DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1371 of 2895

(11) Fill Cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(12) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(13) Connect battery negative cable.

INSTALLATIONÐLEFT SIDE

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the cylin-

der head cover. Prolonged contact with other

objects may wear a hole in the engine cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

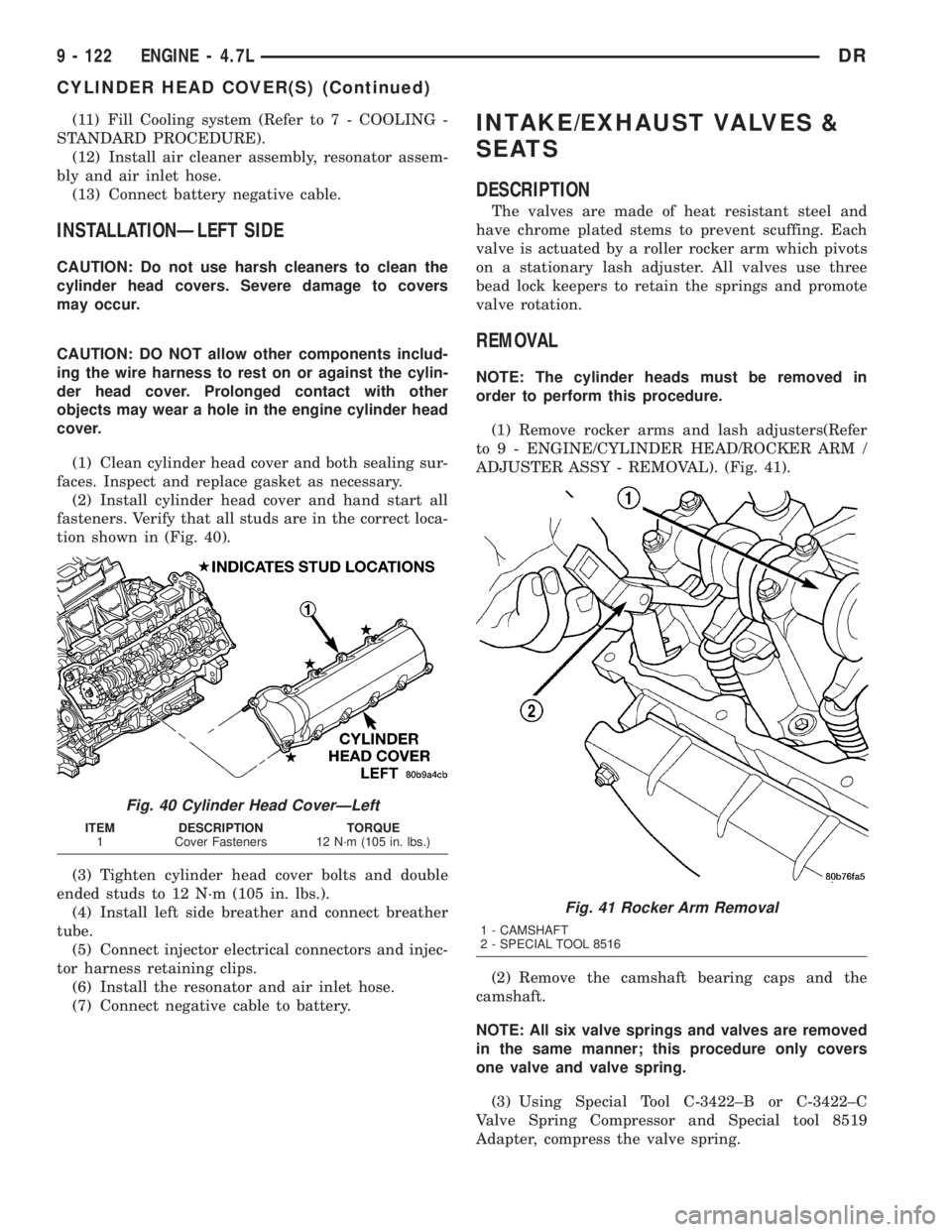

(2) Install cylinder head cover and hand start all

fasteners. Verify that all studs are in the correct loca-

tion shown in (Fig. 40).

(3) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs.).

(4) Install left side breather and connect breather

tube.

(5) Connect injector electrical connectors and injec-

tor harness retaining clips.

(6) Install the resonator and air inlet hose.

(7) Connect negative cable to battery.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

REMOVAL

NOTE: The cylinder heads must be removed in

order to perform this procedure.

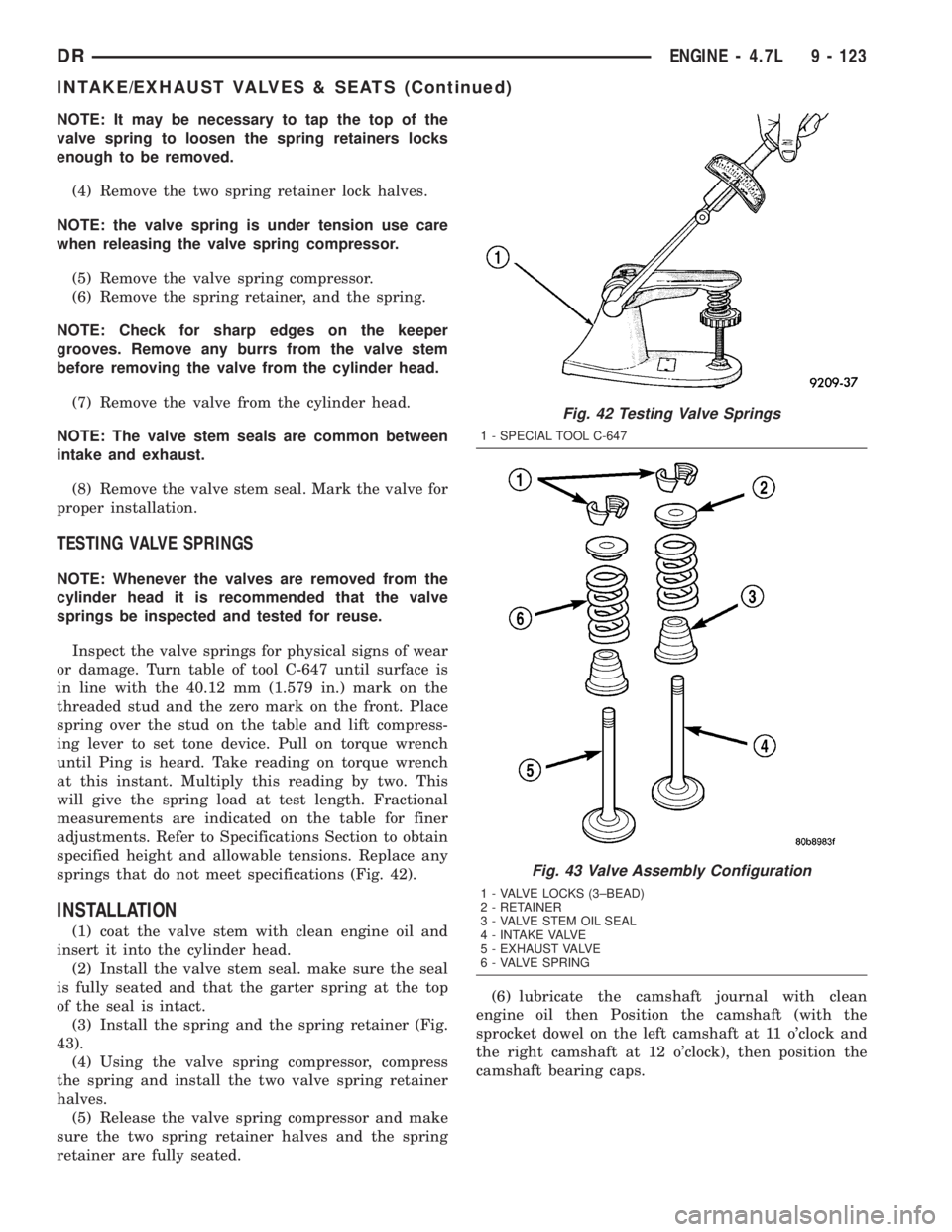

(1) Remove rocker arms and lash adjusters(Refer

to 9 - ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - REMOVAL). (Fig. 41).

(2) Remove the camshaft bearing caps and the

camshaft.

NOTE: All six valve springs and valves are removed

in the same manner; this procedure only covers

one valve and valve spring.

(3) Using Special Tool C-3422±B or C-3422±C

Valve Spring Compressor and Special tool 8519

Adapter, compress the valve spring.

Fig. 40 Cylinder Head CoverÐLeft

ITEM DESCRIPTION TORQUE

1 Cover Fasteners 12 N´m (105 in. lbs.)

Fig. 41 Rocker Arm Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

9 - 122 ENGINE - 4.7LDR

CYLINDER HEAD COVER(S) (Continued)

Page 1372 of 2895

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(4) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(5) Remove the valve spring compressor.

(6) Remove the spring retainer, and the spring.

NOTE: Check for sharp edges on the keeper

grooves. Remove any burrs from the valve stem

before removing the valve from the cylinder head.

(7) Remove the valve from the cylinder head.

NOTE: The valve stem seals are common between

intake and exhaust.

(8) Remove the valve stem seal. Mark the valve for

proper installation.

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear

or damage. Turn table of tool C-647 until surface is

in line with the 40.12 mm (1.579 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over the stud on the table and lift compress-

ing lever to set tone device. Pull on torque wrench

until Ping is heard. Take reading on torque wrench

at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional

measurements are indicated on the table for finer

adjustments. Refer to Specifications Section to obtain

specified height and allowable tensions. Replace any

springs that do not meet specifications (Fig. 42).

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

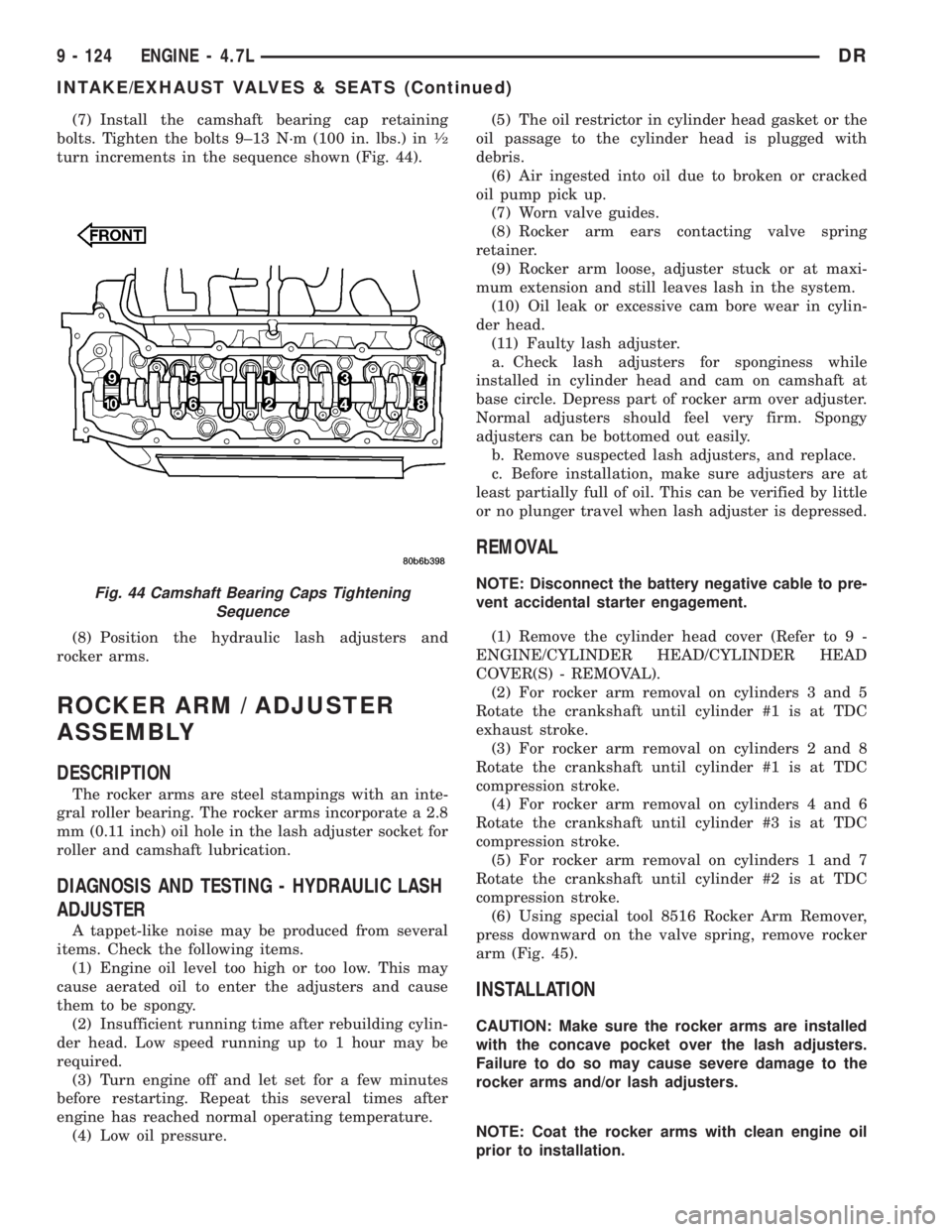

(3) Install the spring and the spring retainer (Fig.

43).

(4) Using the valve spring compressor, compress

the spring and install the two valve spring retainer

halves.

(5) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.(6) lubricate the camshaft journal with clean

engine oil then Position the camshaft (with the

sprocket dowel on the left camshaft at 11 o'clock and

the right camshaft at 12 o'clock), then position the

camshaft bearing caps.

Fig. 42 Testing Valve Springs

1 - SPECIAL TOOL C-647

Fig. 43 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

DRENGINE - 4.7L 9 - 123

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1373 of 2895

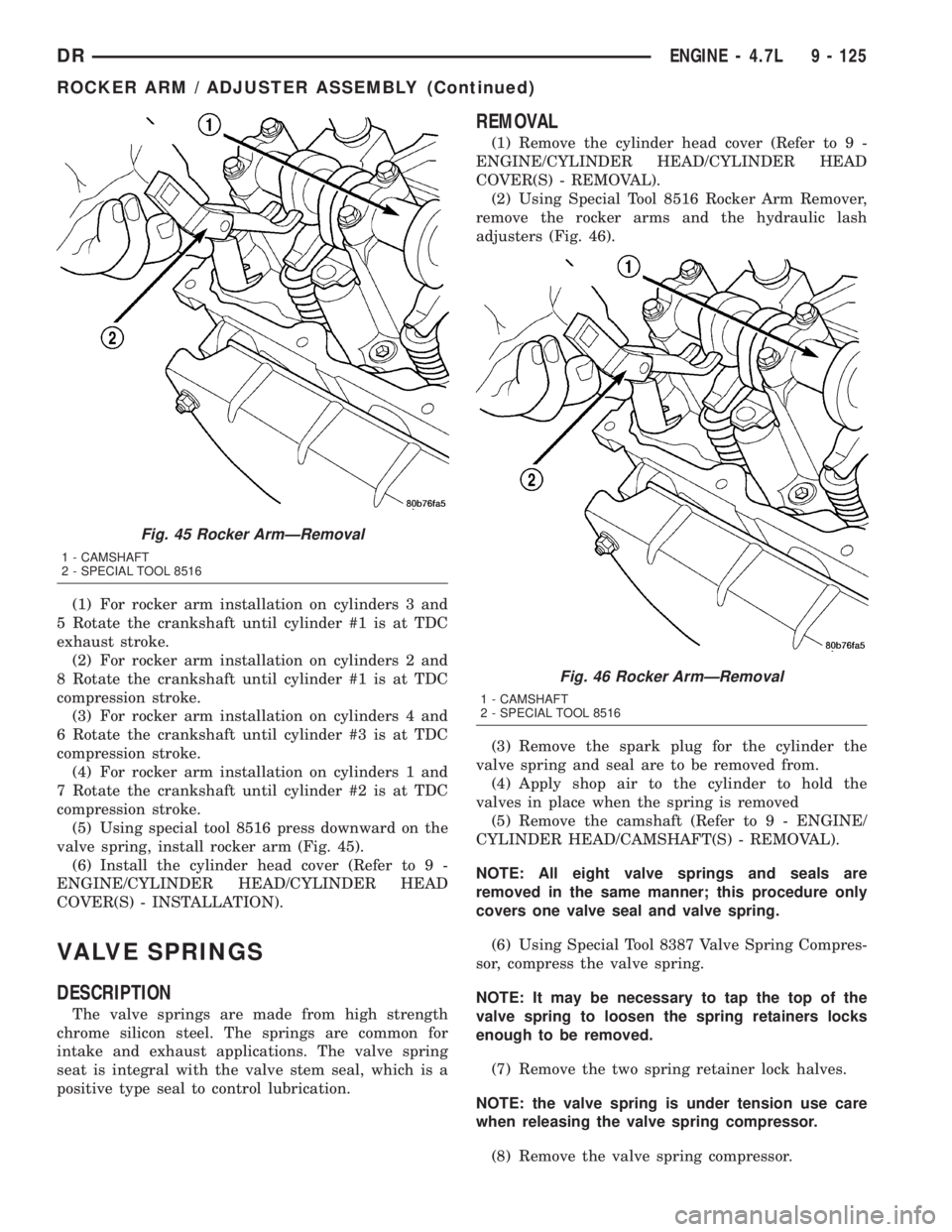

(7) Install the camshaft bearing cap retaining

bolts. Tighten the bolts 9±13 N´m (100 in. lbs.) in1¤2

turn increments in the sequence shown (Fig. 44).

(8) Position the hydraulic lash adjusters and

rocker arms.

ROCKER ARM / ADJUSTER

ASSEMBLY

DESCRIPTION

The rocker arms are steel stampings with an inte-

gral roller bearing. The rocker arms incorporate a 2.8

mm (0.11 inch) oil hole in the lash adjuster socket for

roller and camshaft lubrication.

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) Turn engine off and let set for a few minutes

before restarting. Repeat this several times after

engine has reached normal operating temperature.

(4) Low oil pressure.(5) The oil restrictor in cylinder head gasket or the

oil passage to the cylinder head is plugged with

debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Oil leak or excessive cam bore wear in cylin-

der head.

(11) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

REMOVAL

NOTE: Disconnect the battery negative cable to pre-

vent accidental starter engagement.

(1) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) For rocker arm removal on cylinders 3 and 5

Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(3) For rocker arm removal on cylinders 2 and 8

Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(4) For rocker arm removal on cylinders 4 and 6

Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

(5) For rocker arm removal on cylinders 1 and 7

Rotate the crankshaft until cylinder #2 is at TDC

compression stroke.

(6) Using special tool 8516 Rocker Arm Remover,

press downward on the valve spring, remove rocker

arm (Fig. 45).

INSTALLATION

CAUTION: Make sure the rocker arms are installed

with the concave pocket over the lash adjusters.

Failure to do so may cause severe damage to the

rocker arms and/or lash adjusters.

NOTE: Coat the rocker arms with clean engine oil

prior to installation.

Fig. 44 Camshaft Bearing Caps Tightening

Sequence

9 - 124 ENGINE - 4.7LDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1374 of 2895

(1) For rocker arm installation on cylinders 3 and

5 Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(2) For rocker arm installation on cylinders 2 and

8 Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(3) For rocker arm installation on cylinders 4 and

6 Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

(4) For rocker arm installation on cylinders 1 and

7 Rotate the crankshaft until cylinder #2 is at TDC

compression stroke.

(5) Using special tool 8516 press downward on the

valve spring, install rocker arm (Fig. 45).

(6) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE SPRINGS

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. The springs are common for

intake and exhaust applications. The valve spring

seat is integral with the valve stem seal, which is a

positive type seal to control lubrication.

REMOVAL

(1) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Using Special Tool 8516 Rocker Arm Remover,

remove the rocker arms and the hydraulic lash

adjusters (Fig. 46).

(3) Remove the spark plug for the cylinder the

valve spring and seal are to be removed from.

(4) Apply shop air to the cylinder to hold the

valves in place when the spring is removed

(5) Remove the camshaft (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - REMOVAL).

NOTE: All eight valve springs and seals are

removed in the same manner; this procedure only

covers one valve seal and valve spring.

(6) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(7) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(8) Remove the valve spring compressor.

Fig. 45 Rocker ArmÐRemoval

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

Fig. 46 Rocker ArmÐRemoval

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

DRENGINE - 4.7L 9 - 125

ROCKER ARM / ADJUSTER ASSEMBLY (Continued)

Page 1375 of 2895

(9) Remove the spring retainer, and the spring.

(10) Remove the valve stem seal.

NOTE: The valve stem seals are common between

intake and exhaust.

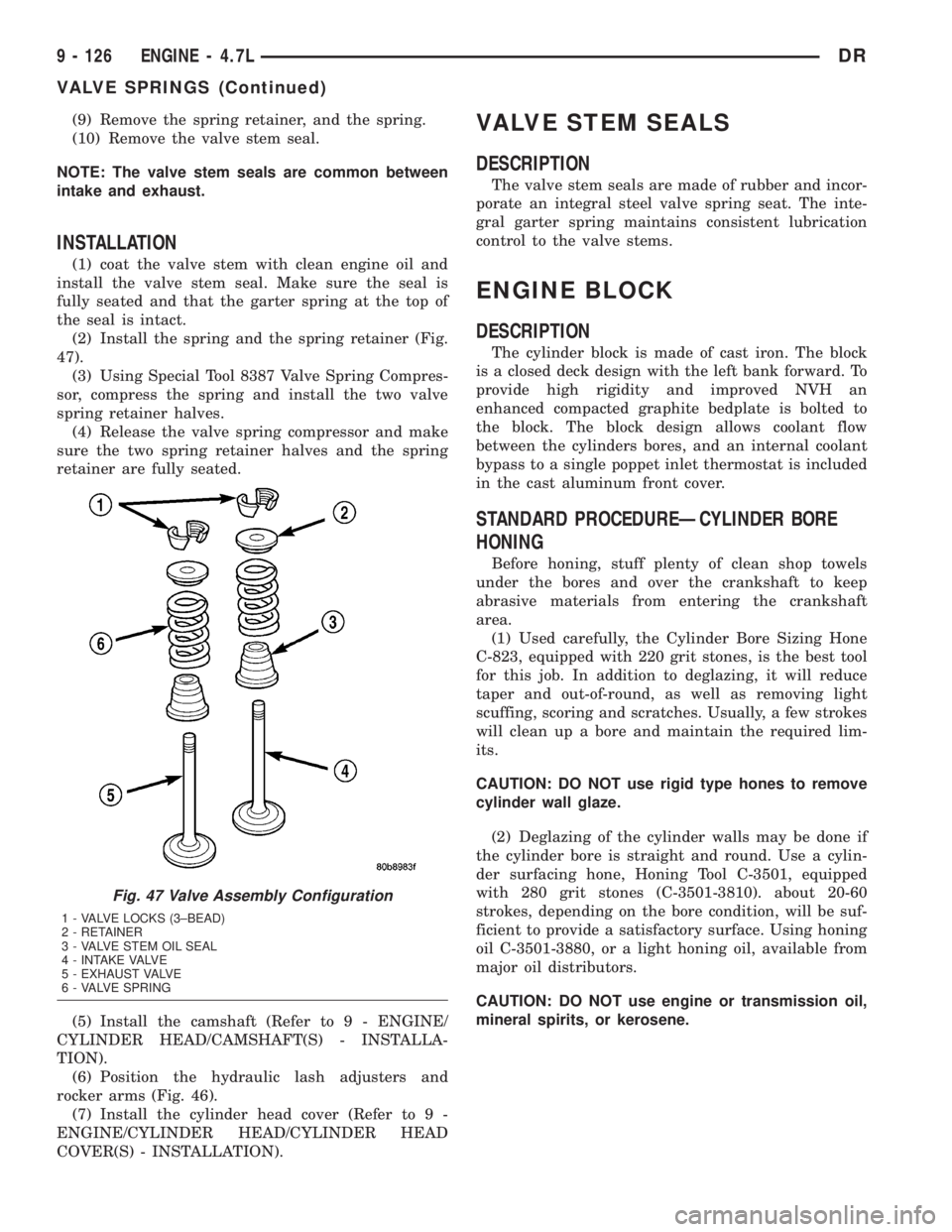

INSTALLATION

(1) coat the valve stem with clean engine oil and

install the valve stem seal. Make sure the seal is

fully seated and that the garter spring at the top of

the seal is intact.

(2) Install the spring and the spring retainer (Fig.

47).

(3) Using Special Tool 8387 Valve Spring Compres-

sor, compress the spring and install the two valve

spring retainer halves.

(4) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(5) Install the camshaft (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - INSTALLA-

TION).

(6) Position the hydraulic lash adjusters and

rocker arms (Fig. 46).

(7) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE STEM SEALS

DESCRIPTION

The valve stem seals are made of rubber and incor-

porate an integral steel valve spring seat. The inte-

gral garter spring maintains consistent lubrication

control to the valve stems.

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron. The block

is a closed deck design with the left bank forward. To

provide high rigidity and improved NVH an

enhanced compacted graphite bedplate is bolted to

the block. The block design allows coolant flow

between the cylinders bores, and an internal coolant

bypass to a single poppet inlet thermostat is included

in the cast aluminum front cover.

STANDARD PROCEDUREÐCYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

Fig. 47 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

9 - 126 ENGINE - 4.7LDR

VALVE SPRINGS (Continued)

Page 1376 of 2895

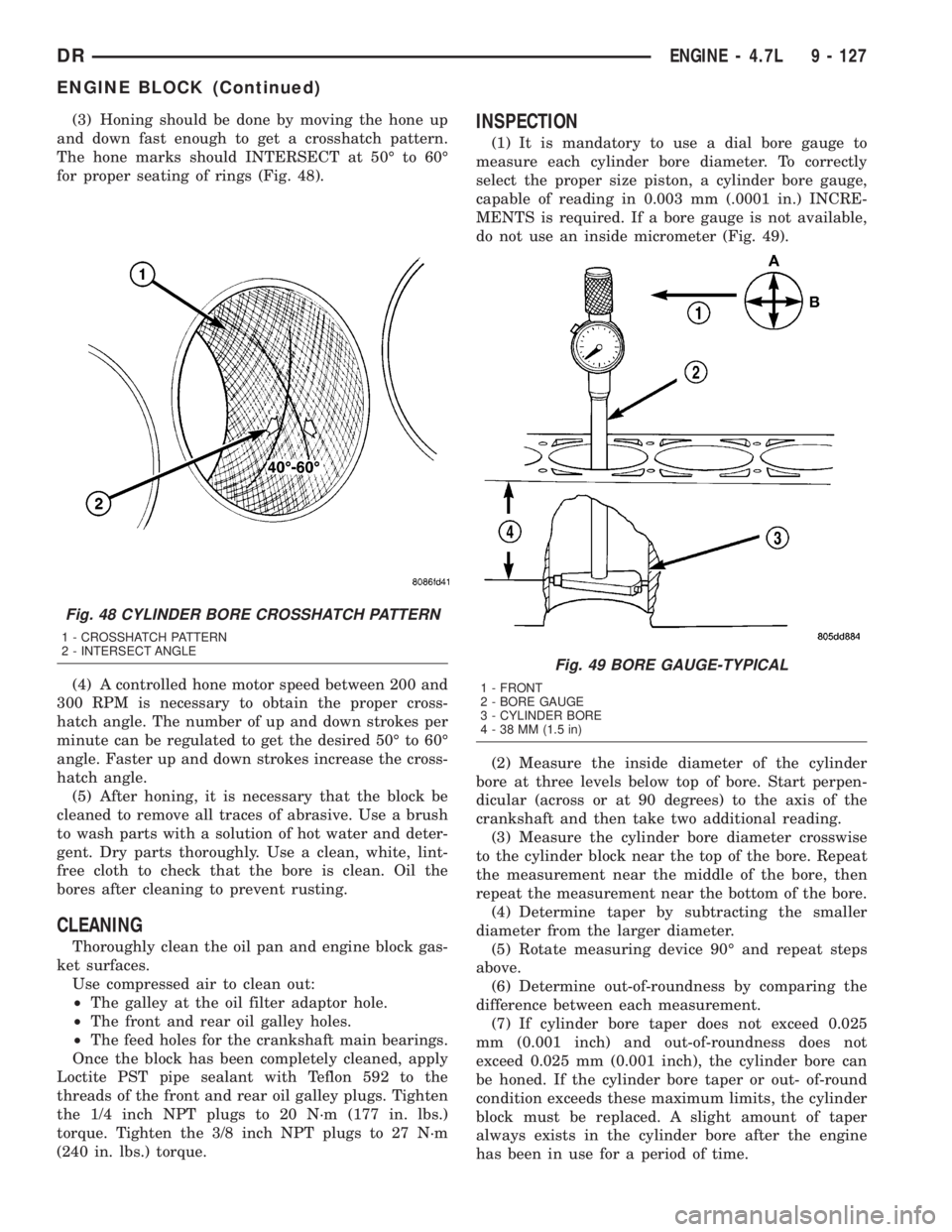

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 48).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the 1/4 inch NPT plugs to 20 N´m (177 in. lbs.)

torque. Tighten the 3/8 inch NPT plugs to 27 N´m

(240 in. lbs.) torque.

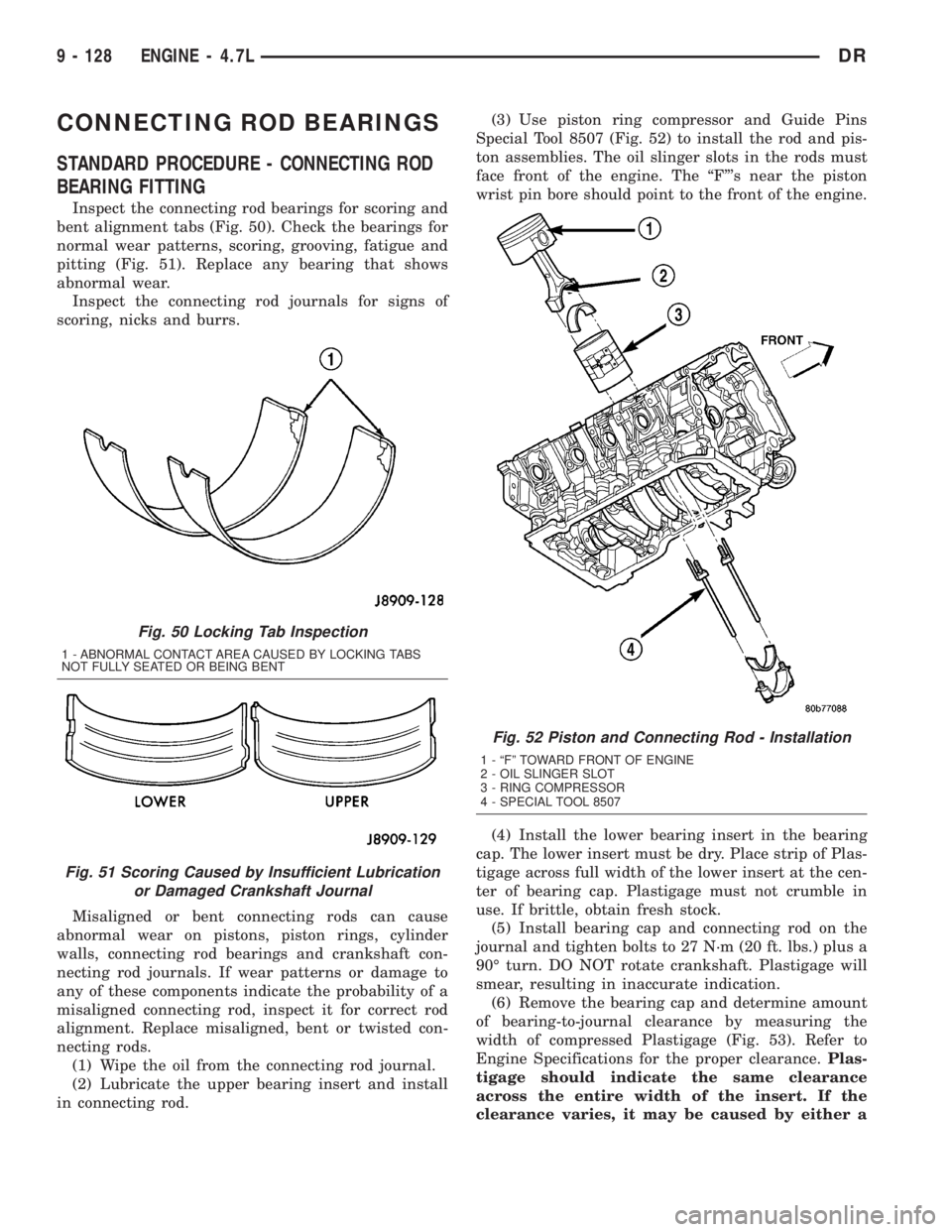

INSPECTION

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore gauge,

capable of reading in 0.003 mm (.0001 in.) INCRE-

MENTS is required. If a bore gauge is not available,

do not use an inside micrometer (Fig. 49).

(2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.

(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

block must be replaced. A slight amount of taper

always exists in the cylinder bore after the engine

has been in use for a period of time.

Fig. 48 CYLINDER BORE CROSSHATCH PATTERN

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

Fig. 49 BORE GAUGE-TYPICAL

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

DRENGINE - 4.7L 9 - 127

ENGINE BLOCK (Continued)

Page 1377 of 2895

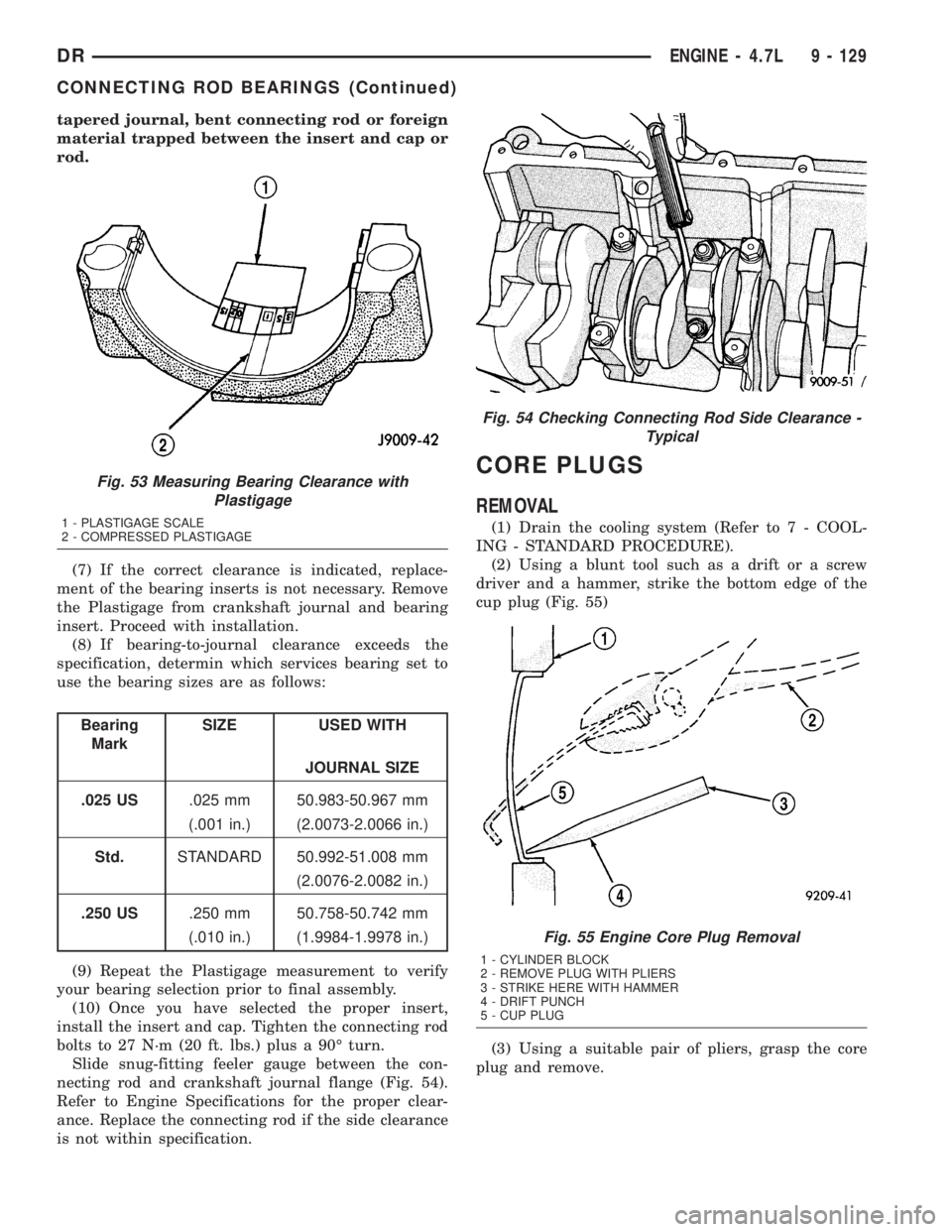

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING ROD

BEARING FITTING

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Fig. 50). Check the bearings for

normal wear patterns, scoring, grooving, fatigue and

pitting (Fig. 51). Replace any bearing that shows

abnormal wear.

Inspect the connecting rod journals for signs of

scoring, nicks and burrs.

Misaligned or bent connecting rods can cause

abnormal wear on pistons, piston rings, cylinder

walls, connecting rod bearings and crankshaft con-

necting rod journals. If wear patterns or damage to

any of these components indicate the probability of a

misaligned connecting rod, inspect it for correct rod

alignment. Replace misaligned, bent or twisted con-

necting rods.

(1) Wipe the oil from the connecting rod journal.

(2) Lubricate the upper bearing insert and install

in connecting rod.(3) Use piston ring compressor and Guide Pins

Special Tool 8507 (Fig. 52) to install the rod and pis-

ton assemblies. The oil slinger slots in the rods must

face front of the engine. The ªFº's near the piston

wrist pin bore should point to the front of the engine.

(4) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plas-

tigage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

(5) Install bearing cap and connecting rod on the

journal and tighten bolts to 27 N´m (20 ft. lbs.) plus a

90É turn. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(6) Remove the bearing cap and determine amount

of bearing-to-journal clearance by measuring the

width of compressed Plastigage (Fig. 53). Refer to

Engine Specifications for the proper clearance.Plas-

tigage should indicate the same clearance

across the entire width of the insert. If the

clearance varies, it may be caused by either a

Fig. 50 Locking Tab Inspection

1 - ABNORMAL CONTACT AREA CAUSED BY LOCKING TABS

NOT FULLY SEATED OR BEING BENT

Fig. 51 Scoring Caused by Insufficient Lubrication

or Damaged Crankshaft Journal

Fig. 52 Piston and Connecting Rod - Installation

1 - ªFº TOWARD FRONT OF ENGINE

2 - OIL SLINGER SLOT

3 - RING COMPRESSOR

4 - SPECIAL TOOL 8507

9 - 128 ENGINE - 4.7LDR

Page 1378 of 2895

tapered journal, bent connecting rod or foreign

material trapped between the insert and cap or

rod.

(7) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(8) If bearing-to-journal clearance exceeds the

specification, determin which services bearing set to

use the bearing sizes are as follows:

Bearing

MarkSIZE USED WITH

JOURNAL SIZE

.025 US.025 mm 50.983-50.967 mm

(.001 in.) (2.0073-2.0066 in.)

Std.STANDARD 50.992-51.008 mm

(2.0076-2.0082 in.)

.250 US.250 mm 50.758-50.742 mm

(.010 in.) (1.9984-1.9978 in.)

(9) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(10) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 27 N´m (20 ft. lbs.) plus a 90É turn.

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 54).

Refer to Engine Specifications for the proper clear-

ance. Replace the connecting rod if the side clearance

is not within specification.

CORE PLUGS

REMOVAL

(1) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(2) Using a blunt tool such as a drift or a screw

driver and a hammer, strike the bottom edge of the

cup plug (Fig. 55)

(3) Using a suitable pair of pliers, grasp the core

plug and remove.

Fig. 53 Measuring Bearing Clearance with

Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

Fig. 54 Checking Connecting Rod Side Clearance -

Typical

Fig. 55 Engine Core Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

DRENGINE - 4.7L 9 - 129

CONNECTING ROD BEARINGS (Continued)

Page 1379 of 2895

INSTALLATION

NOTE: Thoroughly clean core plug bore, remove all

of the old sealer.

(1)

Coat the edges of the engine core plug and the

core plug bore with Mopar Gasket Maker, or equivalent.

NOTE: It is not necessary to wait for the sealant to

cure on the core plugs. The cooling system can be

filled and the vehicle returned to service immediately.

(2) Using proper plug driver, drive core plug into

the core plug bore. The sharp edge of the core plug

should be at least 0.50 mm (0.020 in.) inside the lead

in chamfer.

(3) Refill the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a crosshaped four throw design with

eight counterweights for balancing purposes. The crank-

shaft is supported by five select fit main bearings with

the number three serving as the thrust washer location.

The main journals of the crankshaft are cross drilled to

improve rod bearing lubrication. The number eight

counterweight has provisions for crankshaft position

sensor target wheel mounting. The select fit main bear-

ing markings are located on the rear side of the target

wheel. The crankshaft oil seals are one piece design.

The front oil seal is retained in the timing chain cover,

and the rear seal is pressed in to a bore formed by the

cylinder block and the bedplate assembly.

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine. (Refer to 9 - ENGINE -

REMOVAL).

(2) Remove the engine oil pump.(Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - REMOVAL).

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).(4) Remove the oil pump pickup tube and oil pan

gasket /windage tray.

(5) Remove the bedplate mounting bolts. Note the

location of the three stud bolts for installation.

(6)

Remove the connecting rods from the crankshaft.

CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

sever damage to the crankshaft.

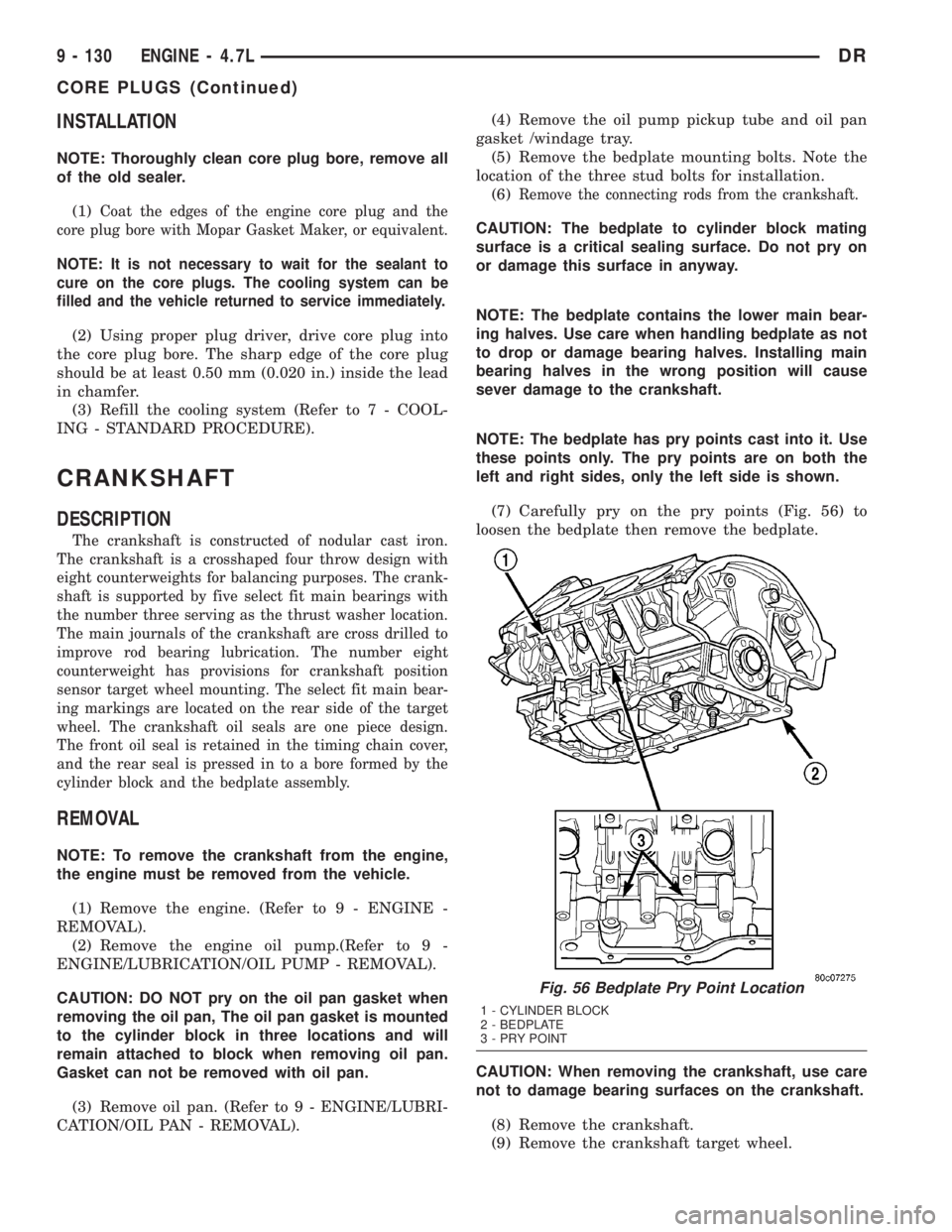

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are on both the

left and right sides, only the left side is shown.

(7) Carefully pry on the pry points (Fig. 56) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(8) Remove the crankshaft.

(9) Remove the crankshaft target wheel.

Fig. 56 Bedplate Pry Point Location

1 - CYLINDER BLOCK

2 - BEDPLATE

3 - PRY POINT

9 - 130 ENGINE - 4.7LDR

CORE PLUGS (Continued)

Page 1380 of 2895

INSPECTION

NOTE: Thoroughly inspect the connecting rod bear-

ing bores and main bearing bores for scoring, blue-

ing or severe scratches. Further disassembly may

be required.

If connecting rod bearing bores show damage, the

cylinder heads must be removed to service the piston

and rod assemblies. If the bedplate or the cylinder

block main bearing bores show damage the engine

must be replaced.

(1) If required, remove the main bearing halves

from the cylinder block and bedplate.

(2) Thoroughly clean the bedplate to cylinder block

sealing surfaces and main bearing bores. Remove all

oil and sealant residue.

(3) Inspect the bedplate main bearing bores for

cracks, scoring or severe blueing. If either condition

exists the engine must be replaced.

(4) Inspect the crankshaft thrust washers for scor-

ing, scratches, wear or blueing. If either condition

exist replace the thrust washer.

(5) Inspect the oil pan gasket/windage tray for

splits, tears or cracks in the gasket sealing surfaces.

Replace gasket as necessary.

INSTALLATION

CAUTION: Main bearings are select fit. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) for proper

bearing selections.

(1) Lubricate upper main bearing halves with

clean engine oil.

CAUTION: When installing crankshaft, use care not

to damage bearing surfaces on the crankshaft.

NOTE: Apply sealant to the target wheel retaining

screws prior to installation.

(2) Install the crankshaft target wheel. Torque the

mounting screws to 15 N´m (12 ft. lbs.).

(3) Position crankshaft in cylinder block.

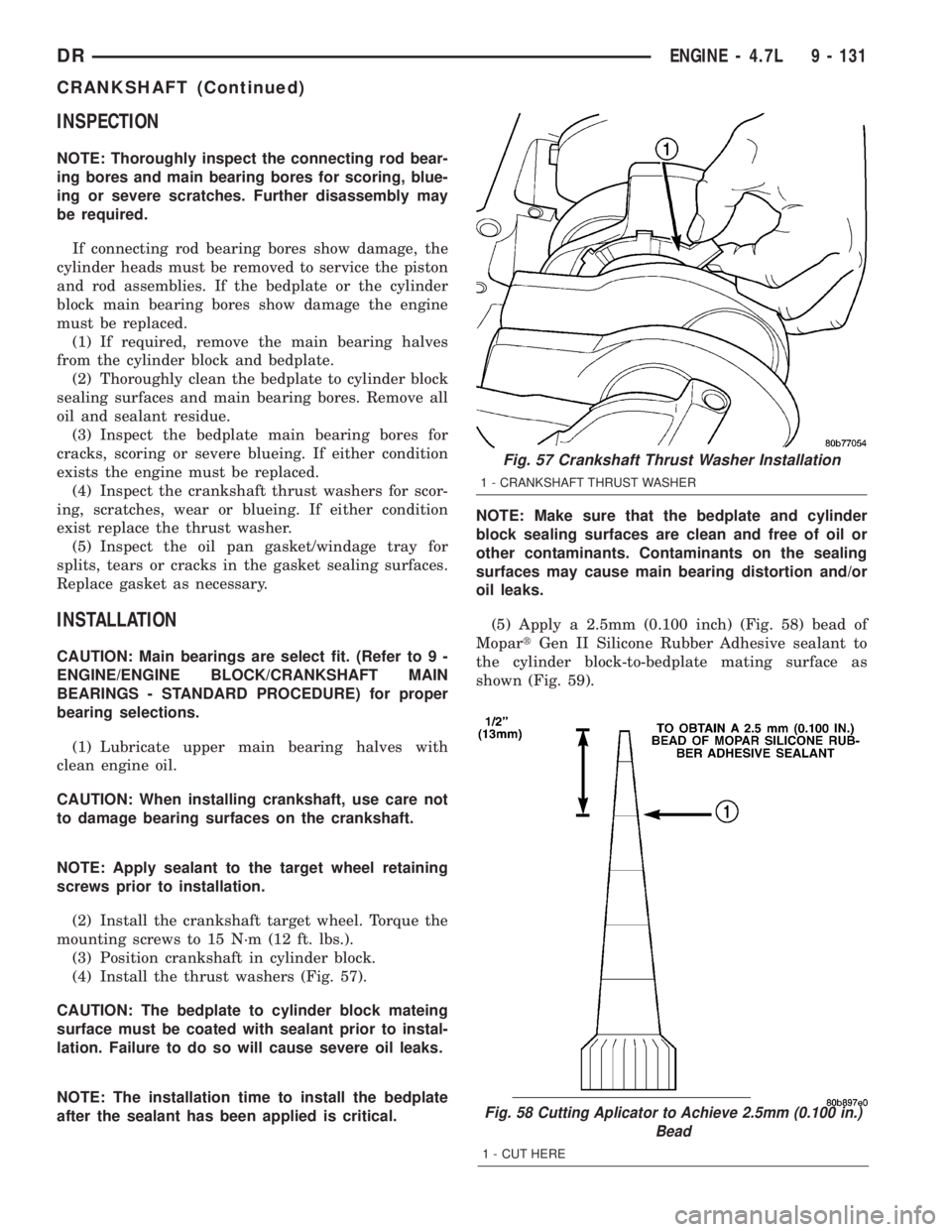

(4) Install the thrust washers (Fig. 57).

CAUTION: The bedplate to cylinder block mateing

surface must be coated with sealant prior to instal-

lation. Failure to do so will cause severe oil leaks.

NOTE: The installation time to install the bedplate

after the sealant has been applied is critical.NOTE: Make sure that the bedplate and cylinder

block sealing surfaces are clean and free of oil or

other contaminants. Contaminants on the sealing

surfaces may cause main bearing distortion and/or

oil leaks.

(5) Apply a 2.5mm (0.100 inch) (Fig. 58) bead of

MopartGen II Silicone Rubber Adhesive sealant to

the cylinder block-to-bedplate mating surface as

shown (Fig. 59).

Fig. 58 Cutting Aplicator to Achieve 2.5mm (0.100 in.)

Bead

1 - CUT HERE

Fig. 57 Crankshaft Thrust Washer Installation

1 - CRANKSHAFT THRUST WASHER

DRENGINE - 4.7L 9 - 131

CRANKSHAFT (Continued)