DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1411 of 2895

INSTALLATION

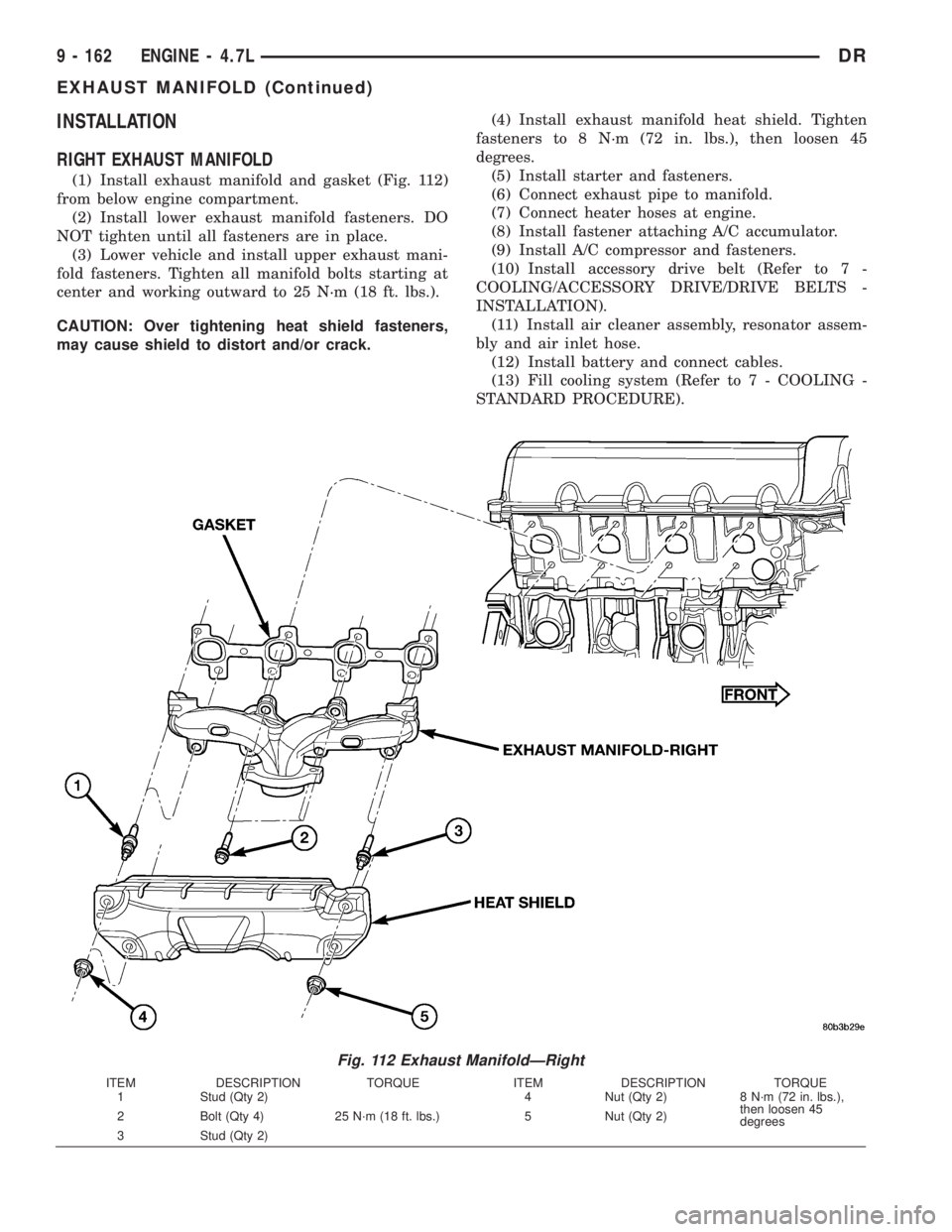

RIGHT EXHAUST MANIFOLD

(1) Install exhaust manifold and gasket (Fig. 112)

from below engine compartment.

(2) Install lower exhaust manifold fasteners. DO

NOT tighten until all fasteners are in place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners. Tighten all manifold bolts starting at

center and working outward to 25 N´m (18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.(4) Install exhaust manifold heat shield. Tighten

fasteners to 8 N´m (72 in. lbs.), then loosen 45

degrees.

(5) Install starter and fasteners.

(6) Connect exhaust pipe to manifold.

(7) Connect heater hoses at engine.

(8) Install fastener attaching A/C accumulator.

(9) Install A/C compressor and fasteners.

(10) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(11) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(12) Install battery and connect cables.

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Fig. 112 Exhaust ManifoldÐRight

ITEM DESCRIPTION TORQUE ITEM DESCRIPTION TORQUE

1 Stud (Qty 2)

25 N´m (18 ft. lbs.)4 Nut (Qty 2) 8 N´m (72 in. lbs.),

then loosen 45

degrees 2 Bolt (Qty 4) 5 Nut (Qty 2)

3 Stud (Qty 2)

9 - 162 ENGINE - 4.7LDR

EXHAUST MANIFOLD (Continued)

Page 1412 of 2895

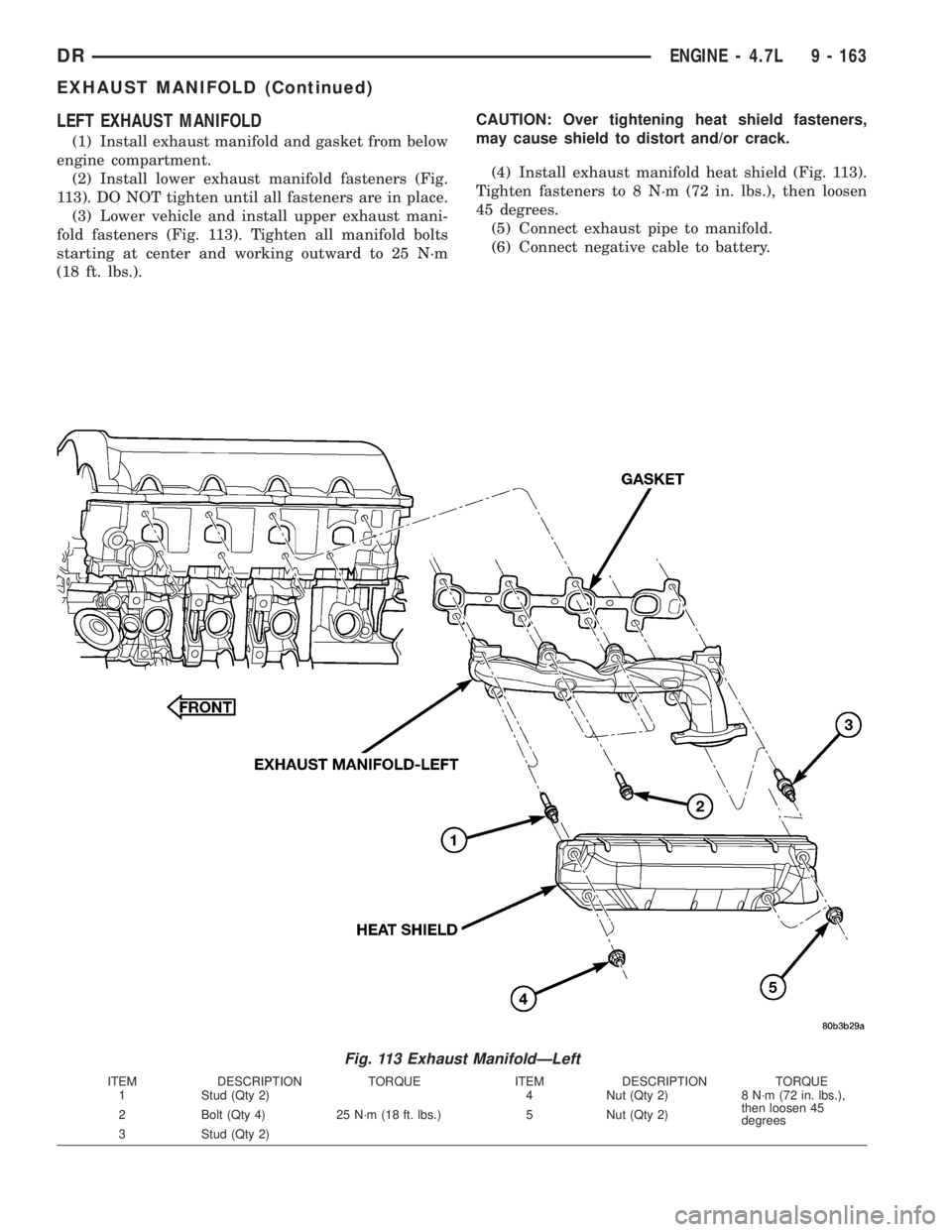

LEFT EXHAUST MANIFOLD

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners (Fig.

113). DO NOT tighten until all fasteners are in place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners (Fig. 113). Tighten all manifold bolts

starting at center and working outward to 25 N´m

(18 ft. lbs.).CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield (Fig. 113).

Tighten fasteners to 8 N´m (72 in. lbs.), then loosen

45 degrees.

(5) Connect exhaust pipe to manifold.

(6) Connect negative cable to battery.

Fig. 113 Exhaust ManifoldÐLeft

ITEM DESCRIPTION TORQUE ITEM DESCRIPTION TORQUE

1 Stud (Qty 2)

25 N´m (18 ft. lbs.)4 Nut (Qty 2) 8 N´m (72 in. lbs.),

then loosen 45

degrees 2 Bolt (Qty 4) 5 Nut (Qty 2)

3 Stud (Qty 2)

DRENGINE - 4.7L 9 - 163

EXHAUST MANIFOLD (Continued)

Page 1413 of 2895

VALVE TIMING

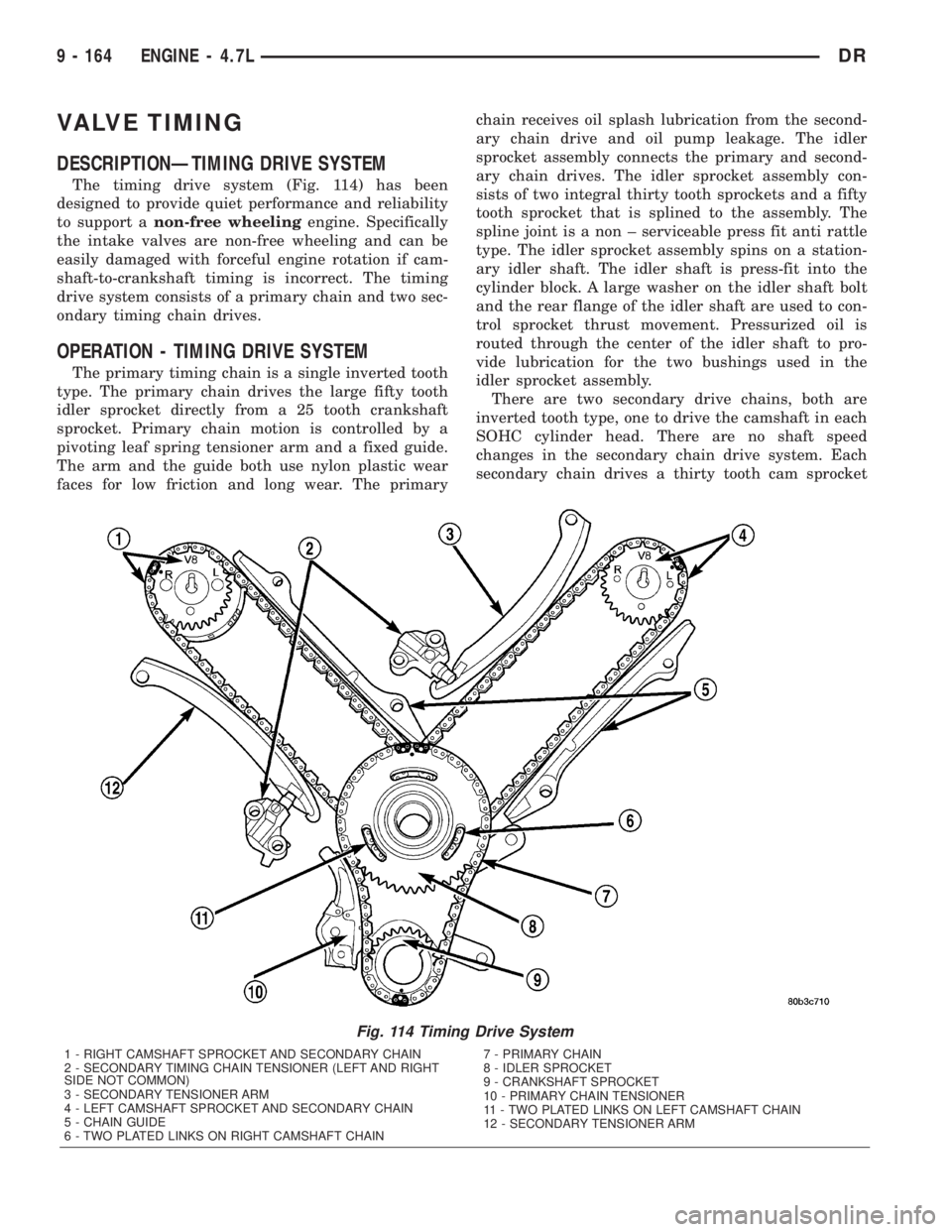

DESCRIPTIONÐTIMING DRIVE SYSTEM

The timing drive system (Fig. 114) has been

designed to provide quiet performance and reliability

to support anon-free wheelingengine. Specifically

the intake valves are non-free wheeling and can be

easily damaged with forceful engine rotation if cam-

shaft-to-crankshaft timing is incorrect. The timing

drive system consists of a primary chain and two sec-

ondary timing chain drives.

OPERATION - TIMING DRIVE SYSTEM

The primary timing chain is a single inverted tooth

type. The primary chain drives the large fifty tooth

idler sprocket directly from a 25 tooth crankshaft

sprocket. Primary chain motion is controlled by a

pivoting leaf spring tensioner arm and a fixed guide.

The arm and the guide both use nylon plastic wear

faces for low friction and long wear. The primarychain receives oil splash lubrication from the second-

ary chain drive and oil pump leakage. The idler

sprocket assembly connects the primary and second-

ary chain drives. The idler sprocket assembly con-

sists of two integral thirty tooth sprockets and a fifty

tooth sprocket that is splined to the assembly. The

spline joint is a non ± serviceable press fit anti rattle

type. The idler sprocket assembly spins on a station-

ary idler shaft. The idler shaft is press-fit into the

cylinder block. A large washer on the idler shaft bolt

and the rear flange of the idler shaft are used to con-

trol sprocket thrust movement. Pressurized oil is

routed through the center of the idler shaft to pro-

vide lubrication for the two bushings used in the

idler sprocket assembly.

There are two secondary drive chains, both are

inverted tooth type, one to drive the camshaft in each

SOHC cylinder head. There are no shaft speed

changes in the secondary chain drive system. Each

secondary chain drives a thirty tooth cam sprocket

Fig. 114 Timing Drive System

1 - RIGHT CAMSHAFT SPROCKET AND SECONDARY CHAIN

2 - SECONDARY TIMING CHAIN TENSIONER (LEFT AND RIGHT

SIDE NOT COMMON)

3 - SECONDARY TENSIONER ARM

4 - LEFT CAMSHAFT SPROCKET AND SECONDARY CHAIN

5 - CHAIN GUIDE

6 - TWO PLATED LINKS ON RIGHT CAMSHAFT CHAIN7 - PRIMARY CHAIN

8 - IDLER SPROCKET

9 - CRANKSHAFT SPROCKET

10 - PRIMARY CHAIN TENSIONER

11 - TWO PLATED LINKS ON LEFT CAMSHAFT CHAIN

12 - SECONDARY TENSIONER ARM

9 - 164 ENGINE - 4.7LDR

Page 1414 of 2895

directly from the thirty tooth sprocket on the idler

sprocket assembly. A fixed chain guide and a hydrau-

lic oil damped tensioner are used to maintain tension

in each secondary chain system. The hydraulic ten-

sioners for the secondary chain systems are fed pres-

surized oil from oil reservoir pockets in the block.

Each tensioner also has a mechanical ratchet system

that limits chain slack if the tensioner piston bleeds

down after engine shut down. The tensioner arms

and guides also utilize nylon wear faces for low fric-

tion and long wear. The secondary timing chains

receive lubrication from a small orifice in the ten-

sioners. This orifice is protected from clogging by a

fine mesh screen which is located on the back of the

hydraulic tensioners.

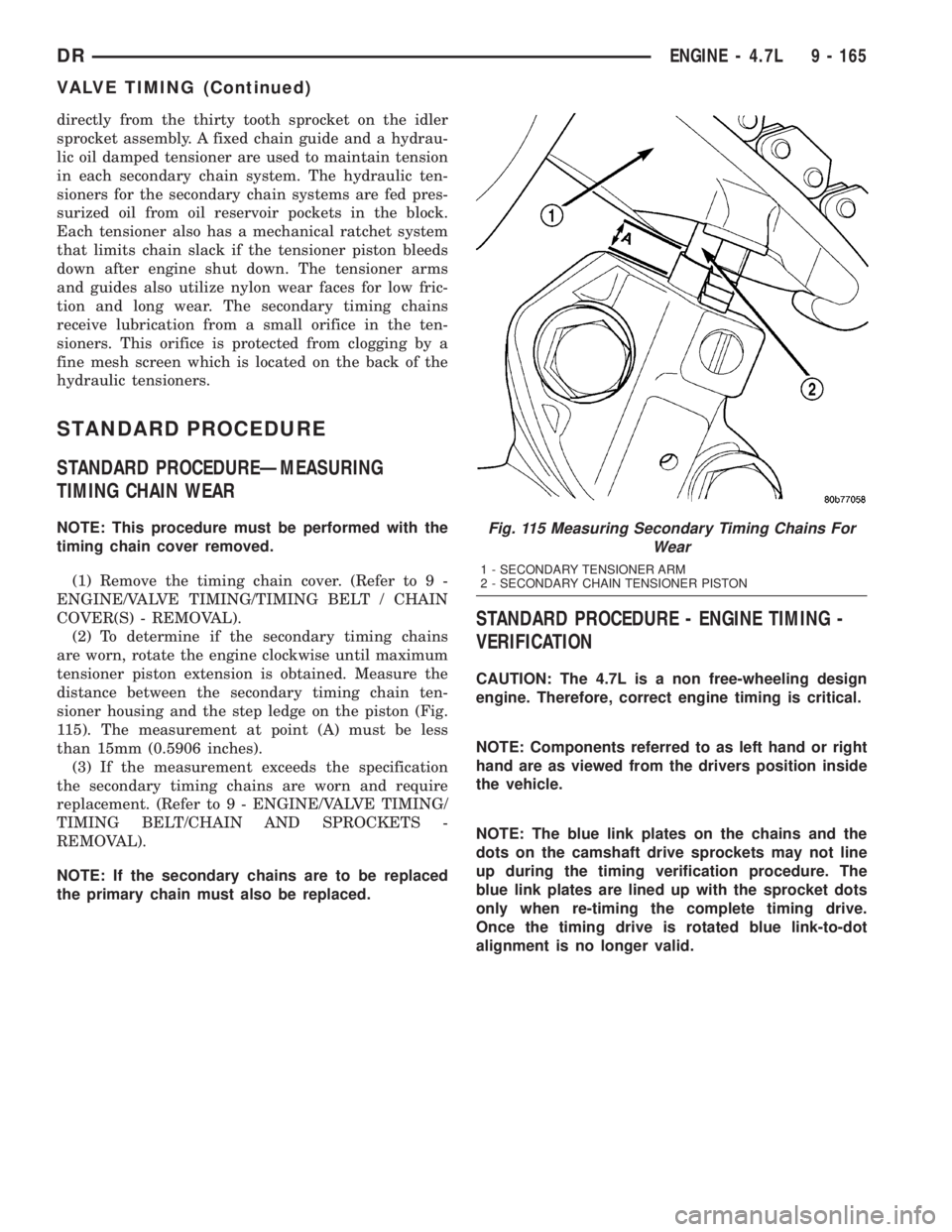

STANDARD PROCEDURE

STANDARD PROCEDUREÐMEASURING

TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed.

(1) Remove the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(2) To determine if the secondary timing chains

are worn, rotate the engine clockwise until maximum

tensioner piston extension is obtained. Measure the

distance between the secondary timing chain ten-

sioner housing and the step ledge on the piston (Fig.

115). The measurement at point (A) must be less

than 15mm (0.5906 inches).

(3) If the measurement exceeds the specification

the secondary timing chains are worn and require

replacement. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL).

NOTE: If the secondary chains are to be replaced

the primary chain must also be replaced.

STANDARD PROCEDURE - ENGINE TIMING -

VERIFICATION

CAUTION: The 4.7L is a non free-wheeling design

engine. Therefore, correct engine timing is critical.

NOTE: Components referred to as left hand or right

hand are as viewed from the drivers position inside

the vehicle.

NOTE: The blue link plates on the chains and the

dots on the camshaft drive sprockets may not line

up during the timing verification procedure. The

blue link plates are lined up with the sprocket dots

only when re-timing the complete timing drive.

Once the timing drive is rotated blue link-to-dot

alignment is no longer valid.

Fig. 115 Measuring Secondary Timing Chains For

Wear

1 - SECONDARY TENSIONER ARM

2 - SECONDARY CHAIN TENSIONER PISTON

DRENGINE - 4.7L 9 - 165

VALVE TIMING (Continued)

Page 1415 of 2895

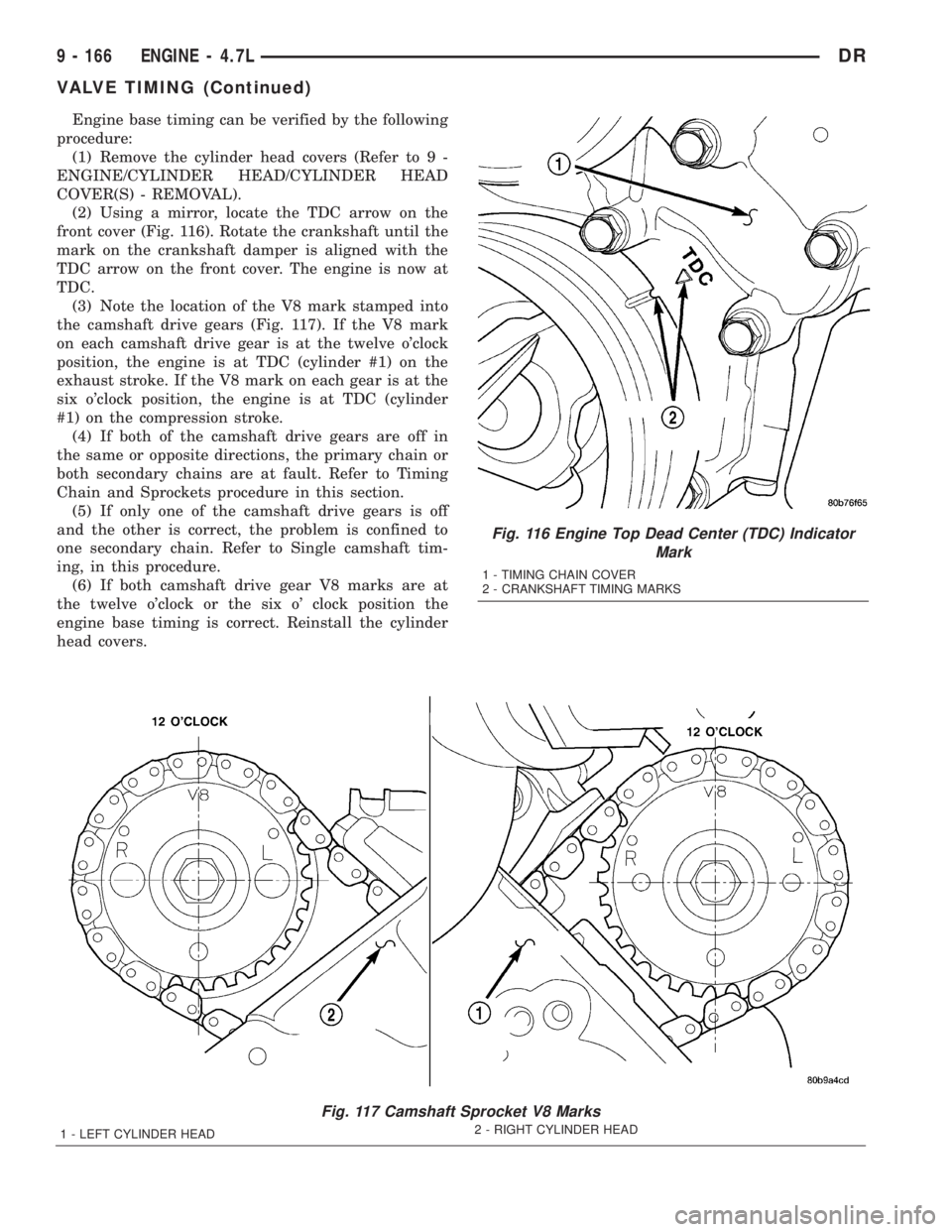

Engine base timing can be verified by the following

procedure:

(1) Remove the cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Using a mirror, locate the TDC arrow on the

front cover (Fig. 116). Rotate the crankshaft until the

mark on the crankshaft damper is aligned with the

TDC arrow on the front cover. The engine is now at

TDC.

(3) Note the location of the V8 mark stamped into

the camshaft drive gears (Fig. 117). If the V8 mark

on each camshaft drive gear is at the twelve o'clock

position, the engine is at TDC (cylinder #1) on the

exhaust stroke. If the V8 mark on each gear is at the

six o'clock position, the engine is at TDC (cylinder

#1) on the compression stroke.

(4) If both of the camshaft drive gears are off in

the same or opposite directions, the primary chain or

both secondary chains are at fault. Refer to Timing

Chain and Sprockets procedure in this section.

(5) If only one of the camshaft drive gears is off

and the other is correct, the problem is confined to

one secondary chain. Refer to Single camshaft tim-

ing, in this procedure.

(6) If both camshaft drive gear V8 marks are at

the twelve o'clock or the six o' clock position the

engine base timing is correct. Reinstall the cylinder

head covers.

Fig. 116 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

Fig. 117 Camshaft Sprocket V8 Marks

1 - LEFT CYLINDER HEAD2 - RIGHT CYLINDER HEAD

9 - 166 ENGINE - 4.7LDR

VALVE TIMING (Continued)

Page 1416 of 2895

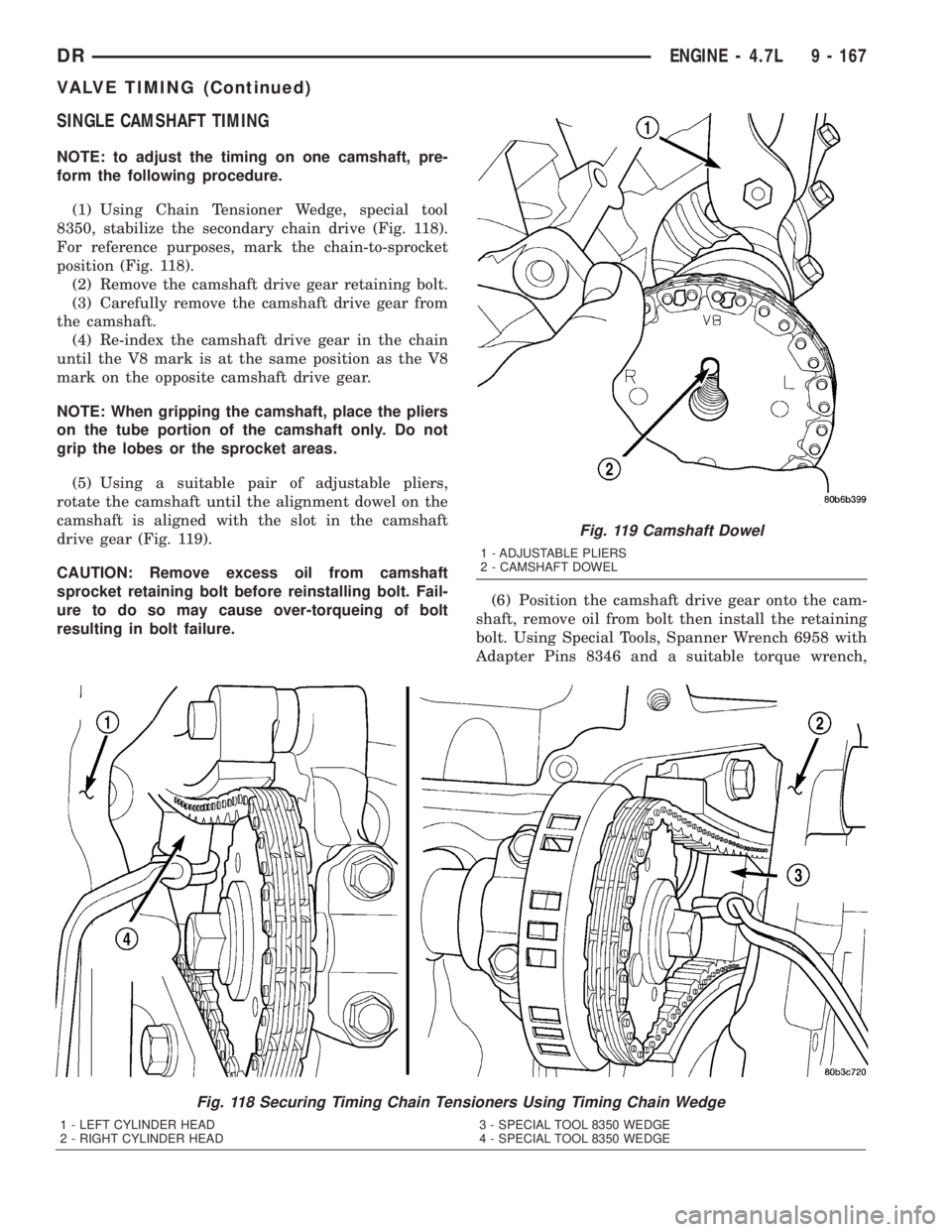

SINGLE CAMSHAFT TIMING

NOTE: to adjust the timing on one camshaft, pre-

form the following procedure.

(1) Using Chain Tensioner Wedge, special tool

8350, stabilize the secondary chain drive (Fig. 118).

For reference purposes, mark the chain-to-sprocket

position (Fig. 118).

(2) Remove the camshaft drive gear retaining bolt.

(3) Carefully remove the camshaft drive gear from

the camshaft.

(4) Re-index the camshaft drive gear in the chain

until the V8 mark is at the same position as the V8

mark on the opposite camshaft drive gear.

NOTE: When gripping the camshaft, place the pliers

on the tube portion of the camshaft only. Do not

grip the lobes or the sprocket areas.

(5) Using a suitable pair of adjustable pliers,

rotate the camshaft until the alignment dowel on the

camshaft is aligned with the slot in the camshaft

drive gear (Fig. 119).

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Fail-

ure to do so may cause over-torqueing of bolt

resulting in bolt failure.(6) Position the camshaft drive gear onto the cam-

shaft, remove oil from bolt then install the retaining

bolt. Using Special Tools, Spanner Wrench 6958 with

Adapter Pins 8346 and a suitable torque wrench,

Fig. 118 Securing Timing Chain Tensioners Using Timing Chain Wedge

1 - LEFT CYLINDER HEAD

2 - RIGHT CYLINDER HEAD3 - SPECIAL TOOL 8350 WEDGE

4 - SPECIAL TOOL 8350 WEDGE

Fig. 119 Camshaft Dowel

1 - ADJUSTABLE PLIERS

2 - CAMSHAFT DOWEL

DRENGINE - 4.7L 9 - 167

VALVE TIMING (Continued)

Page 1417 of 2895

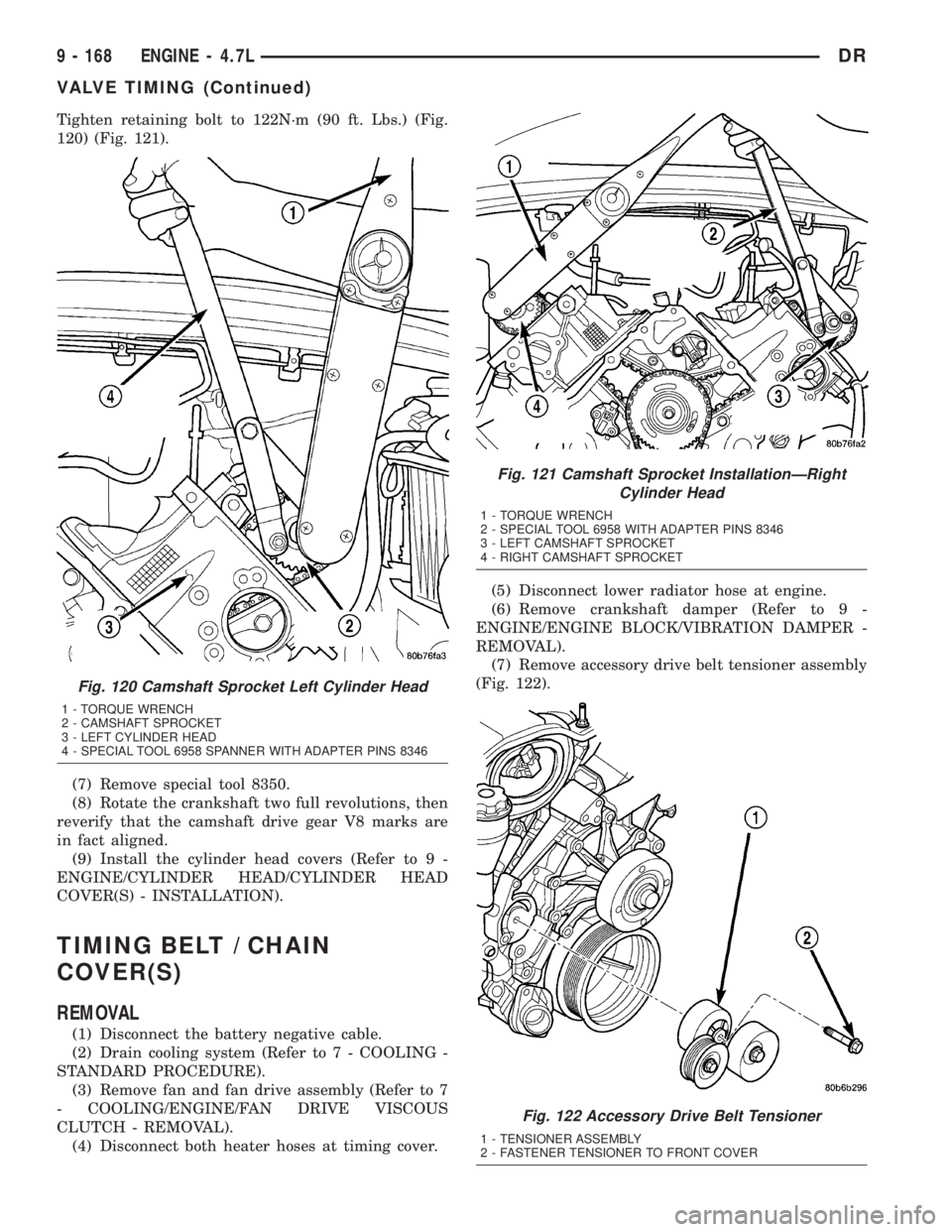

Tighten retaining bolt to 122N´m (90 ft. Lbs.) (Fig.

120) (Fig. 121).

(7) Remove special tool 8350.

(8) Rotate the crankshaft two full revolutions, then

reverify that the camshaft drive gear V8 marks are

in fact aligned.

(9) Install the cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove fan and fan drive assembly (Refer to 7

- COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

(4) Disconnect both heater hoses at timing cover.(5) Disconnect lower radiator hose at engine.

(6) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(7) Remove accessory drive belt tensioner assembly

(Fig. 122).

Fig. 120 Camshaft Sprocket Left Cylinder Head

1 - TORQUE WRENCH

2 - CAMSHAFT SPROCKET

3 - LEFT CYLINDER HEAD

4 - SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

Fig. 121 Camshaft Sprocket InstallationÐRight

Cylinder Head

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKET

Fig. 122 Accessory Drive Belt Tensioner

1 - TENSIONER ASSEMBLY

2 - FASTENER TENSIONER TO FRONT COVER

9 - 168 ENGINE - 4.7LDR

VALVE TIMING (Continued)

Page 1418 of 2895

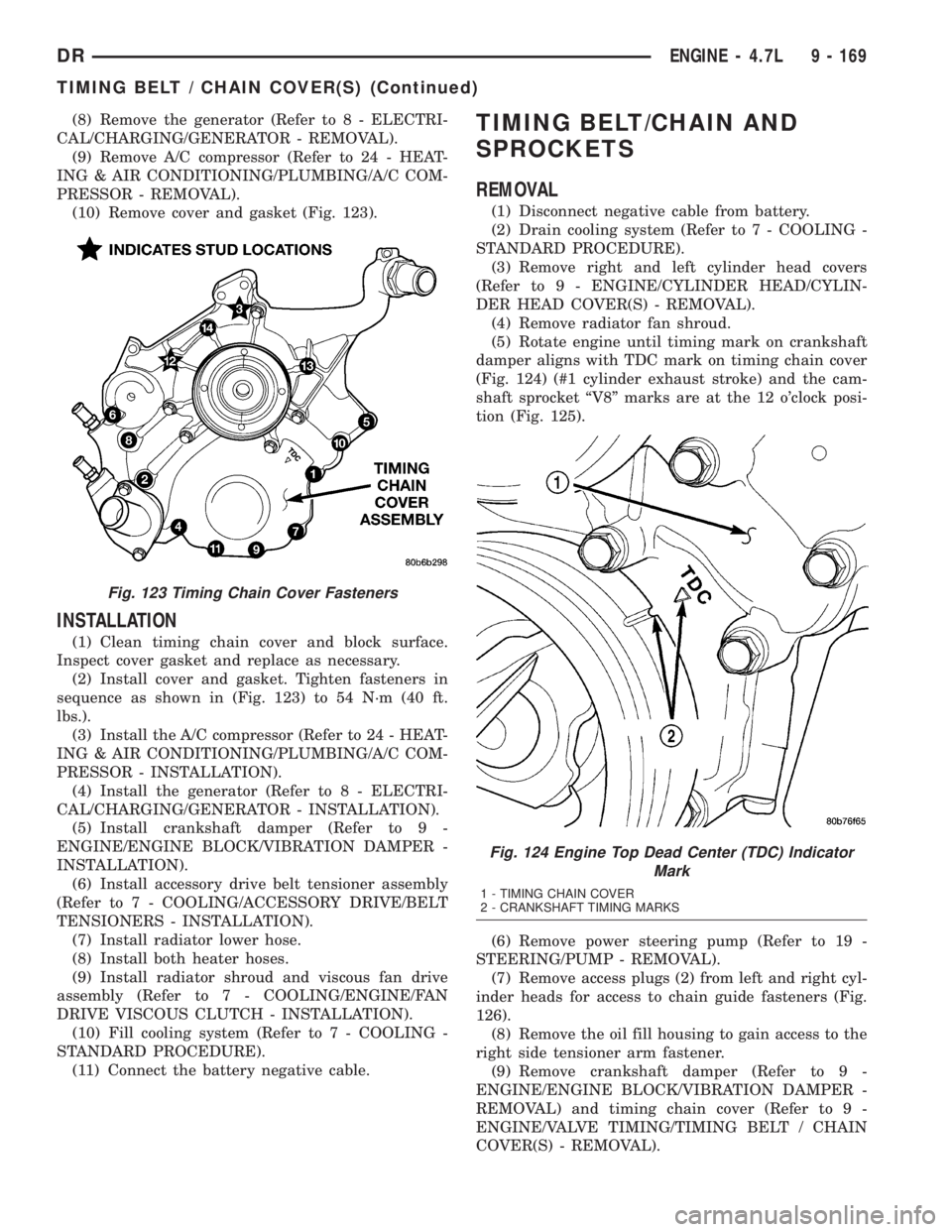

(8) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(9) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

(10) Remove cover and gasket (Fig. 123).

INSTALLATION

(1) Clean timing chain cover and block surface.

Inspect cover gasket and replace as necessary.

(2) Install cover and gasket. Tighten fasteners in

sequence as shown in (Fig. 123) to 54 N´m (40 ft.

lbs.).

(3) Install the A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(4) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION).

(5) Install crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(6) Install accessory drive belt tensioner assembly

(Refer to 7 - COOLING/ACCESSORY DRIVE/BELT

TENSIONERS - INSTALLATION).

(7) Install radiator lower hose.

(8) Install both heater hoses.

(9) Install radiator shroud and viscous fan drive

assembly (Refer to 7 - COOLING/ENGINE/FAN

DRIVE VISCOUS CLUTCH - INSTALLATION).

(10) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Connect the battery negative cable.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove right and left cylinder head covers

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(4) Remove radiator fan shroud.

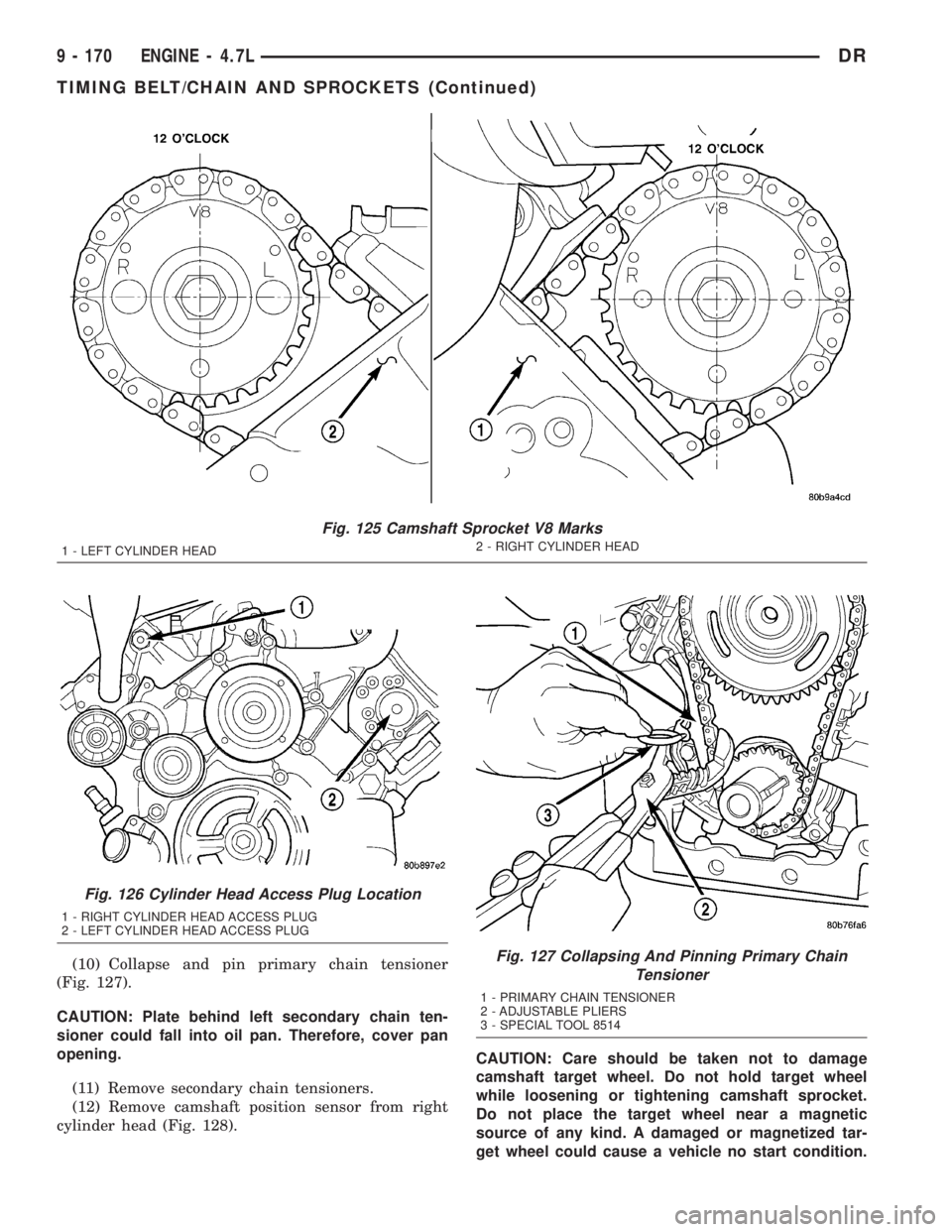

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 124) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket ªV8º marks are at the 12 o'clock posi-

tion (Fig. 125).

(6) Remove power steering pump (Refer to 19 -

STEERING/PUMP - REMOVAL).

(7) Remove access plugs (2) from left and right cyl-

inder heads for access to chain guide fasteners (Fig.

126).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

Fig. 123 Timing Chain Cover Fasteners

Fig. 124 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

DRENGINE - 4.7L 9 - 169

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1419 of 2895

(10) Collapse and pin primary chain tensioner

(Fig. 127).

CAUTION: Plate behind left secondary chain ten-

sioner could fall into oil pan. Therefore, cover pan

opening.

(11) Remove secondary chain tensioners.

(12) Remove camshaft position sensor from right

cylinder head (Fig. 128).CAUTION: Care should be taken not to damage

camshaft target wheel. Do not hold target wheel

while loosening or tightening camshaft sprocket.

Do not place the target wheel near a magnetic

source of any kind. A damaged or magnetized tar-

get wheel could cause a vehicle no start condition.

Fig. 125 Camshaft Sprocket V8 Marks

1 - LEFT CYLINDER HEAD2 - RIGHT CYLINDER HEAD

Fig. 126 Cylinder Head Access Plug Location

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

Fig. 127 Collapsing And Pinning Primary Chain

Tensioner

1 - PRIMARY CHAIN TENSIONER

2 - ADJUSTABLE PLIERS

3 - SPECIAL TOOL 8514

9 - 170 ENGINE - 4.7LDR

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1420 of 2895

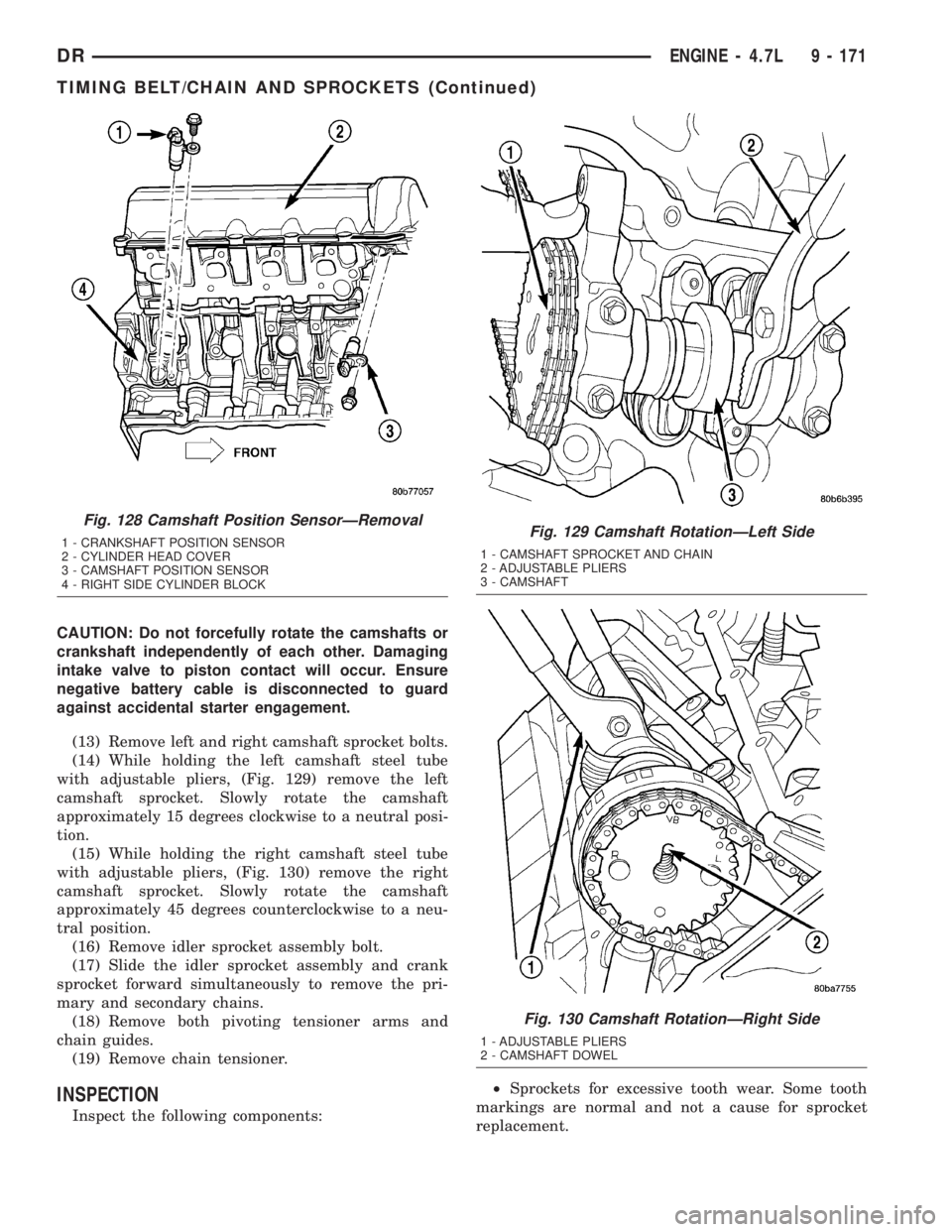

CAUTION: Do not forcefully rotate the camshafts or

crankshaft independently of each other. Damaging

intake valve to piston contact will occur. Ensure

negative battery cable is disconnected to guard

against accidental starter engagement.

(13) Remove left and right camshaft sprocket bolts.

(14) While holding the left camshaft steel tube

with adjustable pliers, (Fig. 129) remove the left

camshaft sprocket. Slowly rotate the camshaft

approximately 15 degrees clockwise to a neutral posi-

tion.

(15) While holding the right camshaft steel tube

with adjustable pliers, (Fig. 130) remove the right

camshaft sprocket. Slowly rotate the camshaft

approximately 45 degrees counterclockwise to a neu-

tral position.

(16) Remove idler sprocket assembly bolt.

(17) Slide the idler sprocket assembly and crank

sprocket forward simultaneously to remove the pri-

mary and secondary chains.

(18) Remove both pivoting tensioner arms and

chain guides.

(19) Remove chain tensioner.

INSPECTION

Inspect the following components:²Sprockets for excessive tooth wear. Some tooth

markings are normal and not a cause for sprocket

replacement.

Fig. 128 Camshaft Position SensorÐRemoval

1 - CRANKSHAFT POSITION SENSOR

2 - CYLINDER HEAD COVER

3 - CAMSHAFT POSITION SENSOR

4 - RIGHT SIDE CYLINDER BLOCKFig. 129 Camshaft RotationÐLeft Side

1 - CAMSHAFT SPROCKET AND CHAIN

2 - ADJUSTABLE PLIERS

3 - CAMSHAFT

Fig. 130 Camshaft RotationÐRight Side

1 - ADJUSTABLE PLIERS

2 - CAMSHAFT DOWEL

DRENGINE - 4.7L 9 - 171

TIMING BELT/CHAIN AND SPROCKETS (Continued)