

that excess sealant does not enter the intake runners

causing a restriction. Whenever the intake manifold

is removed inspect the plenum pan for evidence of

excess oil buildup, this condition indicates that the

plenum pan gasket is leaking.

OPERATION

The intake manifold, meters and delivers air to the

combustion chambers allowing the fuel delivered by

the fuel injectors to ignite, thus producing power.

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.(3) If a change in RPMs occur, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL).

(4) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner.

(7) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel lines (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect the accelerator linkage (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL) and if so equipped,

the speed control and transmission kickdown cables.

(9) Remove the return spring.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the heat indicator sending unit

wire.

Fig. 64 Intake Manifold and Throttle BodyÐV-8 Gas

Engines Typical

1 - FUEL RAIL ASSEMBLY

2 - FUEL RAIL MOUNTING BOLTS

3 - FUEL RAIL CONNECTING HOSES

9 - 50 ENGINE 5.9LBR/BE

OIL PUMP (Continued)

Page 1134 of 2255

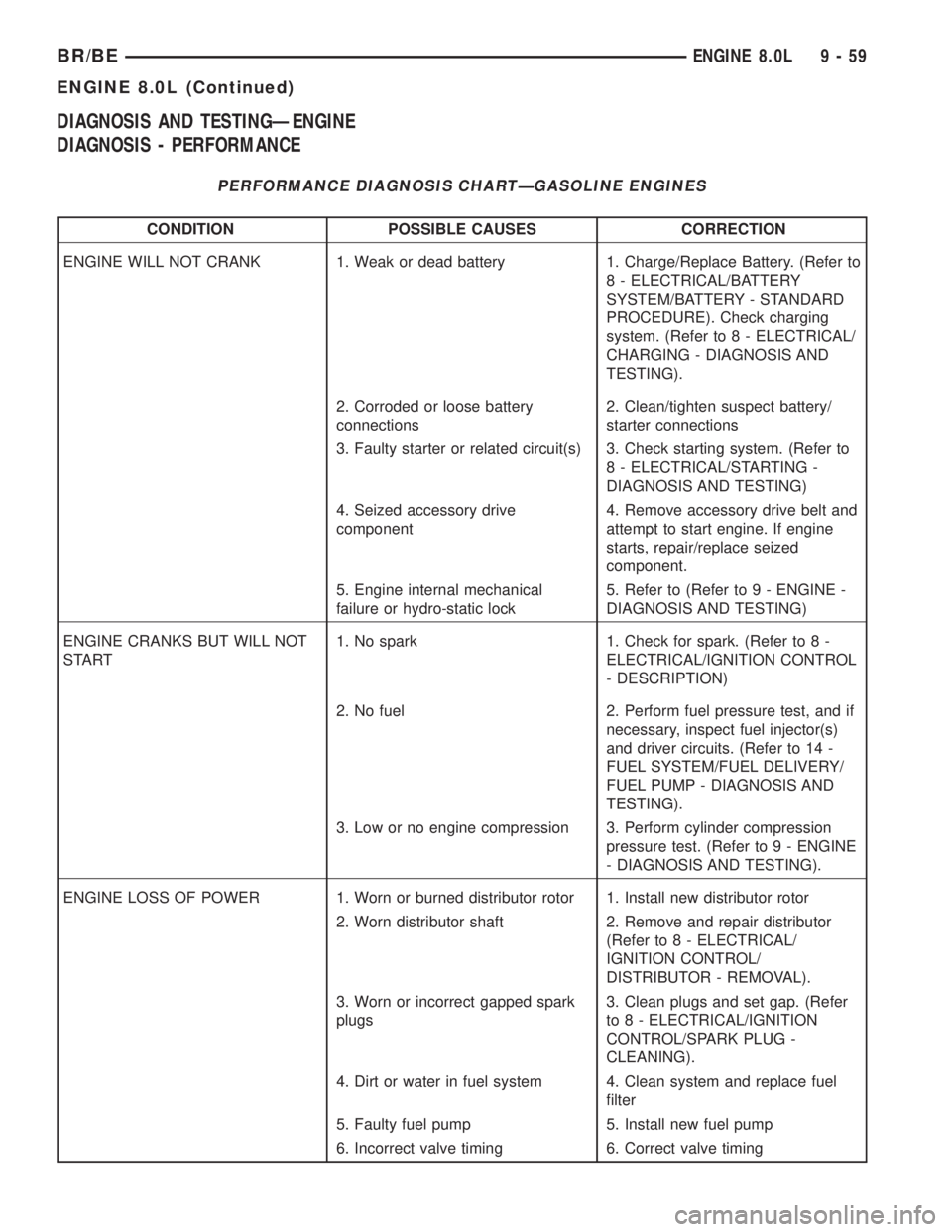

DIAGNOSIS AND TESTINGÐENGINE

DIAGNOSIS - PERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to

8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD

PROCEDURE). Check charging

system. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND

TESTING).

2. Corroded or loose battery

connections2. Clean/tighten suspect battery/

starter connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to

8 - ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Seized accessory drive

component4. Remove accessory drive belt and

attempt to start engine. If engine

starts, repair/replace seized

component.

5. Engine internal mechanical

failure or hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT WILL NOT

START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL

- DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s)

and driver circuits. (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/

FUEL PUMP - DIAGNOSIS AND

TESTING).

3. Low or no engine compression 3. Perform cylinder compression

pressure test. (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor

(Refer to 8 - ELECTRICAL/

IGNITION CONTROL/

DISTRIBUTOR - REMOVAL).

3. Worn or incorrect gapped spark

plugs3. Clean plugs and set gap. (Refer

to 8 - ELECTRICAL/IGNITION

CONTROL/SPARK PLUG -

CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel

filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

BR/BEENGINE 8.0L 9 - 59

ENGINE 8.0L (Continued)

Page 1142 of 2255

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

REMOVAL

(1) Remove the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Discharge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(4) Remove the upper crossmember.

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(6) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(7) Remove the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

REMOVAL). Set aside.

(8) If equipped, remove the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).(9) Remove the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS -

REMOVAL AND INSTALLATION).

(10) Disconnect the top radiator hose.

(11) Remove the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).

(12) Remove the fan shroud.

(13) Disconnect the lower radiator hose.

(14) Disconnect the transmission cooler lines.

(15) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(16) Remove the generator with the wire connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - REMOVAL).

(17) Remove the air cleaner.

(18) Disconnect the throttle linkage.

(19) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(20) Remove the upper intake manifold (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(21) Remove the coil assemblies with the ignition

cables.

(22) Disconnect the heater hoses.

(23) Disconnect the power steering hoses, if

equipped.

(24) Perform the Fuel System Pressure release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). Disconnect

the fuel line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(25) On Manual Transmission vehicles, remove the

shift lever.

(26) Raise and support the vehicle on a hoist.

(27) Remove the drain plug and drain the engine

oil.

(28) Loosen front engine mount thru-bolt nuts.

(29) Remove the transmission cooler line brackets

from oil pan.

(30) Disconnect exhaust pipe at manifold.

(31) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(32) Remove transmission.

(33) Lower vehicle.

CAUTION: DO NOT lift the engine by the intake

manifold.

(34) Install an engine lifting fixture.

(35) Remove engine from vehicle and install

engine assembly on a repair stand.

BR/BEENGINE 8.0L 9 - 67

ENGINE 8.0L (Continued)

Page 1143 of 2255

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install Transmission.

(5) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(6) Install exhaust pipe to manifold.

(7) Install the transmission cooler line brackets

from oil pan.

(8) Tighten the Front mount thru-bolts and nuts to

102N´m (75 ft. lbs.).

(9) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(10) Prime oil pump by squirting oil in the oil fil-

ter mounting hole and filling the J-trap of the front

timing cover. When oil is running out, install oil filter

that has been filled with oil.

(11) Lower the vehicle.

(12) Remove engine lifting fixture.

(13) On Manual Transmission vehicles, install the

shift lever.

(14) Connect the fuel lines (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(15) Connect the heater hoses.

(16) Install the upper intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Install the coil assemblies with the ignition

cables.

(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Connect the throttle linkage.

(20) Install the air cleaner box.

(21) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(22) Install the upper crossmember.

(23) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(24) Connect the lower radiator hose.

(25) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(26) Connect the transmission cooler lines.

(27) Connect the power steering hoses, if equipped.

(28) Install the fan shroud.

(29) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(30) Connect the top radiator hose.(31) Install the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS - INSTAL-

LATION).

(32) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(33) Install the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION).

(34) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(35) Evacuate (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE) and charge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(36) Add coolant to the cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(37) Install the battery.

(38) Warm engine and adjust as required.

(39) Road test vehicle.

SPECIFICATIONS

8.OL ENGINE

DESCRIPTION SPECIFICATION

CAMSHAFT

Bearing Diameter

No. 1 53.16 ± 53.19 mm

(2.093 ± 2.094 in.)

No. 2 52.76 ± 52.78 mm

(2.077 ± 2.078 in.)

No. 3 52.35 ± 52.37 mm

No. 4 51.94 ± 51.97 mm

(2.045 ± 2.046 in.)

No. 5 51.54 ± 51.56 mm

(2.029 ± 2.030 in.)

No. 6 48.74 ± 48.77 mm

(1.919 ± 1.920 in.)

Bearing Journal Diameter

No. 1 53.11 ± 53.14 mm

(2.091 ± 2.092 in.)

No. 2 52.69 ± 52.72 mm

9 - 68 ENGINE 8.0LBR/BE

ENGINE 8.0L (Continued)

Page 1151 of 2255

CYLINDER HEAD

DESCRIPTION

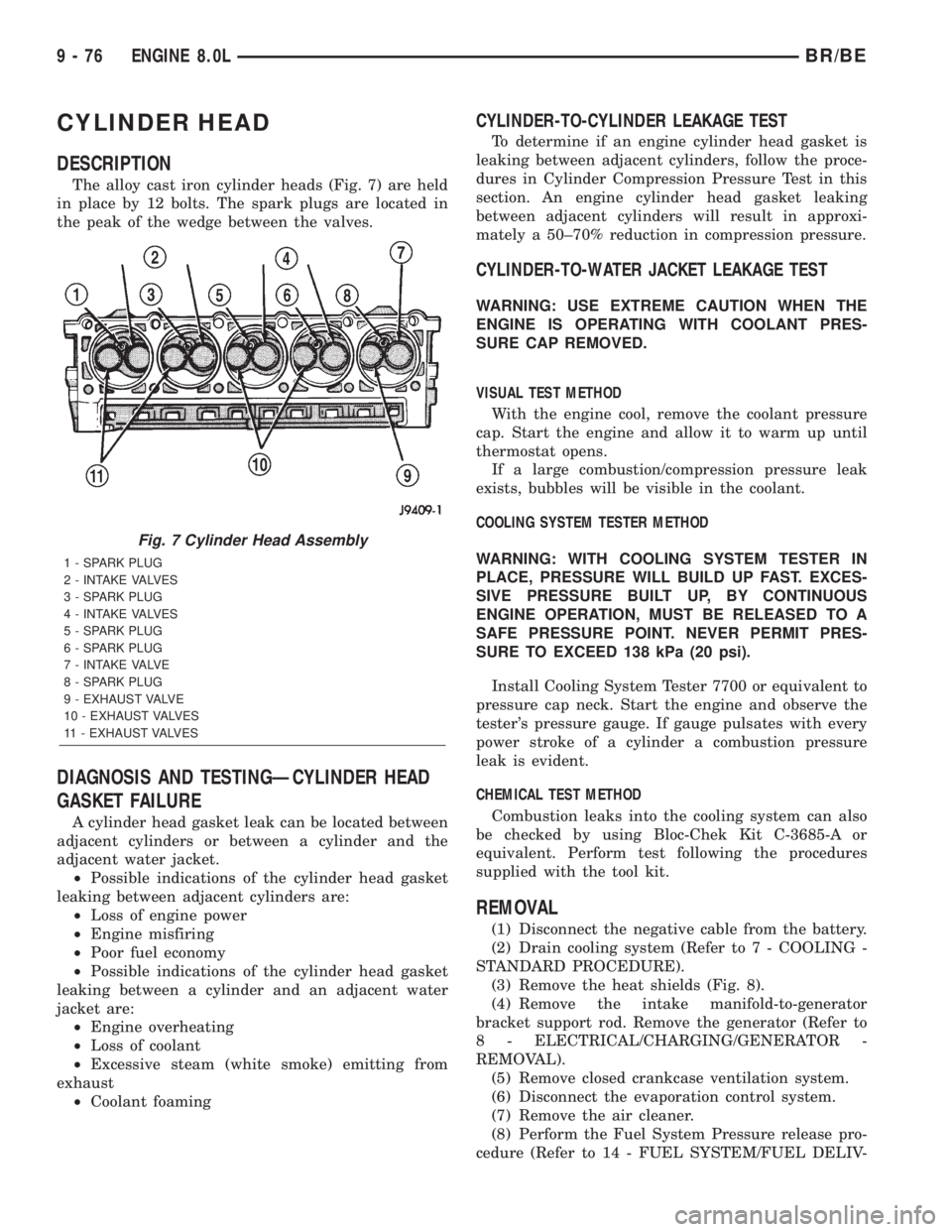

The alloy cast iron cylinder heads (Fig. 7) are held

in place by 12 bolts. The spark plugs are located in

the peak of the wedge between the valves.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the heat shields (Fig. 8).

(4) Remove the intake manifold-to-generator

bracket support rod. Remove the generator (Refer to

8 - ELECTRICAL/CHARGING/GENERATOR -

REMOVAL).

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Remove the air cleaner.

(8) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

Fig. 7 Cylinder Head Assembly

1 - SPARK PLUG

2 - INTAKE VALVES

3 - SPARK PLUG

4 - INTAKE VALVES

5 - SPARK PLUG

6 - SPARK PLUG

7 - INTAKE VALVE

8 - SPARK PLUG

9 - EXHAUST VALVE

10 - EXHAUST VALVES

11 - EXHAUST VALVES

9 - 76 ENGINE 8.0LBR/BE