Wiring schematics DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1368 of 2255

(7) Attach the other jumper wire (12V +) to termi-

nal number 86. This will activate the relay. Continu-

ity should now be present between terminals number

87 and 30. Continuity should not be present between

terminals number 87A and 30.

(8) Disconnect jumper wires from relay and 12 Volt

power source.

(9) If continuity or resistance tests did not pass,

replace relay. If tests passed, refer to 8, Wiring Dia-

grams for (fuel system) relay wiring schematics and

for additional circuit information.

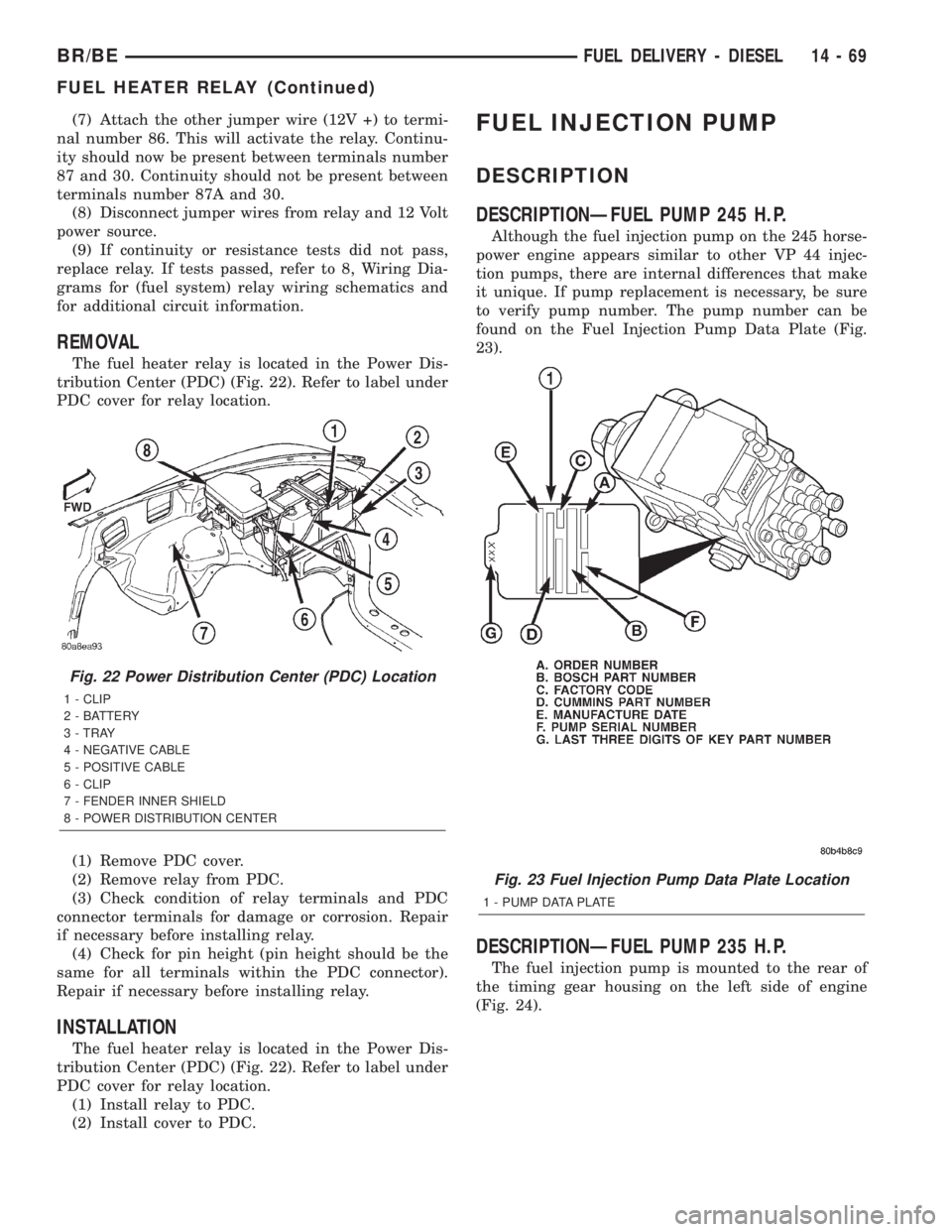

REMOVAL

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 22). Refer to label under

PDC cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 22). Refer to label under

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

FUEL INJECTION PUMP

DESCRIPTION

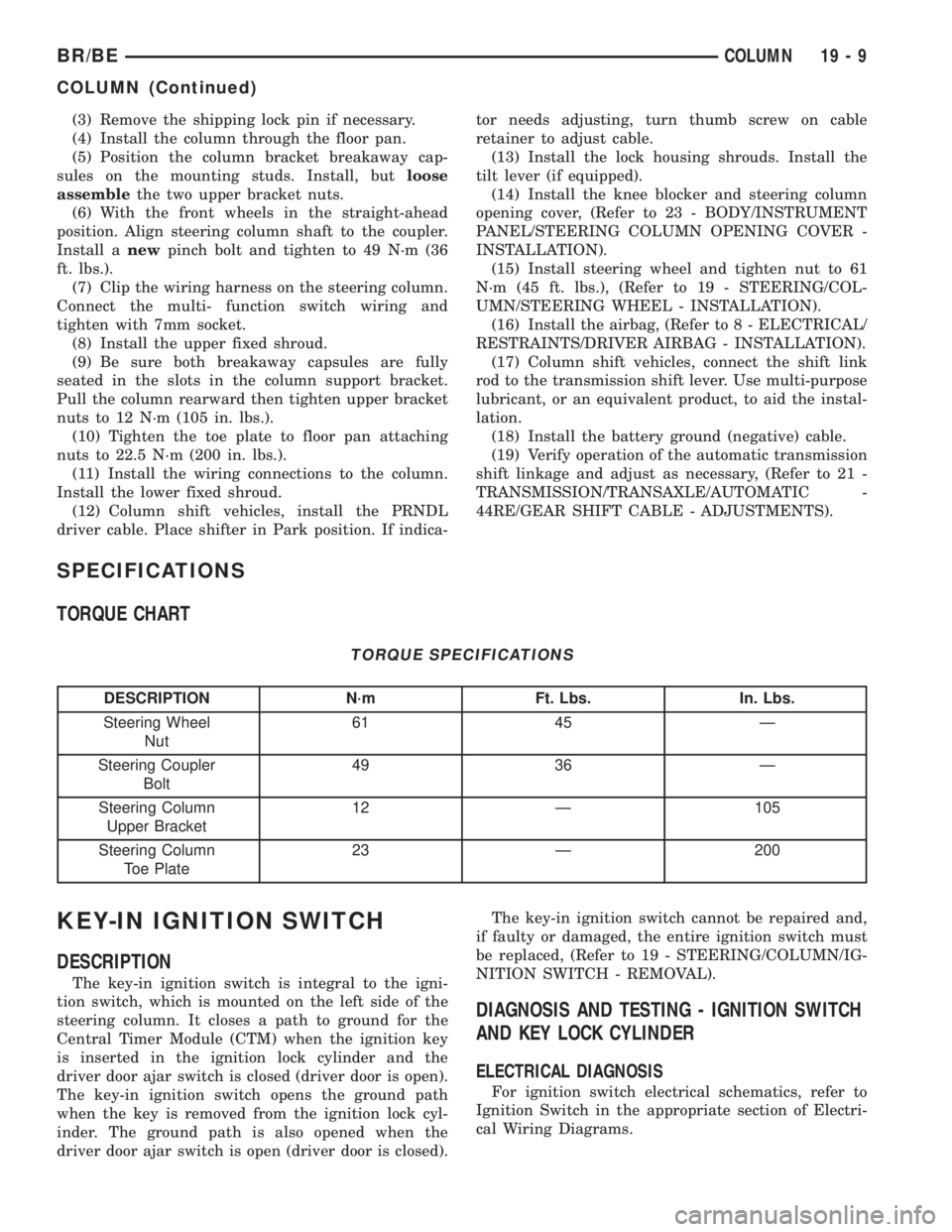

DESCRIPTIONÐFUEL PUMP 245 H.P.

Although the fuel injection pump on the 245 horse-

power engine appears similar to other VP 44 injec-

tion pumps, there are internal differences that make

it unique. If pump replacement is necessary, be sure

to verify pump number. The pump number can be

found on the Fuel Injection Pump Data Plate (Fig.

23).

DESCRIPTIONÐFUEL PUMP 235 H.P.

The fuel injection pump is mounted to the rear of

the timing gear housing on the left side of engine

(Fig. 24).

Fig. 22 Power Distribution Center (PDC) Location

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

Fig. 23 Fuel Injection Pump Data Plate Location

1 - PUMP DATA PLATE

BR/BEFUEL DELIVERY - DIESEL 14 - 69

FUEL HEATER RELAY (Continued)

Page 1418 of 2255

(3) Remove the shipping lock pin if necessary.

(4) Install the column through the floor pan.

(5) Position the column bracket breakaway cap-

sules on the mounting studs. Install, butloose

assemblethe two upper bracket nuts.

(6) With the front wheels in the straight-ahead

position. Align steering column shaft to the coupler.

Install anewpinch bolt and tighten to 49 N´m (36

ft. lbs.).

(7) Clip the wiring harness on the steering column.

Connect the multi- function switch wiring and

tighten with 7mm socket.

(8) Install the upper fixed shroud.

(9) Be sure both breakaway capsules are fully

seated in the slots in the column support bracket.

Pull the column rearward then tighten upper bracket

nuts to 12 N´m (105 in. lbs.).

(10) Tighten the toe plate to floor pan attaching

nuts to 22.5 N´m (200 in. lbs.).

(11) Install the wiring connections to the column.

Install the lower fixed shroud.

(12) Column shift vehicles, install the PRNDL

driver cable. Place shifter in Park position. If indica-tor needs adjusting, turn thumb screw on cable

retainer to adjust cable.

(13) Install the lock housing shrouds. Install the

tilt lever (if equipped).

(14) Install the knee blocker and steering column

opening cover, (Refer to 23 - BODY/INSTRUMENT

PANEL/STEERING COLUMN OPENING COVER -

INSTALLATION).

(15) Install steering wheel and tighten nut to 61

N´m (45 ft. lbs.), (Refer to 19 - STEERING/COL-

UMN/STEERING WHEEL - INSTALLATION).

(16) Install the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(17) Column shift vehicles, connect the shift link

rod to the transmission shift lever. Use multi-purpose

lubricant, or an equivalent product, to aid the instal-

lation.

(18) Install the battery ground (negative) cable.

(19) Verify operation of the automatic transmission

shift linkage and adjust as necessary, (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

44RE/GEAR SHIFT CABLE - ADJUSTMENTS).

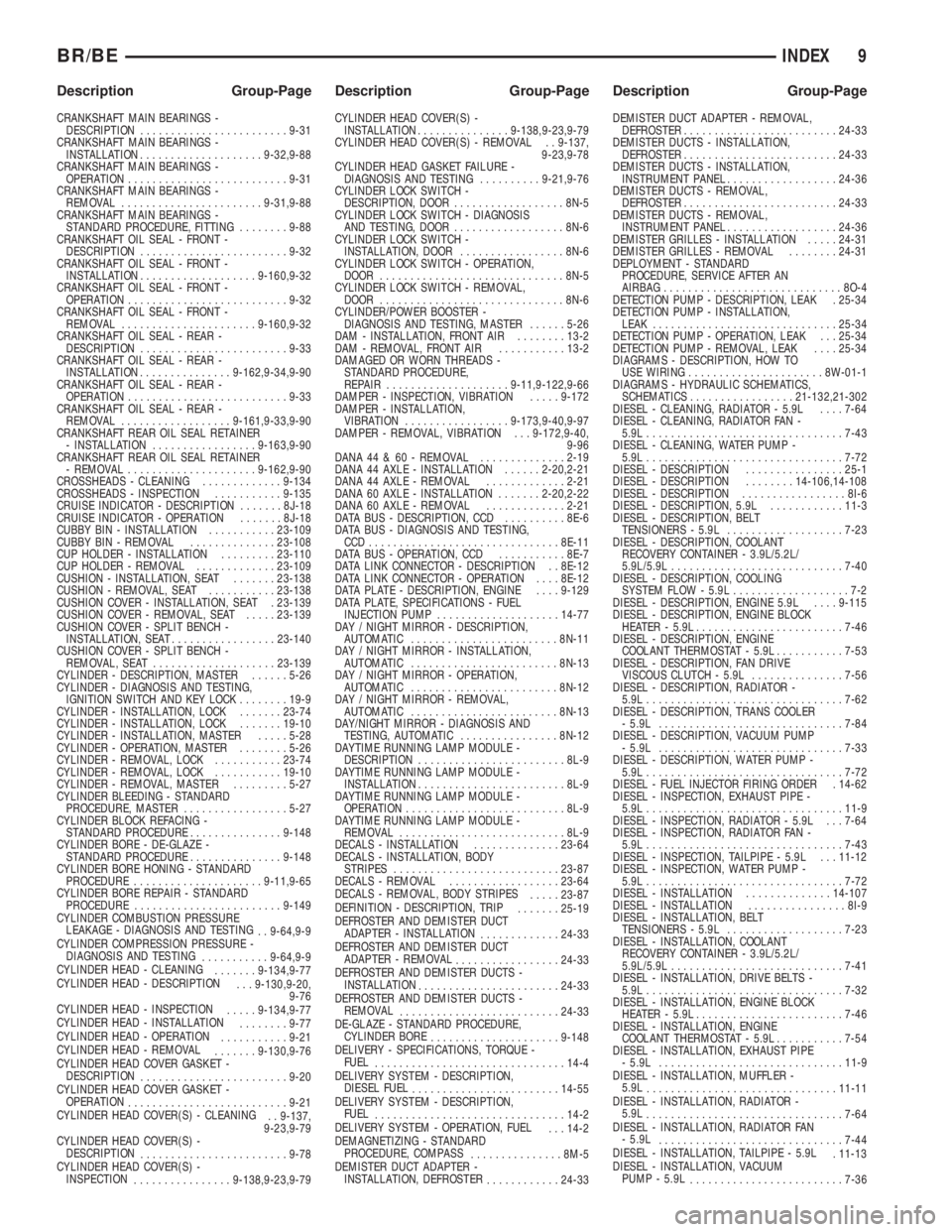

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Wheel

Nut61 45 Ð

Steering Coupler

Bolt49 36 Ð

Steering Column

Upper Bracket12 Ð 105

Steering Column

Toe Plate23 Ð 200

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the left side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition lock cylinder and the

driver door ajar switch is closed (driver door is open).

The key-in ignition switch opens the ground path

when the key is removed from the ignition lock cyl-

inder. The ground path is also opened when the

driver door ajar switch is open (driver door is closed).The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced, (Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

DIAGNOSIS AND TESTING - IGNITION SWITCH

AND KEY LOCK CYLINDER

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, refer to

Ignition Switch in the appropriate section of Electri-

cal Wiring Diagrams.

BR/BECOLUMN 19 - 9

COLUMN (Continued)

Page 2226 of 2255

CRANKSHAFT MAIN BEARINGS -

DESCRIPTION........................9-31

CRANKSHAFT MAIN BEARINGS -

INSTALLATION....................9-32,9-88

CRANKSHAFT MAIN BEARINGS -

OPERATION..........................9-31

CRANKSHAFT MAIN BEARINGS -

REMOVAL.......................9-31,9-88

CRANKSHAFT MAIN BEARINGS -

STANDARD PROCEDURE, FITTING........9-88

CRANKSHAFT OIL SEAL - FRONT -

DESCRIPTION........................9-32

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION...................9-160,9-32

CRANKSHAFT OIL SEAL - FRONT -

OPERATION..........................9-32

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL......................9-160,9-32

CRANKSHAFT OIL SEAL - REAR -

DESCRIPTION........................9-33

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION...............9-162,9-34,9-90

CRANKSHAFT OIL SEAL - REAR -

OPERATION..........................9-33

CRANKSHAFT OIL SEAL - REAR -

REMOVAL..................9-161,9-33,9-90

CRANKSHAFT REAR OIL SEAL RETAINER

- INSTALLATION.................9-163,9-90

CRANKSHAFT REAR OIL SEAL RETAINER

- REMOVAL.....................9-162,9-90

CROSSHEADS - CLEANING.............9-134

CROSSHEADS - INSPECTION...........9-135

CRUISE INDICATOR - DESCRIPTION.......8J-18

CRUISE INDICATOR - OPERATION.......8J-18

CUBBY BIN - INSTALLATION...........23-109

CUBBY BIN - REMOVAL..............23-108

CUP HOLDER - INSTALLATION.........23-110

CUP HOLDER - REMOVAL.............23-109

CUSHION - INSTALLATION, SEAT.......23-138

CUSHION - REMOVAL, SEAT...........23-138

CUSHION COVER - INSTALLATION, SEAT . 23-139

CUSHION COVER - REMOVAL, SEAT.....23-139

CUSHION COVER - SPLIT BENCH -

INSTALLATION, SEAT.................23-140

CUSHION COVER - SPLIT BENCH -

REMOVAL, SEAT....................23-139

CYLINDER - DESCRIPTION, MASTER......5-26

CYLINDER - DIAGNOSIS AND TESTING,

IGNITION SWITCH AND KEY LOCK........19-9

CYLINDER - INSTALLATION, LOCK.......23-74

CYLINDER - INSTALLATION, LOCK.......19-10

CYLINDER - INSTALLATION, MASTER.....5-28

CYLINDER - OPERATION, MASTER........5-26

CYLINDER - REMOVAL, LOCK...........23-74

CYLINDER - REMOVAL, LOCK...........19-10

CYLINDER - REMOVAL, MASTER.........5-27

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-27

CYLINDER BLOCK REFACING -

STANDARD PROCEDURE...............9-148

CYLINDER BORE - DE-GLAZE -

STANDARD PROCEDURE...............9-148

CYLINDER BORE HONING - STANDARD

PROCEDURE.....................9-11,9-65

CYLINDER BORE REPAIR - STANDARD

PROCEDURE........................9-149

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING

. . 9-64,9-9

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING

...........9-64,9-9

CYLINDER HEAD - CLEANING

.......9-134,9-77

CYLINDER HEAD - DESCRIPTION

. . . 9-130,9-20,

9-76

CYLINDER HEAD - INSPECTION

.....9-134,9-77

CYLINDER HEAD - INSTALLATION

........9-77

CYLINDER HEAD - OPERATION

...........9-21

CYLINDER HEAD - REMOVAL

.......9-130,9-76

CYLINDER HEAD COVER GASKET -

DESCRIPTION

........................9-20

CYLINDER HEAD COVER GASKET -

OPERATION

..........................9-21

CYLINDER HEAD COVER(S) - CLEANING

. . 9-137,

9-23,9-79

CYLINDER HEAD COVER(S) -

DESCRIPTION

........................9-78

CYLINDER HEAD COVER(S) -

INSPECTION

................9-138,9-23,9-79CYLINDER HEAD COVER(S) -

INSTALLATION...............9-138,9-23,9-79

CYLINDER HEAD COVER(S) - REMOVAL . . 9-137,

9-23,9-78

CYLINDER HEAD GASKET FAILURE -

DIAGNOSIS AND TESTING..........9-21,9-76

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR..................8N-5

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR..................8N-6

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8N-6

CYLINDER LOCK SWITCH - OPERATION,

DOOR..............................8N-5

CYLINDER LOCK SWITCH - REMOVAL,

DOOR..............................8N-6

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER......5-26

DAM - INSTALLATION, FRONT AIR........13-2

DAM - REMOVAL, FRONT AIR...........13-2

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE,

REPAIR ....................9-11,9-122,9-66

DAMPER - INSPECTION, VIBRATION.....9-172

DAMPER - INSTALLATION,

VIBRATION.................9-173,9-40,9-97

DAMPER - REMOVAL, VIBRATION . . . 9-172,9-40,

9-96

DANA 44 & 60 - REMOVAL..............2-19

DANA 44 AXLE - INSTALLATION......2-20,2-21

DANA 44 AXLE - REMOVAL.............2-21

DANA 60 AXLE - INSTALLATION.......2-20,2-22

DANA 60 AXLE - REMOVAL.............2-21

DATA BUS - DESCRIPTION, CCD..........8E-6

DATA BUS - DIAGNOSIS AND TESTING,

CCD ...............................8E-11

DATA BUS - OPERATION, CCD...........8E-7

DATA LINK CONNECTOR - DESCRIPTION . . 8E-12

DATA LINK CONNECTOR - OPERATION....8E-12

DATA PLATE - DESCRIPTION, ENGINE....9-129

DATA PLATE, SPECIFICATIONS - FUEL

INJECTION PUMP....................14-77

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC........................8N-11

DAY / NIGHT MIRROR - INSTALLATION,

AUTOMATIC........................8N-13

DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-12

DAY / NIGHT MIRROR - REMOVAL,

AUTOMATIC........................8N-13

DAY/NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-12

DAYTIME RUNNING LAMP MODULE -

DESCRIPTION........................8L-9

DAYTIME RUNNING LAMP MODULE -

INSTALLATION........................8L-9

DAYTIME RUNNING LAMP MODULE -

OPERATION..........................8L-9

DAYTIME RUNNING LAMP MODULE -

REMOVAL...........................8L-9

DECALS - INSTALLATION..............23-64

DECALS - INSTALLATION, BODY

STRIPES...........................23-87

DECALS - REMOVAL..................23-64

DECALS - REMOVAL, BODY STRIPES

.....23-87

DEFINITION - DESCRIPTION, TRIP

.......25-19

DEFROSTER AND DEMISTER DUCT

ADAPTER - INSTALLATION

.............24-33

DEFROSTER AND DEMISTER DUCT

ADAPTER - REMOVAL

.................24-33

DEFROSTER AND DEMISTER DUCTS -

INSTALLATION

.......................24-33

DEFROSTER AND DEMISTER DUCTS -

REMOVAL

..........................24-33

DE-GLAZE - STANDARD PROCEDURE,

CYLINDER BORE

.....................9-148

DELIVERY - SPECIFICATIONS, TORQUE -

FUEL

...............................14-4

DELIVERY SYSTEM - DESCRIPTION,

DIESEL FUEL

........................14-55

DELIVERY SYSTEM - DESCRIPTION,

FUEL

...............................14-2

DELIVERY SYSTEM - OPERATION, FUEL

. . . 14-2

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS

...............8M-5

DEMISTER DUCT ADAPTER -

INSTALLATION, DEFROSTER

............24-33DEMISTER DUCT ADAPTER - REMOVAL,

DEFROSTER.........................24-33

DEMISTER DUCTS - INSTALLATION,

DEFROSTER.........................24-33

DEMISTER DUCTS - INSTALLATION,

INSTRUMENT PANEL..................24-36

DEMISTER DUCTS - REMOVAL,

DEFROSTER.........................24-33

DEMISTER DUCTS - REMOVAL,

INSTRUMENT PANEL..................24-36

DEMISTER GRILLES - INSTALLATION.....24-31

DEMISTER GRILLES - REMOVAL........24-31

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN

AIRBAG.............................8O-4

DETECTION PUMP - DESCRIPTION, LEAK . 25-34

DETECTION PUMP - INSTALLATION,

LEAK..............................25-34

DETECTION PUMP - OPERATION, LEAK . . . 25-34

DETECTION PUMP - REMOVAL, LEAK....25-34

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.................21-132,21-302

DIESEL - CLEANING, RADIATOR - 5.9L....7-64

DIESEL - CLEANING, RADIATOR FAN -

5.9L................................7-43

DIESEL - CLEANING, WATER PUMP -

5.9L................................7-72

DIESEL - DESCRIPTION................25-1

DIESEL - DESCRIPTION........14-106,14-108

DIESEL - DESCRIPTION.................8I-6

DIESEL - DESCRIPTION, 5.9L............11-3

DIESEL - DESCRIPTION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - DESCRIPTION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-40

DIESEL - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-2

DIESEL - DESCRIPTION, ENGINE 5.9L....9-115

DIESEL - DESCRIPTION, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - DESCRIPTION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-53

DIESEL - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-56

DIESEL - DESCRIPTION, RADIATOR -

5.9L................................7-62

DIESEL - DESCRIPTION, TRANS COOLER

- 5.9L..............................7-84

DIESEL - DESCRIPTION, VACUUM PUMP

- 5.9L..............................7-33

DIESEL - DESCRIPTION, WATER PUMP -

5.9L................................7-72

DIESEL - FUEL INJECTOR FIRING ORDER . 14-62

DIESEL - INSPECTION, EXHAUST PIPE -

5.9L................................11-9

DIESEL - INSPECTION, RADIATOR - 5.9L . . . 7-64

DIESEL - INSPECTION, RADIATOR FAN -

5.9L................................7-43

DIESEL - INSPECTION, TAILPIPE - 5.9L . . . 11-12

DIESEL - INSPECTION, WATER PUMP -

5.9L................................7-72

DIESEL - INSTALLATION..............14-107

DIESEL - INSTALLATION................8I-9

DIESEL - INSTALLATION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - INSTALLATION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-41

DIESEL - INSTALLATION, DRIVE BELTS -

5.9L................................7-32

DIESEL - INSTALLATION, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - INSTALLATION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-54

DIESEL - INSTALLATION, EXHAUST PIPE

- 5.9L..............................11-9

DIESEL - INSTALLATION, MUFFLER -

5.9L

...............................11-11

DIESEL - INSTALLATION, RADIATOR -

5.9L

................................7-64

DIESEL - INSTALLATION, RADIATOR FAN

- 5.9L

..............................7-44

DIESEL - INSTALLATION, TAILPIPE - 5.9L

. 11-13

DIESEL - INSTALLATION, VACUUM

PUMP - 5.9L

.........................7-36

BR/BEINDEX 9

Description Group-Page Description Group-Page Description Group-Page