frame DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1836 of 2895

HOSES - I.F.S.

REMOVAL

REMOVAL - RETURN HOSE - GEAR TO

COOLER

(1) Drain and siphon the power steering system.

(2) Raise and support the vehicle.

(3) Disconnect the return hose at the cooler.

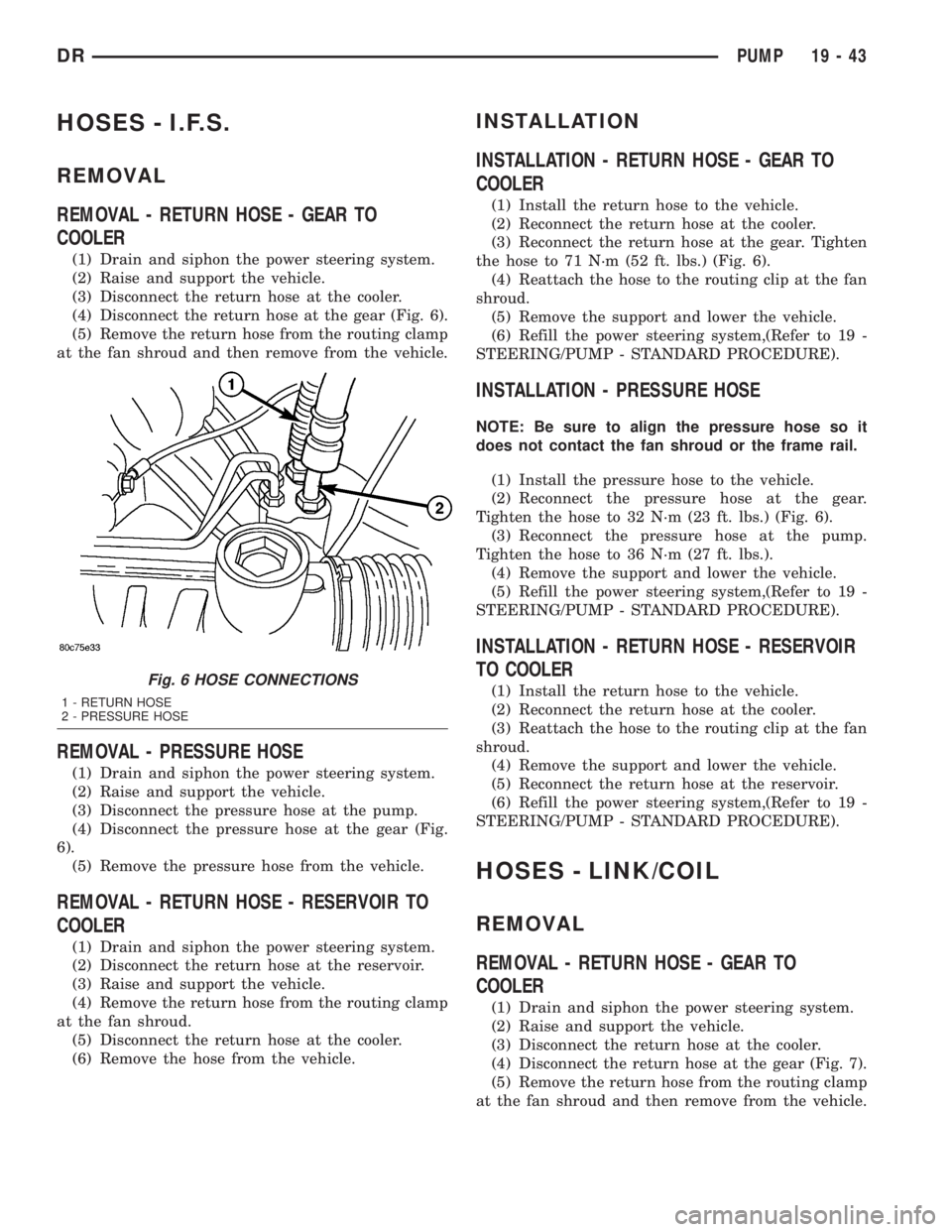

(4) Disconnect the return hose at the gear (Fig. 6).

(5) Remove the return hose from the routing clamp

at the fan shroud and then remove from the vehicle.

REMOVAL - PRESSURE HOSE

(1) Drain and siphon the power steering system.

(2) Raise and support the vehicle.

(3) Disconnect the pressure hose at the pump.

(4) Disconnect the pressure hose at the gear (Fig.

6).

(5) Remove the pressure hose from the vehicle.

REMOVAL - RETURN HOSE - RESERVOIR TO

COOLER

(1) Drain and siphon the power steering system.

(2) Disconnect the return hose at the reservoir.

(3) Raise and support the vehicle.

(4) Remove the return hose from the routing clamp

at the fan shroud.

(5) Disconnect the return hose at the cooler.

(6) Remove the hose from the vehicle.

INSTALLATION

INSTALLATION - RETURN HOSE - GEAR TO

COOLER

(1) Install the return hose to the vehicle.

(2) Reconnect the return hose at the cooler.

(3) Reconnect the return hose at the gear. Tighten

the hose to 71 N´m (52 ft. lbs.) (Fig. 6).

(4) Reattach the hose to the routing clip at the fan

shroud.

(5) Remove the support and lower the vehicle.

(6) Refill the power steering system,(Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - PRESSURE HOSE

NOTE: Be sure to align the pressure hose so it

does not contact the fan shroud or the frame rail.

(1) Install the pressure hose to the vehicle.

(2) Reconnect the pressure hose at the gear.

Tighten the hose to 32 N´m (23 ft. lbs.) (Fig. 6).

(3) Reconnect the pressure hose at the pump.

Tighten the hose to 36 N´m (27 ft. lbs.).

(4) Remove the support and lower the vehicle.

(5) Refill the power steering system,(Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - RETURN HOSE - RESERVOIR

TO COOLER

(1) Install the return hose to the vehicle.

(2) Reconnect the return hose at the cooler.

(3) Reattach the hose to the routing clip at the fan

shroud.

(4) Remove the support and lower the vehicle.

(5) Reconnect the return hose at the reservoir.

(6) Refill the power steering system,(Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

HOSES - LINK/COIL

REMOVAL

REMOVAL - RETURN HOSE - GEAR TO

COOLER

(1) Drain and siphon the power steering system.

(2) Raise and support the vehicle.

(3) Disconnect the return hose at the cooler.

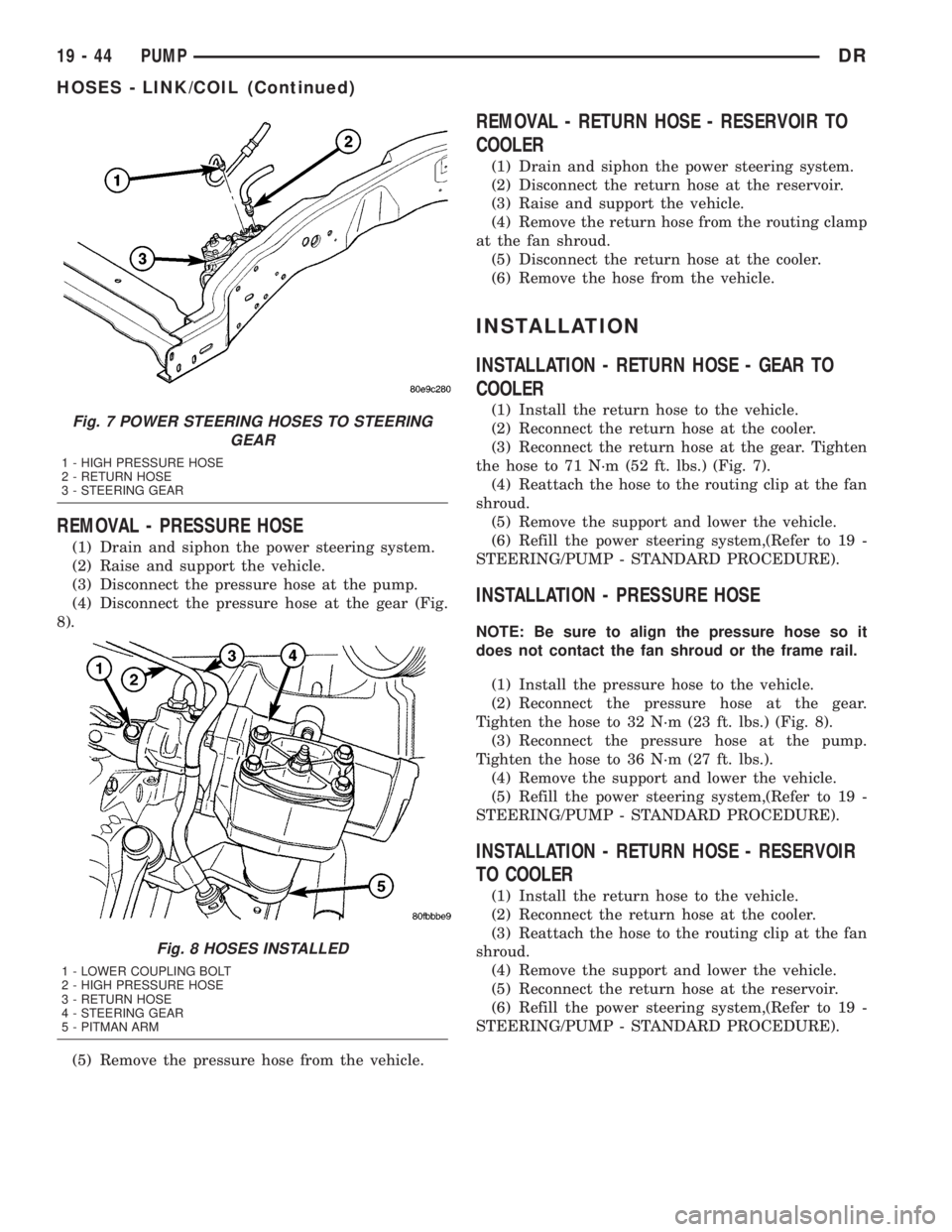

(4) Disconnect the return hose at the gear (Fig. 7).

(5) Remove the return hose from the routing clamp

at the fan shroud and then remove from the vehicle.

Fig. 6 HOSE CONNECTIONS

1 - RETURN HOSE

2 - PRESSURE HOSE

DRPUMP 19 - 43

Page 1837 of 2895

REMOVAL - PRESSURE HOSE

(1) Drain and siphon the power steering system.

(2) Raise and support the vehicle.

(3) Disconnect the pressure hose at the pump.

(4) Disconnect the pressure hose at the gear (Fig.

8).

(5) Remove the pressure hose from the vehicle.

REMOVAL - RETURN HOSE - RESERVOIR TO

COOLER

(1) Drain and siphon the power steering system.

(2) Disconnect the return hose at the reservoir.

(3) Raise and support the vehicle.

(4) Remove the return hose from the routing clamp

at the fan shroud.

(5) Disconnect the return hose at the cooler.

(6) Remove the hose from the vehicle.

INSTALLATION

INSTALLATION - RETURN HOSE - GEAR TO

COOLER

(1) Install the return hose to the vehicle.

(2) Reconnect the return hose at the cooler.

(3) Reconnect the return hose at the gear. Tighten

the hose to 71 N´m (52 ft. lbs.) (Fig. 7).

(4) Reattach the hose to the routing clip at the fan

shroud.

(5) Remove the support and lower the vehicle.

(6) Refill the power steering system,(Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - PRESSURE HOSE

NOTE: Be sure to align the pressure hose so it

does not contact the fan shroud or the frame rail.

(1) Install the pressure hose to the vehicle.

(2) Reconnect the pressure hose at the gear.

Tighten the hose to 32 N´m (23 ft. lbs.) (Fig. 8).

(3) Reconnect the pressure hose at the pump.

Tighten the hose to 36 N´m (27 ft. lbs.).

(4) Remove the support and lower the vehicle.

(5) Refill the power steering system,(Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - RETURN HOSE - RESERVOIR

TO COOLER

(1) Install the return hose to the vehicle.

(2) Reconnect the return hose at the cooler.

(3) Reattach the hose to the routing clip at the fan

shroud.

(4) Remove the support and lower the vehicle.

(5) Reconnect the return hose at the reservoir.

(6) Refill the power steering system,(Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

Fig. 7 POWER STEERING HOSES TO STEERING

GEAR

1 - HIGH PRESSURE HOSE

2 - RETURN HOSE

3 - STEERING GEAR

Fig. 8 HOSES INSTALLED

1 - LOWER COUPLING BOLT

2 - HIGH PRESSURE HOSE

3 - RETURN HOSE

4 - STEERING GEAR

5 - PITMAN ARM

19 - 44 PUMPDR

HOSES - LINK/COIL (Continued)

Page 1995 of 2895

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

NOTE: The overdrive unit can be removed and ser-

viced separately. It is not necessary to remove the

entire transmission assembly to perform overdrive

unit repairs.

(1) Disconnect battery negative cable.

(2) Raise vehicle.

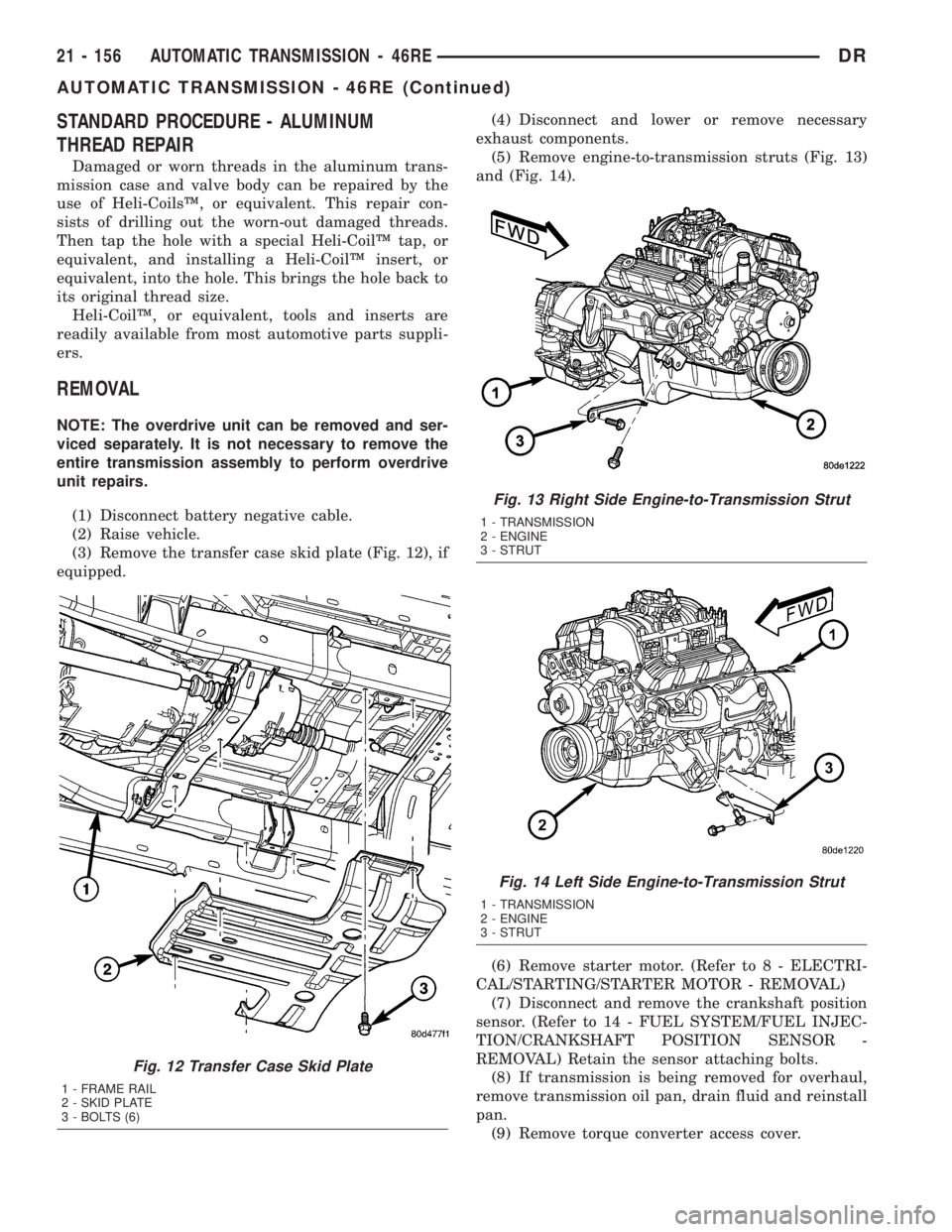

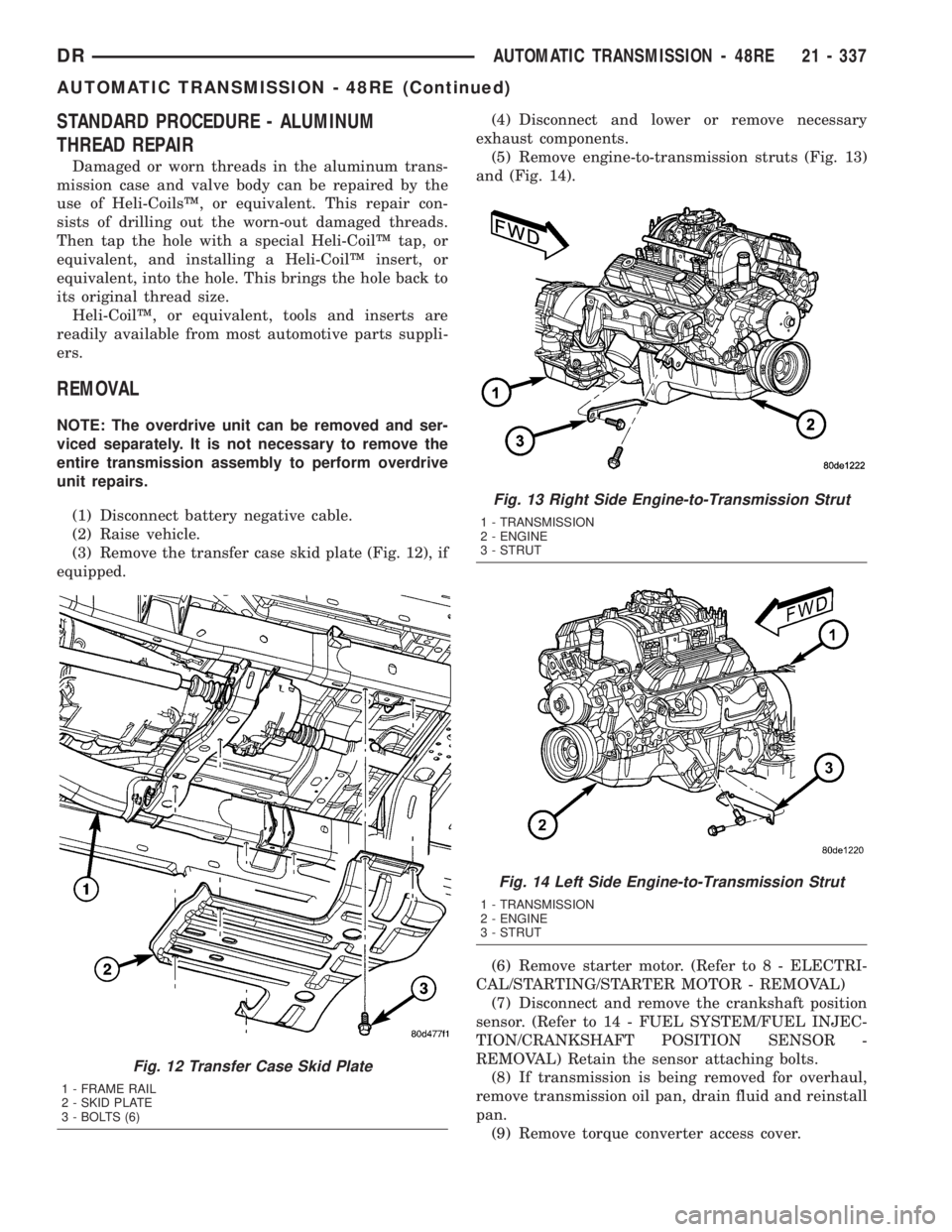

(3) Remove the transfer case skid plate (Fig. 12), if

equipped.(4) Disconnect and lower or remove necessary

exhaust components.

(5) Remove engine-to-transmission struts (Fig. 13)

and (Fig. 14).

(6) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(7) Disconnect and remove the crankshaft position

sensor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain the sensor attaching bolts.

(8) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

(9) Remove torque converter access cover.

Fig. 12 Transfer Case Skid Plate

1 - FRAME RAIL

2 - SKID PLATE

3 - BOLTS (6)

Fig. 13 Right Side Engine-to-Transmission Strut

1 - TRANSMISSION

2 - ENGINE

3 - STRUT

Fig. 14 Left Side Engine-to-Transmission Strut

1 - TRANSMISSION

2 - ENGINE

3 - STRUT

21 - 156 AUTOMATIC TRANSMISSION - 46REDR

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1996 of 2895

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(12) Disconnect wires from the transmission range

sensor and transmission solenoid connector.

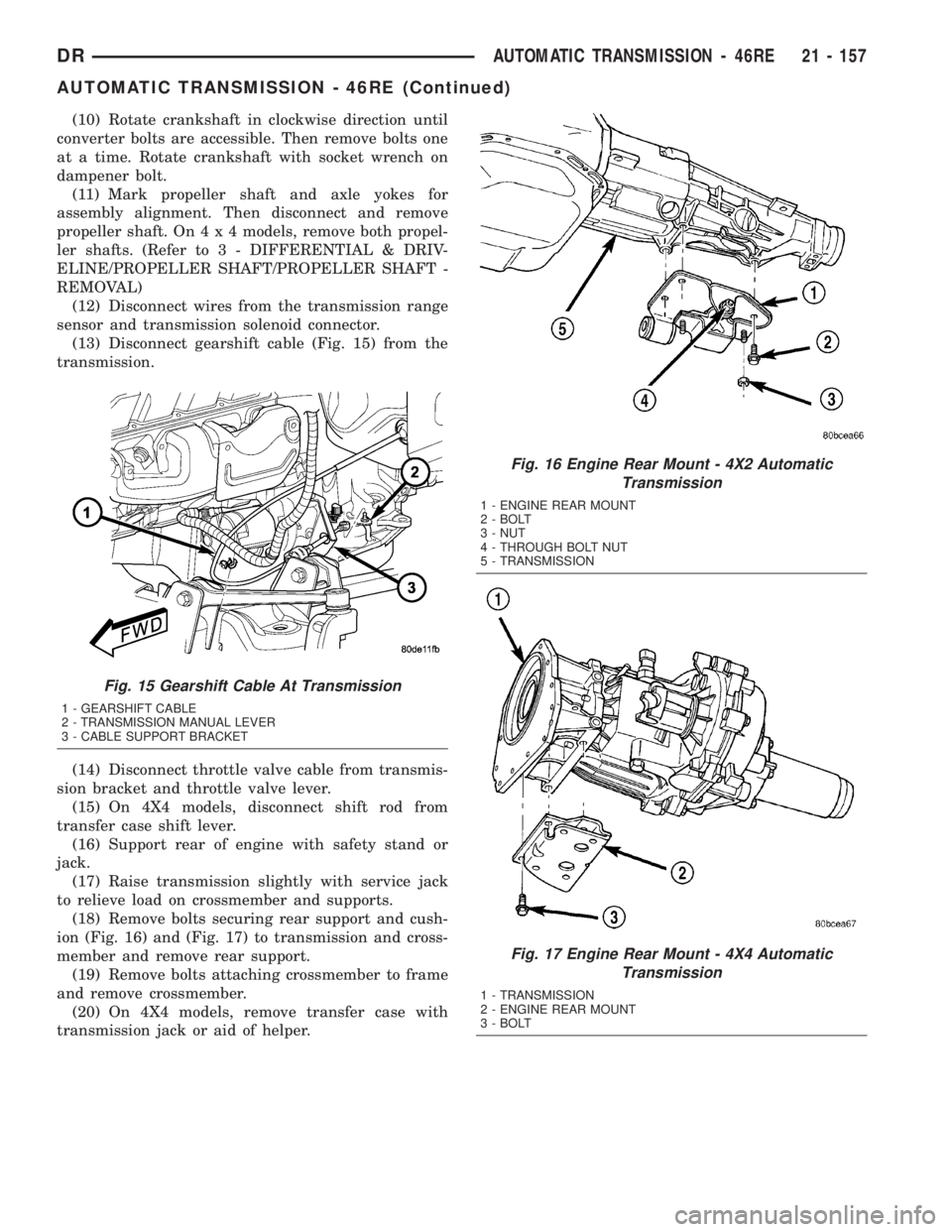

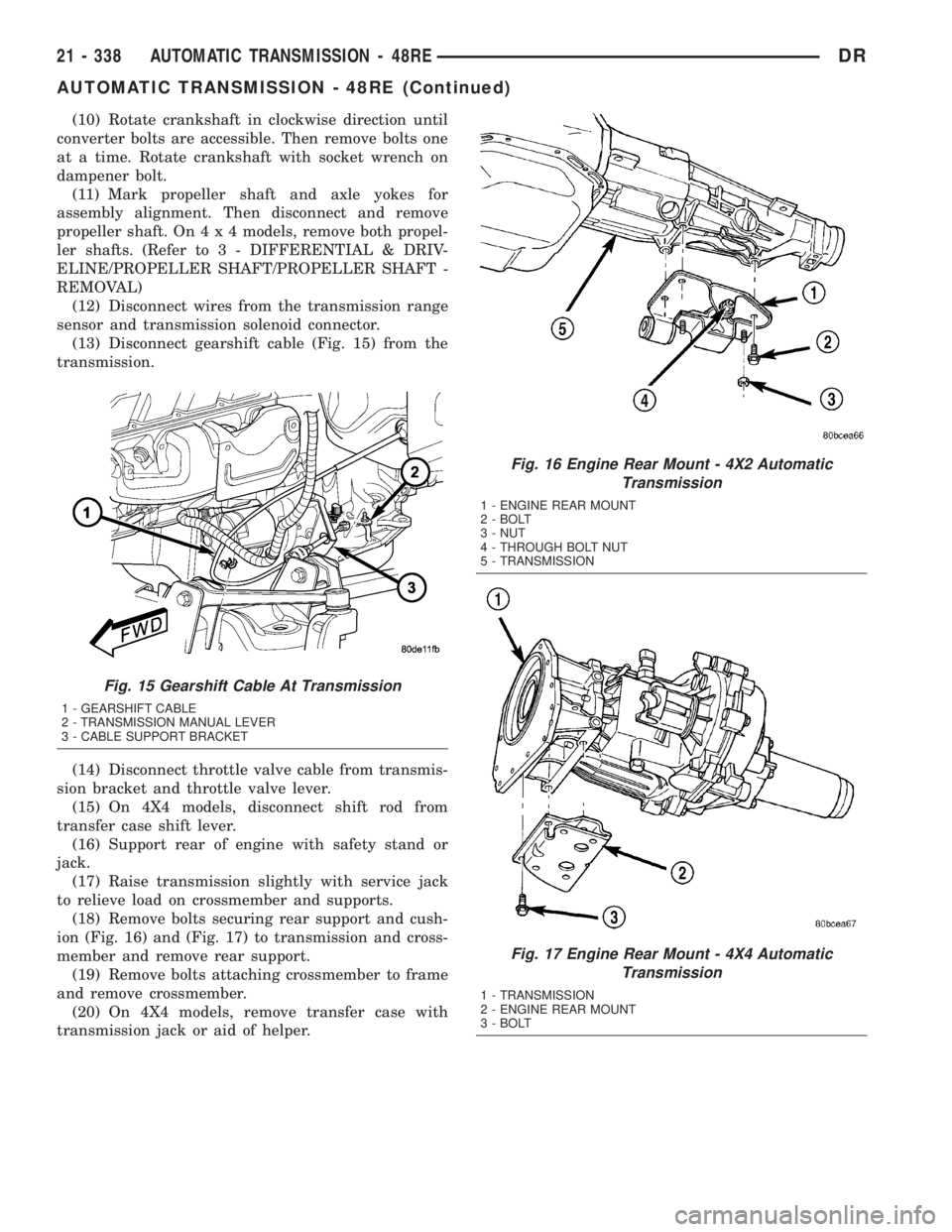

(13) Disconnect gearshift cable (Fig. 15) from the

transmission.

(14) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever.

(15) On 4X4 models, disconnect shift rod from

transfer case shift lever.

(16) Support rear of engine with safety stand or

jack.

(17) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

(18) Remove bolts securing rear support and cush-

ion (Fig. 16) and (Fig. 17) to transmission and cross-

member and remove rear support.

(19) Remove bolts attaching crossmember to frame

and remove crossmember.

(20) On 4X4 models, remove transfer case with

transmission jack or aid of helper.

Fig. 15 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

Fig. 16 Engine Rear Mount - 4X2 Automatic

Transmission

1 - ENGINE REAR MOUNT

2 - BOLT

3 - NUT

4 - THROUGH BOLT NUT

5 - TRANSMISSION

Fig. 17 Engine Rear Mount - 4X4 Automatic

Transmission

1 - TRANSMISSION

2 - ENGINE REAR MOUNT

3 - BOLT

DRAUTOMATIC TRANSMISSION - 46RE 21 - 157

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2176 of 2895

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

NOTE: The overdrive unit can be removed and ser-

viced separately. It is not necessary to remove the

entire transmission assembly to perform overdrive

unit repairs.

(1) Disconnect battery negative cable.

(2) Raise vehicle.

(3) Remove the transfer case skid plate (Fig. 12), if

equipped.(4) Disconnect and lower or remove necessary

exhaust components.

(5) Remove engine-to-transmission struts (Fig. 13)

and (Fig. 14).

(6) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(7) Disconnect and remove the crankshaft position

sensor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain the sensor attaching bolts.

(8) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

(9) Remove torque converter access cover.

Fig. 12 Transfer Case Skid Plate

1 - FRAME RAIL

2 - SKID PLATE

3 - BOLTS (6)

Fig. 13 Right Side Engine-to-Transmission Strut

1 - TRANSMISSION

2 - ENGINE

3 - STRUT

Fig. 14 Left Side Engine-to-Transmission Strut

1 - TRANSMISSION

2 - ENGINE

3 - STRUT

DRAUTOMATIC TRANSMISSION - 48RE 21 - 337

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2177 of 2895

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(12) Disconnect wires from the transmission range

sensor and transmission solenoid connector.

(13) Disconnect gearshift cable (Fig. 15) from the

transmission.

(14) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever.

(15) On 4X4 models, disconnect shift rod from

transfer case shift lever.

(16) Support rear of engine with safety stand or

jack.

(17) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

(18) Remove bolts securing rear support and cush-

ion (Fig. 16) and (Fig. 17) to transmission and cross-

member and remove rear support.

(19) Remove bolts attaching crossmember to frame

and remove crossmember.

(20) On 4X4 models, remove transfer case with

transmission jack or aid of helper.

Fig. 15 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

Fig. 16 Engine Rear Mount - 4X2 Automatic

Transmission

1 - ENGINE REAR MOUNT

2 - BOLT

3 - NUT

4 - THROUGH BOLT NUT

5 - TRANSMISSION

Fig. 17 Engine Rear Mount - 4X4 Automatic

Transmission

1 - TRANSMISSION

2 - ENGINE REAR MOUNT

3 - BOLT

21 - 338 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2334 of 2895

NOTE: The air supply which is used must be free of

moisture and dirt. Use a pressure of 30 psi to test

clutch operation.

Apply air pressure at each port. If the clutch is

functioning, a soft thump will be heard as the clutch

is applied. The clutch application can also be felt by

touching the appropriate element while applying air

pressure. As the air pressure is released, the clutch

should also release.

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks,

two items must be established before repair.

(1) Verify that a leak condition actually exists.

(2) Determined the true source of the leak.

Some suspected converter housing fluid leaks may not

be leaks at all. They may only be the result of residual

fluid in the converter housing, or excess fluid spilled dur-

ing factory fill or fill after repair. Converter housing

leaks have several potential sources. Through careful

observation, a leak source can be identified before remov-

ing the transmission for repair. Torque converter seal

leaks tend to move along the drive hub and onto the rear

of the converter. Pump cover seal tend to run down the

cover and the inside surface of the bellhousing.

Some leaks, or suspected leaks, may be particu-

larly difficult to locate. If necessary, a Mopart

approved dye may be used to locate a leak.

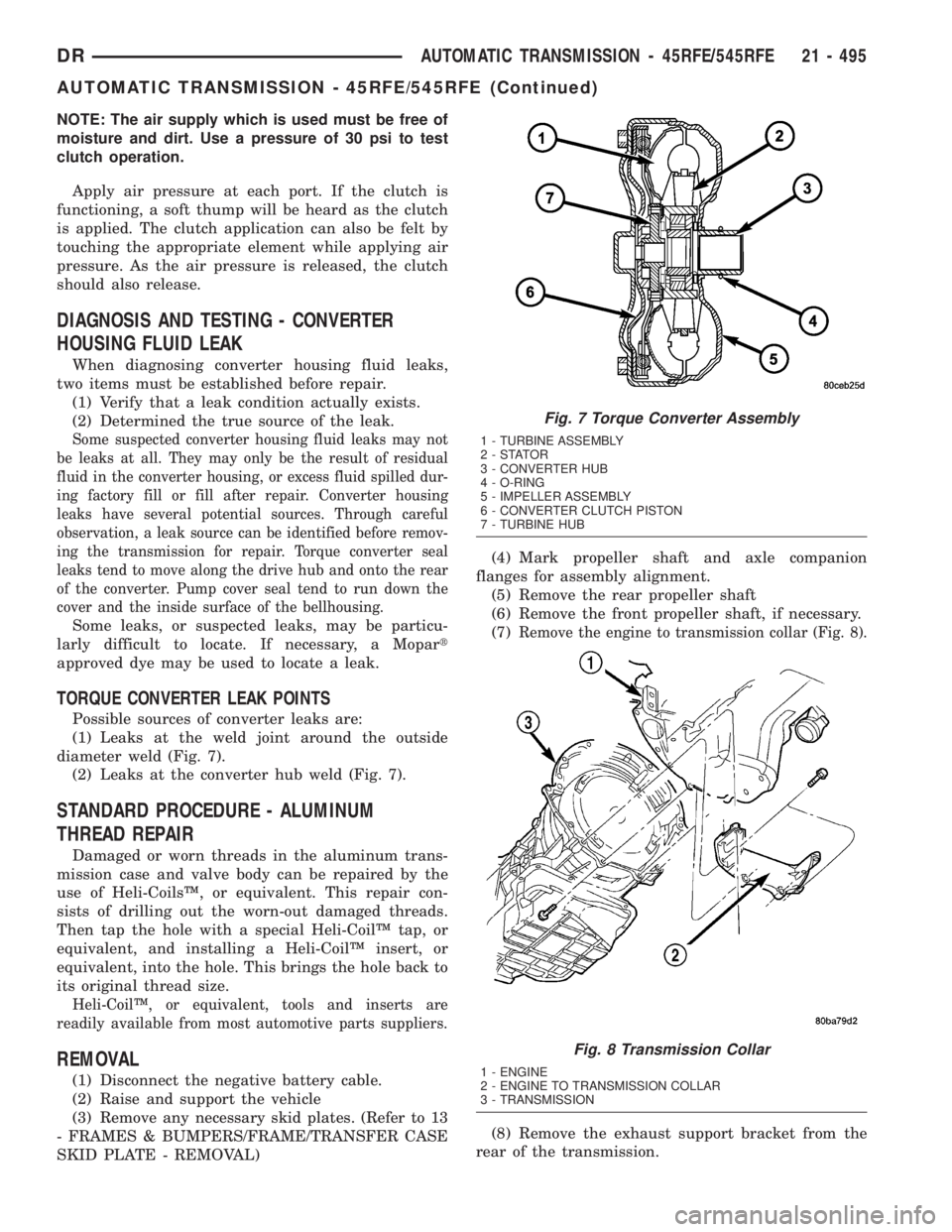

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 7).

(2) Leaks at the converter hub weld (Fig. 7).

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppliers.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle

(3) Remove any necessary skid plates. (Refer to 13

- FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)(4) Mark propeller shaft and axle companion

flanges for assembly alignment.

(5) Remove the rear propeller shaft

(6) Remove the front propeller shaft, if necessary.

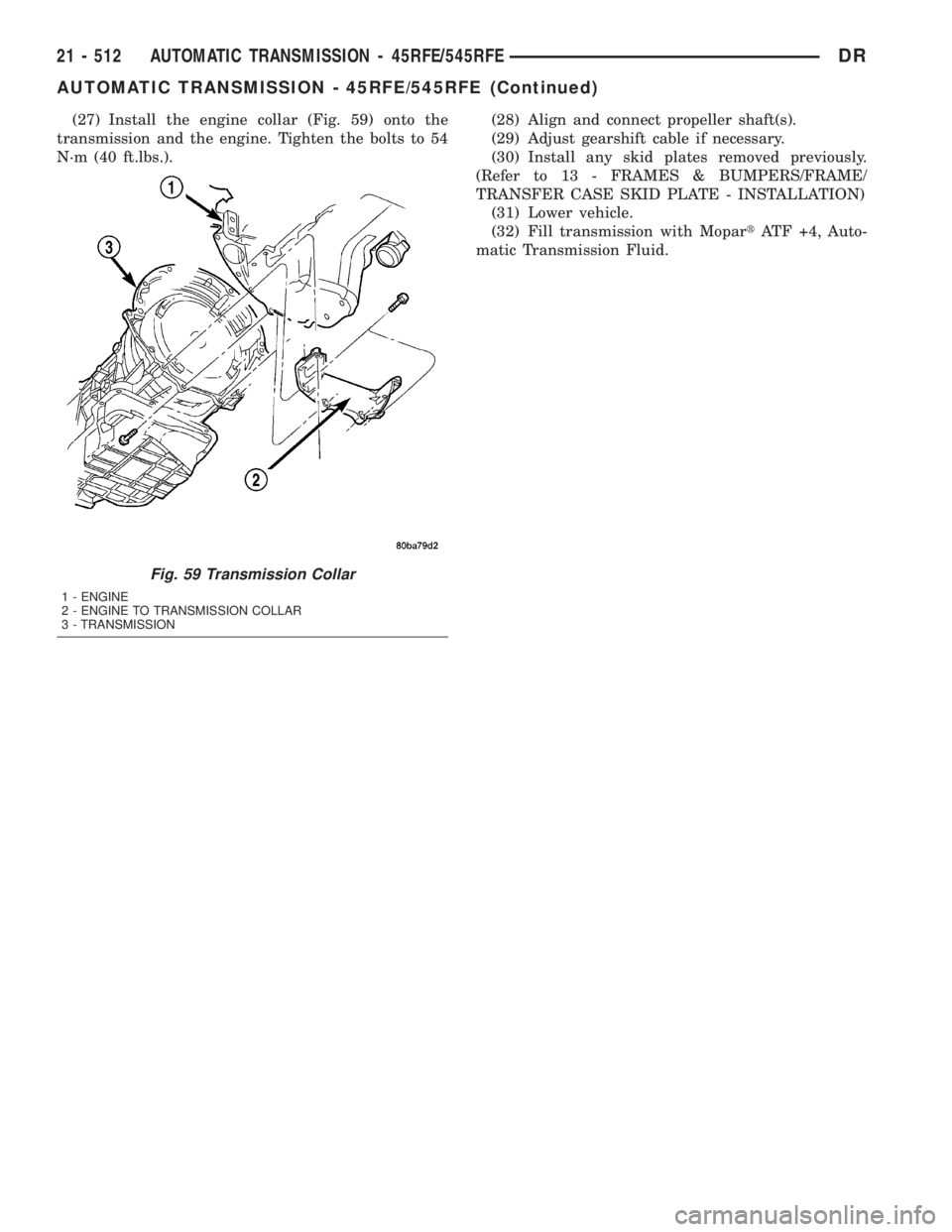

(7)

Remove the engine to transmission collar (Fig. 8).

(8) Remove the exhaust support bracket from the

rear of the transmission.

Fig. 7 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

Fig. 8 Transmission Collar

1 - ENGINE

2 - ENGINE TO TRANSMISSION COLLAR

3 - TRANSMISSION

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 495

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2351 of 2895

(27) Install the engine collar (Fig. 59) onto the

transmission and the engine. Tighten the bolts to 54

N´m (40 ft.lbs.).(28) Align and connect propeller shaft(s).

(29) Adjust gearshift cable if necessary.

(30) Install any skid plates removed previously.

(Refer to 13 - FRAMES & BUMPERS/FRAME/

TRANSFER CASE SKID PLATE - INSTALLATION)

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission Fluid.

Fig. 59 Transmission Collar

1 - ENGINE

2 - ENGINE TO TRANSMISSION COLLAR

3 - TRANSMISSION

21 - 512 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2432 of 2895

Condition Possible Cause Correction

Noisy in, or jumps out of, four wheel

drive low range.1) Transfer case not completely

engaged in 4L position.1) With the transmission in

NEUTRAL, or the clutch depressed

in the case of a manual

transmission and the vehicle moving

under 3-4 km/h (2-3 mph), shift the

transfer case to NEUTRAL and then

shift into the 4L position.

2) Shift linkage out of adjustment. 2) Adjust linkage.

3) Shift linkage loose or binding. 3) Tighten, lubricate, or repair

linkage as necessary.

4) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.4) Disassemble unit and repair as

necessary.

5) Low range gear worn or

damaged.5) Disassemble unit and repair as

necessary.

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Vent closed or restricted. 2) Clear or replace vent as

necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary.

Check to ensure that another

component, the propeller shaft slip

yoke for example, is not causing

damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H

position on hard, dry surfaces.

REMOVAL

(1) Raise and support vehicle.

(2) Remove skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

(3) Position drain oil container under transfer

case.

(4) Remove transfer case drain plug and drain

lubricant into container.

(5) Disconnect vent hose and transfer case position

sensor connector.

(6) Disconnect shift rod from grommet in transfer

case shift lever, or from floor shift arm whichever

provides easy access. Use channel lock style pliers to

press rod out of lever grommet.

(7) Support transmission with jack stand.

(8) Mark front and rear propeller shafts for assem-

bly reference.(9) Remove front and rear propeller shafts. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL)

(10) Support transfer case with suitable jack.

Secure transfer case to jack with safety chains.

(11) Remove nuts attaching transfer case to trans-

mission.

(12) Move transfer case assembly rearward until

free of transmission output shaft.

(13) Lower jack and move transfer case from

under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

DRTRANSFER CASE - NV241 GENII 21 - 593

TRANSFER CASE - NV241 GENII (Continued)

Page 2453 of 2895

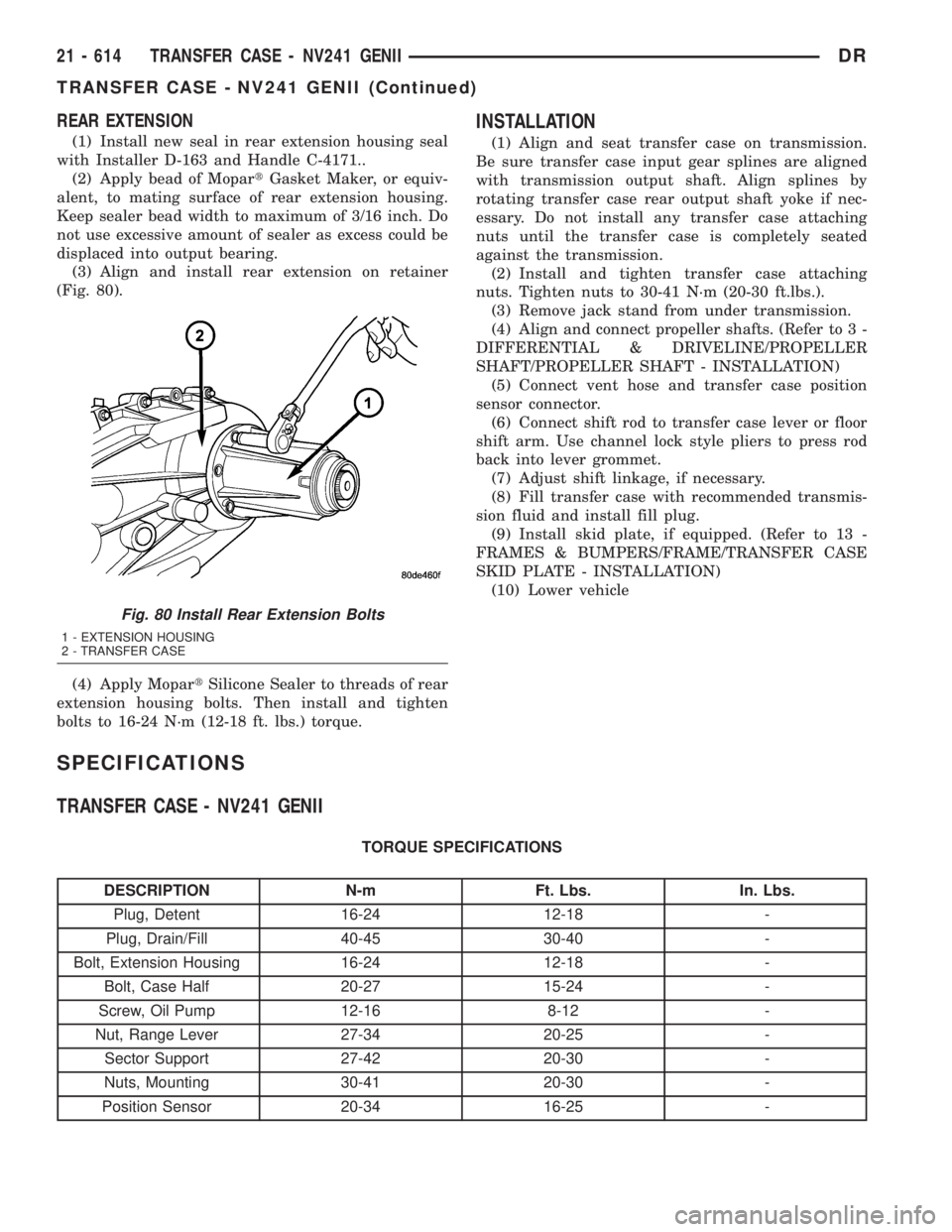

REAR EXTENSION

(1) Install new seal in rear extension housing seal

with Installer D-163 and Handle C-4171..

(2) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of rear extension housing.

Keep sealer bead width to maximum of 3/16 inch. Do

not use excessive amount of sealer as excess could be

displaced into output bearing.

(3) Align and install rear extension on retainer

(Fig. 80).

(4) Apply MopartSilicone Sealer to threads of rear

extension housing bolts. Then install and tighten

bolts to 16-24 N´m (12-18 ft. lbs.) torque.

INSTALLATION

(1) Align and seat transfer case on transmission.

Be sure transfer case input gear splines are aligned

with transmission output shaft. Align splines by

rotating transfer case rear output shaft yoke if nec-

essary. Do not install any transfer case attaching

nuts until the transfer case is completely seated

against the transmission.

(2) Install and tighten transfer case attaching

nuts. Tighten nuts to 30-41 N´m (20-30 ft.lbs.).

(3) Remove jack stand from under transmission.

(4) Align and connect propeller shafts. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(5) Connect vent hose and transfer case position

sensor connector.

(6) Connect shift rod to transfer case lever or floor

shift arm. Use channel lock style pliers to press rod

back into lever grommet.

(7) Adjust shift linkage, if necessary.

(8) Fill transfer case with recommended transmis-

sion fluid and install fill plug.

(9) Install skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

(10) Lower vehicle

SPECIFICATIONS

TRANSFER CASE - NV241 GENII

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Plug, Drain/Fill 40-45 30-40 -

Bolt, Extension Housing 16-24 12-18 -

Bolt, Case Half 20-27 15-24 -

Screw, Oil Pump 12-16 8-12 -

Nut, Range Lever 27-34 20-25 -

Sector Support 27-42 20-30 -

Nuts, Mounting 30-41 20-30 -

Position Sensor 20-34 16-25 -

Fig. 80 Install Rear Extension Bolts

1 - EXTENSION HOUSING

2 - TRANSFER CASE

21 - 614 TRANSFER CASE - NV241 GENIIDR

TRANSFER CASE - NV241 GENII (Continued)