DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1291 of 2895

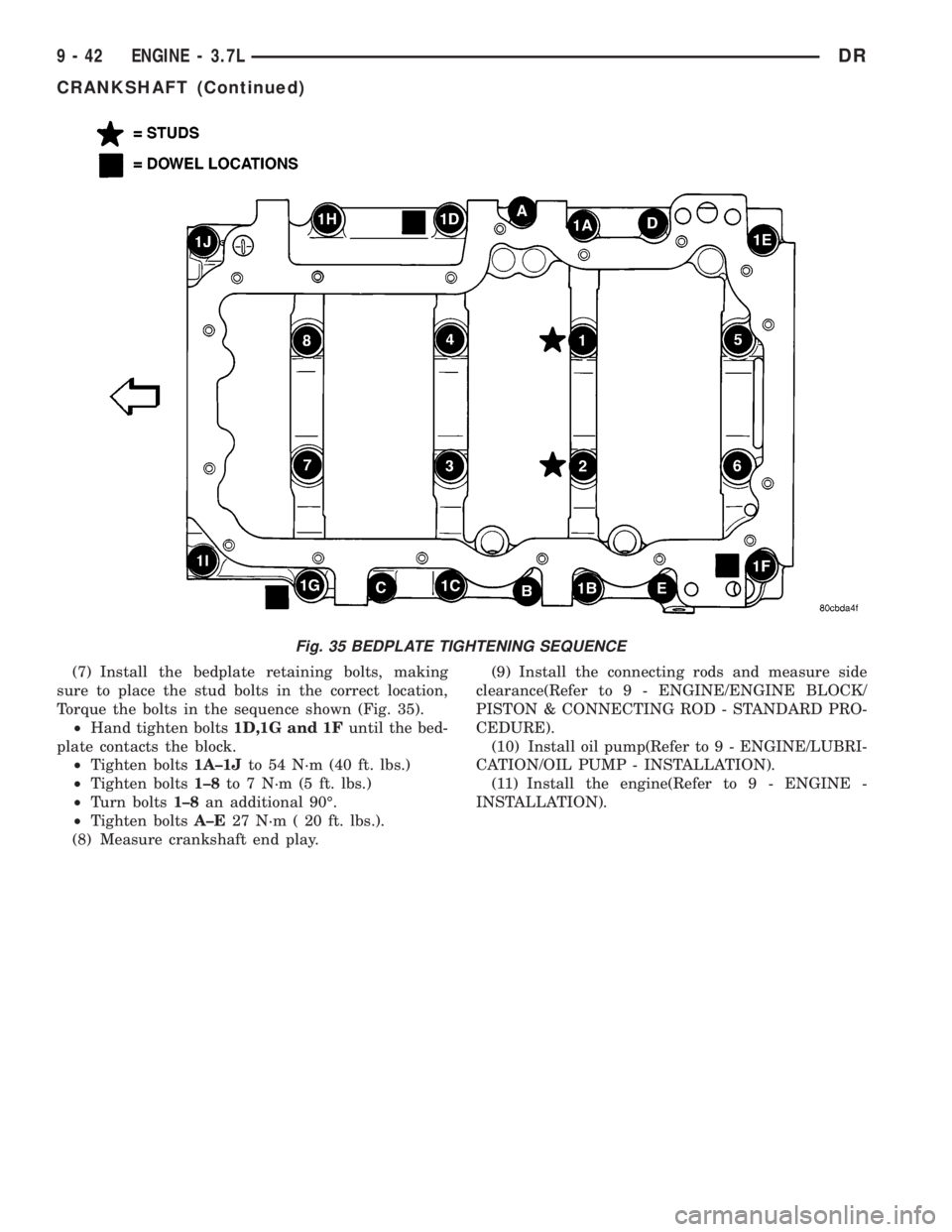

(7) Install the bedplate retaining bolts, making

sure to place the stud bolts in the correct location,

Torque the bolts in the sequence shown (Fig. 35).

²Hand tighten bolts1D,1G and 1Funtil the bed-

plate contacts the block.

²Tighten bolts1A±1Jto 54 N´m (40 ft. lbs.)

²Tighten bolts1±8to 7 N´m (5 ft. lbs.)

²Turn bolts1±8an additional 90É.

²Tighten boltsA±E27 N´m ( 20 ft. lbs.).

(8) Measure crankshaft end play.(9) Install the connecting rods and measure side

clearance(Refer to 9 - ENGINE/ENGINE BLOCK/

PISTON & CONNECTING ROD - STANDARD PRO-

CEDURE).

(10) Install oil pump(Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - INSTALLATION).

(11) Install the engine(Refer to 9 - ENGINE -

INSTALLATION).

Fig. 35 BEDPLATE TIGHTENING SEQUENCE

9 - 42 ENGINE - 3.7LDR

CRANKSHAFT (Continued)

Page 1292 of 2895

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE

MAIN BEARING FITTING

SELECT FIT IDENTIFICATION

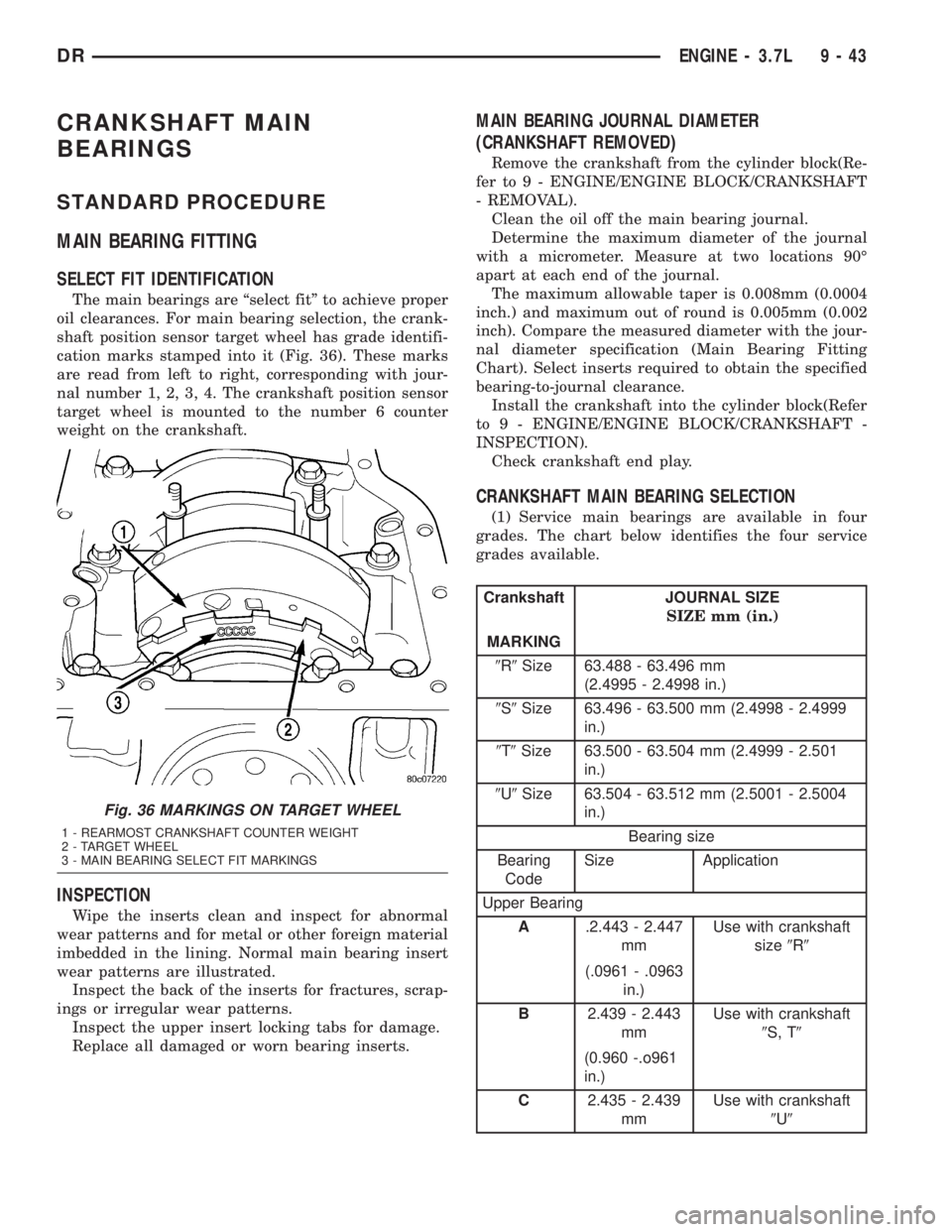

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 36). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4. The crankshaft position sensor

target wheel is mounted to the number 6 counter

weight on the crankshaft.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block(Re-

fer to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

- REMOVAL).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Install the crankshaft into the cylinder block(Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT -

INSPECTION).

Check crankshaft end play.

CRANKSHAFT MAIN BEARING SELECTION

(1) Service main bearings are available in four

grades. The chart below identifies the four service

grades available.

Crankshaft JOURNAL SIZE

SIZE mm (in.)

MARKING

9R9Size 63.488 - 63.496 mm

(2.4995 - 2.4998 in.)

9S9Size 63.496 - 63.500 mm (2.4998 - 2.4999

in.)

9T9Size 63.500 - 63.504 mm (2.4999 - 2.501

in.)

9U9Size 63.504 - 63.512 mm (2.5001 - 2.5004

in.)

Bearing size

Bearing

CodeSize Application

Upper Bearing

A.2.443 - 2.447

mmUse with crankshaft

size9R9

(.0961 - .0963

in.)

B2.439 - 2.443

mmUse with crankshaft

9S, T9

(0.960 -.o961

in.)

C2.435 - 2.439

mmUse with crankshaft

9U9

Fig. 36 MARKINGS ON TARGET WHEEL

1 - REARMOST CRANKSHAFT COUNTER WEIGHT

2 - TARGET WHEEL

3 - MAIN BEARING SELECT FIT MARKINGS

DRENGINE - 3.7L 9 - 43

Page 1293 of 2895

Crankshaft JOURNAL SIZE

SIZE mm (in.)

MARKING

(.0958 - .0960

in.)

Lower Bearing Main919and949

9192.441 - 2.447

mmUse with crankshaft

9R, S9

(.0961 -.0963

in.)

9292.435 - 2.441

mmUse with crankshaft

9T, U9

(.0958 - .0962

in.)

Lower Main Bearing929and939

9392.429 - 2.435

mmUse with crankshaft

9R, S9

(.0956 - .0958

in.)

9492.423 - 2.429

mmUse with crankshaft

9T, U9

(.0953 - .0956

in.)

Bearing Clearances

Main91, 49

Crankshaft

9R9.004 - .034 mm ( .00015 - .0013 in.)

Crankshaft

9S9.004 - .030 mm ( .00015 - .0011 in.)

Crankshaft

9T9.006 - .032 mm (.0002 - .0012 in.)

Crankshaft

9U9.002 - .032 mm (.00007 -. 0012 in.)

Main92, 39

Crankshaft

9R9.016 - .046 mm (.0006 - .0018 in.)

Crankshaft

9S9.016 - .042 mm (.00062 - .016 in.)

Crankshaft

9T9.018 - .044 mm (.0007 - .0017 in.)

Crankshaft

9U9.014 - .044 mm (.0005 - .0017 in.)CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Remove A/C compressor mouning fasteners and

set aside.

(4) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Remove upper radiator hose.

(6) Disconnect electrical connector for fan mounted

inside radiator shroud.

(7) Remove radiator shroud attaching fasteners.

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

(8) Remove radiator cooling fan and shroud (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

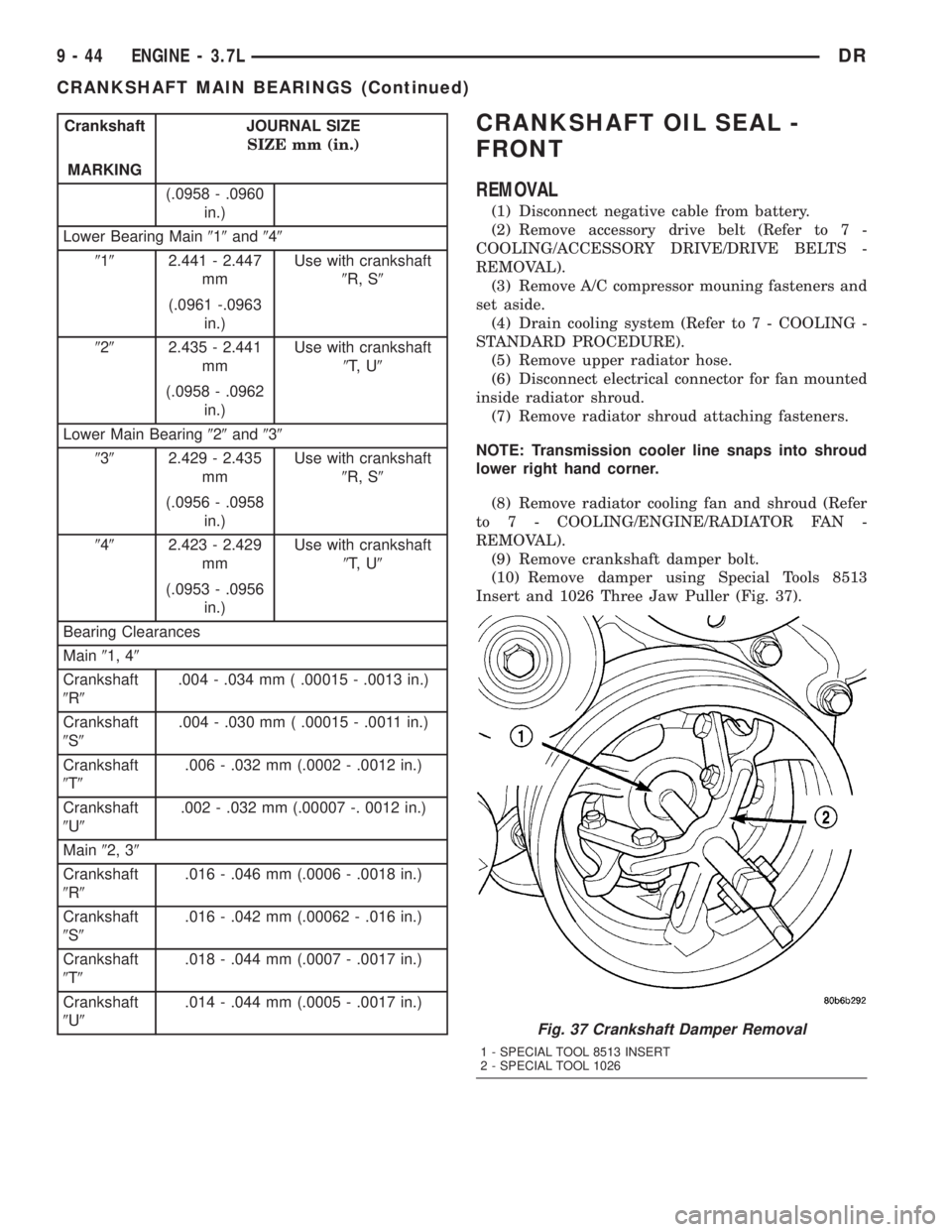

(9) Remove crankshaft damper bolt.

(10) Remove damper using Special Tools 8513

Insert and 1026 Three Jaw Puller (Fig. 37).

Fig. 37 Crankshaft Damper Removal

1 - SPECIAL TOOL 8513 INSERT

2 - SPECIAL TOOL 1026

9 - 44 ENGINE - 3.7LDR

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1294 of 2895

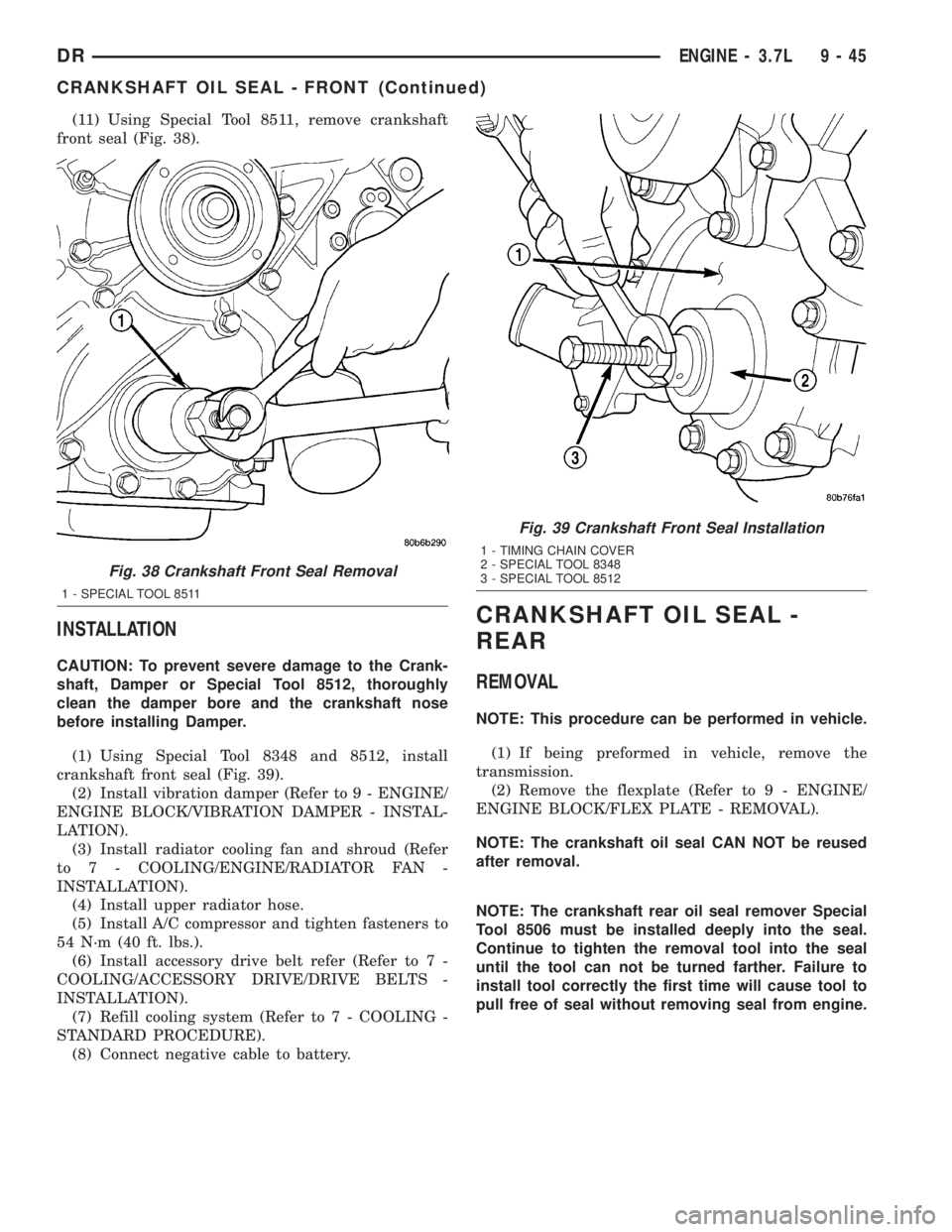

(11) Using Special Tool 8511, remove crankshaft

front seal (Fig. 38).

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

(1) Using Special Tool 8348 and 8512, install

crankshaft front seal (Fig. 39).

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(3) Install radiator cooling fan and shroud (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(4) Install upper radiator hose.

(5) Install A/C compressor and tighten fasteners to

54 N´m (40 ft. lbs.).

(6) Install accessory drive belt refer (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(7) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(8) Connect negative cable to battery.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

NOTE: This procedure can be performed in vehicle.

(1) If being preformed in vehicle, remove the

transmission.

(2) Remove the flexplate (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

Fig. 38 Crankshaft Front Seal Removal

1 - SPECIAL TOOL 8511

Fig. 39 Crankshaft Front Seal Installation

1 - TIMING CHAIN COVER

2 - SPECIAL TOOL 8348

3 - SPECIAL TOOL 8512

DRENGINE - 3.7L 9 - 45

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1295 of 2895

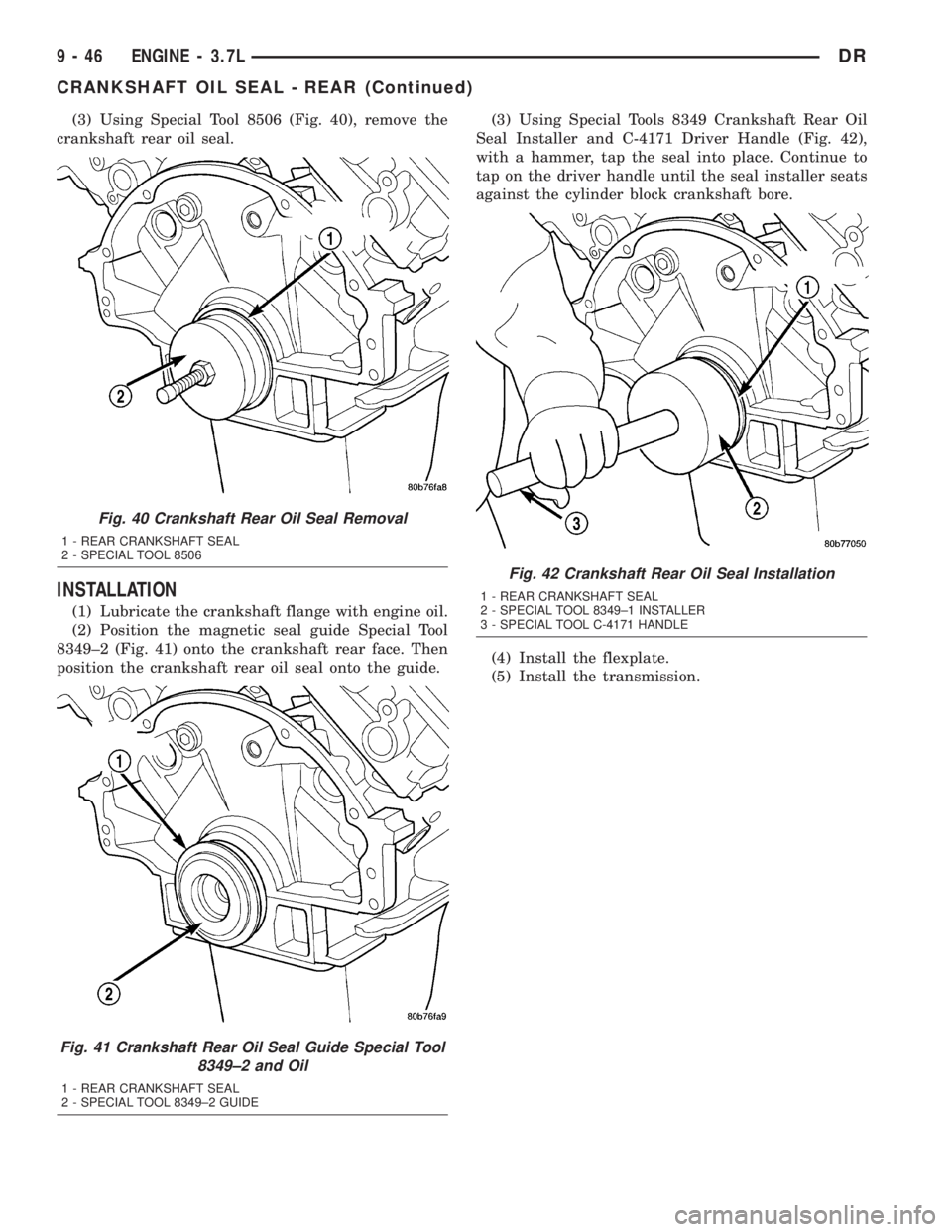

(3) Using Special Tool 8506 (Fig. 40), remove the

crankshaft rear oil seal.

INSTALLATION

(1) Lubricate the crankshaft flange with engine oil.

(2) Position the magnetic seal guide Special Tool

8349±2 (Fig. 41) onto the crankshaft rear face. Then

position the crankshaft rear oil seal onto the guide.(3) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle (Fig. 42),

with a hammer, tap the seal into place. Continue to

tap on the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(4) Install the flexplate.

(5) Install the transmission.

Fig. 40 Crankshaft Rear Oil Seal Removal

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8506

Fig. 41 Crankshaft Rear Oil Seal Guide Special Tool

8349±2 and Oil

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349±2 GUIDE

Fig. 42 Crankshaft Rear Oil Seal Installation

1 - REAR CRANKSHAFT SEAL

2 - SPECIAL TOOL 8349±1 INSTALLER

3 - SPECIAL TOOL C-4171 HANDLE

9 - 46 ENGINE - 3.7LDR

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1296 of 2895

FLEX PLATE

REMOVAL

(1) Remove the transmission.

(2) Remove the bolts and flexplate.

INSTALLATION

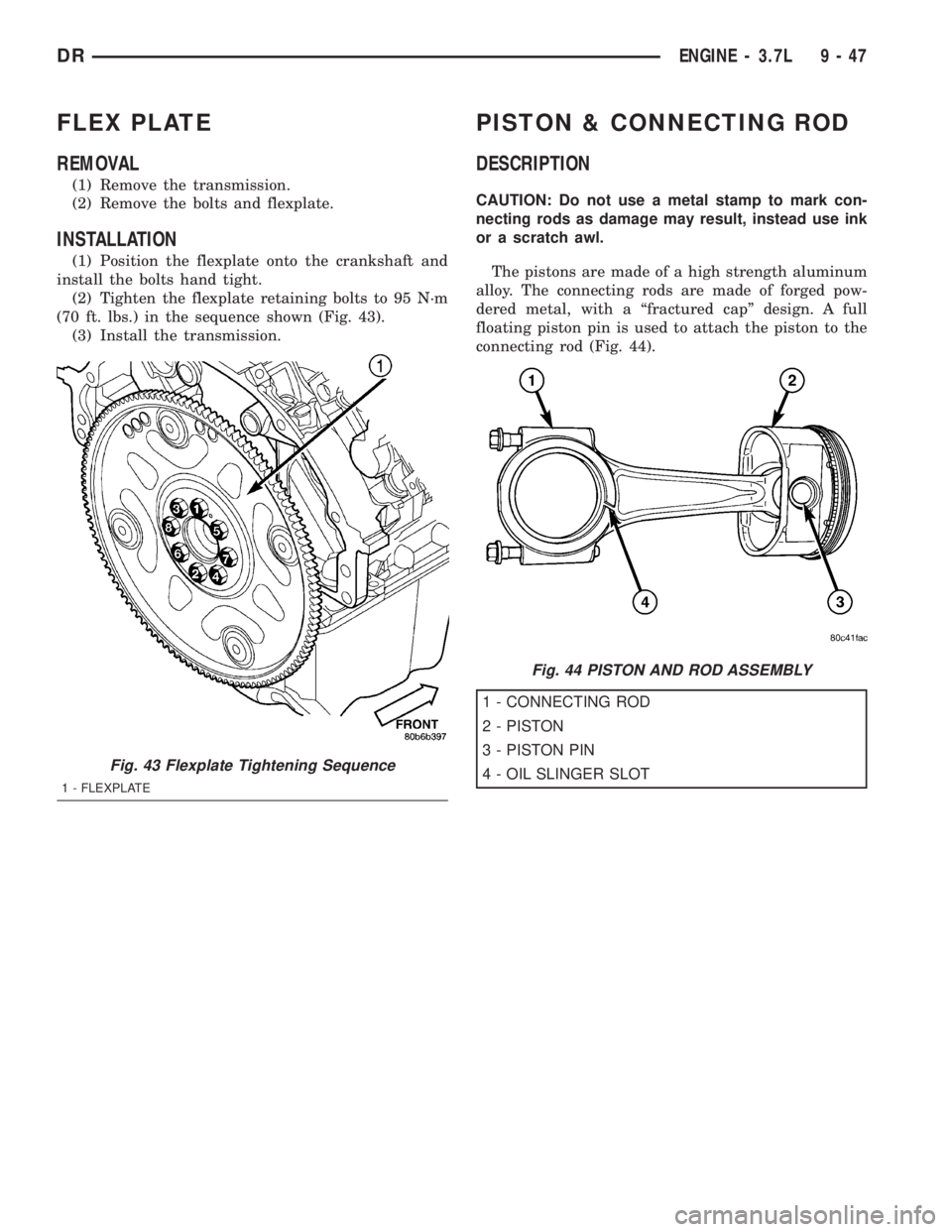

(1) Position the flexplate onto the crankshaft and

install the bolts hand tight.

(2) Tighten the flexplate retaining bolts to 95 N´m

(70 ft. lbs.) in the sequence shown (Fig. 43).

(3) Install the transmission.

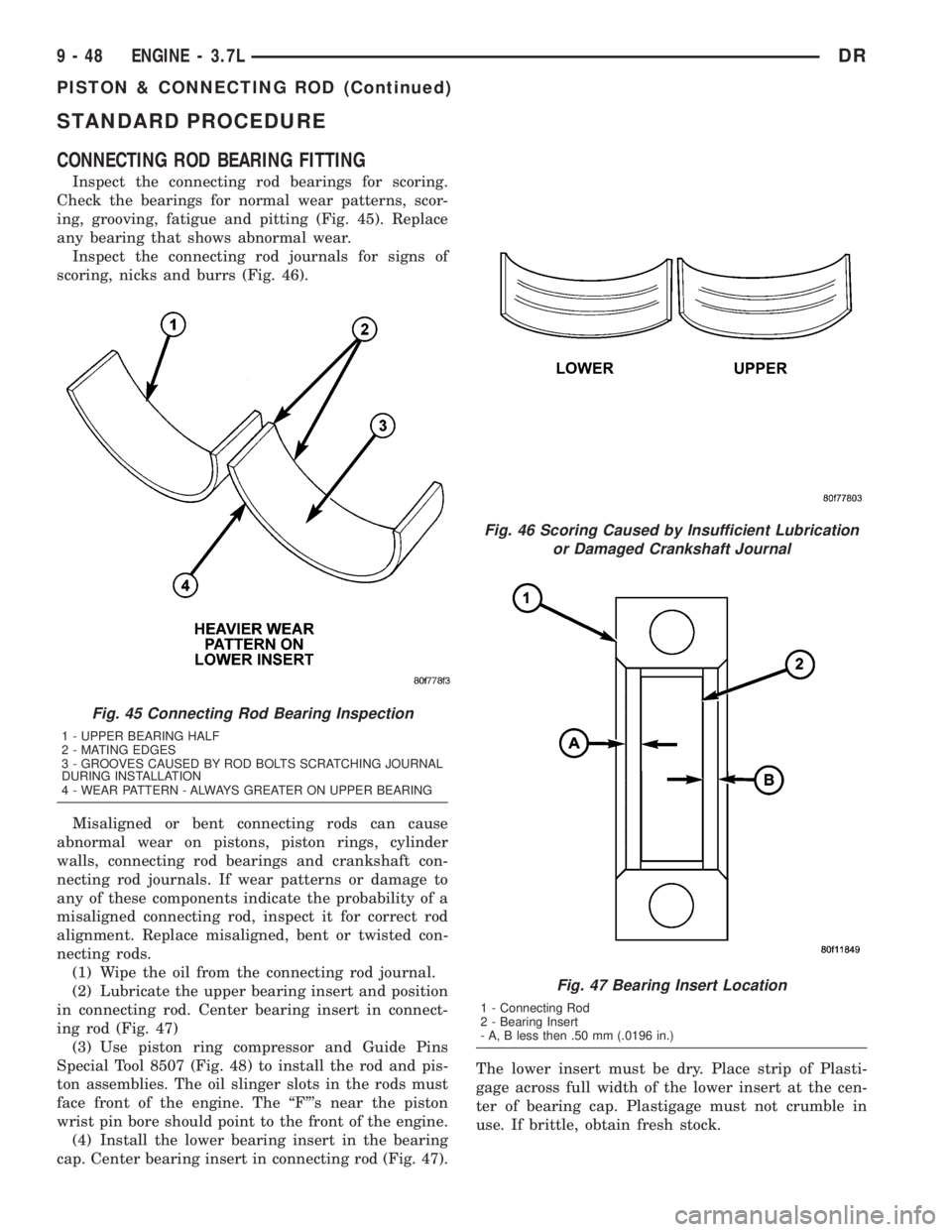

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.

The pistons are made of a high strength aluminum

alloy. The connecting rods are made of forged pow-

dered metal, with a ªfractured capº design. A full

floating piston pin is used to attach the piston to the

connecting rod (Fig. 44).

1 - CONNECTING ROD

2 - PISTON

3 - PISTON PIN

4 - OIL SLINGER SLOT

Fig. 43 Flexplate Tightening Sequence

1 - FLEXPLATE

Fig. 44 PISTON AND ROD ASSEMBLY

DRENGINE - 3.7L 9 - 47

Page 1297 of 2895

STANDARD PROCEDURE

CONNECTING ROD BEARING FITTING

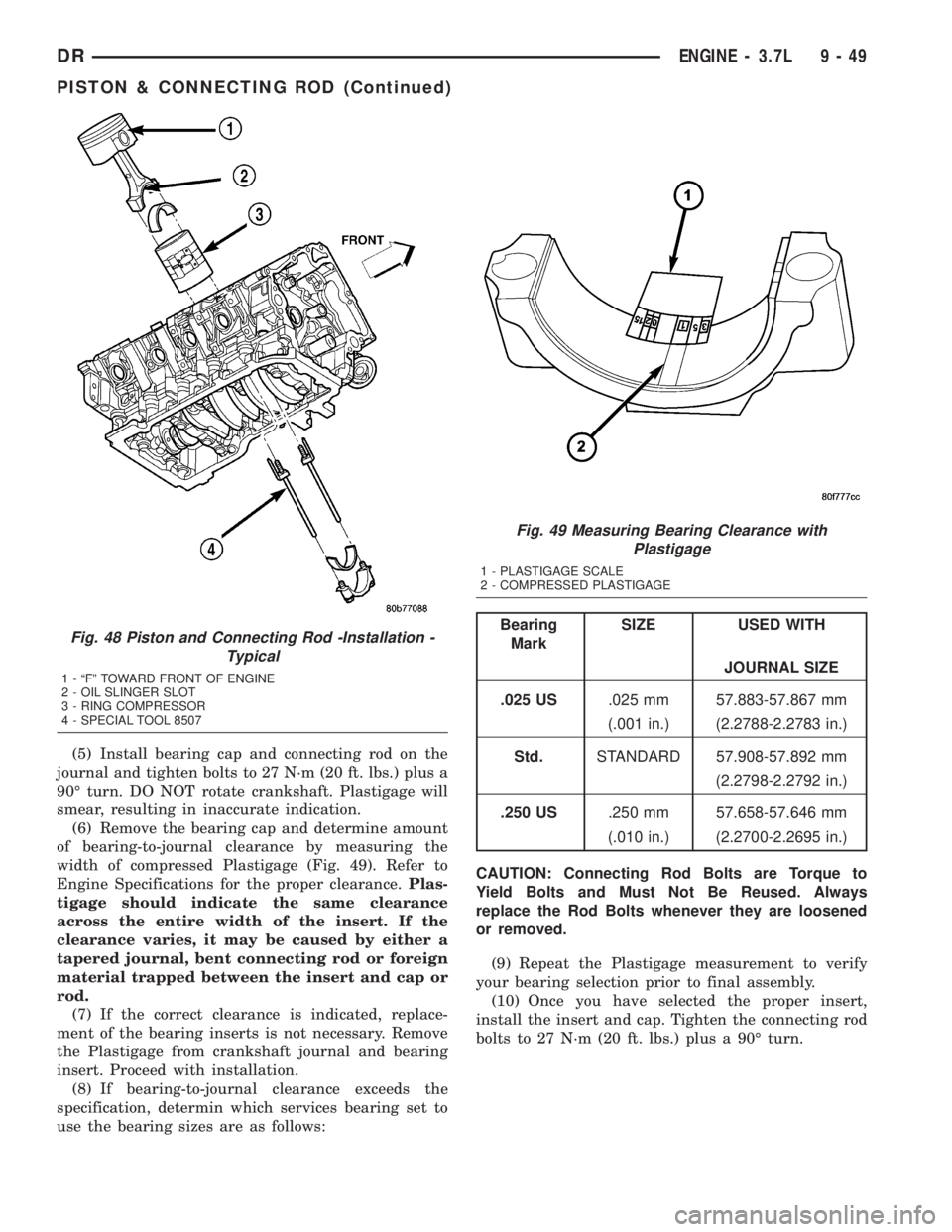

Inspect the connecting rod bearings for scoring.

Check the bearings for normal wear patterns, scor-

ing, grooving, fatigue and pitting (Fig. 45). Replace

any bearing that shows abnormal wear.

Inspect the connecting rod journals for signs of

scoring, nicks and burrs (Fig. 46).

Misaligned or bent connecting rods can cause

abnormal wear on pistons, piston rings, cylinder

walls, connecting rod bearings and crankshaft con-

necting rod journals. If wear patterns or damage to

any of these components indicate the probability of a

misaligned connecting rod, inspect it for correct rod

alignment. Replace misaligned, bent or twisted con-

necting rods.

(1) Wipe the oil from the connecting rod journal.

(2) Lubricate the upper bearing insert and position

in connecting rod. Center bearing insert in connect-

ing rod (Fig. 47)

(3) Use piston ring compressor and Guide Pins

Special Tool 8507 (Fig. 48) to install the rod and pis-

ton assemblies. The oil slinger slots in the rods must

face front of the engine. The ªFº's near the piston

wrist pin bore should point to the front of the engine.

(4) Install the lower bearing insert in the bearing

cap. Center bearing insert in connecting rod (Fig. 47).The lower insert must be dry. Place strip of Plasti-

gage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

Fig. 45 Connecting Rod Bearing Inspection

1 - UPPER BEARING HALF

2 - MATING EDGES

3 - GROOVES CAUSED BY ROD BOLTS SCRATCHING JOURNAL

DURING INSTALLATION

4 - WEAR PATTERN - ALWAYS GREATER ON UPPER BEARING

Fig. 46 Scoring Caused by Insufficient Lubrication

or Damaged Crankshaft Journal

Fig. 47 Bearing Insert Location

1 - Connecting Rod

2 - Bearing Insert

- A, B less then .50 mm (.0196 in.)

9 - 48 ENGINE - 3.7LDR

PISTON & CONNECTING ROD (Continued)

Page 1298 of 2895

(5) Install bearing cap and connecting rod on the

journal and tighten bolts to 27 N´m (20 ft. lbs.) plus a

90É turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 49). Refer to

Engine Specifications for the proper clearance.Plas-

tigage should indicate the same clearance

across the entire width of the insert. If the

clearance varies, it may be caused by either a

tapered journal, bent connecting rod or foreign

material trapped between the insert and cap or

rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

Bearing

MarkSIZE USED WITH

JOURNAL SIZE

.025 US.025 mm 57.883-57.867 mm

(.001 in.) (2.2788-2.2783 in.)

Std.STANDARD 57.908-57.892 mm

(2.2798-2.2792 in.)

.250 US.250 mm 57.658-57.646 mm

(.010 in.) (2.2700-2.2695 in.)

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

(9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N´m (20 ft. lbs.) plus a 90É turn.Fig. 48 Piston and Connecting Rod -Installation -

Typical

1 - ªFº TOWARD FRONT OF ENGINE

2 - OIL SLINGER SLOT

3 - RING COMPRESSOR

4 - SPECIAL TOOL 8507

Fig. 49 Measuring Bearing Clearance with

Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

DRENGINE - 3.7L 9 - 49

PISTON & CONNECTING ROD (Continued)

Page 1299 of 2895

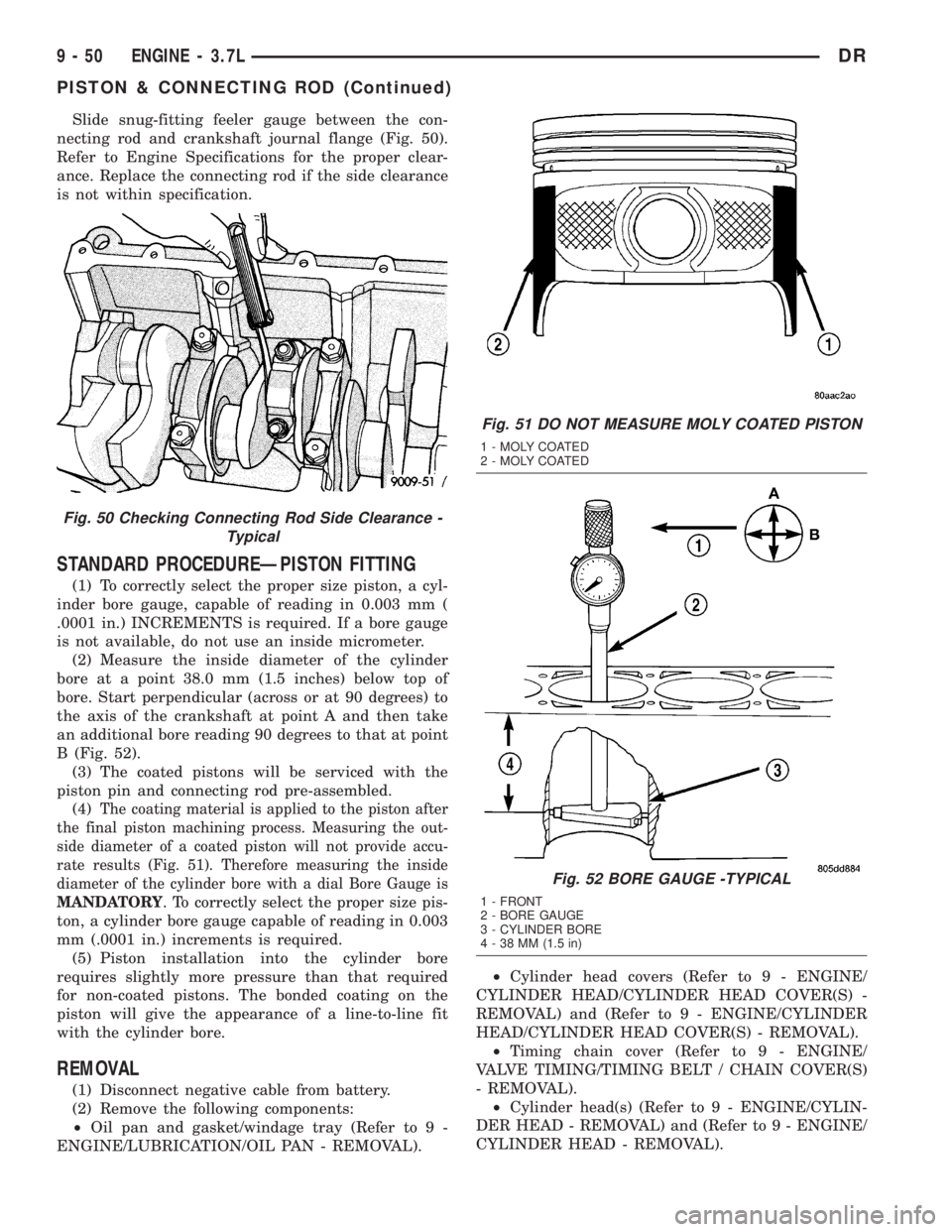

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 50).

Refer to Engine Specifications for the proper clear-

ance. Replace the connecting rod if the side clearance

is not within specification.

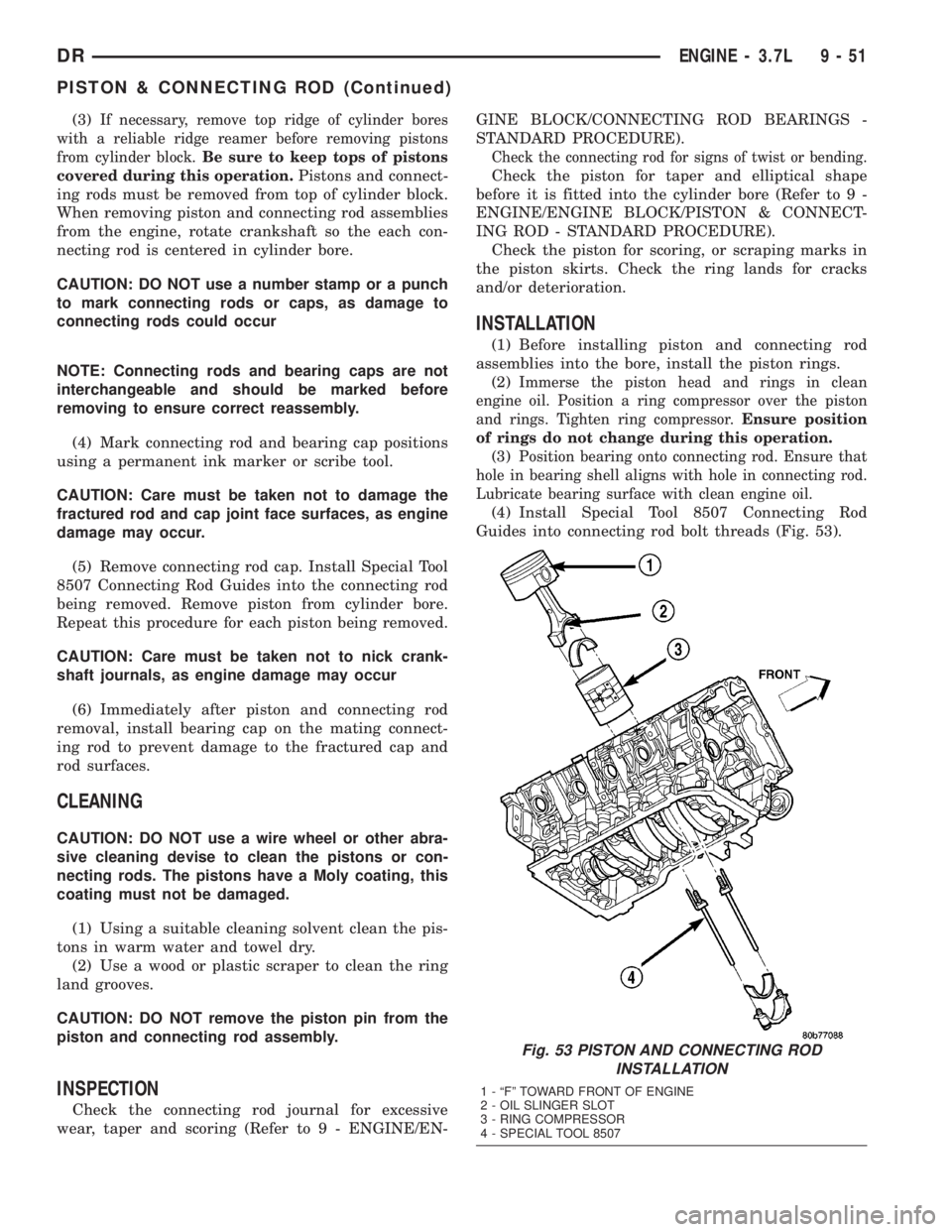

STANDARD PROCEDUREÐPISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (

.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 52).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled.

(4)

The coating material is applied to the piston after

the final piston machining process. Measuring the out-

side diameter of a coated piston will not provide accu-

rate results (Fig. 51). Therefore measuring the inside

diameter of the cylinder bore with a dial Bore Gauge is

MANDATORY

. To correctly select the proper size pis-

ton, a cylinder bore gauge capable of reading in 0.003

mm (.0001 in.) increments is required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

²Cylinder head(s) (Refer to 9 - ENGINE/CYLIN-

DER HEAD - REMOVAL) and (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

Fig. 50 Checking Connecting Rod Side Clearance -

Typical

Fig. 51 DO NOT MEASURE MOLY COATED PISTON

1 - MOLY COATED

2 - MOLY COATED

Fig. 52 BORE GAUGE -TYPICAL

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

9 - 50 ENGINE - 3.7LDR

PISTON & CONNECTING ROD (Continued)

Page 1300 of 2895

(3)If necessary, remove top ridge of cylinder bores

with a reliable ridge reamer before removing pistons

from cylinder block.Be sure to keep tops of pistons

covered during this operation.

Pistons and connect-

ing rods must be removed from top of cylinder block.

When removing piston and connecting rod assemblies

from the engine, rotate crankshaft so the each con-

necting rod is centered in cylinder bore.

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods or caps, as damage to

connecting rods could occur

NOTE: Connecting rods and bearing caps are not

interchangeable and should be marked before

removing to ensure correct reassembly.

(4) Mark connecting rod and bearing cap positions

using a permanent ink marker or scribe tool.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint face surfaces, as engine

damage may occur.

(5) Remove connecting rod cap. Install Special Tool

8507 Connecting Rod Guides into the connecting rod

being removed. Remove piston from cylinder bore.

Repeat this procedure for each piston being removed.

CAUTION: Care must be taken not to nick crank-

shaft journals, as engine damage may occur

(6) Immediately after piston and connecting rod

removal, install bearing cap on the mating connect-

ing rod to prevent damage to the fractured cap and

rod surfaces.

CLEANING

CAUTION: DO NOT use a wire wheel or other abra-

sive cleaning devise to clean the pistons or con-

necting rods. The pistons have a Moly coating, this

coating must not be damaged.

(1) Using a suitable cleaning solvent clean the pis-

tons in warm water and towel dry.

(2) Use a wood or plastic scraper to clean the ring

land grooves.

CAUTION: DO NOT remove the piston pin from the

piston and connecting rod assembly.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bending.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Before installing piston and connecting rod

assemblies into the bore, install the piston rings.

(2)

Immerse the piston head and rings in clean

engine oil. Position a ring compressor over the piston

and rings. Tighten ring compressor.Ensure position

of rings do not change during this operation.

(3)Position bearing onto connecting rod. Ensure that

hole in bearing shell aligns with hole in connecting rod.

Lubricate bearing surface with clean engine oil.

(4) Install Special Tool 8507 Connecting Rod

Guides into connecting rod bolt threads (Fig. 53).

Fig. 53 PISTON AND CONNECTING ROD

INSTALLATION

1 - ªFº TOWARD FRONT OF ENGINE

2 - OIL SLINGER SLOT

3 - RING COMPRESSOR

4 - SPECIAL TOOL 8507

DRENGINE - 3.7L 9 - 51

PISTON & CONNECTING ROD (Continued)