sensor DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 504 of 2255

played when the ignition switch was turned to the

Off position.

²Trip Odometer Reset- When the trip odome-

ter reset switch is pressed and held for longer than

about two seconds, the trip odometer will be reset to

000.0 kilometers (miles). The VFD must be display-

ing the trip odometer information in order for the

trip odometer information to be reset.

²Message Failure- If the cluster fails to receive

a distance message during normal operation, it will

flash the odometer/trip odometer distance informa-

tion on and off repeatedly until a distance message is

received, or until the ignition switch is turned to the

Off position, whichever occurs first. If the cluster

does not receive a distance message within one sec-

ond after the ignition switch is turned to the On posi-

tion, it will display the last distance message stored

in the cluster memory. If the cluster is unable to dis-

play distance information due to an error internal to

the cluster, the VFD display will be blank.

²Actuator Test- Each time the cluster is put

through the actuator test, the VFD will display all of

its characters at once, then step through each char-

acter segment individually during the VFD portion of

the test to confirm the functionality of the VFD and

the cluster control circuitry.

The PCM continually monitors the vehicle speed

sensor, then sends the proper distance messages to

the instrument cluster. For further diagnosis of the

odometer/trip odometer or the instrument cluster cir-

cuitry that controls these functions, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). For proper diagnosis of the

vehicle speed sensor, the PCM, the CCD data bus, or

the message inputs to the instrument cluster that

control the odometer/trip odometer, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

OIL PRESSURE GAUGE

DESCRIPTION

An oil pressure gauge is standard equipment on all

instrument clusters. The oil pressure gauge is located

in the upper right quadrant of the instrument clus-

ter, above the fuel gauge. The oil pressure gauge con-

sists of a movable gauge needle or pointer controlled

by the instrument cluster circuitry and a fixed 90

degree scale on the cluster overlay that reads left-to-

right either from 0 kPa (0 psi) to 758 kPa (110 psi).

An International Control and Display Symbol icon for

ªEngine Oilº is located on the cluster overlay, directly

below the highest graduation of the gauge scale. The

oil pressure gauge graphics are white against a black

field except for a single red graduation at the lowend of the gauge scale, making them clearly visible

within the instrument cluster in daylight. When illu-

minated from behind by the panel lamps dimmer

controlled cluster illumination lighting with the exte-

rior lamps turned On, the white graphics appear

blue-green and the red graphics appear red. The

orange gauge needle is internally illuminated. Gauge

illumination is provided by replaceable incandescent

bulb and bulb holder units located on the instrument

cluster electronic circuit board. The oil pressure

gauge is serviced as a unit with the instrument clus-

ter.

OPERATION

The oil pressure gauge gives an indication to the

vehicle operator of the engine oil pressure. This

gauge is controlled by the instrument cluster circuit

board based upon the cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Chrysler

Collision Detection (CCD) data bus. The oil pressure

gauge is an air core magnetic unit that receives bat-

tery current on the instrument cluster electronic cir-

cuit board through the fused ignition switch output

(st-run) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Engine Oil Pressure Message- The instru-

ment cluster circuitry restricts the oil pressure gauge

needle operation in order to provide readings that

are consistent with customer expectations. Each time

the cluster receives a message from the PCM indicat-

ing the engine oil pressure is between about 6.9 kPa

(1 psi) and 137.9 kPa (20 psi) for gasoline engines, or

55 kPa (8 psi) and 58.6 kPa (8.5 psi) for diesel

engines, the cluster holds the gauge needle at a point

about 11 degrees above the low end of normal incre-

ment on the gauge scale. Each time the cluster

receives a message from the PCM indicating the

engine oil pressure is between about 517.1 kPa (75

psi) and 755 kPa (109.5 psi) for gasoline engines, or

551.6 kPa (80 psi) and 755 kPa (109.5 psi) for diesel

engines, the cluster holds the gauge needle at a point

about 7.4 degrees below the high end of normal

increment on the gauge scale. When the cluster

receives messages from the PCM indicating the

engine oil pressure is between about 137.9 kPa (20

psi) and 517.1 kPa (75 psi) for gasoline engines, or

58.6 kPa (8.5 psi) and 551.6 kPa (80 psi) for diesel

engines], the gauge needle is moved to the actual

pressure position on the gauge scale.

BR/BEINSTRUMENT CLUSTER 8J - 25

ODOMETER (Continued)

Page 505 of 2255

²Engine Oil Pressure Low Message- Each

time the cluster receives a message from the PCM

indicating the engine oil pressure is below about 6.9

kPa (1 psi) for gasoline engines, or 55 kPa (8 psi) for

diesel engines, the gauge needle is moved to the 0

kPa (0 psi) graduation at the far left (low) end of the

gauge scale, the check gauges indicator is illumi-

nated, and a single chime tone is generated. The

gauge needle remains at the low end of the scale and

the check gauges indicator remains illuminated until

the cluster receives a message from the PCM indicat-

ing that the engine oil pressure is above about 6.9

kPa (1 psi) for gasoline engines, or 55 kPa (8 psi) for

diesel engines, or until the ignition switch is turned

to the Off position, whichever occurs first. The clus-

ter will only turn the check gauges indicator lamp on

in response to an engine oil pressure low message if

the engine speed message is greater than zero.

²Engine Oil Pressure High Message- Each

time the cluster receives a message from the PCM

indicating the engine oil pressure is above about 755

kPa (109.5 psi) for gasoline or diesel engines, the

gauge needle is moved to the 758.4 kPa (110 psi)

graduation at the far right (high) end of the gauge

scale. The gauge needle remains at the high end of

the scale until the cluster receives a message from

the PCM indicating that the engine oil pressure is

below about 755 kPa (109.5 psi) for gasoline or diesel

engines, or until the ignition switch is turned to the

Off position, whichever occurs first.

²Message Failure- If the cluster fails to receive

an engine oil pressure message, it will hold the

gauge needle at the last indication until a new mes-

sage is received, or until the ignition switch is turned

to the Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in a prescribed sequence in order to confirm the func-

tionality of the gauge and the cluster control cir-

cuitry.

The PCM continually monitors the engine oil pres-

sure sensor to determine the engine oil pressure. The

PCM then sends the proper engine oil pressure mes-

sages to the instrument cluster. For further diagnosis

of the oil pressure gauge or the instrument cluster

circuitry that controls the gauge, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). If the instrument cluster turns on

the check gauges indicator due to a low oil pressure

gauge reading, it may indicate that the engine or the

engine oiling system requires service. For proper

diagnosis of the engine oil pressure sensor, the PCM,

the CCD data bus, or the message inputs to the

instrument cluster that control the oil pressuregauge, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

OVERDRIVE OFF INDICATOR

DESCRIPTION

An overdrive off indicator is standard equipment

on all instrument clusters. However, on vehicles not

equipped with the optional overdrive automatic

transmission, this indicator is electronically disabled.

The overdrive off indicator is located near the lower

edge of the instrument cluster overlay, to the right of

center. The overdrive off indicator consists of a sten-

cilled cutout of the words ªO/D OFFº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. An

amber lens behind the cutout in the opaque layer of

the overlay causes the ªO/D OFFº text to appear in

amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by a Light Emitting Diode (LED) soldered

onto the instrument cluster electronic circuit board.

The overdrive off indicator is serviced as a unit with

the instrument cluster.

OPERATION

The overdrive off indicator gives an indication to

the vehicle operator when the Off position of the

overdrive off switch has been selected, disabling the

electronically controlled overdrive feature of the auto-

matic transmission. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon the cluster programming and electronic

messages received by the cluster from the Powertrain

Control Module (PCM) over the Chrysler Collision

Detection (CCD) data bus. The overdrive off indicator

Light Emitting Diode (LED) receives battery current

on the instrument cluster electronic circuit board

through the fused ignition switch output (st-run) cir-

cuit whenever the ignition switch is in the On or

Start positions; therefore, the LED will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is pro-

vided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

overdrive off indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the overdrive off indicator

is illuminated for about two seconds as a bulb test.

²Overdrive Off Lamp-On Message- Each time

the cluster receives an overdrive off lamp-on message

from the PCM indicating that the Off position of the

overdrive off switch has been selected, the overdrive

off indicator will be illuminated. The indicator

8J - 26 INSTRUMENT CLUSTERBR/BE

OIL PRESSURE GAUGE (Continued)

Page 507 of 2255

overlay causes the ªMAINT REQDº text to appear in

amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by a Light Emitting Diode (LED) soldered

onto the instrument cluster electronic circuit board.

The SRI is serviced as a unit with the instrument

cluster.

OPERATION

The Service Reminder Indicator (SRI) gives an

indication to the vehicle operator when engine emis-

sions maintenance procedures should be performed.

This indicator is controlled by a transistor on the

instrument cluster circuit board based upon the clus-

ter programming and electronic messages received by

the cluster from the Powertrain Control Module

(PCM) over the Chrysler Collision Detection (CCD)

data bus. The SRI Light Emitting Diode (LED)

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (st-run) circuit whenever the ignition

switch is in the On or Start positions; therefore, the

LED will always be off when the ignition switch is in

any position except On or Start. The LED only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. The instrument cluster

will turn on the SRI for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the SRI is illuminated for

about two seconds as a bulb test.

²Service Required Lamp-On Message- Each

time the cluster receives a service required lamp-on

message from the PCM indicating that an emissions

maintenance interval has been reached, the SRI will

be illuminated. The indicator remains illuminated

until the cluster receives a service required lamp-off

message from the PCM, or until the ignition switch

is turned to the Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the SRI will be turned on

during the bulb check portion of the test to confirm

the functionality of the LED and the cluster control

circuitry.

The PCM continually monitors the vehicle speed

sensor to determine the distance the vehicle has been

driven, then sends the proper messages to the instru-

ment cluster. Once the SRI has been illuminated and

the required emissions maintenance procedures have

been completed, the PCM must be reset using a

DRBIIItscan tool before it will send the proper ser-

vice required lamp-off message to the instrument

cluster. Refer to the appropriate diagnostic informa-

tion. For further diagnosis of the SRI or the instru-

ment cluster circuitry that controls the LED, (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER -

DIAGNOSIS AND TESTING). For proper diagnosisof the PCM, the CCD data bus, or the message

inputs to the instrument cluster that control the SRI,

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.

SHIFT INDICATOR (TRANSFER

CASE)

DESCRIPTION

A four-wheel drive indicator is standard equipment

on all instrument clusters. However, on vehicles not

equipped with the optional four-wheel drive system,

this indicator is mechanically disabled. The four-

wheel drive indicator is located near the lower edge

of the instrument cluster overlay, to the right of cen-

ter. The four-wheel drive indicator consists of a sten-

cilled cutout of the text ª4WDº in the opaque layer of

the instrument cluster overlay. The dark outer layer

of the overlay prevents the indicator from being

clearly visible when it is not illuminated. An amber

lens behind the cutout in the opaque layer of the

overlay causes the ª4WDº text to appear in amber

through the translucent outer layer of the overlay

when the indicator is illuminated from behind by a

Light Emitting Diode (LED) soldered onto the instru-

ment cluster electronic circuit board. The four-wheel

drive indicator is serviced as a unit with the instru-

ment cluster.

OPERATION

The four-wheel drive indicator lamp gives an indi-

cation to the vehicle operator that a four-wheel drive

operating mode is engaged. The indicator will be illu-

minated when either high range (4H) or low range

(4L) have been selected with the transfer case shift

lever. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon the

cluster programming, and a hard wired input from

the four-wheel drive switch on the front axle discon-

nect housing. The four-wheel drive indicator Light

Emitting Diode (LED) receives battery current on the

instrument cluster electronic circuit board through

the fused ignition switch output (st-run) circuit

whenever the ignition switch is in the On or Start

positions; therefore, the lamp will always be off when

the ignition switch is in any position except On or

Start. The LED only illuminates when it is switched

to ground by the instrument cluster transistor.

The four-wheel drive switch is connected in series

between ground and the four-wheel drive switch

sense input to the instrument cluster. For further

information on the transfer case and the transfer

case operating ranges, (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/TRANSFER CASE - OPERA-

TION. For further information on the front axle

8J - 28 INSTRUMENT CLUSTERBR/BE

SERVICE REMINDER INDICATOR (Continued)

Page 509 of 2255

illumination lighting with the exterior lamps turned

On, the white graphics appear blue-green, while the

red graphics still appear red. The orange gauge nee-

dle is internally illuminated. Gauge illumination is

provided by replaceable incandescent bulb and bulb

holder units located on the instrument cluster elec-

tronic circuit board. The speedometer is serviced as a

unit with the instrument cluster.

OPERATION

The speedometer gives an indication to the vehicle

operator of the vehicle road speed. This gauge is con-

trolled by the instrument cluster circuit board based

upon the cluster programming and electronic mes-

sages received by the cluster from the Powertrain

Control Module (PCM) over the Chrysler Collision

Detection (CCD) data bus. The speedometer is an air

core magnetic unit that receives battery current on

the instrument cluster electronic circuit board

through the fused ignition switch output (st-run) cir-

cuit whenever the ignition switch is in the On or

Start positions. The cluster is programmed to move

the gauge needle back to the low end of the scale

after the ignition switch is turned to the Off position.

The instrument cluster circuitry controls the gauge

needle position and provides the following features:

²Message Failure- If the cluster fails to receive

a speedometer message, it will hold the gauge needle

at the last indication for about four seconds, or until

the ignition switch is turned to the Off position,

whichever occurs first. If a new speedometer message

is not received after about four seconds, the gauge

needle will return to the far left (low) end of the

scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in a prescribed sequence in order to confirm the func-

tionality of the gauge and the cluster control cir-

cuitry.

The PCM continually monitors the vehicle speed

sensor to determine the vehicle road speed, then

sends the proper vehicle speed messages to the

instrument cluster. For further diagnosis of the

speedometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the vehicle speed

sensor, the PCM, the CCD data bus, or the message

inputs to the instrument cluster that control the

speedometer, a DRBIIItscan tool is required. Refer

to the appropriate diagnostic information.

TACHOMETER

DESCRIPTION

A tachometer is standard equipment on all instru-

ment clusters. The tachometer is located just to the

left of the speedometer near the center of the instru-

ment cluster. The tachometer consists of a movable

gauge needle or pointer controlled by the instrument

cluster circuitry and a fixed 210 degree scale on the

gauge dial face that reads left-to-right either from 0

to 6 for gasoline engines, or from 0 to 4 for diesel

engines. The text ªRPM X 1000º imprinted on the

cluster overlay directly below the hub of the tachom-

eter needle identifies that each number on the

tachometer scale is to be multiplied times 1000 rpm.

The gauge scale of the gasoline engine tachometer is

red lined at 5000 rpm, while the diesel engine

tachometer is red lined at 3375 rpm. The diesel

engine tachometer also includes text that specifies

ªDIESEL FUEL ONLYº located just above the hub of

the tachometer needle. The tachometer graphics are

white and red against a black field, making them

clearly visible within the instrument cluster in day-

light. When illuminated from behind by the panel

lamps dimmer controlled cluster illumination lighting

with the exterior lamps turned On, the white graph-

ics appear blue-green, while the red graphics still

appear red. The orange gauge needle is internally

illuminated. Gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. The tachometer is serviced as a unit with the

instrument cluster.

OPERATION

The tachometer gives an indication to the vehicle

operator of the engine speed. This gauge is controlled

by the instrument cluster circuit board based upon

the cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) over the Chrysler Collision Detection

(CCD) data bus. The tachometer is an air core mag-

netic unit that receives battery current on the instru-

ment cluster electronic circuit board through the

fused ignition switch output (st-run) circuit whenever

the ignition switch is in the On or Start positions.

The cluster is programmed to move the gauge needle

back to the low end of the scale after the ignition

switch is turned to the Off position. The instrument

cluster circuitry controls the gauge needle position

and provides the following features:

²Message Failure- If the cluster fails to receive

an engine speed message, it will hold the gauge nee-

dle at the last indication for about four seconds, or

until the ignition switch is turned to the Off position,

whichever occurs first. If a new engine speed mes-

8J - 30 INSTRUMENT CLUSTERBR/BE

SPEEDOMETER (Continued)

Page 510 of 2255

sage is not received after about four seconds, the

gauge needle will return to the far left (low) end of

the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in a prescribed sequence in order to confirm the func-

tionality of the gauge and the cluster control cir-

cuitry.

The PCM continually monitors the crankshaft posi-

tion sensor to determine the engine speed, then

sends the proper engine speed messages to the

instrument cluster. For further diagnosis of the

tachometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the crankshaft position

sensor, the PCM, the CCD data bus, or the message

inputs to the instrument cluster that control the

tachometer, a DRBIIItscan tool is required. Refer to

the appropriate diagnostic information.

TRANS OVERTEMP

INDICATOR

DESCRIPTION

A transmission over-temperature indicator lamp is

standard equipment on all instrument clusters. How-

ever, on vehicles not equipped with the optional auto-

matic transmission, this indicator is electronically

disabled. The transmission over-temperature indica-

tor is located near the lower edge of the instrument

cluster overlay, to the left of center. The transmission

over-temperature indicator consists of a stencilled

cutout of the words ªTRANS TEMPº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A red

lens behind the cutout in the opaque layer of the

overlay causes the ªTRANS TEMPº text to appear in

red through the translucent outer layer of the over-

lay when the indicator is illuminated from behind by

a Light Emitting Diode (LED) soldered onto the

instrument cluster electronic circuit board. The

transmission over-temperature indicator is serviced

as a unit with the instrument cluster.

OPERATION

The transmission over-temperature indicator gives

an indication to the vehicle operator when the trans-

mission fluid temperature is excessive, which may

lead to accelerated transmission component wear or

failure. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon the

cluster programming and electronic messagesreceived by the cluster from the Powertrain Control

Module (PCM) over the Chrysler Collision Detection

(CCD) data bus. The transmission over-temperature

indicator Light Emitting Diode (LED) receives bat-

tery current on the instrument cluster electronic cir-

cuit board through the fused ignition switch output

(st-run) circuit whenever the ignition switch is in the

On or Start positions; therefore, the LED will always

be off when the ignition switch is in any position

except On or Start. The LED only illuminates when

it is provided a path to ground by the instrument

cluster transistor. The instrument cluster will turn

on the transmission over-temperature indicator for

the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the transmission over-tem-

perature indicator is illuminated for about two sec-

onds as a bulb test.

²Trans Over-Temp Lamp-On Message- Each

time the cluster receives a trans over-temp lamp-on

message from the PCM indicating that the transmis-

sion fluid temperature is 135É C (275É F) or higher,

the indicator will be illuminated and a single chime

tone is sounded. The lamp remains illuminated until

the cluster receives a trans over-temp lamp-off mes-

sage from the PCM, or until the ignition switch is

turned to the Off position, whichever occurs first.

The chime tone feature will only repeat during the

same ignition cycle if the transmission over-tempera-

ture indicator is cycled off and then on again by the

appropriate trans over-temp messages from the PCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The PCM continually monitors the transmission

temperature sensor to determine the transmission

operating condition, then sends the proper messages

to the instrument cluster. If the instrument cluster

turns on the transmission over-temperature indicator

due to a high transmission oil temperature condition,

it may indicate that the transmission and/or the

transmission cooling system are being overloaded or

that they require service. For further diagnosis of the

transmission over-temperature indicator or the

instrument cluster circuitry that controls the LED,

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). For proper

diagnosis of the transmission temperature sensor, the

PCM, the CCD data bus, or the message inputs to

the instrument cluster that control the transmission

over-temperature indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

BR/BEINSTRUMENT CLUSTER 8J - 31

TACHOMETER (Continued)

Page 513 of 2255

graduation and the check gauges indicator remains

illuminated until the cluster receives a message from

the PCM indicating there is no charge fail condition

(system voltage is 10.9 volts or higher, but lower

than 16.7 volts), or until the ignition switch is turned

to the Off position, whichever occurs first. On models

equipped with the optional diesel engine, the instru-

ment cluster is programmed to support the voltmeter

gauge needle above the low end of normal graduation

and suppress the check gauges indicator operation

until ten seconds after the engine intake manifold air

heater has completed its cycle.

²Voltage High Message- Each time the cluster

receives a message from the PCM indicating a volt-

age high condition (system voltage is 16.7 volts or

higher), the gauge needle is moved to the 18 volt

graduation on the gauge scale and the check gauges

indicator is illuminated. The gauge needle remains

on the 18 volt graduation and the check gauges indi-

cator remains illuminated until the cluster receives a

message from the PCM indicating there is no voltage

high condition (system voltage is 16.6 volts or lower,

but higher than 10.9 volts), or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Message Failure- If the cluster fails to receive

a system voltage message, it will hold the gauge nee-

dle at the last indication until a new message is

received, or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in a prescribed sequence in order to confirm the func-

tionality of the gauge and the cluster control cir-

cuitry.

The PCM continually monitors the system voltage

to control the generator output. The PCM then sends

the proper system voltage messages to the instru-

ment cluster. For further diagnosis of the voltage

gauge or the instrument cluster circuitry that con-

trols the gauge, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING). If

the instrument cluster turns on the check gauges

indicator due to a charge fail or voltage high condi-

tion, it may indicate that the charging system

requires service. For proper diagnosis of the charging

system, the CCD data bus, or the message inputs to

the instrument cluster that control the voltage

gauge, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is standard equipment on

all instrument clusters, but is only functional in vehi-

cles equipped with an optional diesel engine. The

wait-to-start indicator is located near the lower edge

of the instrument cluster overlay, to the right of cen-

ter. The wait-to-start indicator consists of a stenciled

cutout of the text ªWAIT TO STARTº in the opaque

layer of the cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. A red lens located

behind the cutout causes the ªWAIT TO STARTº text

to appear in red through the translucent outer layer

of the overlay when the indicator is illuminated from

behind by a Light Emitting Diode (LED) that is sol-

dered onto the instrument cluster electronic circuit

board. The wait-to-start indicator is serviced as a

unit with the instrument cluster.

OPERATION

The wait-to-start indicator gives an indication to

the vehicle operator when the diesel engine intake

air heater is energized in its preheat operating mode.

This indicator is controlled by a hard wired input to

the instrument cluster from the Engine Control Mod-

ule (ECM). The wait-to-start indicator Light Emitting

Diode (LED) receives battery current on the instru-

ment cluster electronic circuit board through the

fused ignition switch output (st-run) circuit whenever

the ignition switch is in the On or Start positions;

therefore, the lamp will always be off when the igni-

tion switch is in any position except On or Start. The

indicator LED only illuminates when it is switched to

ground by the input from the ECM. The ECM will

turn on the wait-to-start indicator by pulling the

wait-to-start indicator driver circuit to ground each

time the ignition switch is turned to the On or Start

positions. The indicator then remains illuminated

until the ECM detects that the air within the intake

manifold is the proper temperature to ensure reliable

and efficient engine starting, until the ECM detects

that the engine is running, or until the ignition

switch is turned to the Off position, whichever occurs

first.

The ECM continually monitors the intake manifold

air temperature sensor, the Manifold Absolute Pres-

sure (MAP) sensor, and many other vehicle condi-

tions to determine when the wait-to-start indicator

should be illuminated. For proper diagnosis of the

wait-to-start indicator, the ECM, or the inputs the

ECM uses to control the wait-to-start indicator oper-

ation, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

8J - 34 INSTRUMENT CLUSTERBR/BE

VOLTAGE GAUGE (Continued)

Page 515 of 2255

INDICATOR DOES NOT ILLUMINATE WITH WASHER

RESERVOIR EMPTY

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit cav-

ity of the headlamp and dash wire harness connector

for the washer fluid level switch and a good ground.

There should be continuity. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground (G100)

as required.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid switch sense circuit cavities of the headlamp

and dash wire harness connector for the washer fluid

level switch and the instrument panel wire harness

connector (Connector C2) for the instrument cluster.

If OK, replace the faulty washer fluid level switch. If

not OK, repair the open washer fluid switch sense

circuit between the washer fluid level switch and the

instrument cluster as required.

INDICATOR STAYS ILLUMINATED WITH WASHER

RESERVOIR FULL

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit ter-

minal and the washer fluid switch sense terminal in

the washer fluid level switch connector receptacle.

There should be no continuity. If OK, go to Step 2. If

not OK, replace the faulty washer fluid level switch.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid switch sense circuit cavity of the headlamp and

dash wire harness connector for the washer fluid

level switch and a good ground. There should be no

continuity. If not OK, repair the shorted washer fluid

switch sense circuit between the washer fluid level

switch and the instrument cluster as required.

WATER-IN-FUEL INDICATOR

DESCRIPTION

A water-in-fuel indicator is standard equipment on

all instrument clusters, but is only functional in vehi-

cles equipped with an optional diesel engine. The

water-in-fuel indicator is located near the lower edge

of the instrument cluster overlay, to the left of center.

The water-in-fuel indicator consists of a stencilled

cutout of the text ªWATER IN FUELº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A redlens located behind the cutout causes the ªWATER

IN FUELº text to appear in red through the translu-

cent outer layer of the overlay when the indicator is

illuminated from behind by a Light Emitting Diode

(LED) soldered onto the instrument cluster electronic

circuit board. The water-in-fuel indicator is serviced

as a unit with the instrument cluster.

OPERATION

The water-in-fuel indicator gives an indication to

the vehicle operator when the water accumulated in

the diesel engine fuel filter/separator filter bowl

requires draining. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Engine Control

Module (ECM) over the Chrysler Collision Detection

(CCD) data bus. The water-in-fuel indicator Light

Emitting Diode (LED) receives battery current on the

instrument cluster electronic circuit board through

the fused ignition switch output (st-run) circuit

whenever the ignition switch is in the On or Start

positions; therefore, the indicator will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is

switched to ground by the instrument cluster transis-

tor. The instrument cluster will turn on the water-in-

fuel indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the indicator is illuminated

for about two seconds as a bulb test.

²Water-In-Fuel Lamp-On Message- Each time

the cluster receives a water-in-fuel lamp-on message

from the ECM, the indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a water-in-fuel lamp-off message from the

ECM or until the ignition switch is turned to the Off

position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The ECM continually monitors the water-in-fuel

sensor, then sends the proper messages to the instru-

ment cluster. For further diagnosis of the water-in-

fuel indicator or the instrument cluster circuitry that

controls the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the water-in-fuel

sensor, the ECM, the CCD data bus, or the message

inputs to the instrument cluster that control the

water-in-fuel indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic

information.

8J - 36 INSTRUMENT CLUSTERBR/BE

WASHER FLUID INDICATOR (Continued)

Page 519 of 2255

(9) Disconnect the instrument panel wire harness

connector for the multi-function switch from the

switch connector receptacle. Check for continuity

between the hazard flasher signal circuit cavities in

the JB receptacle for the combination flasher and the

instrument panel wire harness connector for the

multi-function switch. There should be continuity. If

OK, go to Step 10. If not OK, repair the open hazard

flasher signal circuit between the JB and the multi-

function switch as required.

(10) Check for continuity between the flasher out-

put circuit cavities of the JB receptacle for the com-

bination flasher and in the instrument panel wire

harness connector for the multi-function switch.

There should be continuity. If OK, test the multi-

function switch. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/MULTI-FUNCTION

SWITCH - DIAGNOSIS AND TESTING). If not OK,

repair the open flasher output circuit between the JB

and the multi-function switch as required.

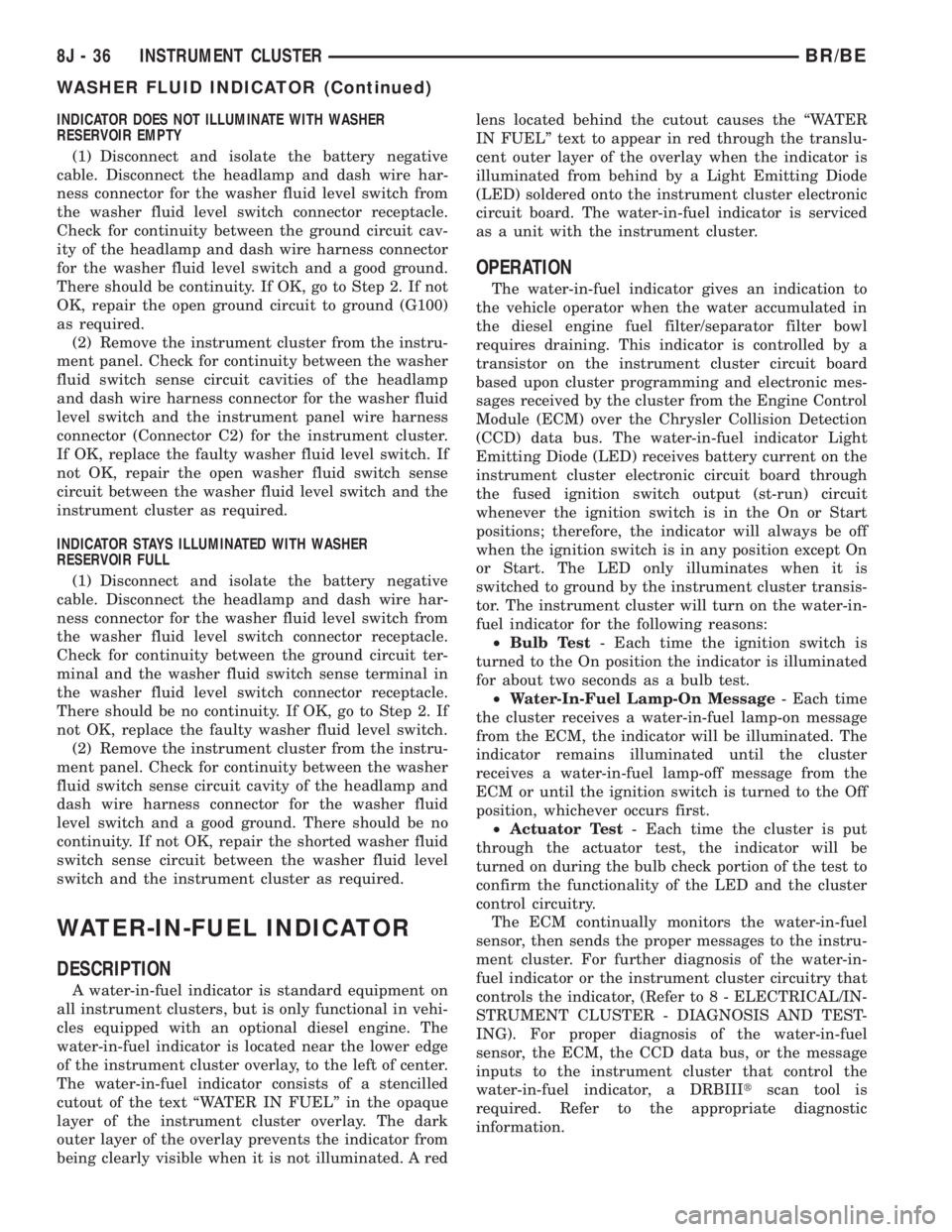

SPECIFICATIONS

EXTERIOR LAMPS

LAMP BULB

Back-up 3157

Cargo 921

Center High Mounted

Stop921

Clearance Roof Mounted 168

Fog Lamps 896

Headlamp - SLT 9004LL

Headlamp - Sport Low

Beam9007

Headlamp - Sport High

Beam9004LL

License Plate w/o

Bumper1155

License Plate -Step

Bumper168

Park/Turn Signal 3157NA

Snow Plow Control 161

Tail/Brake/Turn Signal 3157

Tail/Brake/Cab - Chassis 1157

Underhood 105

SPECIAL TOOLS

HEADLAMP ALIGNMENT

BRAKE LAMP SWITCH

DESCRIPTION

The plunger type brake lamp switch is mounted on

a bracket attached to the brake pedal support under

the instrument panel.

CAUTION: The switch can only be adjusted during

initial installation. If the switch is not adjusted prop-

erly a new switch must be installed.

OPERATION

The brake lamp switch is used for the brake lamp,

speed control brake sensor circuits and electronic

brake distribution (EBD). The brake lamp circuit is

open until the plunger is depressed. The speed con-

trol and brake sensor circuits are closed until the

plunger is depressed.

When the brake light switch is activated, the Pow-

ertrain Control Module (PCM) receives an input indi-

cating that the brakes are being applied. After

receiving this input, the PCM maintains idle speed to

a scheduled rpm through control of the Idle Air Con-

trol (IAC) motor. The brake switch input is also used

to disable vent and vacuum solenoid output signals

to the speed control servo.

Vehicles equipped with the speed control option use

a dual function brake lamp switch. The PCM moni-

tors the state of the dual function brake lamp switch.

Refer to the Brake section for more information on

brake lamp switch service and adjustment proce-

dures.

Headlamp Aiming Kit C-4466±A

8L - 4 LAMPS/LIGHTING - EXTERIORBR/BE

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 524 of 2255

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

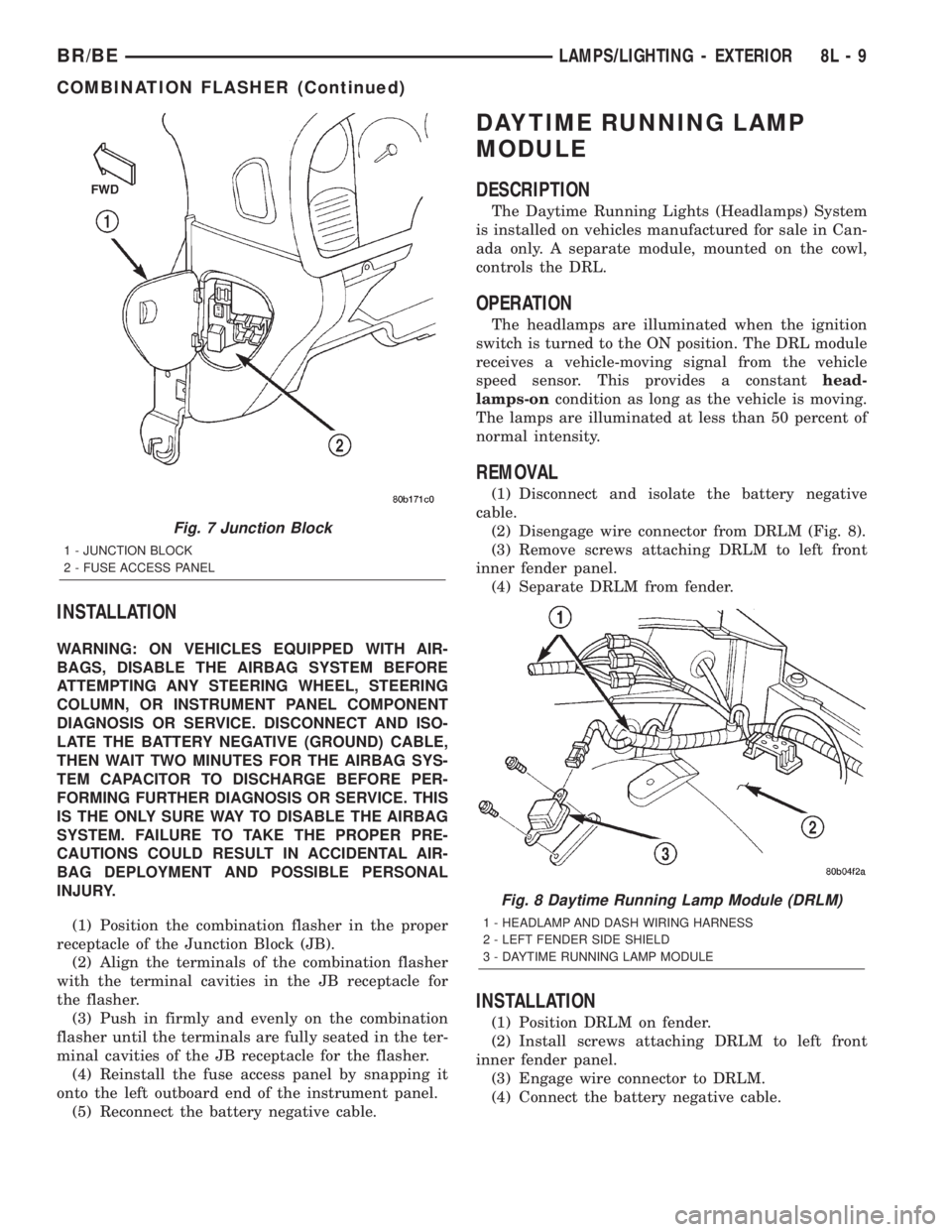

(1) Position the combination flasher in the proper

receptacle of the Junction Block (JB).

(2) Align the terminals of the combination flasher

with the terminal cavities in the JB receptacle for

the flasher.

(3) Push in firmly and evenly on the combination

flasher until the terminals are fully seated in the ter-

minal cavities of the JB receptacle for the flasher.

(4) Reinstall the fuse access panel by snapping it

onto the left outboard end of the instrument panel.

(5) Reconnect the battery negative cable.

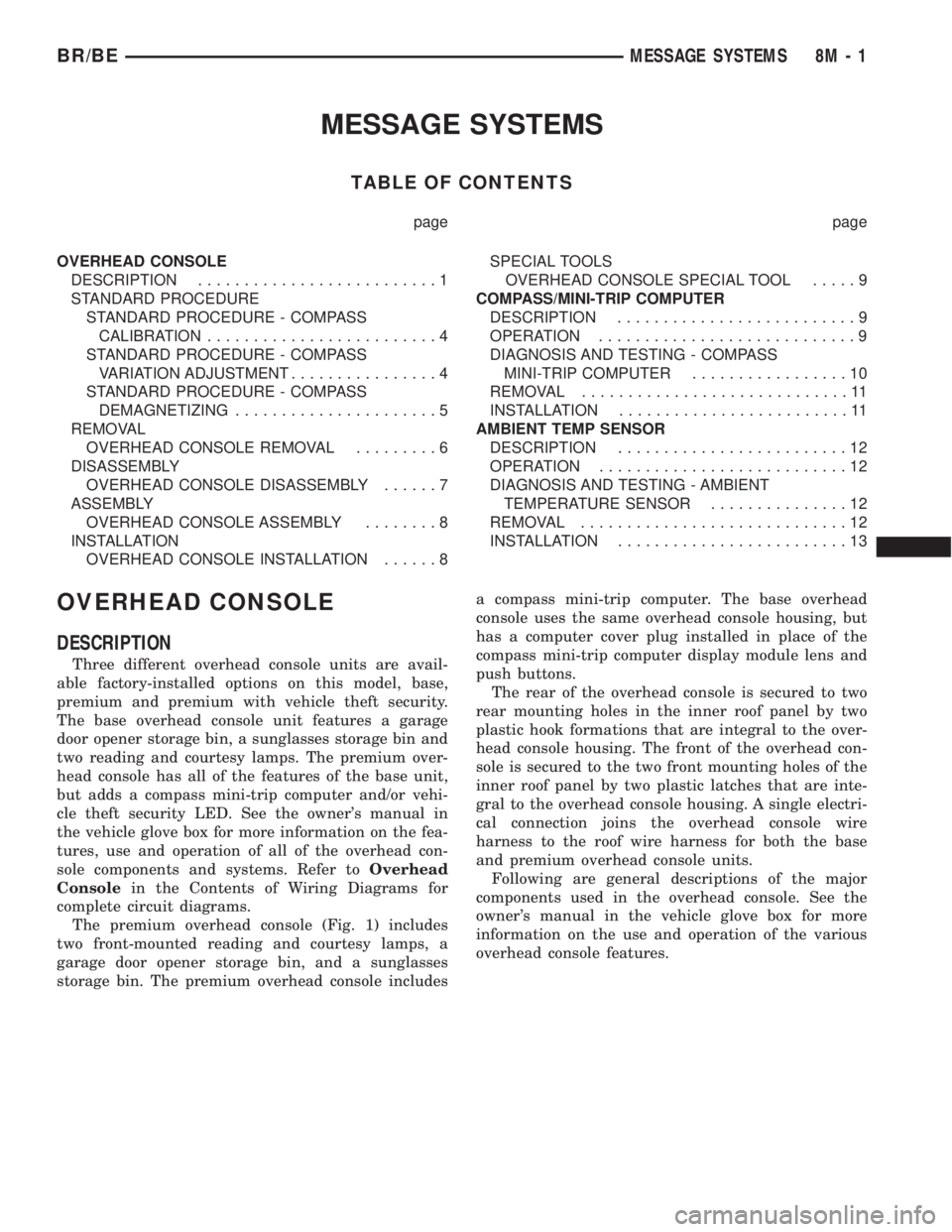

DAYTIME RUNNING LAMP

MODULE

DESCRIPTION

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. A separate module, mounted on the cowl,

controls the DRL.

OPERATION

The headlamps are illuminated when the ignition

switch is turned to the ON position. The DRL module

receives a vehicle-moving signal from the vehicle

speed sensor. This provides a constanthead-

lamps-oncondition as long as the vehicle is moving.

The lamps are illuminated at less than 50 percent of

normal intensity.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disengage wire connector from DRLM (Fig. 8).

(3) Remove screws attaching DRLM to left front

inner fender panel.

(4) Separate DRLM from fender.

INSTALLATION

(1) Position DRLM on fender.

(2) Install screws attaching DRLM to left front

inner fender panel.

(3) Engage wire connector to DRLM.

(4) Connect the battery negative cable.

Fig. 7 Junction Block

1 - JUNCTION BLOCK

2 - FUSE ACCESS PANEL

Fig. 8 Daytime Running Lamp Module (DRLM)

1 - HEADLAMP AND DASH WIRING HARNESS

2 - LEFT FENDER SIDE SHIELD

3 - DAYTIME RUNNING LAMP MODULE

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 9

COMBINATION FLASHER (Continued)

Page 554 of 2255

MESSAGE SYSTEMS

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................1

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPASS

CALIBRATION.........................4

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT................4

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING......................5

REMOVAL

OVERHEAD CONSOLE REMOVAL.........6

DISASSEMBLY

OVERHEAD CONSOLE DISASSEMBLY......7

ASSEMBLY

OVERHEAD CONSOLE ASSEMBLY........8

INSTALLATION

OVERHEAD CONSOLE INSTALLATION......8SPECIAL TOOLS

OVERHEAD CONSOLE SPECIAL TOOL.....9

COMPASS/MINI-TRIP COMPUTER

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER.................10

REMOVAL.............................11

INSTALLATION.........................11

AMBIENT TEMP SENSOR

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR...............12

REMOVAL.............................12

INSTALLATION.........................13

OVERHEAD CONSOLE

DESCRIPTION

Three different overhead console units are avail-

able factory-installed options on this model, base,

premium and premium with vehicle theft security.

The base overhead console unit features a garage

door opener storage bin, a sunglasses storage bin and

two reading and courtesy lamps. The premium over-

head console has all of the features of the base unit,

but adds a compass mini-trip computer and/or vehi-

cle theft security LED. See the owner's manual in

the vehicle glove box for more information on the fea-

tures, use and operation of all of the overhead con-

sole components and systems. Refer toOverhead

Consolein the Contents of Wiring Diagrams for

complete circuit diagrams.

The premium overhead console (Fig. 1) includes

two front-mounted reading and courtesy lamps, a

garage door opener storage bin, and a sunglasses

storage bin. The premium overhead console includesa compass mini-trip computer. The base overhead

console uses the same overhead console housing, but

has a computer cover plug installed in place of the

compass mini-trip computer display module lens and

push buttons.

The rear of the overhead console is secured to two

rear mounting holes in the inner roof panel by two

plastic hook formations that are integral to the over-

head console housing. The front of the overhead con-

sole is secured to the two front mounting holes of the

inner roof panel by two plastic latches that are inte-

gral to the overhead console housing. A single electri-

cal connection joins the overhead console wire

harness to the roof wire harness for both the base

and premium overhead console units.

Following are general descriptions of the major

components used in the overhead console. See the

owner's manual in the vehicle glove box for more

information on the use and operation of the various

overhead console features.

BR/BEMESSAGE SYSTEMS 8M - 1