oil type DODGE RAM 2003 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1708 of 2895

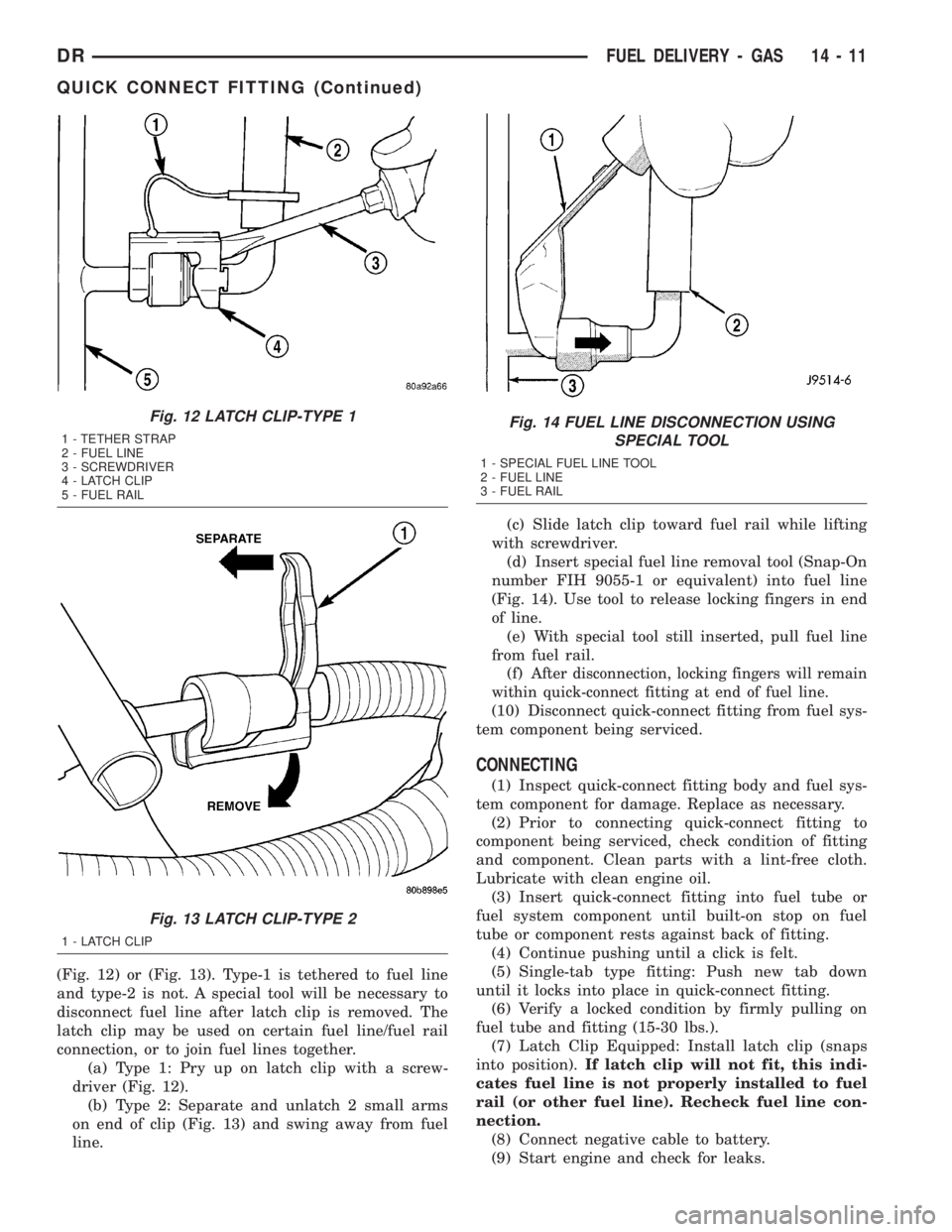

(Fig. 12) or (Fig. 13). Type-1 is tethered to fuel line

and type-2 is not. A special tool will be necessary to

disconnect fuel line after latch clip is removed. The

latch clip may be used on certain fuel line/fuel rail

connection, or to join fuel lines together.

(a) Type 1: Pry up on latch clip with a screw-

driver (Fig. 12).

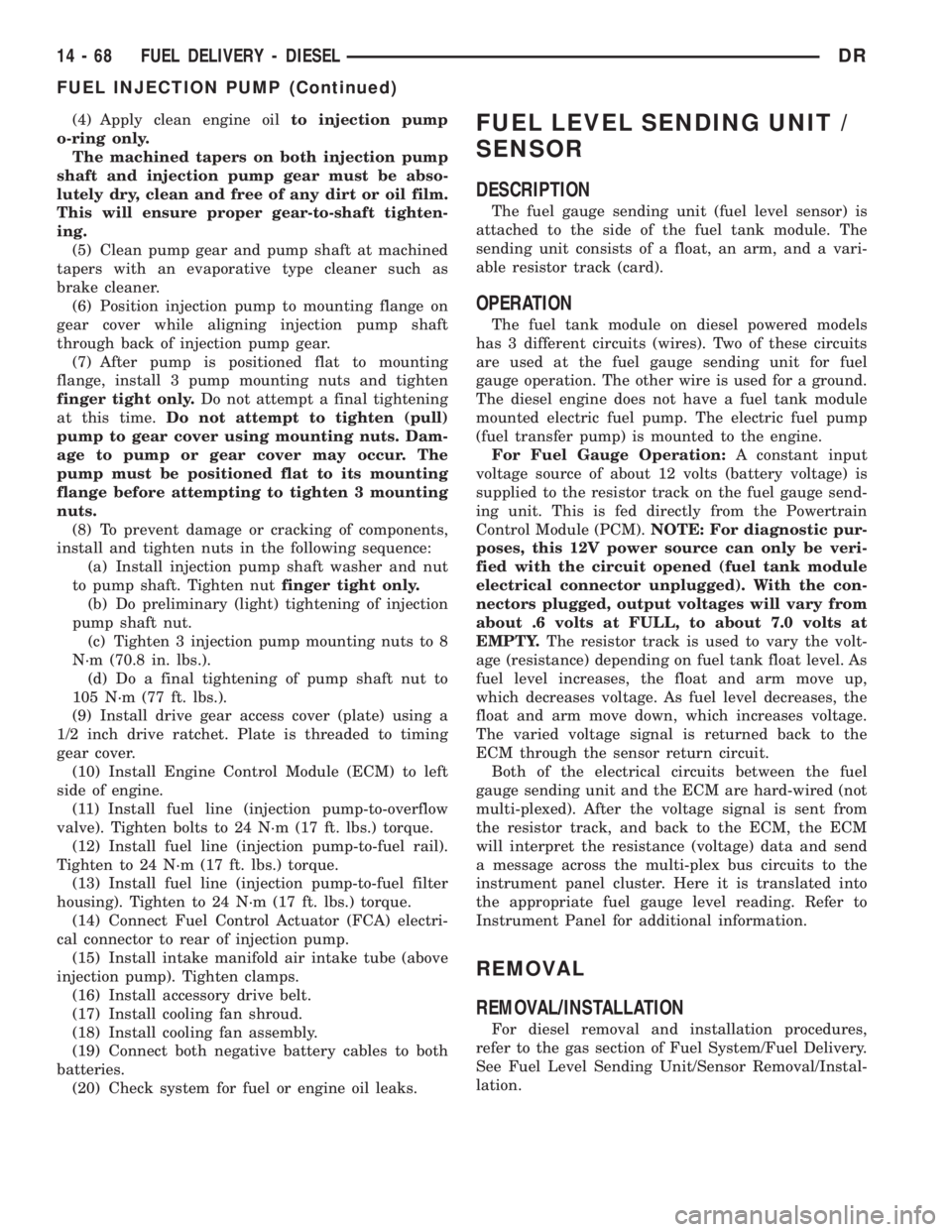

(b) Type 2: Separate and unlatch 2 small arms

on end of clip (Fig. 13) and swing away from fuel

line.(c) Slide latch clip toward fuel rail while lifting

with screwdriver.

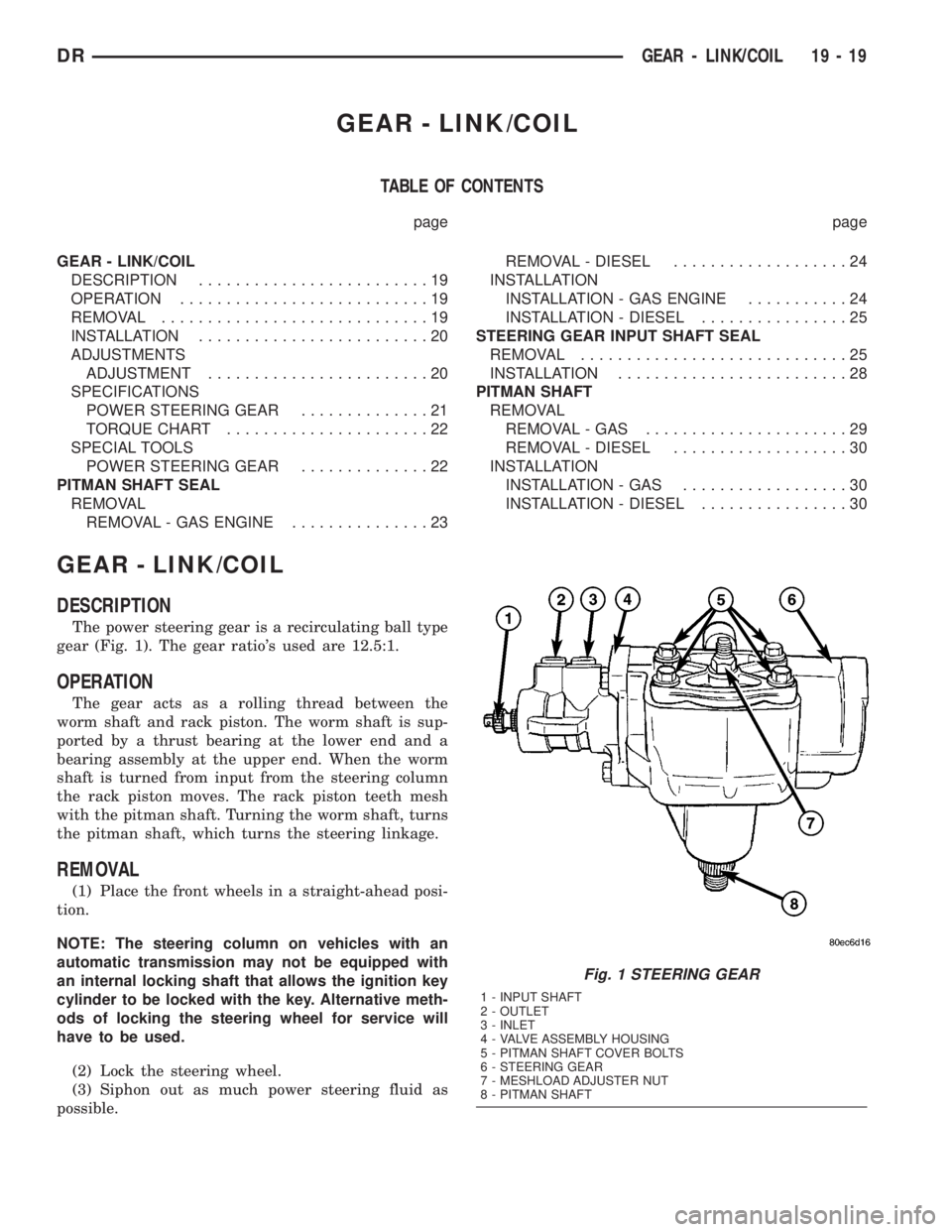

(d) Insert special fuel line removal tool (Snap-On

number FIH 9055-1 or equivalent) into fuel line

(Fig. 14). Use tool to release locking fingers in end

of line.

(e) With special tool still inserted, pull fuel line

from fuel rail.

(f)

After disconnection, locking fingers will remain

within quick-connect fitting at end of fuel line.

(10) Disconnect quick-connect fitting from fuel sys-

tem component being serviced.

CONNECTING

(1) Inspect quick-connect fitting body and fuel sys-

tem component for damage. Replace as necessary.

(2) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(3) Insert quick-connect fitting into fuel tube or

fuel system component until built-on stop on fuel

tube or component rests against back of fitting.

(4) Continue pushing until a click is felt.

(5) Single-tab type fitting: Push new tab down

until it locks into place in quick-connect fitting.

(6) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(7) Latch Clip Equipped: Install latch clip (snaps

into position).If latch clip will not fit, this indi-

cates fuel line is not properly installed to fuel

rail (or other fuel line). Recheck fuel line con-

nection.

(8) Connect negative cable to battery.

(9) Start engine and check for leaks.

Fig. 12 LATCH CLIP-TYPE 1

1 - TETHER STRAP

2 - FUEL LINE

3 - SCREWDRIVER

4 - LATCH CLIP

5 - FUEL RAIL

Fig. 13 LATCH CLIP-TYPE 2

1 - LATCH CLIP

Fig. 14 FUEL LINE DISCONNECTION USING

SPECIAL TOOL

1 - SPECIAL FUEL LINE TOOL

2 - FUEL LINE

3 - FUEL RAIL

DRFUEL DELIVERY - GAS 14 - 11

QUICK CONNECT FITTING (Continued)

Page 1765 of 2895

(4) Apply clean engine oilto injection pump

o-ring only.

The machined tapers on both injection pump

shaft and injection pump gear must be abso-

lutely dry, clean and free of any dirt or oil film.

This will ensure proper gear-to-shaft tighten-

ing.

(5) Clean pump gear and pump shaft at machined

tapers with an evaporative type cleaner such as

brake cleaner.

(6) Position injection pump to mounting flange on

gear cover while aligning injection pump shaft

through back of injection pump gear.

(7) After pump is positioned flat to mounting

flange, install 3 pump mounting nuts and tighten

finger tight only.Do not attempt a final tightening

at this time.Do not attempt to tighten (pull)

pump to gear cover using mounting nuts. Dam-

age to pump or gear cover may occur. The

pump must be positioned flat to its mounting

flange before attempting to tighten 3 mounting

nuts.

(8) To prevent damage or cracking of components,

install and tighten nuts in the following sequence:

(a) Install injection pump shaft washer and nut

to pump shaft. Tighten nutfinger tight only.

(b) Do preliminary (light) tightening of injection

pump shaft nut.

(c) Tighten 3 injection pump mounting nuts to 8

N´m (70.8 in. lbs.).

(d) Do a final tightening of pump shaft nut to

105 N´m (77 ft. lbs.).

(9) Install drive gear access cover (plate) using a

1/2 inch drive ratchet. Plate is threaded to timing

gear cover.

(10) Install Engine Control Module (ECM) to left

side of engine.

(11) Install fuel line (injection pump-to-overflow

valve). Tighten bolts to 24 N´m (17 ft. lbs.) torque.

(12) Install fuel line (injection pump-to-fuel rail).

Tighten to 24 N´m (17 ft. lbs.) torque.

(13) Install fuel line (injection pump-to-fuel filter

housing). Tighten to 24 N´m (17 ft. lbs.) torque.

(14) Connect Fuel Control Actuator (FCA) electri-

cal connector to rear of injection pump.

(15) Install intake manifold air intake tube (above

injection pump). Tighten clamps.

(16) Install accessory drive belt.

(17) Install cooling fan shroud.

(18) Install cooling fan assembly.

(19) Connect both negative battery cables to both

batteries.

(20) Check system for fuel or engine oil leaks.FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel tank module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel tank module on diesel powered models

has 3 different circuits (wires). Two of these circuits

are used at the fuel gauge sending unit for fuel

gauge operation. The other wire is used for a ground.

The diesel engine does not have a fuel tank module

mounted electric fuel pump. The electric fuel pump

(fuel transfer pump) is mounted to the engine.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Powertrain

Control Module (PCM).NOTE: For diagnostic pur-

poses, this 12V power source can only be veri-

fied with the circuit opened (fuel tank module

electrical connector unplugged). With the con-

nectors plugged, output voltages will vary from

about .6 volts at FULL, to about 7.0 volts at

EMPTY.The resistor track is used to vary the volt-

age (resistance) depending on fuel tank float level. As

fuel level increases, the float and arm move up,

which decreases voltage. As fuel level decreases, the

float and arm move down, which increases voltage.

The varied voltage signal is returned back to the

ECM through the sensor return circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the ECM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the ECM, the ECM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

REMOVAL

REMOVAL/INSTALLATION

For diesel removal and installation procedures,

refer to the gas section of Fuel System/Fuel Delivery.

See Fuel Level Sending Unit/Sensor Removal/Instal-

lation.

14 - 68 FUEL DELIVERY - DIESELDR

FUEL INJECTION PUMP (Continued)

Page 1812 of 2895

GEAR - LINK/COIL

TABLE OF CONTENTS

page page

GEAR - LINK/COIL

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................19

INSTALLATION.........................20

ADJUSTMENTS

ADJUSTMENT........................20

SPECIFICATIONS

POWER STEERING GEAR..............21

TORQUE CHART......................22

SPECIAL TOOLS

POWER STEERING GEAR..............22

PITMAN SHAFT SEAL

REMOVAL

REMOVAL - GAS ENGINE...............23REMOVAL - DIESEL...................24

INSTALLATION

INSTALLATION - GAS ENGINE...........24

INSTALLATION - DIESEL................25

STEERING GEAR INPUT SHAFT SEAL

REMOVAL.............................25

INSTALLATION.........................28

PITMAN SHAFT

REMOVAL

REMOVAL - GAS......................29

REMOVAL - DIESEL...................30

INSTALLATION

INSTALLATION - GAS..................30

INSTALLATION - DIESEL................30

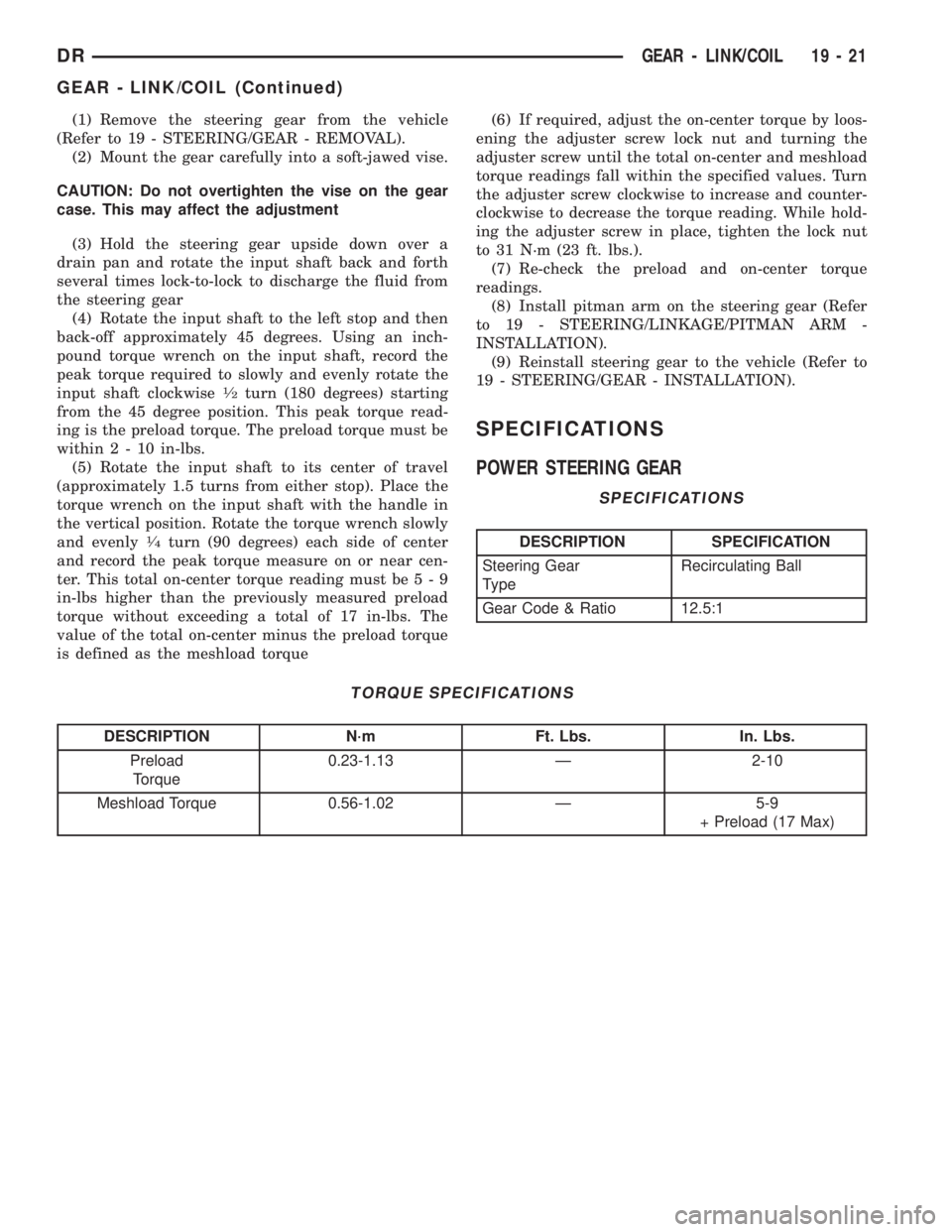

GEAR - LINK/COIL

DESCRIPTION

The power steering gear is a recirculating ball type

gear (Fig. 1). The gear ratio's used are 12.5:1.

OPERATION

The gear acts as a rolling thread between the

worm shaft and rack piston. The worm shaft is sup-

ported by a thrust bearing at the lower end and a

bearing assembly at the upper end. When the worm

shaft is turned from input from the steering column

the rack piston moves. The rack piston teeth mesh

with the pitman shaft. Turning the worm shaft, turns

the pitman shaft, which turns the steering linkage.

REMOVAL

(1) Place the front wheels in a straight-ahead posi-

tion.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.

(2) Lock the steering wheel.

(3) Siphon out as much power steering fluid as

possible.

Fig. 1 STEERING GEAR

1 - INPUT SHAFT

2 - OUTLET

3 - INLET

4 - VALVE ASSEMBLY HOUSING

5 - PITMAN SHAFT COVER BOLTS

6 - STEERING GEAR

7 - MESHLOAD ADJUSTER NUT

8 - PITMAN SHAFT

DRGEAR - LINK/COIL 19 - 19

Page 1814 of 2895

(1) Remove the steering gear from the vehicle

(Refer to 19 - STEERING/GEAR - REMOVAL).

(2) Mount the gear carefully into a soft-jawed vise.

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(3) Hold the steering gear upside down over a

drain pan and rotate the input shaft back and forth

several times lock-to-lock to discharge the fluid from

the steering gear

(4) Rotate the input shaft to the left stop and then

back-off approximately 45 degrees. Using an inch-

pound torque wrench on the input shaft, record the

peak torque required to slowly and evenly rotate the

input shaft clockwise

1¤2turn (180 degrees) starting

from the 45 degree position. This peak torque read-

ing is the preload torque. The preload torque must be

within2-10in-lbs.

(5) Rotate the input shaft to its center of travel

(approximately 1.5 turns from either stop). Place the

torque wrench on the input shaft with the handle in

the vertical position. Rotate the torque wrench slowly

and evenly

1¤4turn (90 degrees) each side of center

and record the peak torque measure on or near cen-

ter. This total on-center torque reading must be5-9

in-lbs higher than the previously measured preload

torque without exceeding a total of 17 in-lbs. The

value of the total on-center minus the preload torque

is defined as the meshload torque(6) If required, adjust the on-center torque by loos-

ening the adjuster screw lock nut and turning the

adjuster screw until the total on-center and meshload

torque readings fall within the specified values. Turn

the adjuster screw clockwise to increase and counter-

clockwise to decrease the torque reading. While hold-

ing the adjuster screw in place, tighten the lock nut

to 31 N´m (23 ft. lbs.).

(7) Re-check the preload and on-center torque

readings.

(8) Install pitman arm on the steering gear (Refer

to 19 - STEERING/LINKAGE/PITMAN ARM -

INSTALLATION).

(9) Reinstall steering gear to the vehicle (Refer to

19 - STEERING/GEAR - INSTALLATION).

SPECIFICATIONS

POWER STEERING GEAR

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Steering Gear

TypeRecirculating Ball

Gear Code & Ratio 12.5:1

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Preload

Torque0.23-1.13 Ð 2-10

Meshload Torque 0.56-1.02 Ð 5-9

+ Preload (17 Max)

DRGEAR - LINK/COIL 19 - 21

GEAR - LINK/COIL (Continued)

Page 1831 of 2895

PUMP

TABLE OF CONTENTS

page page

PUMP

DESCRIPTION.........................38

OPERATION...........................38

DIAGNOSIS AND TESTING - PUMP LEAKAGE . 39

STANDARD PROCEDURE

STANDARD PROCEDURE - POWER

STEERING PUMP - INITIAL OPERATION....39

STANDARD PROCEDURE - FLUSHING

POWER STEERING SYSTEM............39

REMOVAL

REMOVAL - GAS......................40

REMOVAL - DIESEL...................40

INSTALLATION

INSTALLATION - GAS..................41

INSTALLATION - DIESEL................41

SPECIFICATIONS

TORQUE CHART......................41

FLUID

DESCRIPTION.........................42

STANDARD PROCEDURE - POWER

STEERING FLUID LEVEL CHECKING......42

FLUID COOLER

REMOVAL.............................42

INSTALLATION.........................42

HOSES - I.F.S.

REMOVAL

REMOVAL - RETURN HOSE - GEAR TO

COOLER............................43

REMOVAL - PRESSURE HOSE...........43

REMOVAL - RETURN HOSE - RESERVOIR

TO COOLER.........................43INSTALLATION

INSTALLATION - RETURN HOSE - GEAR TO

COOLER............................43

INSTALLATION - PRESSURE HOSE.......43

INSTALLATION - RETURN HOSE -

RESERVOIR TO COOLER...............43

HOSES - LINK/COIL

REMOVAL

REMOVAL - RETURN HOSE - GEAR TO

COOLER............................43

REMOVAL - PRESSURE HOSE...........44

REMOVAL - RETURN HOSE - RESERVOIR

TO COOLER.........................44

INSTALLATION

INSTALLATION - RETURN HOSE - GEAR TO

COOLER............................44

INSTALLATION - PRESSURE HOSE.......44

INSTALLATION - RETURN HOSE -

RESERVOIR TO COOLER...............44

POWER STEERING PRESSURE SWITCH

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL - 3.7L, 4.7L & 5.7L..............45

INSTALLATION - 3.7L, 4.7L & 5.7L..........45

PULLEY

REMOVAL.............................45

INSTALLATION.........................46

RESERVOIR

REMOVAL.............................46

INSTALLATION.........................46

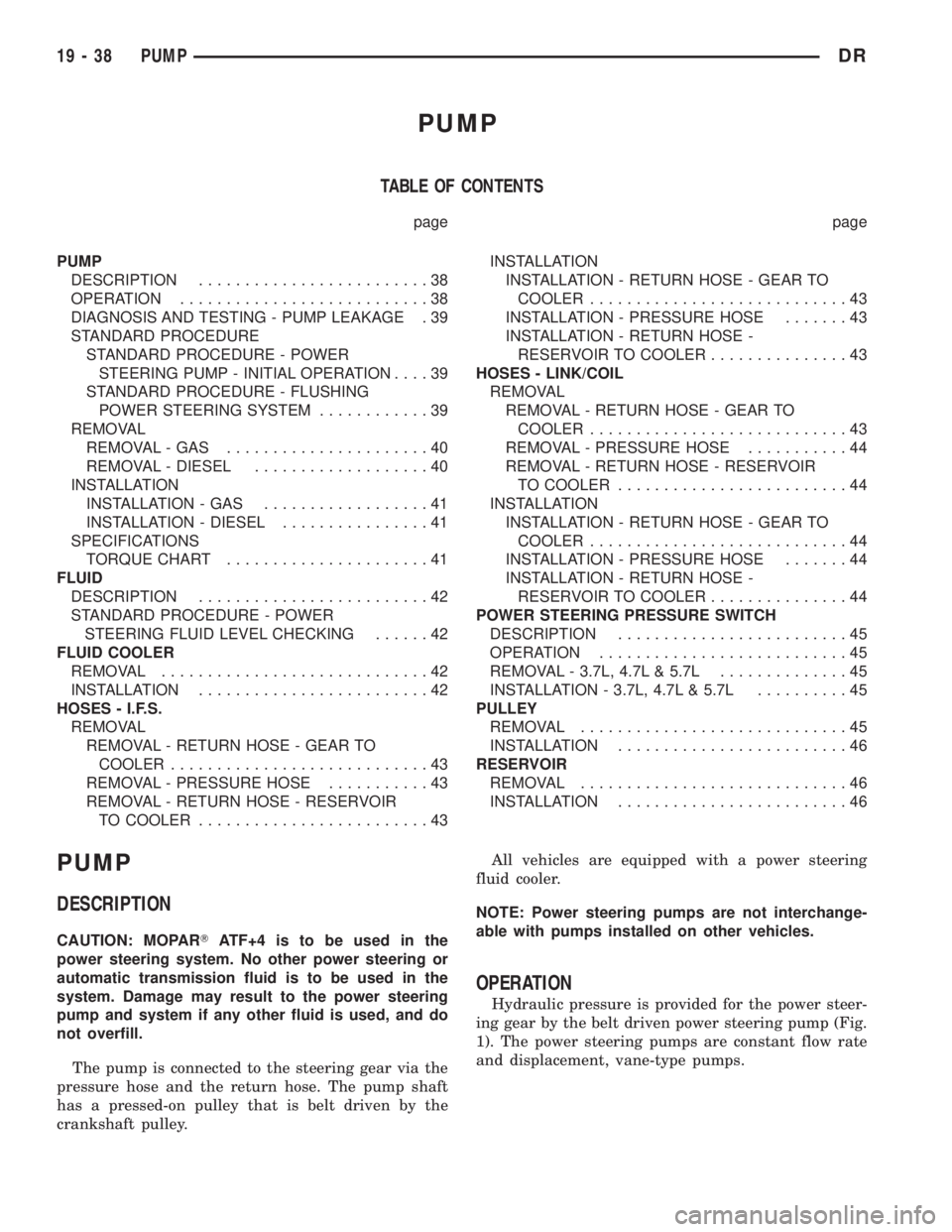

PUMP

DESCRIPTION

CAUTION: MOPARTATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

The pump is connected to the steering gear via the

pressure hose and the return hose. The pump shaft

has a pressed-on pulley that is belt driven by the

crankshaft pulley.All vehicles are equipped with a power steering

fluid cooler.

NOTE: Power steering pumps are not interchange-

able with pumps installed on other vehicles.

OPERATION

Hydraulic pressure is provided for the power steer-

ing gear by the belt driven power steering pump (Fig.

1). The power steering pumps are constant flow rate

and displacement, vane-type pumps.

19 - 38 PUMPDR

Page 1832 of 2895

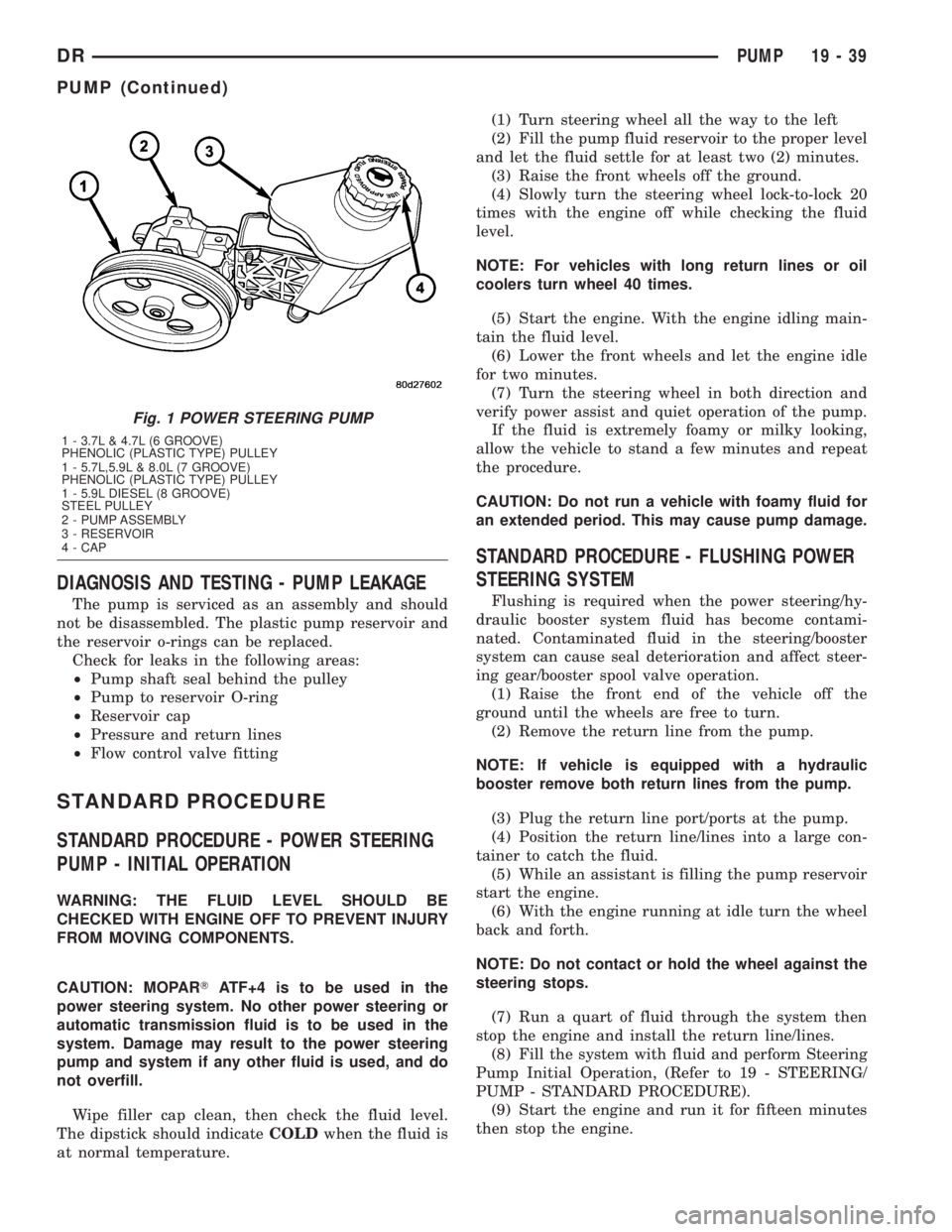

DIAGNOSIS AND TESTING - PUMP LEAKAGE

The pump is serviced as an assembly and should

not be disassembled. The plastic pump reservoir and

the reservoir o-rings can be replaced.

Check for leaks in the following areas:

²Pump shaft seal behind the pulley

²Pump to reservoir O-ring

²Reservoir cap

²Pressure and return lines

²Flow control valve fitting

STANDARD PROCEDURE

STANDARD PROCEDURE - POWER STEERING

PUMP - INITIAL OPERATION

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: MOPARTATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature.(1) Turn steering wheel all the way to the left

(2) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes.

(3) Raise the front wheels off the ground.

(4) Slowly turn the steering wheel lock-to-lock 20

times with the engine off while checking the fluid

level.

NOTE: For vehicles with long return lines or oil

coolers turn wheel 40 times.

(5) Start the engine. With the engine idling main-

tain the fluid level.

(6) Lower the front wheels and let the engine idle

for two minutes.

(7) Turn the steering wheel in both direction and

verify power assist and quiet operation of the pump.

If the fluid is extremely foamy or milky looking,

allow the vehicle to stand a few minutes and repeat

the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

STANDARD PROCEDURE - FLUSHING POWER

STEERING SYSTEM

Flushing is required when the power steering/hy-

draulic booster system fluid has become contami-

nated. Contaminated fluid in the steering/booster

system can cause seal deterioration and affect steer-

ing gear/booster spool valve operation.

(1) Raise the front end of the vehicle off the

ground until the wheels are free to turn.

(2) Remove the return line from the pump.

NOTE: If vehicle is equipped with a hydraulic

booster remove both return lines from the pump.

(3) Plug the return line port/ports at the pump.

(4) Position the return line/lines into a large con-

tainer to catch the fluid.

(5) While an assistant is filling the pump reservoir

start the engine.

(6) With the engine running at idle turn the wheel

back and forth.

NOTE: Do not contact or hold the wheel against the

steering stops.

(7) Run a quart of fluid through the system then

stop the engine and install the return line/lines.

(8) Fill the system with fluid and perform Steering

Pump Initial Operation, (Refer to 19 - STEERING/

PUMP - STANDARD PROCEDURE).

(9) Start the engine and run it for fifteen minutes

then stop the engine.

Fig. 1 POWER STEERING PUMP

1 - 3.7L & 4.7L (6 GROOVE)

PHENOLIC (PLASTIC TYPE) PULLEY

1 - 5.7L,5.9L & 8.0L (7 GROOVE)

PHENOLIC (PLASTIC TYPE) PULLEY

1 - 5.9L DIESEL (8 GROOVE)

STEEL PULLEY

2 - PUMP ASSEMBLY

3 - RESERVOIR

4 - CAP

DRPUMP 19 - 39

PUMP (Continued)

Page 2004 of 2895

NOTE: Do not use shop towels or rags to dry the

case (or any other transmission component) unless

they are made from lint-free materials. Lint will stick

to case surfaces and transmission components and

circulate throughout the transmission after assem-

bly. A sufficient quantity of lint can block fluid pas-

sages and interfere with valve body operation.

Lubricate transmission parts with MopartATF +4,

Automatic Transmission fluid during overhaul and

assembly. Use petroleum jelly to prelubricate seals,

O-rings, and thrust washers. Petroleum jelly can also

be used to hold parts in place during reassembly.

INSPECTION

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Inspect the transmission bushings during overhaul.

Bushing condition is important as worn, scored bush-

ings contribute to low pressures, clutch slip and

accelerated wear of other components. However, do

not replace bushings as a matter of course. Replace

bushings only when they are actually worn, or

scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install, and

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B.Pre-sized service bushings are available for

replacement purposes. Only the sun gear bushings

are not serviced.

The use of crocus cloth is permissible where neces-

sary, providing it is used carefully. When used on

shafts, or valves, use extreme care to avoid rounding

off sharp edges. Sharp edges are vital as they pre-

vent foreign matter from getting between the valve

and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts

as well.

ASSEMBLY

Do not allow dirt, grease, or foreign material to

enter the case or transmission components during

assembly. Keep the transmission case and compo-

nents clean. Also make sure the tools and workbench

area used for reassembly operations are equally

clean.

Shop towels used for wiping off tools and your

hands must be made fromlint freematerials. Lint

will stick to transmission parts and could interfere

with valve operation or even restrict fluid passages.

Lubricate transmission clutch and gear compo-

nents with MopartATF +4, Automatic Transmission

fluid, during reassembly. Soak clutch discs in trans-

mission fluid before installation.

Use MopartDoor Ease, or Ru-GlydeŸ on piston

seals and O-rings to ease installation. Petroleum jelly

can also be used to lubricate and hold thrust washers

and plates in position during assembly.

Do not use chassis grease, bearing grease,

white grease, or similar lubricants on any part.

These types of lubricants can eventually block or

restrict fluid passages and valve operation. Use

petroleum jelly only.

Do not force parts into place. The transmission

components and sub-assemblies are easily installed

by hand when properly aligned. If a part seems dif-

ficult to install, it is either misaligned or incorrectly

assembled. Verify that thrust washers, thrust plates

and seal rings are correctly positioned.

The planetary geartrain, front/rear clutch assem-

blies and oil pump are all much easier to install

when the transmission case is upright. Either tilt the

case upward with wood blocks, or cut a hole in the

bench large enough for the intermediate shaft and

rear support. Then lower the shaft and support into

the hole and support the rear of the case directly on

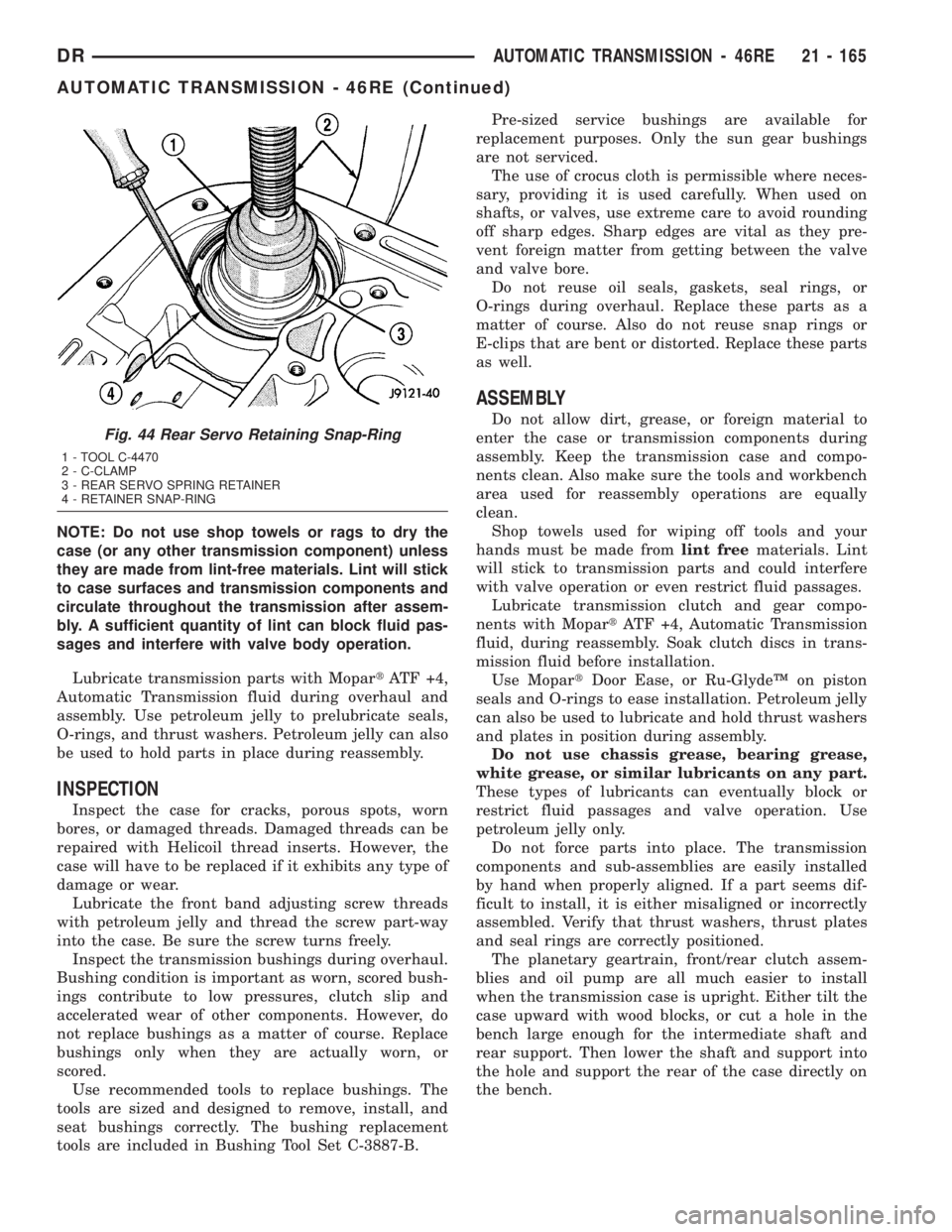

the bench.Fig. 44 Rear Servo Retaining Snap-Ring

1 - TOOL C-4470

2 - C-CLAMP

3 - REAR SERVO SPRING RETAINER

4 - RETAINER SNAP-RING

DRAUTOMATIC TRANSMISSION - 46RE 21 - 165

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2032 of 2895

BANDS

DESCRIPTION

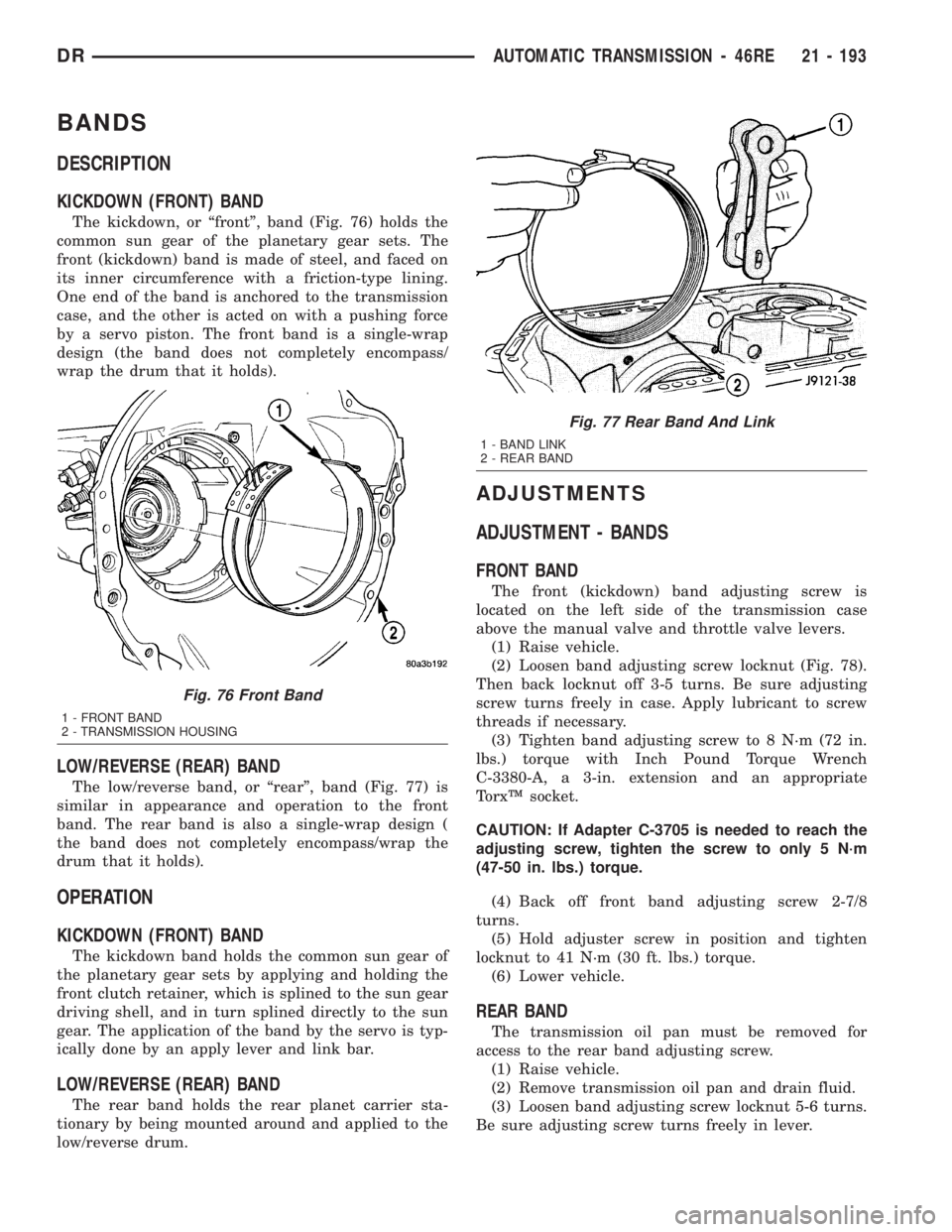

KICKDOWN (FRONT) BAND

The kickdown, or ªfrontº, band (Fig. 76) holds the

common sun gear of the planetary gear sets. The

front (kickdown) band is made of steel, and faced on

its inner circumference with a friction-type lining.

One end of the band is anchored to the transmission

case, and the other is acted on with a pushing force

by a servo piston. The front band is a single-wrap

design (the band does not completely encompass/

wrap the drum that it holds).

LOW/REVERSE (REAR) BAND

The low/reverse band, or ªrearº, band (Fig. 77) is

similar in appearance and operation to the front

band. The rear band is also a single-wrap design (

the band does not completely encompass/wrap the

drum that it holds).

OPERATION

KICKDOWN (FRONT) BAND

The kickdown band holds the common sun gear of

the planetary gear sets by applying and holding the

front clutch retainer, which is splined to the sun gear

driving shell, and in turn splined directly to the sun

gear. The application of the band by the servo is typ-

ically done by an apply lever and link bar.

LOW/REVERSE (REAR) BAND

The rear band holds the rear planet carrier sta-

tionary by being mounted around and applied to the

low/reverse drum.

ADJUSTMENTS

ADJUSTMENT - BANDS

FRONT BAND

The front (kickdown) band adjusting screw is

located on the left side of the transmission case

above the manual valve and throttle valve levers.

(1) Raise vehicle.

(2) Loosen band adjusting screw locknut (Fig. 78).

Then back locknut off 3-5 turns. Be sure adjusting

screw turns freely in case. Apply lubricant to screw

threads if necessary.

(3) Tighten band adjusting screw to 8 N´m (72 in.

lbs.) torque with Inch Pound Torque Wrench

C-3380-A, a 3-in. extension and an appropriate

TorxŸ socket.

CAUTION: If Adapter C-3705 is needed to reach the

adjusting screw, tighten the screw to only 5 N´m

(47-50 in. lbs.) torque.

(4) Back off front band adjusting screw 2-7/8

turns.

(5) Hold adjuster screw in position and tighten

locknut to 41 N´m (30 ft. lbs.) torque.

(6) Lower vehicle.

REAR BAND

The transmission oil pan must be removed for

access to the rear band adjusting screw.

(1) Raise vehicle.

(2) Remove transmission oil pan and drain fluid.

(3) Loosen band adjusting screw locknut 5-6 turns.

Be sure adjusting screw turns freely in lever.

Fig. 76 Front Band

1 - FRONT BAND

2 - TRANSMISSION HOUSING

Fig. 77 Rear Band And Link

1 - BAND LINK

2 - REAR BAND

DRAUTOMATIC TRANSMISSION - 46RE 21 - 193

Page 2040 of 2895

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has two primary causes.

(1) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(2) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failuredue to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The torque converter should be replaced whenever

a failure generates sludge and debris. This is neces-

sary because normal converter flushing procedures

will not remove all contaminants.

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

Fluid level is checked with the engine running at

curb idle speed, the transmission in NEUTRAL and

the transmission fluid at normal operating tempera-

ture.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.

The transmission fluid level can be checked two

ways.

PROCEDURE ONE

(1) Transmission fluid must be at normal operat-

ing temperature for accurate fluid level check. Drive

DRAUTOMATIC TRANSMISSION - 46RE 21 - 201

Page 2137 of 2895

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if either

part has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, thefilter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

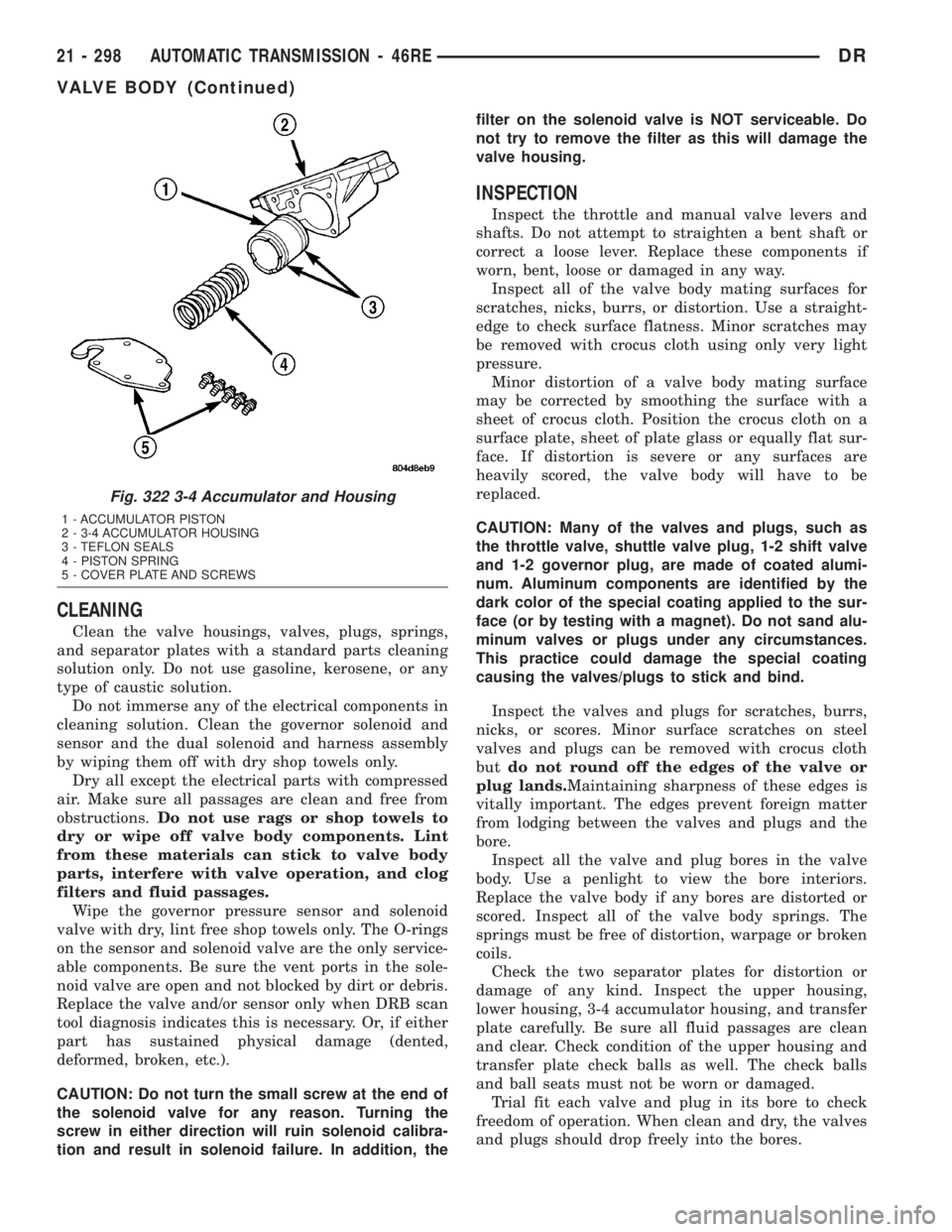

Fig. 322 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 298 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)