oil type DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1465 of 2895

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 in the 5.7L engines.

These are specified with a dual SAE viscosity grade

which indicates the cold-to-hot temperature viscosity

range. Select an engine oil that is best suited to your

particular temperature range and variation.

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 26).

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the left

hand of the engine on the 5.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about tenminutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately five

minutes for oil to settle to bottom of crankcase,

remove engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules(Refer to LUBRI-

CATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION).

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase. Torque to 34

N´m ( 25 ft. lbs.).

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

Fig. 26 API SYMBOL

9 - 216 ENGINE - 5.7LDR

OIL (Continued)

Page 1473 of 2895

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTINGÐHYDRAULIC

TAPPETS...........................258

REMOVAL............................259

CLEANING...........................260

INSTALLATION........................260

PISTON & CONNECTING ROD

DESCRIPTION........................260

STANDARD PROCEDURE - PISTON FITTING . 260

REMOVAL............................261

CLEANING...........................261

INSPECTION.........................261

INSTALLATION........................261

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING............................262

VIBRATION DAMPER

REMOVAL............................263

INSTALLATION........................263

FRONT MOUNT

REMOVAL............................264

INSTALLATION........................265

REAR MOUNT

REMOVAL............................266

INSTALLATION........................267

LUBRICATION

DESCRIPTION........................267

OPERATION..........................267

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS.............................269

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE.........................269

OIL

STANDARD PROCEDURE - ENGINE OIL....269

OIL FILTER

REMOVAL............................270INSTALLATION........................270

OIL PAN

REMOVAL............................270

CLEANING...........................270

INSPECTION.........................271

INSTALLATION........................271

OIL PUMP

REMOVAL............................272

DISASSEMBLY........................272

INSPECTION.........................272

ASSEMBLY...........................274

INSTALLATION........................274

INTAKE MANIFOLD

DESCRIPTION........................274

OPERATION..........................274

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE.................274

REMOVAL............................275

CLEANING...........................275

INSPECTION.........................275

INSTALLATION........................275

EXHAUST MANIFOLD

DESCRIPTION........................277

OPERATION..........................277

REMOVAL............................277

CLEANING...........................277

INSPECTION.........................277

INSTALLATION........................277

TIMING BELT / CHAIN COVER(S)

REMOVAL............................278

INSTALLATION........................278

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL............................279

INSPECTIONÐMEASURING TIMING CHAIN

STRETCH..........................279

INSTALLATION........................279

ENGINE - 5.9L

DESCRIPTION

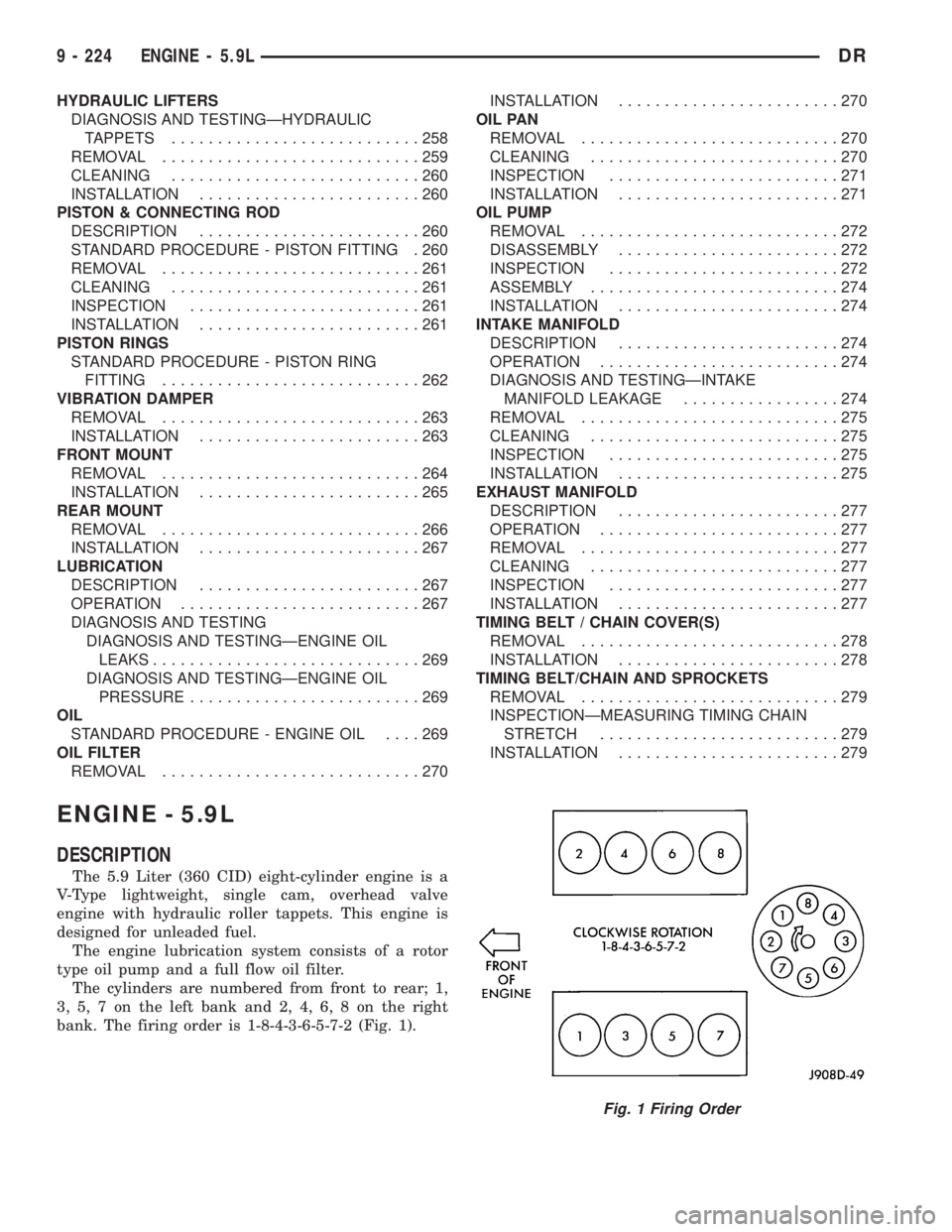

The 5.9 Liter (360 CID) eight-cylinder engine is a

V-Type lightweight, single cam, overhead valve

engine with hydraulic roller tappets. This engine is

designed for unleaded fuel.

The engine lubrication system consists of a rotor

type oil pump and a full flow oil filter.

The cylinders are numbered from front to rear; 1,

3, 5, 7 on the left bank and 2, 4, 6, 8 on the right

bank. The firing order is 1-8-4-3-6-5-7-2 (Fig. 1).

Fig. 1 Firing Order

9 - 224 ENGINE - 5.9LDR

Page 1474 of 2895

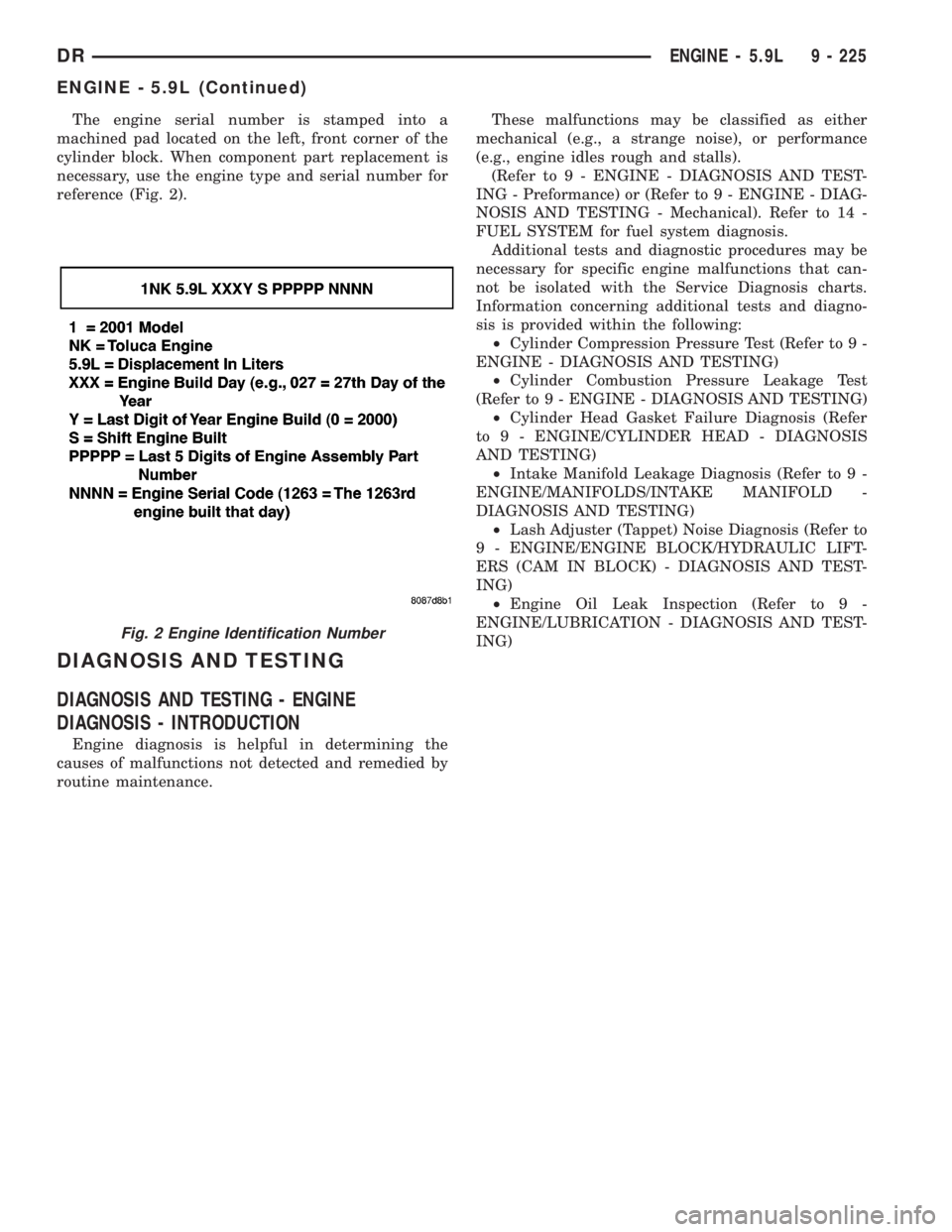

The engine serial number is stamped into a

machined pad located on the left, front corner of the

cylinder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 2).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING - Preformance) or (Refer to 9 - ENGINE - DIAG-

NOSIS AND TESTING - Mechanical). Refer to 14 -

FUEL SYSTEM for fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Head Gasket Failure Diagnosis (Refer

to 9 - ENGINE/CYLINDER HEAD - DIAGNOSIS

AND TESTING)

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING)

²Lash Adjuster (Tappet) Noise Diagnosis (Refer to

9 - ENGINE/ENGINE BLOCK/HYDRAULIC LIFT-

ERS (CAM IN BLOCK) - DIAGNOSIS AND TEST-

ING)

²Engine Oil Leak Inspection (Refer to 9 -

ENGINE/LUBRICATION - DIAGNOSIS AND TEST-

ING)

Fig. 2 Engine Identification Number

DRENGINE - 5.9L 9 - 225

ENGINE - 5.9L (Continued)

Page 1481 of 2895

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

9 - 232 ENGINE - 5.9LDR

ENGINE - 5.9L (Continued)

Page 1482 of 2895

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

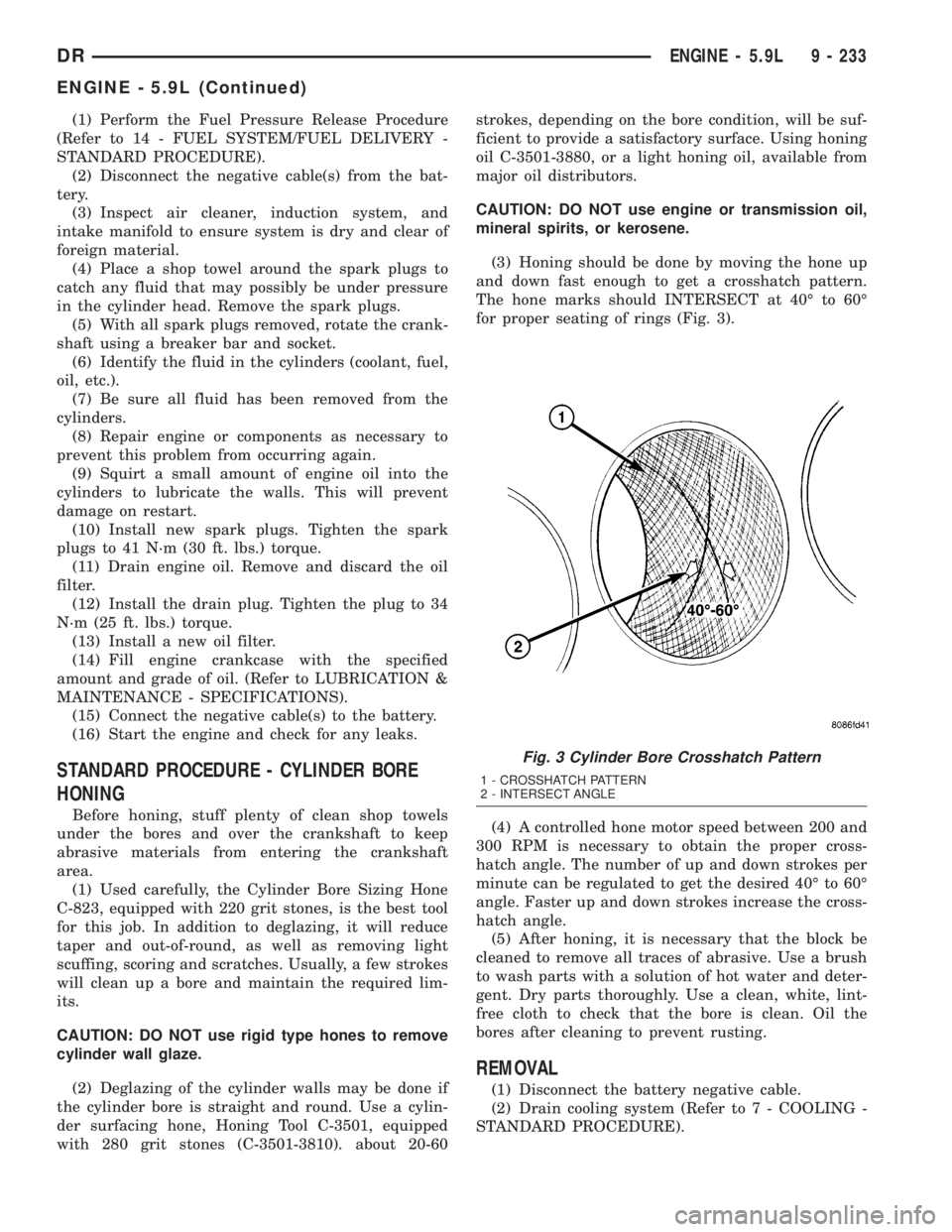

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

DRENGINE - 5.9L 9 - 233

ENGINE - 5.9L (Continued)

Page 1484 of 2895

(19) Install the distributor cap and wiring.

(20) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(21) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(22) Connect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION).

(23) Install the air cleaner resonator and duct

work..

(24) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(25) Install a/c compressor and lines (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

(26) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(27) Install upper radiator support crossmember.

(28) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(29) Connect the radiator lower hose.

(30) Connect the transmission oil cooler lines to

the radiator.

(31) Install the fan shroud.

(32) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(33) Connect the radiator upper hose.

(34) Install the washer bottle.

(35) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(36) Connect the transmission cooler lines.

(37) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(38) Evacuate and charge the air conditioning sys-

tem, if equipped (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(39) Add engine oil to crankcase (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES - SPEC-

IFICATIONS).

(40) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(41) Connect battery negative cable.

(42) Start engine and inspect for leaks.

(43) Road test vehicle.SPECIFICATIONS

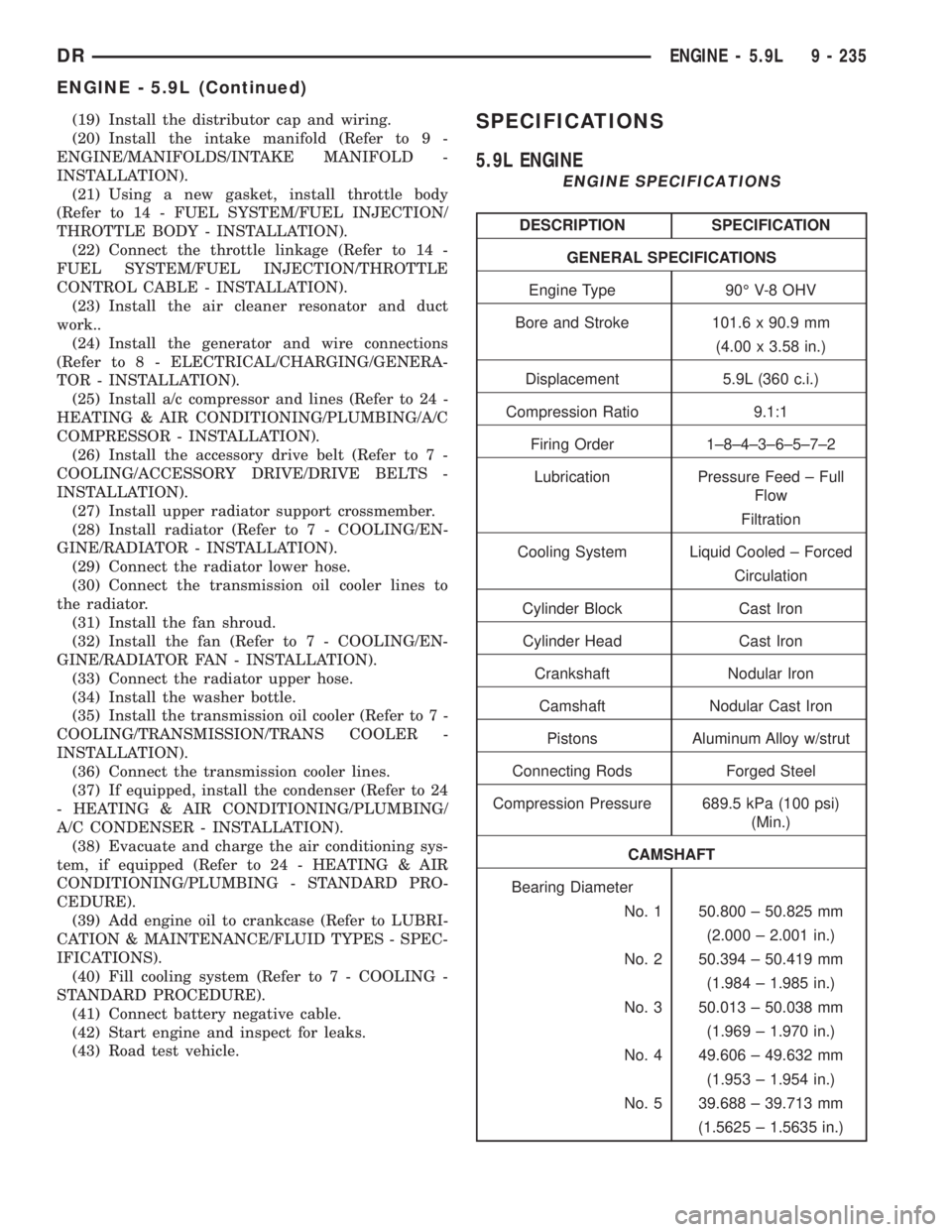

5.9L ENGINE

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É V-8 OHV

Bore and Stroke 101.6 x 90.9 mm

(4.00 x 3.58 in.)

Displacement 5.9L (360 c.i.)

Compression Ratio 9.1:1

Firing Order 1±8±4±3±6±5±7±2

Lubrication Pressure Feed ± Full

Flow

Filtration

Cooling System Liquid Cooled ± Forced

Circulation

Cylinder Block Cast Iron

Cylinder Head Cast Iron

Crankshaft Nodular Iron

Camshaft Nodular Cast Iron

Pistons Aluminum Alloy w/strut

Connecting Rods Forged Steel

Compression Pressure 689.5 kPa (100 psi)

(Min.)

CAMSHAFT

Bearing Diameter

No. 1 50.800 ± 50.825 mm

(2.000 ± 2.001 in.)

No. 2 50.394 ± 50.419 mm

(1.984 ± 1.985 in.)

No. 3 50.013 ± 50.038 mm

(1.969 ± 1.970 in.)

No. 4 49.606 ± 49.632 mm

(1.953 ± 1.954 in.)

No. 5 39.688 ± 39.713 mm

(1.5625 ± 1.5635 in.)

DRENGINE - 5.9L 9 - 235

ENGINE - 5.9L (Continued)

Page 1501 of 2895

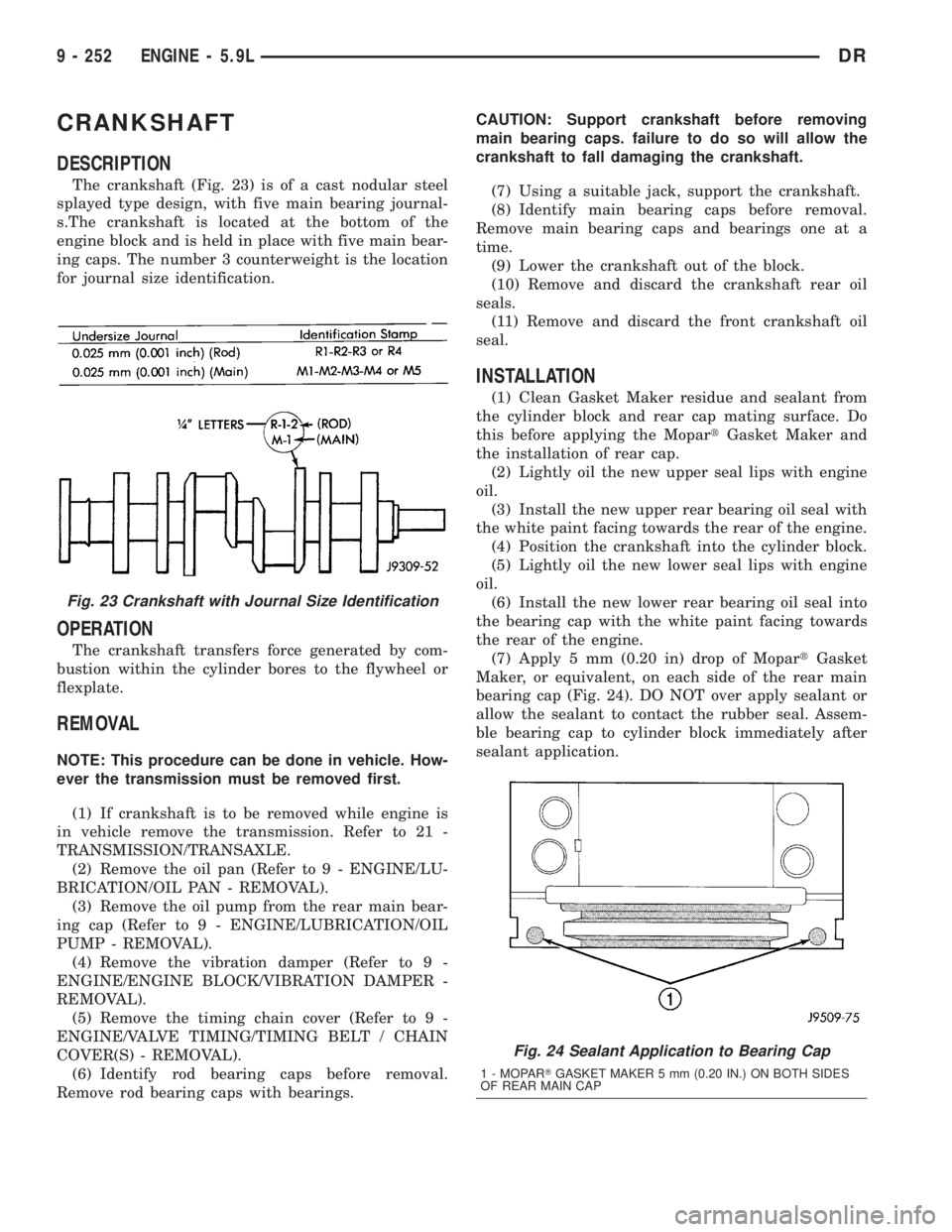

CRANKSHAFT

DESCRIPTION

The crankshaft (Fig. 23) is of a cast nodular steel

splayed type design, with five main bearing journal-

s.The crankshaft is located at the bottom of the

engine block and is held in place with five main bear-

ing caps. The number 3 counterweight is the location

for journal size identification.

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder bores to the flywheel or

flexplate.

REMOVAL

NOTE: This procedure can be done in vehicle. How-

ever the transmission must be removed first.

(1) If crankshaft is to be removed while engine is

in vehicle remove the transmission. Refer to 21 -

TRANSMISSION/TRANSAXLE.

(2) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the oil pump from the rear main bear-

ing cap (Refer to 9 - ENGINE/LUBRICATION/OIL

PUMP - REMOVAL).

(4) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(5) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(6) Identify rod bearing caps before removal.

Remove rod bearing caps with bearings.CAUTION: Support crankshaft before removing

main bearing caps. failure to do so will allow the

crankshaft to fall damaging the crankshaft.

(7) Using a suitable jack, support the crankshaft.

(8) Identify main bearing caps before removal.

Remove main bearing caps and bearings one at a

time.

(9) Lower the crankshaft out of the block.

(10) Remove and discard the crankshaft rear oil

seals.

(11) Remove and discard the front crankshaft oil

seal.

INSTALLATION

(1) Clean Gasket Maker residue and sealant from

the cylinder block and rear cap mating surface. Do

this before applying the MopartGasket Maker and

the installation of rear cap.

(2) Lightly oil the new upper seal lips with engine

oil.

(3) Install the new upper rear bearing oil seal with

the white paint facing towards the rear of the engine.

(4) Position the crankshaft into the cylinder block.

(5) Lightly oil the new lower seal lips with engine

oil.

(6) Install the new lower rear bearing oil seal into

the bearing cap with the white paint facing towards

the rear of the engine.

(7) Apply 5 mm (0.20 in) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 24). DO NOT over apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

Fig. 23 Crankshaft with Journal Size Identification

Fig. 24 Sealant Application to Bearing Cap

1 - MOPARTGASKET MAKER 5 mm (0.20 IN.) ON BOTH SIDES

OF REAR MAIN CAP

9 - 252 ENGINE - 5.9LDR

Page 1516 of 2895

(5) Raise the transmission enough to remove the

mount from the crossmember.

(6) Remove the mount.

INSTALLATION

NOTE: Threadlocking compound must be applied to

the bolts before installation.

(1) Install the two bolts that attach the transmis-

sion mount to the transmission bracket.

(2) Torque the bolts to 61N´m (45 ft.lbs.) torque.

(3) Lower the transmission so the transmission

mount rests on the crossmember, and the studs of

the transmission mount are aligned in the slots in

the crossmember.

(4) Install the nuts onto the transmission mount

studs through the crossmember access slot.

(5) Torque the nuts to 54N´m (40 ft. lbs.).

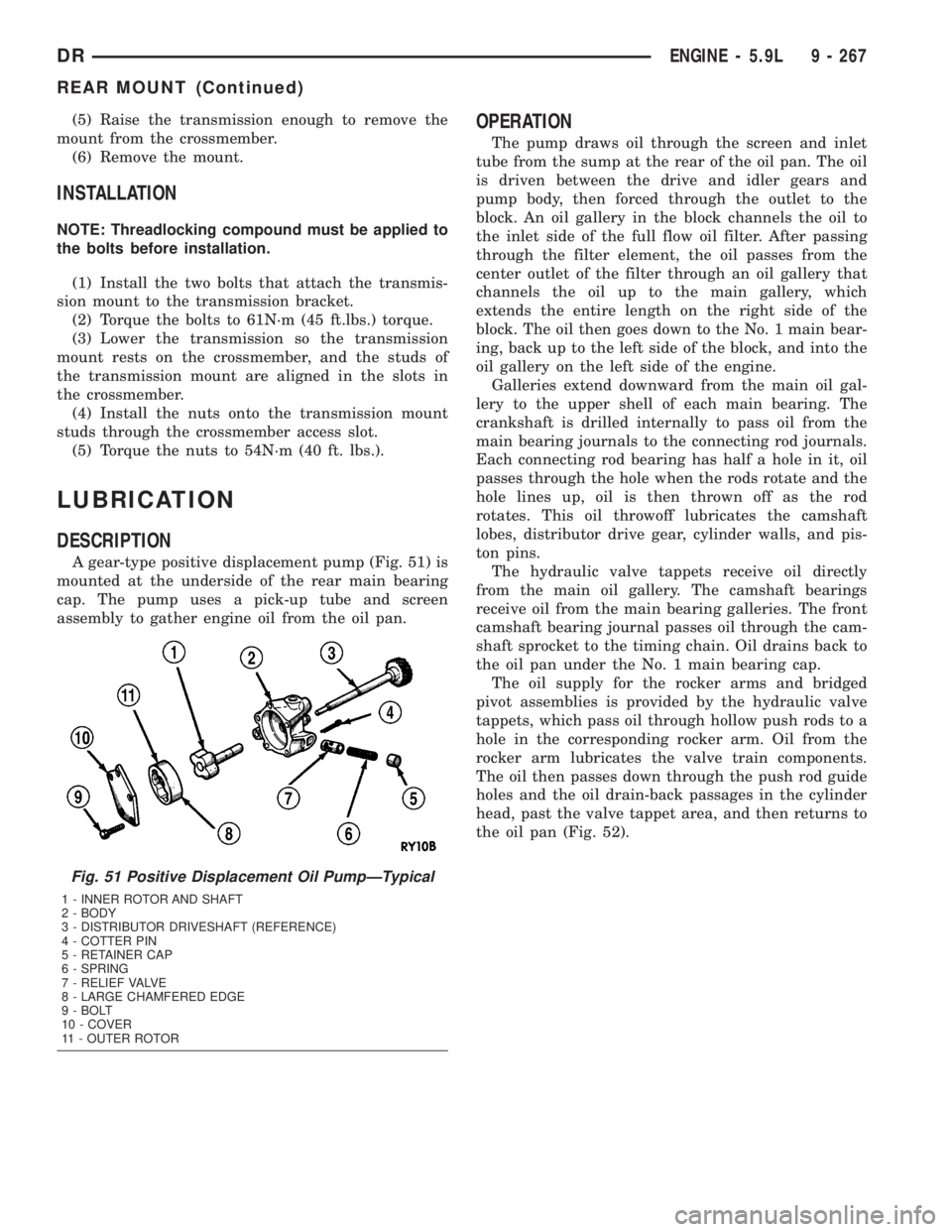

LUBRICATION

DESCRIPTION

A gear-type positive displacement pump (Fig. 51) is

mounted at the underside of the rear main bearing

cap. The pump uses a pick-up tube and screen

assembly to gather engine oil from the oil pan.

OPERATION

The pump draws oil through the screen and inlet

tube from the sump at the rear of the oil pan. The oil

is driven between the drive and idler gears and

pump body, then forced through the outlet to the

block. An oil gallery in the block channels the oil to

the inlet side of the full flow oil filter. After passing

through the filter element, the oil passes from the

center outlet of the filter through an oil gallery that

channels the oil up to the main gallery, which

extends the entire length on the right side of the

block. The oil then goes down to the No. 1 main bear-

ing, back up to the left side of the block, and into the

oil gallery on the left side of the engine.

Galleries extend downward from the main oil gal-

lery to the upper shell of each main bearing. The

crankshaft is drilled internally to pass oil from the

main bearing journals to the connecting rod journals.

Each connecting rod bearing has half a hole in it, oil

passes through the hole when the rods rotate and the

hole lines up, oil is then thrown off as the rod

rotates. This oil throwoff lubricates the camshaft

lobes, distributor drive gear, cylinder walls, and pis-

ton pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. The camshaft bearings

receive oil from the main bearing galleries. The front

camshaft bearing journal passes oil through the cam-

shaft sprocket to the timing chain. Oil drains back to

the oil pan under the No. 1 main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets, which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components.

The oil then passes down through the push rod guide

holes and the oil drain-back passages in the cylinder

head, past the valve tappet area, and then returns to

the oil pan (Fig. 52).

Fig. 51 Positive Displacement Oil PumpÐTypical

1 - INNER ROTOR AND SHAFT

2 - BODY

3 - DISTRIBUTOR DRIVESHAFT (REFERENCE)

4 - COTTER PIN

5 - RETAINER CAP

6 - SPRING

7 - RELIEF VALVE

8 - LARGE CHAMFERED EDGE

9 - BOLT

10 - COVER

11 - OUTER ROTOR

DRENGINE - 5.9L 9 - 267

REAR MOUNT (Continued)

Page 1519 of 2895

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in the owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist vehicle.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

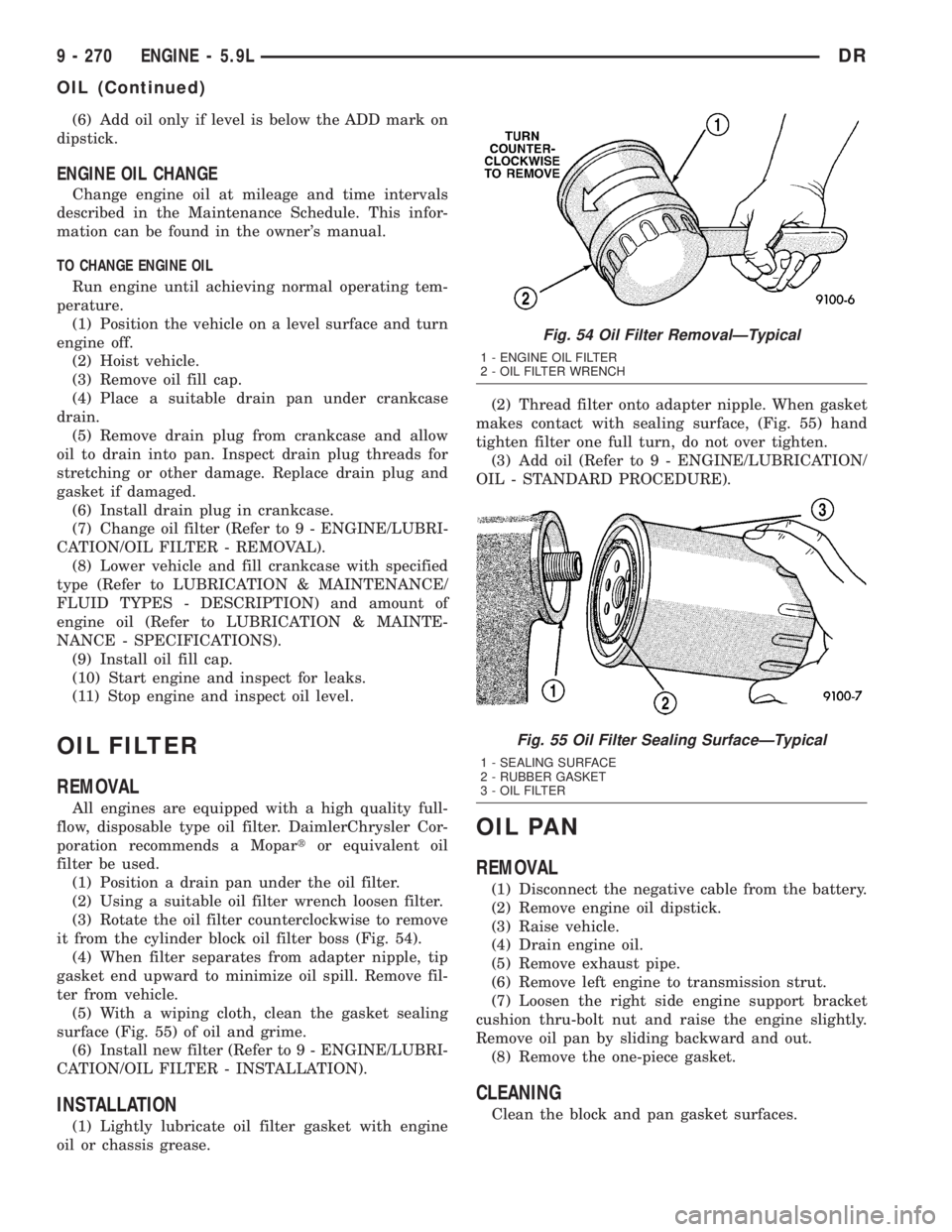

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 54).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 55) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 55) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove exhaust pipe.

(6) Remove left engine to transmission strut.

(7) Loosen the right side engine support bracket

cushion thru-bolt nut and raise the engine slightly.

Remove oil pan by sliding backward and out.

(8) Remove the one-piece gasket.

CLEANING

Clean the block and pan gasket surfaces.

Fig. 54 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 55 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

9 - 270 ENGINE - 5.9LDR

OIL (Continued)

Page 1531 of 2895

ENGINE 5.9L DIESEL

DESCRIPTION

The cylinder block is constructed of cast iron. The

casting is a skirted design which incorporates longi-

tudal ribs for superior strength and noise reduction.

The block incorporates metric straight thread o-ring

fittings at lubrication oil access points. The engine

(Fig. 1) is manufactured with the cylinders being a

non-sleeved type cylinder. However, one approved

service method is to bore out the cylinders and add

cylinder sleeves to the cylinder block.

The cylinders are numbered front to rear (Fig. 2); 1

to 6. The firing order is 1±5±3±6±2±4.

Fig. 1 CumminsT24-Valve Turbo-Diesel Engine

Fig. 2 Cylinder Numbering

9 - 282 ENGINE 5.9L DIESELDR