C1 terminal DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2790 of 2895

INSTALLATION

(1) Plug the two wire harness connectors into the

back of the A/C Heater control.

(2) Position the A/C Heater control in the instru-

ment panel bezel and secure it with four screws.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Reinstall the center bezel onto the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - INSTALLA-

TION).

(4) Connect the battery negative cable.

A/C PRESSURE TRANSDUCER

DESCRIPTION - A/C PRESSURE TRANSDUCER

The A/C pressure transducer is a switch that is

installed on a fitting located on the refrigerant dis-

charge line between the compressor and the conden-

sor in the front corner of the engine compartment. An

internally threaded hex fitting on the transducer con-

nects it to the externally threaded Schrader-type fit-

ting on the liquid line. A rubber O-ring seals the

connection between the transducer and the discharge

line fitting. Three terminals within a molded plastic

connector receptacle on the top of the transducer con-

nect it to the vehicle electrical system through a take

out and connector of the headlamp and dash wire

harness.

The A/C pressure transducer cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the discharge

line. The transducer will change its internal resis-

tance in response to the pressures it monitors. The

Powertrain Control Module (PCM) provides a five

volt reference signal and a sensor ground to the

transducer, then monitors the output voltage of the

transducer on a sensor return circuit to determine

refrigerant pressure. The PCM is programmed to

respond to this and other sensor inputs by controlling

the operation of the air conditioning compressor

clutch and the radiator cooling fan to help optimize

air conditioning system performance and to protect

the system components from damage. The A/C pres-

sure transducer input to the PCM will also prevent

the air conditioning compressor clutch from engaging

when ambient temperatures are below about 10É C

due to the pressure/temperature relationship of the

refrigerant. The Schrader-type valve in the discharge

line fitting permits the A/C pressure transducer to be

removed or installed without disturbing the refriger-

ant in the system. The A/C pressure transducer is

diagnosed using a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER

The A/C pressure transducer is tested using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information. Before testing the A/C pressure

transducer, be certain that the transducer wire har-

ness connection is clean of corrosion and properly

connected. For the air conditioning system to operate,

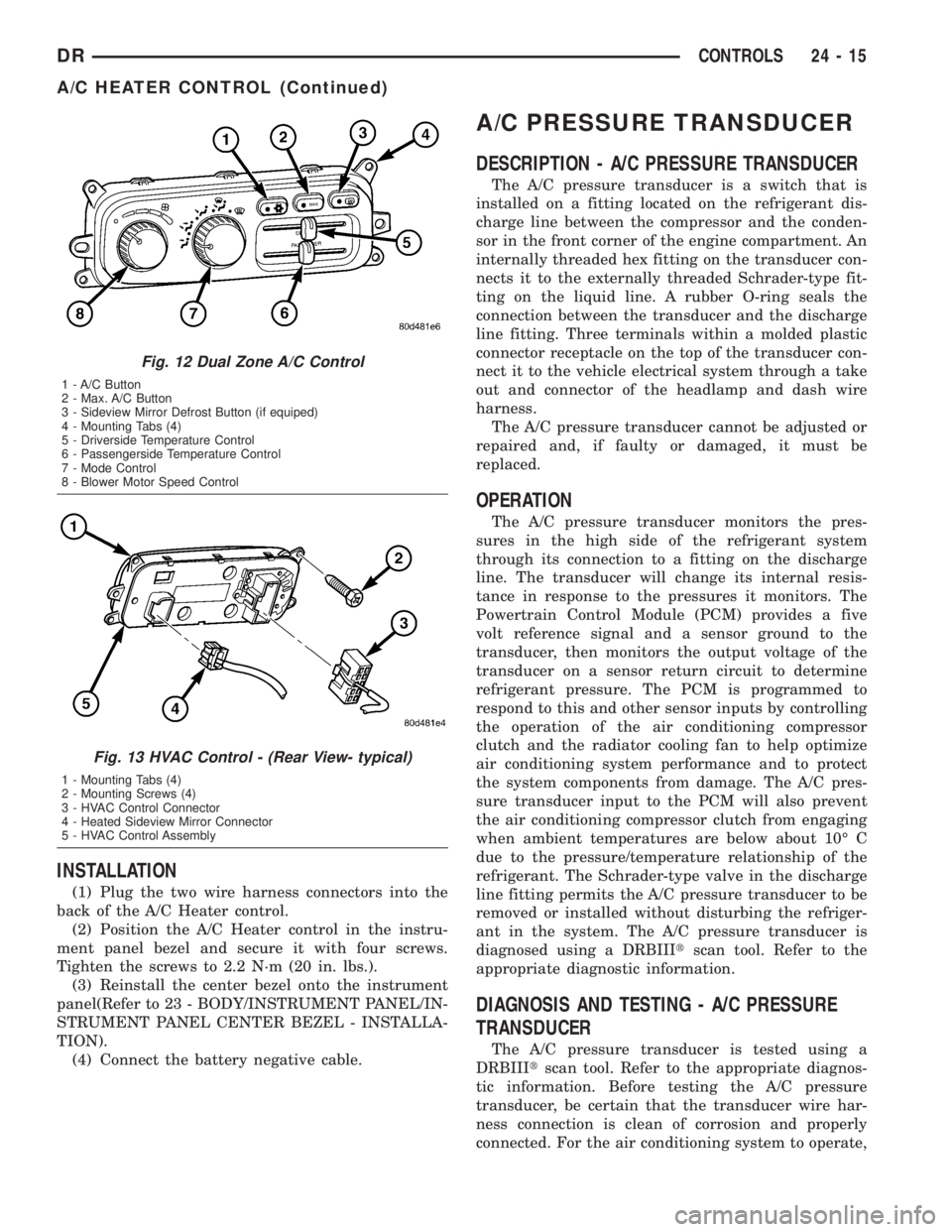

Fig. 12 Dual Zone A/C Control

1 - A/C Button

2 - Max. A/C Button

3 - Sideview Mirror Defrost Button (if equiped)

4 - Mounting Tabs (4)

5 - Driverside Temperature Control

6 - Passengerside Temperature Control

7 - Mode Control

8 - Blower Motor Speed Control

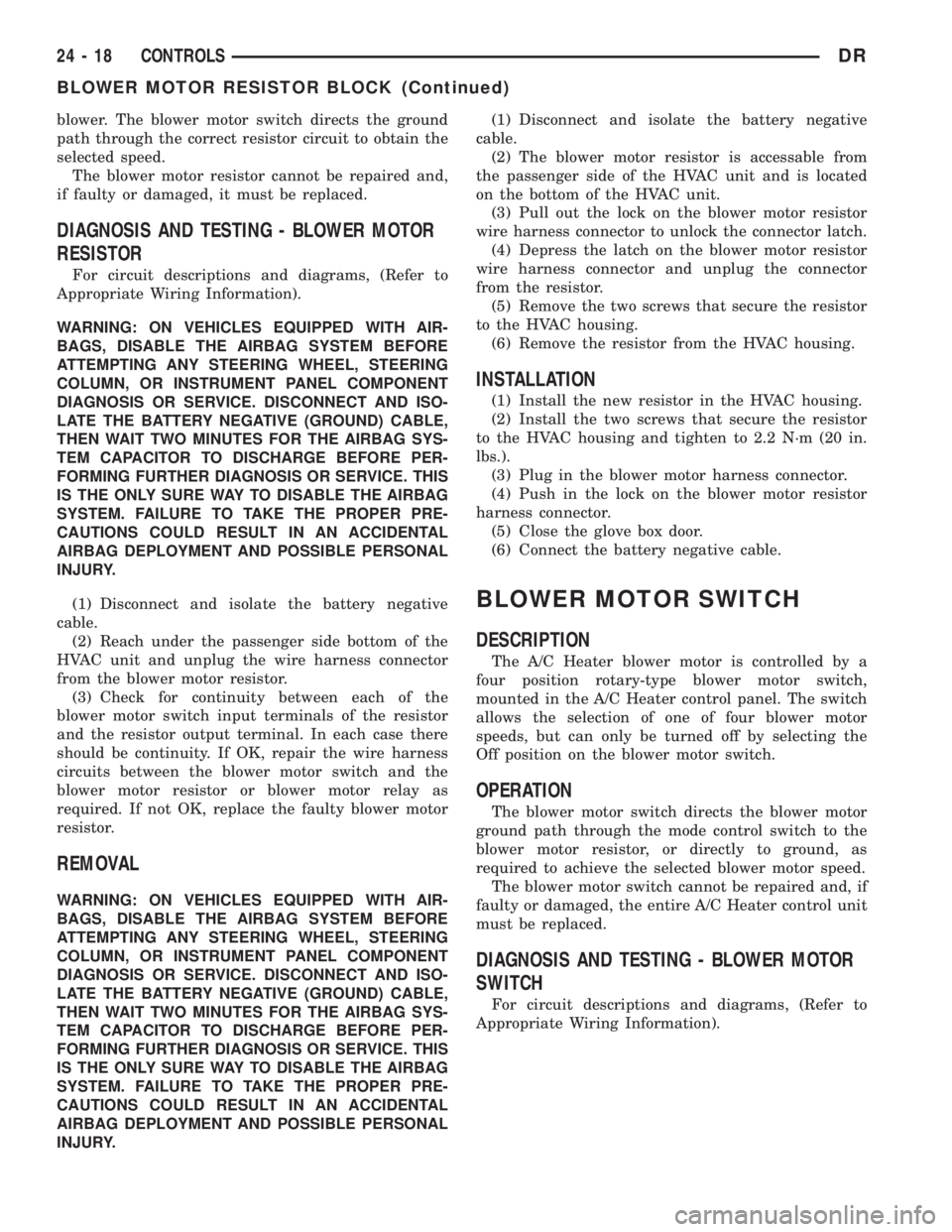

Fig. 13 HVAC Control - (Rear View- typical)

1 - Mounting Tabs (4)

2 - Mounting Screws (4)

3 - HVAC Control Connector

4 - Heated Sideview Mirror Connector

5 - HVAC Control Assembly

DRCONTROLS 24 - 15

A/C HEATER CONTROL (Continued)

Page 2793 of 2895

blower. The blower motor switch directs the ground

path through the correct resistor circuit to obtain the

selected speed.

The blower motor resistor cannot be repaired and,

if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the passenger side bottom of the

HVAC unit and unplug the wire harness connector

from the blower motor resistor.

(3) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor or blower motor relay as

required. If not OK, replace the faulty blower motor

resistor.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) The blower motor resistor is accessable from

the passenger side of the HVAC unit and is located

on the bottom of the HVAC unit.

(3) Pull out the lock on the blower motor resistor

wire harness connector to unlock the connector latch.

(4) Depress the latch on the blower motor resistor

wire harness connector and unplug the connector

from the resistor.

(5) Remove the two screws that secure the resistor

to the HVAC housing.

(6) Remove the resistor from the HVAC housing.

INSTALLATION

(1) Install the new resistor in the HVAC housing.

(2) Install the two screws that secure the resistor

to the HVAC housing and tighten to 2.2 N´m (20 in.

lbs.).

(3) Plug in the blower motor harness connector.

(4) Push in the lock on the blower motor resistor

harness connector.

(5) Close the glove box door.

(6) Connect the battery negative cable.

BLOWER MOTOR SWITCH

DESCRIPTION

The A/C Heater blower motor is controlled by a

four position rotary-type blower motor switch,

mounted in the A/C Heater control panel. The switch

allows the selection of one of four blower motor

speeds, but can only be turned off by selecting the

Off position on the blower motor switch.

OPERATION

The blower motor switch directs the blower motor

ground path through the mode control switch to the

blower motor resistor, or directly to ground, as

required to achieve the selected blower motor speed.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire A/C Heater control unit

must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

24 - 18 CONTROLSDR

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2794 of 2895

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the A/C Heater control from the instrument

panel. Check for continuity between the ground cir-

cuit cavity of the A/C Heater control wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 3. If not OK, repair the open

circuit to ground as required.

(3) With the A/C Heater control wire harness con-

nector unplugged, place the A/C Heater mode control

switch knob in any position except the Off position.

Check for continuity between the ground circuit ter-

minal and each of the blower motor driver circuit ter-

minals of the A/C Heater control as you move the

blower motor switch knob to each of the four speed

positions. There should be continuity at each driver

circuit terminal in only one blower motor switch

speed position. If OK, test and repair the blower

driver circuits between the A/C Heater control con-

nector and the blower motor resistor as required. If

not OK, replace the faulty A/C Heater control unit.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.The blower motor switch cannot be repaired and, if

faulty or damaged, the entire A/C Heater control unit

must be replaced. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C HEATER CON-

TROL - REMOVAL)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) The blower motor switch cannot be repaired

and, if faulty or damaged the entire A/C heater con-

trol unit must be replaced(Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - INSTALLATION).

DEFROST DOOR ACTUATOR

REMOVAL - FLOOR - DEFROST DOOR

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel assembly from

the vehicle(Refer to 23 - BODY/INSTRUMENT

PANEL - REMOVAL).

(3) Remove the electrical connector from the actua-

tor (Fig. 15).

DRCONTROLS 24 - 19

BLOWER MOTOR SWITCH (Continued)

Page 2889 of 2895

TACHOMETER - DESCRIPTION..........8J-37

TACHOMETER - OPERATION............8J-37

TAIL LAMP - INSTALLATION............8L-21

TAIL LAMP - REMOVAL................8L-21

TAIL LAMP UNIT - INSTALLATION.......8L-21

TAIL LAMP UNIT - REMOVAL...........8L-21

TAILGATE - INSTALLATION.............23-17

TAILGATE - REMOVAL.................23-17

TAILPIPE - 5.9L DIESEL - INSPECTION....11-9

TAILPIPE - 5.9L DIESEL - INSTALLATION . . . 11-9

TAILPIPE - 5.9L DIESEL - REMOVAL......11-9

TAILPIPE - INSPECTION...............11-10

TAILPIPE - INSTALLATION..............11-10

TAILPIPE - REMOVAL.................11-10

TANK - DESCRIPTION, FUEL............14-20

TANK - OPERATION, FUEL..............14-20

TANK MODULE - DESCRIPTION, FUEL....14-75

TANK MODULE - INSTALLATION, FUEL....14-75

TANK MODULE - OPERATION, FUEL......14-75

TANK MODULE - REMOVAL, FUEL.......14-75

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC....................9-258,9-386

TASK MANAGER - DESCRIPTION.........25-1

TASK MANAGER - OPERATION...........25-5

TCM QUICK LEARN - STANDARD

PROCEDURE........................8E-21

TEMP INDICATOR - DESCRIPTION,

TRANS.............................8J-38

TEMP INDICATOR - OPERATION, TRANS . . 8J-38

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-10

TEMP SENSOR - OPERATION, AMBIENT . . 8M-10

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-23

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-23

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-21

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - DESCRIPTION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION.........21-267,21-445,21-583

TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT..............8M-11

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-21

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT........7-47

TEMPERATURE SENSOR -

INSTALLATION, INTAKE AIR............14-38

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-21

TEMPERATURE SENSOR - OPERATION,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - OPERATION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION.........21-267,21-445,21-583

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-21

TEMPERATURE SENSOR - REMOVAL,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - REMOVAL,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR CIRCUIT -

DIAGNOSIS AND TESTING, AMBIENT....8M-11

TEMPERATURE SENSOR/MAP SENSOR -

DESCRIPTION, INTAKE AIR.............14-93

TEMPERATURE SENSOR/MAP SENSOR -

INSTALLATION, INTAKE AIR............14-94

TEMPERATURE SENSOR/MAP SENSOR -

OPERATION, INTAKE AIR...............14-93

TEMPERATURE SENSOR/MAP SENSOR -

REMOVAL, INTAKE AIR................14-93

TEMPERATURE SENSOR/PRESSURE

SENSOR - DESCRIPTION, INLET AIR.....14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - INSTALLATION, INLET AIR

.....14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - OPERATION, INLET AIR

.......14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - REMOVAL, INLET AIR

........14-90

TEMPORARY - DESCRIPTION, SPARE

TIRE

................................22-5

TEMPORARY TIRE - DESCRIPTION,

SPARE

.............................22-15TENSION REDUCER - DESCRIPTION,

SEAT BELT .........................8O-48

TENSION REDUCER - DIAGNOSIS AND

TESTING, SEAT BELT.................8O-49

TENSION REDUCER - OPERATION, SEAT

BELT ..............................8O-49

TENSIONER - DESCRIPTION, SEAT BELT . . 8O-47

TENSIONER - OPERATION, SEAT BELT....8O-48

TENSIONERS - 3.7L / 4.7L -

DESCRIPTION, BELT...................7-22

TENSIONERS - 3.7L / 4.7L -

INSTALLATION, BELT...................7-23

TENSIONERS - 3.7L / 4.7L - OPERATION,

BELT ...............................7-22

TENSIONERS - 3.7L / 4.7L - REMOVAL,

BELT ...............................7-22

TENSIONERS - 5.9L - DESCRIPTION,

BELT ...............................7-23

TENSIONERS - 5.9L - INSTALLATION,

BELT ...............................7-24

TENSIONERS - 5.9L - OPERATION, BELT . . . 7-23

TENSIONERS - 5.9L - REMOVAL, BELT.....7-23

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-24

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-25

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-24

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-25

TERMINAL - INSTALLATION.........8W-01-14

TERMINAL - REMOVAL..............8W-01-14

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE . . 21-140,21-321,21-493

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-3

TEST - DIAGNOSIS AND TESTING,

VACUUM SUPPLY.....................8P-2

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-11

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-10

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-8

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION..........................25-1

TEST MODE - DESCRIPTION, STATE

DISPLAY............................25-1

TESTER - STANDARD PROCEDURE,

USING MICRO 420 BATTERY............8F-12

TESTS - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION/LEAKAGE.....9-288

THEFT SECURITY SYSTEM, DIAGNOSIS

AND TESTING - VEHICLE...............8Q-3

THERMOSTAT - 3.7L/4.7L -

DESCRIPTION, ENGINE COOLANT.........7-50

THERMOSTAT - 3.7L/4.7L -

INSTALLATION, ENGINE COOLANT........7-51

THERMOSTAT - 3.7L/4.7L - OPERATION,

ENGINE COOLANT.....................7-51

THERMOSTAT - 3.7L/4.7L - REMOVAL,

ENGINE COOLANT.....................7-51

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT.........7-52

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT........7-53

THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE COOLANT..........7-52

THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE COOLANT............7-53

THERMOSTAT - DIAGNOSIS AND

TESTING....................7-48,7-51,7-52

THERMOSTAT-5.7L/5.9L - DESCRIPTION,

ENGINE COOLANT.....................7-47

THERMOSTAT-5.7L/5.9L -

INSTALLATION, ENGINE COOLANT........7-49

THERMOSTAT-5.7L/5.9L - OPERATION,

ENGINE COOLANT

.....................7-48

THERMOSTAT-5.7L/5.9L - REMOVAL,

ENGINE COOLANT

.....................7-48

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM

. 21-156,21-337,21-495

THREADED HOLE REPAIR -

DESCRIPTION

......................Intro.-9

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN

.....9-186,9-232,

9-289,9-361,9-9,9-93THROTTLE BODY - DESCRIPTION........14-45

THROTTLE BODY - INSTALLATION.......14-47

THROTTLE BODY - OPERATION.........14-45

THROTTLE BODY - REMOVAL...........14-45

THROTTLE CONTROL CABLE -

INSTALLATION..................14-51,14-96

THROTTLE CONTROL CABLE - REMOVAL . 14-49,

14-94

THROTTLE POSITION SENSOR -

DESCRIPTION.......................14-52

THROTTLE POSITION SENSOR -

INSTALLATION.......................14-54

THROTTLE POSITION SENSOR -

OPERATION.........................14-52

THROTTLE POSITION SENSOR -

REMOVAL..........................14-53

THROTTLE VALVE CABLE -

ADJUSTMENTS...............21-255,21-432

THROTTLE VALVE CABLE -

DESCRIPTION................21-254,21-432

TIE DOWN - INSTALLATION, CARGO BOX . 23-37

TIE DOWN - REMOVAL, CARGO BOX.....23-37

TIE ROD END - DIAGNOSIS AND

TESTING, OUTER.....................19-31

TIE ROD END - INSTALLATION..........19-37

TIE ROD END - INSTALLATION, OUTER . . . 19-32

TIE ROD END - REMOVAL..............19-36

TIE ROD END - REMOVAL, OUTER.......19-31

TIMING - DESCRIPTION, VALVE..........9-75

TIMING - DIAGNOSIS AND TESTING,

FUEL INJECTION PUMP...............14-65

TIMING - OPERATION, VALVE............9-75

TIMING - VERIFICATION - STANDARD

PROCEDURE, ENGINE.................9-165

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........9-169,9-278,9-404,9-81

TIMING BELT / CHAIN COVER(S) -

REMOVAL............9-168,9-278,9-404,9-80

TIMING BELT/CHAIN AND SPROCKETS -

INSPECTION....................9-171,9-83

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION........9-172,9-279,9-406,9-84

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL............9-169,9-279,9-405,9-81

TIMING CHAIN STRETCH - INSPECTION,

MEASURING...................9-279,9-405

TIMING CHAIN WEAR - STANDARD

PROCEDURE, MEASURING.............9-165

TIMING CHAIN WEAR, STANDARD

PROCEDURE - MEASURING.............9-76

TIMING CHAIN/TENSIONER -

DESCRIPTION.......................9-222

TIMING CHAIN/TENSIONER - OPERATION . 9-222

TIMING DRIVE SYSTEM - DESCRIPTION . . 9-164

TIMING DRIVE SYSTEM - OPERATION....9-164

TIMING, SPECIFICATIONS - IGNITION......8I-6

TIMING VERIFICATION - SERVICE

PROCEDURE.........................9-76

TIMING VERIFICATION - STANDARD

PROCEDURE........................9-348

TIMING/CHAIN AND SPROCKETS -

INSTALLATION.......................9-222

TIMING/CHAIN AND SPROCKETS -

REMOVAL..........................9-221

TIMING/CHAIN COVER - INSTALLATION

. . . 9-221

TIMING/CHAIN COVER - REMOVAL

.......9-220

TIP INSERTS - INSTALLATION, SPRING

....2-42

TIP INSERTS - REMOVAL, SPRING

........2-41

TIP REPLACEMENT - STANDARD

PROCEDURE, LIGHT DUTY FRONT

FRAME RAIL

.........................13-4

TIRE - DESCRIPTION, FULL SIZE, SPARE

WHEEL WITH MATCHING

..............22-15

TIRE - DESCRIPTION, SPARE /

TEMPORARY

........................22-15

TIRE / TEMPORARY - DESCRIPTION,

SPARE

..............................22-5

TIRE AND WHEEL BALANCE -

STANDARD PROCEDURE

................22-4

TIRE AND WHEEL RUNOUT - DIAGNOSIS

AND TESTING

........................22-1

TIRE INFLATION PRESSURES -

DESCRIPTION

........................22-6

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING

........................22-7

TIRE PRESSURE FOR HIGH SPEEDS -

DESCRIPTION

........................22-6

34 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2890 of 2895

TIRE REVOLUTIONS PER MILE,

SPECIFICATIONS.....................22-10

TIRE ROTATION - STANDARD

PROCEDURE.........................22-2

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-8

TIRES - DESCRIPTION.................22-5

TIRES - DESCRIPTION, RADIAL - PLY.....22-6

TIRES - DESCRIPTION, REPLACEMENT....22-6

TIRE/VEHICLE LEAD - DIAGNOSIS AND

TESTING............................22-8

TO COOLER - INSTALLATION, RETURN

HOSE - GEAR..................19-43,19-44

TO COOLER - INSTALLATION, RETURN

HOSE - RESERVOIR.............19-43,19-44

TO COOLER - REMOVAL, RETURN HOSE

- GEAR............................19-43

TO COOLER - REMOVAL, RETURN HOSE

- RESERVOIR..................19-43,19-44

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-9

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT . 8W-01-10

TO OIL COOLER - INSTALLATION, AIR.....7-75

TO OIL COOLER - REMOVAL, AIR.........7-74

TO OIL COOLER - REMOVAL, WATER......7-74

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOE ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

TOE ADJUSTMENT - STANDARD

PROCEDURE, CAMBER, CASTER..........2-4

TOOL - ADJUSTMENT, WITH ADJUSTING . . . 5-36

TOOLS - 4.7L ENGINE, SPECIAL.........9-102

TOOLS - 5.7L ENGINE, SPECIAL.........9-192

TOOLS - 5.9L DIESEL ENGINE, SPECIAL . . 9-294

TOOLS - 5.9L ENGINE, SPECIAL.........9-240

TOOLS - 8.0L ENGINE, SPECIAL.........9-367

TOOLS - 9 1/4 AA, SPECIAL.............2-29

TOOLS - BASE BRAKES, SPECIAL.........5-5

TOOLS - BATTERY SYSTEM SPECIAL

TOOLS, SPECIAL......................8F-7

TOOLS - BODY, SPECIAL...............23-14

TOOLS - COOLING, SPECIAL.............7-20

TOOLS - DIESEL FUEL SYSTEM,

SPECIAL...........................14-60

TOOLS - FRONT SUSPENSION, SPECIAL . . . 2-11

TOOLS - FUEL SYSTEM, SPECIAL........14-5

TOOLS - OVERHEAD CONSOLE, SPECIAL . . 8M-6

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL................8W-97-2

TOOLS - POWER STEERING GEAR,

SPECIAL...........................19-22

TOOLS - RE TRANSMISSION, SPECIAL . . 21-189,

21-370

TOOLS - RFE TRANSMISSION, SPECIAL . . 21-535

TOOLS - STEERING LINKAGE, SPECIAL . . . 19-35

TOOLS - STEERING, SPECIAL............19-5

TOOLS - TRANSFER CASE NV271/NV273,

SPECIAL....................21-650,21-714

TOOLS - WHEEL ALIGNMENT, SPECIAL.....2-7

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-10

TOOLS, DIAGNOSIS AND TESTING -

SPECIAL............................11-4

TOOLS, FRONT AXLE - 9 1/4 AA -

SPECIAL............................3-53

TOOLS, FRONT AXLE - C205F - SPECIAL . . . 3-30

TOOLS, HALF SHAFT - SPECIAL..........3-12

TOOLS, HEADLAMP ALIGNMENT -

SPECIAL............................8L-7

TOOLS, MANUAL TRANSMISSION -

NV3500 - SPECIAL...................21-40

TOOLS, MANUAL TRANSMISSION -

NV4500 - SPECIAL...................21-79

TOOLS, MANUAL TRANSMISSION -

NV5600 - SPECIAL..................21-122

TOOLS, PROPELLER SHAFT - SPECIAL.....3-6

TOOLS, REAR AXLE - 10 1/2 AA -

SPECIAL...........................3-108

TOOLS, REAR AXLE - 11 1/2 AA -

SPECIAL

...........................3-135

TOOLS, REAR AXLE - 9 1/4 - SPECIAL

.....3-80

TOOLS, SPECIAL TOOLS - BATTERY

SYSTEM SPECIAL

.....................8F-7

TOOLS, SPECIFICATIONS - SPECIAL

.......9-16

TOP COVER - INSTALLATION,

INSTRUMENT PANEL

..................23-60TOP COVER - REMOVAL, INSTRUMENT

PANEL.............................23-59

TORSION BAR - DESCRIPTION...........2-25

TORSION BAR - INSTALLATION..........2-26

TORSION BAR - OPERATION.............2-25

TORSION BAR - REMOVAL..............2-25

TORSION BAR CROSS MEMBER

BUSHING - INSTALLATION..............2-14

TORSION BAR CROSSMEMBER

BUSHING - REMOVAL..................2-12

TOUCH-UP - DESCRIPTION, PAINT.......23-75

TOUCH-UP - STANDARD PROCEDURE,

PAINT.............................23-75

TOW HOOK ASSEMBLY - INSTALLATION,

FRONT.............................13-26

TOW HOOK ASSEMBLY - REMOVAL,

FRONT.............................13-26

TOW WIRING - DESCRIPTION, TRAILER . . 8L-22

TOWING - STANDARD PROCEDURE.......0-15

TRACK - DESCRIPTION, POWER SEAT....8N-18

TRACK - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-18

TRACK - INSTALLATION, POWER SEAT . . . 8N-19

TRACK - INSTALLATION, SEAT..........23-83

TRACK - OPERATION, POWER SEAT.....8N-18

TRACK - REMOVAL, POWER SEAT.......8N-19

TRACK - REMOVAL, SEAT..............23-83

TRACK BAR - INSTALLATION...........19-37

TRACK BAR - REMOVAL................19-37

TRAC-RITE - ASSEMBLY, DIFFERENTIAL . . 3-120,

3-147

TRAC-RITE - CLEANING, DIFFERENTIAL . . 3-119,

3-146

TRAC-RITE - DESCRIPTION,

DIFFERENTIAL..................3-118,3-145

TRAC-RITE - DISASSEMBLY,

DIFFERENTIAL..................3-118,3-145

TRAC-RITE - INSPECTION, DIFFERENTIAL . 3-119,

3-146

TRAC-RITE - OPERATION, DIFFERENTIAL . 3-118,

3-145

TRAILER HITCH - INSTALLATION........13-25

TRAILER HITCH - REMOVAL............13-25

TRAILER TOW WIRING - DESCRIPTION . . . 8L-22

TRANS COOLER - 5.9L DIESEL -

DESCRIPTION........................7-73

TRANS COOLER - 5.9L DIESEL -

OPERATION..........................7-74

TRANS TEMP INDICATOR -

DESCRIPTION.......................8J-38

TRANS TEMP INDICATOR - OPERATION . . . 8J-38

TRANSDUCER - DESCRIPTION, A/C

PRESSURE.........................24-15

TRANSDUCER - DIAGNOSIS AND

TESTING, A/C PRESSURE..............24-15

TRANSDUCER - INSTALLATION, A/C

PRESSURE.........................24-16

TRANSDUCER - OPERATION, A/C

PRESSURE.........................24-15

TRANSDUCER - REMOVAL, A/C

PRESSURE.........................24-16

TRANSFER CASE - NV241 GENII -

ASSEMBLY.........................21-604

TRANSFER CASE - NV241 GENII -

CLEANING

.........................21-602

TRANSFER CASE - NV241 GENII -

DESCRIPTION

.........................0-4

TRANSFER CASE - NV241 GENII -

DESCRIPTION

......................21-591

TRANSFER CASE - NV241 GENII -

DIAGNOSIS AND TESTING

............21-592

TRANSFER CASE - NV241 GENII -

DISASSEMBLY

......................21-593

TRANSFER CASE - NV241 GENII -

INSPECTION

.......................21-602

TRANSFER CASE - NV241 GENII -

INSTALLATION

......................21-614

TRANSFER CASE - NV241 GENII -

OPERATION

........................21-591

TRANSFER CASE - NV241 GENII -

REMOVAL

.........................21-593

TRANSFER CASE - NV243 - ASSEMBLY

. . 21-670

TRANSFER CASE - NV243 - CLEANING

. . 21-668

TRANSFER CASE - NV243 -

DESCRIPTION

.........................0-4

TRANSFER CASE - NV243 -

DESCRIPTION

......................21-658TRANSFER CASE - NV243 - DIAGNOSIS

AND TESTING......................21-659

TRANSFER CASE - NV243 -

DISASSEMBLY......................21-660

TRANSFER CASE - NV243 - INSPECTION . 21-668

TRANSFER CASE - NV243 -

INSTALLATION......................21-679

TRANSFER CASE - NV243 - OPERATION . 21-659

TRANSFER CASE - NV243 - REMOVAL . . . 21-660

TRANSFER CASE - NV271 - ASSEMBLY . . 21-637

TRANSFER CASE - NV271 - CLEANING . . 21-635

TRANSFER CASE - NV271 -

DESCRIPTION.........................0-4

TRANSFER CASE - NV271 -

DESCRIPTION......................21-623

TRANSFER CASE - NV271 - DIAGNOSIS

AND TESTING......................21-624

TRANSFER CASE - NV271 -

DISASSEMBLY......................21-625

TRANSFER CASE - NV271 - INSPECTION . 21-635

TRANSFER CASE - NV271 -

INSTALLATION......................21-649

TRANSFER CASE - NV271 - OPERATION . 21-623

TRANSFER CASE - NV271 - REMOVAL . . . 21-625

TRANSFER CASE - NV273 - ASSEMBLY . . 21-701

TRANSFER CASE - NV273 - CLEANING . . 21-698

TRANSFER CASE - NV273 -

DESCRIPTION.........................0-4

TRANSFER CASE - NV273 -

DESCRIPTION......................21-687

TRANSFER CASE - NV273 - DIAGNOSIS

AND TESTING......................21-688

TRANSFER CASE - NV273 -

DISASSEMBLY......................21-689

TRANSFER CASE - NV273 - INSPECTION . 21-699

TRANSFER CASE - NV273 -

INSTALLATION......................21-713

TRANSFER CASE - NV273 - OPERATION . 21-688

TRANSFER CASE - NV273 - REMOVAL . . . 21-689

TRANSFER CASE CONTROL MODULE -

DESCRIPTION.......................8E-15

TRANSFER CASE CONTROL MODULE -

OPERATION.........................8E-15

TRANSFER CASE, NV241 GENII........21-614

TRANSFER CASE, NV241/NV243 . . 21-615,21-680

TRANSFER CASE, NV243.............21-680

TRANSFER CASE, NV271.............21-649

TRANSFER CASE NV271/NV273, SPECIAL

TOOLS......................21-650,21-714

TRANSFER CASE, NV273.............21-713

TRANSFER CASE SKID PLATE -

INSTALLATION.......................13-26

TRANSFER CASE SKID PLATE -

REMOVAL..........................13-26

TRANSFER PUMP - DESCRIPTION, FUEL . . 14-75

TRANSFER PUMP - INSTALLATION, FUEL . 14-76

TRANSFER PUMP - OPERATION, FUEL....14-76

TRANSFER PUMP - REMOVAL, FUEL.....14-76

TRANSMISSION - 45RFE/545RFE -

DESCRIPTION, AUTOMATIC............21-489

TRANSMISSION - 45RFE/545RFE -

OPERATION, AUTOMATIC.............21-490

TRANSMISSION - 46RE - DESCRIPTION,

AUTOMATIC

........................21-131

TRANSMISSION - 46RE - OPERATION,

AUTOMATIC

........................21-133

TRANSMISSION - 48RE - DESCRIPTION,

AUTOMATIC

........................21-312

TRANSMISSION - 48RE - OPERATION,

AUTOMATIC

........................21-314

TRANSMISSION - CLEANING

..........21-104

TRANSMISSION - DESCRIPTION,

MANUAL

.............................0-4

TRANSMISSION - DIAGNOSIS AND

TESTING, AUTOMATIC

....21-139,21-320,21-491

TRANSMISSION - NV3500 - ASSEMBLY,

MANUAL

...........................21-17

TRANSMISSION - NV3500 - CLEANING,

MANUAL

...........................21-15

TRANSMISSION - NV3500 -

DESCRIPTION, MANUAL

................21-1

TRANSMISSION - NV3500 - DIAGNOSIS

AND TESTING, MANUAL

................21-3

TRANSMISSION - NV3500 -

DISASSEMBLY, MANUAL

................21-4

TRANSMISSION - NV3500 -

INSPECTION, MANUAL

................21-15

DRINDEX 35

Description Group-Page Description Group-Page Description Group-Page

Page 2893 of 2895

VOLUME CHECK - STANDARD

PROCEDURE, OIL PUMP..............21-563

WAIT-TO-START INDICATOR -

DESCRIPTION.......................8J-42

WAIT-TO-START INDICATOR -

OPERATION.........................8J-42

WARNING - INSTALLATION.............23-88

WARNING - REMOVAL................23-88

WARNING - SAFETY PRECAUTIONS AND

WARNINGS..........................23-1

WARNING - SERVICE WARNINGS........24-32

WARNING - WINDSHIELD SAFETY

PRECAUTIONS.......................23-88

WARNING, CLUTCH.....................6-2

WARNINGS, GENERAL..............8W-01-7

WARNINGS, RESTRAINT SYSTEM........8O-5

WARNINGS, WARNING - SAFETY

PRECAUTIONS........................23-1

WARNINGS, WARNING - SERVICE.......24-32

WASHER FLUID INDICATOR -

DESCRIPTION.......................8J-42

WASHER FLUID INDICATOR -

OPERATION.........................8J-42

WASHER FLUID LEVEL SWITCH -

DESCRIPTION........................8R-9

WASHER FLUID LEVEL SWITCH -

INSTALLATION......................8R-11

WASHER FLUID LEVEL SWITCH -

OPERATION..........................8R-9

WASHER FLUID LEVEL SWITCH -

REMOVAL..........................8R-10

WASHER HOSES/TUBES - DESCRIPTION . . 8R-11

WASHER HOSES/TUBES - OPERATION....8R-11

WASHER NOZZLE - DESCRIPTION.......8R-12

WASHER NOZZLE - INSTALLATION......8R-12

WASHER NOZZLE - OPERATION.........8R-12

WASHER NOZZLE - REMOVAL..........8R-12

WASHER PUMP/MOTOR - DESCRIPTION . . 8R-13

WASHER PUMP/MOTOR - INSTALLATION . 8R-14

WASHER PUMP/MOTOR - OPERATION . . . 8R-13

WASHER PUMP/MOTOR - REMOVAL.....8R-14

WASHER RESERVOIR - DESCRIPTION....8R-15

WASHER RESERVOIR - OPERATION......8R-15

WASHER SYSTEM - CLEANING, WIPER....8R-6

WASHER SYSTEM - DIAGNOSIS AND

TESTING, WIPER.....................8R-6

WASHER SYSTEM - INSPECTION, WIPER . . 8R-7

WATER DRAINING AT FUEL FILTER -

STANDARD PROCEDURES..............14-57

WATER IN FUEL SENSOR -

DESCRIPTION.......................14-77

WATER IN FUEL SENSOR - OPERATION . . . 14-78

WATER IN FUEL SENSOR - REMOVAL....14-78

WATER LEAKS - DIAGNOSIS AND

TESTING............................23-1

WATER PUMP - 5.7L - INSTALLATION.....7-71

WATER PUMP - 5.7L - REMOVAL.........7-70

WATER PUMP - 5.9L - CLEANING........7-64

WATER PUMP - 5.9L - DESCRIPTION......7-62

WATER PUMP - 5.9L - INSPECTION.......7-64

WATER PUMP - 5.9L - INSTALLATION.....7-64

WATER PUMP - 5.9L - OPERATION.......7-62

WATER PUMP - 5.9L - REMOVAL.........7-63

WATER PUMP - 5.9L DIESEL -

CLEANING...........................7-67

WATER PUMP - 5.9L DIESEL -

DESCRIPTION........................7-67

WATER PUMP - 5.9L DIESEL -

INSPECTION.........................7-68

WATER PUMP - 5.9L DIESEL -

INSTALLATION........................7-68

WATER PUMP - 5.9L DIESEL -

OPERATION

..........................7-67

WATER PUMP - 5.9L DIESEL - REMOVAL

. . 7-67

WATER PUMP - DESCRIPTION

...........7-64

WATER PUMP - DIAGNOSIS AND

TESTING

........................7-62,7-67

WATER PUMP - OPERATION

.............7-64

WATER PUMP BYPASS - DESCRIPTION

....7-64

WATER PUMP BYPASS - OPERATION

......7-65

WATER PUMP BYPASS HOSE WITH AIR

CONDITIONING - INSTALLATION

..........7-70WATER PUMP BYPASS HOSE WITH AIR

CONDITIONING - REMOVAL.............7-68

WATER PUMP BYPASS HOSE WITHOUT

AIR CONDITIONING - INSTALLATION......7-70

WATER PUMP BYPASS HOSE WITHOUT

AIR CONDITIONING - REMOVAL..........7-69

WATER SEPARATOR - DESCRIPTION,

FUEL FILTER........................14-61

WATER SEPARATOR - INSTALLATION,

FUEL FILTER........................14-62

WATER SEPARATOR - OPERATION, FUEL

FILTER.............................14-61

WATER SEPARATOR - REMOVAL, FUEL

FILTER.............................14-61

WATER TO OIL COOLER - REMOVAL......7-74

WATERDAM - INSTALLATION......23-25,23-34

WATERDAM - REMOVAL..........23-25,23-34

WATER-IN-FUEL INDICATOR -

DESCRIPTION.......................8J-43

WATER-IN-FUEL INDICATOR -

OPERATION.........................8J-43

WEAR - STANDARD PROCEDURE,

MEASURING TIMING CHAIN............9-165

WEAR INDICATORS - DIAGNOSIS AND

TESTING, TREAD......................22-7

WEAR PATTERNS - DIAGNOSIS AND

TESTING, TIRE.......................22-8

WEAR, STANDARD PROCEDURE -

MEASURING TIMING CHAIN.............9-76

WEATHERSTRIP - INSTALLATION, DRIP

RAIL..............................23-91

WEATHERSTRIP - INSTALLATION, FRONT

DOOR GLASS RUN.....................23-92

WEATHERSTRIP - INSTALLATION, REAR

DOOR GLASS RUN...................23-93

WEATHERSTRIP - REMOVAL, DRIP RAIL . . 23-91

WEATHERSTRIP - REMOVAL, FRONT

DOOR GLASS RUN...................23-92

WEATHERSTRIP - REMOVAL, REAR

DOOR GLASS RUN...................23-93

WEATHERSTRIP RETAINER -

INSTALLATION, A-PILLAR..............23-91

WEATHERSTRIP RETAINER -

INSTALLATION, DRIP RAIL.............23-92

WEATHERSTRIP RETAINER - REMOVAL,

A-PILLAR...........................23-91

WEATHERSTRIP RETAINER - REMOVAL,

DRIP RAIL..........................23-92

WELD LOCATIONS - SPECIFICATIONS . . . 23-122

WHEEL - INSTALLATION, STEERING......19-15

WHEEL - REMOVAL, STEERING.........19-15

WHEEL ALIGNMENT - DESCRIPTION.......2-1

WHEEL ALIGNMENT - OPERATION.........2-2

WHEEL ALIGNMENT, SPECIAL TOOLS......2-7

WHEEL ANTILOCK - DIAGNOSIS AND

TESTING, REAR.......................5-42

WHEEL BALANCE - STANDARD

PROCEDURE, TIRE....................22-4

WHEEL COVER - REMOVAL............22-14

WHEEL INSPECTION, DIAGNOSIS AND

TESTING...........................22-11

WHEEL INSTALLATION - STANDARD

PROCEDURE, DUAL REAR.............22-12

WHEEL REPLACEMENT - STANDARD

PROCEDURE........................22-12

WHEEL RUNOUT - DIAGNOSIS AND

TESTING, TIRE.......................22-1

WHEEL SPEED SENSOR - DESCRIPTION,

FRONT..............................5-41

WHEEL SPEED SENSOR - DIAGNOSIS

AND TESTING, REAR...................5-43

WHEEL SPEED SENSOR -

INSTALLATION, FRONT.................5-42

WHEEL SPEED SENSOR -

INSTALLATION, REAR..................5-43

WHEEL SPEED SENSOR - OPERATION,

FRONT..............................5-41

WHEEL SPEED SENSOR - REMOVAL,

FRONT..............................5-41

WHEEL SPEED SENSOR - REMOVAL,

REAR...............................5-42

WHEEL WITH MATCHING TIRE -

DESCRIPTION, FULL SIZE, SPARE.......22-15WHEELHOUSE SPLASH SHIELD -

INSTALLATION, FRONT................23-41

WHEELHOUSE SPLASH SHIELD -

INSTALLATION, REAR.................23-41

WHEELHOUSE SPLASH SHIELD -

REMOVAL, FRONT....................23-40

WHEELHOUSE SPLASH SHIELD -

REMOVAL, REAR.....................23-41

WHEELS - DESCRIPTION..............22-11

WHEELS - OPERATION................22-11

WIND NOISE - DIAGNOSIS AND TESTING . . 23-2

WINDOW MOTOR - REMOVAL..........8N-22

WINDOW REGULATOR - MANUAL -

INSTALLATION..................23-26,23-35

WINDOW REGULATOR - MANUAL -

REMOVAL.....................23-26,23-35

WINDOW REGULATOR - POWER -

INSTALLATION..................23-25,23-34

WINDOW REGULATOR - POWER -

REMOVAL.....................23-25,23-34

WINDOW SWITCH - DIAGNOSIS AND

TESTING...........................8N-22

WINDOW SWITCH - INSTALLATION......8N-23

WINDOW SWITCH - REMOVAL..........8N-23

WINDOWS - DESCRIPTION, POWER.....8N-21

WINDOWS - DIAGNOSIS AND TESTING,

POWER............................8N-21

WINDOWS - OPERATION, POWER.......8N-21

WINDSHIELD SAFETY PRECAUTIONS,

WARNING..........................23-88

WIPER & WASHER SYSTEM - CLEANING....8R-6

WIPER & WASHER SYSTEM -

DIAGNOSIS AND TESTING..............8R-6

WIPER & WASHER SYSTEM -

INSPECTION.........................8R-7

WIPER ARM - DESCRIPTION...........8R-18

WIPER ARM - INSTALLATION...........8R-19

WIPER ARM - OPERATION.............8R-18

WIPER ARM - REMOVAL..............8R-18

WIPER BLADE - DESCRIPTION..........8R-19

WIPER BLADE - INSTALLATION.........8R-20

WIPER BLADE - OPERATION...........8R-19

WIPER BLADE - REMOVAL.............8R-19

WIPER HIGH/LOW RELAY -

DESCRIPTION.......................8R-20

WIPER HIGH/LOW RELAY - DIAGNOSIS

AND TESTING.......................8R-21

WIPER HIGH/LOW RELAY -

INSTALLATION......................8R-21

WIPER HIGH/LOW RELAY - OPERATION . . 8R-20

WIPER HIGH/LOW RELAY - REMOVAL....8R-21

WIPER MODULE - DESCRIPTION........8R-22

WIPER MODULE - INSTALLATION.......8R-23

WIPER MODULE - OPERATION..........8R-23

WIPER MODULE - REMOVAL...........8R-23

WIPER ON/OFF RELAY - DESCRIPTION . . . 8R-25

WIPER ON/OFF RELAY - DIAGNOSIS AND

TESTING...........................8R-26

WIPER ON/OFF RELAY - INSTALLATION . . . 8R-26

WIPER ON/OFF RELAY - OPERATION.....8R-25

WIPER ON/OFF RELAY - REMOVAL......8R-26

WIPERS/WASHERS - DESCRIPTION.......8R-1

WIPERS/WASHERS - OPERATION........8R-4

WIRE SPLICING - STANDARD

PROCEDURE

.....................8W-01-15

WIRING - DESCRIPTION, TRAILER TOW

. . 8L-22

WIRING DIAGRAMS - DESCRIPTION,

HOW TO USE

.....................8W-01-1

WIRING HARNESS - DIAGNOSIS AND

TESTING

.........................8W-01-7

WIRING/TERMINAL, SPECIAL TOOLS

. . 8W-01-10

WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS

HOSE

...............................7-70

WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS

HOSE

...............................7-69

WORN THREADS - STANDARD

PROCEDURE,

REPAIR DAMAGED OR

......9-186,9-232,9-289,

9-361,9-9,9-93

38 INDEXDR

Description Group-Page Description Group-Page Description Group-Page