DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1331 of 2895

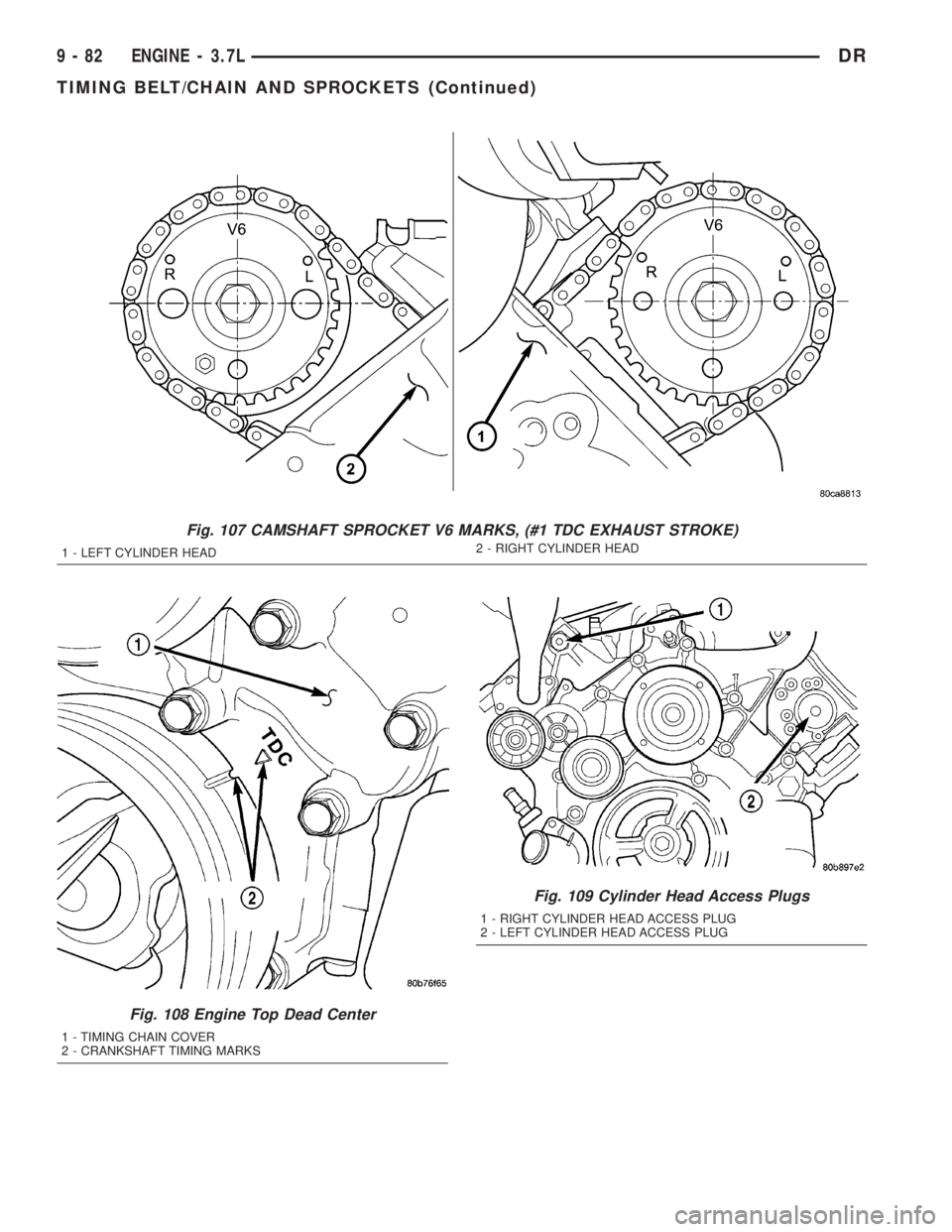

Fig. 107 CAMSHAFT SPROCKET V6 MARKS, (#1 TDC EXHAUST STROKE)

1 - LEFT CYLINDER HEAD2 - RIGHT CYLINDER HEAD

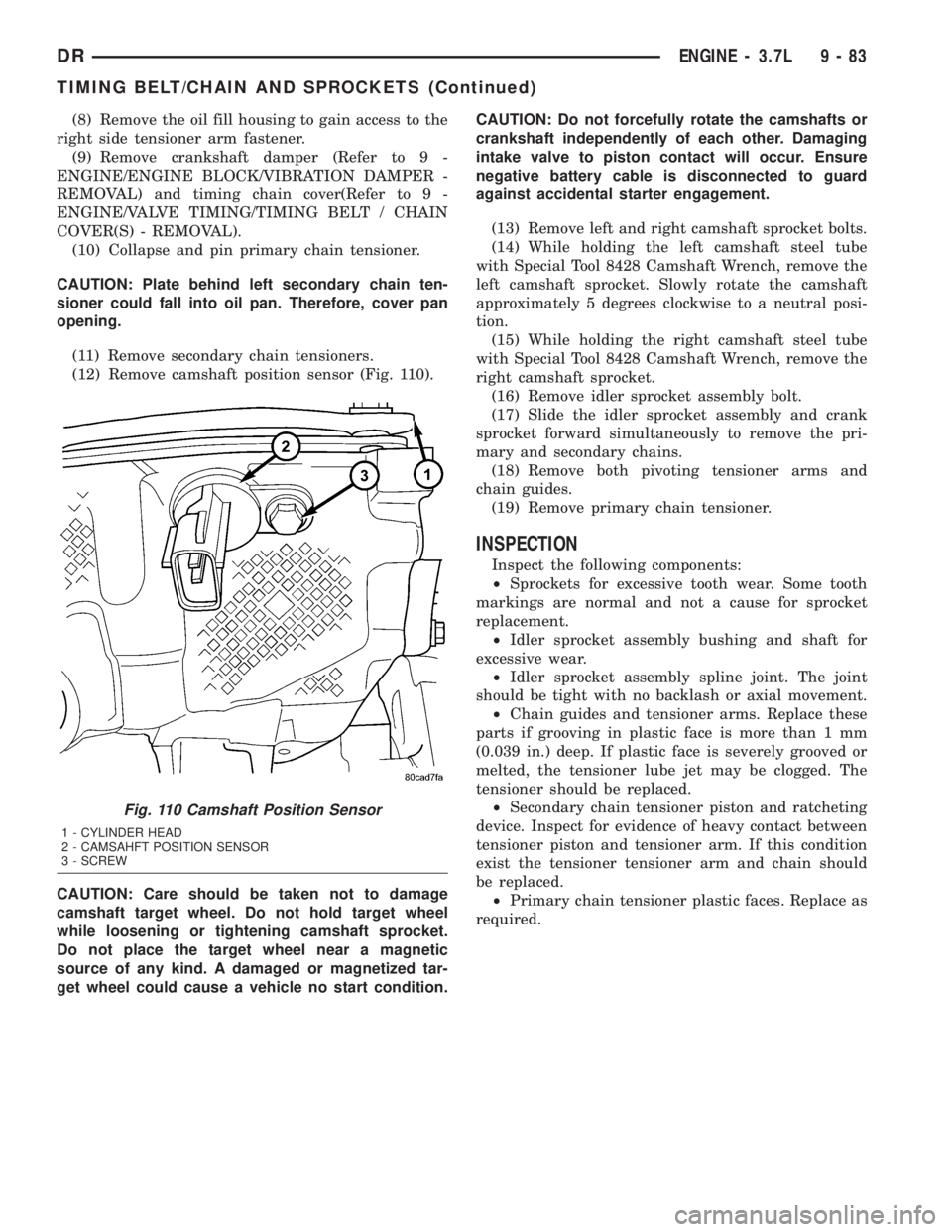

Fig. 108 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

Fig. 109 Cylinder Head Access Plugs

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

9 - 82 ENGINE - 3.7LDR

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1332 of 2895

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(10) Collapse and pin primary chain tensioner.

CAUTION: Plate behind left secondary chain ten-

sioner could fall into oil pan. Therefore, cover pan

opening.

(11) Remove secondary chain tensioners.

(12) Remove camshaft position sensor (Fig. 110).

CAUTION: Care should be taken not to damage

camshaft target wheel. Do not hold target wheel

while loosening or tightening camshaft sprocket.

Do not place the target wheel near a magnetic

source of any kind. A damaged or magnetized tar-

get wheel could cause a vehicle no start condition.CAUTION: Do not forcefully rotate the camshafts or

crankshaft independently of each other. Damaging

intake valve to piston contact will occur. Ensure

negative battery cable is disconnected to guard

against accidental starter engagement.

(13) Remove left and right camshaft sprocket bolts.

(14) While holding the left camshaft steel tube

with Special Tool 8428 Camshaft Wrench, remove the

left camshaft sprocket. Slowly rotate the camshaft

approximately 5 degrees clockwise to a neutral posi-

tion.

(15) While holding the right camshaft steel tube

with Special Tool 8428 Camshaft Wrench, remove the

right camshaft sprocket.

(16) Remove idler sprocket assembly bolt.

(17) Slide the idler sprocket assembly and crank

sprocket forward simultaneously to remove the pri-

mary and secondary chains.

(18) Remove both pivoting tensioner arms and

chain guides.

(19) Remove primary chain tensioner.

INSPECTION

Inspect the following components:

²Sprockets for excessive tooth wear. Some tooth

markings are normal and not a cause for sprocket

replacement.

²Idler sprocket assembly bushing and shaft for

excessive wear.

²Idler sprocket assembly spline joint. The joint

should be tight with no backlash or axial movement.

²Chain guides and tensioner arms. Replace these

parts if grooving in plastic face is more than 1 mm

(0.039 in.) deep. If plastic face is severely grooved or

melted, the tensioner lube jet may be clogged. The

tensioner should be replaced.

²Secondary chain tensioner piston and ratcheting

device. Inspect for evidence of heavy contact between

tensioner piston and tensioner arm. If this condition

exist the tensioner tensioner arm and chain should

be replaced.

²Primary chain tensioner plastic faces. Replace as

required.

Fig. 110 Camshaft Position Sensor

1 - CYLINDER HEAD

2 - CAMSAHFT POSITION SENSOR

3 - SCREW

DRENGINE - 3.7L 9 - 83

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1333 of 2895

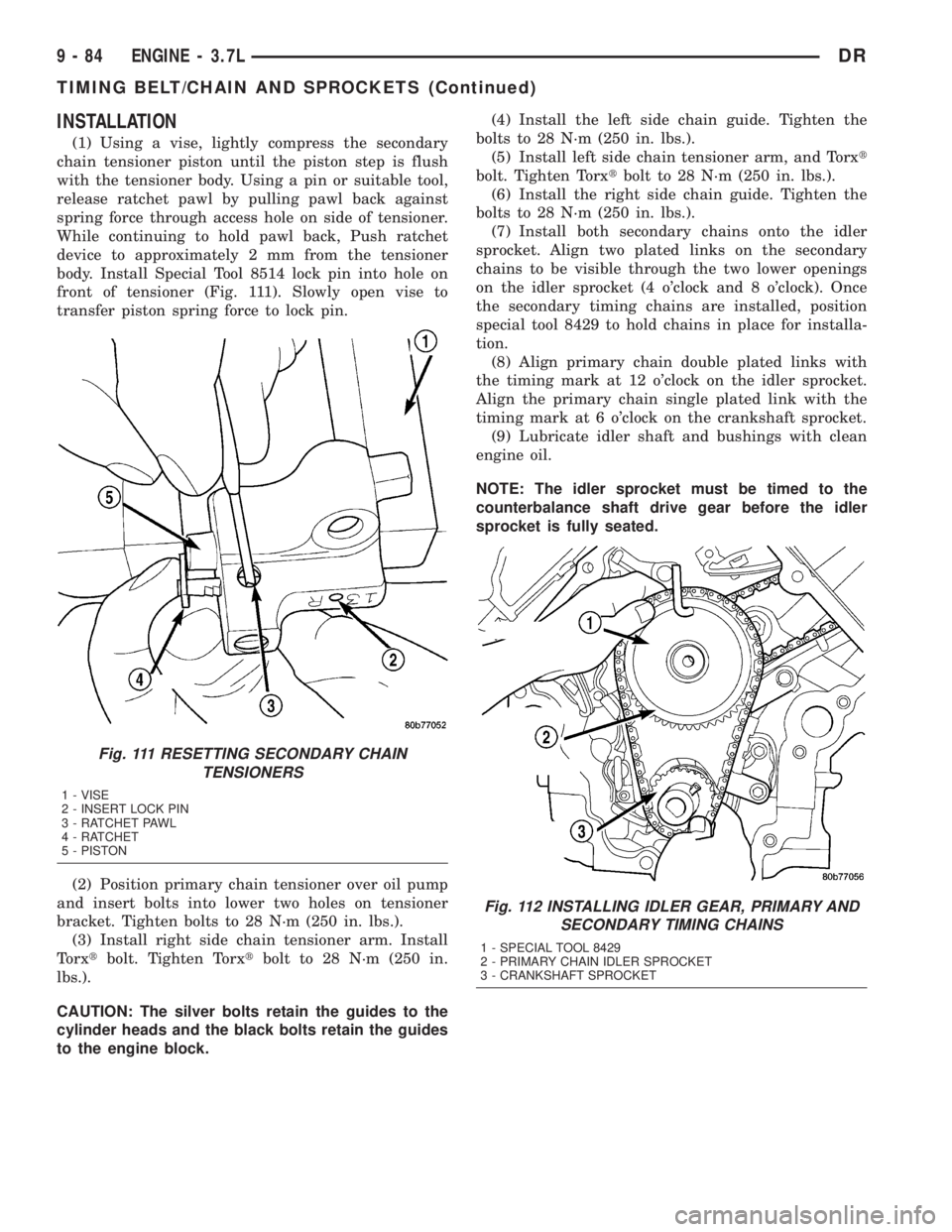

INSTALLATION

(1) Using a vise, lightly compress the secondary

chain tensioner piston until the piston step is flush

with the tensioner body. Using a pin or suitable tool,

release ratchet pawl by pulling pawl back against

spring force through access hole on side of tensioner.

While continuing to hold pawl back, Push ratchet

device to approximately 2 mm from the tensioner

body. Install Special Tool 8514 lock pin into hole on

front of tensioner (Fig. 111). Slowly open vise to

transfer piston spring force to lock pin.

(2) Position primary chain tensioner over oil pump

and insert bolts into lower two holes on tensioner

bracket. Tighten bolts to 28 N´m (250 in. lbs.).

(3) Install right side chain tensioner arm. Install

Torxtbolt. Tighten Torxtbolt to 28 N´m (250 in.

lbs.).

CAUTION: The silver bolts retain the guides to the

cylinder heads and the black bolts retain the guides

to the engine block.(4) Install the left side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

(5) Install left side chain tensioner arm, and Torxt

bolt. Tighten Torxtbolt to 28 N´m (250 in. lbs.).

(6) Install the right side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

(7) Install both secondary chains onto the idler

sprocket. Align two plated links on the secondary

chains to be visible through the two lower openings

on the idler sprocket (4 o'clock and 8 o'clock). Once

the secondary timing chains are installed, position

special tool 8429 to hold chains in place for installa-

tion.

(8) Align primary chain double plated links with

the timing mark at 12 o'clock on the idler sprocket.

Align the primary chain single plated link with the

timing mark at 6 o'clock on the crankshaft sprocket.

(9) Lubricate idler shaft and bushings with clean

engine oil.

NOTE: The idler sprocket must be timed to the

counterbalance shaft drive gear before the idler

sprocket is fully seated.

Fig. 111 RESETTING SECONDARY CHAIN

TENSIONERS

1 - VISE

2 - INSERT LOCK PIN

3 - RATCHET PAWL

4 - RATCHET

5 - PISTON

Fig. 112 INSTALLING IDLER GEAR, PRIMARY AND

SECONDARY TIMING CHAINS

1 - SPECIAL TOOL 8429

2 - PRIMARY CHAIN IDLER SPROCKET

3 - CRANKSHAFT SPROCKET

9 - 84 ENGINE - 3.7LDR

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1334 of 2895

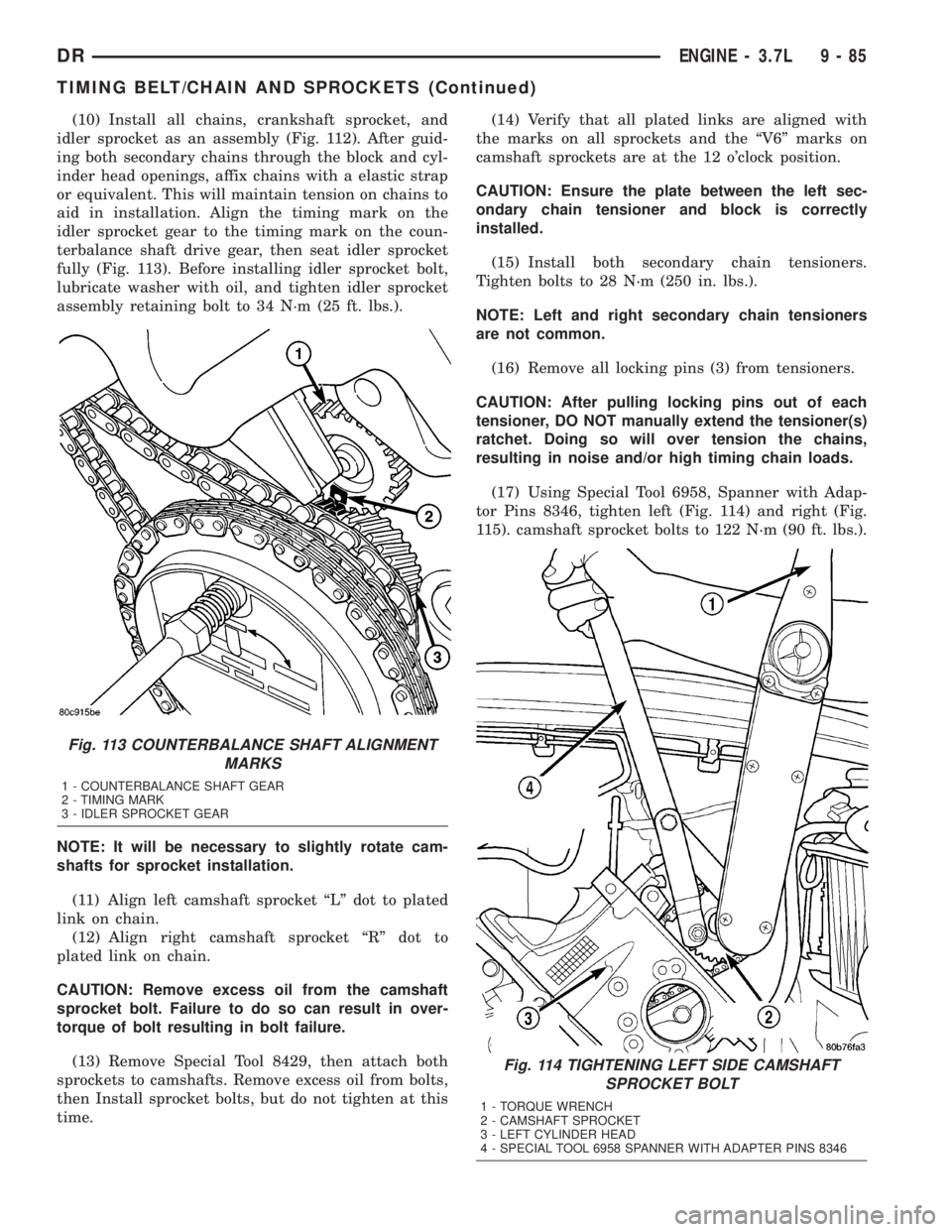

(10) Install all chains, crankshaft sprocket, and

idler sprocket as an assembly (Fig. 112). After guid-

ing both secondary chains through the block and cyl-

inder head openings, affix chains with a elastic strap

or equivalent. This will maintain tension on chains to

aid in installation. Align the timing mark on the

idler sprocket gear to the timing mark on the coun-

terbalance shaft drive gear, then seat idler sprocket

fully (Fig. 113). Before installing idler sprocket bolt,

lubricate washer with oil, and tighten idler sprocket

assembly retaining bolt to 34 N´m (25 ft. lbs.).

NOTE: It will be necessary to slightly rotate cam-

shafts for sprocket installation.

(11) Align left camshaft sprocket ªLº dot to plated

link on chain.

(12) Align right camshaft sprocket ªRº dot to

plated link on chain.

CAUTION: Remove excess oil from the camshaft

sprocket bolt. Failure to do so can result in over-

torque of bolt resulting in bolt failure.

(13) Remove Special Tool 8429, then attach both

sprockets to camshafts. Remove excess oil from bolts,

then Install sprocket bolts, but do not tighten at this

time.(14) Verify that all plated links are aligned with

the marks on all sprockets and the ªV6º marks on

camshaft sprockets are at the 12 o'clock position.

CAUTION: Ensure the plate between the left sec-

ondary chain tensioner and block is correctly

installed.

(15) Install both secondary chain tensioners.

Tighten bolts to 28 N´m (250 in. lbs.).

NOTE: Left and right secondary chain tensioners

are not common.

(16) Remove all locking pins (3) from tensioners.

CAUTION: After pulling locking pins out of each

tensioner, DO NOT manually extend the tensioner(s)

ratchet. Doing so will over tension the chains,

resulting in noise and/or high timing chain loads.

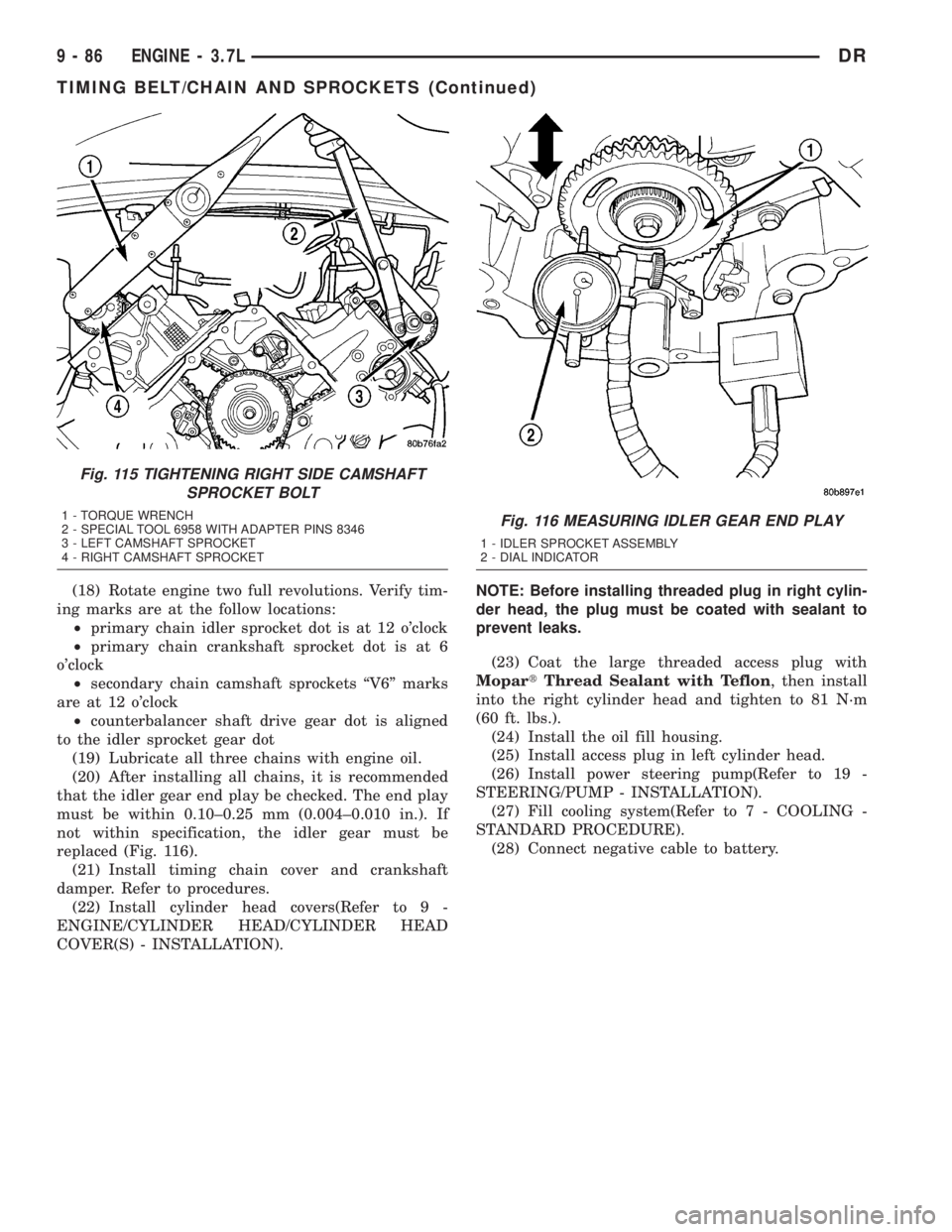

(17) Using Special Tool 6958, Spanner with Adap-

tor Pins 8346, tighten left (Fig. 114) and right (Fig.

115). camshaft sprocket bolts to 122 N´m (90 ft. lbs.).

Fig. 113 COUNTERBALANCE SHAFT ALIGNMENT

MARKS

1 - COUNTERBALANCE SHAFT GEAR

2 - TIMING MARK

3 - IDLER SPROCKET GEAR

Fig. 114 TIGHTENING LEFT SIDE CAMSHAFT

SPROCKET BOLT

1 - TORQUE WRENCH

2 - CAMSHAFT SPROCKET

3 - LEFT CYLINDER HEAD

4 - SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

DRENGINE - 3.7L 9 - 85

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1335 of 2895

(18) Rotate engine two full revolutions. Verify tim-

ing marks are at the follow locations:

²primary chain idler sprocket dot is at 12 o'clock

²primary chain crankshaft sprocket dot is at 6

o'clock

²secondary chain camshaft sprockets ªV6º marks

are at 12 o'clock

²counterbalancer shaft drive gear dot is aligned

to the idler sprocket gear dot

(19) Lubricate all three chains with engine oil.

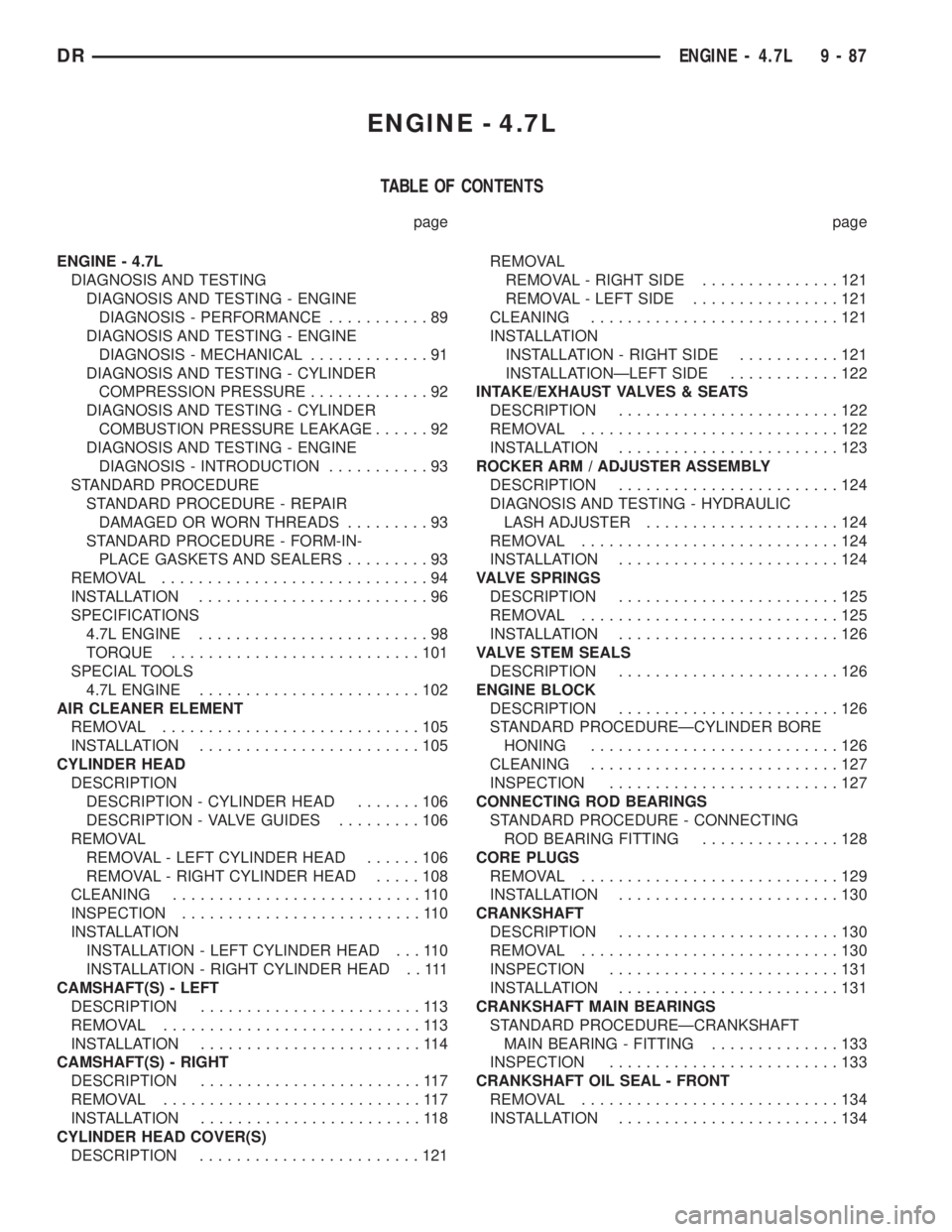

(20) After installing all chains, it is recommended

that the idler gear end play be checked. The end play

must be within 0.10±0.25 mm (0.004±0.010 in.). If

not within specification, the idler gear must be

replaced (Fig. 116).

(21) Install timing chain cover and crankshaft

damper. Refer to procedures.

(22) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).NOTE: Before installing threaded plug in right cylin-

der head, the plug must be coated with sealant to

prevent leaks.

(23) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.).

(24) Install the oil fill housing.

(25) Install access plug in left cylinder head.

(26) Install power steering pump(Refer to 19 -

STEERING/PUMP - INSTALLATION).

(27) Fill cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(28) Connect negative cable to battery.

Fig. 115 TIGHTENING RIGHT SIDE CAMSHAFT

SPROCKET BOLT

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKETFig. 116 MEASURING IDLER GEAR END PLAY

1 - IDLER SPROCKET ASSEMBLY

2 - DIAL INDICATOR

9 - 86 ENGINE - 3.7LDR

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1336 of 2895

ENGINE - 4.7L

TABLE OF CONTENTS

page page

ENGINE - 4.7L

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE...........89

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL.............91

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE.............92

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE......92

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION...........93

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS.........93

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.........93

REMOVAL.............................94

INSTALLATION.........................96

SPECIFICATIONS

4.7L ENGINE.........................98

TORQUE...........................101

SPECIAL TOOLS

4.7L ENGINE........................102

AIR CLEANER ELEMENT

REMOVAL............................105

INSTALLATION........................105

CYLINDER HEAD

DESCRIPTION

DESCRIPTION - CYLINDER HEAD.......106

DESCRIPTION - VALVE GUIDES.........106

REMOVAL

REMOVAL - LEFT CYLINDER HEAD......106

REMOVAL - RIGHT CYLINDER HEAD.....108

CLEANING...........................110

INSPECTION..........................110

INSTALLATION

INSTALLATION - LEFT CYLINDER HEAD . . . 110

INSTALLATION - RIGHT CYLINDER HEAD . . 111

CAMSHAFT(S) - LEFT

DESCRIPTION........................113

REMOVAL............................113

INSTALLATION........................114

CAMSHAFT(S) - RIGHT

DESCRIPTION........................117

REMOVAL............................117

INSTALLATION........................118

CYLINDER HEAD COVER(S)

DESCRIPTION........................121REMOVAL

REMOVAL - RIGHT SIDE...............121

REMOVAL - LEFT SIDE................121

CLEANING...........................121

INSTALLATION

INSTALLATION - RIGHT SIDE...........121

INSTALLATIONÐLEFT SIDE............122

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION........................122

REMOVAL............................122

INSTALLATION........................123

ROCKER ARM / ADJUSTER ASSEMBLY

DESCRIPTION........................124

DIAGNOSIS AND TESTING - HYDRAULIC

LASH ADJUSTER.....................124

REMOVAL............................124

INSTALLATION........................124

VALVE SPRINGS

DESCRIPTION........................125

REMOVAL............................125

INSTALLATION........................126

VALVE STEM SEALS

DESCRIPTION........................126

ENGINE BLOCK

DESCRIPTION........................126

STANDARD PROCEDUREÐCYLINDER BORE

HONING...........................126

CLEANING...........................127

INSPECTION.........................127

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING

ROD BEARING FITTING...............128

CORE PLUGS

REMOVAL............................129

INSTALLATION........................130

CRANKSHAFT

DESCRIPTION........................130

REMOVAL............................130

INSPECTION.........................131

INSTALLATION........................131

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDUREÐCRANKSHAFT

MAIN BEARING - FITTING..............133

INSPECTION.........................133

CRANKSHAFT OIL SEAL - FRONT

REMOVAL............................134

INSTALLATION........................134

DRENGINE - 4.7L 9 - 87

Page 1337 of 2895

CRANKSHAFT OIL SEAL - REAR

DIAGNOSIS AND TESTING - REAR SEAL

AREA LEAKS........................135

REMOVAL............................135

INSTALLATION........................136

FLEX PLATE

REMOVAL............................137

INSTALLATION........................137

PISTON & CONNECTING ROD

DESCRIPTION........................137

STANDARD PROCEDUREÐPISTON FITTING . 137

REMOVAL............................137

CLEANING...........................138

INSPECTION.........................138

INSTALLATION........................139

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING............................140

VIBRATION DAMPER

REMOVAL............................141

INSTALLATION........................142

STRUCTURAL COVER

DESCRIPTION........................143

OPERATION..........................143

REMOVAL............................143

INSTALLATION........................143

FRONT MOUNT

REMOVAL............................144

INSTALLATION........................144

REAR MOUNT

REMOVAL............................147

INSTALLATION........................147

LUBRICATION

DESCRIPTION........................148

OPERATION..........................148

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE...............150

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAK..............................150

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE...........................151

OIL FILTER

REMOVAL............................152

INSTALLATION........................153

OIL PAN

REMOVAL............................153

INSTALLATION........................153OIL PRESSURE SENSOR/SWITCH

DESCRIPTION

DESCRIPTION.......................154

DESCRIPTION.......................154

OPERATION

OPERATION........................154

OPERATION........................154

REMOVAL............................154

INSTALLATION........................154

OIL PUMP

REMOVAL............................154

DISASSEMBLY........................155

CLEANING...........................155

INSPECTION.........................155

ASSEMBLY...........................156

INSTALLATION........................157

INTAKE MANIFOLD

DESCRIPTION........................157

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE.................157

REMOVAL............................157

CLEANING...........................158

INSPECTION.........................158

INSTALLATION........................158

EXHAUST MANIFOLD

DESCRIPTION........................159

REMOVAL............................159

CLEANING...........................161

INSPECTION.........................161

INSTALLATION........................162

VALVE TIMING

DESCRIPTIONÐTIMING DRIVE SYSTEM....164

OPERATION - TIMING DRIVE SYSTEM.....164

STANDARD PROCEDURE

STANDARD PROCEDUREÐMEASURING

TIMING CHAIN WEAR.................165

STANDARD PROCEDURE - ENGINE TIMING

- VERIFICATION.....................165

TIMING BELT / CHAIN COVER(S)

REMOVAL............................168

INSTALLATION........................169

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL............................169

INSPECTION.........................171

INSTALLATION........................172

IDLER SHAFT

REMOVAL............................175

INSTALLATION........................175

9 - 88 ENGINE - 4.7LDR

Page 1338 of 2895

ENGINE - 4.7L

DIAGNOSIS AND TESTING

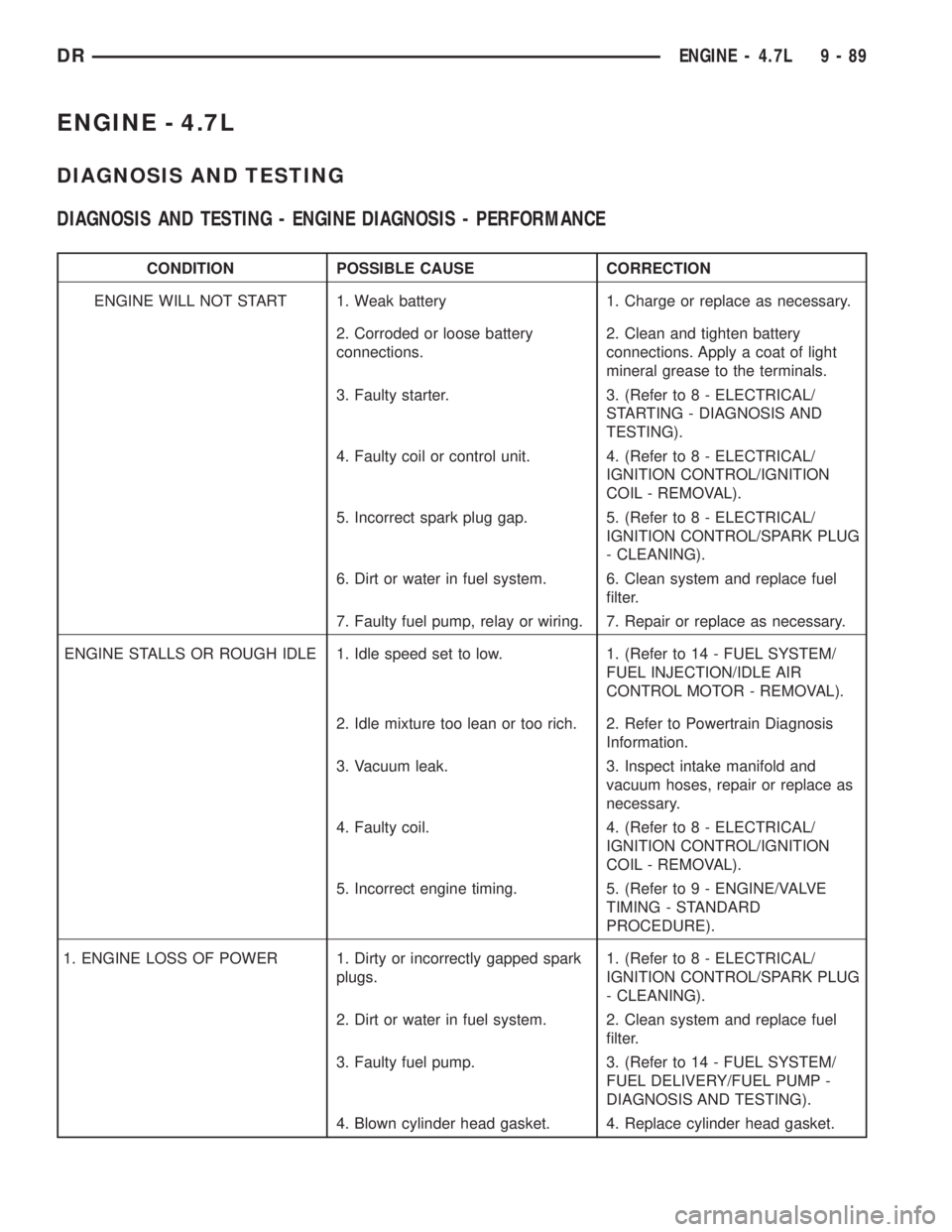

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND

TESTING).

4. Faulty coil or control unit. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect spark plug gap. 5. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

6. Dirt or water in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump, relay or wiring. 7. Repair or replace as necessary.

ENGINE STALLS OR ROUGH IDLE 1. Idle speed set to low. 1. (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/IDLE AIR

CONTROL MOTOR - REMOVAL).

2. Idle mixture too lean or too rich. 2. Refer to Powertrain Diagnosis

Information.

3. Vacuum leak. 3. Inspect intake manifold and

vacuum hoses, repair or replace as

necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect engine timing. 5. (Refer to 9 - ENGINE/VALVE

TIMING - STANDARD

PROCEDURE).

1. ENGINE LOSS OF POWER 1. Dirty or incorrectly gapped spark

plugs.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

2. Dirt or water in fuel system. 2. Clean system and replace fuel

filter.

3. Faulty fuel pump. 3. (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING).

4. Blown cylinder head gasket. 4. Replace cylinder head gasket.

DRENGINE - 4.7L 9 - 89

Page 1339 of 2895

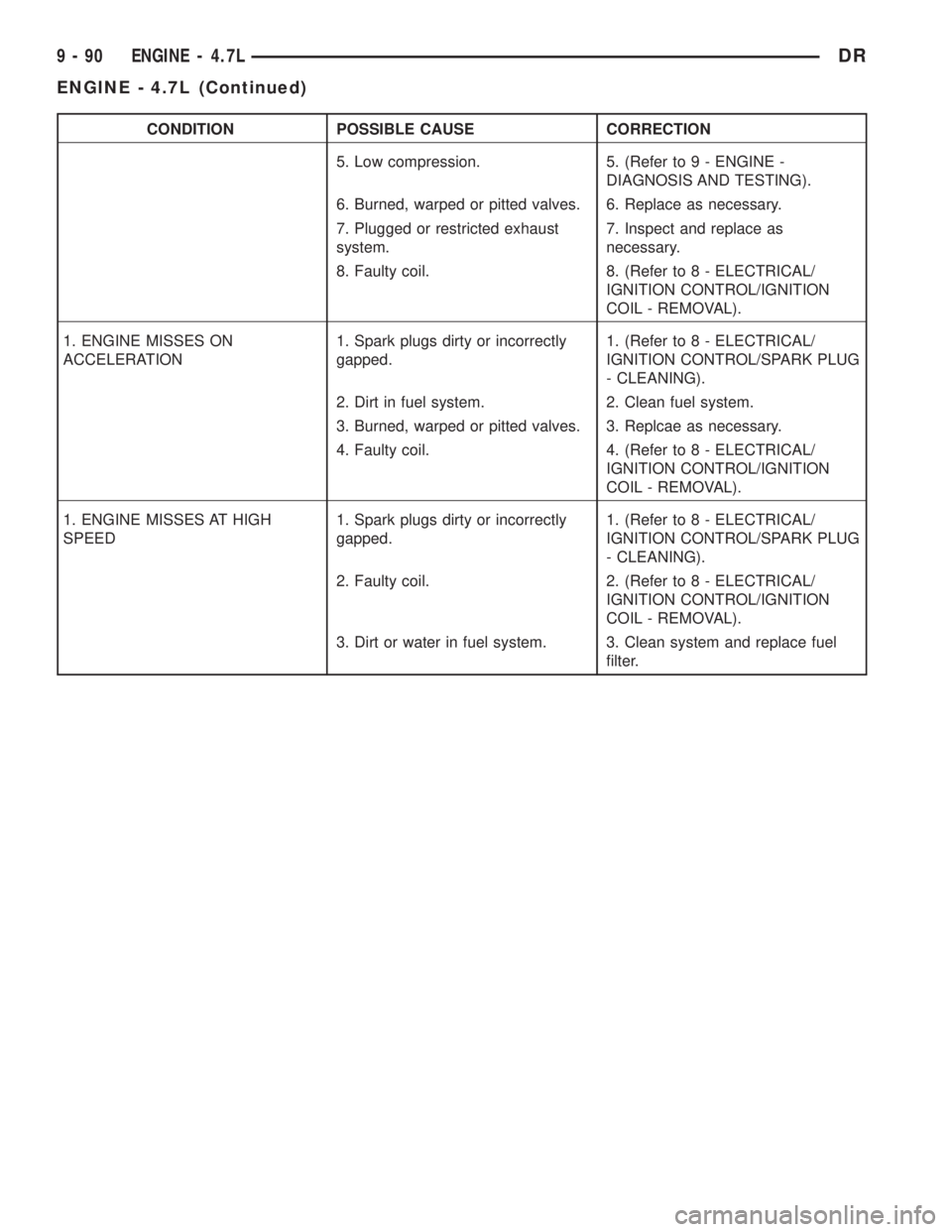

CONDITION POSSIBLE CAUSE CORRECTION

5. Low compression. 5. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

6. Burned, warped or pitted valves. 6. Replace as necessary.

7. Plugged or restricted exhaust

system.7. Inspect and replace as

necessary.

8. Faulty coil. 8. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

1. ENGINE MISSES ON

ACCELERATION1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

2. Dirt in fuel system. 2. Clean fuel system.

3. Burned, warped or pitted valves. 3. Replcae as necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

1. ENGINE MISSES AT HIGH

SPEED1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

2. Faulty coil. 2. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

3. Dirt or water in fuel system. 3. Clean system and replace fuel

filter.

9 - 90 ENGINE - 4.7LDR

ENGINE - 4.7L (Continued)

Page 1340 of 2895

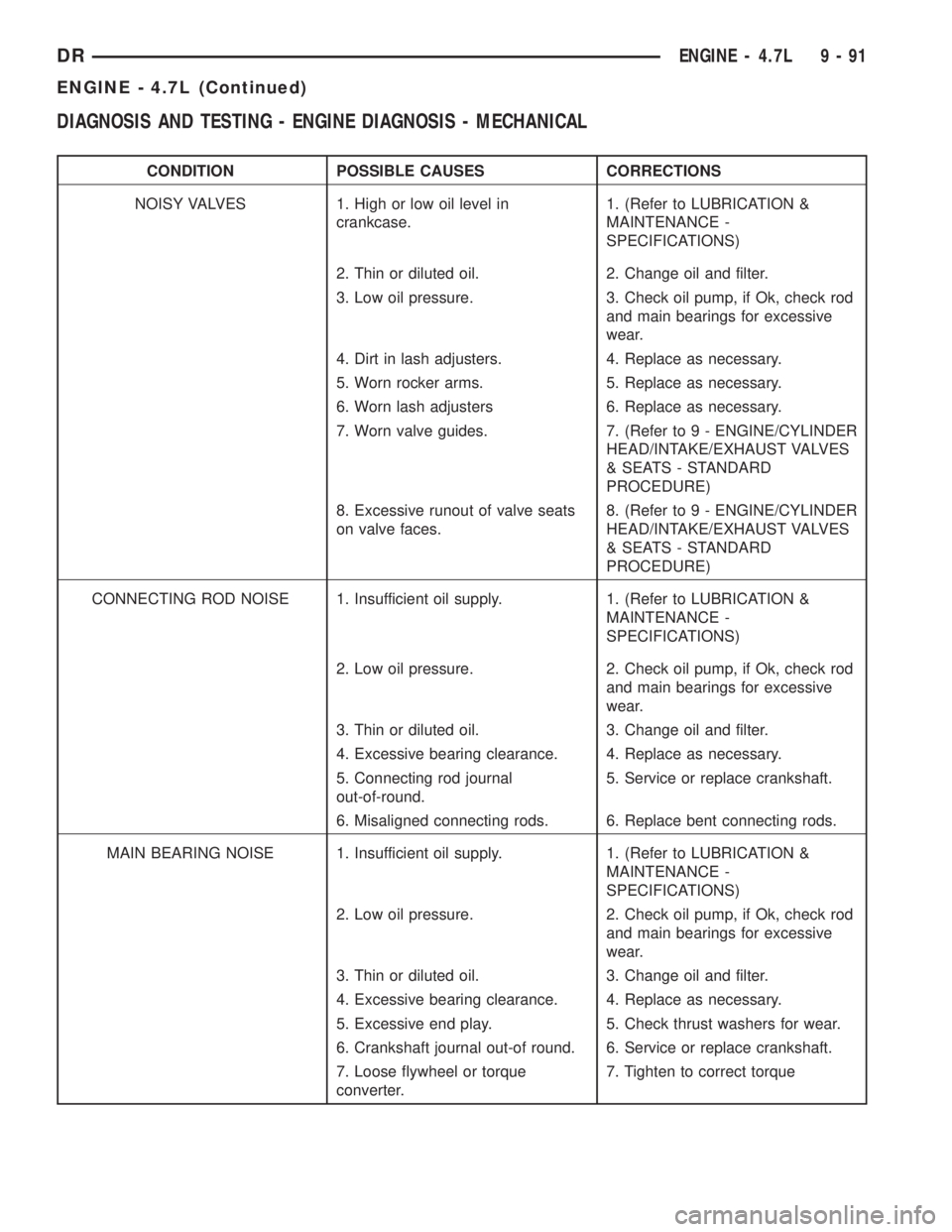

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in

crankcase.1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

4. Dirt in lash adjusters. 4. Replace as necessary.

5. Worn rocker arms. 5. Replace as necessary.

6. Worn lash adjusters 6. Replace as necessary.

7. Worn valve guides. 7. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE)

8. Excessive runout of valve seats

on valve faces.8. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE)

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal

out-of-round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check thrust washers for wear.

6. Crankshaft journal out-of round. 6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.7. Tighten to correct torque

DRENGINE - 4.7L 9 - 91

ENGINE - 4.7L (Continued)