oil type DODGE RAM 2003 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1248 of 2895

DIAGNOSIS & TESTING - RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the integrated power module is connected to battery

voltage and should be hot at all times. Check for bat-

tery voltage at the fused B(+) circuit cavity in the

integrated power module receptacle for the relay. If

OK, go to Step 2. If not OK, repair the fused B(+) cir-

cuit to the integrated power module fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the fused B(+) fuse in the integrated power module

that feeds the accessory when the relay is energized

by the ignition switch. There should be continuity

between the integrated power module cavity for relay

terminal 87 and the fused B(+) fuse in the integrated

power module at all times. If OK, go to Step 4. If not

OK, repair the open fused B(+) circuit to the inte-

grated power module fuse as required.

(4) The coil ground terminal (85) is connected to

the electromagnet in the relay. It receives battery

feed to energize the relay when the ignition switch is

in the Accessory or Run positions. Turn the ignition

switch to the On position. Check for battery voltage

at the fused ignition switch output (acc/run) circuit

cavity for relay terminal 85 in the integrated power

module receptacle for the relay. If OK, go to Step 5. If

not OK, repair the open fused ignition switch output

(acc/run) circuit to the ignition switch as required.

(5) The coil battery terminal (86) is connected to

the electromagnet in the relay. The integrated power

module cavity for this terminal should have continu-

ity to ground at all times. If not OK, repair the open

ground circuit to ground as required.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the relay by grasping it firmly and

pulling it straight out from its receptacle. A slight

back and fourth rocking motion may help the

removal process.

INSTALLATION

(1) Position the relay to the proper receptacle.

(2) Align the relay terminals with the terminal

cavities in the receptacle.

(3) Push firmly and evenly on the top of the relay

until the terminals are fully seated in the terminal

cavities in the receptacle.

(4) Connect the negative battery cable.

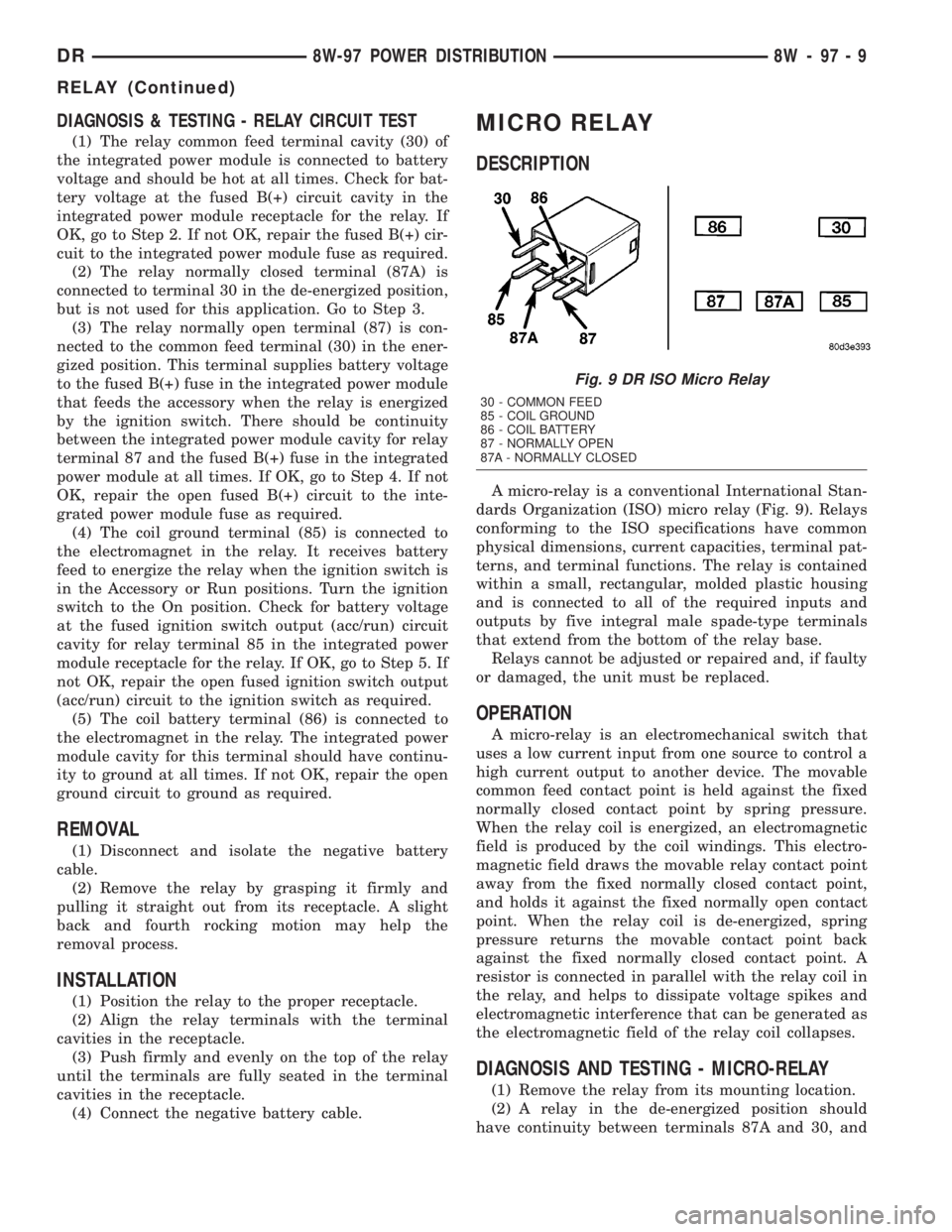

MICRO RELAY

DESCRIPTION

A micro-relay is a conventional International Stan-

dards Organization (ISO) micro relay (Fig. 9). Relays

conforming to the ISO specifications have common

physical dimensions, current capacities, terminal pat-

terns, and terminal functions. The relay is contained

within a small, rectangular, molded plastic housing

and is connected to all of the required inputs and

outputs by five integral male spade-type terminals

that extend from the bottom of the relay base.

Relays cannot be adjusted or repaired and, if faulty

or damaged, the unit must be replaced.

OPERATION

A micro-relay is an electromechanical switch that

uses a low current input from one source to control a

high current output to another device. The movable

common feed contact point is held against the fixed

normally closed contact point by spring pressure.

When the relay coil is energized, an electromagnetic

field is produced by the coil windings. This electro-

magnetic field draws the movable relay contact point

away from the fixed normally closed contact point,

and holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

DIAGNOSIS AND TESTING - MICRO-RELAY

(1) Remove the relay from its mounting location.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

Fig. 9 DR ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DR8W-97 POWER DISTRIBUTION 8W - 97 - 9

RELAY (Continued)

Page 1258 of 2895

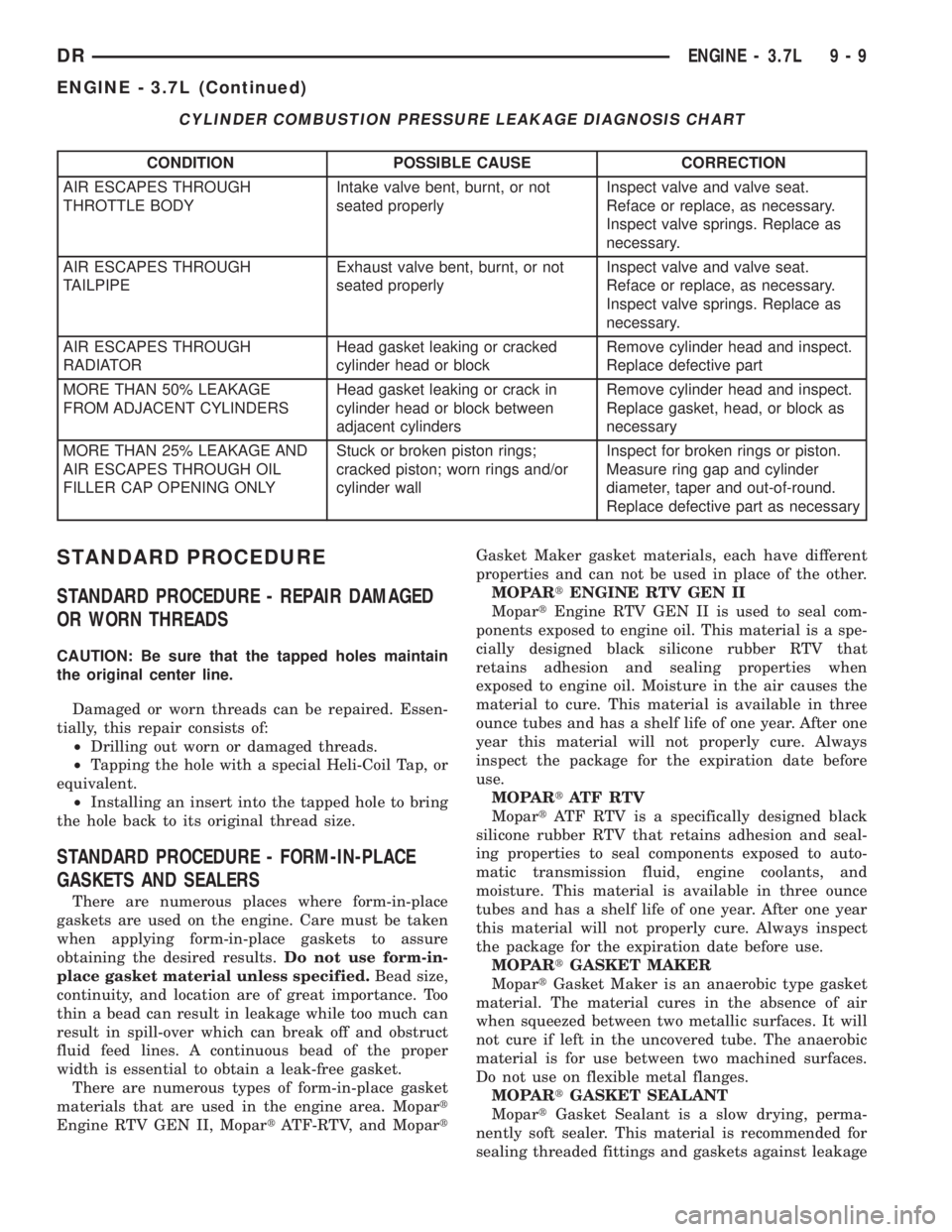

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and MopartGasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

DRENGINE - 3.7L 9 - 9

ENGINE - 3.7L (Continued)

Page 1261 of 2895

(17) Connect the engine to body ground straps at

the left side of the cowl.

(18) Install the intake manifold.

(19) Install the engine oil dipstick tube.

(20) Install the power brake booster vacuum hose.

(21) Install the breather hoses.

(22) Install the PCV hose.

(23) Install the fuel rail.

(24) Install the coil over plugs.

(25) Connect the engine wiring harness at the fol-

lowing points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(26) Reinstall the radiator/cooling module assem-

bly.

(27) Connect lower radiator hose.

(28) Connect upper radiator hose.

(29) Connect throttle and speed control cables.

(30) Install the heater hose assembly.

(31) Install coolant recovery bottle.

(32) Install the power steering pump.

(33) Install the generator.

(34) Install the A/C compressor.

(35) Install the drive belt.

(36) Install the fan shroud with the viscous fan

assembly.

(37) Install the radiator core support bracket.

(38) Install the air cleaner assembly.

(39) Refill the engine cooling system.

(40) Recharge the air conditioning.

(41) Install the hood.

(42) Check and fill engine oil.

(43) Connect the battery negative cable.

(44) Start the engine and check for leaks.SPECIFICATIONS

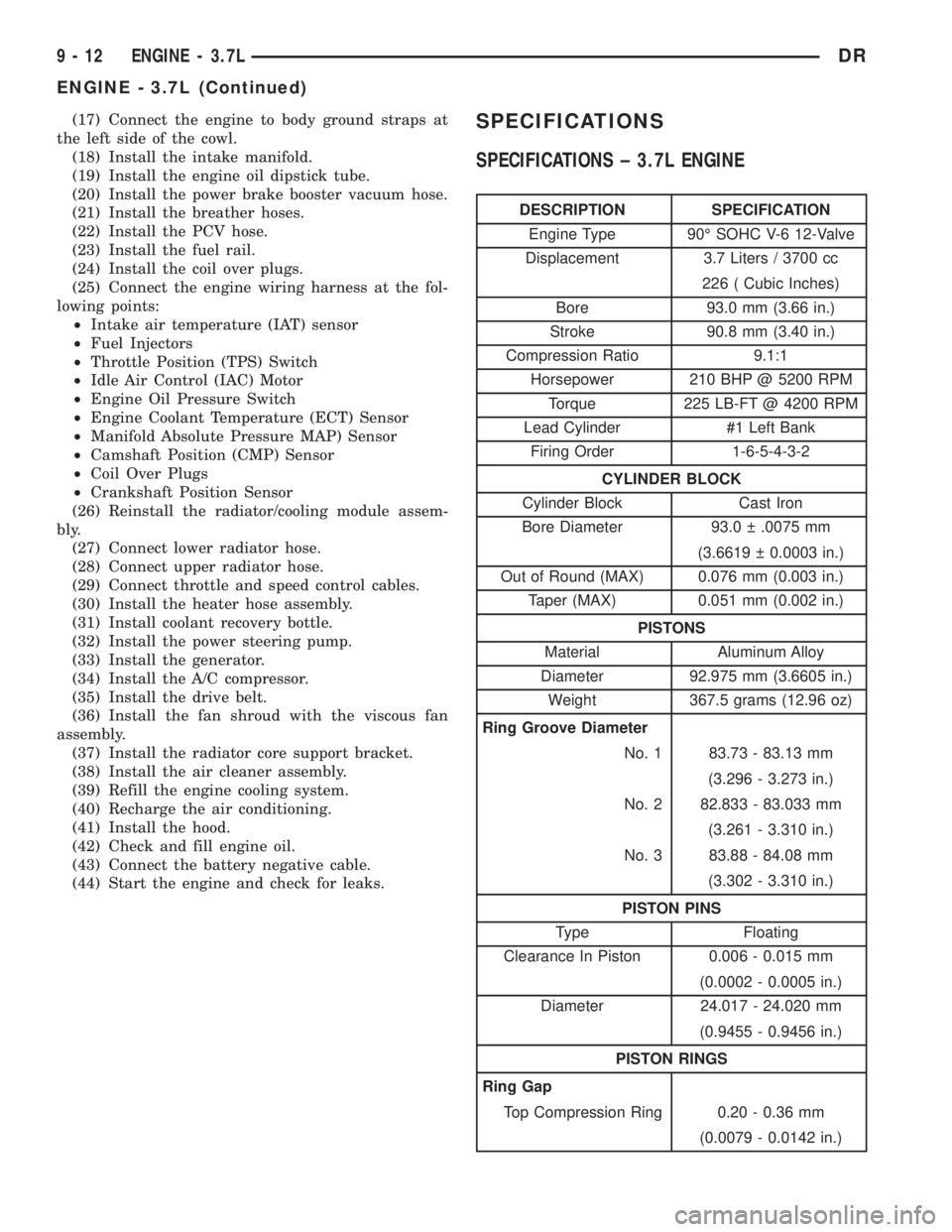

SPECIFICATIONS ± 3.7L ENGINE

DESCRIPTION SPECIFICATION

Engine Type 90É SOHC V-6 12-Valve

Displacement 3.7 Liters / 3700 cc

226 ( Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 90.8 mm (3.40 in.)

Compression Ratio 9.1:1

Horsepower 210 BHP @ 5200 RPM

Torque 225 LB-FT @ 4200 RPM

Lead Cylinder #1 Left Bank

Firing Order 1-6-5-4-3-2

CYLINDER BLOCK

Cylinder Block Cast Iron

Bore Diameter 93.0 .0075 mm

(3.6619 0.0003 in.)

Out of Round (MAX) 0.076 mm (0.003 in.)

Taper (MAX) 0.051 mm (0.002 in.)

PISTONS

Material Aluminum Alloy

Diameter 92.975 mm (3.6605 in.)

Weight 367.5 grams (12.96 oz)

Ring Groove Diameter

No. 1 83.73 - 83.13 mm

(3.296 - 3.273 in.)

No. 2 82.833 - 83.033 mm

(3.261 - 3.310 in.)

No. 3 83.88 - 84.08 mm

(3.302 - 3.310 in.)

PISTON PINS

Type Floating

Clearance In Piston 0.006 - 0.015 mm

(0.0002 - 0.0005 in.)

Diameter 24.017 - 24.020 mm

(0.9455 - 0.9456 in.)

PISTON RINGS

Ring Gap

Top Compression Ring 0.20 - 0.36 mm

(0.0079 - 0.0142 in.)

9 - 12 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1280 of 2895

VALVE GUIDE SEALS

DESCRIPTION

The valve guide seals are made of rubber and

incorporate an integral steel valve spring seat. The

integral garter spring maintains consistent lubrica-

tion control to the valve stems.

VALVE SPRINGS

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. The springs are NOT common

for intake and exhaust applications. The valve spring

seat is integral with the valve stem seal, which is a

positive type seal to control lubrication.

REMOVAL

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Using Special Tool 8516 Valve Spring Compres-

sor, remove the rocker arms and the hydraulic lash

adjusters.

(3) Remove the spark plug for the cylinder the

valve spring and seal are to be removed from.

(4) Apply shop air to the cylinder to hold the

valves in place when the spring is removed.

NOTE: All six valve springs and seals are removed

in the same manner; this procedure only covers

one valve seal and valve spring.

(5) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(6) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(7) Remove the valve spring compressor.

NOTE: The valve springs are NOT common between

intake and exhaust.

(8) Remove the spring retainer, and the spring.

(9) Remove the valve stem seal.

NOTE: The valve stem seals are common between

intake and exhaust.

INSTALLATION

NOTE: All six valve springs and seals are removed

in the same manner; this procedure only covers

one valve seal and valve spring.

(1) Apply shop air to the cylinder to hold the

valves in place while the spring is installed.

NOTE: The valve stem seals are common between

intake and exhaust.

(2) Install the valve stem seal.

NOTE: The valve springs are NOT common between

intake and exhaust.

(3) Install the spring retainer, and the spring.

(4) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

(5) Install the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(6) Remove the valve spring compressor.

(7) Disconnect the shop air to the cylinder.

(8) Install the spark plug for the cylinder the valve

spring and seal was installed on.

(9) Using Special Tool 8516 Valve Spring Compres-

sor, install the rocker arms and the hydraulic lash

adjusters.

(10) Install the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

CYLINDER HEAD - RIGHT

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) Turn engine off and let set for a few minutes

before restarting. Repeat this several times after

engine has reached normal operating temperature.

(4) Low oil pressure.

(5) The oil restrictor in cylinder head gasket or the

oil passage to the cylinder head is plugged with

debris.

DRENGINE - 3.7L 9 - 31

Page 1285 of 2895

(12) Remove cylinder head cover retaining bolts.

(13) Remove cylinder head cover.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs).

(3) Install right rear breather tube and filter

assembly.

(4) Connect injector, ignition coil electrical connec-

tors and harness retaining clips.

(5) Install the oil fill tube.

(6) Install PCV hose.

(7) Install heater hoses.

(8) Install air conditioning compressor retaining

bolts.

(9) Install accessory drive belt(Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(10) Fill Cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(12) Connect battery negative cable.

ROCKER ARM

DESCRIPTION

The rocker arms are steel stampings with an inte-

gral roller bearing. The rocker arms incorporate a 2.8

mm (0.11 inch) oil hole in the lash adjuster socket for

roller and camshaft lubrication.

REMOVAL

NOTE: Disconnect the battery negative cable to pre-

vent accidental starter engagement.

(1) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

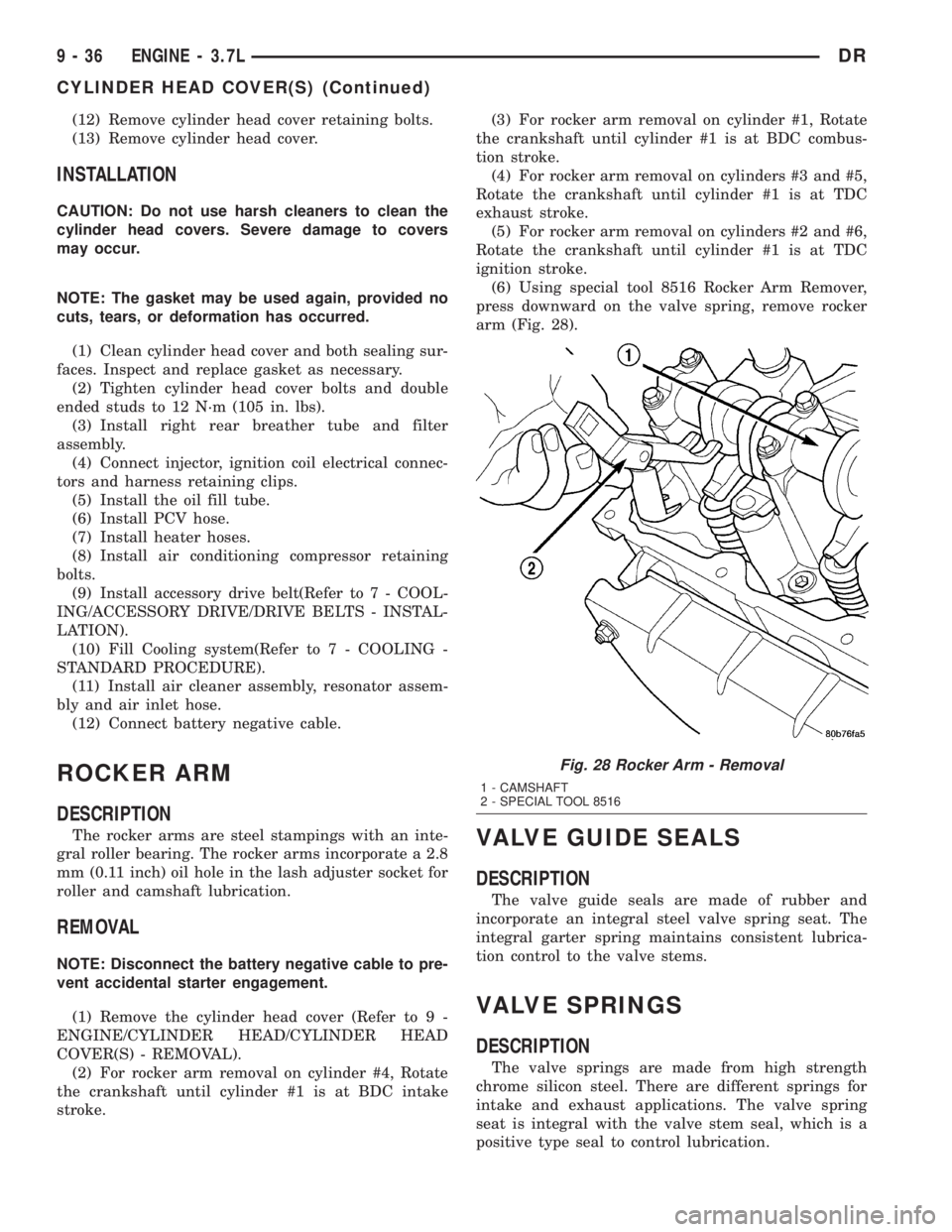

(2) For rocker arm removal on cylinder #4, Rotate

the crankshaft until cylinder #1 is at BDC intake

stroke.(3) For rocker arm removal on cylinder #1, Rotate

the crankshaft until cylinder #1 is at BDC combus-

tion stroke.

(4) For rocker arm removal on cylinders #3 and #5,

Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(5) For rocker arm removal on cylinders #2 and #6,

Rotate the crankshaft until cylinder #1 is at TDC

ignition stroke.

(6) Using special tool 8516 Rocker Arm Remover,

press downward on the valve spring, remove rocker

arm (Fig. 28).

VALVE GUIDE SEALS

DESCRIPTION

The valve guide seals are made of rubber and

incorporate an integral steel valve spring seat. The

integral garter spring maintains consistent lubrica-

tion control to the valve stems.

VALVE SPRINGS

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. There are different springs for

intake and exhaust applications. The valve spring

seat is integral with the valve stem seal, which is a

positive type seal to control lubrication.

Fig. 28 Rocker Arm - Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

9 - 36 ENGINE - 3.7LDR

CYLINDER HEAD COVER(S) (Continued)

Page 1309 of 2895

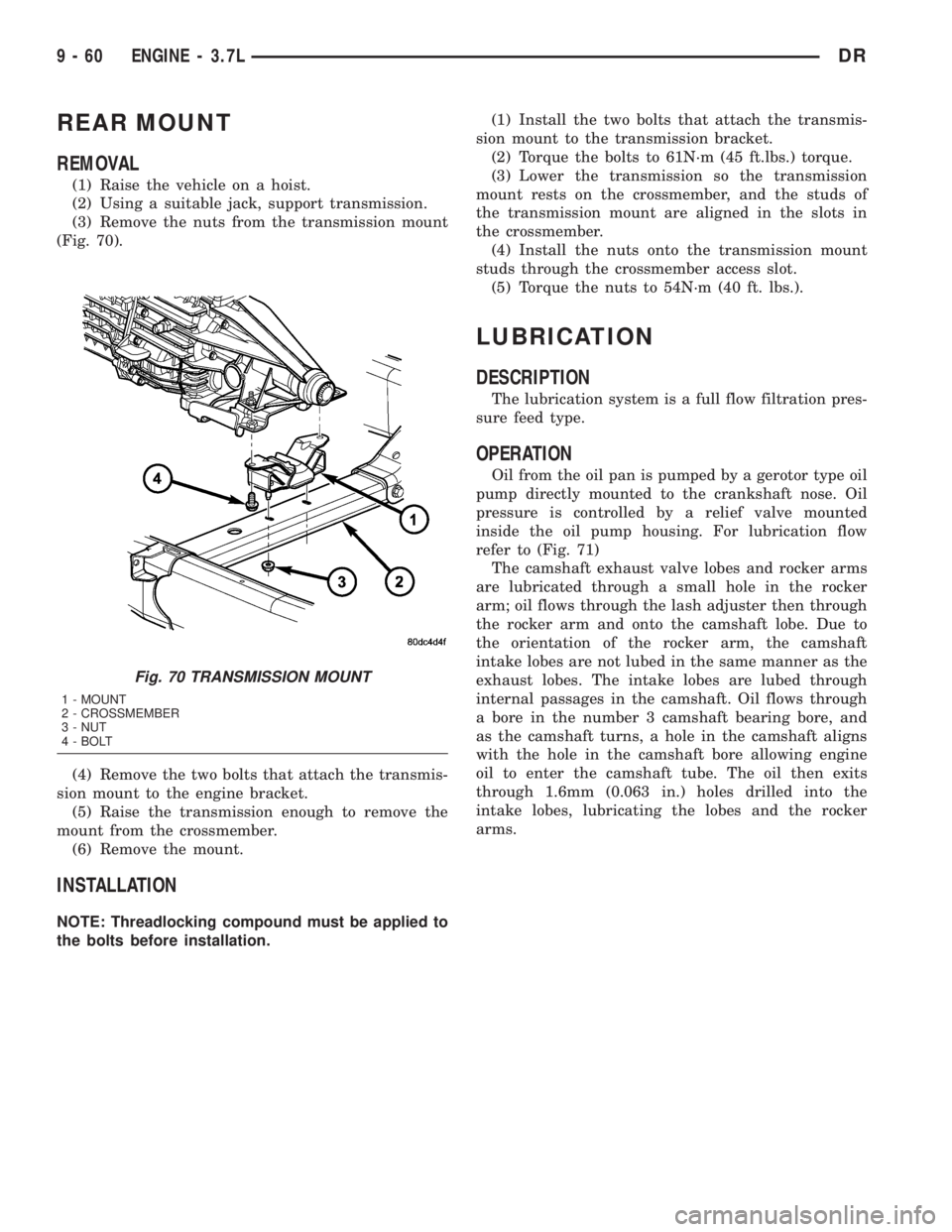

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Using a suitable jack, support transmission.

(3) Remove the nuts from the transmission mount

(Fig. 70).

(4) Remove the two bolts that attach the transmis-

sion mount to the engine bracket.

(5) Raise the transmission enough to remove the

mount from the crossmember.

(6) Remove the mount.

INSTALLATION

NOTE: Threadlocking compound must be applied to

the bolts before installation.(1) Install the two bolts that attach the transmis-

sion mount to the transmission bracket.

(2) Torque the bolts to 61N´m (45 ft.lbs.) torque.

(3) Lower the transmission so the transmission

mount rests on the crossmember, and the studs of

the transmission mount are aligned in the slots in

the crossmember.

(4) Install the nuts onto the transmission mount

studs through the crossmember access slot.

(5) Torque the nuts to 54N´m (40 ft. lbs.).

LUBRICATION

DESCRIPTION

The lubrication system is a full flow filtration pres-

sure feed type.

OPERATION

Oil from the oil pan is pumped by a gerotor type oil

pump directly mounted to the crankshaft nose. Oil

pressure is controlled by a relief valve mounted

inside the oil pump housing. For lubrication flow

refer to (Fig. 71)

The camshaft exhaust valve lobes and rocker arms

are lubricated through a small hole in the rocker

arm; oil flows through the lash adjuster then through

the rocker arm and onto the camshaft lobe. Due to

the orientation of the rocker arm, the camshaft

intake lobes are not lubed in the same manner as the

exhaust lobes. The intake lobes are lubed through

internal passages in the camshaft. Oil flows through

a bore in the number 3 camshaft bearing bore, and

as the camshaft turns, a hole in the camshaft aligns

with the hole in the camshaft bore allowing engine

oil to enter the camshaft tube. The oil then exits

through 1.6mm (0.063 in.) holes drilled into the

intake lobes, lubricating the lobes and the rocker

arms.

Fig. 70 TRANSMISSION MOUNT

1 - MOUNT

2 - CROSSMEMBER

3 - NUT

4 - BOLT

9 - 60 ENGINE - 3.7LDR

Page 1318 of 2895

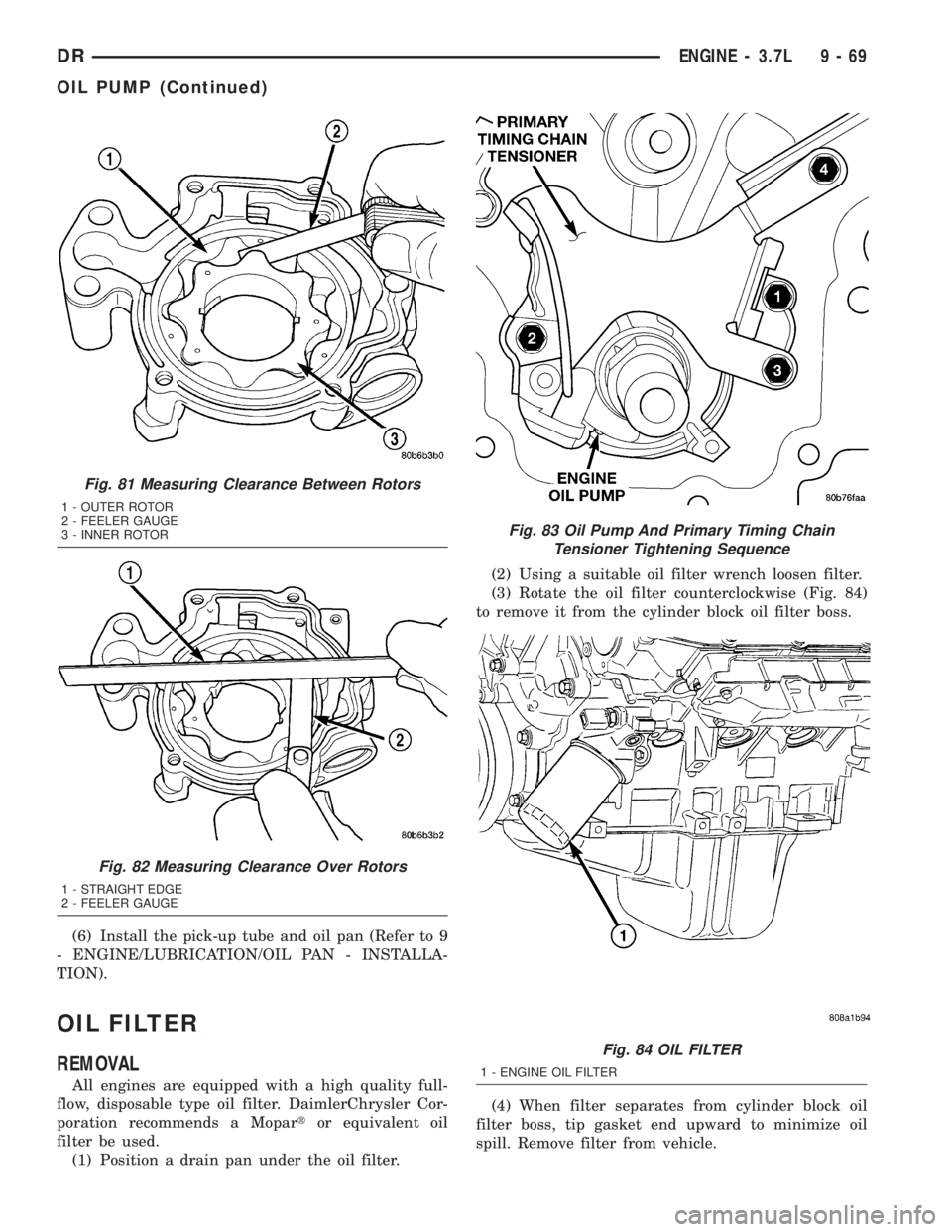

(6) Install the pick-up tube and oil pan (Refer to 9

- ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

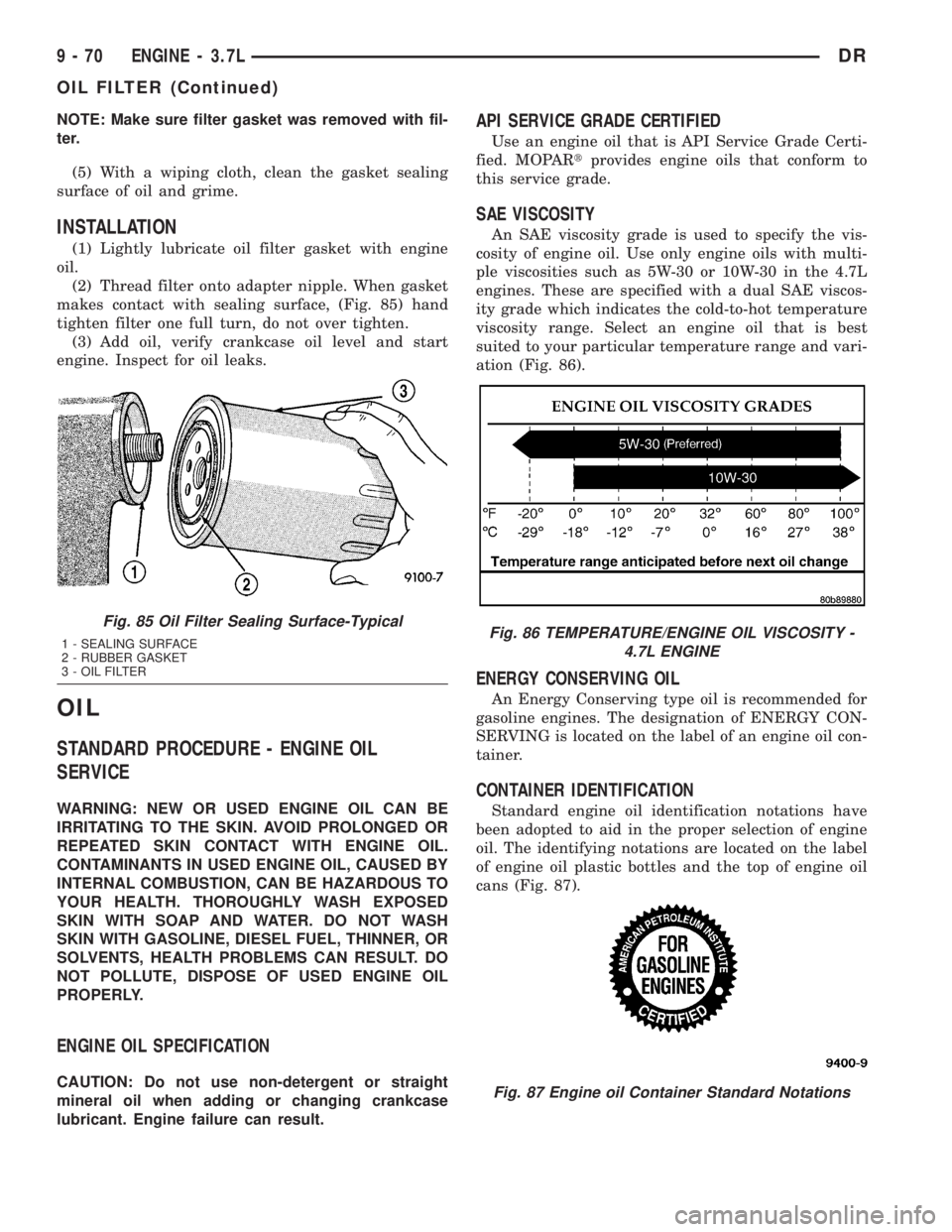

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise (Fig. 84)

to remove it from the cylinder block oil filter boss.

(4) When filter separates from cylinder block oil

filter boss, tip gasket end upward to minimize oil

spill. Remove filter from vehicle.

Fig. 81 Measuring Clearance Between Rotors

1 - OUTER ROTOR

2 - FEELER GAUGE

3 - INNER ROTOR

Fig. 82 Measuring Clearance Over Rotors

1 - STRAIGHT EDGE

2 - FEELER GAUGE

Fig. 83 Oil Pump And Primary Timing Chain

Tensioner Tightening Sequence

Fig. 84 OIL FILTER

1 - ENGINE OIL FILTER

DRENGINE - 3.7L 9 - 69

OIL PUMP (Continued)

Page 1319 of 2895

NOTE: Make sure filter gasket was removed with fil-

ter.

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 85) hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 or 10W-30 in the 4.7L

engines. These are specified with a dual SAE viscos-

ity grade which indicates the cold-to-hot temperature

viscosity range. Select an engine oil that is best

suited to your particular temperature range and vari-

ation (Fig. 86).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 87).

Fig. 85 Oil Filter Sealing Surface-Typical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTERFig. 86 TEMPERATURE/ENGINE OIL VISCOSITY -

4.7L ENGINE

Fig. 87 Engine oil Container Standard Notations

9 - 70 ENGINE - 3.7LDR

OIL FILTER (Continued)

Page 1320 of 2895

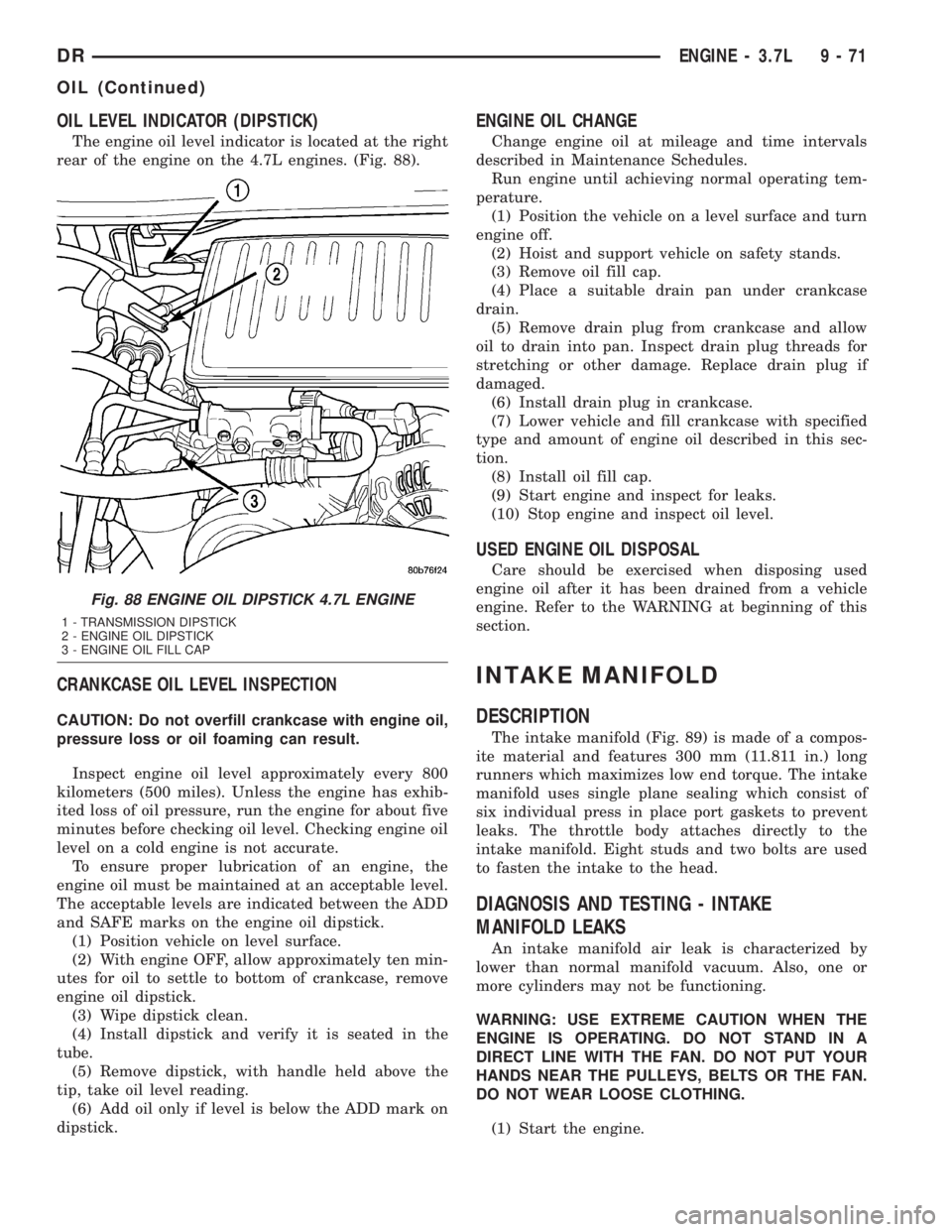

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

rear of the engine on the 4.7L engines. (Fig. 88).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about five

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

INTAKE MANIFOLD

DESCRIPTION

The intake manifold (Fig. 89) is made of a compos-

ite material and features 300 mm (11.811 in.) long

runners which maximizes low end torque. The intake

manifold uses single plane sealing which consist of

six individual press in place port gaskets to prevent

leaks. The throttle body attaches directly to the

intake manifold. Eight studs and two bolts are used

to fasten the intake to the head.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

Fig. 88 ENGINE OIL DIPSTICK 4.7L ENGINE

1 - TRANSMISSION DIPSTICK

2 - ENGINE OIL DIPSTICK

3 - ENGINE OIL FILL CAP

DRENGINE - 3.7L 9 - 71

OIL (Continued)

Page 1324 of 2895

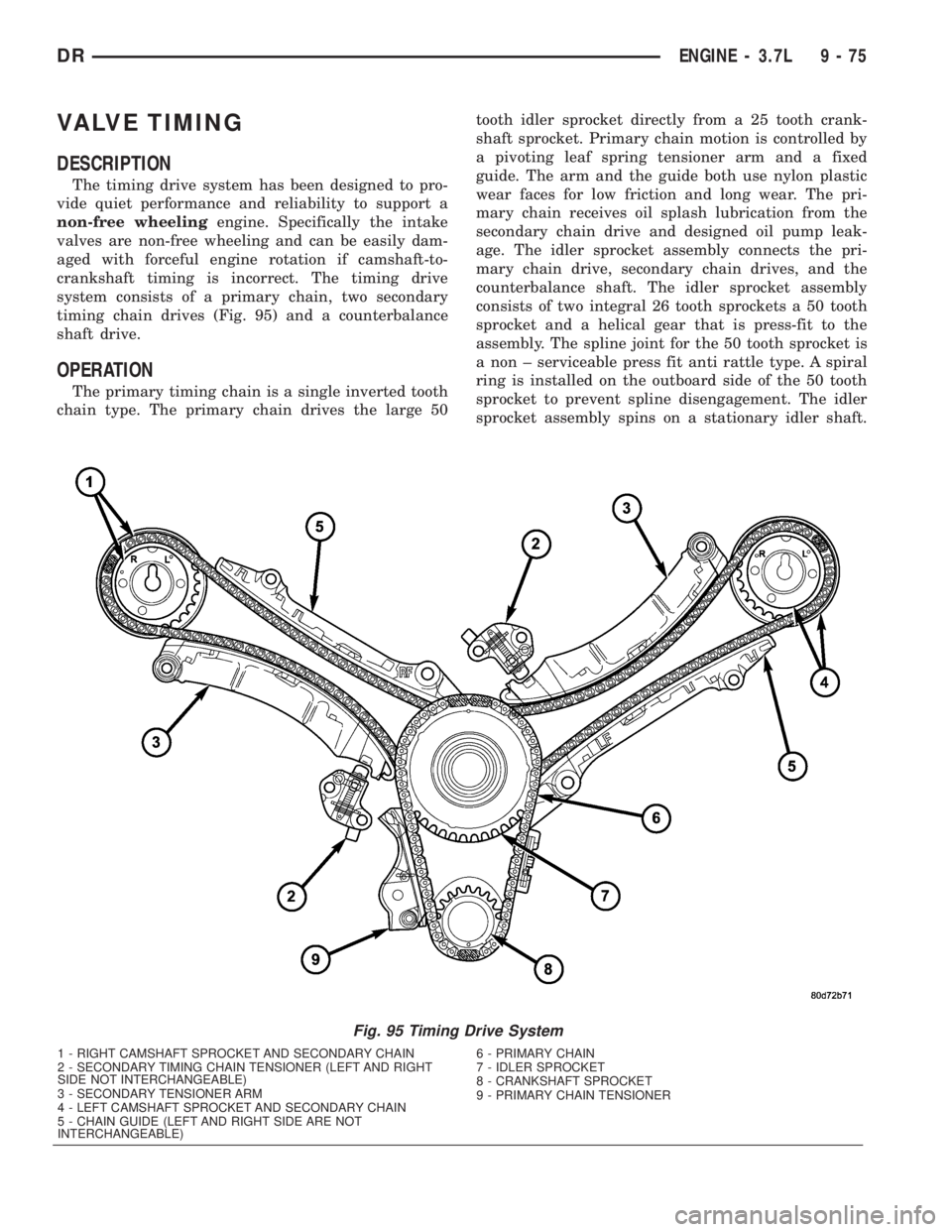

VALVE TIMING

DESCRIPTION

The timing drive system has been designed to pro-

vide quiet performance and reliability to support a

non-free wheelingengine. Specifically the intake

valves are non-free wheeling and can be easily dam-

aged with forceful engine rotation if camshaft-to-

crankshaft timing is incorrect. The timing drive

system consists of a primary chain, two secondary

timing chain drives (Fig. 95) and a counterbalance

shaft drive.

OPERATION

The primary timing chain is a single inverted tooth

chain type. The primary chain drives the large 50tooth idler sprocket directly from a 25 tooth crank-

shaft sprocket. Primary chain motion is controlled by

a pivoting leaf spring tensioner arm and a fixed

guide. The arm and the guide both use nylon plastic

wear faces for low friction and long wear. The pri-

mary chain receives oil splash lubrication from the

secondary chain drive and designed oil pump leak-

age. The idler sprocket assembly connects the pri-

mary chain drive, secondary chain drives, and the

counterbalance shaft. The idler sprocket assembly

consists of two integral 26 tooth sprockets a 50 tooth

sprocket and a helical gear that is press-fit to the

assembly. The spline joint for the 50 tooth sprocket is

a non ± serviceable press fit anti rattle type. A spiral

ring is installed on the outboard side of the 50 tooth

sprocket to prevent spline disengagement. The idler

sprocket assembly spins on a stationary idler shaft.

Fig. 95 Timing Drive System

1 - RIGHT CAMSHAFT SPROCKET AND SECONDARY CHAIN

2 - SECONDARY TIMING CHAIN TENSIONER (LEFT AND RIGHT

SIDE NOT INTERCHANGEABLE)

3 - SECONDARY TENSIONER ARM

4 - LEFT CAMSHAFT SPROCKET AND SECONDARY CHAIN

5 - CHAIN GUIDE (LEFT AND RIGHT SIDE ARE NOT

INTERCHANGEABLE)6 - PRIMARY CHAIN

7 - IDLER SPROCKET

8 - CRANKSHAFT SPROCKET

9 - PRIMARY CHAIN TENSIONER

DRENGINE - 3.7L 9 - 75