frame DODGE RAM 2003 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1688 of 2895

CAUTION:

All welds should conform to DaimlerChrysler vehicle engineering process standard ªps 9472º.

WELD PROCESS SPECIFICATIONS

WELDING PROCESS FLUX CORED ARC GAS METAL ARC (MIG)* SHIELDED METAL ARC

(STICK)

Material Thickness3.7 mm to 4.2 mm 3.7 mm to 4.2 mm 3.7 mm to 4.2 mm

Electrode TypeLincoln Electrical Co.

Product #: NR-211 MP

(Do Not Substitute)AWS ER70S-3

(Do Not Substitute)** AWS E 7018

Electrodes Size Inches.045 Tubular .035 Solid 3/329

Electrode Stick Out3/89- 1/291/29- 5/89N/A

PolarityElectrode9-9

Work Piece9+9Electrode9+9

Work Piece9-9Electrode9+9

Work Piece9-9

Shielding GasSelf Shielded 75% Ar

25% CO2Self Shielded

Gas Flow RateN/A 25 - 35 CFM N/A

Wire Feed Speed

(inches per minute)110 - 130 Vertical Down

70 - 90 Flat & Overhead245 - 250 Vertical Down

210 - 225 Flat &

OverheadN/A

Approximate Amperage

Vertical110 - 130 175 85 (3/329Diameter)

Flat & Overhead70 - 90 155 90 (3/329Diameter)

Voltage15-18 19-20 N/A

Direction of Welding

VerticalVertical Down Hill (only) Vertical Down Hill (only) Vertical - Up Hill (only)

Flat & OverheadFlat - Push or Drag Flat - Push or Drag Flat - Drag

*First choice - Gas Metal Arc Welding Process:

Butt joints - apply two layers (passes) of weld metal.

First pass should only fill approximately

1¤2the thick-

ness. Vertical position welds - maintain electrode

wire at leading edge of weld puddle while traveling

down hill to produce maximum penetration into the

sleeve. These techniques work for FCAW as well.

**E7018new electrodes may be exposed to the

atmosphere for up to ten hours with no harmful

effect. Reconditioning schedules should come from

the manufacturer.

SPECIFICATIONS

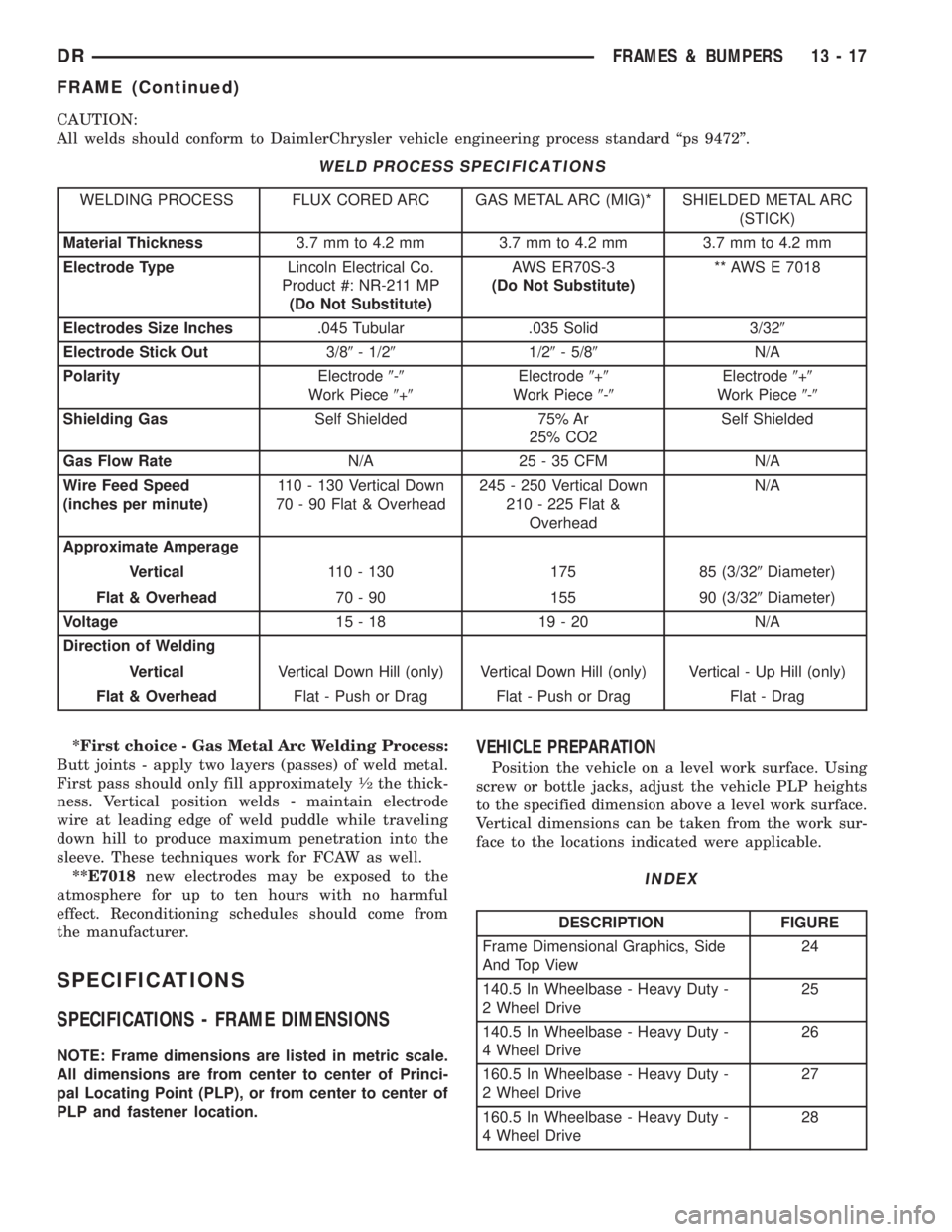

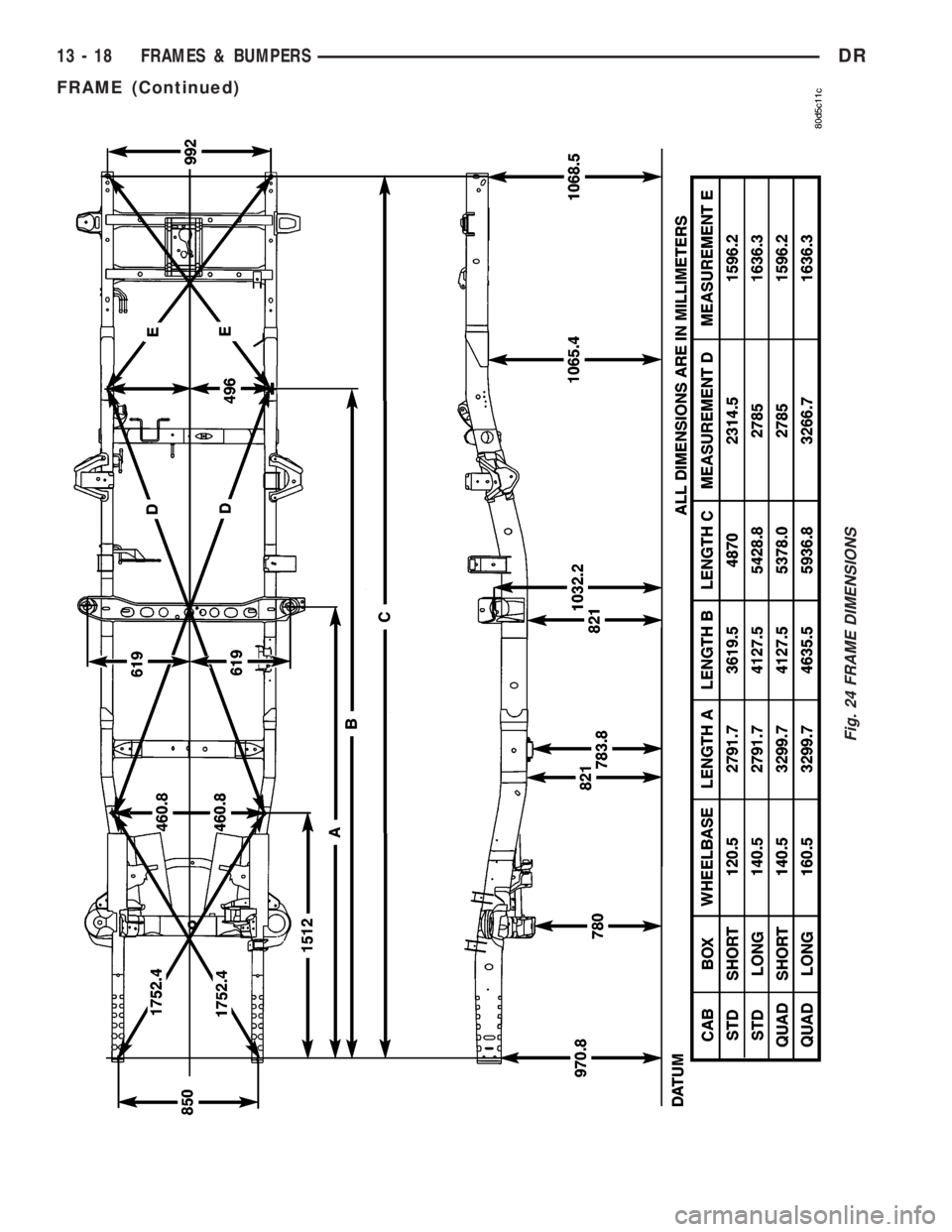

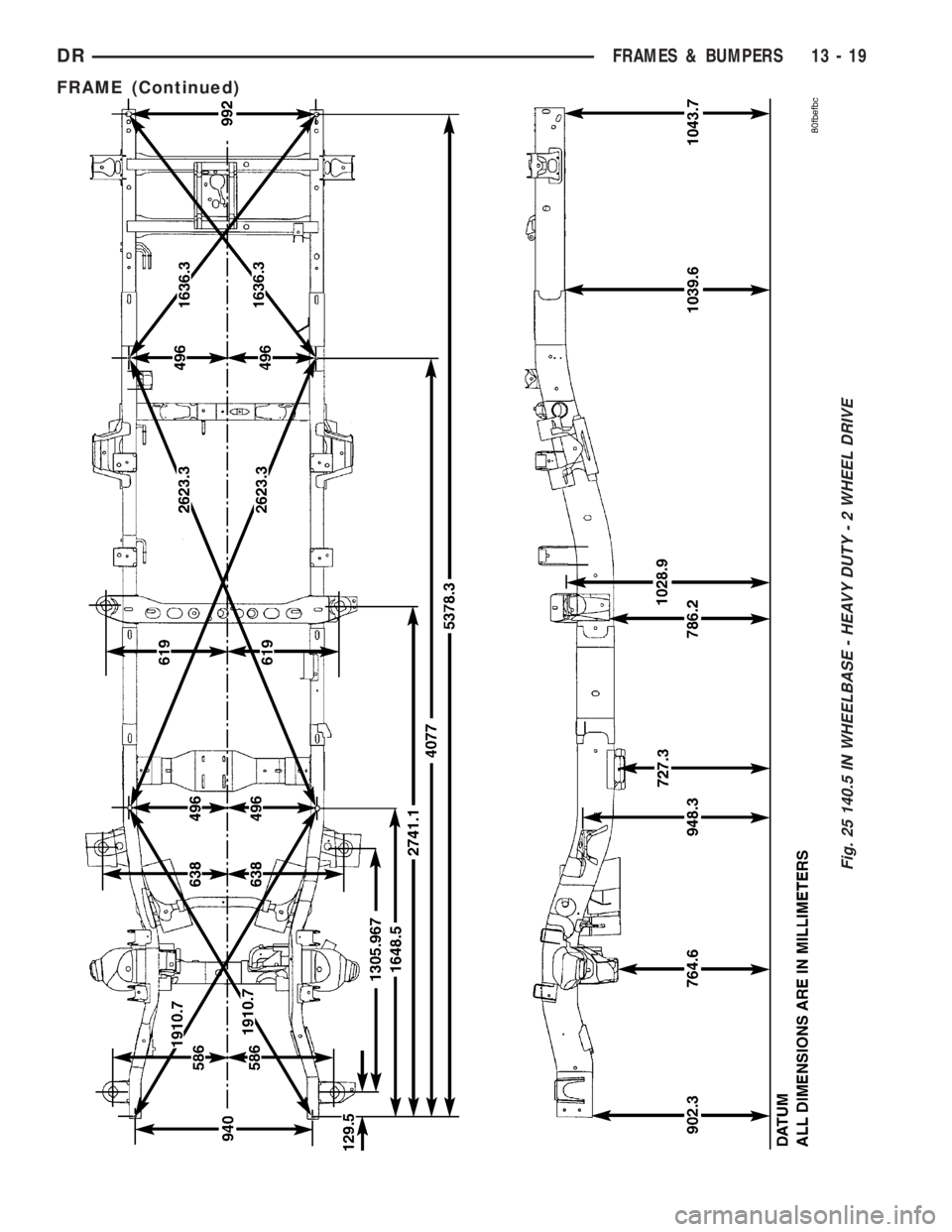

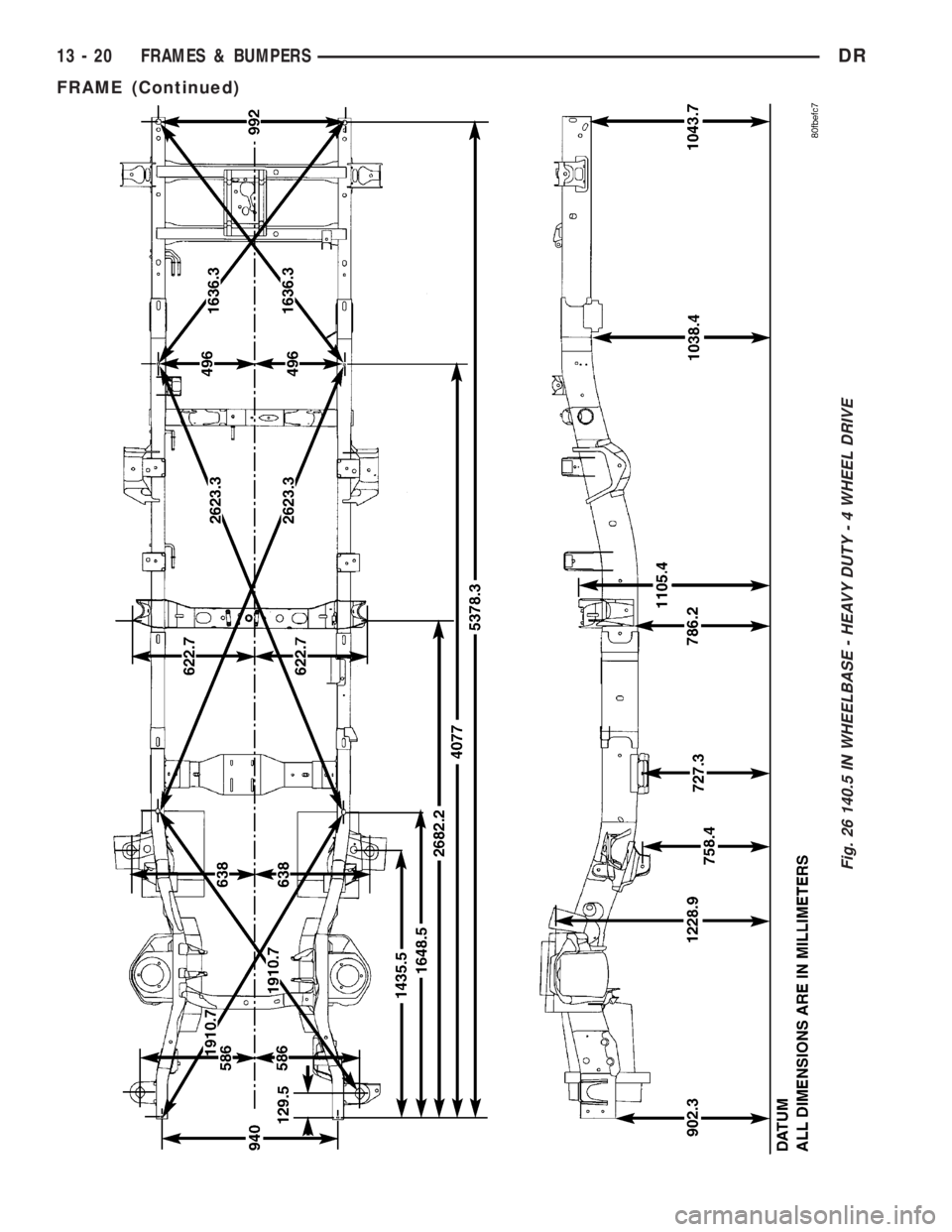

SPECIFICATIONS - FRAME DIMENSIONS

NOTE: Frame dimensions are listed in metric scale.

All dimensions are from center to center of Princi-

pal Locating Point (PLP), or from center to center of

PLP and fastener location.

VEHICLE PREPARATION

Position the vehicle on a level work surface. Using

screw or bottle jacks, adjust the vehicle PLP heights

to the specified dimension above a level work surface.

Vertical dimensions can be taken from the work sur-

face to the locations indicated were applicable.

INDEX

DESCRIPTION FIGURE

Frame Dimensional Graphics, Side

And Top View24

140.5 In Wheelbase - Heavy Duty -

2 Wheel Drive25

140.5 In Wheelbase - Heavy Duty -

4 Wheel Drive26

160.5 In Wheelbase - Heavy Duty -

2 Wheel Drive27

160.5 In Wheelbase - Heavy Duty -

4 Wheel Drive28

DRFRAMES & BUMPERS 13 - 17

FRAME (Continued)

Page 1689 of 2895

Fig. 24 FRAME DIMENSIONS

13 - 18 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1690 of 2895

Fig. 25 140.5 IN WHEELBASE - HEAVY DUTY - 2 WHEEL DRIVE

DRFRAMES & BUMPERS 13 - 19

FRAME (Continued)

Page 1691 of 2895

Fig. 26 140.5 IN WHEELBASE - HEAVY DUTY - 4 WHEEL DRIVE

13 - 20 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1692 of 2895

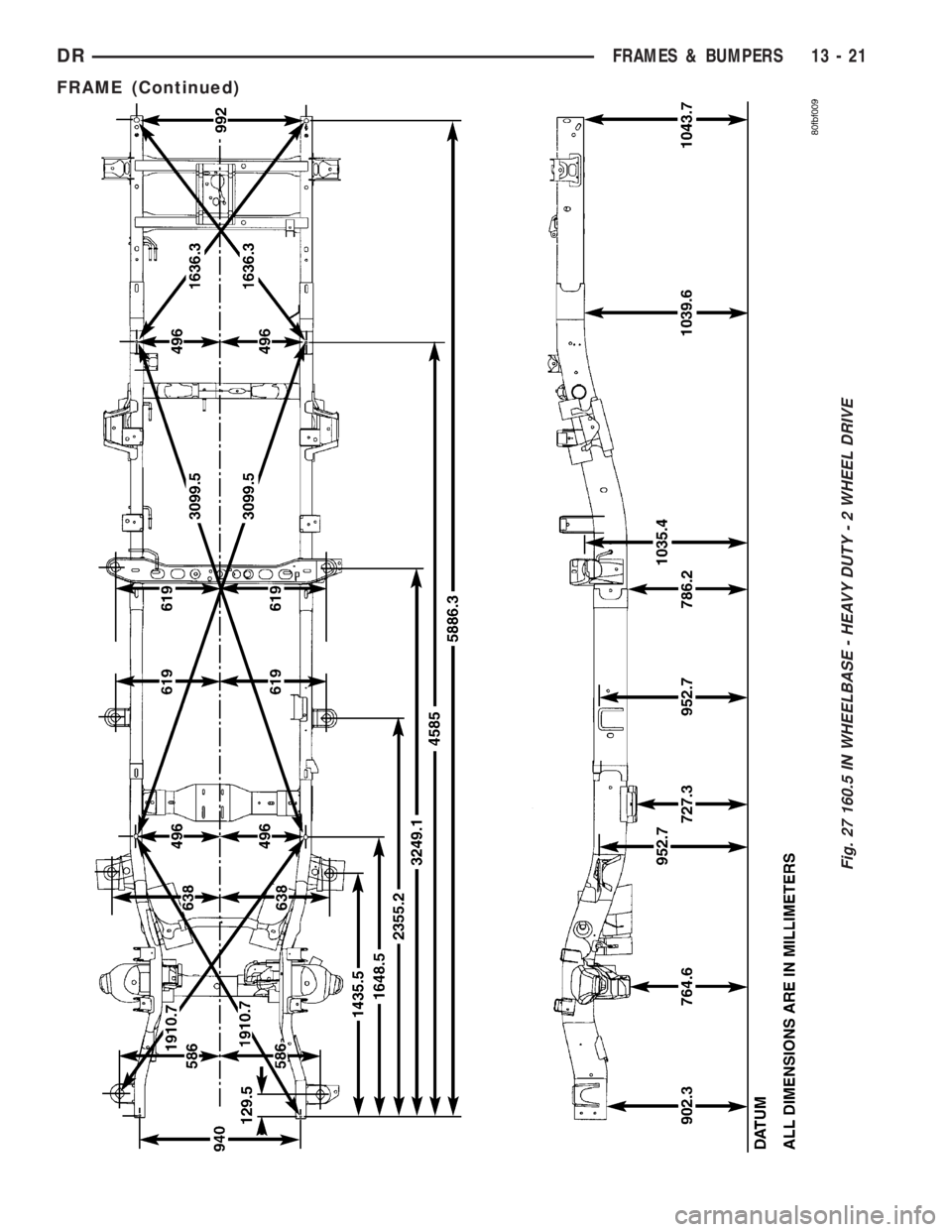

Fig. 27 160.5 IN WHEELBASE - HEAVY DUTY - 2 WHEEL DRIVE

DRFRAMES & BUMPERS 13 - 21

FRAME (Continued)

Page 1693 of 2895

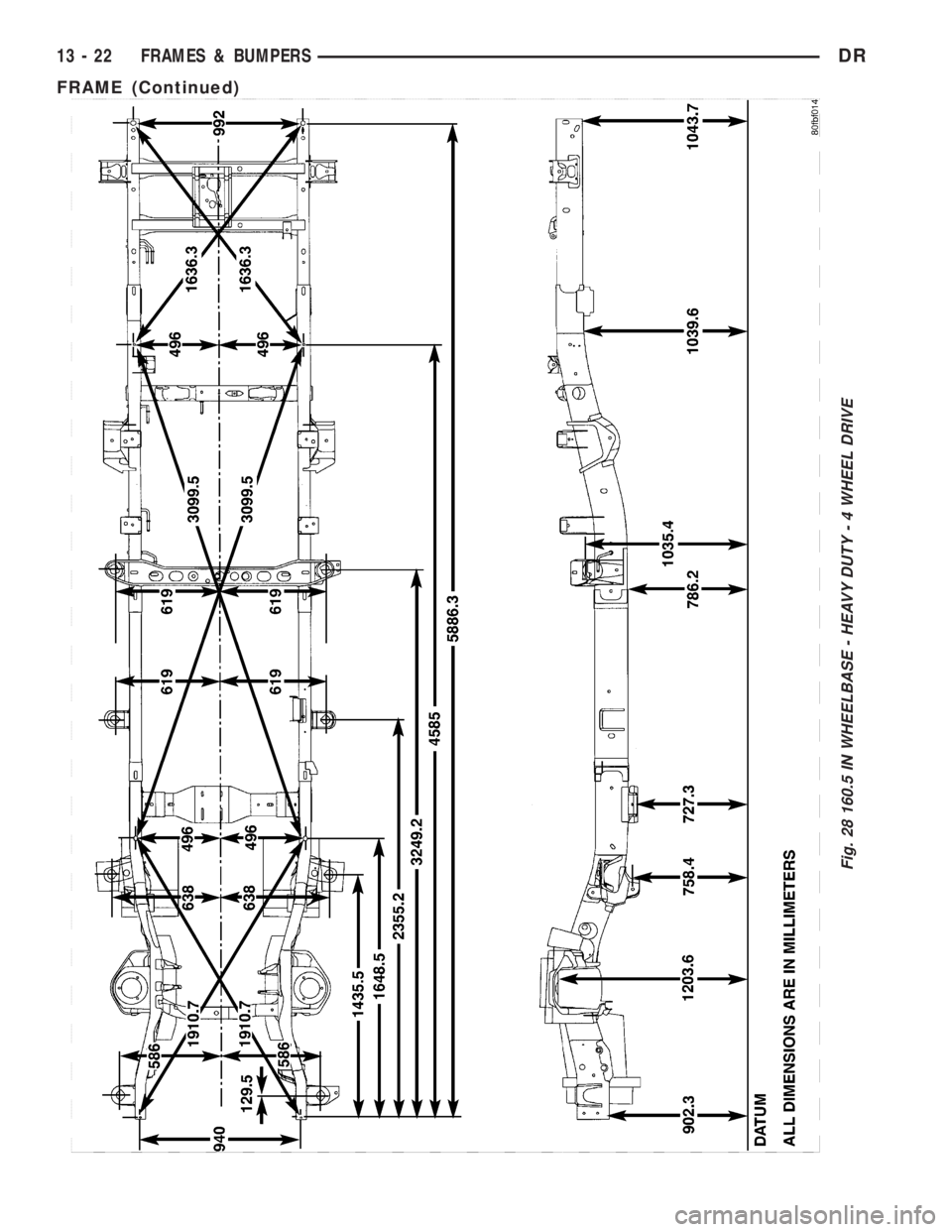

Fig. 28 160.5 IN WHEELBASE - HEAVY DUTY - 4 WHEEL DRIVE

13 - 22 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1694 of 2895

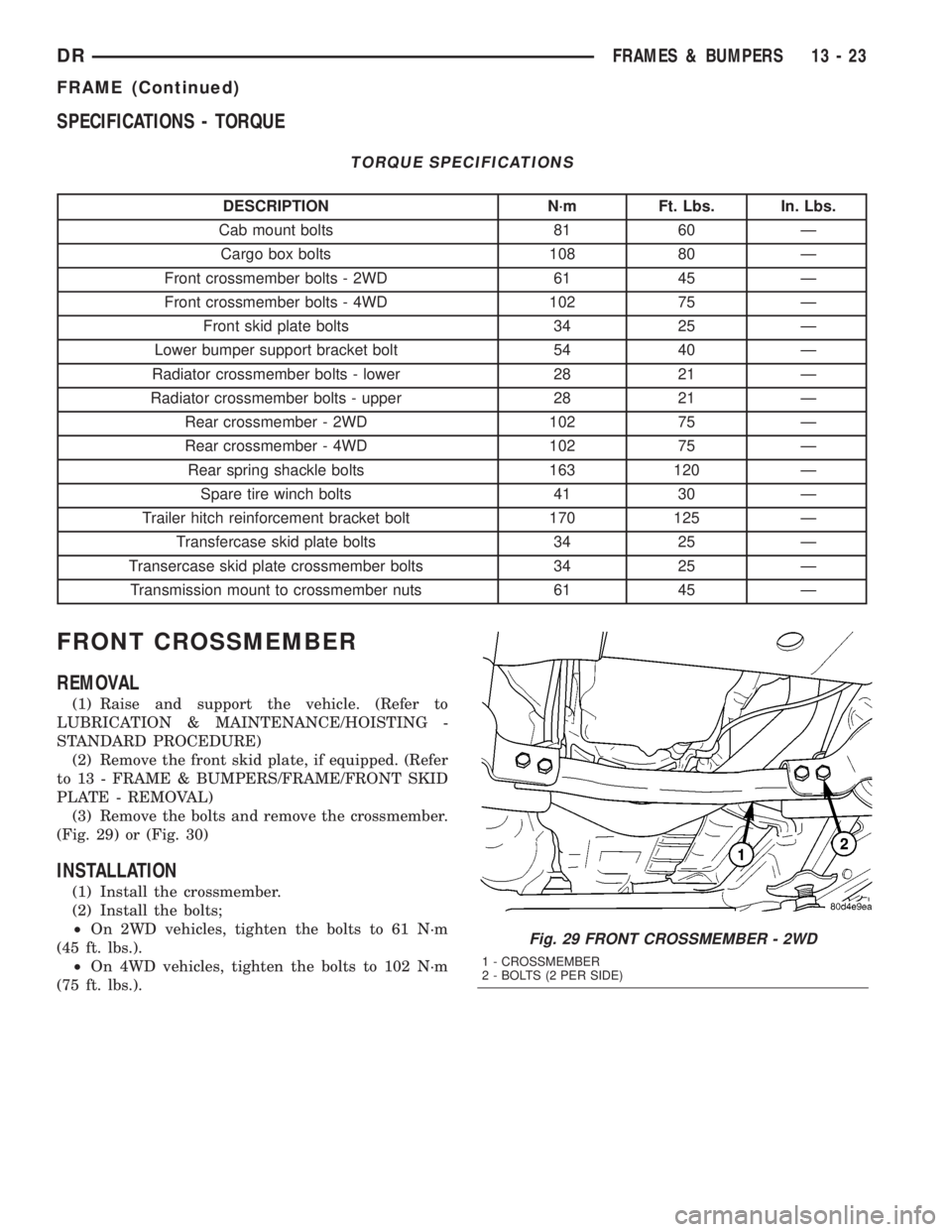

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Cab mount bolts 81 60 Ð

Cargo box bolts 108 80 Ð

Front crossmember bolts - 2WD 61 45 Ð

Front crossmember bolts - 4WD 102 75 Ð

Front skid plate bolts 34 25 Ð

Lower bumper support bracket bolt 54 40 Ð

Radiator crossmember bolts - lower 28 21 Ð

Radiator crossmember bolts - upper 28 21 Ð

Rear crossmember - 2WD 102 75 Ð

Rear crossmember - 4WD 102 75 Ð

Rear spring shackle bolts 163 120 Ð

Spare tire winch bolts 41 30 Ð

Trailer hitch reinforcement bracket bolt 170 125 Ð

Transfercase skid plate bolts 34 25 Ð

Transercase skid plate crossmember bolts 34 25 Ð

Transmission mount to crossmember nuts 61 45 Ð

FRONT CROSSMEMBER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the front skid plate, if equipped. (Refer

to 13 - FRAME & BUMPERS/FRAME/FRONT SKID

PLATE - REMOVAL)

(3) Remove the bolts and remove the crossmember.

(Fig. 29) or (Fig. 30)

INSTALLATION

(1) Install the crossmember.

(2) Install the bolts;

²On 2WD vehicles, tighten the bolts to 61 N´m

(45 ft. lbs.).

²On 4WD vehicles, tighten the bolts to 102 N´m

(75 ft. lbs.).

Fig. 29 FRONT CROSSMEMBER - 2WD

1 - CROSSMEMBER

2 - BOLTS (2 PER SIDE)

DRFRAMES & BUMPERS 13 - 23

FRAME (Continued)

Page 1695 of 2895

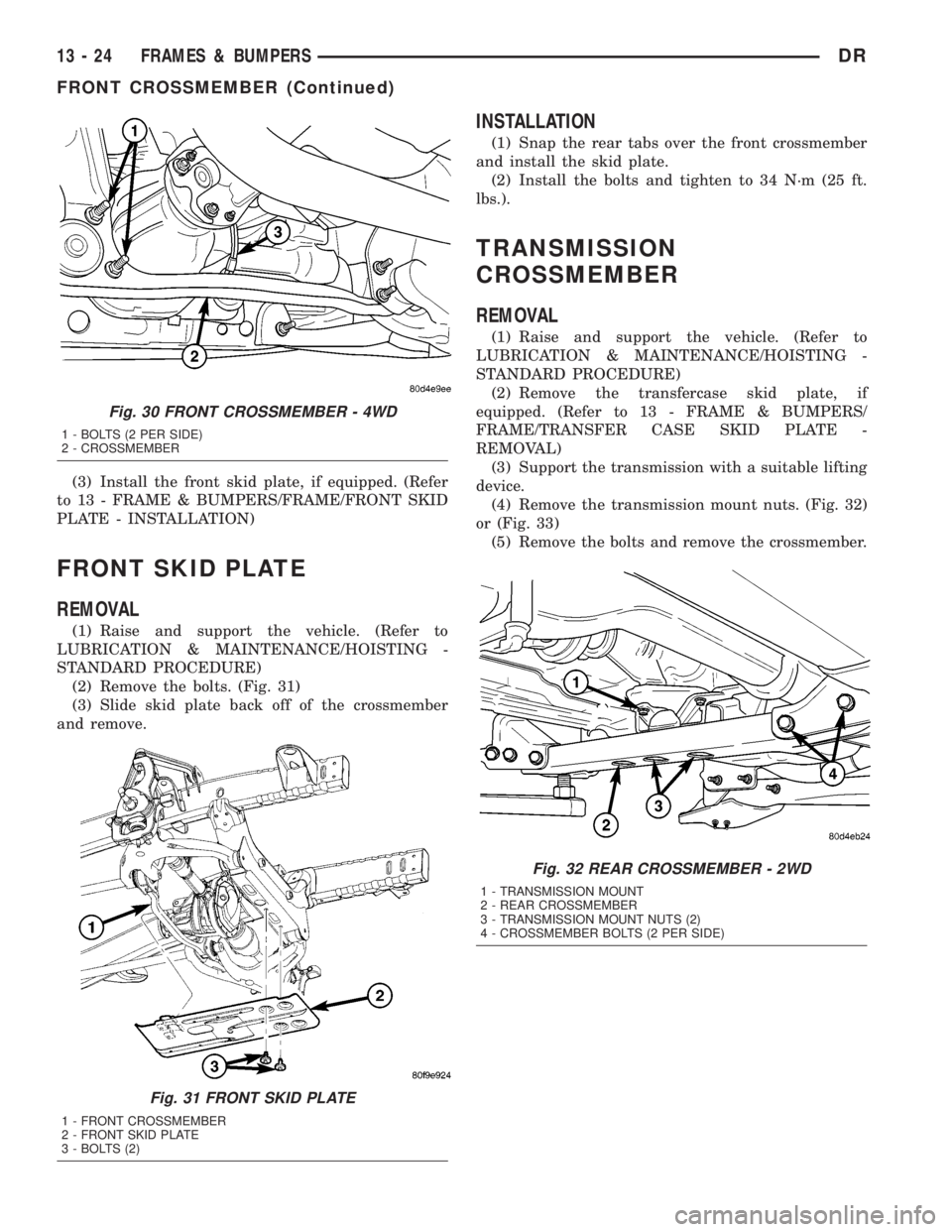

(3) Install the front skid plate, if equipped. (Refer

to 13 - FRAME & BUMPERS/FRAME/FRONT SKID

PLATE - INSTALLATION)

FRONT SKID PLATE

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the bolts. (Fig. 31)

(3) Slide skid plate back off of the crossmember

and remove.

INSTALLATION

(1) Snap the rear tabs over the front crossmember

and install the skid plate.

(2) Install the bolts and tighten to 34 N´m (25 ft.

lbs.).

TRANSMISSION

CROSSMEMBER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the transfercase skid plate, if

equipped. (Refer to 13 - FRAME & BUMPERS/

FRAME/TRANSFER CASE SKID PLATE -

REMOVAL)

(3) Support the transmission with a suitable lifting

device.

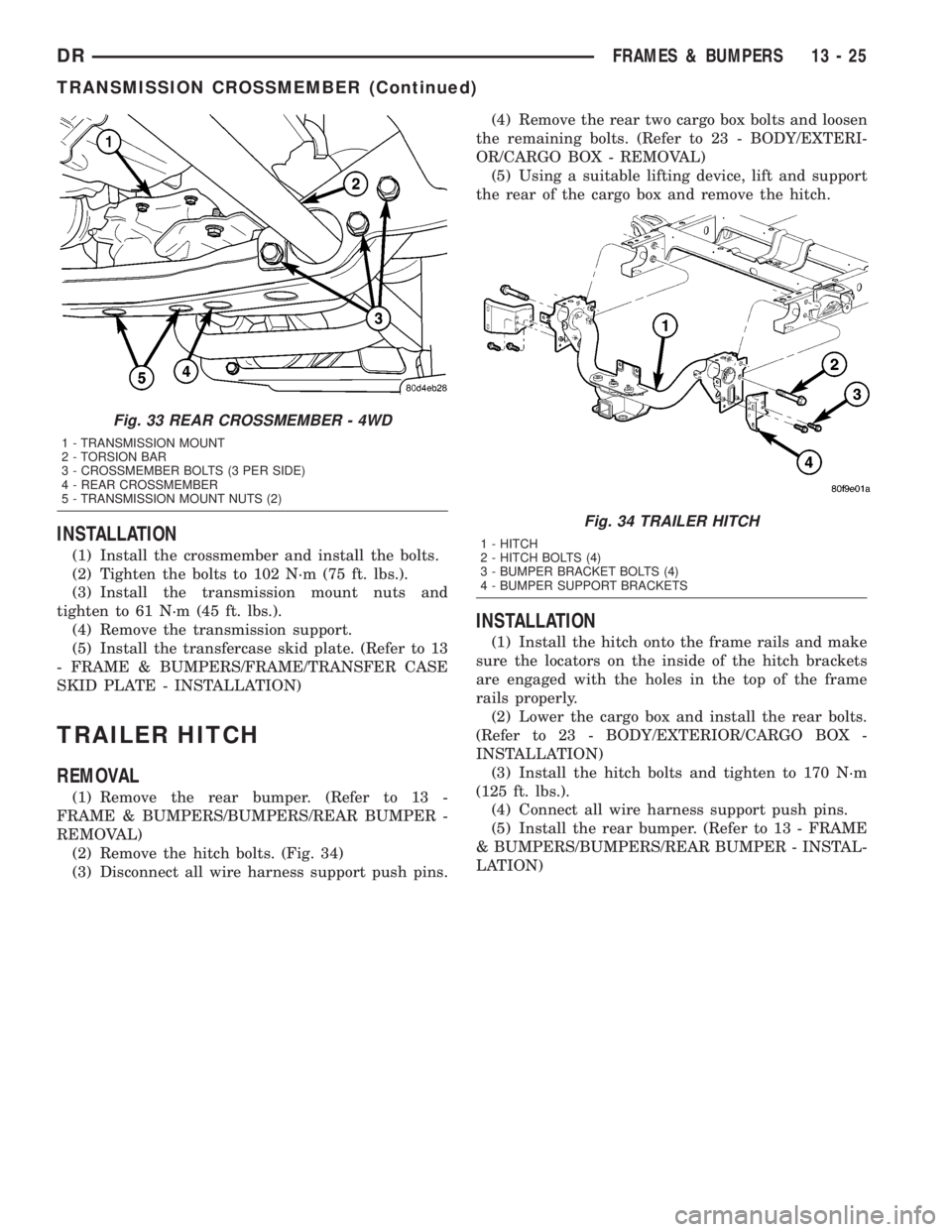

(4) Remove the transmission mount nuts. (Fig. 32)

or (Fig. 33)

(5) Remove the bolts and remove the crossmember.

Fig. 30 FRONT CROSSMEMBER - 4WD

1 - BOLTS (2 PER SIDE)

2 - CROSSMEMBER

Fig. 31 FRONT SKID PLATE

1 - FRONT CROSSMEMBER

2 - FRONT SKID PLATE

3 - BOLTS (2)

Fig. 32 REAR CROSSMEMBER - 2WD

1 - TRANSMISSION MOUNT

2 - REAR CROSSMEMBER

3 - TRANSMISSION MOUNT NUTS (2)

4 - CROSSMEMBER BOLTS (2 PER SIDE)

13 - 24 FRAMES & BUMPERSDR

FRONT CROSSMEMBER (Continued)

Page 1696 of 2895

INSTALLATION

(1) Install the crossmember and install the bolts.

(2) Tighten the bolts to 102 N´m (75 ft. lbs.).

(3) Install the transmission mount nuts and

tighten to 61 N´m (45 ft. lbs.).

(4) Remove the transmission support.

(5) Install the transfercase skid plate. (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

TRAILER HITCH

REMOVAL

(1) Remove the rear bumper. (Refer to 13 -

FRAME & BUMPERS/BUMPERS/REAR BUMPER -

REMOVAL)

(2) Remove the hitch bolts. (Fig. 34)

(3) Disconnect all wire harness support push pins.(4) Remove the rear two cargo box bolts and loosen

the remaining bolts. (Refer to 23 - BODY/EXTERI-

OR/CARGO BOX - REMOVAL)

(5) Using a suitable lifting device, lift and support

the rear of the cargo box and remove the hitch.

INSTALLATION

(1) Install the hitch onto the frame rails and make

sure the locators on the inside of the hitch brackets

are engaged with the holes in the top of the frame

rails properly.

(2) Lower the cargo box and install the rear bolts.

(Refer to 23 - BODY/EXTERIOR/CARGO BOX -

INSTALLATION)

(3) Install the hitch bolts and tighten to 170 N´m

(125 ft. lbs.).

(4) Connect all wire harness support push pins.

(5) Install the rear bumper. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/REAR BUMPER - INSTAL-

LATION)

Fig. 33 REAR CROSSMEMBER - 4WD

1 - TRANSMISSION MOUNT

2 - TORSION BAR

3 - CROSSMEMBER BOLTS (3 PER SIDE)

4 - REAR CROSSMEMBER

5 - TRANSMISSION MOUNT NUTS (2)

Fig. 34 TRAILER HITCH

1 - HITCH

2 - HITCH BOLTS (4)

3 - BUMPER BRACKET BOLTS (4)

4 - BUMPER SUPPORT BRACKETS

DRFRAMES & BUMPERS 13 - 25

TRANSMISSION CROSSMEMBER (Continued)

Page 1697 of 2895

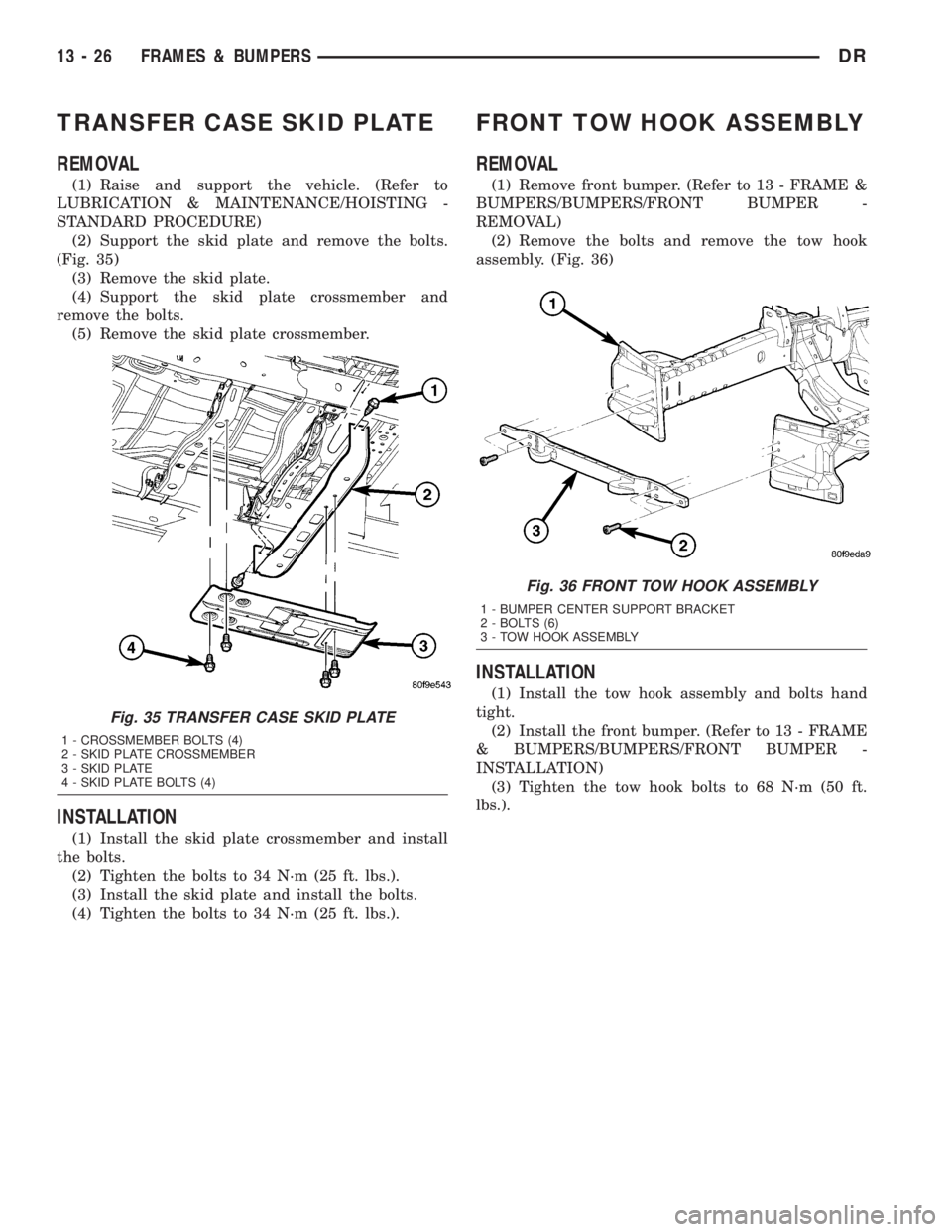

TRANSFER CASE SKID PLATE

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Support the skid plate and remove the bolts.

(Fig. 35)

(3) Remove the skid plate.

(4) Support the skid plate crossmember and

remove the bolts.

(5) Remove the skid plate crossmember.

INSTALLATION

(1) Install the skid plate crossmember and install

the bolts.

(2) Tighten the bolts to 34 N´m (25 ft. lbs.).

(3) Install the skid plate and install the bolts.

(4) Tighten the bolts to 34 N´m (25 ft. lbs.).

FRONT TOW HOOK ASSEMBLY

REMOVAL

(1) Remove front bumper. (Refer to 13 - FRAME &

BUMPERS/BUMPERS/FRONT BUMPER -

REMOVAL)

(2) Remove the bolts and remove the tow hook

assembly. (Fig. 36)

INSTALLATION

(1) Install the tow hook assembly and bolts hand

tight.

(2) Install the front bumper. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/FRONT BUMPER -

INSTALLATION)

(3) Tighten the tow hook bolts to 68 N´m (50 ft.

lbs.).

Fig. 35 TRANSFER CASE SKID PLATE

1 - CROSSMEMBER BOLTS (4)

2 - SKID PLATE CROSSMEMBER

3 - SKID PLATE

4 - SKID PLATE BOLTS (4)

Fig. 36 FRONT TOW HOOK ASSEMBLY

1 - BUMPER CENTER SUPPORT BRACKET

2 - BOLTS (6)

3 - TOW HOOK ASSEMBLY

13 - 26 FRAMES & BUMPERSDR