ABS DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 556 of 2255

GARAGE DOOR OPENER STORAGE BIN

A compartment near the front of the overhead con-

sole is designed to hold most garage door opener

remote control transmitters. The transmitter is

mounted within the compartment with an adhesive-

backed hook and loop fastener patch and, when the

compartment is closed, a push button in the center of

the compartment door is depressed to actuate the

transmitter.

A transmitter mounting kit including the adhesive-

backed hook and loop fastener material is available

for service. The garage door opener storage bin door

and the push button with three assorted length

adapter pegs are also available for service replace-

ment.

The garage door opener storage compartment door

is opened by pressing the integral latch towards the

front of the vehicle. When the compartment door is

opened, the push button unit is removed from the

compartment by squeezing the latch tabs and pulling

the unit downward. With the push button removed,

the garage door opener can be installed in the com-

partment using the adhesive-backed hook and loop

fastener material provided.

With the transmitter mounted in the storage bin,

adapter pegs located on the garage door opener push

button unit are selected and mounted on one of two

posts on the back side of the push button. The com-

bination of the adapter peg length and the push but-

ton post location must be suitable to depress the

button of the transmitter when the push button in

the center of the garage door opener storage bin door

is depressed. When the proper combination has been

selected, the push button is reinstalled in the com-

partment and the compartment door is closed.

SUNGLASS STORAGE BIN

A sunglasses storage bin is included in the over-

head console. The storage bin is located near the rear

of the overhead console and is held in the closed posi-

tion by a latch that is integral to the storage bin

door. The interior of the bin is lined with a foam rub-

ber padding material to protect the sunglasses from

being scratched. Dampening springs that are located

on the back of the overhead console reading andcourtesy lamp housing contact the hinges of the sun-

glasses storage bin for a smooth opening action.

The sunglasses storage bin and door unit is avail-

able for service replacement. The hinge dampening

springs are serviced as a unit with the overhead con-

sole reading and courtesy lamp housing.

The sunglasses storage bin is opened by pressing

the latch on the rear edge of the door towards the

front of the vehicle, then pulling the bin downward to

the open position. The integral latch on the sun-

glasses bin door will automatically engage when the

bin is closed. See the owner's manual in the vehicle

glove box for more information on the use and oper-

ation of the sunglasses storage bin.

COMPASS

While in the compass/temperature mode, the com-

pass will display the direction in which the vehicle is

pointed using the eight major compass headings

(Examples: north is N, northeast is NE), along with

the outside ambient temperature. When the compass

unit is placed in the compass/compass in degrees

mode, the compass will display the direction the

vehicle is heading using the eight major compass

headings and in degrees (0 to 359 degrees). North is

0 degrees, East is 90 degrees, South is 180 degrees

and West is 270 degrees. It will not display the head-

ings in minutes or seconds.

The self-calibrating compass unit requires no

adjusting in normal use. The compass unit will com-

pensate for magnetism the body of the vehicle may

acquire during normal use. However, avoid placing

anything magnetic directly on the roof of the vehicle.

Magnetic mounts for an antenna, a repair order hat,

or a funeral procession flag can exceed the compen-

sating ability of the compass unit if placed on the

roof panel. If the vehicle roof should become magne-

tized, the demagnetizing and calibration procedures

found in this group may be required to restore proper

compass operation.

THERMOMETER

The thermometer displays the outside ambient

temperature in whole degrees. The temperature dis-

play can be changed from Fahrenheit to Celsius

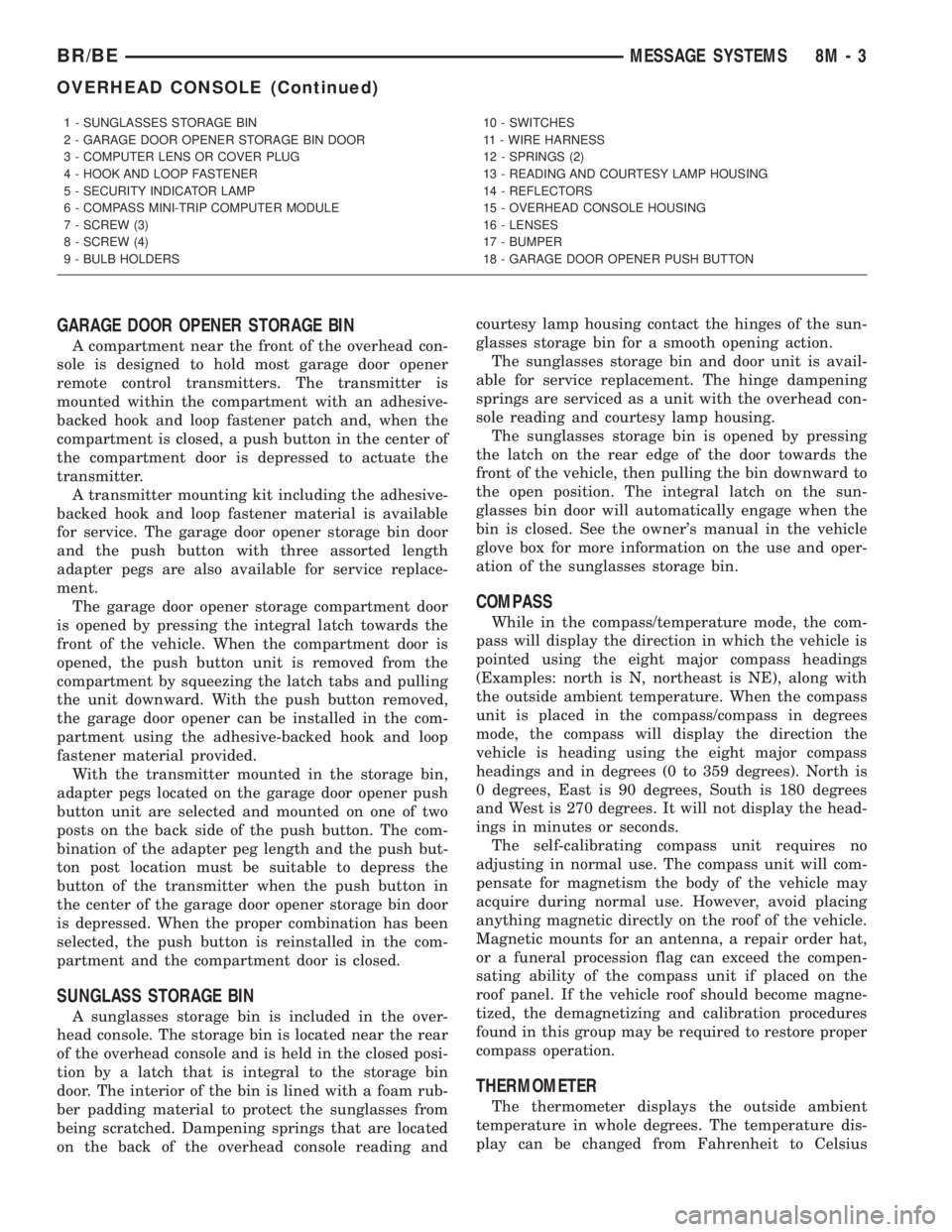

1 - SUNGLASSES STORAGE BIN

2 - GARAGE DOOR OPENER STORAGE BIN DOOR

3 - COMPUTER LENS OR COVER PLUG

4 - HOOK AND LOOP FASTENER

5 - SECURITY INDICATOR LAMP

6 - COMPASS MINI-TRIP COMPUTER MODULE

7 - SCREW (3)

8 - SCREW (4)

9 - BULB HOLDERS10 - SWITCHES

11 - WIRE HARNESS

12 - SPRINGS (2)

13 - READING AND COURTESY LAMP HOUSING

14 - REFLECTORS

15 - OVERHEAD CONSOLE HOUSING

16 - LENSES

17 - BUMPER

18 - GARAGE DOOR OPENER PUSH BUTTON

BR/BEMESSAGE SYSTEMS 8M - 3

OVERHEAD CONSOLE (Continued)

Page 559 of 2255

(4) Contact the head of the screw with the plastic

coated tip of the degaussing tool for about two sec-

onds.

(5) With the degaussing tool still energized, slowly

back it away from the screw. When the tip of the tool

is at least 61 centimeters (2 feet) from the screw

head, disconnect the tool.

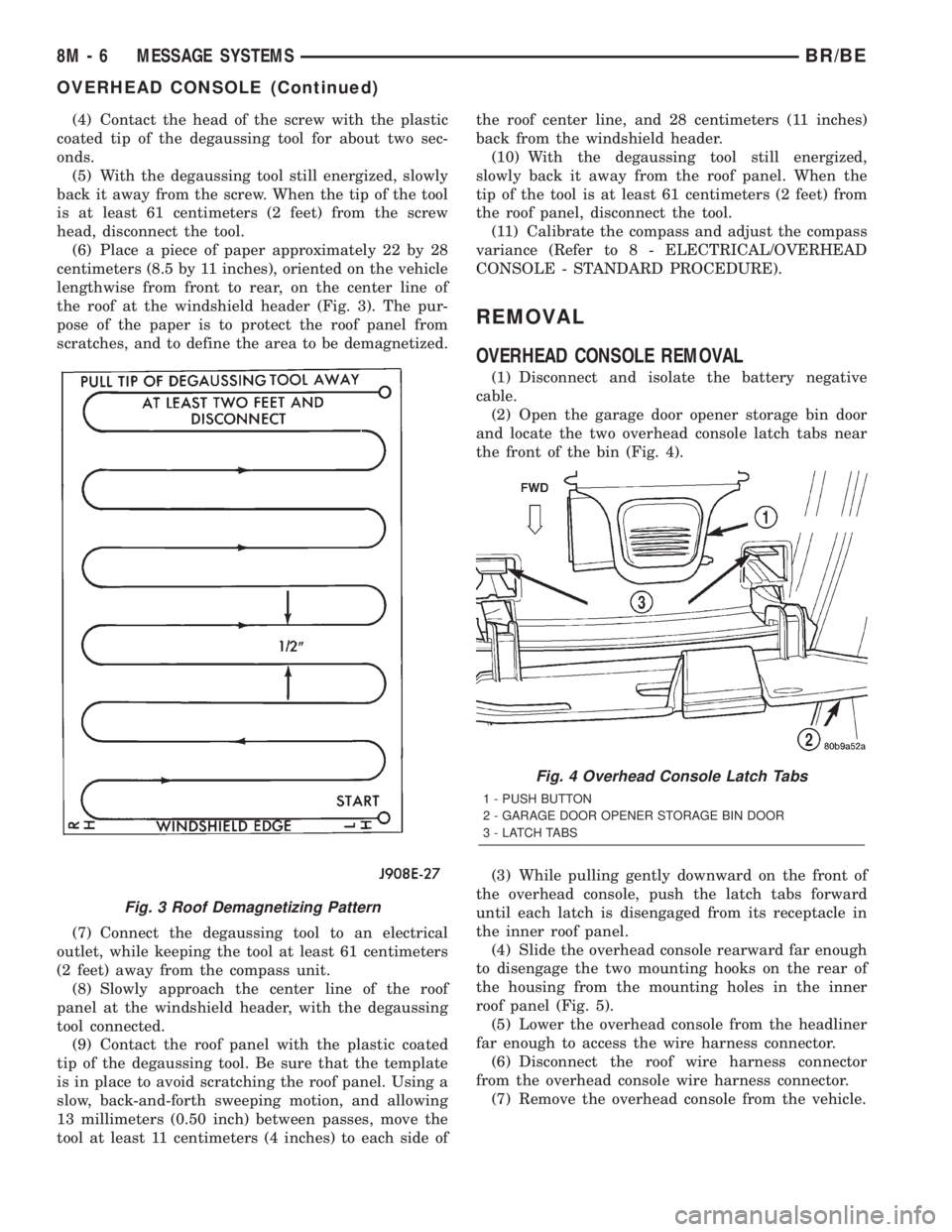

(6) Place a piece of paper approximately 22 by 28

centimeters (8.5 by 11 inches), oriented on the vehicle

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 3). The pur-

pose of the paper is to protect the roof panel from

scratches, and to define the area to be demagnetized.

(7) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(8) Slowly approach the center line of the roof

panel at the windshield header, with the degaussing

tool connected.

(9) Contact the roof panel with the plastic coated

tip of the degaussing tool. Be sure that the template

is in place to avoid scratching the roof panel. Using a

slow, back-and-forth sweeping motion, and allowing

13 millimeters (0.50 inch) between passes, move the

tool at least 11 centimeters (4 inches) to each side ofthe roof center line, and 28 centimeters (11 inches)

back from the windshield header.

(10) With the degaussing tool still energized,

slowly back it away from the roof panel. When the

tip of the tool is at least 61 centimeters (2 feet) from

the roof panel, disconnect the tool.

(11) Calibrate the compass and adjust the compass

variance (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE - STANDARD PROCEDURE).

REMOVAL

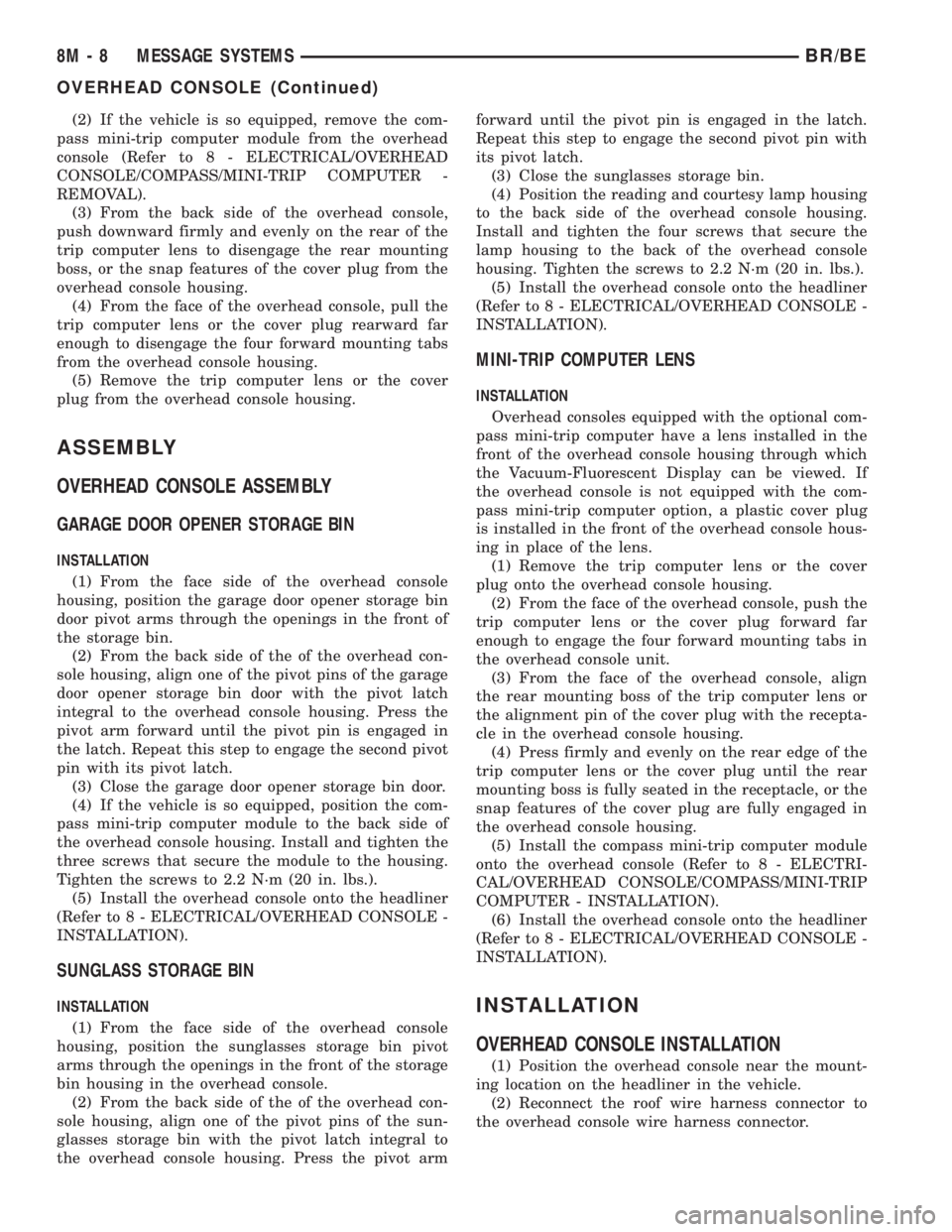

OVERHEAD CONSOLE REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Open the garage door opener storage bin door

and locate the two overhead console latch tabs near

the front of the bin (Fig. 4).

(3) While pulling gently downward on the front of

the overhead console, push the latch tabs forward

until each latch is disengaged from its receptacle in

the inner roof panel.

(4) Slide the overhead console rearward far enough

to disengage the two mounting hooks on the rear of

the housing from the mounting holes in the inner

roof panel (Fig. 5).

(5) Lower the overhead console from the headliner

far enough to access the wire harness connector.

(6) Disconnect the roof wire harness connector

from the overhead console wire harness connector.

(7) Remove the overhead console from the vehicle.

Fig. 3 Roof Demagnetizing Pattern

Fig. 4 Overhead Console Latch Tabs

1 - PUSH BUTTON

2 - GARAGE DOOR OPENER STORAGE BIN DOOR

3 - LATCH TABS

8M - 6 MESSAGE SYSTEMSBR/BE

OVERHEAD CONSOLE (Continued)

Page 561 of 2255

(2) If the vehicle is so equipped, remove the com-

pass mini-trip computer module from the overhead

console (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/COMPASS/MINI-TRIP COMPUTER -

REMOVAL).

(3) From the back side of the overhead console,

push downward firmly and evenly on the rear of the

trip computer lens to disengage the rear mounting

boss, or the snap features of the cover plug from the

overhead console housing.

(4) From the face of the overhead console, pull the

trip computer lens or the cover plug rearward far

enough to disengage the four forward mounting tabs

from the overhead console housing.

(5) Remove the trip computer lens or the cover

plug from the overhead console housing.

ASSEMBLY

OVERHEAD CONSOLE ASSEMBLY

GARAGE DOOR OPENER STORAGE BIN

INSTALLATION

(1) From the face side of the overhead console

housing, position the garage door opener storage bin

door pivot arms through the openings in the front of

the storage bin.

(2) From the back side of the of the overhead con-

sole housing, align one of the pivot pins of the garage

door opener storage bin door with the pivot latch

integral to the overhead console housing. Press the

pivot arm forward until the pivot pin is engaged in

the latch. Repeat this step to engage the second pivot

pin with its pivot latch.

(3) Close the garage door opener storage bin door.

(4) If the vehicle is so equipped, position the com-

pass mini-trip computer module to the back side of

the overhead console housing. Install and tighten the

three screws that secure the module to the housing.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(5) Install the overhead console onto the headliner

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

INSTALLATION).

SUNGLASS STORAGE BIN

INSTALLATION

(1) From the face side of the overhead console

housing, position the sunglasses storage bin pivot

arms through the openings in the front of the storage

bin housing in the overhead console.

(2) From the back side of the of the overhead con-

sole housing, align one of the pivot pins of the sun-

glasses storage bin with the pivot latch integral to

the overhead console housing. Press the pivot armforward until the pivot pin is engaged in the latch.

Repeat this step to engage the second pivot pin with

its pivot latch.

(3) Close the sunglasses storage bin.

(4) Position the reading and courtesy lamp housing

to the back side of the overhead console housing.

Install and tighten the four screws that secure the

lamp housing to the back of the overhead console

housing. Tighten the screws to 2.2 N´m (20 in. lbs.).

(5) Install the overhead console onto the headliner

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

INSTALLATION).

MINI-TRIP COMPUTER LENS

INSTALLATION

Overhead consoles equipped with the optional com-

pass mini-trip computer have a lens installed in the

front of the overhead console housing through which

the Vacuum-Fluorescent Display can be viewed. If

the overhead console is not equipped with the com-

pass mini-trip computer option, a plastic cover plug

is installed in the front of the overhead console hous-

ing in place of the lens.

(1) Remove the trip computer lens or the cover

plug onto the overhead console housing.

(2) From the face of the overhead console, push the

trip computer lens or the cover plug forward far

enough to engage the four forward mounting tabs in

the overhead console unit.

(3) From the face of the overhead console, align

the rear mounting boss of the trip computer lens or

the alignment pin of the cover plug with the recepta-

cle in the overhead console housing.

(4) Press firmly and evenly on the rear edge of the

trip computer lens or the cover plug until the rear

mounting boss is fully seated in the receptacle, or the

snap features of the cover plug are fully engaged in

the overhead console housing.

(5) Install the compass mini-trip computer module

onto the overhead console (Refer to 8 - ELECTRI-

CAL/OVERHEAD CONSOLE/COMPASS/MINI-TRIP

COMPUTER - INSTALLATION).

(6) Install the overhead console onto the headliner

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

INSTALLATION).

INSTALLATION

OVERHEAD CONSOLE INSTALLATION

(1) Position the overhead console near the mount-

ing location on the headliner in the vehicle.

(2) Reconnect the roof wire harness connector to

the overhead console wire harness connector.

8M - 8 MESSAGE SYSTEMSBR/BE

OVERHEAD CONSOLE (Continued)

Page 585 of 2255

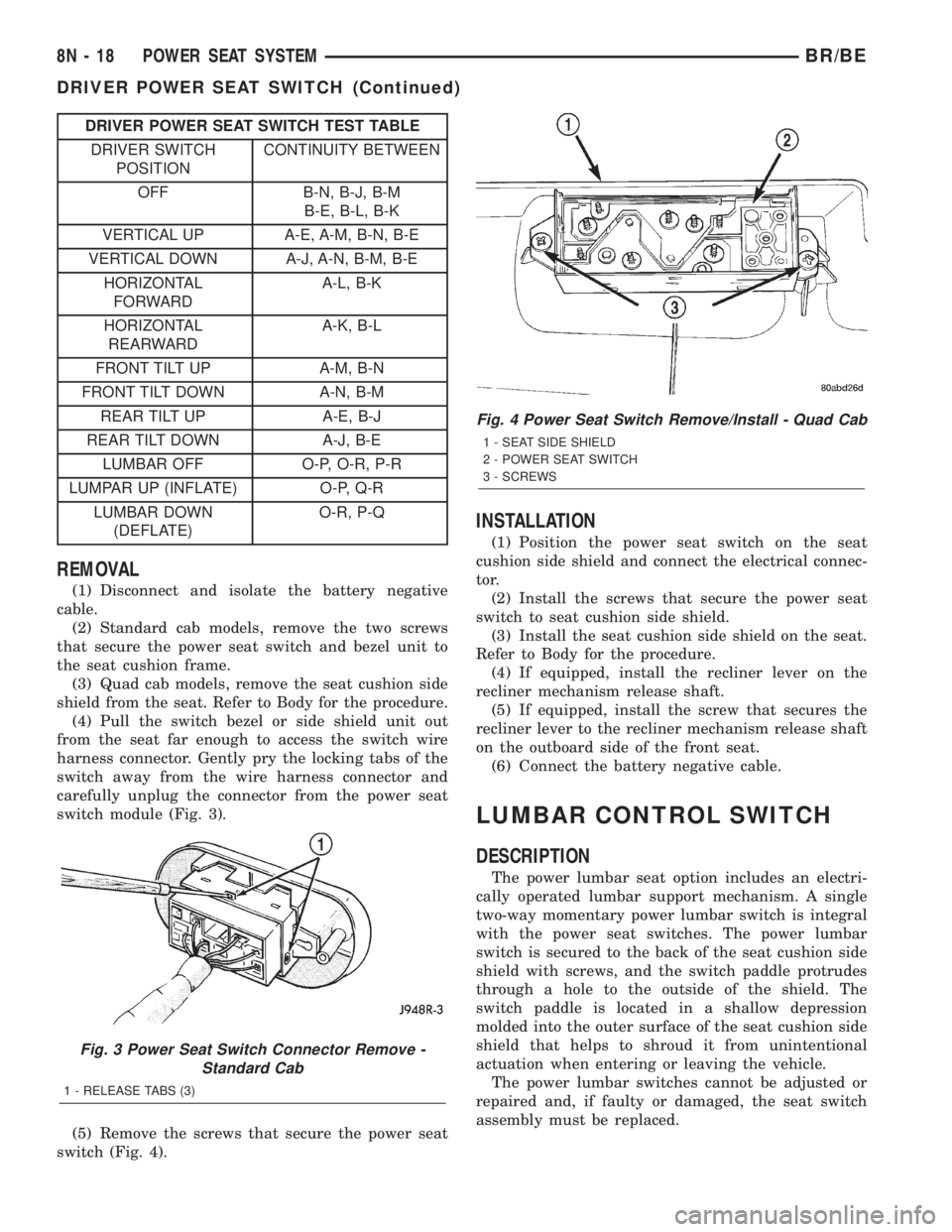

DRIVER POWER SEAT SWITCH TEST TABLE

DRIVER SWITCH

POSITIONCONTINUITY BETWEEN

OFF B-N, B-J, B-M

B-E, B-L, B-K

VERTICAL UP A-E, A-M, B-N, B-E

VERTICAL DOWN A-J, A-N, B-M, B-E

HORIZONTAL

FORWARDA-L, B-K

HORIZONTAL

REARWARDA-K, B-L

FRONT TILT UP A-M, B-N

FRONT TILT DOWN A-N, B-M

REAR TILT UP A-E, B-J

REAR TILT DOWN A-J, B-E

LUMBAR OFF O-P, O-R, P-R

LUMPAR UP (INFLATE) O-P, Q-R

LUMBAR DOWN

(DEFLATE)O-R, P-Q

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Standard cab models, remove the two screws

that secure the power seat switch and bezel unit to

the seat cushion frame.

(3) Quad cab models, remove the seat cushion side

shield from the seat. Refer to Body for the procedure.

(4) Pull the switch bezel or side shield unit out

from the seat far enough to access the switch wire

harness connector. Gently pry the locking tabs of the

switch away from the wire harness connector and

carefully unplug the connector from the power seat

switch module (Fig. 3).

(5) Remove the screws that secure the power seat

switch (Fig. 4).

INSTALLATION

(1) Position the power seat switch on the seat

cushion side shield and connect the electrical connec-

tor.

(2) Install the screws that secure the power seat

switch to seat cushion side shield.

(3) Install the seat cushion side shield on the seat.

Refer to Body for the procedure.

(4) If equipped, install the recliner lever on the

recliner mechanism release shaft.

(5) If equipped, install the screw that secures the

recliner lever to the recliner mechanism release shaft

on the outboard side of the front seat.

(6) Connect the battery negative cable.

LUMBAR CONTROL SWITCH

DESCRIPTION

The power lumbar seat option includes an electri-

cally operated lumbar support mechanism. A single

two-way momentary power lumbar switch is integral

with the power seat switches. The power lumbar

switch is secured to the back of the seat cushion side

shield with screws, and the switch paddle protrudes

through a hole to the outside of the shield. The

switch paddle is located in a shallow depression

molded into the outer surface of the seat cushion side

shield that helps to shroud it from unintentional

actuation when entering or leaving the vehicle.

The power lumbar switches cannot be adjusted or

repaired and, if faulty or damaged, the seat switch

assembly must be replaced.

Fig. 3 Power Seat Switch Connector Remove -

Standard Cab

1 - RELEASE TABS (3)

Fig. 4 Power Seat Switch Remove/Install - Quad Cab

1 - SEAT SIDE SHIELD

2 - POWER SEAT SWITCH

3 - SCREWS

8N - 18 POWER SEAT SYSTEMBR/BE

DRIVER POWER SEAT SWITCH (Continued)

Page 588 of 2255

PASSENGER POWER SEAT SWITCH TEST TABLE

PASSENGER SWITCH

POSITIONCONTINUITY BETWEEN

OFF B-N, B-J, B-M,B-E, B-L,

B-K

VERTICAL DOWN A-E, A-M, B-N, B-E

VERTICAL UP A-J, A-N, B-M, B-E

HORIZONTAL

FORWARDA-L, B-K

HORIZONTAL

REARWARDA-K, B-L

FRONT TILT DOWN A-M, B-N

FRONT TILT UP A-N, B-M

REAR TILT DOWN A-E, B-J

REAR TILT UP A-J, B-E

LUMBAR OFF O-P, O-R, P-R

LUMBAR DOWN

(DEFLATE)O-P, Q-R

LUMBAR UP (INFLATE) O-R, P-Q

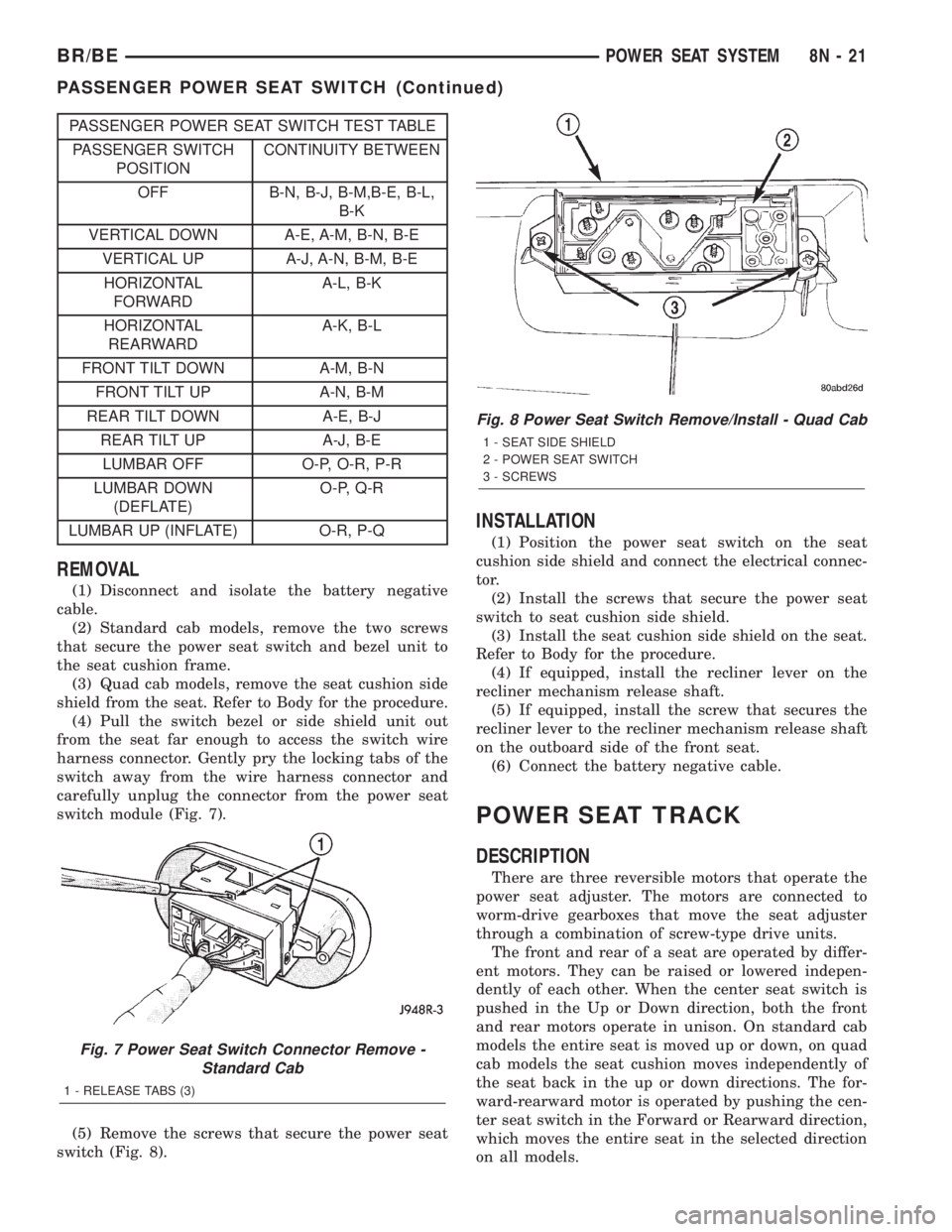

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Standard cab models, remove the two screws

that secure the power seat switch and bezel unit to

the seat cushion frame.

(3) Quad cab models, remove the seat cushion side

shield from the seat. Refer to Body for the procedure.

(4) Pull the switch bezel or side shield unit out

from the seat far enough to access the switch wire

harness connector. Gently pry the locking tabs of the

switch away from the wire harness connector and

carefully unplug the connector from the power seat

switch module (Fig. 7).

(5) Remove the screws that secure the power seat

switch (Fig. 8).

INSTALLATION

(1) Position the power seat switch on the seat

cushion side shield and connect the electrical connec-

tor.

(2) Install the screws that secure the power seat

switch to seat cushion side shield.

(3) Install the seat cushion side shield on the seat.

Refer to Body for the procedure.

(4) If equipped, install the recliner lever on the

recliner mechanism release shaft.

(5) If equipped, install the screw that secures the

recliner lever to the recliner mechanism release shaft

on the outboard side of the front seat.

(6) Connect the battery negative cable.

POWER SEAT TRACK

DESCRIPTION

There are three reversible motors that operate the

power seat adjuster. The motors are connected to

worm-drive gearboxes that move the seat adjuster

through a combination of screw-type drive units.

The front and rear of a seat are operated by differ-

ent motors. They can be raised or lowered indepen-

dently of each other. When the center seat switch is

pushed in the Up or Down direction, both the front

and rear motors operate in unison. On standard cab

models the entire seat is moved up or down, on quad

cab models the seat cushion moves independently of

the seat back in the up or down directions. The for-

ward-rearward motor is operated by pushing the cen-

ter seat switch in the Forward or Rearward direction,

which moves the entire seat in the selected direction

on all models.

Fig. 7 Power Seat Switch Connector Remove -

Standard Cab

1 - RELEASE TABS (3)

Fig. 8 Power Seat Switch Remove/Install - Quad Cab

1 - SEAT SIDE SHIELD

2 - POWER SEAT SWITCH

3 - SCREWS

BR/BEPOWER SEAT SYSTEM 8N - 21

PASSENGER POWER SEAT SWITCH (Continued)

Page 593 of 2255

INSTALLATION

(1) Connect the power window switch to the har-

ness connector.

(2) Insert the rear of the switch and bezel unit into

the opening.

(3) Push down on the front and rear of the switch

until the retaining tabs snap into place.

(4) Reconnect the battery negative cable.

WINDOW MOTOR

DESCRIPTION

A permanent magnet reversible motor moves the

window regulator through an integral gearbox mech-

anism. A positive and negative battery connection to

the two motor terminals will cause the motor to

rotate in one direction. Reversing the current

through these same two connections will cause the

motor to rotate in the opposite direction.

In addition, each power window motor is equipped

with an integral self-resetting circuit breaker to pro-

tect the motor from overloads. The power window

motor and gearbox assembly cannot be repaired and,

if faulty or damaged, the entire power window regu-

lator assembly must be replaced.

DIAGNOSIS AND TESTING - WINDOW MOTOR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds. Before you proceed withthis diagnosis, confirm proper switch operation.

(Refer to 8 - ELECTRICAL/POWER WINDOWS/

POWER WINDOW SWITCH - DIAGNOSIS AND

TESTING).

(1) Disconnect and isolate the battery negative

cable. Remove the trim panel from the door with the

inoperative power window.

(2) Unplug the power window motor wire harness

connector. Apply 12 volts across the motor terminals

to check its operation in one direction. Reverse the

connections across the motor terminals to check the

operation in the other direction. Remember, if the

window is in the full up or full down position, the

motor will not operate in that direction by design. If

OK, repair the circuits from the power window motor

to the power window switch as required. If not OK,

replace the faulty motor.

(3) If the motor operates in both directions, check

the operation of the window glass and lift mechanism

through its complete up and down travel. There

should be no binding or sticking of the window glass

or lift mechanism through the entire travel range. If

not OK, (Refer to 23 - BODY/DOOR - FRONT/WIN-

DOW REGULATOR - REMOVAL).

REMOVAL

The power window motor and mechanism is inte-

gral to the power window regulator unit. If the power

window motor or mechanism is faulty or damaged,

the entire power window regulator unit must be

replaced. (Refer to 23 - BODY/DOOR - FRONT/WIN-

DOW REGULATOR - REMOVAL) for the window

regulator service procedures.

8N - 26 POWER WINDOWSBR/BE

POWER WINDOW SWITCH (Continued)

Page 596 of 2255

circumstances necessitate that a child, or an adult

with certain medical conditions be placed in the front

passenger seating position. Refer to the owner's man-

ual in the vehicle glove box for specific recommenda-

tions concerning the specific circumstances where the

passenger airbag on/off switch should be used to dis-

able the passenger airbag.

Deployment of the airbags depends upon the angle

and severity of the impact. The airbag system is

designed to deploy upon a frontal impact within a

thirty degree angle from either side of the vehicle

center line. Deployment is not based upon vehicle

speed; rather, deployment is based upon the rate of

deceleration as measured by the forces of gravity (G

force) upon the airbag system impact sensor, which is

integral to the ACM. When a frontal impact is severe

enough, the microprocessor in the ACM signals the

inflator units of both airbag modules to deploy the

airbags. During a frontal vehicle impact, the knee

blockers work in concert with properly fastened and

adjusted seat belts to restrain both the driver and

the front seat passenger in the proper position for an

airbag deployment. The knee blockers also absorb

and distribute the crash energy from the driver and

the front seat passenger to the structure of the

instrument panel.

Typically, the driver and front seat passenger recall

more about the events preceding and following a col-

lision than they have of the airbag deployment itself.

This is because the airbag deployment and deflation

occur so rapidly. In a typical 48 kilometer-per-hour

(30 mile-per-hour) barrier impact, from the moment

of impact until both airbags are fully inflated takes

about 40 milliseconds. Within one to two seconds

from the moment of impact, both airbags are almost

entirely deflated. The times cited for these events are

approximations, which apply only to a barrier impact

at the given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

airbag system circuits or components, it stores a

fault code or Diagnostic Trouble Code (DTC) in its

memory circuit and sends an electronic message to

the EMIC to turn on the airbag indicator. Proper

testing of the airbag system components, the

Chrysler Collision Detection (CCD) data bus, the

data bus message inputs to and outputs from the

EMIC or the ACM, as well as the retrieval or erasure

of a DTC from the ACM requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passenger restraints,

including the airbag system.WARNING

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTROMECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY AIR-

BAG SYSTEM OR RELATED STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENTS YOU MUST FIRST DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE (GROUND)

CABLE. THEN WAIT TWO MINUTES FOR THE SYS-

TEM CAPACITOR TO DISCHARGE BEFORE FUR-

THER SYSTEM SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO DO THIS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE DRIVER AIRBAG INFLATOR UNIT

CONTAINS SODIUM AZIDE AND POTASSIUM

NITRATE. THESE MATERIALS ARE POISONOUS

AND EXTREMELY FLAMMABLE. CONTACT WITH

ACID, WATER, OR HEAVY METALS MAY PRODUCE

HARMFUL AND IRRITATING GASES (SODIUM

HYDROXIDE IS FORMED IN THE PRESENCE OF

MOISTURE) OR COMBUSTIBLE COMPOUNDS. THE

PASSENGER AIRBAG UNIT CONTAINS ARGON GAS

PRESSURIZED TO OVER 2500 PSI. DO NOT

ATTEMPT TO DISMANTLE AN AIRBAG UNIT OR

TAMPER WITH ITS INFLATOR. DO NOT PUNCTURE,

INCINERATE, OR BRING INTO CONTACT WITH

ELECTRICITY. DO NOT STORE AT TEMPERATURES

EXCEEDING 93É C (200É F).

WARNING: REPLACE AIRBAG SYSTEM COMPO-

NENTS ONLY WITH PARTS SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

SUBSTITUTE PARTS MAY APPEAR INTERCHANGE-

ABLE, BUT INTERNAL DIFFERENCES MAY RESULT

IN INFERIOR OCCUPANT PROTECTION.

WARNING: THE FASTENERS, SCREWS, AND

BOLTS ORIGINALLY USED FOR THE AIRBAG SYS-

TEM COMPONENTS HAVE SPECIAL COATINGS

AND ARE SPECIFICALLY DESIGNED FOR THE AIR-

BAG SYSTEM. THEY MUST NEVER BE REPLACED

WITH ANY SUBSTITUTES. ANY TIME A NEW FAS-

TENER IS NEEDED, REPLACE IT WITH THE COR-

RECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

BR/BERESTRAINTS 8O - 3

RESTRAINTS (Continued)

Page 603 of 2255

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the child tether anchor (standard cab)

or child tether (club/quad cab) onto the cab back

panel (Fig. 7).

(2) Install and tighten the screw that secures the

child tether anchor (standard cab) or child tether

(club/quad cab) onto the cab back panel. Tighten the

screw to 13.5 N´m (120 in. lbs.).

(3) Reinstall the trim onto the inside of the cab

back panel. (Refer to 23 - BODY/INTERIOR/REAR

CLOSURE PANEL TRIM - INSTALLATION).

CLOCKSPRING

DESCRIPTION

The clockspring assembly is secured with two inte-

gral plastic latches onto the steering column lock

housing near the top of the steering column, behind

the steering wheel. The clockspring consists of a flat,

round molded plastic case with a stubby tail that

hangs below the steering column and contains a con-

nector receptacle and a long pigtail wire with connec-

tor that face toward the instrument panel. Within

the plastic housing is a spool-like molded plastic

rotor with a large exposed hub. The upper surface of

the rotor hub has a large center hole, two large flats,

two auto-locking tabs, and three short pigtail wires

with connectors that face toward the steering wheel.

The lower surface of the rotor hub has two integral

turn signal cancelling cam lobes. Within the plastic

case and wound around the rotor spool is a long rib-

bon-like tape that consists of several thin copper wire

leads sandwiched between two thin plastic mem-

branes. The outer end of the tape terminates at the

connector receptacle and pigtail wire that face the

instrument panel, while the inner end of the tape

terminates at the pigtail wires on the hub of the

clockspring rotor that face the steering wheel.

Service replacement clocksprings are shipped pre-

centered and with a piece of tape covering theengaged auto-locking tabs. The auto-locking tabs

secure the centered clockspring rotor to the clock-

spring case during shipment, but these tabs are auto-

matically disengaged once the clockspring is installed

on the steering column. (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - STANDARD PRO-

CEDURE - CLOCKSPRING CENTERING).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mounted

on or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,

and the remote radio switches if the vehicle is so

equipped. The clockspring case is positioned and

secured to the upper steering column lock housing by

two integral plastic latches. The connector receptacle

on the tail of the fixed clockspring housing connect

the clockspring to the vehicle electrical system

through a take out with connector from the instru-

ment panel wire harness. The lower clockspring pig-

tail on the tail of the clockspring housing connect the

clockspring driver airbag circuits to a separate take

out and connector of the instrument panel wire har-

ness located near the lower instrument panel rein-

forcement, below the steering column. The

clockspring rotor is movable and is keyed to the hub

of the steering wheel by two large flats that are

molded into the rotor hub. The two lobes on the

lower surface of the clockspring rotor hub contact a

turn signal cancel actuator of the multi-function

switch to provide automatic turn signal cancellation.

The pigtail wires on the upper surface of the clock-

spring connect the clockspring to the horn switch, the

two speed control switches, and the remote radio

switches on vehicles that are so equipped.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring must be centered when it is installed on

the steering column. Centering the clockspring

indexes the clockspring spool to the movable steering

components so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components and must be re-cen-

tered following completion of the service or the tape

8O - 10 RESTRAINTSBR/BE

CHILD TETHER (Continued)

Page 604 of 2255

may be damaged. Service replacement clocksprings

are shipped pre-centered and with the auto-locking

tabs engaged. A piece of tape covers the auto-locking

tabs to discourage tampering. These auto-locking

tabs should not be disengaged until the clockspring

has been installed on the steering column. If this

shipping tape is removed or damaged, or if the auto-

locking tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING).

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

from the centered position, without damaging the

clockspring tape.

However, if the clockspring is removed for service

or if the steering column is disconnected from the

steering gear, the clockspring tape can change posi-

tion relative to the other steering components. The

clockspring must then be re-centered following com-

pletion of such service or the clockspring tape may be

damaged. Service replacement clocksprings are

shipped pre-centered and with the auto-locking tabs

engaged (raised). These auto-locking tabs should not

be disengaged until the clockspring has been

installed on the steering column. If the auto-locking

tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the clockspring from the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL).

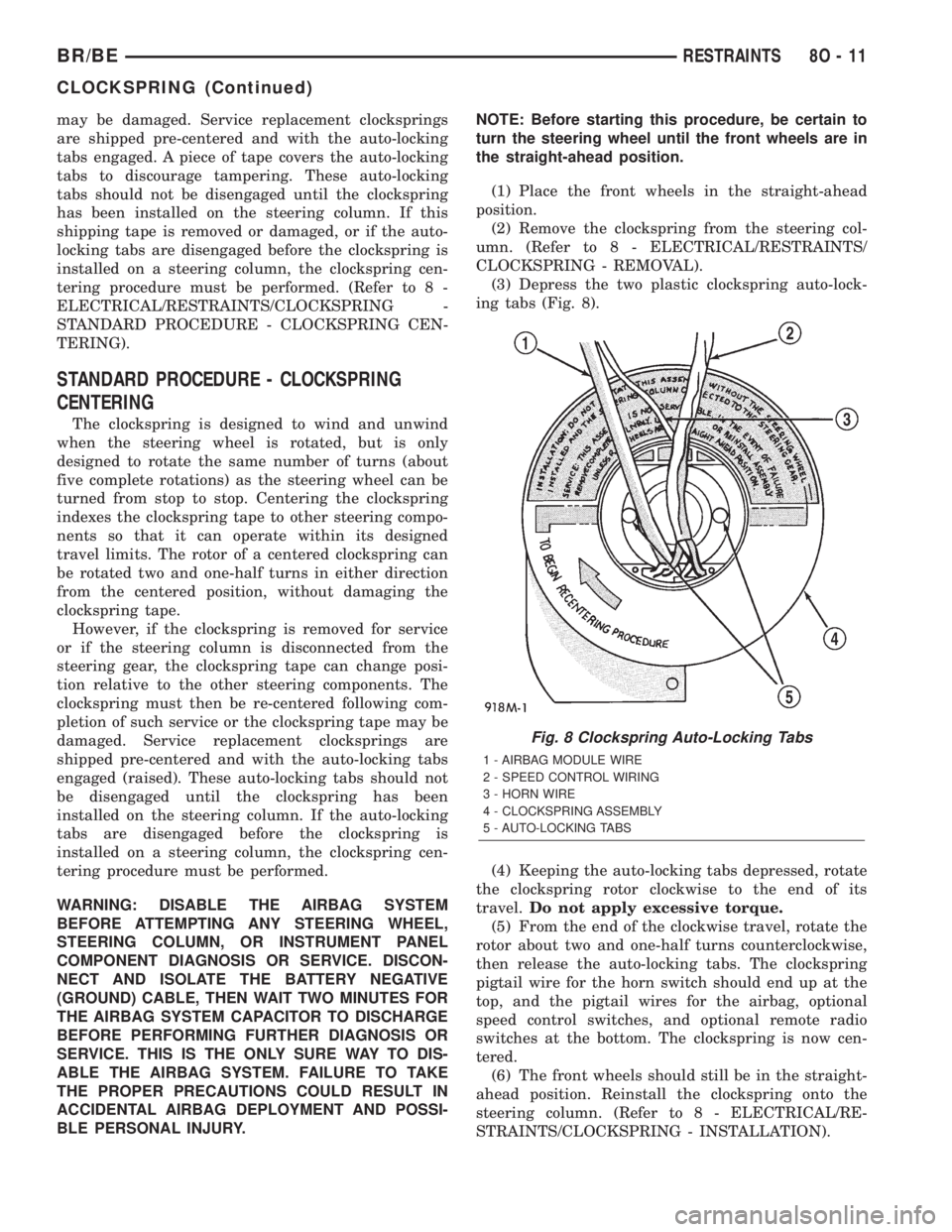

(3) Depress the two plastic clockspring auto-lock-

ing tabs (Fig. 8).

(4) Keeping the auto-locking tabs depressed, rotate

the clockspring rotor clockwise to the end of its

travel.Do not apply excessive torque.

(5) From the end of the clockwise travel, rotate the

rotor about two and one-half turns counterclockwise,

then release the auto-locking tabs. The clockspring

pigtail wire for the horn switch should end up at the

top, and the pigtail wires for the airbag, optional

speed control switches, and optional remote radio

switches at the bottom. The clockspring is now cen-

tered.

(6) The front wheels should still be in the straight-

ahead position. Reinstall the clockspring onto the

steering column. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - INSTALLATION).

Fig. 8 Clockspring Auto-Locking Tabs

1 - AIRBAG MODULE WIRE

2 - SPEED CONTROL WIRING

3 - HORN WIRE

4 - CLOCKSPRING ASSEMBLY

5 - AUTO-LOCKING TABS

BR/BERESTRAINTS 8O - 11

CLOCKSPRING (Continued)

Page 606 of 2255

not maintained, the clockspring must be centered

again before it is reinstalled. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - STANDARD

PROCEDURE - CLOCKSPRING CENTERING).

INSTALLATION

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

If the clockspring is not properly centered in rela-

tion to the steering wheel, steering shaft and steer-

ing gear, it may be damaged. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING). Service replacement clocksprings are

shipped pre-centered and with a piece of tape cover-

ing the engaged clockspring auto-locking tabs. This

tape should not be removed until the clockspring has

been installed on the steering column. If the tape is

removed before the clockspring is installed on a

steering column, the clockspring centering procedure

must be performed.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain

that the front wheels are still in the straight-ahead

position.

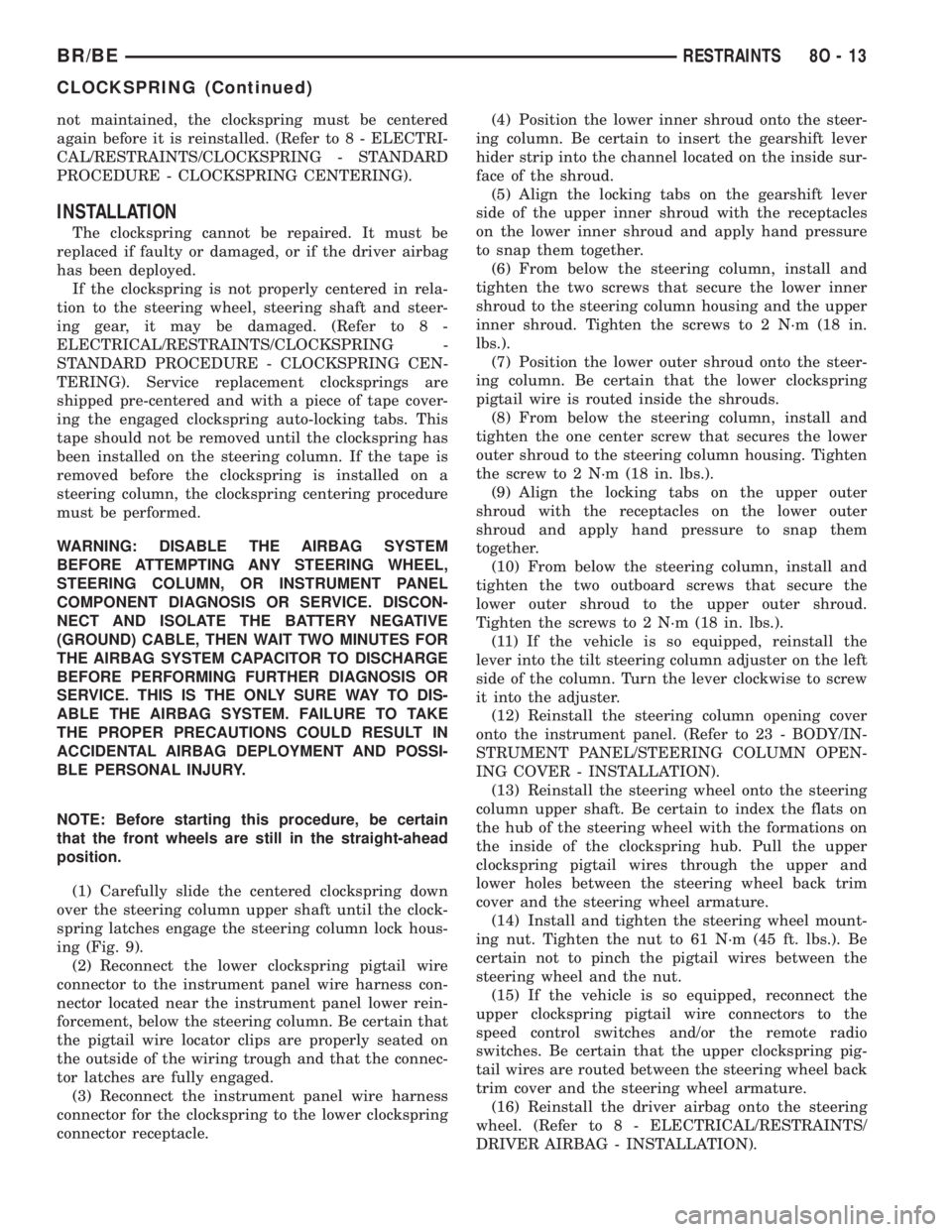

(1) Carefully slide the centered clockspring down

over the steering column upper shaft until the clock-

spring latches engage the steering column lock hous-

ing (Fig. 9).

(2) Reconnect the lower clockspring pigtail wire

connector to the instrument panel wire harness con-

nector located near the instrument panel lower rein-

forcement, below the steering column. Be certain that

the pigtail wire locator clips are properly seated on

the outside of the wiring trough and that the connec-

tor latches are fully engaged.

(3) Reconnect the instrument panel wire harness

connector for the clockspring to the lower clockspring

connector receptacle.(4) Position the lower inner shroud onto the steer-

ing column. Be certain to insert the gearshift lever

hider strip into the channel located on the inside sur-

face of the shroud.

(5) Align the locking tabs on the gearshift lever

side of the upper inner shroud with the receptacles

on the lower inner shroud and apply hand pressure

to snap them together.

(6) From below the steering column, install and

tighten the two screws that secure the lower inner

shroud to the steering column housing and the upper

inner shroud. Tighten the screws to 2 N´m (18 in.

lbs.).

(7) Position the lower outer shroud onto the steer-

ing column. Be certain that the lower clockspring

pigtail wire is routed inside the shrouds.

(8) From below the steering column, install and

tighten the one center screw that secures the lower

outer shroud to the steering column housing. Tighten

the screw to 2 N´m (18 in. lbs.).

(9) Align the locking tabs on the upper outer

shroud with the receptacles on the lower outer

shroud and apply hand pressure to snap them

together.

(10) From below the steering column, install and

tighten the two outboard screws that secure the

lower outer shroud to the upper outer shroud.

Tighten the screws to 2 N´m (18 in. lbs.).

(11) If the vehicle is so equipped, reinstall the

lever into the tilt steering column adjuster on the left

side of the column. Turn the lever clockwise to screw

it into the adjuster.

(12) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(13) Reinstall the steering wheel onto the steering

column upper shaft. Be certain to index the flats on

the hub of the steering wheel with the formations on

the inside of the clockspring hub. Pull the upper

clockspring pigtail wires through the upper and

lower holes between the steering wheel back trim

cover and the steering wheel armature.

(14) Install and tighten the steering wheel mount-

ing nut. Tighten the nut to 61 N´m (45 ft. lbs.). Be

certain not to pinch the pigtail wires between the

steering wheel and the nut.

(15) If the vehicle is so equipped, reconnect the

upper clockspring pigtail wire connectors to the

speed control switches and/or the remote radio

switches. Be certain that the upper clockspring pig-

tail wires are routed between the steering wheel back

trim cover and the steering wheel armature.

(16) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

BR/BERESTRAINTS 8O - 13

CLOCKSPRING (Continued)