frame DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2464 of 2895

Condition Possible Cause Correction

Noisy in, or jumps out of, four wheel

drive low range.1) Transfer case not completely

engaged in 4L position.1) With the transmission in

NEUTRAL, or the clutch depressed

in the case of a manual

transmission and the vehicle moving

under 3-4 km/h (2-3 mph), shift the

transfer case to NEUTRAL and then

shift into the 4L position.

2) Shift linkage out of adjustment. 2) Adjust linkage.

3) Shift linkage loose or binding. 3) Tighten, lubricate, or repair

linkage as necessary.

4) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.4) Disassemble unit and repair as

necessary.

5) Low range gear worn or

damaged.5) Disassemble unit and repair as

necessary.

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Vent closed or restricted. 2) Clear or replace vent as

necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary.

Check to ensure that another

component, the propeller shaft slip

yoke for example, is not causing

damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H

position on hard, dry surfaces.

REMOVAL

(1) Raise and support vehicle.

(2) Remove skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

(3) Position drain oil container under transfer

case.

(4) Remove transfer case drain plug and drain

lubricant into container.

(5) Disconnect vent hose and transfer case position

sensor connector.

(6) Disconnect shift rod from grommet in transfer

case shift lever, or from floor shift arm whichever

provides easy access. Use channel lock style pliers to

press rod out of lever grommet.

(7) Support transmission with jack stand.

(8) Mark front and rear propeller shafts for assem-

bly reference.

(9) Remove front and rear propeller shafts. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL)(10) Support transfer case with suitable jack.

Secure transfer case to jack with safety chains.

(11) Remove nuts attaching transfer case to trans-

mission.

(12) Move transfer case assembly rearward until

free of transmission output shaft.

(13) Lower jack and move transfer case from

under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

COMPANION FLANGE AND EXTENSION HOUSING

(1) Install two bolts 180É apart into the front out-

put shaft companion flange.

(2) Place holder over the bolts and against the

companion flange (Fig. 3).

(3) Remove and discard the front companion flange

nut.

DRTRANSFER CASE - NV271 21 - 625

TRANSFER CASE - NV271 (Continued)

Page 2488 of 2895

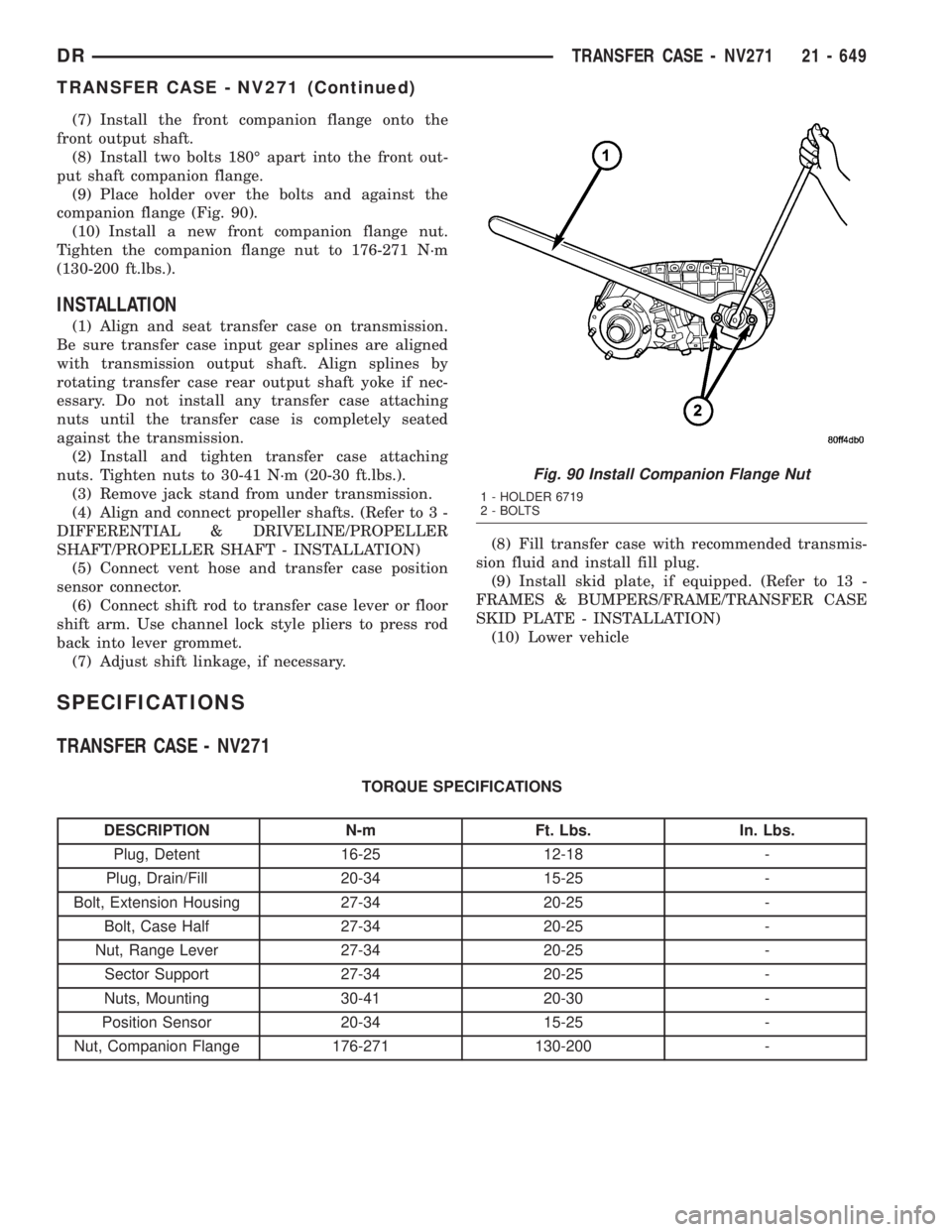

(7) Install the front companion flange onto the

front output shaft.

(8) Install two bolts 180É apart into the front out-

put shaft companion flange.

(9) Place holder over the bolts and against the

companion flange (Fig. 90).

(10) Install a new front companion flange nut.

Tighten the companion flange nut to 176-271 N´m

(130-200 ft.lbs.).

INSTALLATION

(1) Align and seat transfer case on transmission.

Be sure transfer case input gear splines are aligned

with transmission output shaft. Align splines by

rotating transfer case rear output shaft yoke if nec-

essary. Do not install any transfer case attaching

nuts until the transfer case is completely seated

against the transmission.

(2) Install and tighten transfer case attaching

nuts. Tighten nuts to 30-41 N´m (20-30 ft.lbs.).

(3) Remove jack stand from under transmission.

(4) Align and connect propeller shafts. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(5) Connect vent hose and transfer case position

sensor connector.

(6) Connect shift rod to transfer case lever or floor

shift arm. Use channel lock style pliers to press rod

back into lever grommet.

(7) Adjust shift linkage, if necessary.(8) Fill transfer case with recommended transmis-

sion fluid and install fill plug.

(9) Install skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

(10) Lower vehicle

SPECIFICATIONS

TRANSFER CASE - NV271

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-25 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 27-34 20-25 -

Bolt, Case Half 27-34 20-25 -

Nut, Range Lever 27-34 20-25 -

Sector Support 27-34 20-25 -

Nuts, Mounting 30-41 20-30 -

Position Sensor 20-34 15-25 -

Nut, Companion Flange 176-271 130-200 -

Fig. 90 Install Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

DRTRANSFER CASE - NV271 21 - 649

TRANSFER CASE - NV271 (Continued)

Page 2605 of 2895

DOOR GLASS

REMOVAL

(1) Remove the glass run channels. (Refer to 23 -

BODY/DOORS - REAR/GLASS RUN CHANNEL -

REMOVAL)

(2) Remove the glass support and place the glass

into the bottom of the door.

(3) Separate the glass run weatherstrip from the

rear of the window opening.

(4) Remove the inner belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - REMOVAL)

(5) Remove the glass from the window opening.

INSTALLATION

(1) Install the glass through the window opening

and pace the glass into the bottom of the door.

(2) Install the inner belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - INSTALLATION)

(3) Stuff the glass run weatherstrip into the win-

dow frame.

(4) Secure the glass in the up position using a

wood wedge or equivalent.

(5) Install the glass run channels. (Refer to 23 -

BODY/DOORS - REAR/GLASS RUN CHANNEL -

INSTALLATION)

EXTERIOR HANDLE

REMOVAL

(1) Remove the front glass run channel. (Refer to

23 - BODY/DOORS - REAR/GLASS RUN CHANNEL

- REMOVAL)

(2) Disconnect the latch actuator rod. (Fig. 2)

(3) Remove the nuts and remove the handle.

INSTALLATION

(1) Install the latch and install the nuts.

(2) Connect the latch actuator rod.

(3) Install the front glass run channel. (Refer to 23

- BODY/DOORS - REAR/GLASS RUN CHANNEL -

INSTALLATION)

GLASS RUN CHANNEL

REMOVAL

(1) Remove the window regulator. (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

REMOVAL)

(2) Remove the bottom screws and loosen the top

screws from bolt channels. (Fig. 3) and (Fig. 4)(3) Slide the channels up to disengage from the

keyhole slots.

(4) Separate the glass run weatherstrip from the

channel and remove the channels.

Fig. 2 EXTERIOR HANDLE

1 - LATCH ACTUATOR ROD

2-LATCH

3 - NUTS (2)

Fig. 3 FRONT RUN CHANNEL

1 - BOLTS

2 - FRONT RUN CHANNEL

23 - 30 DOORS - REARDR

Page 2611 of 2895

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL.............................36

INSTALLATION.........................36

BODY ISOLATORS

REMOVAL.............................36

INSTALLATION.........................37

CARGO BOX

REMOVAL.............................37

INSTALLATION.........................37

CARGO BOX - TIE DOWN

REMOVAL.............................37

INSTALLATION.........................37

COWL GRILLE

REMOVAL.............................38

INSTALLATION.........................38

EXTERIOR NAME PLATES

REMOVAL.............................38

INSTALLATION.........................38

FRONT FENDER

REMOVAL.............................39

INSTALLATION.........................39

FUEL FILL DOOR

REMOVAL.............................39

INSTALLATION.........................39GRILLE

REMOVAL.............................39

INSTALLATION.........................40

GRILLE FRAME

REMOVAL.............................40

INSTALLATION.........................40

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL.............................40

INSTALLATION.........................41

REAR WHEELHOUSE SPLASH SHIELD

REMOVAL.............................41

INSTALLATION.........................41

SIDE VIEW MIRROR

REMOVAL.............................41

INSTALLATION.........................41

UPPER RADIATOR CROSSMEMBER

REMOVAL.............................42

INSTALLATION.........................42

SIDE VIEW MIRROR GLASS

REMOVAL.............................42

INSTALLATION.........................44

REAR FENDER

REMOVAL.............................44

INSTALLATION.........................44

BODY SIDE MOLDINGS

REMOVAL

NOTE: Body side moldings are attached to the body

panels with adhesive tape.

(1) Apply a length of masking tape on the body

panel, parallel to the top edge of the molding and to

one end to use as a guide for installation, if neces-

sary.

(2) If temperature is below 21ÉC (70ÉF) warm

molding with a heat lamp or gun. Do not exceed 52ÉC

(120ÉF) when heating molding.

(3) Using a trim stick C-4755 or equivalent,

remove and discard the molding from the outside of

the body panel.

INSTALLATION

(1) Thoroughly clean all residue from the body side

molding attachment area of the body panel.(2) Wipe area with a clean lint free cloth moist-

ened with a 50% solution of water and alcohol and

wipe dry immediately with a dry lint free cloth.

(3) Apply new body side molding using the guide

tape on the body panel and apply consistent and uni-

form pressure of approximately 40 p.s.i. over the

entire surface of the molding.

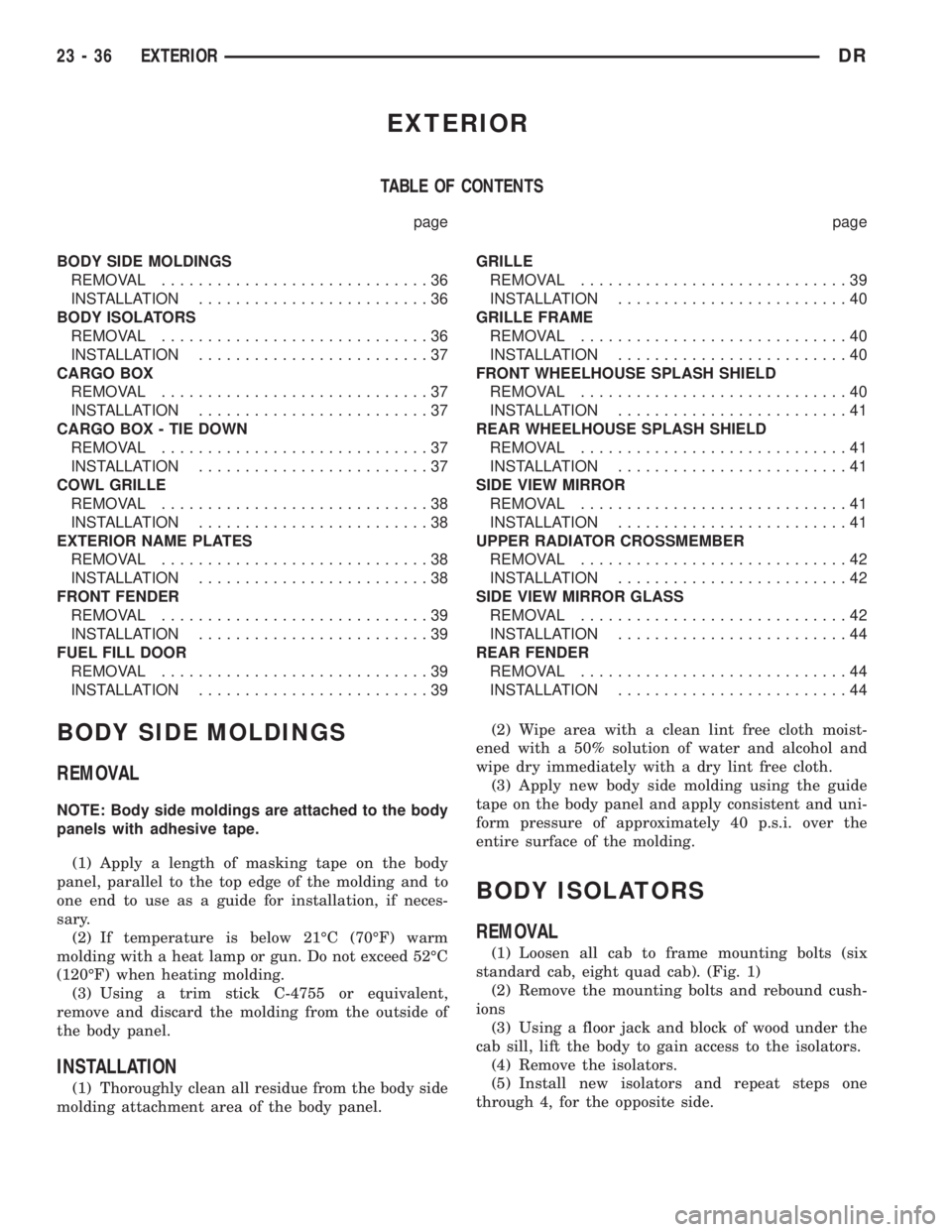

BODY ISOLATORS

REMOVAL

(1) Loosen all cab to frame mounting bolts (six

standard cab, eight quad cab). (Fig. 1)

(2) Remove the mounting bolts and rebound cush-

ions

(3) Using a floor jack and block of wood under the

cab sill, lift the body to gain access to the isolators.

(4) Remove the isolators.

(5) Install new isolators and repeat steps one

through 4, for the opposite side.

23 - 36 EXTERIORDR

Page 2612 of 2895

INSTALLATION

(1) For the rear isolators install the rebound cush-

ions, washers, reinforcement plates and bolts. (Fig. 1)

(2) Install the remaining rebound cushions and

bolts.

(3) Tighten the bolts to 81 N´m (60 ft. lbs.).

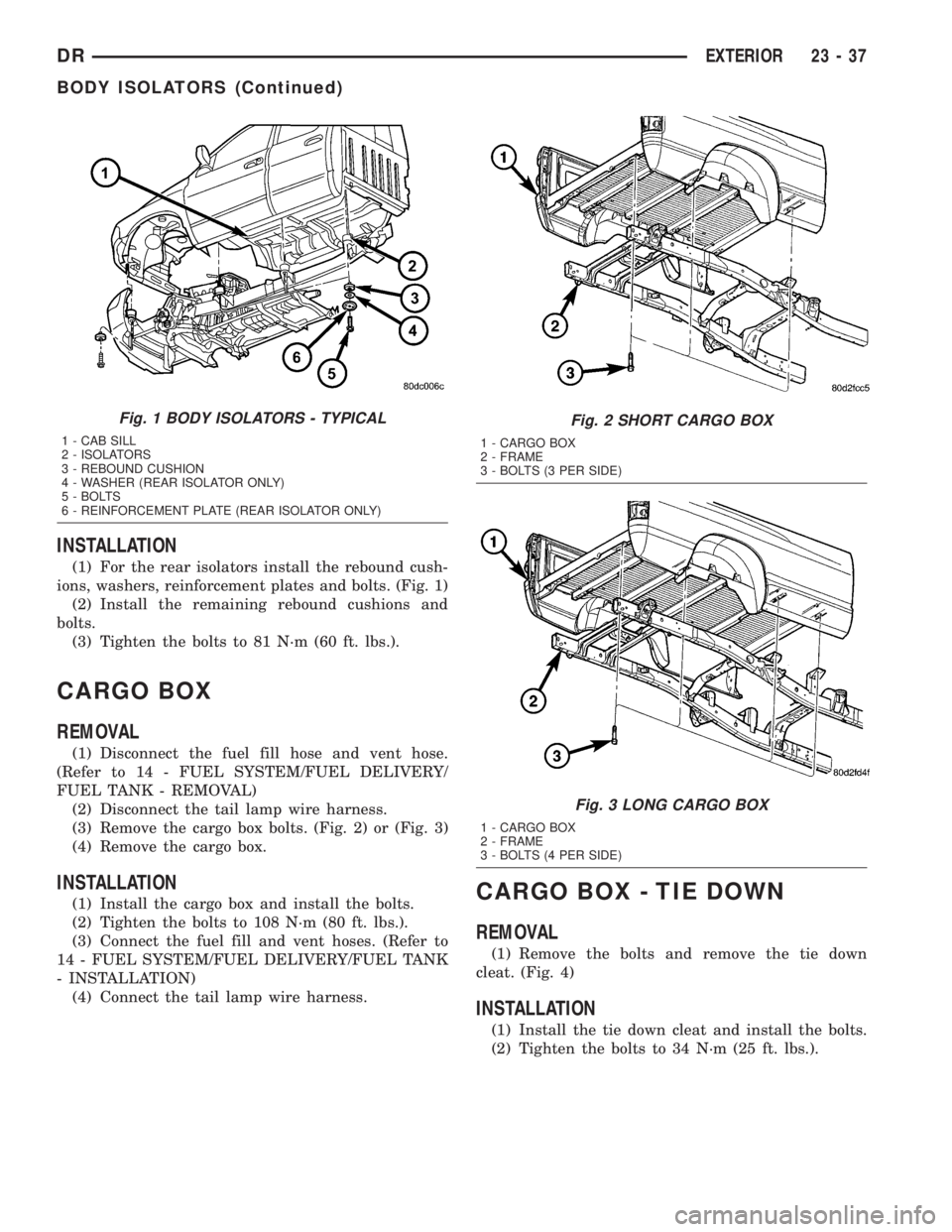

CARGO BOX

REMOVAL

(1) Disconnect the fuel fill hose and vent hose.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL TANK - REMOVAL)

(2) Disconnect the tail lamp wire harness.

(3) Remove the cargo box bolts. (Fig. 2) or (Fig. 3)

(4) Remove the cargo box.

INSTALLATION

(1) Install the cargo box and install the bolts.

(2) Tighten the bolts to 108 N´m (80 ft. lbs.).

(3) Connect the fuel fill and vent hoses. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL TANK

- INSTALLATION)

(4) Connect the tail lamp wire harness.CARGO BOX - TIE DOWN

REMOVAL

(1) Remove the bolts and remove the tie down

cleat. (Fig. 4)

INSTALLATION

(1) Install the tie down cleat and install the bolts.

(2) Tighten the bolts to 34 N´m (25 ft. lbs.).

Fig. 1 BODY ISOLATORS - TYPICAL

1 - CAB SILL

2 - ISOLATORS

3 - REBOUND CUSHION

4 - WASHER (REAR ISOLATOR ONLY)

5 - BOLTS

6 - REINFORCEMENT PLATE (REAR ISOLATOR ONLY)

Fig. 2 SHORT CARGO BOX

1 - CARGO BOX

2 - FRAME

3 - BOLTS (3 PER SIDE)

Fig. 3 LONG CARGO BOX

1 - CARGO BOX

2 - FRAME

3 - BOLTS (4 PER SIDE)

DREXTERIOR 23 - 37

BODY ISOLATORS (Continued)

Page 2614 of 2895

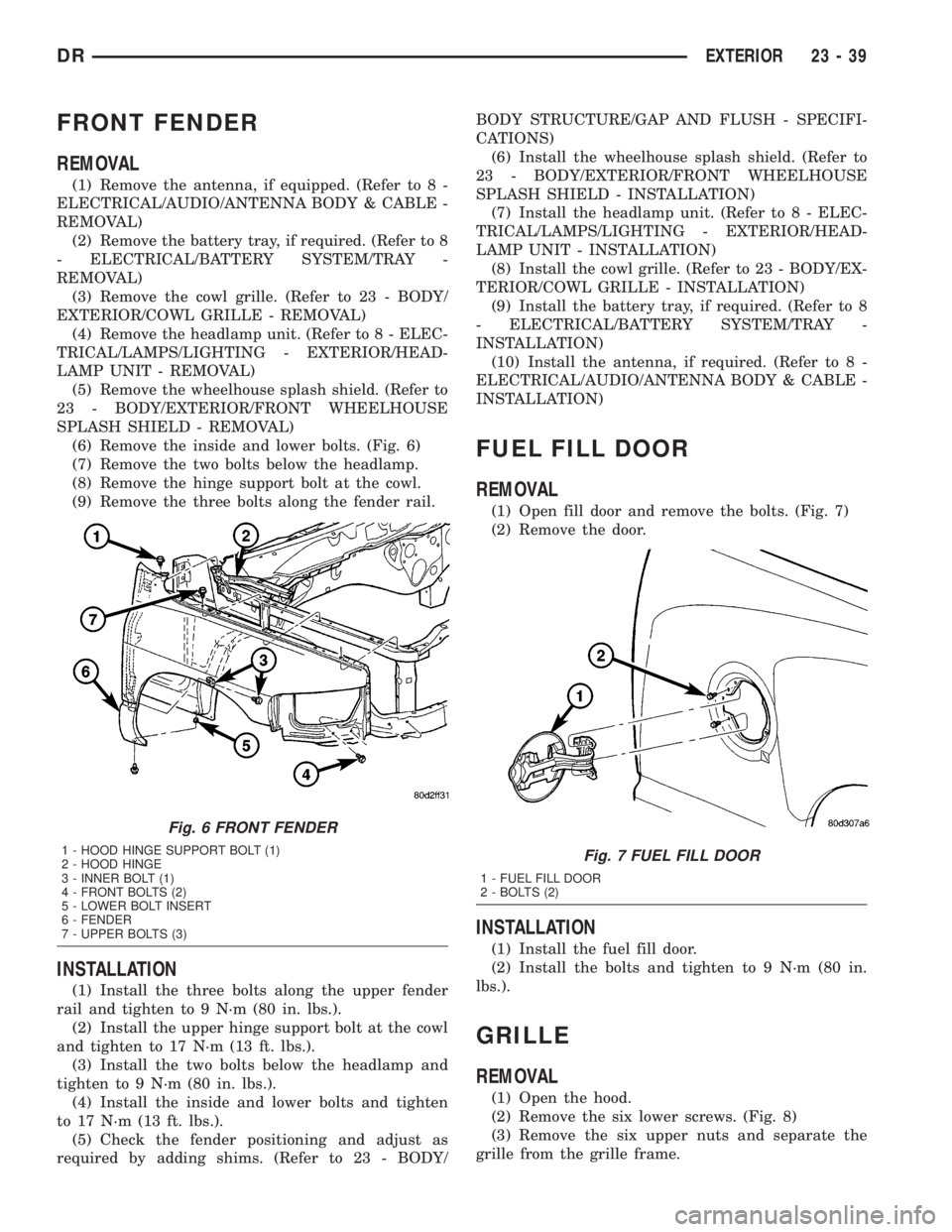

FRONT FENDER

REMOVAL

(1) Remove the antenna, if equipped. (Refer to 8 -

ELECTRICAL/AUDIO/ANTENNA BODY & CABLE -

REMOVAL)

(2) Remove the battery tray, if required. (Refer to 8

- ELECTRICAL/BATTERY SYSTEM/TRAY -

REMOVAL)

(3) Remove the cowl grille. (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL)

(4) Remove the headlamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - REMOVAL)

(5) Remove the wheelhouse splash shield. (Refer to

23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - REMOVAL)

(6) Remove the inside and lower bolts. (Fig. 6)

(7) Remove the two bolts below the headlamp.

(8) Remove the hinge support bolt at the cowl.

(9) Remove the three bolts along the fender rail.

INSTALLATION

(1) Install the three bolts along the upper fender

rail and tighten to 9 N´m (80 in. lbs.).

(2) Install the upper hinge support bolt at the cowl

and tighten to 17 N´m (13 ft. lbs.).

(3) Install the two bolts below the headlamp and

tighten to 9 N´m (80 in. lbs.).

(4) Install the inside and lower bolts and tighten

to 17 N´m (13 ft. lbs.).

(5) Check the fender positioning and adjust as

required by adding shims. (Refer to 23 - BODY/BODY STRUCTURE/GAP AND FLUSH - SPECIFI-

CATIONS)

(6) Install the wheelhouse splash shield. (Refer to

23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - INSTALLATION)

(7) Install the headlamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - INSTALLATION)

(8) Install the cowl grille. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION)

(9) Install the battery tray, if required. (Refer to 8

- ELECTRICAL/BATTERY SYSTEM/TRAY -

INSTALLATION)

(10) Install the antenna, if required. (Refer to 8 -

ELECTRICAL/AUDIO/ANTENNA BODY & CABLE -

INSTALLATION)

FUEL FILL DOOR

REMOVAL

(1) Open fill door and remove the bolts. (Fig. 7)

(2) Remove the door.

INSTALLATION

(1) Install the fuel fill door.

(2) Install the bolts and tighten to 9 N´m (80 in.

lbs.).

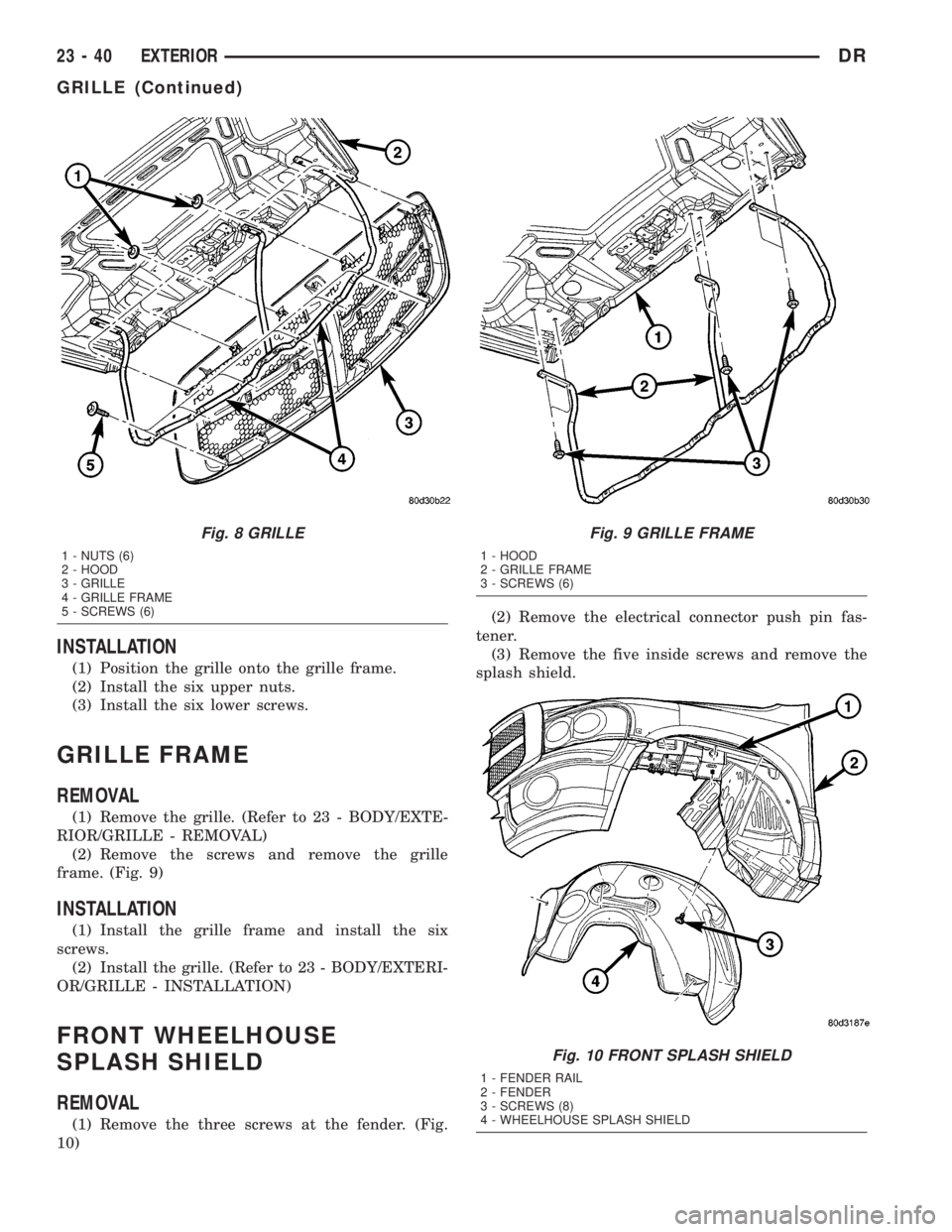

GRILLE

REMOVAL

(1) Open the hood.

(2) Remove the six lower screws. (Fig. 8)

(3) Remove the six upper nuts and separate the

grille from the grille frame.

Fig. 6 FRONT FENDER

1 - HOOD HINGE SUPPORT BOLT (1)

2 - HOOD HINGE

3 - INNER BOLT (1)

4 - FRONT BOLTS (2)

5 - LOWER BOLT INSERT

6 - FENDER

7 - UPPER BOLTS (3)Fig. 7 FUEL FILL DOOR

1 - FUEL FILL DOOR

2 - BOLTS (2)

DREXTERIOR 23 - 39

Page 2615 of 2895

INSTALLATION

(1) Position the grille onto the grille frame.

(2) Install the six upper nuts.

(3) Install the six lower screws.

GRILLE FRAME

REMOVAL

(1) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(2) Remove the screws and remove the grille

frame. (Fig. 9)

INSTALLATION

(1) Install the grille frame and install the six

screws.

(2) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

FRONT WHEELHOUSE

SPLASH SHIELD

REMOVAL

(1) Remove the three screws at the fender. (Fig.

10)(2) Remove the electrical connector push pin fas-

tener.

(3) Remove the five inside screws and remove the

splash shield.

Fig. 8 GRILLE

1 - NUTS (6)

2 - HOOD

3 - GRILLE

4 - GRILLE FRAME

5 - SCREWS (6)

Fig. 9 GRILLE FRAME

1 - HOOD

2 - GRILLE FRAME

3 - SCREWS (6)

Fig. 10 FRONT SPLASH SHIELD

1 - FENDER RAIL

2 - FENDER

3 - SCREWS (8)

4 - WHEELHOUSE SPLASH SHIELD

23 - 40 EXTERIORDR

GRILLE (Continued)

Page 2623 of 2895

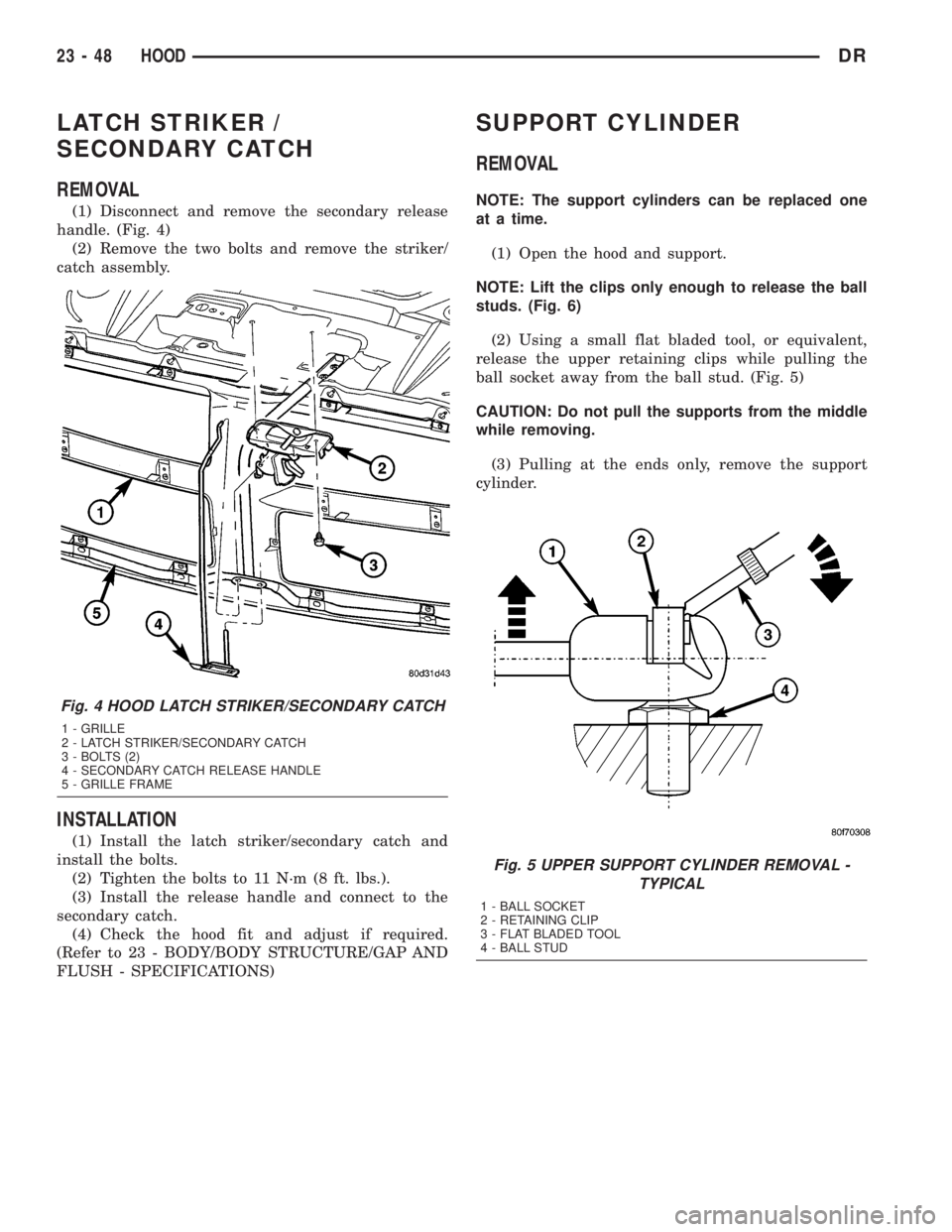

LATCH STRIKER /

SECONDARY CATCH

REMOVAL

(1) Disconnect and remove the secondary release

handle. (Fig. 4)

(2) Remove the two bolts and remove the striker/

catch assembly.

INSTALLATION

(1) Install the latch striker/secondary catch and

install the bolts.

(2) Tighten the bolts to 11 N´m (8 ft. lbs.).

(3) Install the release handle and connect to the

secondary catch.

(4) Check the hood fit and adjust if required.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

SUPPORT CYLINDER

REMOVAL

NOTE: The support cylinders can be replaced one

at a time.

(1) Open the hood and support.

NOTE: Lift the clips only enough to release the ball

studs. (Fig. 6)

(2) Using a small flat bladed tool, or equivalent,

release the upper retaining clips while pulling the

ball socket away from the ball stud. (Fig. 5)

CAUTION: Do not pull the supports from the middle

while removing.

(3) Pulling at the ends only, remove the support

cylinder.

Fig. 4 HOOD LATCH STRIKER/SECONDARY CATCH

1 - GRILLE

2 - LATCH STRIKER/SECONDARY CATCH

3 - BOLTS (2)

4 - SECONDARY CATCH RELEASE HANDLE

5 - GRILLE FRAME

Fig. 5 UPPER SUPPORT CYLINDER REMOVAL -

TYPICAL

1 - BALL SOCKET

2 - RETAINING CLIP

3 - FLAT BLADED TOOL

4 - BALL STUD

23 - 48 HOODDR

Page 2647 of 2895

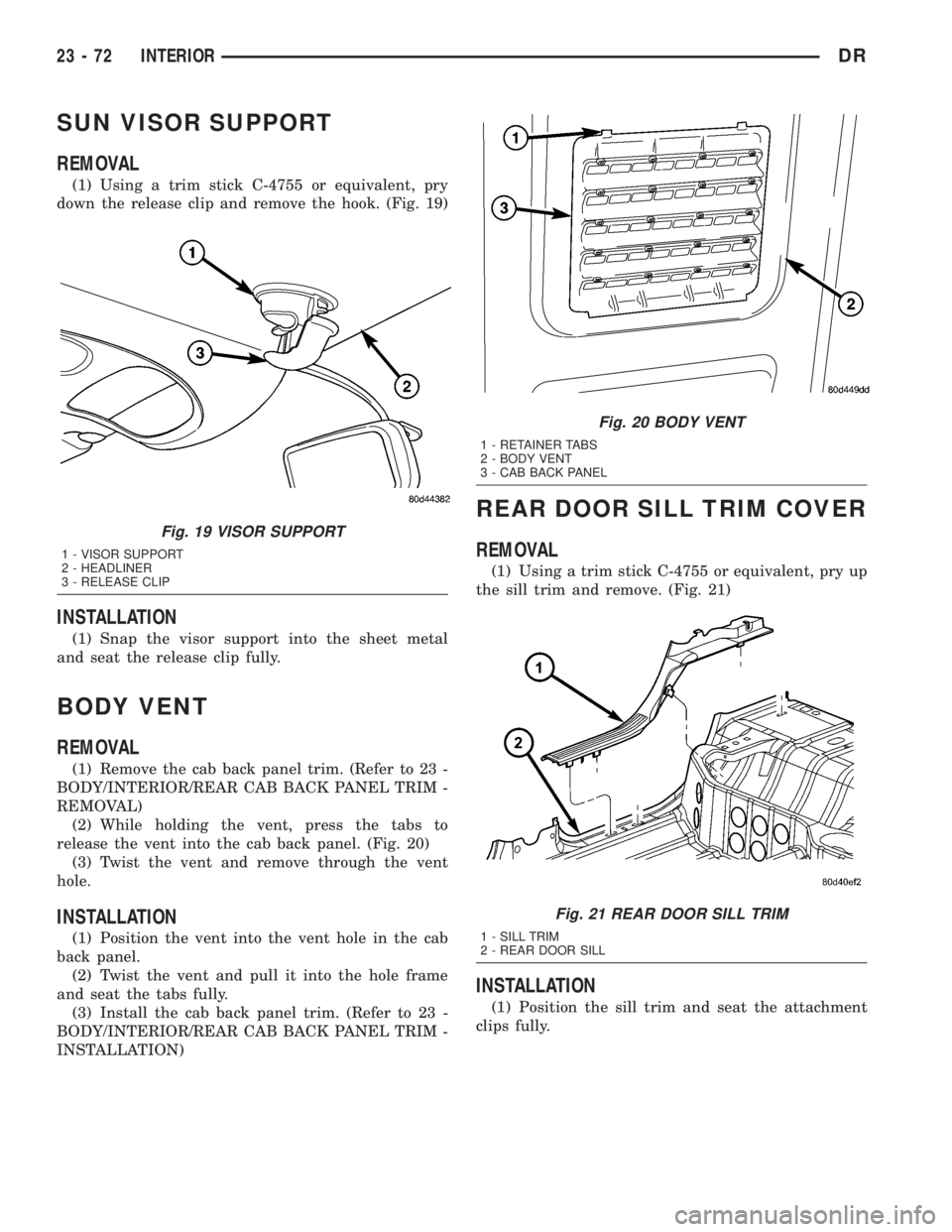

SUN VISOR SUPPORT

REMOVAL

(1) Using a trim stick C-4755 or equivalent, pry

down the release clip and remove the hook. (Fig. 19)

INSTALLATION

(1) Snap the visor support into the sheet metal

and seat the release clip fully.

BODY VENT

REMOVAL

(1) Remove the cab back panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CAB BACK PANEL TRIM -

REMOVAL)

(2) While holding the vent, press the tabs to

release the vent into the cab back panel. (Fig. 20)

(3) Twist the vent and remove through the vent

hole.

INSTALLATION

(1) Position the vent into the vent hole in the cab

back panel.

(2) Twist the vent and pull it into the hole frame

and seat the tabs fully.

(3) Install the cab back panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CAB BACK PANEL TRIM -

INSTALLATION)

REAR DOOR SILL TRIM COVER

REMOVAL

(1) Using a trim stick C-4755 or equivalent, pry up

the sill trim and remove. (Fig. 21)

INSTALLATION

(1) Position the sill trim and seat the attachment

clips fully.

Fig. 19 VISOR SUPPORT

1 - VISOR SUPPORT

2 - HEADLINER

3 - RELEASE CLIP

Fig. 20 BODY VENT

1 - RETAINER TABS

2 - BODY VENT

3 - CAB BACK PANEL

Fig. 21 REAR DOOR SILL TRIM

1 - SILL TRIM

2 - REAR DOOR SILL

23 - 72 INTERIORDR

Page 2651 of 2895

SEATS

TABLE OF CONTENTS

page page

CENTER SEAT

REMOVAL.............................76

INSTALLATION.........................77

CENTER ARMREST / SEAT BACK

REMOVAL.............................77

INSTALLATION.........................78

CENTER SEAT BACK INERTIA HINGE COVER

REMOVAL.............................78

INSTALLATION.........................78

CENTER SEAT BACK HINGE

REMOVAL.............................79

INSTALLATION.........................80

CENTER SEAT BACK LID

REMOVAL.............................80

INSTALLATION.........................80

CENTER SEAT CUSHION

REMOVAL.............................80

INSTALLATION.........................80

CENTER SEAT CUSHION COVER

REMOVAL.............................81

INSTALLATION.........................81

UNDER SEAT STORAGE BIN

REMOVAL.............................81

INSTALLATION.........................81

UNDER SEAT STORAGE BIN COVERING

REMOVAL.............................81

INSTALLATION.........................81

UNDER SEAT STORAGE BIN LATCH

REMOVAL.............................81

INSTALLATION.........................81

HEADREST

REMOVAL.............................82

INSTALLATION.........................82

HEADREST SLEEVE

REMOVAL.............................82INSTALLATION.........................82

SEAT - FRONT

REMOVAL.............................82

INSTALLATION.........................82

SEAT BACK CUSHION / COVER - FRONT

REMOVAL.............................83

INSTALLATION.........................83

SEAT CUSHION / COVER - FRONT

REMOVAL.............................83

INSTALLATION.........................83

SEAT TRACK

REMOVAL.............................83

INSTALLATION.........................83

SEAT - REAR

REMOVAL.............................84

INSTALLATION.........................84

SEAT BACK - REAR

REMOVAL.............................84

INSTALLATION.........................84

SEAT BACK CUSHION / COVER - REAR

REMOVAL.............................85

INSTALLATION.........................85

SEAT CUSHION / COVER - REAR

REMOVAL.............................85

INSTALLATION.........................85

SEAT CUSHION FRAME - REAR

REMOVAL.............................85

INSTALLATION.........................85

SEAT BACK REAR - FOOTMANS LOOP

BRACKETS

REMOVAL.............................85

INSTALLATION.........................85

CENTER SEAT

REMOVAL

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Remove and discard the front bolts. (Fig. 1)

(2) Position the seats forward, remove the rear

bolts and discard.

(3) Disconnect the 12v power supply electrical con-

nector, if equipped. (Fig. 2)(4) Fold the seat backs forward and roll the seat

assembly back in the vehicle.

(5) Remove the nuts attaching the center seat to

the drivers seat and the passenger seat and discard.

(Fig. 3)

(6) Roll the seat assembly forward and remove the

center seat portion.

23 - 76 SEATSDR