check engine light DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1740 of 2255

(13) Disconnect gearshift rod and torque shaft

assembly from transmission.

(14) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever.

(15) On4x4models, disconnect shift rod from

transfer case shift lever.

(16) Support rear of engine with safety stand or

jack.

(17) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

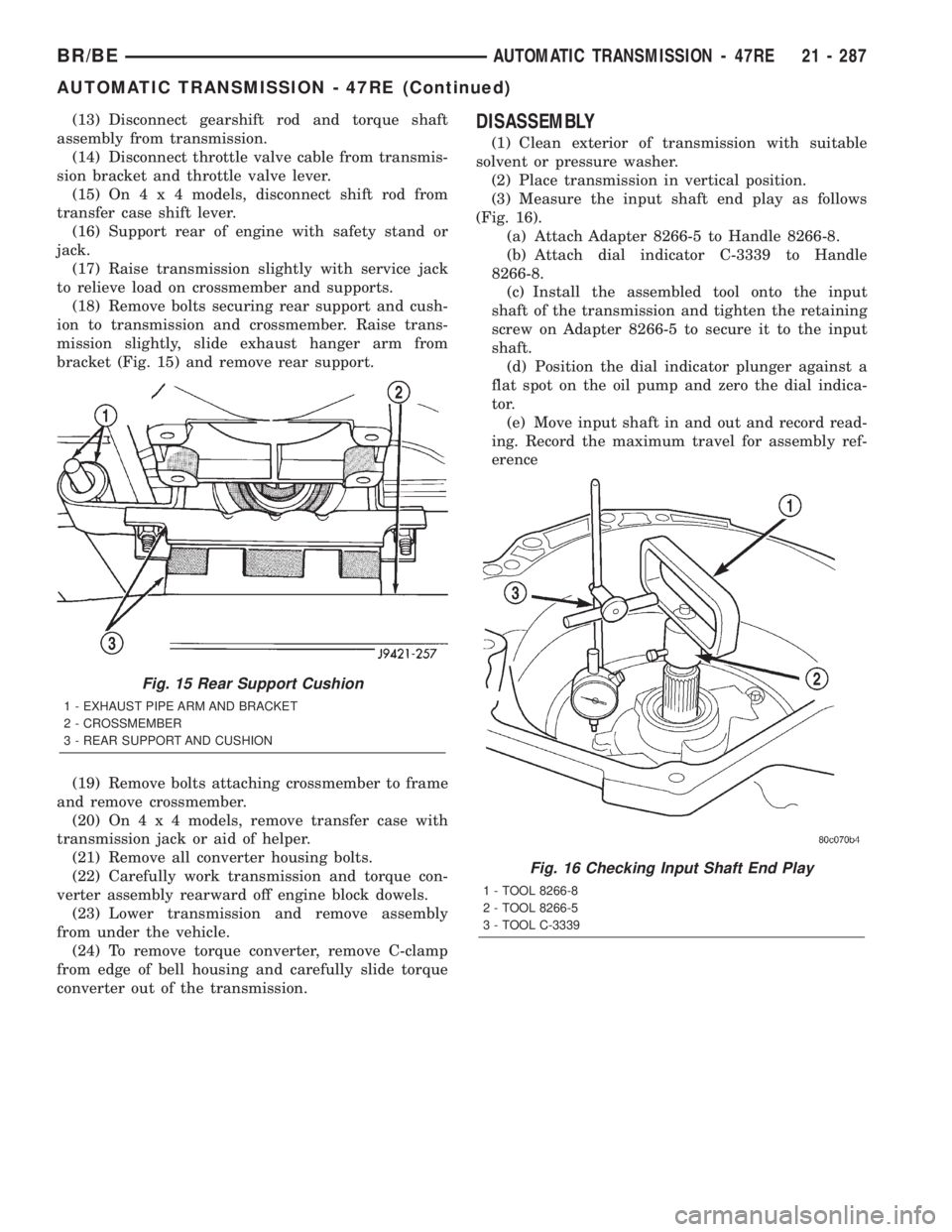

(18) Remove bolts securing rear support and cush-

ion to transmission and crossmember. Raise trans-

mission slightly, slide exhaust hanger arm from

bracket (Fig. 15) and remove rear support.

(19) Remove bolts attaching crossmember to frame

and remove crossmember.

(20) On4x4models, remove transfer case with

transmission jack or aid of helper.

(21) Remove all converter housing bolts.

(22) Carefully work transmission and torque con-

verter assembly rearward off engine block dowels.

(23) Lower transmission and remove assembly

from under the vehicle.

(24) To remove torque converter, remove C-clamp

from edge of bell housing and carefully slide torque

converter out of the transmission.DISASSEMBLY

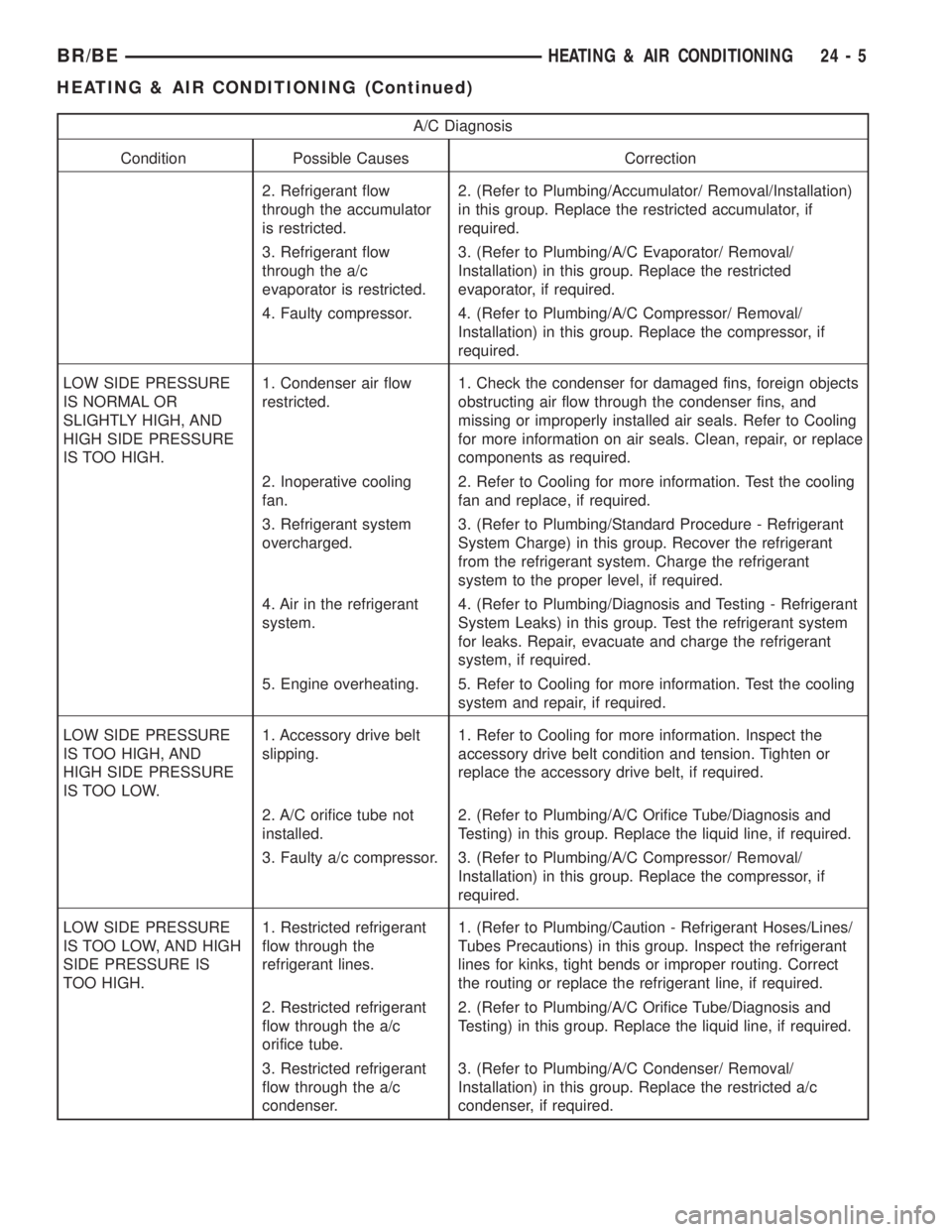

(1) Clean exterior of transmission with suitable

solvent or pressure washer.

(2) Place transmission in vertical position.

(3) Measure the input shaft end play as follows

(Fig. 16).

(a) Attach Adapter 8266-5 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move input shaft in and out and record read-

ing. Record the maximum travel for assembly ref-

erence

Fig. 15 Rear Support Cushion

1 - EXHAUST PIPE ARM AND BRACKET

2 - CROSSMEMBER

3 - REAR SUPPORT AND CUSHION

Fig. 16 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-5

3 - TOOL C-3339

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 287

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 2126 of 2255

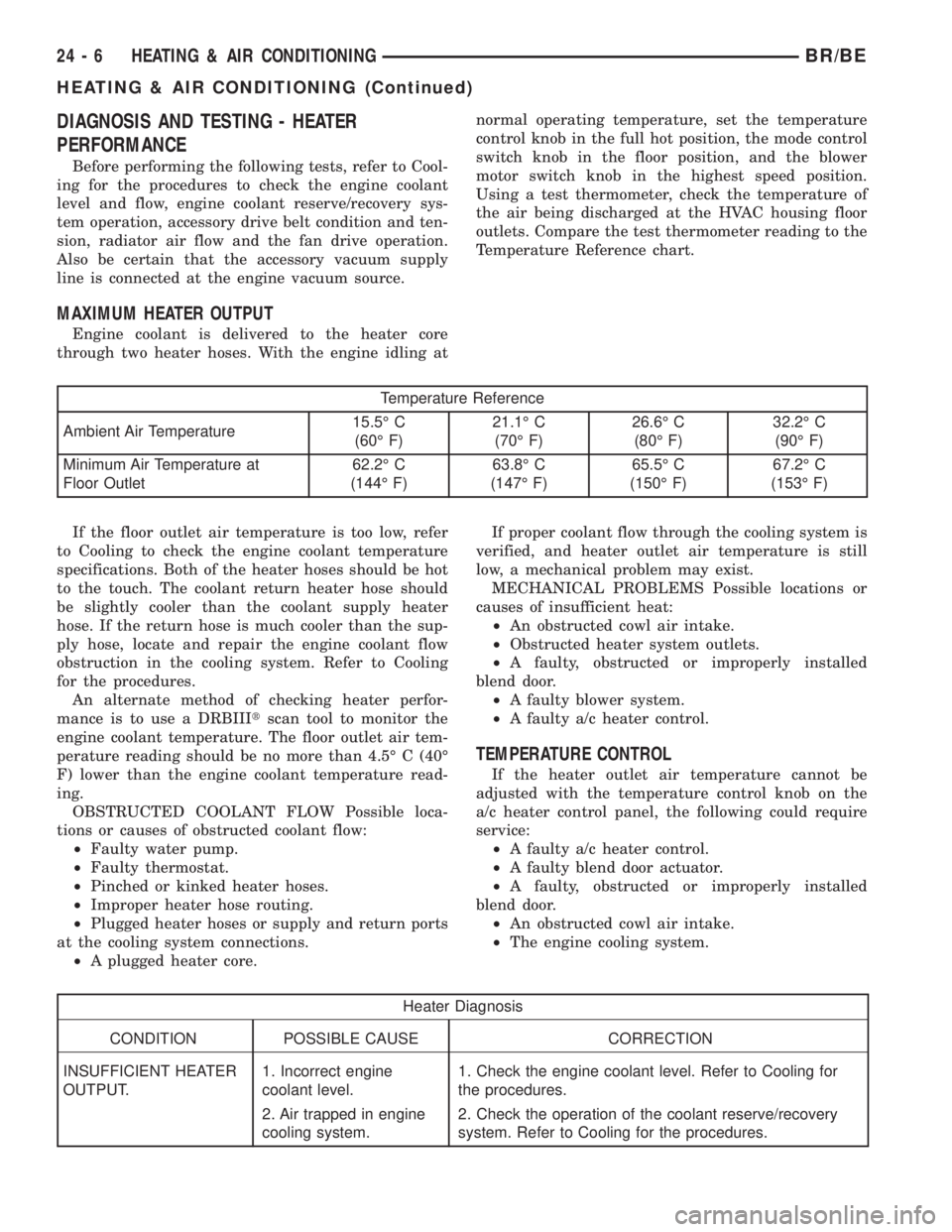

A/C Diagnosis

Condition Possible Causes Correction

2. Refrigerant flow

through the accumulator

is restricted.2. (Refer to Plumbing/Accumulator/ Removal/Installation)

in this group. Replace the restricted accumulator, if

required.

3. Refrigerant flow

through the a/c

evaporator is restricted.3. (Refer to Plumbing/A/C Evaporator/ Removal/

Installation) in this group. Replace the restricted

evaporator, if required.

4. Faulty compressor. 4. (Refer to Plumbing/A/C Compressor/ Removal/

Installation) in this group. Replace the compressor, if

required.

LOW SIDE PRESSURE

IS NORMAL OR

SLIGHTLY HIGH, AND

HIGH SIDE PRESSURE

IS TOO HIGH.1. Condenser air flow

restricted.1. Check the condenser for damaged fins, foreign objects

obstructing air flow through the condenser fins, and

missing or improperly installed air seals. Refer to Cooling

for more information on air seals. Clean, repair, or replace

components as required.

2. Inoperative cooling

fan.2. Refer to Cooling for more information. Test the cooling

fan and replace, if required.

3. Refrigerant system

overcharged.3. (Refer to Plumbing/Standard Procedure - Refrigerant

System Charge) in this group. Recover the refrigerant

from the refrigerant system. Charge the refrigerant

system to the proper level, if required.

4. Air in the refrigerant

system.4. (Refer to Plumbing/Diagnosis and Testing - Refrigerant

System Leaks) in this group. Test the refrigerant system

for leaks. Repair, evacuate and charge the refrigerant

system, if required.

5. Engine overheating. 5. Refer to Cooling for more information. Test the cooling

system and repair, if required.

LOW SIDE PRESSURE

IS TOO HIGH, AND

HIGH SIDE PRESSURE

IS TOO LOW.1. Accessory drive belt

slipping.1. Refer to Cooling for more information. Inspect the

accessory drive belt condition and tension. Tighten or

replace the accessory drive belt, if required.

2. A/C orifice tube not

installed.2. (Refer to Plumbing/A/C Orifice Tube/Diagnosis and

Testing) in this group. Replace the liquid line, if required.

3. Faulty a/c compressor. 3. (Refer to Plumbing/A/C Compressor/ Removal/

Installation) in this group. Replace the compressor, if

required.

LOW SIDE PRESSURE

IS TOO LOW, AND HIGH

SIDE PRESSURE IS

TOO HIGH.1. Restricted refrigerant

flow through the

refrigerant lines.1. (Refer to Plumbing/Caution - Refrigerant Hoses/Lines/

Tubes Precautions) in this group. Inspect the refrigerant

lines for kinks, tight bends or improper routing. Correct

the routing or replace the refrigerant line, if required.

2. Restricted refrigerant

flow through the a/c

orifice tube.2. (Refer to Plumbing/A/C Orifice Tube/Diagnosis and

Testing) in this group. Replace the liquid line, if required.

3. Restricted refrigerant

flow through the a/c

condenser.3. (Refer to Plumbing/A/C Condenser/ Removal/

Installation) in this group. Replace the restricted a/c

condenser, if required.

BR/BEHEATING & AIR CONDITIONING 24 - 5

HEATING & AIR CONDITIONING (Continued)

Page 2127 of 2255

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE

Before performing the following tests, refer to Cool-

ing for the procedures to check the engine coolant

level and flow, engine coolant reserve/recovery sys-

tem operation, accessory drive belt condition and ten-

sion, radiator air flow and the fan drive operation.

Also be certain that the accessory vacuum supply

line is connected at the engine vacuum source.

MAXIMUM HEATER OUTPUT

Engine coolant is delivered to the heater core

through two heater hoses. With the engine idling atnormal operating temperature, set the temperature

control knob in the full hot position, the mode control

switch knob in the floor position, and the blower

motor switch knob in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged at the HVAC housing floor

outlets. Compare the test thermometer reading to the

Temperature Reference chart.

Temperature Reference

Ambient Air Temperature15.5É C

(60É F)21.1É C

(70É F)26.6É C

(80É F)32.2É C

(90É F)

Minimum Air Temperature at

Floor Outlet62.2É C

(144É F)63.8É C

(147É F)65.5É C

(150É F)67.2É C

(153É F)

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

An alternate method of checking heater perfor-

mance is to use a DRBIIItscan tool to monitor the

engine coolant temperature. The floor outlet air tem-

perature reading should be no more than 4.5É C (40É

F) lower than the engine coolant temperature read-

ing.

OBSTRUCTED COOLANT FLOW Possible loca-

tions or causes of obstructed coolant flow:

²Faulty water pump.

²Faulty thermostat.

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS Possible locations or

causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A faulty, obstructed or improperly installed

blend door.

²A faulty blower system.

²A faulty a/c heater control.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob on the

a/c heater control panel, the following could require

service:

²A faulty a/c heater control.

²A faulty blend door actuator.

²A faulty, obstructed or improperly installed

blend door.

²An obstructed cowl air intake.

²The engine cooling system.

Heater Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

INSUFFICIENT HEATER

OUTPUT.1. Incorrect engine

coolant level.1. Check the engine coolant level. Refer to Cooling for

the procedures.

2. Air trapped in engine

cooling system.2. Check the operation of the coolant reserve/recovery

system. Refer to Cooling for the procedures.

24 - 6 HEATING & AIR CONDITIONINGBR/BE

HEATING & AIR CONDITIONING (Continued)

Page 2137 of 2255

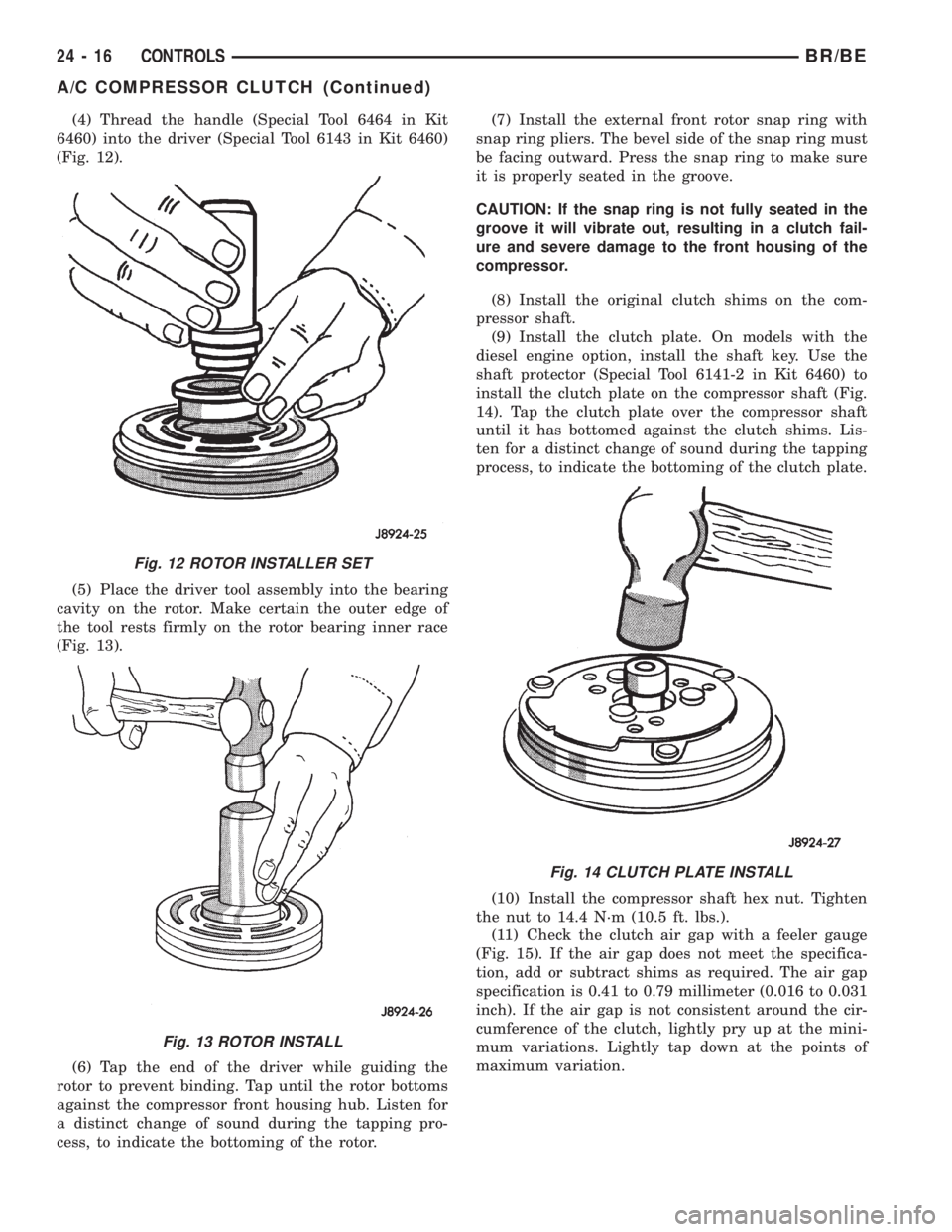

(4) Thread the handle (Special Tool 6464 in Kit

6460) into the driver (Special Tool 6143 in Kit 6460)

(Fig. 12).

(5) Place the driver tool assembly into the bearing

cavity on the rotor. Make certain the outer edge of

the tool rests firmly on the rotor bearing inner race

(Fig. 13).

(6) Tap the end of the driver while guiding the

rotor to prevent binding. Tap until the rotor bottoms

against the compressor front housing hub. Listen for

a distinct change of sound during the tapping pro-

cess, to indicate the bottoming of the rotor.(7) Install the external front rotor snap ring with

snap ring pliers. The bevel side of the snap ring must

be facing outward. Press the snap ring to make sure

it is properly seated in the groove.

CAUTION: If the snap ring is not fully seated in the

groove it will vibrate out, resulting in a clutch fail-

ure and severe damage to the front housing of the

compressor.

(8) Install the original clutch shims on the com-

pressor shaft.

(9) Install the clutch plate. On models with the

diesel engine option, install the shaft key. Use the

shaft protector (Special Tool 6141-2 in Kit 6460) to

install the clutch plate on the compressor shaft (Fig.

14). Tap the clutch plate over the compressor shaft

until it has bottomed against the clutch shims. Lis-

ten for a distinct change of sound during the tapping

process, to indicate the bottoming of the clutch plate.

(10) Install the compressor shaft hex nut. Tighten

the nut to 14.4 N´m (10.5 ft. lbs.).

(11) Check the clutch air gap with a feeler gauge

(Fig. 15). If the air gap does not meet the specifica-

tion, add or subtract shims as required. The air gap

specification is 0.41 to 0.79 millimeter (0.016 to 0.031

inch). If the air gap is not consistent around the cir-

cumference of the clutch, lightly pry up at the mini-

mum variations. Lightly tap down at the points of

maximum variation.

Fig. 12 ROTOR INSTALLER SET

Fig. 13 ROTOR INSTALL

Fig. 14 CLUTCH PLATE INSTALL

24 - 16 CONTROLSBR/BE

A/C COMPRESSOR CLUTCH (Continued)

Page 2175 of 2255

(2) Reassemble and reinstall the HVAC housing in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

NOTE: If the evaporator is replaced, add 60 millili-

ters (2 fluid ounces) of refrigerant oil to the refrig-

erant system.

A/C ORIFICE TUBE

DESCRIPTION

The fixed orifice tube is installed in the liquid line

between the outlet of the condenser and the inlet of

the evaporator. The fixed orifice tube is only serviced

as an integral part of the liquid line.

OPERATION

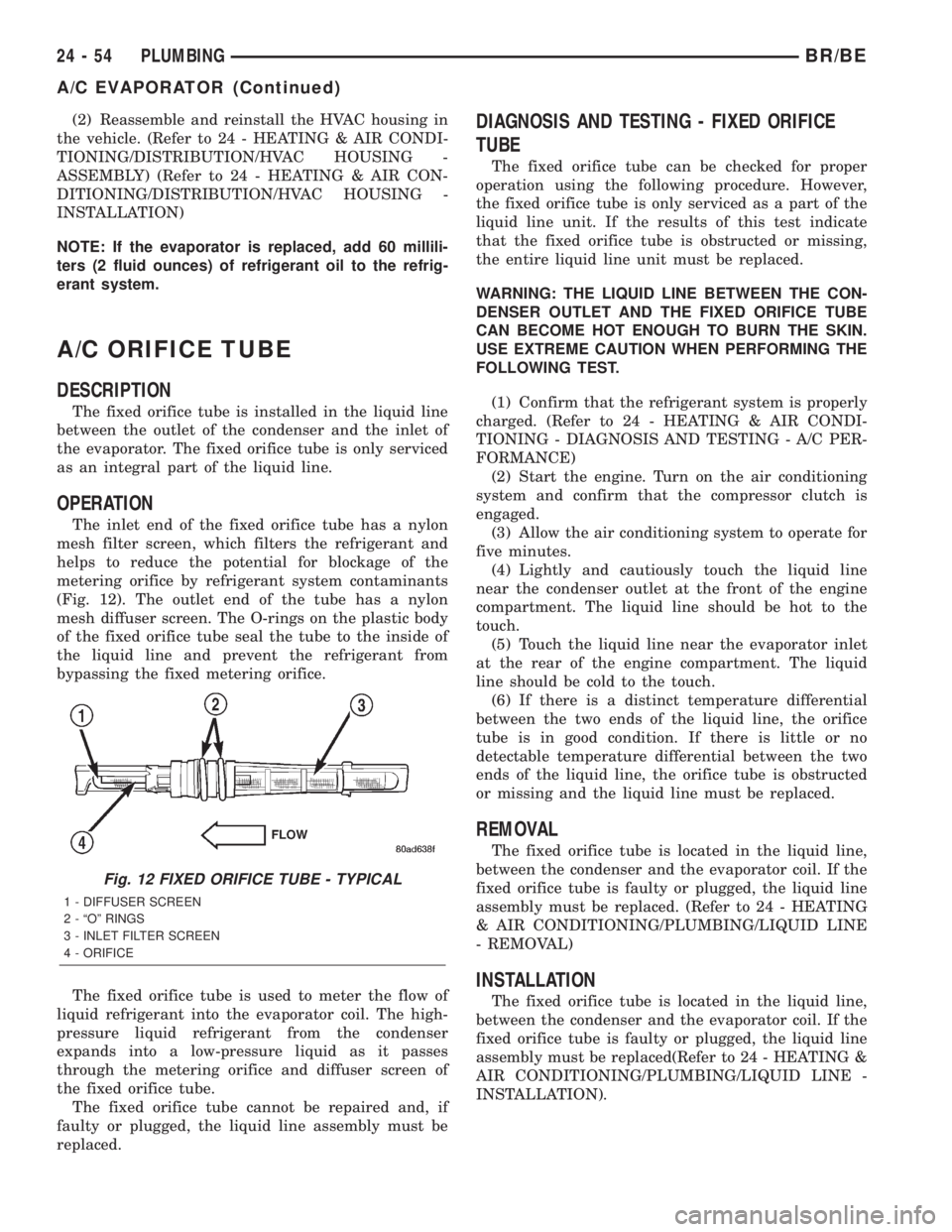

The inlet end of the fixed orifice tube has a nylon

mesh filter screen, which filters the refrigerant and

helps to reduce the potential for blockage of the

metering orifice by refrigerant system contaminants

(Fig. 12). The outlet end of the tube has a nylon

mesh diffuser screen. The O-rings on the plastic body

of the fixed orifice tube seal the tube to the inside of

the liquid line and prevent the refrigerant from

bypassing the fixed metering orifice.

The fixed orifice tube is used to meter the flow of

liquid refrigerant into the evaporator coil. The high-

pressure liquid refrigerant from the condenser

expands into a low-pressure liquid as it passes

through the metering orifice and diffuser screen of

the fixed orifice tube.

The fixed orifice tube cannot be repaired and, if

faulty or plugged, the liquid line assembly must be

replaced.

DIAGNOSIS AND TESTING - FIXED ORIFICE

TUBE

The fixed orifice tube can be checked for proper

operation using the following procedure. However,

the fixed orifice tube is only serviced as a part of the

liquid line unit. If the results of this test indicate

that the fixed orifice tube is obstructed or missing,

the entire liquid line unit must be replaced.

WARNING: THE LIQUID LINE BETWEEN THE CON-

DENSER OUTLET AND THE FIXED ORIFICE TUBE

CAN BECOME HOT ENOUGH TO BURN THE SKIN.

USE EXTREME CAUTION WHEN PERFORMING THE

FOLLOWING TEST.

(1) Confirm that the refrigerant system is properly

charged. (Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING - A/C PER-

FORMANCE)

(2) Start the engine. Turn on the air conditioning

system and confirm that the compressor clutch is

engaged.

(3) Allow the air conditioning system to operate for

five minutes.

(4) Lightly and cautiously touch the liquid line

near the condenser outlet at the front of the engine

compartment. The liquid line should be hot to the

touch.

(5) Touch the liquid line near the evaporator inlet

at the rear of the engine compartment. The liquid

line should be cold to the touch.

(6) If there is a distinct temperature differential

between the two ends of the liquid line, the orifice

tube is in good condition. If there is little or no

detectable temperature differential between the two

ends of the liquid line, the orifice tube is obstructed

or missing and the liquid line must be replaced.

REMOVAL

The fixed orifice tube is located in the liquid line,

between the condenser and the evaporator coil. If the

fixed orifice tube is faulty or plugged, the liquid line

assembly must be replaced. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/LIQUID LINE

- REMOVAL)

INSTALLATION

The fixed orifice tube is located in the liquid line,

between the condenser and the evaporator coil. If the

fixed orifice tube is faulty or plugged, the liquid line

assembly must be replaced(Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/LIQUID LINE -

INSTALLATION).

Fig. 12 FIXED ORIFICE TUBE - TYPICAL

1 - DIFFUSER SCREEN

2 - ªOº RINGS

3 - INLET FILTER SCREEN

4 - ORIFICE

24 - 54 PLUMBINGBR/BE

A/C EVAPORATOR (Continued)

Page 2223 of 2255

CENTRAL TIMER MODULE - REMOVAL....8E-5

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY...................Intro.-1

CHAIN COVER(S) - INSTALLATION,

TIMING BELT....................9-110,9-54

CHAIN COVER(S) - REMOVAL, TIMING

BELT ..........................9-110,9-53

CHAIN STRETCH - INSPECTION,

MEASURING TIMING..............9-111,9-54

CHANNEL - INSTALLATION, GLASS RUN . . 23-71

CHANNEL - REMOVAL, GLASS RUN......23-71

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-46

CHARGE AIR COOLER AND PLUMBING -

CLEANING..........................11-19

CHARGE AIR COOLER AND PLUMBING -

DESCRIPTION.......................11-18

CHARGE AIR COOLER AND PLUMBING -

INSPECTION........................11-19

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION.......................11-20

CHARGE AIR COOLER AND PLUMBING -

OPERATION.........................11-18

CHARGE AIR COOLER AND PLUMBING -

REMOVAL..........................11-18

CHARGE AIR COOLER SYSTEM - LEAKS

- DIAGNOSIS AND TESTING............11-18

CHARGING - DESCRIPTION.............8F-25

CHARGING - OPERATION..............8F-25

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-8

CHARGING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-25

CHART, SPECIFICATIONS - TORQUE....5-3,5-37

CHART, SPECIFICATIONS -

TORQUE.............19-21,19-41,19-43,19-9

CHART, SPECIFICATIONS -

TORQUE.....................2-15,2-26,2-8

CHART, SPECIFICATIONS - TORQUE......22-11

CHARTS - DIAGNOSIS AND TESTING,

DIAGNOSIS..................21-102,21-274

CHARTS - DIAGNOSIS AND TESTING,

SMOKE DIAGNOSIS...................9-118

CHASSIS ADAPTER BRACKET -

INSTALLATION, CAB..................13-10

CHASSIS ADAPTER BRACKET -

REMOVAL, CAB......................13-10

CHECK - INSTALLATION...............23-78

CHECK - REMOVAL...................23-78

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL......................7-16

CHECK - STANDARD PROCEDURE, FLUID

LEVEL......................21-157,21-328

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME...............21-166,21-336

CHECK CABLE - INSTALLATION.........23-67

CHECK CABLE - REMOVAL.............23-67

CHECK GAUGES INDICATOR -

DESCRIPTION.......................8J-17

CHECK GAUGES INDICATOR -

OPERATION.........................8J-17

CHECK VALVE - DESCRIPTION, FUEL

TANK ..............................14-21

CHECK VALVE - DESCRIPTION, ONE WAY . 25-31

CHECK VALVE - DESCRIPTION, VACUUM . . 24-28

CHECK VALVE - DIAGNOSIS AND

TESTING, ONE-WAY..................25-31

CHECK VALVE - INSTALLATION, FUEL

TANK ..............................14-23

CHECK VALVE - INSTALLATION, ONE

WAY...............................25-31

CHECK VALVE - INSTALLATION, VACUUM

. 24-29

CHECK VALVE - OPERATION, ONE WAY

. . . 25-31

CHECK VALVE - OPERATION, VACUUM

....24-28

CHECK VALVE - REMOVAL, FUEL TANK

. . . 14-22

CHECK VALVE - REMOVAL, ONE WAY

....25-31

CHECK VALVE - REMOVAL, VACUUM

.....24-29

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY

.........................7-4

CHILD TETHER - INSTALLATION

..........8O-9

CHILD TETHER - REMOVAL

.............8O-9

CHIME WARNING SYSTEM -

DESCRIPTION

........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING

........................8B-2

CHIME WARNING SYSTEM - OPERATION

. . . 8B-1

CHOKE RELAY - DESCRIPTION, RADIO

....8A-7CHOKE RELAY - DIAGNOSIS AND

TESTING, RADIO......................8A-8

CHOKE RELAY - INSTALLATION, RADIO....8A-9

CHOKE RELAY - OPERATION, RADIO......8A-8

CHOKE RELAY - REMOVAL, RADIO.......8A-8

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET -

INSTALLATION....................8W-97-4

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIGAR LIGHTER OUTLET - REMOVAL . . 8W-97-3

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-2

CIRCUIT BREAKER - DESCRIPTION....8W-97-4

CIRCUIT BREAKER - DIAGNOSIS AND

TESTING.........................8W-97-4

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-4

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-4

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-17

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-19

CIRCUITS - DIESEL - OPERATION,

NON-MONITORED....................25-24

CIRCUITS - GAS ENGINES - OPERATION,

NON-MONITORED....................25-24

CLAMPS - DESCRIPTION, HOSE...........7-4

CLAMPS - OPERATION, HOSE.............7-4

CLASSIFICATION OF LUBRICANTS -

STANDARD PROCEDURE..................0-1

CLEANER ELEMENT - INSTALLATION,

AIR ...............................9-130

CLEANER ELEMENT - REMOVAL, AIR.....9-129

CLEANING AND INSPECTION, OIL

COOLER & LINES....................9-179

CLEANING, BATTERY SYSTEM...........8F-5

CLEANING, CHARGE AIR COOLER AND

PLUMBING.........................11-19

CLEANING, CROSSHEADS..............9-134

CLEANING, CYLINDER HEAD.......9-134,9-77

CLEANING, CYLINDER HEAD

COVER(S)..................9-137,9-23,9-79

CLEANING, ENGINE BLOCK..........9-27,9-85

CLEANING, EXHAUST

MANIFOLD.................9-109,9-185,9-53

CLEANING, FRONT SERVO......21-164,21-334

CLEANING FUEL SYSTEM PARTS -

STANDARD PROCEDURES..............14-61

CLEANING, HYDRAULIC LIFTERS.....9-37,9-92

CLEANING, INTAKE MANIFOLD . 9-107,9-184,9-51

CLEANING, INTAKE/EXHAUST VALVES &

SEATS ..............................9-26

CLEANING, MANUAL - NV4500..........21-20

CLEANING, MANUAL - NV5600..........21-63

CLEANING, OIL PAN.........9-103,9-179,9-46

CLEANING, OIL PRESSURE RELIEF

VALVE .............................9-180

CLEANING, OIL PUMP............9-104,9-181

CLEANING, OIL PUMP..........21-168,21-338

CLEANING, OPERATION.................9-22

CLEANING, OVERDRIVE UNIT....21-179,21-353

CLEANING, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER...................21-192,21-364

CLEANING, PISTON & CONNECTING

ROD.......................9-169,9-39,9-94

CLEANING, PUSHRODS................9-134

CLEANING, RADIATOR - 5.9L............7-59

CLEANING, RADIATOR - 5.9L DIESEL......7-64

CLEANING, RADIATOR - 8.0L............7-61

CLEANING, RADIATOR FAN - 5.9L

DIESEL.............................7-43

CLEANING, RADIATOR FAN - 5.9L/8.0L....7-42

CLEANING, REAR CLUTCH

......21-204,21-377

CLEANING, REAR SERVO

.......21-207,21-379

CLEANING, ROCKER ARM / ADJUSTER

ASSY

..............................9-146

CLEANING, SOLID LIFTERS/TAPPETS

.....9-164

CLEANING, SPARK PLUG

...............8I-20

CLEANING, TRANSFER CASE - NV241HD

. 21-476

CLEANING, TRANSFER CASE - NV241LD

. 21-441

CLEANING, TURBOCHARGER

...........11-16

CLEANING, VALVE BODY

........21-244,21-418

CLEANING, WATER PUMP - 5.9L

.........7-68

CLEANING, WATER PUMP - 5.9L DIESEL

. . . 7-72

CLEANING, WATER PUMP - 8.0L

.........7-71

CLEANING, WIPER & WASHER SYSTEM

. . . 8R-6CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-158

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-159

CLEARANCE LAMP - INSTALLATION.......8L-7

CLEARANCE LAMP - REMOVAL..........8L-7

CLOCKSPRING - DESCRIPTION.........8O-10

CLOCKSPRING - INSTALLATION.........8O-13

CLOCKSPRING - OPERATION...........8O-10

CLOCKSPRING - REMOVAL............8O-12

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-11

CLOSURE PANEL TRIM - INSTALLATION,

REAR.............................23-121

CLOSURE PANEL TRIM - REMOVAL,

REAR.............................23-120

CLUB/QUAD CAB - INSTALLATION.......8O-20

CLUB/QUAD CAB - REMOVAL...........8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-12

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-6

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-10

CLUSTER - INSTALLATION, INSTRUMENT . 8J-13

CLUSTER - OPERATION, INSTRUMENT.....8J-3

CLUSTER - REMOVAL, INSTRUMENT......8J-10

CLUSTER BEZEL - INSTALLATION.......23-108

CLUSTER BEZEL - REMOVAL..........23-108

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L/8.0L - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L/8.0L - OPERATION, FAN

DRIVE VISCOUS......................7-55

CLUTCH - ASSEMBLY, FRONT....21-162,21-333

CLUTCH - ASSEMBLY, REAR.....21-205,21-377

CLUTCH - CLEANING, REAR.....21-204,21-377

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR.......................24-11

CLUTCH - DESCRIPTION, FRONT . 21-160,21-330

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-172,

21-343

CLUTCH - DESCRIPTION, REAR . . 21-203,21-375

CLUTCH - DIAGNOSIS AND TESTING

.......6-2

CLUTCH - DISASSEMBLY, FRONT

. 21-161,21-331

CLUTCH - DISASSEMBLY, REAR

. . 21-204,21-376

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-15

CLUTCH - INSPECTION, FRONT

. . 21-162,21-332

CLUTCH - INSPECTION, REAR

. . . 21-204,21-377

CLUTCH - INSTALLATION, A/C

COMPRESSOR

.......................24-15

CLUTCH - OPERATION

..................6-2

CLUTCH - OPERATION, A/C

COMPRESSOR

.......................24-13

CLUTCH - OPERATION, FRONT

. . . 21-160,21-330

CLUTCH - OPERATION, OVERDRIVE

....21-172,

21-343

CLUTCH - OPERATION, REAR

....21-203,21-375

CLUTCH - REMOVAL, A/C COMPRESSOR

. . 24-13

CLUTCH - SPECIFICATIONS

...............6-7

CLUTCH - WARNING

....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION

.......21-100,21-272

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR

........24-13

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING

...............21-193,21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING

. 21-192,

21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING

...............21-192,21-363

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING

...............21-192,21-364

6 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2235 of 2255

JOINT MOLDING - REMOVAL, ROOF......23-91

JOINTS - ASSEMBLY, DOUBLE CARDAN

UNIVERSAL..........................3-11

JOINTS - ASSEMBLY, SINGLE CARDAN

UNIVERSAL...........................3-9

JOINTS - DISASSEMBLY, DOUBLE

CARDAN UNIVERSAL..................3-10

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL...................3-8

JOINTS - INSTALLATION, SINGLE

CARDAN UNIVERSAL..................3-35

JOINTS - REMOVAL, SINGLE CARDAN

UNIVERSAL..........................3-34

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-158

JUMP STARTING - STANDARD

PROCEDURE..........................0-7

JUNCTION BLOCK - DESCRIPTION.....8W-97-6

JUNCTION BLOCK - DIAGNOSIS AND

TESTING.........................8W-97-7

JUNCTION BLOCK - INSTALLATION....8W-97-8

JUNCTION BLOCK - OPERATION......8W-97-7

JUNCTION BLOCK - REMOVAL........8W-97-7

KEEPER - INSTALLATION, BACKLITE

LATCH ............................23-146

KEEPER - REMOVAL, BACKLITE LATCH . . 23-146

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH.............19-9

KEY-IN IGNITION SWITCH -

DESCRIPTION........................19-9

KEYLESS ENTRY SYSTEM -

DESCRIPTION, REMOTE................8N-2

KEYLESS ENTRY SYSTEM - DIAGNOSIS

AND TESTING, POWER LOCK &

REMOTE............................8N-5

KEYLESS ENTRY SYSTEM - OPERATION,

REMOTE............................8N-4

KEYLESS ENTRY TRANSMITTER -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

OPERATION, REMOTE..................8N-8

KEYLESS ENTRY TRANSMITTER

BATTERIES - STANDARD PROCEDURE,

REMOTE............................8N-8

KNOB - INSTALLATION, TURNING LOOP

HGT ADJUSTER.....................8O-30

KNOB - REMOVAL, TURNING LOOP HGT

ADJUSTER.........................8O-30

KNUCKLE - INSTALLATION..........2-10,2-19

KNUCKLE - REMOVAL..............2-10,2-19

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION.....................Intro.-1

LAMP - DESCRIPTION, READING........8L-36

LAMP - DESCRIPTION, TAIL............8L-29

LAMP - DIAGNOSIS AND TESTING, FOG . . 8L-10

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - INSTALLATION, CLEARANCE......8L-7

LAMP - INSTALLATION, DOME..........8L-34

LAMP - INSTALLATION, FOG............8L-11

LAMP - INSTALLATION, LICENSE PLATE . . 8L-22

LAMP - INSTALLATION, MARKER........8L-23

LAMP - INSTALLATION, OUTBOARD

IDENTIFICATION.....................8L-29

LAMP - INSTALLATION, PARK/TURN

SIGNAL............................8L-29

LAMP - INSTALLATION, READING........8L-37

LAMP - INSTALLATION, TAIL...........8L-30

LAMP - INSTALLATION, UNDERHOOD....8L-32

LAMP - INSTALLATION, VANITY.........8L-37

LAMP - OPERATION, READING..........8L-36

LAMP - OPERATION, TAIL..............8L-29

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - REMOVAL, CLEARANCE..........8L-7

LAMP - REMOVAL, DOME..............8L-34

LAMP - REMOVAL, FOG...............8L-11

LAMP - REMOVAL, LICENSE PLATE......8L-22

LAMP - REMOVAL, MARKER...........8L-23

LAMP - REMOVAL, OUTBOARD

IDENTIFICATION

.....................8L-28

LAMP - REMOVAL, PARK/TURN SIGNAL

. . 8L-29

LAMP - REMOVAL, READING

...........8L-36

LAMP - REMOVAL, TAIL

...............8L-29

LAMP - REMOVAL, UNDERHOOD

........8L-31LAMP - REMOVAL, VANITY.............8L-37

LAMP AND SWITCH - INSTALLATION,

GLOVE BOX.........................8L-36

LAMP AND SWITCH - REMOVAL, GLOVE

BOX ...............................8L-35

LAMP MIL - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-23

LAMP MIL - OPERATION, MALFUNCTION

INDICATOR.........................8J-23

LAMP MODULE - DESCRIPTION,

DAYTIME RUNNING....................8L-9

LAMP MODULE - INSTALLATION,

DAYTIME RUNNING....................8L-9

LAMP MODULE - OPERATION, DAYTIME

RUNNING............................8L-9

LAMP MODULE - REMOVAL, DAYTIME

RUNNING............................8L-9

LAMP SWITCH - DESCRIPTION, BRAKE....8L-4

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE......................8L-5

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-6

LAMP SWITCH - OPERATION, BRAKE......8L-4

LAMP SWITCH - REMOVAL, BRAKE.......8L-5

LAMP UNIT - ADJUSTMENTS, FOG.......8L-13

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP.................8L-6

LAMP UNIT - INSTALLATION, FOG.......8L-12

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-22

LAMP UNIT - INSTALLATION, PARK/

TURN SIGNAL.......................8L-29

LAMP UNIT - INSTALLATION, TAIL.......8L-30

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-32

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP UNIT - REMOVAL, FOG...........8L-12

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-22

LAMP UNIT - REMOVAL, PARK/TURN

SIGNAL............................8L-29

LAMP UNIT - REMOVAL, TAIL...........8L-30

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-32

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-4

LAMPS, SPECIFICATIONS - INTERIOR....8L-33

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-141

LATCH - ADJUSTMENT, FRONT DOOR....23-73

LATCH - INSTALLATION....23-102,23-65,23-73

LATCH - INSTALLATION, SAFETY.......23-104

LATCH - LOWER - INSTALLATION........23-80

LATCH - LOWER - REMOVAL...........23-80

LATCH - REMOVAL........23-102,23-65,23-72

LATCH - REMOVAL, SAFETY...........23-104

LATCH - UPPER - INSTALLATION........23-81

LATCH - UPPER - REMOVAL............23-81

LATCH AND KEEPER - INSTALLATION,

BACKLITE.........................23-146

LATCH AND KEEPER - REMOVAL,

BACKLITE.........................23-146

LATCH HANDLE - INSTALLATION........23-66

LATCH HANDLE - REMOVAL............23-66

LATCH RELEASE CABLE - INSTALLATION . 23-103

LATCH RELEASE CABLE - REMOVAL....23-103

LATCH STRIKER - INSTALLATION . 23-103,23-66,

23-73

LATCH STRIKER - INSTALLATION, GLOVE

BOX ..............................23-112

LATCH STRIKER - LOWER -

INSTALLATION

.......................23-82

LATCH STRIKER - LOWER - REMOVAL

....23-82

LATCH STRIKER - REMOVAL

.....23-103,23-66,

23-73

LATCH STRIKER - REMOVAL, GLOVE

BOX

..............................23-111

LATCH STRIKER - UPPER -

INSTALLATION

.......................23-82

LATCH STRIKER - UPPER - REMOVAL

....23-82

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID

....21-101,21-273

LEAK DETECTION PUMP - DESCRIPTION

. . 25-34

LEAK DETECTION PUMP - INSTALLATION

. 25-34

LEAK DETECTION PUMP - OPERATION

....25-34

LEAK DETECTION PUMP - REMOVAL

.....25-34

LEAK DOWN TEST - DIAGNOSIS AND

TESTING, FUEL PRESSURE

..............14-2

LEAK VACUUM TEST - DIAGNOSIS AND

TESTING, FUEL SYSTEM AIR

...........14-57LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE . . . 9-64,9-9

LEAKAGE - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD...............9-106,9-50

LEAKAGE - DIAGNOSIS AND TESTING,

POWER STEERING GEAR..............19-16

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-33

LEAKS - DIAGNOSIS AND TESTING,

CHARGE AIR COOLER SYSTEM.........11-18

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-5

LEAKS - DIAGNOSIS AND TESTING,

ENGINE OIL......................9-43,9-99

LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL LINE............14-78

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-43

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-2

LEAKS - STANDARD PROCEDURE,

REPAIRING..........................22-9

LEFT FRONT FENDER - INSTALLATION....23-93

LEFT FRONT FENDER - REMOVAL.......23-93

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID . . 21-157,21-327

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID........................5-15

LEVEL - STANDARD PROCEDURE,

ENGINE OIL.........................9-178

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-57

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT................7-16

LEVEL CHECK - STANDARD

PROCEDURE, FLUID...........21-157,21-328

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL..............14-7,14-77

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL..................14-8

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL................14-7,14-77

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL......................14-7

LEVEL SWITCH - DESCRIPTION,

WASHER FLUID......................8R-7

LEVEL SWITCH - INSTALLATION,

WASHER FLUID......................8R-8

LEVEL SWITCH - OPERATION, WASHER

FLUID..............................8R-7

LEVEL SWITCH - REMOVAL, WASHER

FLUID..............................8R-8

LEVER - ADJUSTMENT, SHIFT . . . 21-463,21-500

LEVER - INSTALLATION, GEAR SHIFT.....19-15

LEVER - INSTALLATION, SHIFT . . . 21-462,21-500

LEVER - REMOVAL, GEAR SHIFT........19-14

LEVER - REMOVAL, SHIFT......21-462,21-499

LICENSE PLATE LAMP - INSTALLATION . . . 8L-22

LICENSE PLATE LAMP - REMOVAL.......8L-22

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-22

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-22

LID - INSTALLATION, CENTER CONSOLE . 23-132

LID - REMOVAL, CENTER CONSOLE.....23-131

LIFTERS - CLEANING, HYDRAULIC....9-37,9-92

LIFTERS - INSTALLATION, HYDRAULIC....9-37,

9-92

LIFTERS - REMOVAL, HYDRAULIC....9-37,9-92

LIFTERS/TAPPETS - CLEANING, SOLID....9-164

LIFTERS/TAPPETS - INSPECTION, SOLID . . 9-165

LIFTERS/TAPPETS - INSTALLATION,

SOLID.............................9-165

LIFTERS/TAPPETS - REMOVAL, SOLID....9-164

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-2

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - INSTALLATION,

CIGAR...........................8W-97-4

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIGHTER OUTLET - REMOVAL, CIGAR . . 8W-97-3

LINE - INSTALLATION, LIQUID

..........24-52

LINE - INSTALLATION, SUCTION AND

DISCHARGE

.........................24-52

LINE - REMOVAL, LIQUID

..............24-52

LINE - REMOVAL, SUCTION AND

DISCHARGE

.........................24-51

LINE COUPLERS - DESCRIPTION, A/C

....24-40

18 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2238 of 2255

NV241LD - CLEANING, TRANSFER CASE . 21-441

NV241LD - DESCRIPTION, TRANSFER

CASE.............................21-430

NV241LD - DISASSEMBLY, TRANSFER

CASE.............................21-432

NV241LD - INSPECTION, TRANSFER

CASE.............................21-442

NV241LD - INSTALLATION, TRANSFER

CASE.............................21-458

NV241LD - OPERATION, TRANSFER

CASE.............................21-430

NV241LD - REMOVAL, TRANSFER CASE . 21-432

NV241LD - TRANSFER CASE...........21-459

NV4500 - ASSEMBLY, MANUAL.........21-21

NV4500 - CLEANING, MANUAL..........21-20

NV4500 - DESCRIPTION, MANUAL........21-1

NV4500 - DIAGNOSIS AND TESTING,

MANUAL............................21-3

NV4500 - DISASSEMBLY, MANUAL........21-5

NV4500 - INSPECTION, MANUAL........21-20

NV4500 - INSTALLATION, ADAPTER

HOUSING SEAL......................21-42

NV4500 - INSTALLATION, EXTENSION

HOUSING SEAL......................21-42

NV4500 - INSTALLATION, MANUAL......21-37

NV4500 - INSTALLATION, SHIFT COVER . . . 21-45

NV4500 - INSTALLATION, SHIFT

MECHANISM........................21-44

NV4500 - OPERATION, MANUAL..........21-3

NV4500 - REMOVAL, ADAPTER

HOUSING SEAL......................21-42

NV4500 - REMOVAL, EXTENSION

HOUSING SEAL......................21-42

NV4500 - REMOVAL, MANUAL...........21-4

NV4500 - REMOVAL, SHIFT COVER......21-45

NV4500 - REMOVAL, SHIFT MECHANISM . . 21-43

NV4500 - SPECIFICATIONS, MANUAL.....21-38

NV5600 - ASSEMBLY, MANUAL.........21-64

NV5600 - CLEANING, MANUAL..........21-63

NV5600 - DESCRIPTION, MANUAL.......21-46

NV5600 - DIAGNOSIS AND TESTING,

MANUAL...........................21-48

NV5600 - DISASSEMBLY, MANUAL.......21-49

NV5600 - INSPECTION, MANUAL........21-63

NV5600 - INSTALLATION, ADAPTER

HOUSING SEAL......................21-85

NV5600 - INSTALLATION, EXTENSION

HOUSING SEAL......................21-85

NV5600 - INSTALLATION, MANUAL......21-78

NV5600 - INSTALLATION, SHIFT COVER . . . 21-86

NV5600 - OPERATION, MANUAL.........21-48

NV5600 - REMOVAL, ADAPTER

HOUSING SEAL......................21-85

NV5600 - REMOVAL, EXTENSION

HOUSING SEAL......................21-85

NV5600 - REMOVAL, MANUAL..........21-49

NV5600 - REMOVAL, SHIFT COVER......21-86

NV5600 - SPECIFICATIONS, MANUAL.....21-79

O2 SENSOR - DESCRIPTION............14-45

O2 SENSOR - INSTALLATION...........14-47

O2 SENSOR - OPERATION.............14-45

O2 SENSOR - REMOVAL...............14-46

ODOMETER - DESCRIPTION............8J-24

ODOMETER - OPERATION..............8J-24

OFF INDICATOR - DESCRIPTION,

OVERDRIVE.........................8J-26

OFF INDICATOR - OPERATION,

OVERDRIVE.........................8J-26

OIL - DESCRIPTION, ENGINE..........0-4,0-5

OIL - DESCRIPTION, REFRIGERANT......24-57

OIL - OPERATION, REFRIGERANT........24-57

OIL - STANDARD PROCEDURE, ENGINE . . 9-101,

9-45

OIL COOLER - INSTALLATION, AIR TO.....7-87

OIL COOLER & LINES - CLEANING AND

INSPECTION........................9-179

OIL COOLER - REMOVAL, AIR TO.........7-86

OIL COOLER - REMOVAL, WATER TO......7-86

OIL FILTER - INSTALLATION . . . 9-102,9-179,9-46

OIL FILTER - REMOVAL......9-102,9-179,9-46

OIL LEAKS - DIAGNOSIS AND TESTING,

ENGINE

.........................9-43,9-99

OIL LEVEL - STANDARD PROCEDURE,

ENGINE

............................9-178

OIL LEVEL - STANDARD PROCEDURE,

REFRIGERANT

.......................24-57

OIL PAN - CLEANING

........9-103,9-179,9-46

OIL PAN - INSPECTION

.......9-103,9-179,9-46OIL PAN - INSTALLATION.....9-103,9-180,9-46

OIL PAN - REMOVAL.........9-102,9-179,9-46

OIL PRESSURE - DIAGNOSIS AND

TESTING, ENGINE...........9-101,9-178,9-45

OIL PRESSURE GAUGE - DESCRIPTION . . . 8J-25

OIL PRESSURE GAUGE - OPERATION.....8J-25

OIL PRESSURE RELIEF VALVE -

CLEANING..........................9-180

OIL PRESSURE RELIEF VALVE -

INSPECTION........................9-180

OIL PRESSURE RELIEF VALVE -

INSTALLATION.......................9-180

OIL PRESSURE RELIEF VALVE -

REMOVAL..........................9-180

OIL PRESSURE SENSOR/SWITCH -

INSTALLATION.......................9-181

OIL PRESSURE SENSOR/SWITCH -

REMOVAL..........................9-181

OIL PUMP - ASSEMBLY................9-49

OIL PUMP - ASSEMBLY........21-169,21-340

OIL PUMP - CLEANING...........9-104,9-181

OIL PUMP - CLEANING.........21-168,21-338

OIL PUMP - DESCRIPTION......21-166,21-336

OIL PUMP - DISASSEMBLY.............9-47

OIL PUMP - DISASSEMBLY......21-167,21-337

OIL PUMP - INSPECTION.....9-104,9-181,9-47

OIL PUMP - INSPECTION.......21-168,21-339

OIL PUMP - INSTALLATION . . . 9-106,9-182,9-50

OIL PUMP - OPERATION.........21-166,21-336

OIL PUMP - REMOVAL.......9-104,9-181,9-47

OIL PUMP VOLUME CHECK - STANDARD

PROCEDURE.................21-166,21-336

OIL SEAL - FRONT - DESCRIPTION,

CRANKSHAFT........................9-32

OIL SEAL - FRONT - INSTALLATION,

CRANKSHAFT...................9-160,9-32

OIL SEAL - FRONT - OPERATION,

CRANKSHAFT........................9-32

OIL SEAL - FRONT - REMOVAL,

CRANKSHAFT...................9-160,9-32

OIL SEAL - FRONT COVER INSTALLED -

INSTALLATION, FRONT.................9-89

OIL SEAL - FRONT COVER INSTALLED -

REMOVAL, FRONT.....................9-89

OIL SEAL - FRONT COVER REMOVED -

INSTALLATION, FRONT.................9-90

OIL SEAL - FRONT COVER REMOVED -

REMOVAL, FRONT.....................9-89

OIL SEAL - REAR - DESCRIPTION,

CRANKSHAFT........................9-33

OIL SEAL - REAR - INSTALLATION,

CRANKSHAFT...............9-162,9-34,9-90

OIL SEAL - REAR - OPERATION,

CRANKSHAFT........................9-33

OIL SEAL - REAR - REMOVAL,

CRANKSHAFT...............9-161,9-33,9-90

OIL SEAL RETAINER - INSTALLATION,

CRANKSHAFT REAR..............9-163,9-90

OIL SEAL RETAINER - REMOVAL,

CRANKSHAFT REAR..............9-162,9-90

OIL SERVICE - STANDARD PROCEDURE,

ENGINE............................9-178

ON-BOARD DIAGNOSTICS (OBD) -

DIAGNOSIS AND TESTING...............7-5

ONE WAY CHECK VALVE - DESCRIPTION . . 25-31

ONE WAY CHECK VALVE - INSTALLATION . 25-31

ONE WAY CHECK VALVE - OPERATION....25-31

ONE WAY CHECK VALVE - REMOVAL.....25-31

ONE-WAY CHECK VALVE - DIAGNOSIS

AND TESTING.......................25-31

ON/OFF SWITCH - DESCRIPTION,

PASSENGER AIRBAG.................8O-23

ON/OFF SWITCH - INSTALLATION,

PASSENGER AIRBAG.................8O-25

ON/OFF SWITCH - OPERATION,

PASSENGER AIRBAG.................8O-24

ON/OFF SWITCH - REMOVAL,

PASSENGER AIRBAG.................8O-24

OPEN-CIRCUIT VOLTAGE TEST -

STANDARD PROCEDURE...............8F-12

OPENING COVER - INSTALLATION,

STEERING COLUMN

.................23-114

OPENING COVER - REMOVAL, STEERING

COLUMN

..........................23-113

OPENING DIMENSIONS, SPECIFICATIONS

- BODY

............................23-60

OPENING SEAL - INSTALLATION, DOOR

. . 23-152

OPENING SEAL - REMOVAL, DOOR

.....23-152OPENING UPPER TRIM - INSTALLATION,

GLOVE BOX........................23-112

OPENING UPPER TRIM - REMOVAL,

GLOVE BOX........................23-112

ORIFICE TUBE - DESCRIPTION, A/C......24-54

ORIFICE TUBE - DIAGNOSIS AND

TESTING, FIXED.....................24-54

ORIFICE TUBE - INSTALLATION, A/C......24-54

ORIFICE TUBE - OPERATION, A/C........24-54

ORIFICE TUBE - REMOVAL, A/C.........24-54

OUTBOARD IDENTIFICATION LAMP -

INSTALLATION.......................8L-29

OUTBOARD IDENTIFICATION LAMP -

REMOVAL..........................8L-28

OUTER BELT WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-153

OUTER BELT WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-153

OUTLET - DESCRIPTION, CIGAR

LIGHTER.........................8W-97-2

OUTLET - DESCRIPTION, POWER.....8W-97-10

OUTLET - DIAGNOSIS AND TESTING,

CIGAR LIGHTER...................8W-97-2

OUTLET - DIAGNOSIS AND TESTING,

POWER.........................8W-97-10

OUTLET - INSTALLATION, CIGAR

LIGHTER.........................8W-97-4

OUTLET - INSTALLATION, POWER....8W-97-11

OUTLET - OPERATION, CIGAR LIGHTER . 8W-97-2

OUTLET - OPERATION, POWER......8W-97-10

OUTLET - REMOVAL, CIGAR LIGHTER . . . 8W-97-3

OUTLET - REMOVAL, POWER........8W-97-11

OUTLET BARRELS - INSTALLATION,

PANEL.............................24-31

OUTLET BARRELS - REMOVAL, PANEL . . . 24-31

OUTPUT - DESCRIPTION, PCM...........8I-4

OUTPUT - DIAGNOSIS AND TESTING,

VACUUM PUMP.......................7-34

OUTPUT - OPERATION, PCM............14-52

OUTPUT - OPERATION, PCM.............8I-4

OUTPUT SHAFT FRONT BEARING -

INSTALLATION................21-171,21-342

OUTPUT SHAFT FRONT BEARING -

REMOVAL...................21-171,21-342

OUTPUT SHAFT REAR BEARING -

INSTALLATION................21-172,21-343

OUTPUT SHAFT REAR BEARING -

REMOVAL...................21-171,21-343

OUTPUT SHAFT SEAL - INSTALLATION,

FRONT......................21-461,21-498

OUTPUT SHAFT SEAL - REMOVAL,

FRONT......................21-461,21-498

OVERDRIVE CLUTCH - DESCRIPTION . . . 21-172,

21-343

OVERDRIVE CLUTCH - OPERATION.....21-172,

21-343

OVERDRIVE ELECTRICAL CONTROLS -

DIAGNOSIS AND TESTING......21-191,21-344

OVERDRIVE OFF INDICATOR -

DESCRIPTION.......................8J-26

OVERDRIVE OFF INDICATOR -

OPERATION.........................8J-26

OVERDRIVE SWITCH - DESCRIPTION . . . 21-190,

21-344

OVERDRIVE SWITCH - INSTALLATION . . . 21-191,

21-345

OVERDRIVE SWITCH - OPERATION.....21-190,

21-344

OVERDRIVE SWITCH - REMOVAL . 21-191,21-344

OVERDRIVE UNIT - ASSEMBLY . . . 21-180,21-354

OVERDRIVE UNIT - CLEANING . . . 21-179,21-353

OVERDRIVE UNIT - DISASSEMBLY.....21-173,

21-346

OVERDRIVE UNIT - INSPECTION . 21-180,21-353

OVERDRIVE UNIT - INSTALLATION.....21-189,

21-362

OVERDRIVE UNIT - REMOVAL . . . 21-173,21-345

OVERFLOW VALVE - DESCRIPTION......14-87

OVERFLOW VALVE - DIAGNOSIS AND

TESTING...........................14-87

OVERFLOW VALVE - INSTALLATION......14-88

OVERFLOW VALVE - OPERATION

........14-87

OVERFLOW VALVE - REMOVAL

..........14-88

OVERHEAD CONSOLE - DESCRIPTION

....8M-1

OVERHEAD CONSOLE ASSEMBLY,

ASSEMBLY

..........................8M-8

OVERHEAD CONSOLE DISASSEMBLY,

DISASSEMBLY

.......................8M-7

BR/BEINDEX 21

Description Group-Page Description Group-Page Description Group-Page