oil type DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1591 of 2895

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter from below using a cap-style filter

wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional

1¤2turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Install engine support fixture # 8534.

(3) Raise vehicle on hoist.

(4) Disconnect starter cables from starter motor.

(5) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(6) Remove transmission and transfer case (if

equipped).

(7) Remove flywheel or flexplate.

(8) Remove the transmission adapter plate.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(9) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).(10) Install the oil pan drain plug if sealing sur-

face is not damaged and tighten to 50 N´m (57 ft.

lbs.) torque.

(11) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(12) Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Place suction tube in oil pan and guide them

into place. Using a new tube to block gasket, install

and tighten the suction tube bolts by hand. Starting

with the oil pump inlet bolts, tighten the bolts to 24

N´m (18 ft. lbs.) torque. Tighten the remaining tube

brace bolts to 43 N´m (32 ft. lbs.) torque.

(3) Starting in the center and working outward,

tighten the oil pan bolts to 28 N´m (21 ft. lbs.)

torque.

(4) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 77 N´m

(57 ft. lbs.) torque.

(5) Connect starter motor cables.

(6) Install the flywheel or flexplate. Torque to 137

N´m (101 ft. lbs.).

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Remove the engine support fixture # 8534.

(10) Install battery negative cables.

(11) Fill the crankcase with new engine oil.

(12) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

9 - 342 ENGINE 5.9L DIESELDR

Page 1602 of 2895

ENGINE 8.0L

DESCRIPTION

The 8.0 Liter (488 CID) ten-cylinder engine is a

V-Type lightweight, single cam, overhead valve

engine with hydraulic roller tappets. This engine is

designed for unleaded fuel.

Engine lubrication system consists of a gerotor

type oil pump mounted in the timing chain cover and

driven by the crankshaft. The V-10 uses a full flow

oil filter.

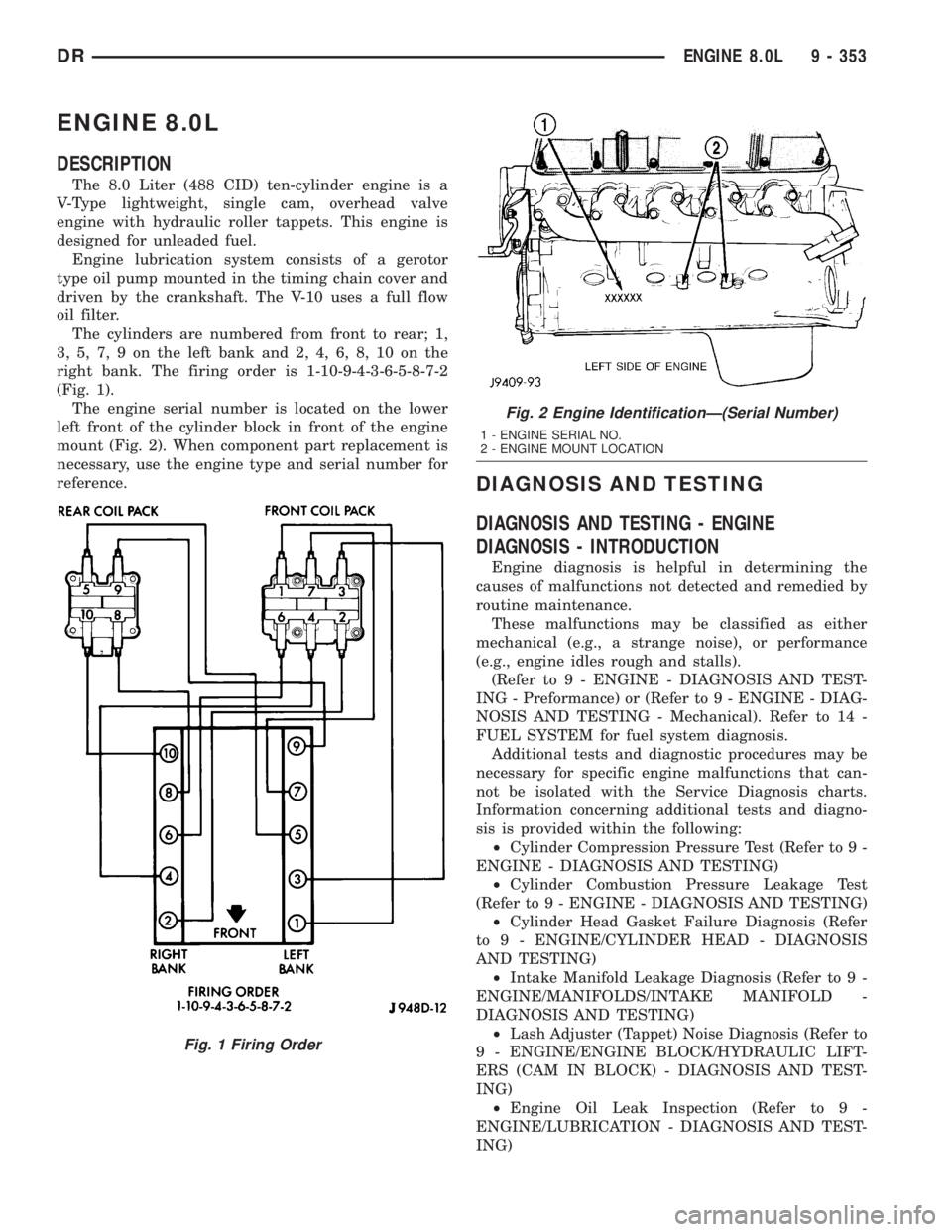

The cylinders are numbered from front to rear; 1,

3, 5, 7, 9 on the left bank and 2, 4, 6, 8, 10 on the

right bank. The firing order is 1-10-9-4-3-6-5-8-7-2

(Fig. 1).

The engine serial number is located on the lower

left front of the cylinder block in front of the engine

mount (Fig. 2). When component part replacement is

necessary, use the engine type and serial number for

reference.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING - Preformance) or (Refer to 9 - ENGINE - DIAG-

NOSIS AND TESTING - Mechanical). Refer to 14 -

FUEL SYSTEM for fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Head Gasket Failure Diagnosis (Refer

to 9 - ENGINE/CYLINDER HEAD - DIAGNOSIS

AND TESTING)

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING)

²Lash Adjuster (Tappet) Noise Diagnosis (Refer to

9 - ENGINE/ENGINE BLOCK/HYDRAULIC LIFT-

ERS (CAM IN BLOCK) - DIAGNOSIS AND TEST-

ING)

²Engine Oil Leak Inspection (Refer to 9 -

ENGINE/LUBRICATION - DIAGNOSIS AND TEST-

ING)

Fig. 1 Firing Order

Fig. 2 Engine IdentificationÐ(Serial Number)

1 - ENGINE SERIAL NO.

2 - ENGINE MOUNT LOCATION

DRENGINE 8.0L 9 - 353

Page 1609 of 2895

STANDARD PROCEDURE

STANDARD PROCEDUREÐCYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

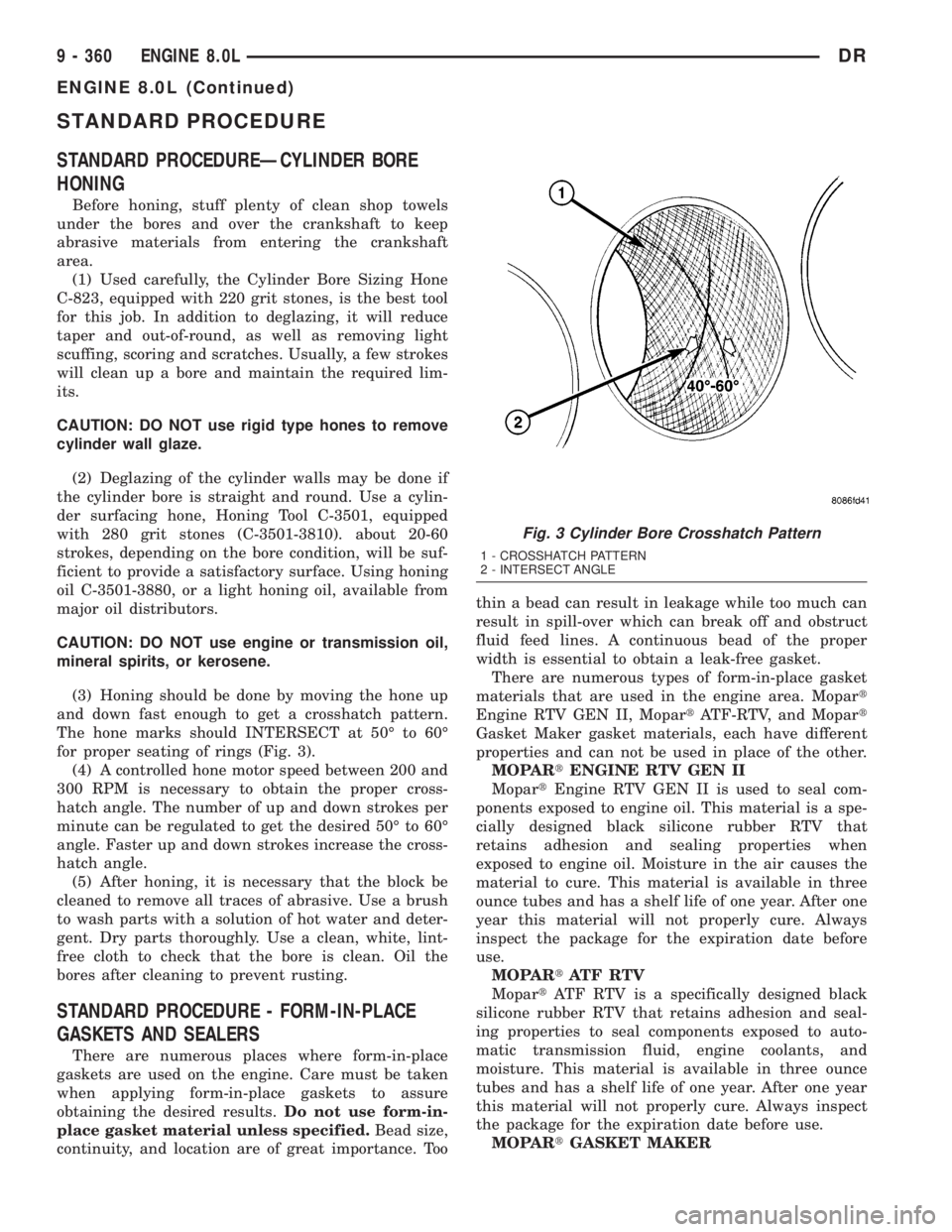

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Toothin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

9 - 360 ENGINE 8.0LDR

ENGINE 8.0L (Continued)

Page 1610 of 2895

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

REMOVAL

(1) Remove the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

DRENGINE 8.0L 9 - 361

ENGINE 8.0L (Continued)

Page 1642 of 2895

(3) Lower engine with support/lifting fixture while

guiding the engine bracket/cushion and thru-bolt into

support cushion brackets.

(4) Install thru-bolt nuts and tighten the nuts to

68 N´m (50 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Remove lifting fixture.

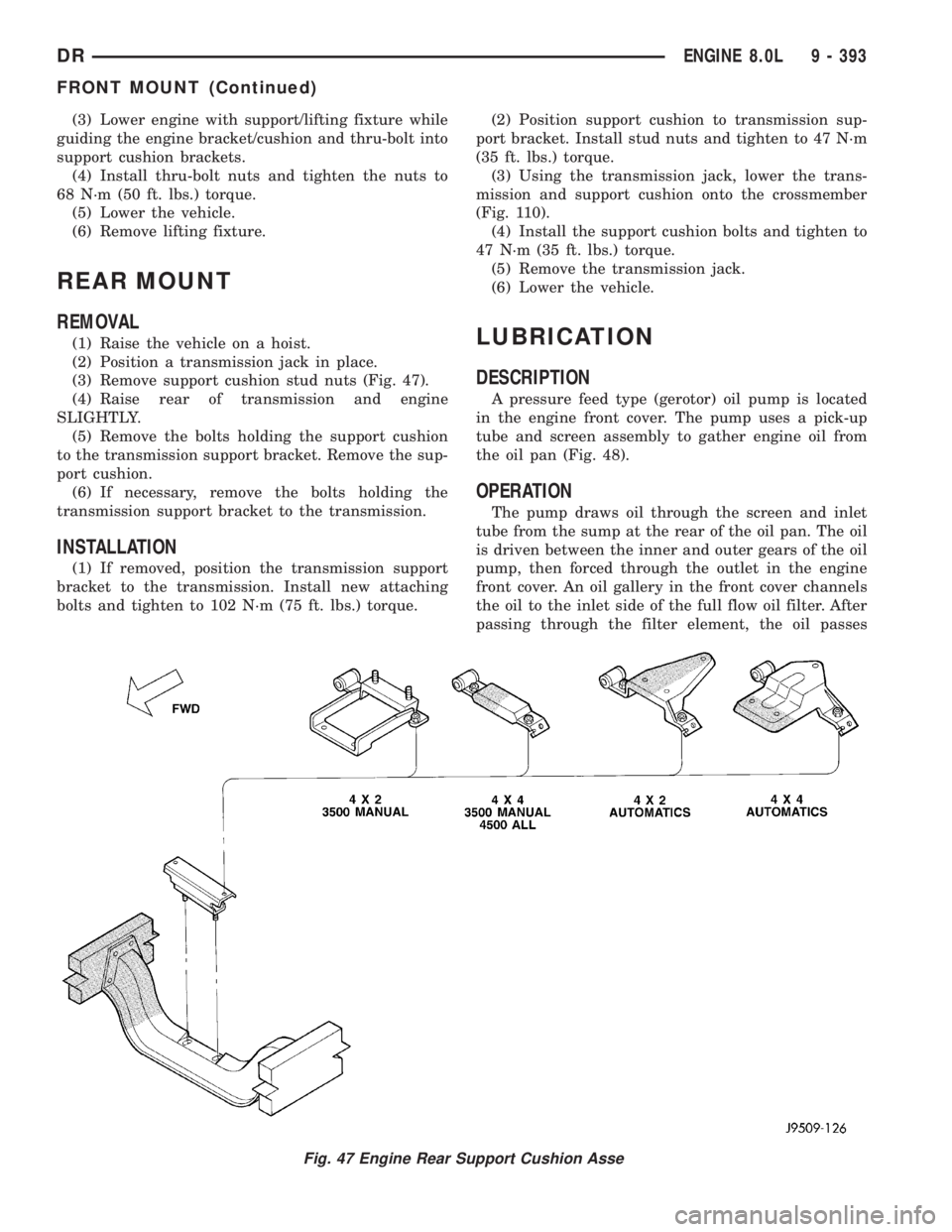

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Position a transmission jack in place.

(3) Remove support cushion stud nuts (Fig. 47).

(4) Raise rear of transmission and engine

SLIGHTLY.

(5) Remove the bolts holding the support cushion

to the transmission support bracket. Remove the sup-

port cushion.

(6) If necessary, remove the bolts holding the

transmission support bracket to the transmission.

INSTALLATION

(1) If removed, position the transmission support

bracket to the transmission. Install new attaching

bolts and tighten to 102 N´m (75 ft. lbs.) torque.(2) Position support cushion to transmission sup-

port bracket. Install stud nuts and tighten to 47 N´m

(35 ft. lbs.) torque.

(3) Using the transmission jack, lower the trans-

mission and support cushion onto the crossmember

(Fig. 110).

(4) Install the support cushion bolts and tighten to

47 N´m (35 ft. lbs.) torque.

(5) Remove the transmission jack.

(6) Lower the vehicle.

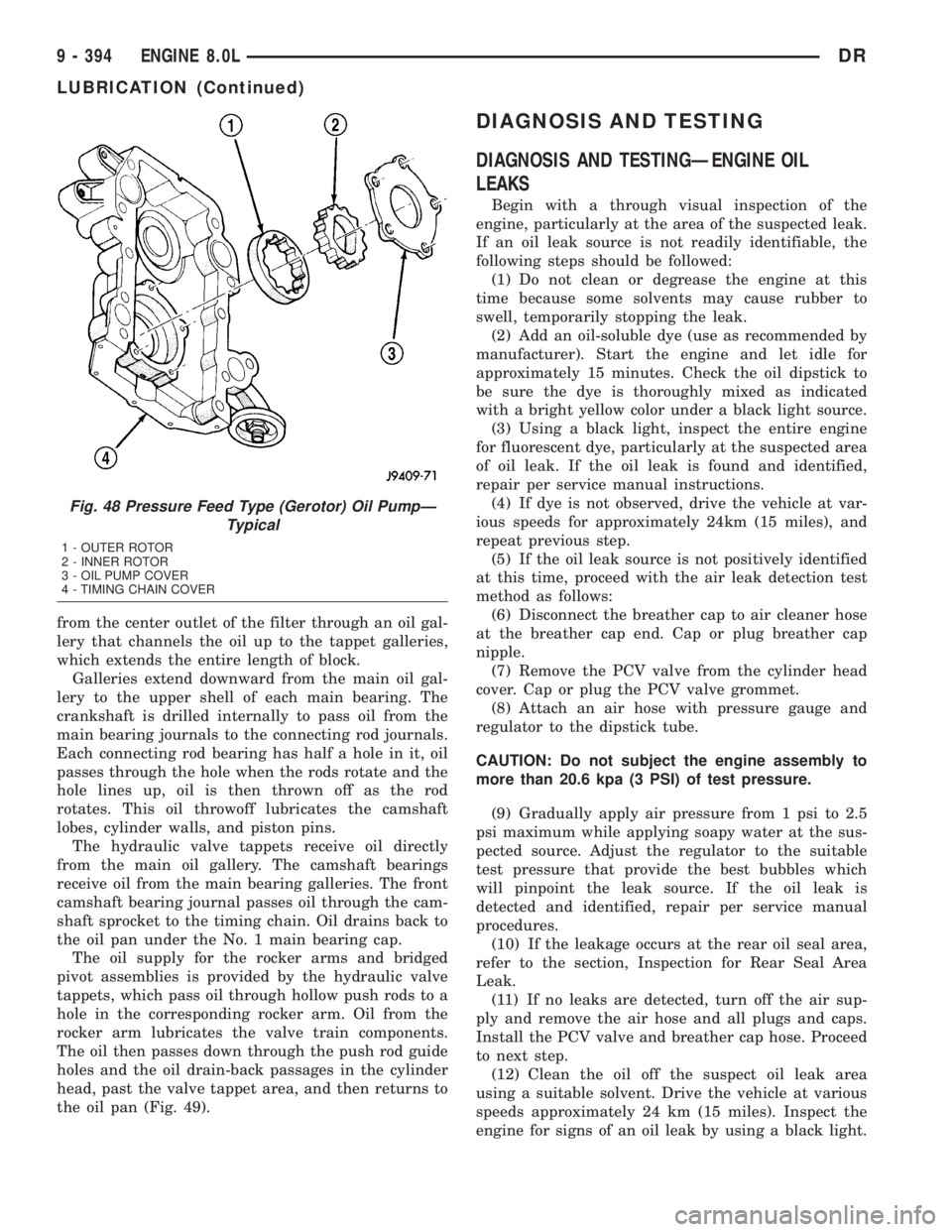

LUBRICATION

DESCRIPTION

A pressure feed type (gerotor) oil pump is located

in the engine front cover. The pump uses a pick-up

tube and screen assembly to gather engine oil from

the oil pan (Fig. 48).

OPERATION

The pump draws oil through the screen and inlet

tube from the sump at the rear of the oil pan. The oil

is driven between the inner and outer gears of the oil

pump, then forced through the outlet in the engine

front cover. An oil gallery in the front cover channels

the oil to the inlet side of the full flow oil filter. After

passing through the filter element, the oil passes

Fig. 47 Engine Rear Support Cushion Asse

DRENGINE 8.0L 9 - 393

FRONT MOUNT (Continued)

Page 1643 of 2895

from the center outlet of the filter through an oil gal-

lery that channels the oil up to the tappet galleries,

which extends the entire length of block.

Galleries extend downward from the main oil gal-

lery to the upper shell of each main bearing. The

crankshaft is drilled internally to pass oil from the

main bearing journals to the connecting rod journals.

Each connecting rod bearing has half a hole in it, oil

passes through the hole when the rods rotate and the

hole lines up, oil is then thrown off as the rod

rotates. This oil throwoff lubricates the camshaft

lobes, cylinder walls, and piston pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. The camshaft bearings

receive oil from the main bearing galleries. The front

camshaft bearing journal passes oil through the cam-

shaft sprocket to the timing chain. Oil drains back to

the oil pan under the No. 1 main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets, which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components.

The oil then passes down through the push rod guide

holes and the oil drain-back passages in the cylinder

head, past the valve tappet area, and then returns to

the oil pan (Fig. 49).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.

(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

Fig. 48 Pressure Feed Type (Gerotor) Oil PumpÐ

Typical

1 - OUTER ROTOR

2 - INNER ROTOR

3 - OIL PUMP COVER

4 - TIMING CHAIN COVER

9 - 394 ENGINE 8.0LDR

LUBRICATION (Continued)

Page 1645 of 2895

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. (Refer to 9

- ENGINE - SPECIFICATIONS).

OIL

STANDARD PROCEDURE - ENGINE OIL

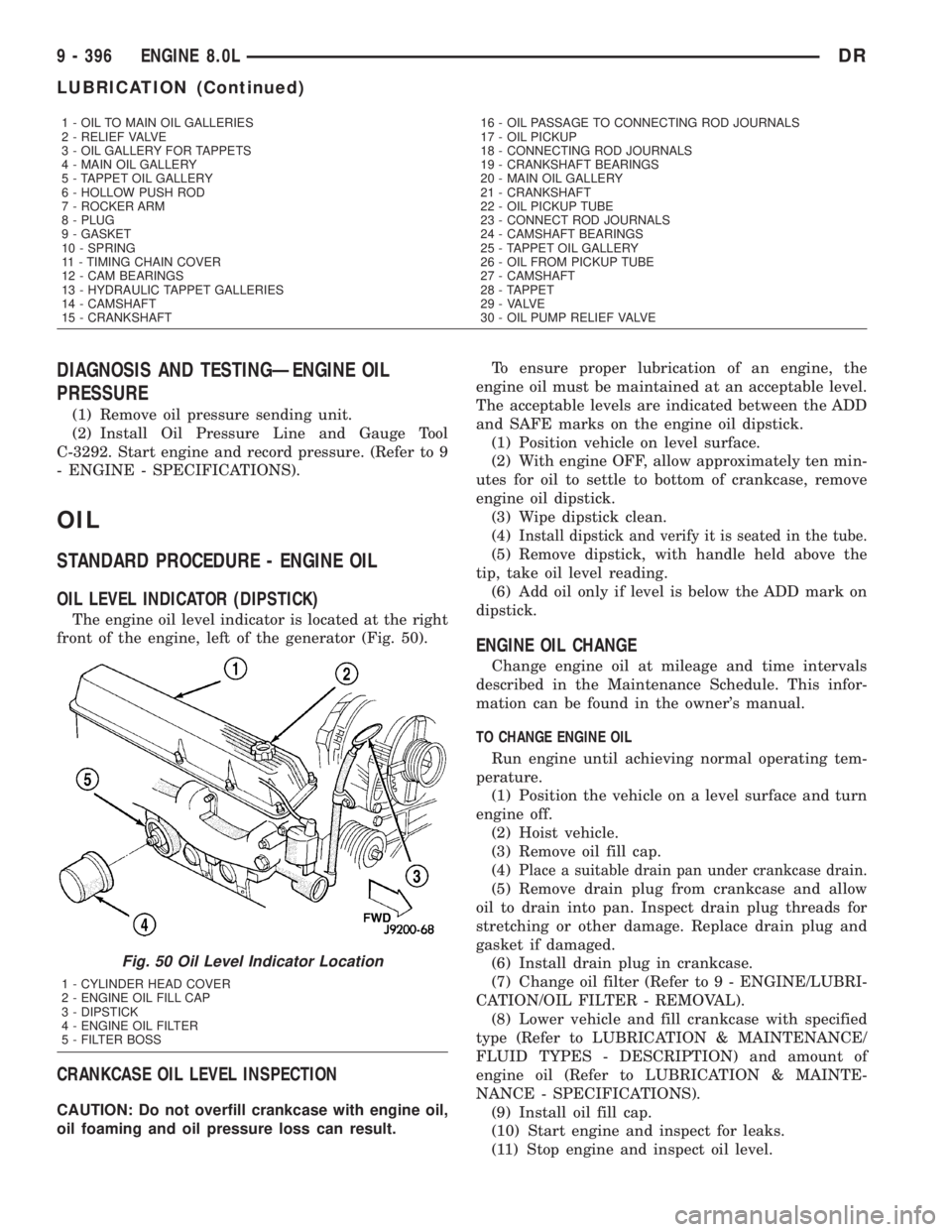

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

front of the engine, left of the generator (Fig. 50).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4)

Install dipstick and verify it is seated in the tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in the owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist vehicle.

(3) Remove oil fill cap.

(4)

Place a suitable drain pan under crankcase drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

1 - OIL TO MAIN OIL GALLERIES

2 - RELIEF VALVE

3 - OIL GALLERY FOR TAPPETS

4 - MAIN OIL GALLERY

5 - TAPPET OIL GALLERY

6 - HOLLOW PUSH ROD

7 - ROCKER ARM

8 - PLUG

9 - GASKET

10 - SPRING

11 - TIMING CHAIN COVER

12 - CAM BEARINGS

13 - HYDRAULIC TAPPET GALLERIES

14 - CAMSHAFT

15 - CRANKSHAFT16 - OIL PASSAGE TO CONNECTING ROD JOURNALS

17 - OIL PICKUP

18 - CONNECTING ROD JOURNALS

19 - CRANKSHAFT BEARINGS

20 - MAIN OIL GALLERY

21 - CRANKSHAFT

22 - OIL PICKUP TUBE

23 - CONNECT ROD JOURNALS

24 - CAMSHAFT BEARINGS

25 - TAPPET OIL GALLERY

26 - OIL FROM PICKUP TUBE

27 - CAMSHAFT

28 - TAPPET

29 - VALVE

30 - OIL PUMP RELIEF VALVE

Fig. 50 Oil Level Indicator Location

1 - CYLINDER HEAD COVER

2 - ENGINE OIL FILL CAP

3 - DIPSTICK

4 - ENGINE OIL FILTER

5 - FILTER BOSS

9 - 396 ENGINE 8.0LDR

LUBRICATION (Continued)

Page 1646 of 2895

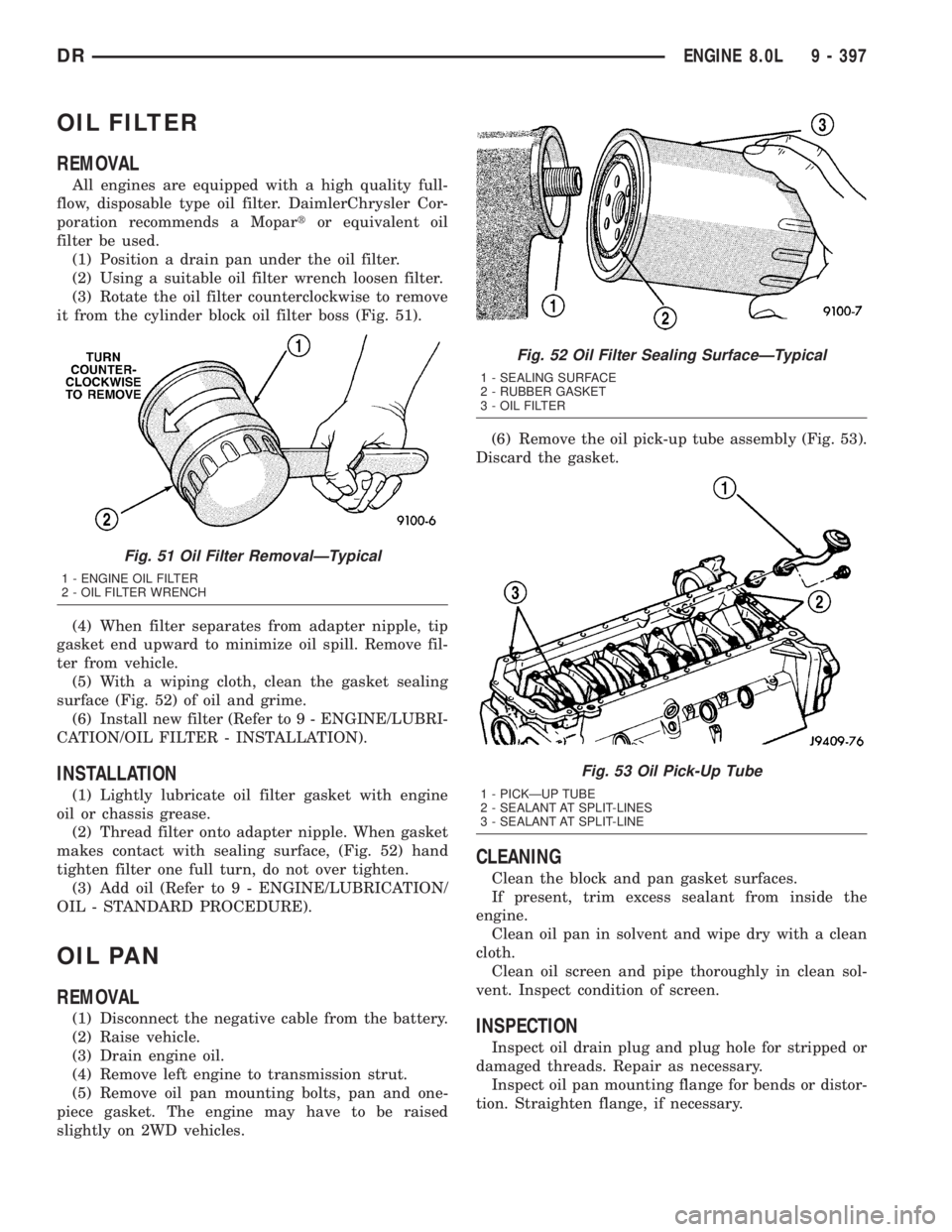

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 51).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 52) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 52) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle.

(3) Drain engine oil.

(4) Remove left engine to transmission strut.

(5) Remove oil pan mounting bolts, pan and one-

piece gasket. The engine may have to be raised

slightly on 2WD vehicles.(6) Remove the oil pick-up tube assembly (Fig. 53).

Discard the gasket.

CLEANING

Clean the block and pan gasket surfaces.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

Fig. 51 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 52 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

Fig. 53 Oil Pick-Up Tube

1 - PICKÐUP TUBE

2 - SEALANT AT SPLIT-LINES

3 - SEALANT AT SPLIT-LINE

DRENGINE 8.0L 9 - 397

Page 1662 of 2895

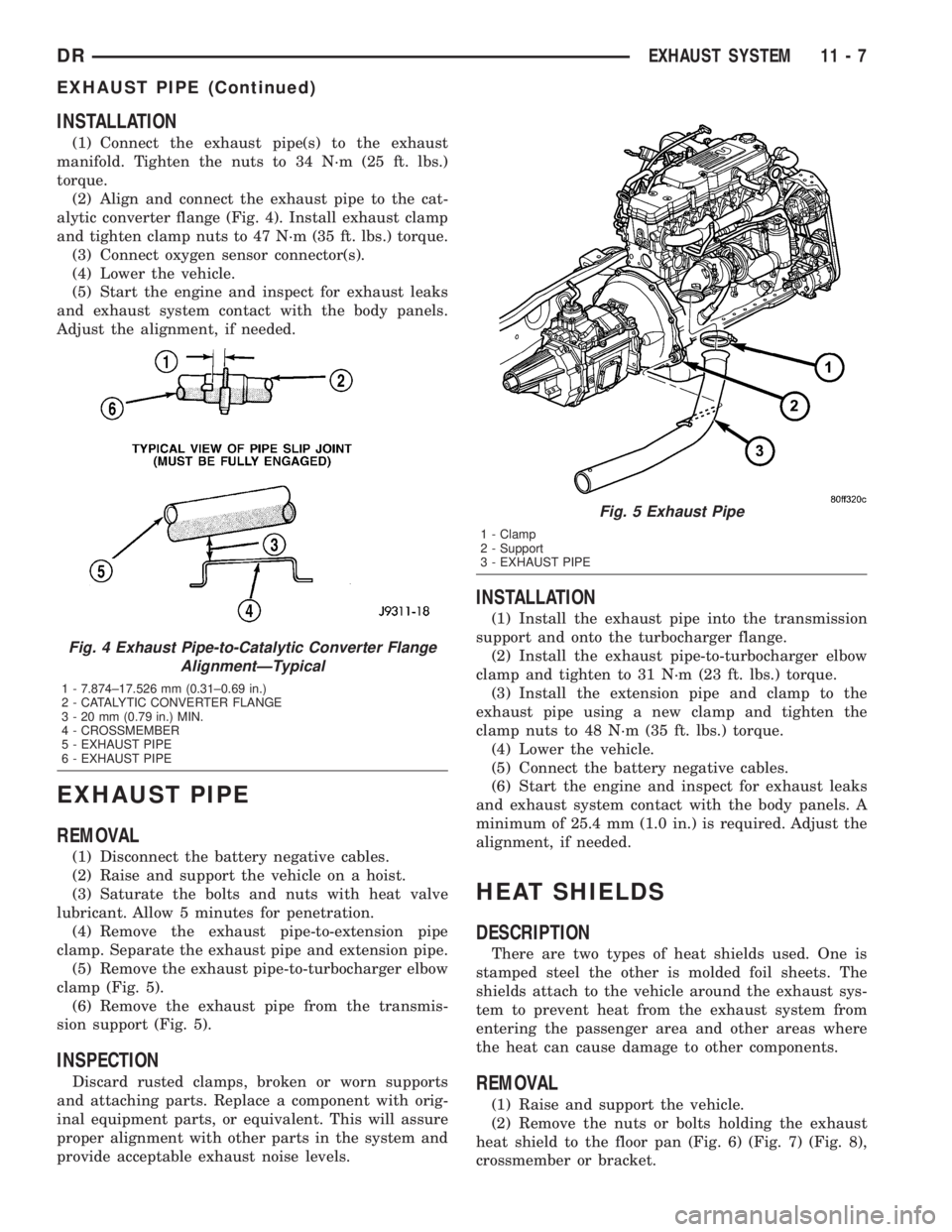

INSTALLATION

(1) Connect the exhaust pipe(s) to the exhaust

manifold. Tighten the nuts to 34 N´m (25 ft. lbs.)

torque.

(2) Align and connect the exhaust pipe to the cat-

alytic converter flange (Fig. 4). Install exhaust clamp

and tighten clamp nuts to 47 N´m (35 ft. lbs.) torque.

(3) Connect oxygen sensor connector(s).

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

EXHAUST PIPE

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise and support the vehicle on a hoist.

(3) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(4) Remove the exhaust pipe-to-extension pipe

clamp. Separate the exhaust pipe and extension pipe.

(5) Remove the exhaust pipe-to-turbocharger elbow

clamp (Fig. 5).

(6) Remove the exhaust pipe from the transmis-

sion support (Fig. 5).

INSPECTION

Discard rusted clamps, broken or worn supports

and attaching parts. Replace a component with orig-

inal equipment parts, or equivalent. This will assure

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

INSTALLATION

(1) Install the exhaust pipe into the transmission

support and onto the turbocharger flange.

(2) Install the exhaust pipe-to-turbocharger elbow

clamp and tighten to 31 N´m (23 ft. lbs.) torque.

(3) Install the extension pipe and clamp to the

exhaust pipe using a new clamp and tighten the

clamp nuts to 48 N´m (35 ft. lbs.) torque.

(4) Lower the vehicle.

(5) Connect the battery negative cables.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels. A

minimum of 25.4 mm (1.0 in.) is required. Adjust the

alignment, if needed.

HEAT SHIELDS

DESCRIPTION

There are two types of heat shields used. One is

stamped steel the other is molded foil sheets. The

shields attach to the vehicle around the exhaust sys-

tem to prevent heat from the exhaust system from

entering the passenger area and other areas where

the heat can cause damage to other components.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the nuts or bolts holding the exhaust

heat shield to the floor pan (Fig. 6) (Fig. 7) (Fig. 8),

crossmember or bracket.

Fig. 4 Exhaust Pipe-to-Catalytic Converter Flange

AlignmentÐTypical

1 - 7.874±17.526 mm (0.31±0.69 in.)

2 - CATALYTIC CONVERTER FLANGE

3 - 20 mm (0.79 in.) MIN.

4 - CROSSMEMBER

5 - EXHAUST PIPE

6 - EXHAUST PIPE

Fig. 5 Exhaust Pipe

1 - Clamp

2 - Support

3 - EXHAUST PIPE

DREXHAUST SYSTEM 11 - 7

EXHAUST PIPE (Continued)

Page 1667 of 2895

²Improved operating economy

²Altitude compensation

²Noise reduction.

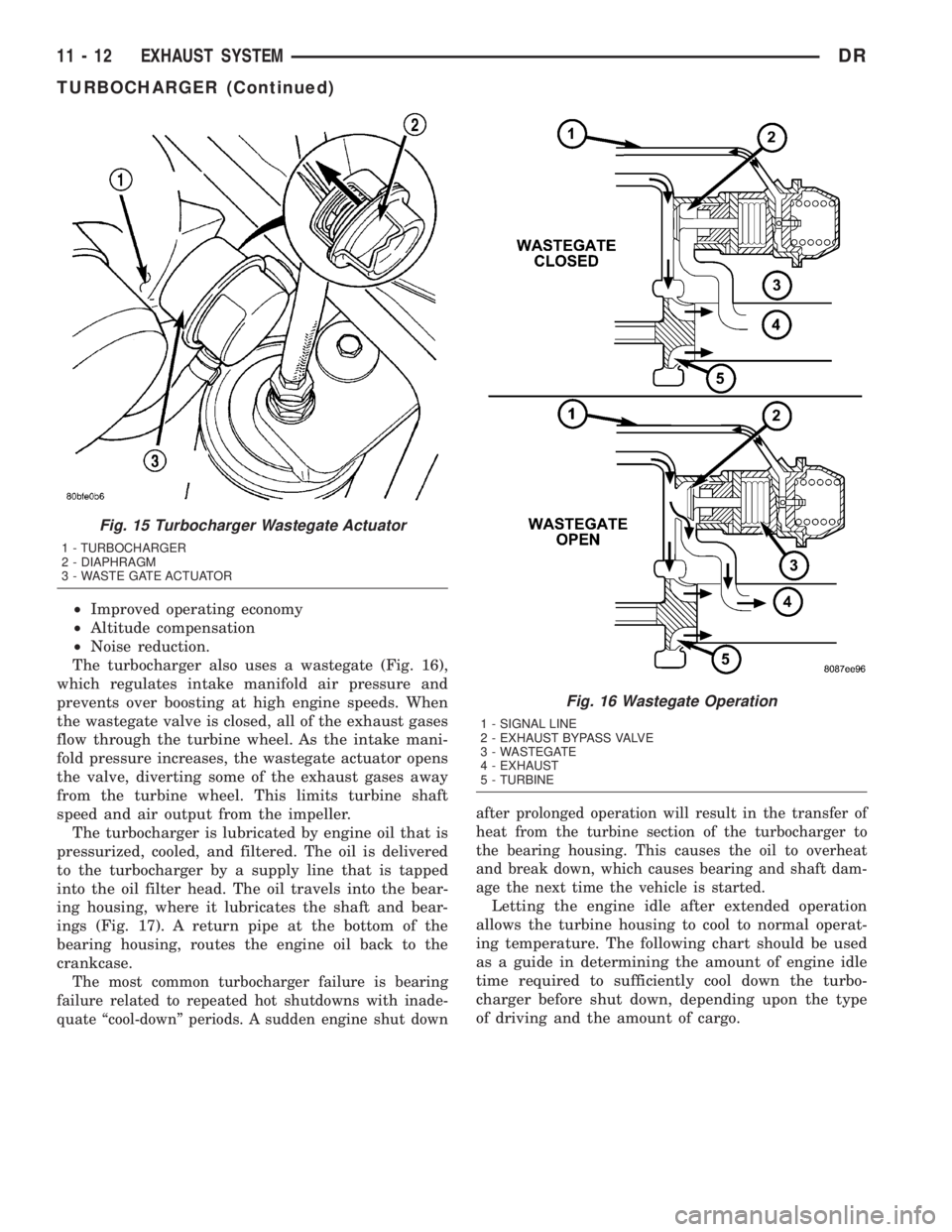

The turbocharger also uses a wastegate (Fig. 16),

which regulates intake manifold air pressure and

prevents over boosting at high engine speeds. When

the wastegate valve is closed, all of the exhaust gases

flow through the turbine wheel. As the intake mani-

fold pressure increases, the wastegate actuator opens

the valve, diverting some of the exhaust gases away

from the turbine wheel. This limits turbine shaft

speed and air output from the impeller.

The turbocharger is lubricated by engine oil that is

pressurized, cooled, and filtered. The oil is delivered

to the turbocharger by a supply line that is tapped

into the oil filter head. The oil travels into the bear-

ing housing, where it lubricates the shaft and bear-

ings (Fig. 17). A return pipe at the bottom of the

bearing housing, routes the engine oil back to the

crankcase.

The most common turbocharger failure is bearing

failure related to repeated hot shutdowns with inade-

quate ªcool-downº periods. A sudden engine shut downafter prolonged operation will result in the transfer of

heat from the turbine section of the turbocharger to

the bearing housing. This causes the oil to overheat

and break down, which causes bearing and shaft dam-

age the next time the vehicle is started.

Letting the engine idle after extended operation

allows the turbine housing to cool to normal operat-

ing temperature. The following chart should be used

as a guide in determining the amount of engine idle

time required to sufficiently cool down the turbo-

charger before shut down, depending upon the type

of driving and the amount of cargo.

Fig. 15 Turbocharger Wastegate Actuator

1 - TURBOCHARGER

2 - DIAPHRAGM

3 - WASTE GATE ACTUATOR

Fig. 16 Wastegate Operation

1 - SIGNAL LINE

2 - EXHAUST BYPASS VALVE

3 - WASTEGATE

4 - EXHAUST

5 - TURBINE

11 - 12 EXHAUST SYSTEMDR

TURBOCHARGER (Continued)